Page 1

Kit Instructions/Parts

Important Safety Instructions

Read all warnings and instructions

in the Husky

®

1050 or Husky® 3300

Air-Operated Diaphragm Pump

manuals. Save all instructions.

Model 24B777 shown

ti14052a

®

DataTrak

For providing pump diagnostics and material usage information for diaphragm pumps.

Conversion Kits - DataTrak with Pulse Count and Runaway Protection

Husky® 1050 - 24B777, 24B784, and 24B793

Husky® 3300 - 24K861 and 24K862

Conversion Kits - DataTrak with Pulse Count

Husky® 1050 and Husky® 3300 - 24B794 and 24B795

Replacement Parts Kits 24B771, 24B772, 24B796, 24B798, 24K863, and 24K864

See page 3 for model information, including agency approvals.

Kits

313840G

EN

Page 2

Contents

DataTrak™ includes agency approvals listed

below.

0359

II 1 G

Ex ia IIA T3 Ga

ITS13ATEX27862X

9902471

Class I, Div. 1,

Group D T3A

Contents

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

DataTrak Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Prepare to Install . . . . . . . . . . . . . . . . . . . . . . . . . 4

Install the Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Check DataTrak Operation . . . . . . . . . . . . . . . . . 5

DataTrak Controls and Indicators . . . . . . . . . . . . . 6

DataTrak Operation . . . . . . . . . . . . . . . . . . . . . . . . . 7

Setup Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Run Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Calibration Procedure . . . . . . . . . . . . . . . . . . . . . 9

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 18

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 18

Related Manuals

Manual Description

1050 Air-Operated Diaphragm Pump,

312877

1050 Air-Operated Diaphragm Pump,

313435

3300 Air-Operated Diaphragm Pump,

3A0410

3300 Air-Operated Diaphragm Pump,

3A0411

Operation

Repair/Parts

Operation

Repair/Parts

2 313840G

Page 3

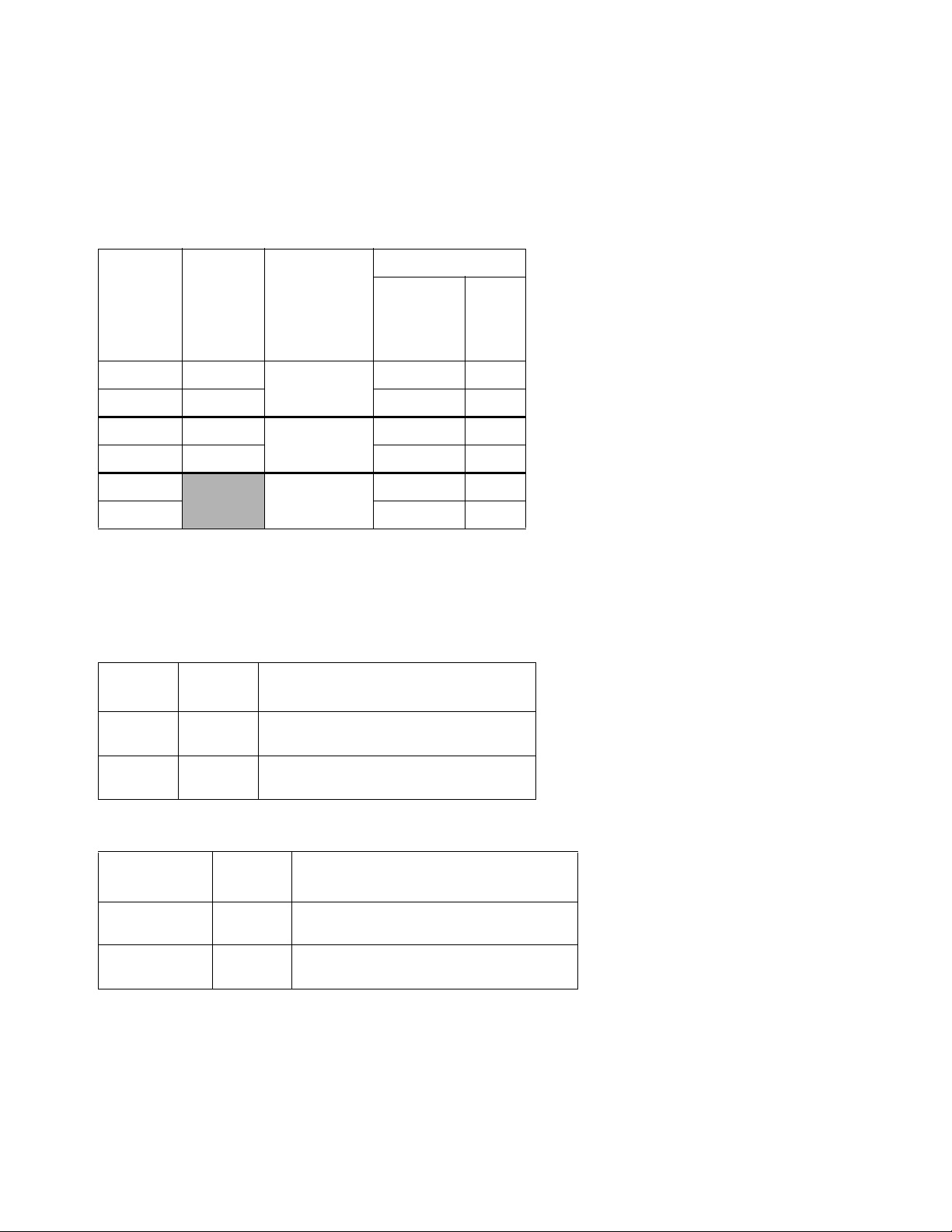

DataTrak Kits

Conversion Kits

Use to add data monitoring capabilities to an existing pump.

Data Monitoring

Pulse

Count and

Husky

1050

Husky

3300

Diaphragm

Pump Material

Runaway

Protection

Pulse

Count

DataTrak Kits

24B777 24K861

24B795 24B795

24B784 24K862

24B794 24B794

24B793

24B794

* Kit includes replacement air valve compatible with solenoid.

Aluminum

Polypropylene

Conductive

Polypropylene

✔*

✔

✔*

✔

✔*

✔

Replacement Part Kits

Aluminum

Husky

1050A

24B772 24K864

24B798 24B798

Husky

3300A Description

Solenoid/Reed Switch Assembly

(pulse count and runaway protection)

Reed Switch Assembly

(pulse count only)

Polypropylene and Conductive Polypropylene

Husky 1050P

or 1050C

24B771 24K863

24B796 24B796

313840G 3

Husky

3300P Description

Solenoid/Reed Switch Assembly

(pulse count and runaway protection)

Reed Switch Assembly

(pulse count only)

Page 4

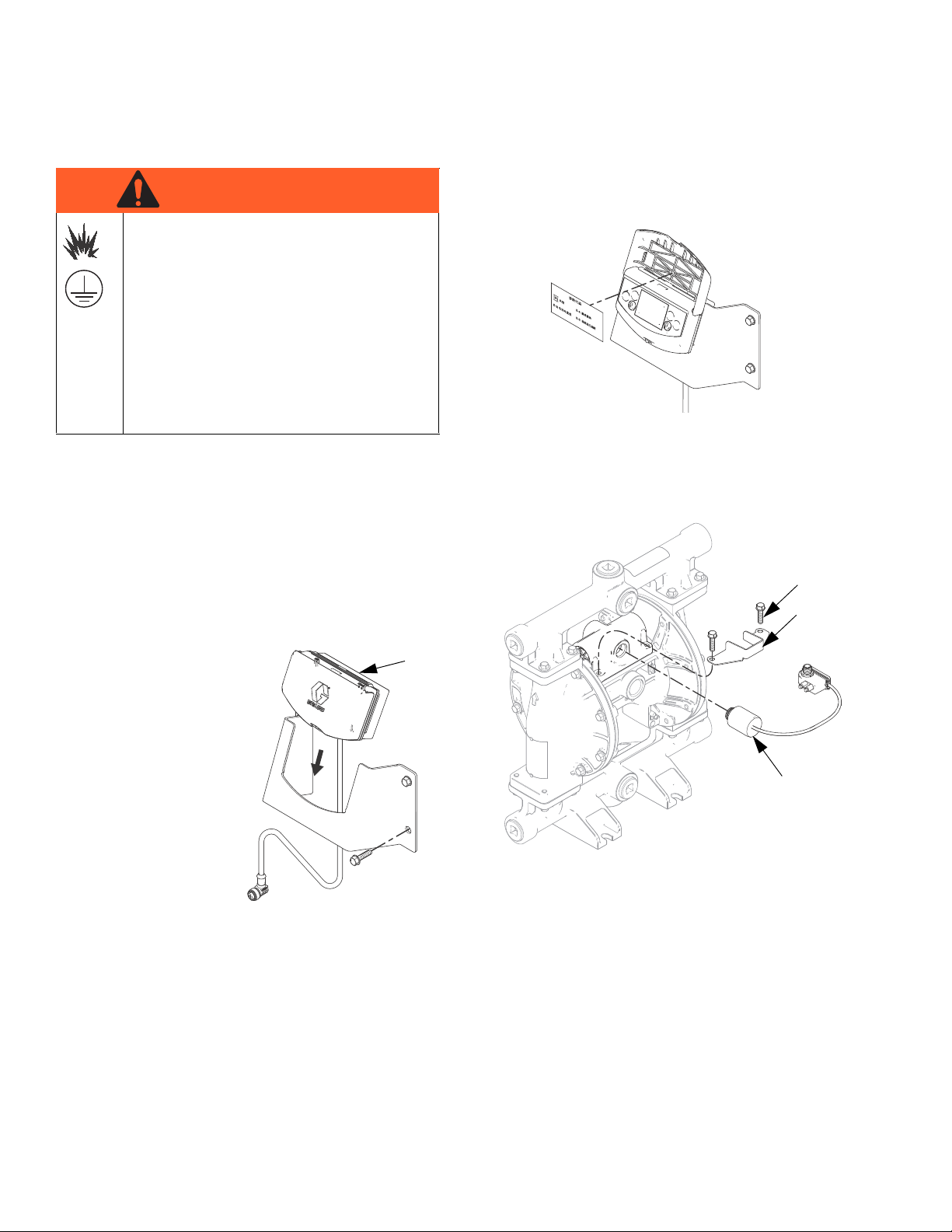

Installation

WARNINGWARNINGWARNING

WARNING

1

ti14055a

ti14223a

ti14058a

S

4d

4c

Installation

SPECIAL CONDITIONS FOR SAFE USE

Equipment must comply with the following

conditions to avoid a hazardous condition

which can cause fire or explosion.

• All label and marking material must be

cleaned with a damp cloth (or equivalent).

• The electronic monitoring system is

required to be grounded. See Ground-

ing instructions in your pump operation

manual.

Prepare to Install

1. Relieve the pressure. Follow instructions in your

Operation manual.

4. Select the Diagnostic Codes card that matches the

operator’s preferred language. Insert it in the inside

of the DataTrak cover for quick reference.

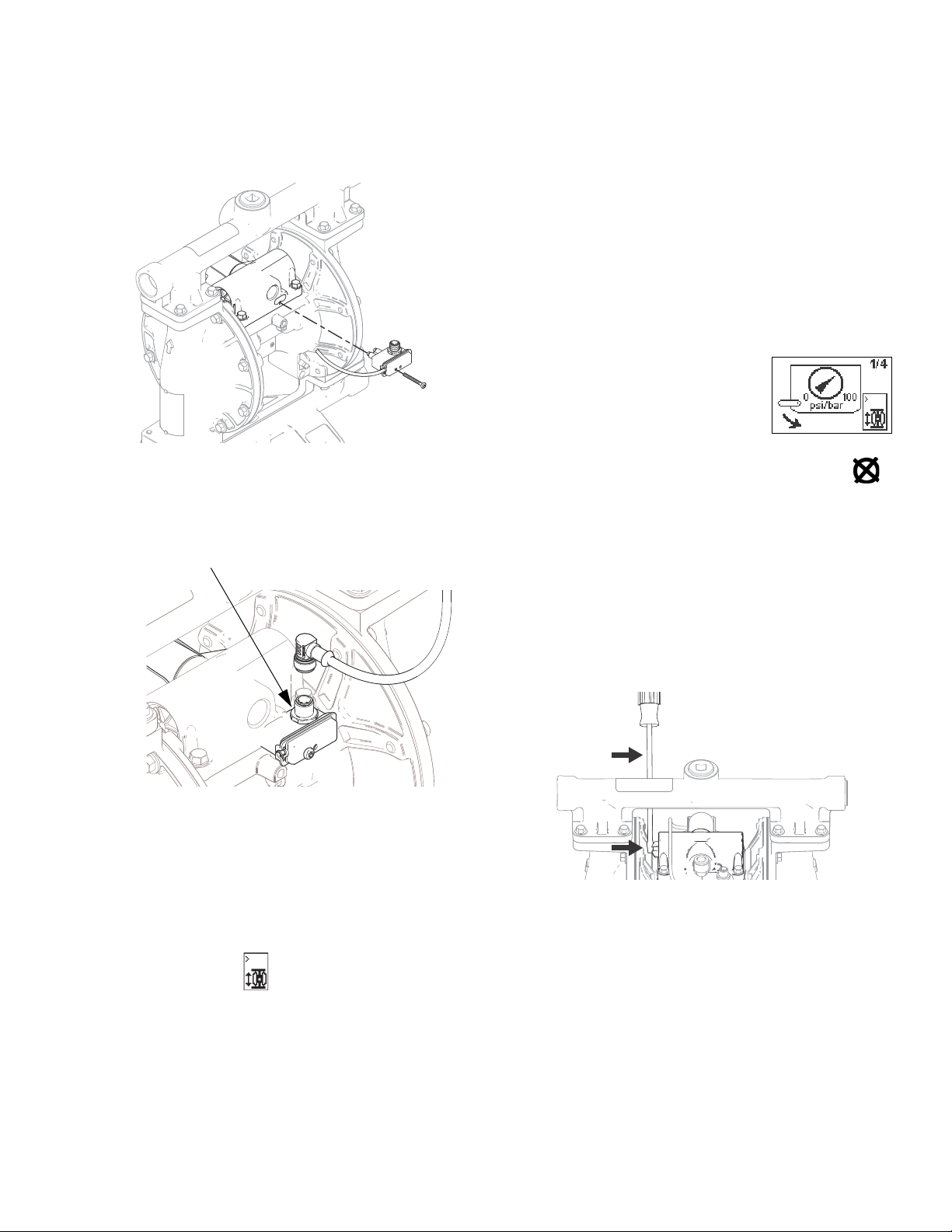

5. DataTrak with runaway protection: Attach the solenoid (S) and bracket (4d) to the air valve. Use the

same screws (4c) that attach the air valve to the

manifold, as shown.

2. Disconnect the air line to the pump.

Install the Kit

1. Mount the bracket

to the wall. Use

approximately

3/8 in. bolts or

screws.

2. Install the DataTrak

module (1) on the

bracket.

3. Conversion Kits include a new air valve that is compatible with the solenoid. Remove the old air valve

and gasket from the pump, and install the replacement air valve and gasket.

4 313840G

Page 5

Installation

ti14056a

5-pin

connector

ti14054a

ti14263a

6. Use the screw provided to attach the reed switch

just behind the air inlet. Remove the muffler, if

needed, for easier access. Rotate the air inlet fitting

as needed so the wrench flat clears the reed switch.

7. Connect the DataTrak cable to the 5-pin connector

on the reed switch. Reconnect the air line to the

motor.

a. The DataTrak pump icon should move when the

air motor changes direction.

b. The Grand Totalizer and Batch Totalizer should

advance.

4. DataTrak with runaway protection: Check for proper

runaway operation.

a. Run the air motor at a speed faster than the run-

away limit.

b. After 5 consecutive cycles,

the DataTrak should stop the

pump and display the runaway diagnostic screen.

c. To reset, turn the pressure off, then push

on the DataTrak module.

d. After resetting, turn on the air supply. The air

motor should run. Shut off the air until ready to

pump.

NOTE: If the DataTrak does not reset, turn air pressure

down, then use a screwdriver to push the solenoid

release button on the side of the air valve.

8. Secure DataTrack data cable. A plastic spiral conduit is provided to help prevent chafing.

5. Configure the DataTrak as needed. See page 7.

Check DataTrak Operation

1. Enable runaway and set the runaway limit. See

Setup Mode, page 7.

2. Run the air motor at a speed slower than the runaway limit.

3. Check for proper reed switch operation.

313840G 5

Page 6

DataTrak Controls and Indicators

/min,

AD

AE, see details at right

CF BT

GT

AC

AA

PF

RK

AB

Run Mode

Setup Mode

TI11883a

RK

PF

ti8622b

ti8623b

DataTrak Controls and Indicators

Key

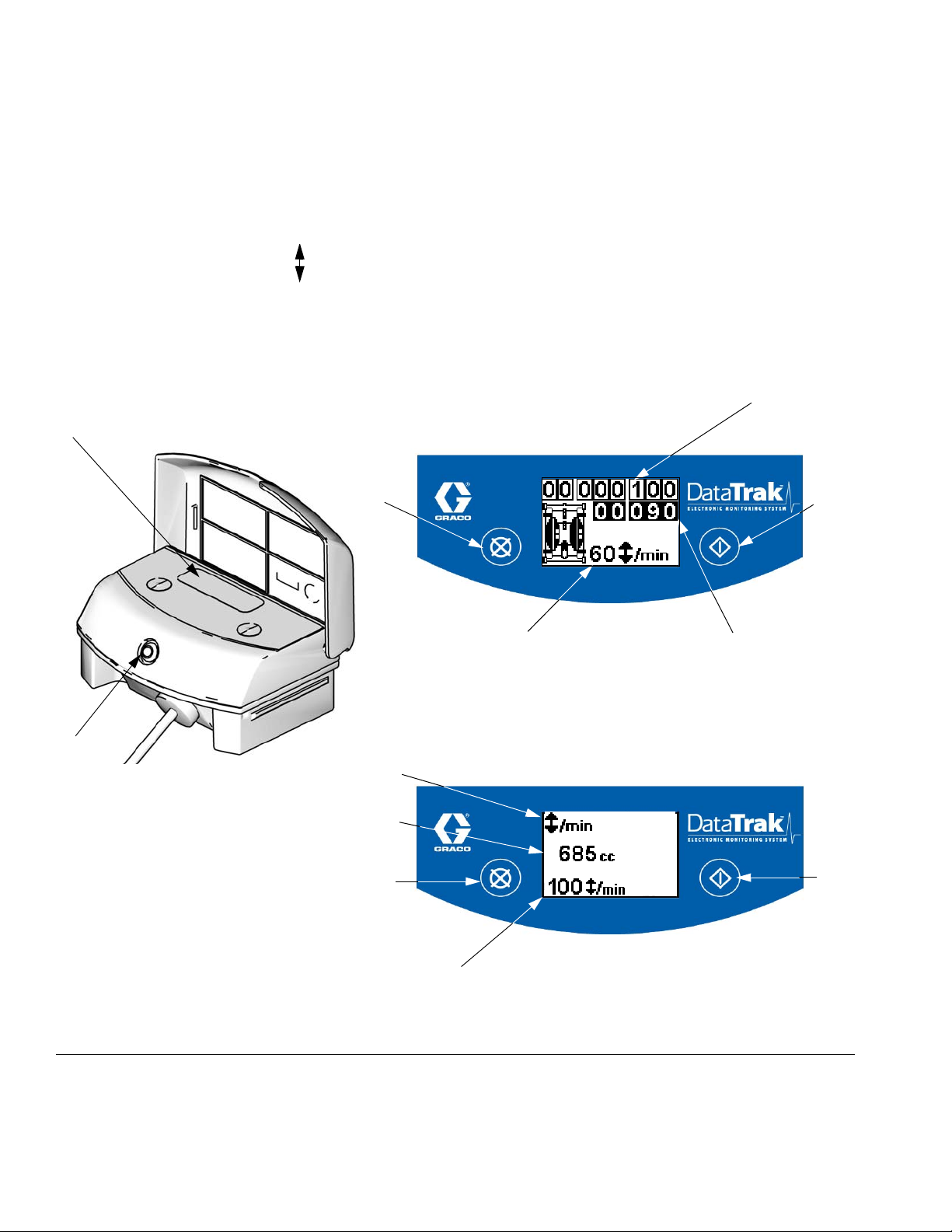

AA Runaway Limit, in cycles per minute (user settable;

00=OFF)

AB Displacement (user settable)

AC Flow Rate Units (user settable to gpm [US],

gpm [Imperial], oz/min [US], oz/min [Imperial], l/min, or

cc/min)

AD LED (fault indicator when flashing)

AE Display

PF Prime/Flush Key (Enables Prime/Flush mode. While in

Prime/Flush mode, runaway protection is disabled and the

batch totalizer [BT] will not count.) LED will flash while in

Prime/Flush mode.

RK Reset Key (Resets faults. Press and hold for 3 seconds to

clear the batch totalizer.) Push to toggle between flow rate

and cycle rate.

CF Cycle/Flow Rate

BT Batch Totalizer (resettable)

GT Grand Totalizer (not resettable)

Fig. 1. DataTrak Controls and Indicators

6 313840G

Page 7

DataTrak Operation

DataTrak Operation

NOTE: The display (AE) will turn off after 1 minute to

save battery life. Press any key to wake up the display.

NOTE: DataTrak is factory set to 685 cc/cycle. This setting is accurate for pumping water at a medium speed

on a Husky 1050 pump (approximately 20 gpm). The

DataTrak can be calibrated for use with a different Husky

model, for greater accuracy, for different pump speeds,

or for different viscosity fluids. See Calibration Proce-

dure, page 9.

Setup Mode

1. See Fig. 1. Press and hold for 5 seconds until

Setup menu appears.

2. To enter settings for flow rate units and displacement, press to change the value, then to

save the value and move the cursor to the next data

field.

3. To enter setting for runaway (if equipped), enter

pump speed in cycles/min. The exact setting will

vary by pump speed and viscosity of fluid. Choose a

setting that is just above the fastest speed expected

during normal operation.

Run Mode

Runaway

1. If pump runaway occurs, the runaway solenoid will

actuate, stopping the pump. The LED (AD) will flash

and the display (AE) will indicate a runaway condition. The display will cycle through four instruction

screens.

2. To reset the runaway solenoid, close the master air

valve. Wait for air to completely bleed off the air

motor.

NOTE: Set the value to zero to disable runaway protection or if your pump is not equipped with a runaway protection solenoid.

NOTE: A flashing LED indicates an error that must be

addressed. The Runaway mode will not stop a runaway

pump while the LED is flashing.

4. Move the cursor to the last field, then press

once more to exit Setup mode.

3. Press to clear the diagnostic code and reset the

runaway solenoid.

4. Open master air valve to restart pump.

313840G 7

Page 8

DataTrak Operation

ti14263a

NOTE: If the DataTrak does not reset, use a screwdriver

to push the solenoid release button on the side of the air

valve.

5. If the solenoid doesn’t actuate:

a. Close the master air valve to stop the pump.

The display will show the Service Component 1

screen.

Counter/Totalizer

To reset the totalizer, press any key to wake up the display, then press and hold for 3 seconds.

• If AC is set to gallons or ounces, BT and GT display gallons.

• If AC is set to liters or cc, BT and GT display

liters.

• If AC is set to cycles, BT and GT display cycles.

NOTE: Press to toggle between flow rate units and

cycles. A letter under the BT display indicates that both

BT and GT are displaying gallons (g) or liters (l). No letter means both BT and GT are displaying cycles.

Display

See Fig. 1. The display (AE) will turn off after 1 minute of

inactivity in Run mode or 3 minutes in Setup mode.

Press any key to wake up the display.

NOTE: DataTrak will continue to count cycles when display is off.

b. See Table 1, Diagnostic Codes, on page 10.

NOTE: To disable runaway monitoring, go to setup

mode and set runaway value to 0 (zero). See Fig. 1.

Prime/Flush

1. See Fig. 1. To enter Prime/Flush mode, press any

key to wake up the display, then press . The

Prime/Flush symbol will appear in the display and

the LED will flash .

2. While in Prime/Flush mode, runaway protection is

disabled and the batch totalizer (BT) will not count.

3. To exit Prime/Flush mode, press any key to wake up

the display, then press . The Prime/Flush sym-

bol will disappear from the display and the LED will

stop flashing.

NOTE: The display (AE) may turn off if a high-level static

discharge is applied to the DataTrak. Press any key to

wake up the display.

Diagnostics

DataTrak can diagnose several problems with the pump.

When the monitor detects a problem, the LED (AD, Fig.

1) will flash and a diagnostic code will appear on the display. See Table 1, page 10.

To acknowledge the diagnosis and return to the normal

operating screen, press once to wake up the display,

and once more to clear the diagnostic code screen.

8 313840G

Page 9

Calibration Procedure

1. Press and hold for 5 seconds until Setup menu

appears.

2. Press once. Change flow rate units to

cycles/min.

3. Return to Run Screen. Press and hold for three

seconds to reset batch totalizer.

4. Dispense fluid from pump into a graduated container.

5. Convert the actual volume dispensed to cubic centimeters (cc). See conversion chart.

Units Measured Multiply by To get

Gallons (U.S.) 3785 cc

Gallons (Imp) 4546 cc

Liters 1000 cc

Quarts 946 cc

Ounces (U.S.) 29.57 cc

Ounces (Imp) 28.41 cc

Cubic inches 16.39 cc

Cubic feet 28,317 cc

Pints 473 cc

cc 1 cc

DataTrak Operation

6. Divide the actual volume dispensed (cc) by the number of cycles indicated on the DataTrak batch totalizer display.

7. Press to enter the Setup screen. Enter the

number from Step 6 in field 2 of the Setup screen.

313840G 9

Page 10

DataTrak Operation

Symbol Code Code Name Diagnosis Cause

Table 1: Diagnostic Codes

Runaway Pump running faster than

set runaway limit.

Increased air pressure.

Increased fluid output.

Exhausted fluid supply.

E-3 Low Battery Battery voltage too low to

stop runaway.

E--4 Service

Component 1

E-4 Disconnected

Problem with stopping

runaway.

Solenoid is disconnected. Solenoid unplugged.

Solenoid

E-6 Blown Fuse Fuse is blown. Replace

fuse; see page 11.

Low battery. Replace battery;

see page 11.

Damaged solenoid.

Damaged valve carriage.

Runaway protection may be

enabled with pump that is not

equipped with a runaway solenoid valve. Enter setup screen

and disable runaway protection.

Damaged solenoid wires.

Faulty solenoid or solenoid

wiring.

Extreme temperatures (above

140°F [60°C]).

Runaway protection may be

enabled with pump that is not

equipped with a runaway solenoid valve. Enter setup screen

and disable runaway protection.

10 313840G

Page 11

Replace DataTrak Battery or Fuse

ti14054a

ti14053a

DataTrak Operation

3. Remove two screws on back of module to access

battery.

To reduce the risk of fire and explosion, the battery

and fuse must be replaced in a non-hazardous location.

Use only an approved replacement battery, shown in

Table 2, and an approved fuse, shown in Table 3. Use

of an unapproved battery or fuse will void Graco’s warranty and Intertek and Ex approvals.

Replace Battery

1. Unscrew cable from the reed switch assembly. See

Fig. 2.

4. Disconnect the used battery and replace with an

approved battery. See Fig. 4.

Table 2. Approved Batteries

Energizer alkaline # 522

Varta alkaline # 4922

Ultralife lithium # U9V

Duracell alkaline # MN1604

Fig. 2. Disconnect DataTrak

2. Remove DataTrak module from bracket. See Fig. 3.

Take module to a non-hazardous location.

Fig. 3. Remove DataTrak

313840G 11

Page 12

DataTrak Operation

ti11994b

Battery

Fuse

Solenoid Cable

Connection

Sensor Cable

Connection

Series Letter

(last digit of code)

Replace Fuse

1. Remove the screw, metal strap, and plastic holder.

2. Pull the fuse away from the board.

3. Replace with a new fuse.

Table 3. Approved Fuses

DataTrak Part

Number Series*

289822

A or B 24C580

C and later 24V216

All other part

numbers

B and later 24V216

A 24C580

Required

* Fig. 4 shows where to find the Series letter.

Fuse

Fig. 4. DataTrak Battery and Fuse Location

12 313840G

Page 13

DataTrak Operation

313840G 13

Page 14

Parts

ti14052a

Aluminum

Plastic

1

2

3

4a

4b

Aluminum

Plastic

6a

6b

6c

6a

6b

6c

4d

4c

ti14226a

ti14225a

4d

4c

Parts

Conversion Kits, Cycle Count and Runaway Protection

Husky 1050 - 24B777 (Aluminum), 24B784 (Polypropylene), and 24B793 (Conductive Polypropylene)

Husky 3300 - 24K861 (Aluminum) and 24K862 (Polypropylene)

14 313840G

Page 15

Parts

Ref.

No. Part No. Description Qty

1 ----- DATATRAK module

(see pages 11 and 12 for battery and

fuse replacement information)

2 ----- CABLE 1

3 ----- BRACKET, wall 1

4 SOLENOID/REED SWITCH, kit

(includes Parts 4a-4d)

24B771 Husky 1050 plastic air valve

24B772 Husky 1050 aluminum air valve

24K863 Husky 3300 plastic air valve

24K864 Husky 3300 aluminum air valve

4a ----- REED SWITCH with SOLENOID 1

4b ----- SCREW, reed switch

8-32 x 1.50 taptite, aluminum air

valve

6-19 x 1-5/8 plastite, plastic air valve

4c ----- BRACKET, solenoid 1

4d ----- FASTENER, solenoid

M6 x 25 screw, aluminum air valve

M6 hex nut, plastic air valve

Ref.

No. Part No. Description Qty

6 AIR VALVE, kit

1

(includes Parts 6a-6c)

24B767 Husky 1050 Aluminum

24B774 Husky 1050 Polypropylene

24B776 Husky 1050 Conductive

1

Polypropylene

24K856 Husky 3300 Aluminum

24K858 Husky 3300 Polypropylene

6a ----- VALVE, air, smart 1

6b ----- GASKET, air valve 1

6c ----- FASTENERS, air valve

M6 x 25 screw, Aluminum air valve

1

M6 hex nut, Plastic air valve

7▲ 15V262 LABEL, warning (not shown) 1

8▲ 16A098 CARD, reference, language (not

shown)

▲ Replacement Warning labels, signs, tags, and cards

2

are available at no cost.

----- Not sold separately.

1

4

1

313840G 15

Page 16

Parts

1

2

3

5a

5b

ti14224a

Conversion Kits, Cycle Count Only

Husky 1050 and Husky 3300 - 24B794 (Aluminum) and 24B795 (Polypropylene and Conductive

Polypropylene)

Ref.

No. Part No. Description Qty

1 ----- DATATRAK module

(see pages 11 and 12 for battery

and fuse replacement information)

2 ----- CABLE, CAN 1

3 ----- BRACKET, wall 1

5 REED SWITCH, kit

(includes Parts 5a-5b)

24B796 Plastic air valve

24B798 Aluminum air valve

5a ----- REED SWITCH 1

5b ----- SCREW, reed switch

8-32 x 1.50 taptite, aluminum air

valve

6-19 x 1-5/8 plastite, plastic air

valve

6▲ 15V262 LABEL, warning (not shown) 1

7▲ 16A098 CARD, reference, language (not

shown)

▲ Replacement Warning labels, signs, tags, and cards

are available at no cost.

1

1

1

1

16 313840G

Page 17

Replacement Kits

Solenoid/Reed Switch

Parts

Husky

1050

24B771 24K863

24B772 24K864

Husky

3300 Air Valve Material Includes

Plastic Reed switch and solenoid (4a),

Aluminum

Reed Switch

Husky

1050 or

Husky

3300 Air Valve Material Includes

24B796

24B798

Plastic

Aluminum

Reed switch (5a)

and fastener (5b)

bracket (4c), and fasteners (4b, 4d)

313840G 17

Page 18

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

For patent information, see www.graco.com/patents.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6921 or Toll Free: 1-800-328-0211 Fax: 612-378-3505

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2009, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

Graco reserves the right to make changes at any time without notice.

Original instructions.This manual contains English. MM 313840

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

www.graco.com

Revision G, July 2014

Loading...

Loading...