Page 1

Operation

311044E

ENG

Self-contained, single color, electronic plural component paint proportioner, with carbon

steel UltraMix™ Pump and remote mix manifold. For professional use only.

250 psi (1.7 MPa, 17 bar) Maximum Fluid Working Pressure

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

See page 3 for model information, including

maximum working pressure.

TI6640a

Conforms to FM std 3600 & 3610 for use in

Class I Div 1 Group D T3 Hazardous Locations

CAN/CSA 22.2 No. 157-92

& No. 1010.1-92

Page 2

Manual Conventions

Contents

Manual Conventions . . . . . . . . . . . . . . . . . . . . . . . . 2

ProMix Easy Models . . . . . . . . . . . . . . . . . . . . . . . . 3

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Air Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Solenoid Module . . . . . . . . . . . . . . . . . . . . . . . . . 7

Fluid Control Valves . . . . . . . . . . . . . . . . . . . . . . 7

Solvent Control Valves . . . . . . . . . . . . . . . . . . . . 9

Hose Bundle/Mix Manifold . . . . . . . . . . . . . . . . 10

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . 13

Mix Manifold to Gun . . . . . . . . . . . . . . . . . . . . . 13

Pump to Gun . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Flushing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Mix Manifold Flushing . . . . . . . . . . . . . . . . . . . . 15

Full System Flushing . . . . . . . . . . . . . . . . . . . . . 16

Flush Sampling Valves . . . . . . . . . . . . . . . . . . . 17

Priming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Pump Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Spraying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Batch Dispense or Ratio Check . . . . . . . . . . . . . . 21

Pot Life Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Recirculation Setting . . . . . . . . . . . . . . . . . . . . . . . 23

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Recalibrate System . . . . . . . . . . . . . . . . . . . . . . . . 25

Set Pump Calibration Value . . . . . . . . . . . . . . . . 25

Calibrate Pump Sensor . . . . . . . . . . . . . . . . . . . 25

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Performance Charts . . . . . . . . . . . . . . . . . . . . . . . . 28

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 30

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 30

Manual Conventions

WARNING

Hazard Symbol

WARNING: a potentially hazardous situation which, if

not avoided, could result in death or serious injury.

Warnings in the instructions usually include a symbol

indicating the hazard. Read the general Warnings

section for additional safety information.

CAUTION

CAUTION: a potentially hazardous situation which, if

not avoided, may result in property damage or

destruction of equipment.

Note

Additional helpful information.

2 311044E

Page 3

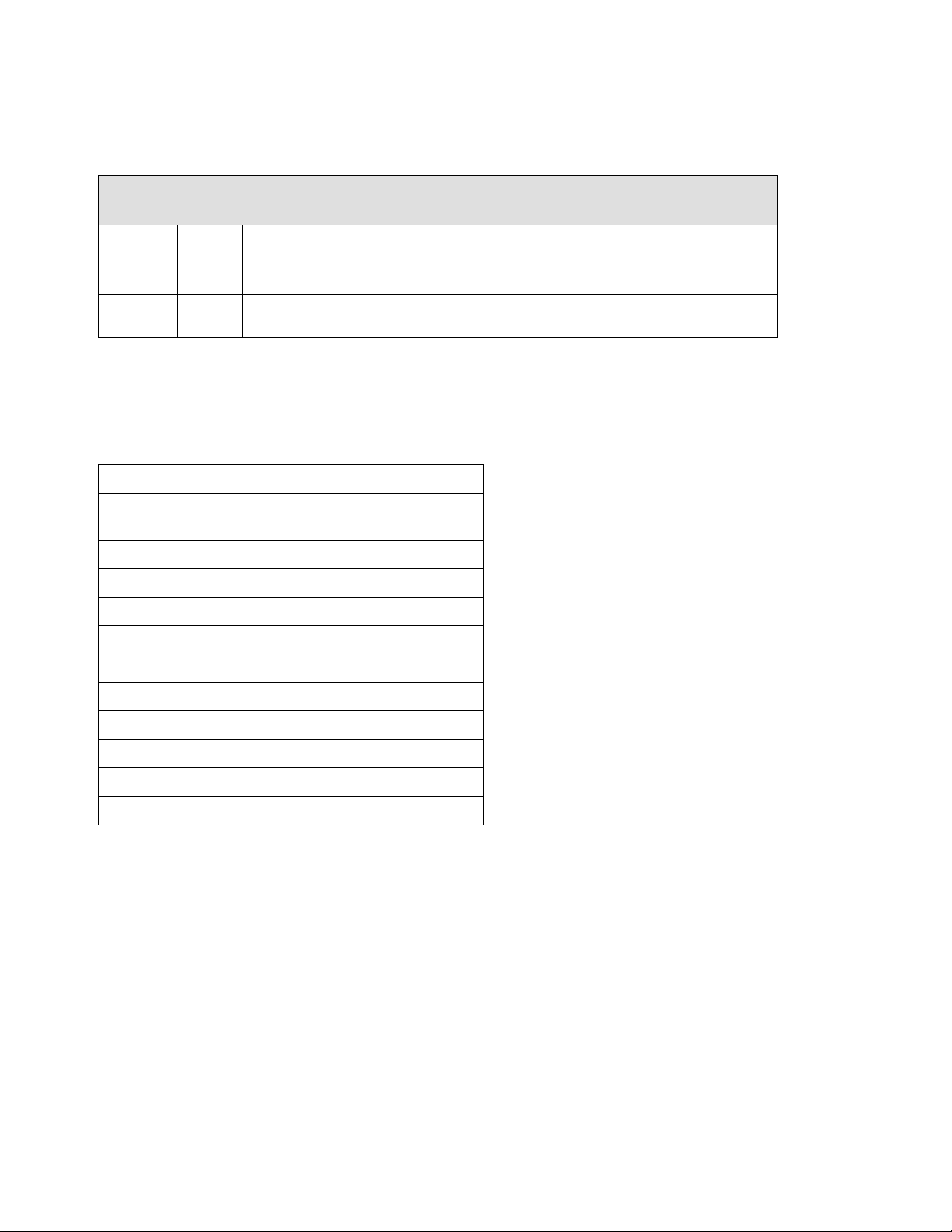

ProMix Easy Models

Approved for Hazardous Location

Class I, Div 1, Group D (North America)

ProMix Easy Models

ProMix

Easy

Part No. Series Description and Approvals

249322 A UltraMix carbon steel pumps and remote mix mani-

fold

Related Manuals

Manual Description

311045 ProMix Easy with Remote Mix Manifold,

Repair-Parts Manual

310655 Dispense Valve

310662 Displacement Pumps

310671 UltraMix Pumps

310673 Circulation Kits

310675 AC Power Supply

Maximum

Working Pressure

psi (MPa, bar)

250 (1.7, 17)

310678 TSL Pump Kits

310700 Gun Air Regulator Kits

309192 ISO Supply Kit

309623 Data Download Kits

308034 Turbine Alternator Repair Kit

311044E 3

Page 4

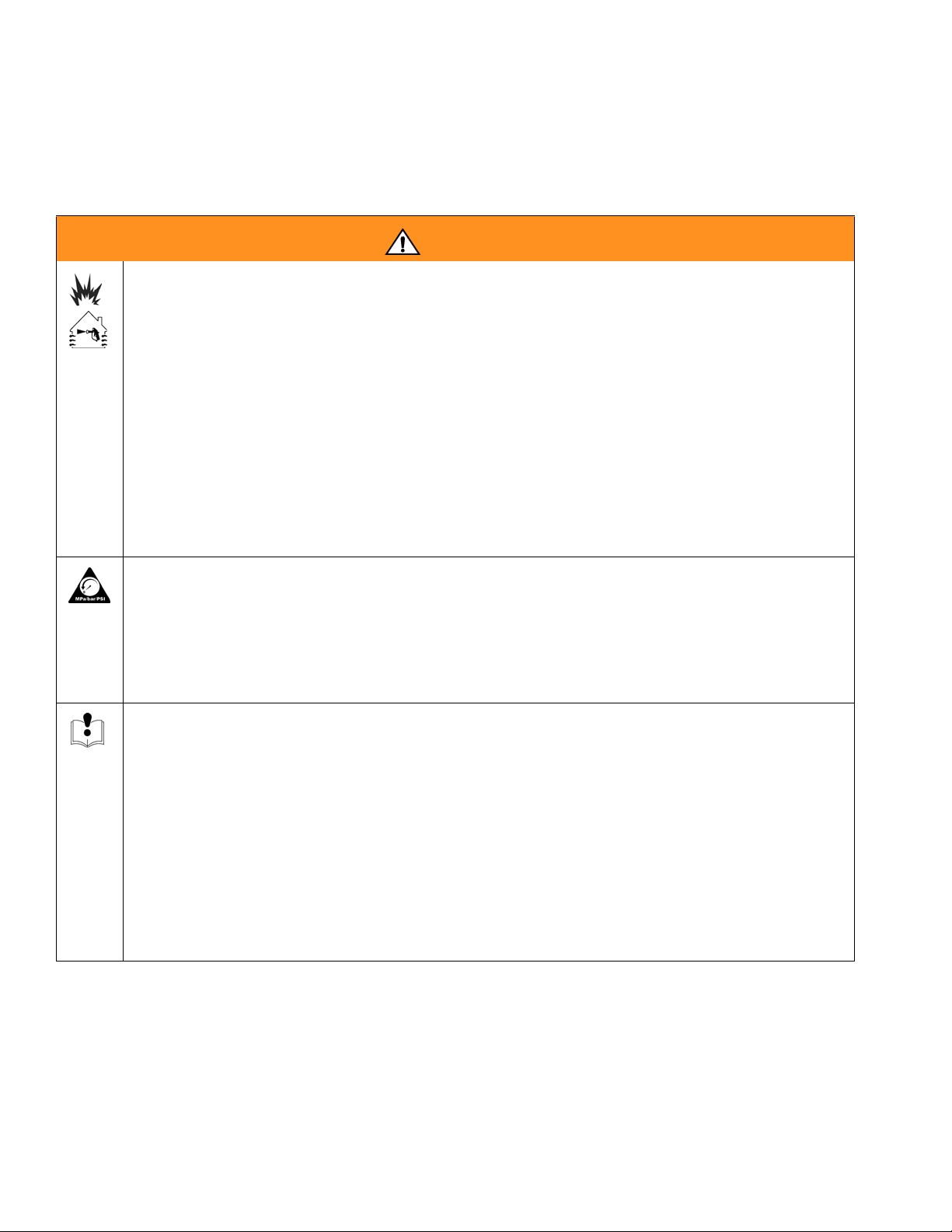

Warnings

Warnings

The following general warnings are related to the safe setup, use, grounding, maintenance, and repair of this equipment. Additional more specific warnings may be found throughout the text of this manual where applicable.

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes

are present.

• Ground all equipment in work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

• Keep a fire extinguisher in the work area.

PRESSURIZED EQUIPMENT HAZARD

Fluid from the gun/dispense valve, leaks, or ruptured components can splash in the eyes or on skin and

cause serious injury.

• Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning,

checking, or servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses, tubes, and couplings daily. Replace worn or damaged parts immediately.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings.

• Check equipment daily. Repair or replace worn or damaged parts immediately.

• Do not alter or modify equipment.

• For professional use only.

• Use equipment only for its intended purpose. Call your Graco distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or overbend hoses or use hoses to pull equipment.

• Comply with all applicable safety regulations.

4 311044E

Page 5

Warnings

WARNING

MOVING PARTS HAZARD

Moving parts can pinch or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment,

follow the Pressure Relief Procedure in this manual. Disconnect power or air supply.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read MSDS’s to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, including eye injury, inhalation of toxic

fumes, burns, and hearing loss. This equipment includes but is not limited to:

• Protective eyewear

• Clothing and respirator as recommended by the fluid and solvent manufacturer

•Gloves

• Hearing protection

311044E 5

Page 6

Overview

Overview

Usage

The ProMix Easy can mix most two-component paints. It

is not for use with “quick-setting” paints (those with a pot

life of less than 5 minutes) without modification. Contact

your distributor for information.

The ProMix Easy is operated with the User Interface, Air

Controls and Fluid Controls, described below and on

page 7. Refer to F

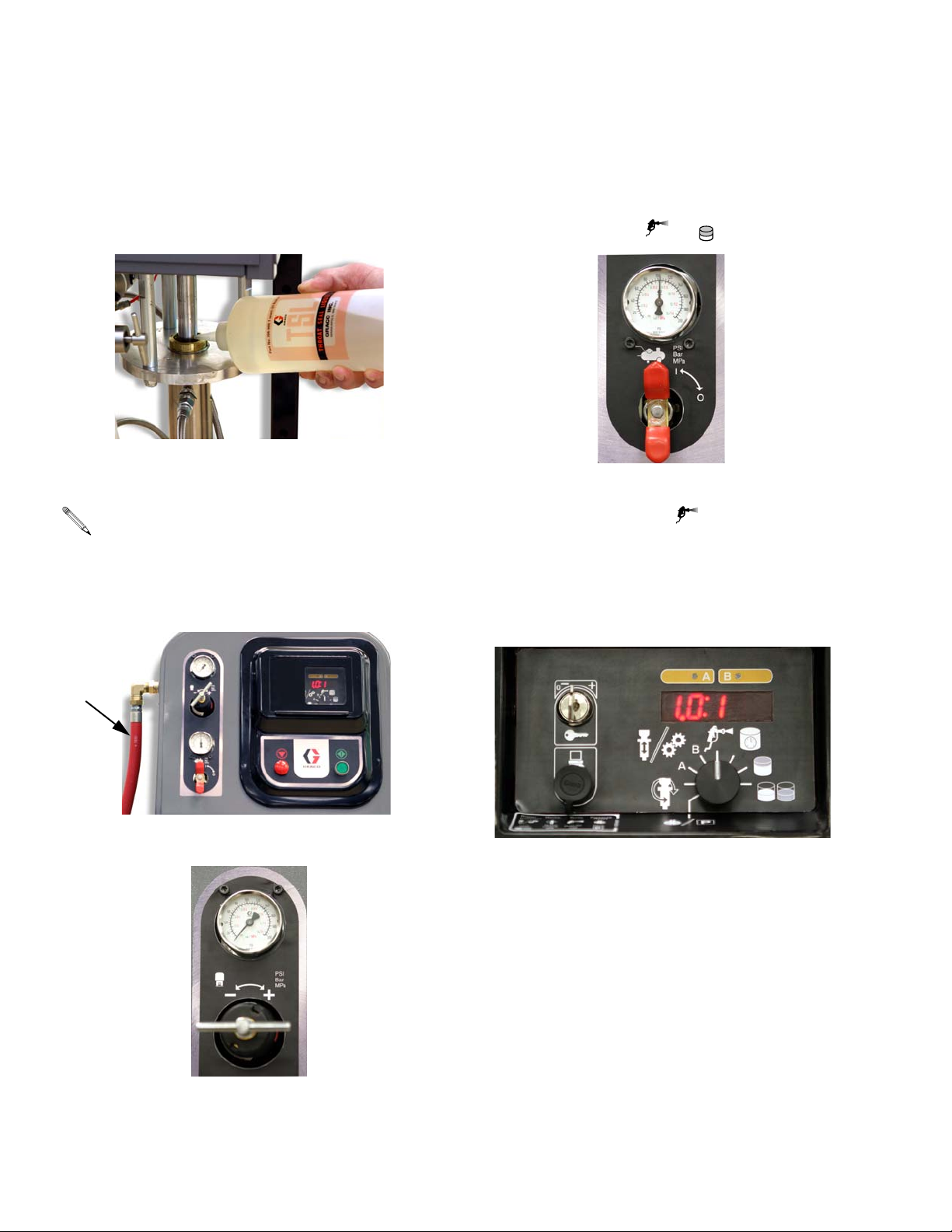

User Interface

The User Interface has 6 main interfaces.

1. Function Knob to select desired function:

Icon Function

IG. 1 and FIG. 3.

Spray: proportion and spray material.

Run A: operate A independent of B (prim-

ing, flushing) for 12 cycles.

Run B: operate B independent of A (prim-

ing, flushing) for 12 cycles.

Batch Dispense: dispense proportioned

amounts of A and B (1 pint/500 cc).

Pump Test: dispense predetermined

amount of A and B to verify pump operation.

Recirculation: optional; requires 248652

Circulation Kit, see page 23.

Pot Life Timer: display potlife time left.

Pressure Relief/Park: allows pressure relief

and runs pumps to the bottom of stroke.

See page 13.

3. Stop button to terminate functions.

4. Key switch to change ratio, pot life time, pot life vol-

ume, or calibration data.

5. Display (five digits) to view:

• Software revision level at startup

•Ratio

• Pot life time and reset volume

• Alarm codes

• Sensor calibration factor.

6. Data port allows for connection to a PC serial port

to download volume totalizer, operation, ratio setting, and error alarm data.

WARNING

To avoid impairing intrinsic safety and reduce the risk

of fire and explosion, the PC must be in a non-hazardous location and a safety barrier must be installed

between the PC and ProMix Easy unit. See data

download kit manual 309623.

LT

4

5

6

1

3

2

• System totalizers count in Spray and Batch

Dispense functions only.

F

• A and B Indicators (LT) show which dispense

valve(s) is open.

2. Start button to initiate functions.

6 311044E

IG. 1. User Interface

You must recalibrate the circuit board whenever the

main circuit board, software, or sensor is replaced,

or when Alarm 8 occurs. See Recalibrate System,

page 25.

Page 7

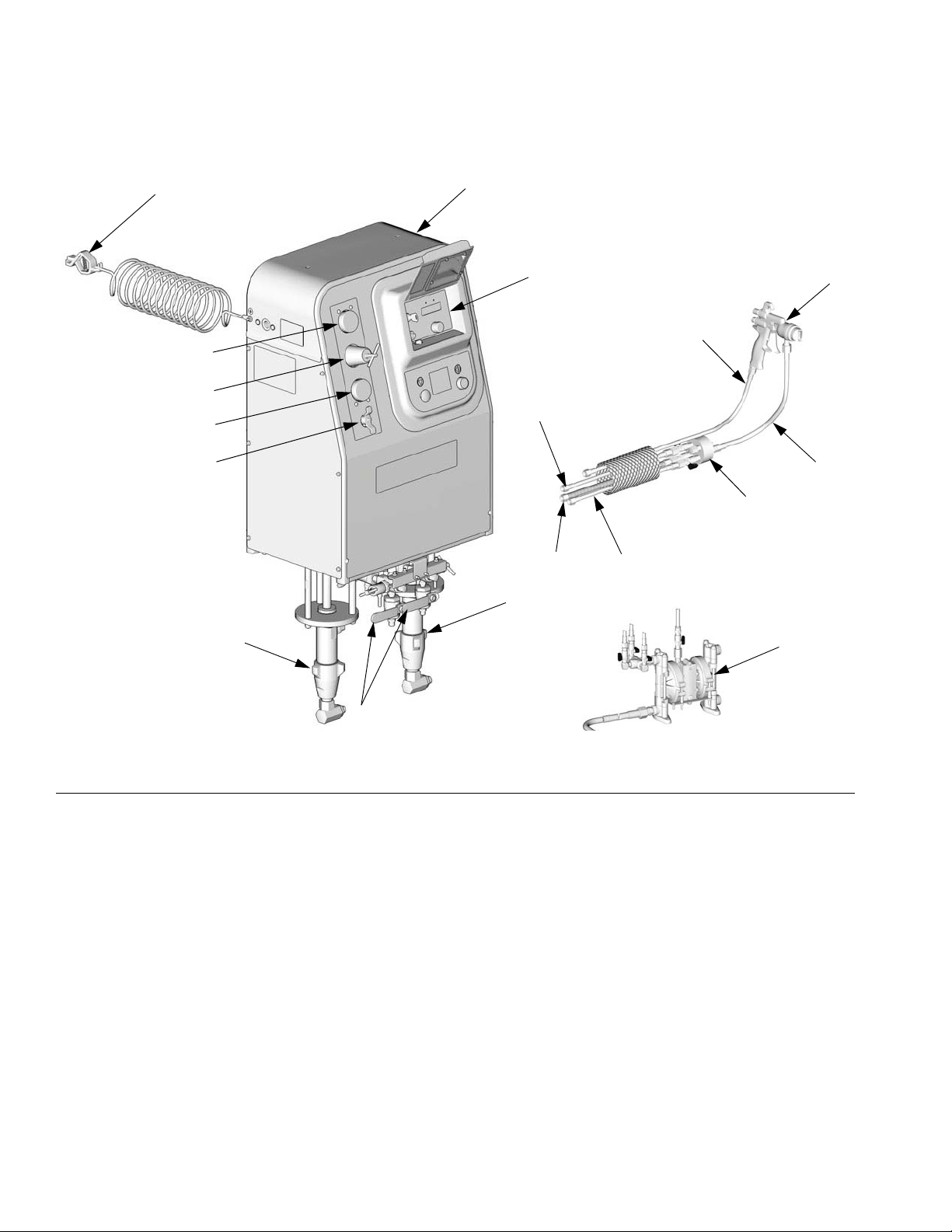

Air Controls

Overview

See FIG. 3.

• Bleed-type main air shutoff valve (C), shuts off all

air to ProMix Easy (including controller power).

• Supply air pressure gauge (D), monitors air pres-

sure to ProMix Easy.

A minimum air pressure supply of 70 psi (483 kPa,

4.8 bar) must be maintained for the ProMix Easy

to operate properly.

• Pump air pressure regulator (E) with gauge (F),

adjusts and monitors pump air pressure.

• Gun air regulator (P) and gauge (shipped loose),

adjusts and monitors gun air pressure.

Solenoid Module

There are two solenoids inside the pneumatic control

box, one to actuate dispense valve A, one to actuate

dispense valve B.

DA

SA

A

DB

SB

B

TI6510a

FIG. 2. Dispense Valves, Sampling Valves, and Fluid

Outlet Valves

AB

TI4808a

Fluid Control Valves

• Dispense valves (DA, DB) dispense the correct

dose of component A and component B to the

remote mix manifold. Solenoids A and B turn the

dispense valves ON and OFF. See F

• Sampling valves (SA, SB), to batch dispense or

test pumps. See F

• Fluid outlet valves allow components A and B to

enter the fluid hoses. See F

IG. 2.

IG. 2.

IG. 2.

311044E 7

Page 8

Overview

Y

V

Z

X

R

F

E

D

C

A

W

T

TI6628a

B

S

K

G

N

FIG. 3. ProMix Easy Proportioner, Major Components

Key for F

A Component A Fluid Hoses

B Component B Fluid Hose (braided)

C Bleed-Type Main Air Shutoff Valve

D Air Supply Pressure Gauge

E Pump Air Regulator

F Pump Air Pressure Gauge

G Component A Pump

K Component B Pump

N Fluid Outlet Valves

P Gun Air Pressure Regulator (not shown)

R Gun Air Supply Hose

S Solvent Supply Hose

T Remote Mix Manifold

U Solvent Pump

V ProMix Easy Plural Component Proportioner

W Fluid Whip Hose/Static Mixer

X Air Spray Gun (not included with system)

Y Ground Wire

IG. 3

TI6640a

Z User Interface (see page 6)

U

TI6425a

8 311044E

Page 9

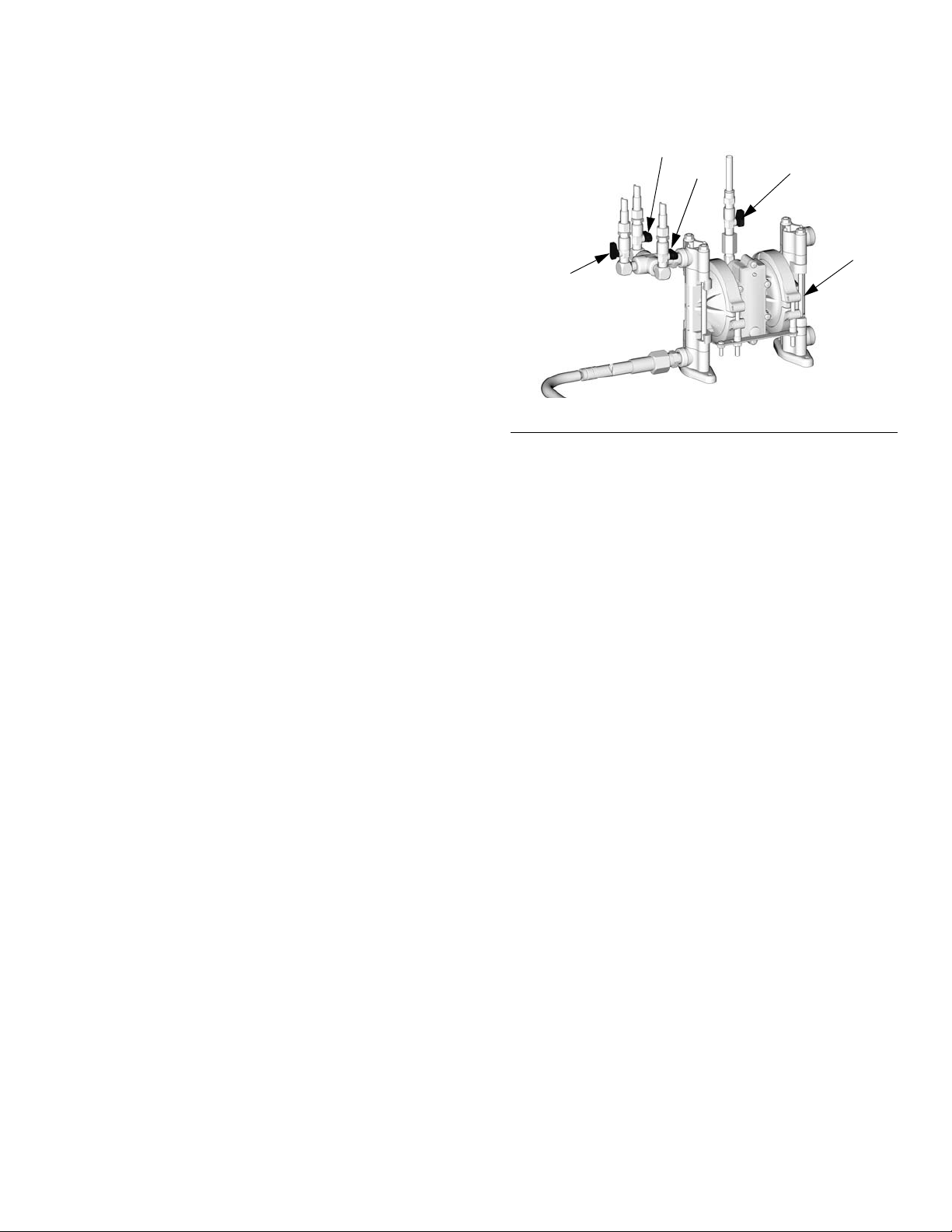

Solvent Control Valves

Solvent pump (U) pumps solvent from a user-supplied

solvent container.

• Solvent pump air valve (SV) turns on the solvent

pump.

• A and B solvent valves (VA, VB) allow flushing of

sampling valves A and B.

• Solvent valves allow flushing of the mix manifold,

whip hose, and gun. Valve S1 is at the solvent pump

outlet. Valve S2 is at the mix manifold.

VB

S1

F

IG. 4. Solvent Pump and Valves

Overview

SVVA

U

TI6425a

311044E 9

Page 10

Overview

Hose Bundle/Mix Manifold

See FIG. 5. Hose bundle includes a gun air supply hose

(R), solvent hose (S), and component A and B hoses.

The component B hose is steel braid. The component A

hose is nylon. Hoses are encased in a protective cover.

The component A and component B hoses have fluid

shutoff valves upstream of the mix manifold. These

valves are both open when spraying. Close these valves

at Shutdown, page 24.

Solvent valve (S2) is always closed except when flushing (see Mix Manifold Flushing, page 15). Check

valves (CB) are provided to prevent cross-contamination

of the solvent line and fluid lines.

CB

A

B

Remote Mix Manifold

• Components A and B are pre-mixed in the mix manifold (T), then uniformly blended in the whip

hose/static mixer (W) before being sprayed.

• Use the built-in fluid regulator (FR) to adjust fluid

pressure to the spray gun. Regulator must be open

to permit flow.

FR

T

TI6606a

W

T

F

IG. 5. Mix Manifold Valves

S2

S

TI6603a

10 311044E

Page 11

Installation

Installation

The Typical Installation shown in FIG. 3 is not an actual

system design. Contact your Graco distributor for assistance in designing your system. Be sure all accessories

are adequately sized and pressure-rated to meet system requirements.

Reference numbers and letters in the text refer to numbers and letters in the figures.

Icons in the text refer to icons on the User Interface.

When the unit is first started up or has been

shutdown for longer than 2 months, you must turn it

on for 8 hours to recharge battery. Reset the date

and time with the Setup program, which is available

with the data download kit.

The unit should be run continuously for 8 hours or

more at least once per month to maintain proper

charge. If the battery is not recharged on a regular

schedule, the date information may be reset. If the

date is reset, the date information will be incorrect

in the data log.

3. Connect the component A and component B fluid

lines of hose bundle (S) to the fluid outlet valves,

according to labels on the hoses.

4. Connect the solvent hose (S) to solvent valve S1 at

the solvent pump (U). (Two hoses to flush sampling

valves are pre-attached at the factory.)

5. Install the gun air regulator (P) in a convenient, eas-

ily accessible location for the operator. See manual

310700.

6. Connect the air hose (R) between the outlet of the

gun air regulator and the air inlet of the spray gun

(X).

X

WARNING

Read warnings, page 4. Ground equipment as

instructed below.

1. Connect ProMix Easy ground wire (Y) to a true earth

ground.

Y

TI4792a

2. Locate the ProMix Easy in a convenient location.

Ensure there is adequate clearance on all sides for

operator access and servicing.

R

TI4837a

7. Connect the fluid whip hose/static mixer (W) to the

fluid inlet of the spray gun (X).

X

W

TI4854a

311044E 11

Page 12

Setup

Setup

1. Tighten all hose connections and all fittings on unit.

2. Fill pumps A and B packing nuts with throat seal liq-

uid (TSL).

3. Connect main air supply line (AL) to air inlet.

Air supply requirement: 110 psi (0.8 MPa, 8 bar)

maximum, 70 psi (483 kPa, 4.8 bar) minimum; 20

scfm (0.56 m

3

/min).

5. Open main air shutoff valve. When starting up, dis-

play will show “88888”, then software revision, then

current ratio (if set to or

).

6. Setup ratio.

a. Turn function knob to .

b. Current ratio displays.

c. To change ratio, turn key to + or – until desired

ratio is displayed, then turn key back to neutral.

AL

4. Set air regulator to 0.

7. Flush and prime system. See pages 15 and 18. Run

Pump Test, page 19 to check ratio accuracy.

12 311044E

Page 13

Pressure Relief Procedure

Pressure Relief

Procedure

WARNING

Relieve pressure from mix manifold to gun whenever

you stop spraying and before servicing gun or removing nozzle.

In addition, relieve pressure from pump to gun at end

of day and before cleaning, checking, or servicing

pump, manifold, or fluid line accessories or transporting equipment. See page 14.

Read warnings, page 4.

Mix Manifold to Gun

1. Press .

2. Close all valves at mix manifold.

3. Hold a metal part of the gun firmly to a grounded

metal pail. Trigger gun to relieve pressure.

TI4836a

311044E 13

Page 14

Pressure Relief Procedure

Pump to Gun

1. Open all fluid valves at mix manifold. Leave solvent

valve (S2) closed.

TI6603a

S2

2. Open all fluid outlet valves.

3. Turn function knob to pressure relief/park .

5. Hold a metal part of the gun firmly to a grounded

metal pail. Trigger gun to relieve component A pressure. Indicator A will stay on for 5 sec after Pump A

reaches Park position, then go off.

TI4836a

6. Indicator B comes on and Pump B pressurizes.

7. Hold a metal part of the gun firmly to a grounded

metal pail. Trigger gun to relieve component B pressure. Indicator B will stay on for 5 sec after Pump B

reaches Park position, then go off.

4. Press . Indicator A comes on, and Pump A pres-

surizes.

Pump air supply pressure must be sufficient to

cause pumps to stroke to bottom-most position

when function knob to is set to pressure relief/park

.

TI4836a

If both pumps are not parked after 1 min, Alarm

26 will sound.

14 311044E

Page 15

Flushing

Flushing

• There are times when you only want to flush the mix

manifold, such as:

• breaks in spraying

• overnight shutdown

• end of potlife

In this manual, this procedure is referred to as Mix

Manifold Flushing (see this page).

• Other times, Full System Flushing (page 16) is

necessary:

• first time material is loaded into equipment*

• material change

•servicing

• putting equipment into storage

* Some Full System Flushing steps are not neces-

sary for initial flushing, as no material has been

loaded into the system yet.

• After doing a pump test or ratio check, you need to

Flush Sampling Valves (page 17).

2. Open valve S2 at mix manifold. Close all other mix

manifold valves.

S2

TI6626a

3. Ensure that valves VA and VB at solvent pump are

closed. Open valve S1. Open valve SV to turn on

solvent pump.

VB

SVVA

U

S1

WARNING

Read warnings, page 4.

• Use the lowest possible pressure when flushing to avoid splashing.

• Before material change or shutdown for storage, flush at a higher flow rate and for a longer

time.

Mix Manifold Flushing

1. Follow complete Pressure Relief Procedure, pages

13 and 14. Ensure that A and B pumps are parked

before proceeding.

CAUTION

Do not exceed 100 psi (0.7 MPa, 7 bar) air input pressure to the solvent pump.

TI6425a

4. Trigger gun into a grounded pail. Flush through gun

until clean solvent flows.

TI4836a

5. Close valve SV to shut off solvent pump.

6. Trigger gun to relieve solvent pressure.

7. Close solvent valve(s) S1, S2.

311044E 15

Page 16

Flushing

Full System Flushing

Use the lowest possible pressure while flushing, to

avoid splashing.

1. Follow Pressure Relief Procedure, page 13. Set air

regulator to 0, and close main air shutoff valve.

2. Replace component A and B supplies with solvent.

3. Set air regulator to 50 psi (345 kPa, 3.4 bar).

4. Turn function knob to A . Press .

7. Open sampling valve SA slowly. Pump A will run for

12 cycles, then stop. Restart as needed. When

clean solvent flows from sampling valve SA, close

valve.

SA

TI6634a

8. Trigger gun into grounded pail until clear solvent

flows from gun. You may have to press more

than once. When solvent is clear, press .

9. Repeat steps 4-8 for the B side.

5. Open fluid outlet valve A.

A

TI6604a

6. Ensure that all valves at mix manifold are open.

TI6627a

SB

TI6635a

10.Follow Pressure Relief Procedure, page 13, and

remove gun from hose. See gun manual to further

clean gun.

Some materials require additional cleaning. You

may need to circulate solvent through the system.

16 311044E

Page 17

Flushing

Flush Sampling Valves

Flush the sampling valves after doing a pump test (page

19) or ratio check (page 21).

1. Follow Pressure Relief Procedure, page 13.

2. Close all fluid outlet valves.

TI6510a

3. Open valve VA and close valves S1 and VB at sol-

vent pump. Turn on solvent pump.

VB

SVVA

5. Close valve VA and open valve VB at solvent pump.

Repeat for component B side.

VB

SVVA

U

S1

TI6426

U

S1

TI6427a

4. Open sampling valve SA. When clean solvent flows

from sampling valve SA, close valve.

SA

SB

TI6510a

311044E 17

Page 18

Priming

Priming

Use the lowest possible pressure while priming, to

avoid splashing.

1. Connect fluid supply hoses to A and B pumps.

Tighten all hose connections and fittings.

2. Set air regulator to 0.

5. Turn function knob to A . Press . Turn up

air regulator slowly until pump A starts. Trigger gun

into grounded pail until fluid flows steadily from gun.

You may have to press more than once. When

1 hose and gun are primed, press .

A

3. Open fluid outlet valve A.

A

TI6604a

4. Open all fluid valves at mix manifold. Leave solvent

valve (S2) closed. Ensure that fluid regulator (FR) is

open, to permit flow.

When run independently (set to A or B), the pump

runs for 12 cycles, then stops. Press and

as needed to prime.

6. Repeat steps 3-5 for the B side.

7. Test spray a pattern to ensure you get desired

results. Perform Pump Test, page 19.

S2

18 311044E

TI6603a

Page 19

Pump Test

Pump Test

Follow this procedure the first time system is operated

(after flushing and priming).

The volume dispensed during the pump test (5 cycles) is

270 cc. Dispense into a container with adequate graduations.

1. Turn function knob to . Set air regulator to 0.

Open main air shutoff valve. Adjust air pressure to

50 psi (0.35 MPa, 3.5 bar).

e. Slowly open and adjust sampling valve SA to

achieve desired flow. The pump stops automatically after 5 cycles. During the last cycle the

pump will stop once on the upstroke and once

on the downstroke to perform a pump stall test.

Indicator A turns off, indicator B comes on.

SA

TI6510a

3. Close sampling valve SA.

4. Dispense fluid B as follows:

a. Place a clean 1 quart (1000 cc) container under

sampling valve SB.

b. Slowly open and adjust sampling valve SB to

achieve desired flow. The pump stops automatically after 5 cycles. Indicator B turns off.

2. Dispense fluid A:

a. Close all fluid outlet valves.

b. Close sampling valves (SA and SB).

c. Place a clean 1 quart (1000 cc) container under

sampling valve SA.

d. Press . Indicator A comes on.

SB

TI6510a

5. Close sampling valve SB.

6. Compare fluid amounts in the containers; they

should be about equal. Repeat test if fluids are not

equal. If problem persists, contact Graco engineering.

If pump fails any of pump stall tests, alarm will display (see alarms 15-20, page 27).

7. Flush Sampling Valves, page 17.

311044E 19

Page 20

Spraying

Spraying

1. Close sampling valves SA and SB.

2. Open fluid outlet valves.

TI6633a

3. At remote mix manifold, close valve S2. Ensure that

all other valves at mix manifold are open.

6. Press .

7. Adjust air regulator to the necessary spraying pres-

sure; see gun manual. You can also adjust fluid

pressure with the fluid regulator on the mix manifold.

Press to proportion and spray a test pattern.

See gun manual for spray pattern adjustments to get

desired results.

8. Follow Mix Manifold Flushing, page 15, or Shut-

down, page 24, when you are done spraying or

before potlife expires.

S2

TI6603a

4. Turn function knob to . Press .

5. Trigger gun into a pail and slowly increase air regula-

tor pressure until pump is running and consistently

mixed material is dispensed.

Mixed material potlife or working time

decreases with increased temperature.

TI4836a

20 311044E

Page 21

Batch Dispense or Ratio Check

Batch Dispense or Ratio Check

Batch dispense is always 1 pint (500 cc) of total

volume, regardless of ratio setting.

Follow this procedure to dispense a batch (into one container) or verify a ratio setting (use separate container

for fluid A and B). Dispense into a container with graduations no greater than 5% of each component.

1. Turn function knob to . Set air regulator to 0.

Open main air shutoff valve. Adjust air pressure to

50 psi (0.35 MPa, 3.5 bar).

e. Slowly open and adjust sampling valve SA to

achieve desired flow. The pump stops automatically when dispense is complete. Indicator A

turns off, indicator B comes on.

SA

TI6510a

3. Close sampling valve SA.

4. Dispense fluid B:

a. Batch dispense: move the 1 quart (1000 cc)

container under sampling valve SB.

Ratio check: place clean 1 quart (1000 cc) container under sampling valve SB.

2. Dispense fluid A:

a. Close all fluid outlet valves.

b. Close sampling valves (SA and SB).

c. Place a clean 1 quart (1000 cc) container under

sampling valve SA.

d. Press . Indicator A comes on.

On higher ratio settings, use a smaller container for

more accurate readings.

b. Slowly open and adjust sampling valve SB to

achieve desired flow. The pump stops automatically when dispense is complete. Indicator B

turns off.

SB

5. Batch dispense: stir material until mixed.

Ratio check: compare A and B fluid dispense.

6. Flush Sampling Valves, page 17.

7. To resume Spraying, see page 20.

TI6510a

311044E 21

Page 22

Pot Life Timer

Pot Life Timer

To Display Pot Life Time Left (in minutes)

Turn the function knob to .

How Pot Life Timer Works

Pot life timer starts to countdown at the start of

Spray mode. Once the pot life timer is active, it will

continue to time down, regardless of which mode the

system is in.

When the timer reaches zero, the system closes all dispense valves and a pot life (code 21) alarm occurs

(audible alarm sounds). Refer to page 26.

To Change Pot Life Time

Approximate Pot Life Volume

Volume of mix manifold, whip hose, and gun = 100 cc.

Pot Life Reset Volume

The timer resets when the total spray volume exceeds

the pot life reset volume.

To change reset value, hold down . Turn the key to

increase/decrease pot life reset volume (cc).

When an Alarm Occurs

Press to clear alarm, then flush system (page 15),

or press and spray until fresh material is loaded

into system.

Hold down . Turn the key to increase/decrease pot

life time (minutes).

Recommend setting pot life time to 1/2 of material

pot life.

22 311044E

Page 23

Recirculation Setting

Recirculation Setting

Fluid can be circulated up to the dispense valves with

the addition of Graco’s Circulation Kit 248652. Consult

your distributor.

During recirculation only the pump runs; A and B

dispense valves do not operate. Material pumped

in recirculation mode is not counted by the totalizer.

To set the ProMix Easy to circulate:

1. Decrease the pump air pressure supply to the mini-

mum required to maintain the desired circulation volume.

2. Turn function knob to .

3. Press .

To terminate circulation, press .

To begin circulating again, press .

To begin spraying, turn function knob to , reset

system to desired ratio, and adjust pump to spray pressure.

CAUTION

Be sure recirculation valve does not leak material

back to fluid supply while spraying.

311044E 23

Page 24

Shutdown

Shutdown

1. Follow Pressure Relief Procedure, page 13. Set air

regulator to 0, and close main air shutoff valve.

2. See Flushing, page 15.

a. For overnight shutdown, follow Mix Manifold

Flushing, page 15.

b. For prolonged shutdown, follow Full System

Flushing, page 16.

3. Follow Pressure Relief Procedure, pages 13 and

14.

4. Close all valves at the mix manifold.

5. Before prolonged shutdown: cap fluid outlets to

keep solvent in the lines. Fill pump A and B packing

nuts and dispense valve A and B wet cups with

throat seal liquid (TSL).

24 311044E

Page 25

Recalibrate System

Recalibrate System

Follow steps 1-9 whenever the main circuit board, software, or sensor is replaced, or when Alarm 8 occurs

(refer to page 26). If sensor only needs recalibration, follow steps 7-9.

If data download is used, set date and time after

calibrating, using ProMix Easy software.

Set Pump Calibration Value

1. Note calibration value (CV) on pump sensor.

CV

Calibrate Pump Sensor

7. Trigger gun into a pail or open sampling valve SA or

SB.

TI4836a

SA

SB

TI6510a

2. Open main air valve to start unit. Allow time for sys-

tem to boot up and display ratio setting.

3. Turn function knob to A or B .

4. Hold down (continue to hold until calibration

value is set in step 6). After 5 seconds, the default

calibration value (between 85000 - 95000) displays.

5. Turn key to change default to calibration value noted

in step 1 (left to decrease, right to increase).

6. Release after entering calibration value.

8. Hold down (continue to hold until told to

release). The current calibration value displays.

9. Press . Release first, then release .

The pump will cycle to the board end of sensor first,

then to the opposite end, and stop.

311044E 25

Page 26

Alarms

Alarms

• An alarm condition will shutdown equipment.

• See ProMix Easy Repair manual for troubleshooting and repair.

Code Alarm Active Problem Cause

Startup Errors

01 Sensor Error A* Always No signal from pump A

sensor

02 Sensor Error B* Always No signal from pump B

sensor

03 Communication Error* Always Loss of communication

between main and display boards

Operating Errors

04 not used

05 not used

06 Pump Error A** Spray

07 Pump Error B**

08 Sensor Code Error Always Sensor values reverted to

09 not used

10 not used

11 Sensor Reading Low A* Spray

12 Sensor Reading Low B*

13 Sensor Reading High A* Spray

14 Sensor Reading High B*

21 Pot Life Error Spray

Te st

Batch

Te st

Batch

Te st

Batch

first, then

Always

Pump does not stall after

top change over

Pump cavitating excessively

default

Pump stroke travels

beyond sensor range at

top change over

Pump stroke travels

beyond sensor range at

bottom change over

Pot life timer timed out Not enough material sprayed after last reset

* Indicates error where audible alarm sounds once briefly.

** Indicates error where audible alarm sound pulses.

Loose cable, failed sensor or cable, failed magnet

assembly

Loose cable, failed sensor or cable, failed magnet

assembly

Loose cable, failed board

Intake valve leak

Air in lines caused by loose fitting or use of agitator

Empty fluid supply

Sensor value data corrupt; board needs replacement

and /or recalibration

Sensor or bracket loose

Sensor magnet dirty

Sensor or bracket loose

Sensor magnet dirty

26 311044E

Page 27

Code Alarm Active Problem Cause

Operating Errors

(continued)

22 not used

23 not used

24 not used

25 not used

26 Park Timeout Park Pumps not at bottom of

stroke

Testing Error

15 Piston packing/ball A* Test Pump does not com16 Piston packing/ball B*

17 Inlet Ball A* Test Pump does not com18 Inlet Ball B*

19 Dispense Valve A* Test Pump does not com20 Dispense Valve B*

27 Pump Calibration

Timeout A

28 Pump Calibration

Timeout B

Run A Pump doesn’t run

Run B

pletely stall in up stroke

pletely stall in downstroke

pletely stall in both up

and down strokes

through calibration

Sampling valves closed, or gun not triggered

Piston packing or ball check failure

Intake valve ball check failure

Throat packing or dispense valve failure

Sampling valves closed

Alarms

311044E 27

Page 28

Performance Charts

Performance Charts

2.5:1 Ratio UltraMix Pump

Tested with 10W oil

250

(1.75, 17.5)

Fluid Outlet Pressure, psi (MPa, bar)

200

(1.4, 14.0)

150

(1.05, 10.5)

100

(0.7, 7.0)

50

(0.35, 3.5)

100 psi (0.7 MPa, 7 bar)

70 psi (0.48 MPa, 4.8 bar)

40 psi (0.28 MPa, 2.8 bar)

0

0

0.1 (0.38) 0.3 (1.14)0.2 (0.76) 0.4 (1.52) 0.5 (1.90)

Fluid Flow, gpm (lpm)

(curves are representative of all ratios)

28 311044E

Page 29

Technical Data

Mix ratio range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.1:1-10:1 (in 0.1 increments)

Ratio tolerance range . . . . . . . . . . . . . . . . . . . . . . . . . . . . up to +/- 5%

Flow rates

Minimum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.02 qt/min (0.02 lpm)*

Maximum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 gpm (3.8 lpm)

Pump size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54 cc/cycle

Pump cycle length

(one cycle = one upstroke and one downstroke) . . . . . . . 6 in. (152 mm)/cycle

Fluid viscosity range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50-2000 cps

Fluid filtration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60 mesh (238 micron) standard

Maximum fluid working pressure . . . . . . . . . . . . . . . . . . . 250 psi (1.7 MPa, 17 bar)

Air supply pressure range . . . . . . . . . . . . . . . . . . . . . . . . . 70-110 psi (483-800 kPa, 4.8-8 bar)

Maximum air consumption at 100 psi (0.7 MPa, 7 bar) . .

Air inlet size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1/2 npt(f)

Ambient temperature range

Operating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32-104° F (0-40° C)

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-160° F (–1-71° C)

Environmental Conditions Rating . . . . . . . . . . . . . . . . . . . Altitude up to 4000 meters

Sound pressure** . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70.3 dBA

Sound power** . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78.4 dBA

Wetted parts

Pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See 310662

Dispense Valves . . . . . . . . . . . . . . . . . . . . . . . . . See 310655

PC Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . RS-232

20 scfm (0.56 m

Maximum relative humidity to 99% up to 40° C

Pollution degree (1)

3

/min)

Technical Data

* Minimum flow rate is dependent on the material being sprayed and mixing capability. Test your material for spe-

cific flow rate.

** Tested in accordance with ISO 3744 at 100 psi (0.7 MPa, 7 bar) inlet air pressure.

311044E 29

Page 30

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor or call to identify the nearest distributor.

Phone: 612-623-6921 or Toll Free: 1-800-328-0211, Fax: 612-378-3505

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM 311044

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

Copyright 2005, Graco Inc. is registered to ISO 9001

www.graco.com

Revised 04/2010

Loading...

Loading...