Graco Inc. 249320, 249321, 258961 Repair - Parts

Repair - Parts

311004F

ENG

Self-contained, single color, electronic plural component paint proportioner, with carbon

steel UltraMix™ Pump and cart. For professional use only.

250 psi (1.7 MPa, 17 bar) Maximum Fluid Working Pressure

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

See page 3 for model information, including

maximum working pressure.

Model 249320 Clear Coat System Shown

Conforms to FM std 3600 & 3610 for use in

Class I Div 1 Group D T3 Hazardous Locations

TI6384a

CAN/CSA 22.2 No. 157-92

& No. 1010.1-92

Contents

Manual Conventions . . . . . . . . . . . . . . . . . . . . . . . . 2

ProMix Easy Models . . . . . . . . . . . . . . . . . . . . . . . . 3

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Pressure Relief Procedure (Models 249320 and

249321) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Fluid Manifold to Gun . . . . . . . . . . . . . . . . . . . . . 6

Pump to Fluid Manifold . . . . . . . . . . . . . . . . . . . . 7

Pressure Relief Procedure (Model 258961) . . . . . . 8

Fluid Manifold to Gun . . . . . . . . . . . . . . . . . . . . . 8

Pump to Fluid Manifold . . . . . . . . . . . . . . . . . . . . 9

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Preventive Maintenance Schedule . . . . . . . . . . 10

Dispense Valve . . . . . . . . . . . . . . . . . . . . . . . . . 10

Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Turbine Alternator . . . . . . . . . . . . . . . . . . . . . . . 10

Air Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Pump Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Wet Cup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Replacing Air Filter Element . . . . . . . . . . . . . . . 16

User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Pneumatic Control . . . . . . . . . . . . . . . . . . . . . . 20

Dispense Valve Assembly . . . . . . . . . . . . . . . . . 22

Pump Assembly . . . . . . . . . . . . . . . . . . . . . . . . 22

Remote Mix Manifold and Fluid Regulator

(249320 and 249321 only) . . . . . . . . . . . . . 23

Electrical Schematic . . . . . . . . . . . . . . . . . . . . . . . 24

Main Control Board Schematic . . . . . . . . . . . . . . . 25

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Part No. 249320 Clear Coat System, Series A

(shown) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Part No. 249321 Primer System, Series A . . . . . 26

Part No. 258961 Primer System, Series A

(shown) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Part No. 249302 Proportioner, Series A . . . . . . . 34

Pneumatic Schematic. . . . . . . . . . . . . . . . . . . . . 40

287230 Pump Air Control . . . . . . . . . . . . . . . . . . 41

248270 Intrinsically Safe Pneumatic Control . . . 42

234620 User Interface . . . . . . . . . . . . . . . . . . . . 44

249329 Pump Inlet Valve Assembly,

for 249320 Clear Coat System only . . . . . . . 45

249328 Pump Outlet Valve Assembly,

for 249320 Clear Coat System only . . . . . . . 45

249326 Dispense Valve Assembly,

for 249320 Clear Coat System. . . . . . . . . . . 46

249387 Dispense Valve Assembly,

for 249321 Primer System . . . . . . . . . . . . . . 47

249333 Hose Bundle and Remote Mix Manifold,

for 249320 Clear Coat System. . . . . . . . . . . 48

249386 Hose Bundle and Remote Mix Manifold,

for 249321 Primer System . . . . . . . . . . . . . . 49

244022 Remote Mix Manifold (249320 and

249321 only) . . . . . . . . . . . . . . . . . . . . . . . . 50

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 52

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 52

2 311004F

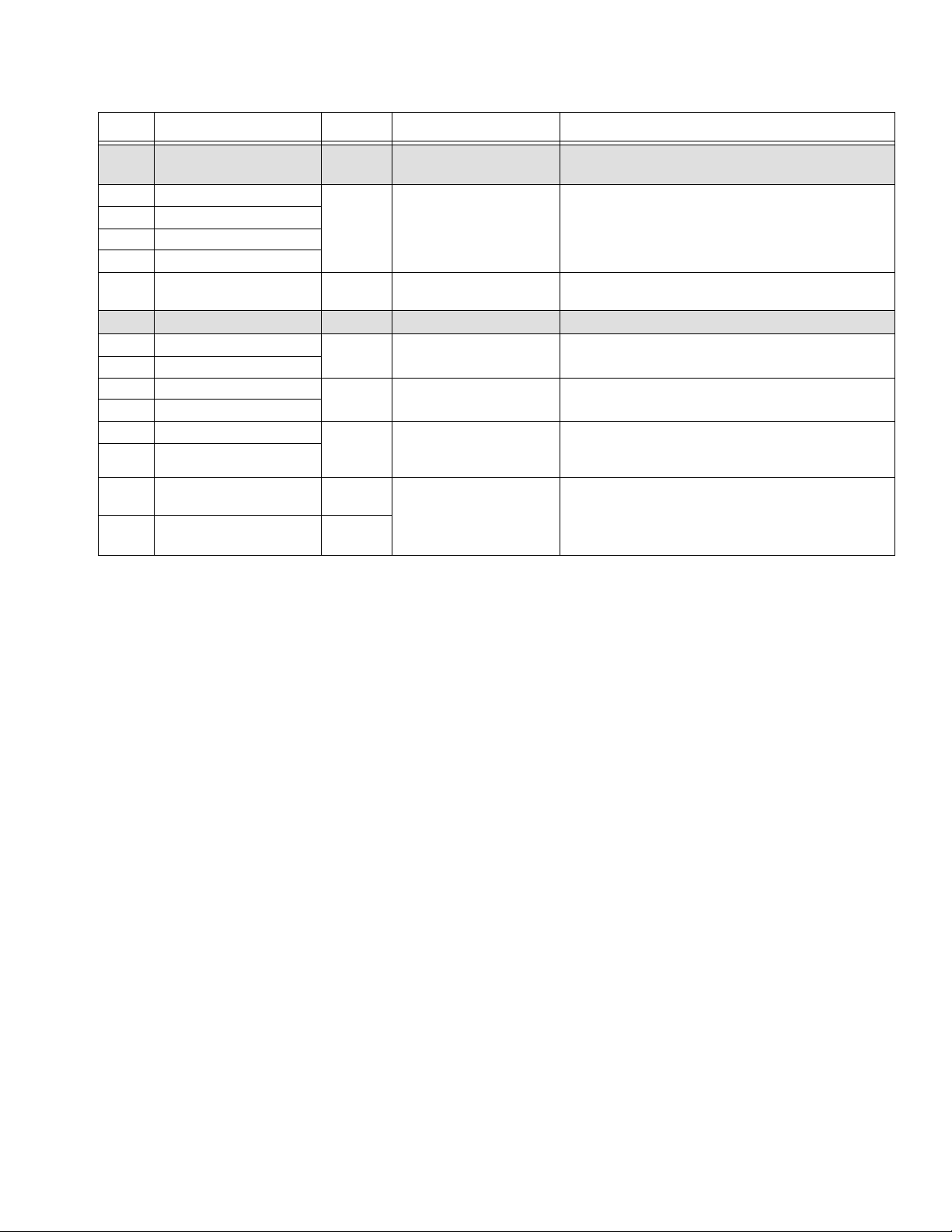

ProMix Easy Models

Approved for Hazardous Location

Class I, Div 1, Group D (North America)

ProMix Easy Models

ProMix

Easy

Part No. Series Description and Approvals

249320 A Clear coat system; cart mount, UltraMix carbon steel

pumps, and remote mix manifold

249321 A Primer system; cart mount, UltraMix carbon steel pumps,

and remote mix manifold

258961 A Primer system; cart mount, UltraMix carbon steel pumps,

standard mix manifold, and automatic flush valves

Related Manuals

Manual Description

311003 ProMix Easy Operation Manual

310655 Dispense Valve

310662 Displacement Pumps

310671 UltraMix Pumps

310673 Circulation Kits

310674 Mounting Kits

310675 AC Power Supply

310678 TSL Pump Kits

310800 Auto Flush Kit

Manual Description

312414 AirPro™ Pressure Feed Airspray Gun

309623 Data Download Kits

308034 Turbine Alternator Repair Kit

308167 Low Volume Air Regulators

308369 Pressure Tanks

308371 Agitators

308375 Pressure Tank Bottom Outlet Kit

308553 Husky

307212 Fluid Pressure Regulators

Maximum Working

Pressure

psi (MPa, bar)

250 (1.7, 17)

250 (1.7, 17)

250 (1.7, 17)

®

307 AODD Pumps

310700 Gun Air Regulator Kits

311004F 3

Warnings

Warnings

The following general warnings are related to the safe setup, use, grounding, maintenance and repair of this equipment. Additional more specific warnings may be found throughout the text of this manual where applicable.

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes

are present.

• Ground all equipment in work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

• Keep a fire extinguisher in the work area.

PRESSURIZED EQUIPMENT HAZARD

Fluid from the gun/dispense valve, leaks, or ruptured components can splash in the eyes or on skin and

cause serious injury.

• Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning,

checking, or servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses, tubes, and couplings daily. Replace worn or damaged parts immediately.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings.

• Check equipment daily. Repair or replace worn or damaged parts immediately.

• Do not alter or modify equipment.

• For professional use only.

• Use equipment only for its intended purpose. Call your Graco distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or overbend hoses or use hoses to pull equipment.

• Comply with all applicable safety regulations.

4 311004F

Warnings

WARNING

MOVING PARTS HAZARD

Moving parts can pinch or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment,

follow the Pressure Relief Procedure in this manual. Disconnect power or air supply.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read MSDS’s to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, including eye injury, inhalation of toxic

fumes, burns, and hearing loss. This equipment includes but is not limited to:

• Protective eyewear

• Clothing and respirator as recommended by the fluid and solvent manufacturer

•Gloves

• Hearing protection

311004F 5

Pressure Relief Procedure (Models 249320 and 249321)

Pressure Relief Procedure (Models 249320 and

249321)

WARNING

Relieve pressure from fluid manifold to gun whenever

you stop spraying and before servicing gun or removing spray tip.

In addition, relieve pressure from pump to fluid manifold at end of day and before cleaning, checking, or

servicing pump, manifold, or fluid line accessories or

transporting equipment.

Read warnings, page 4.

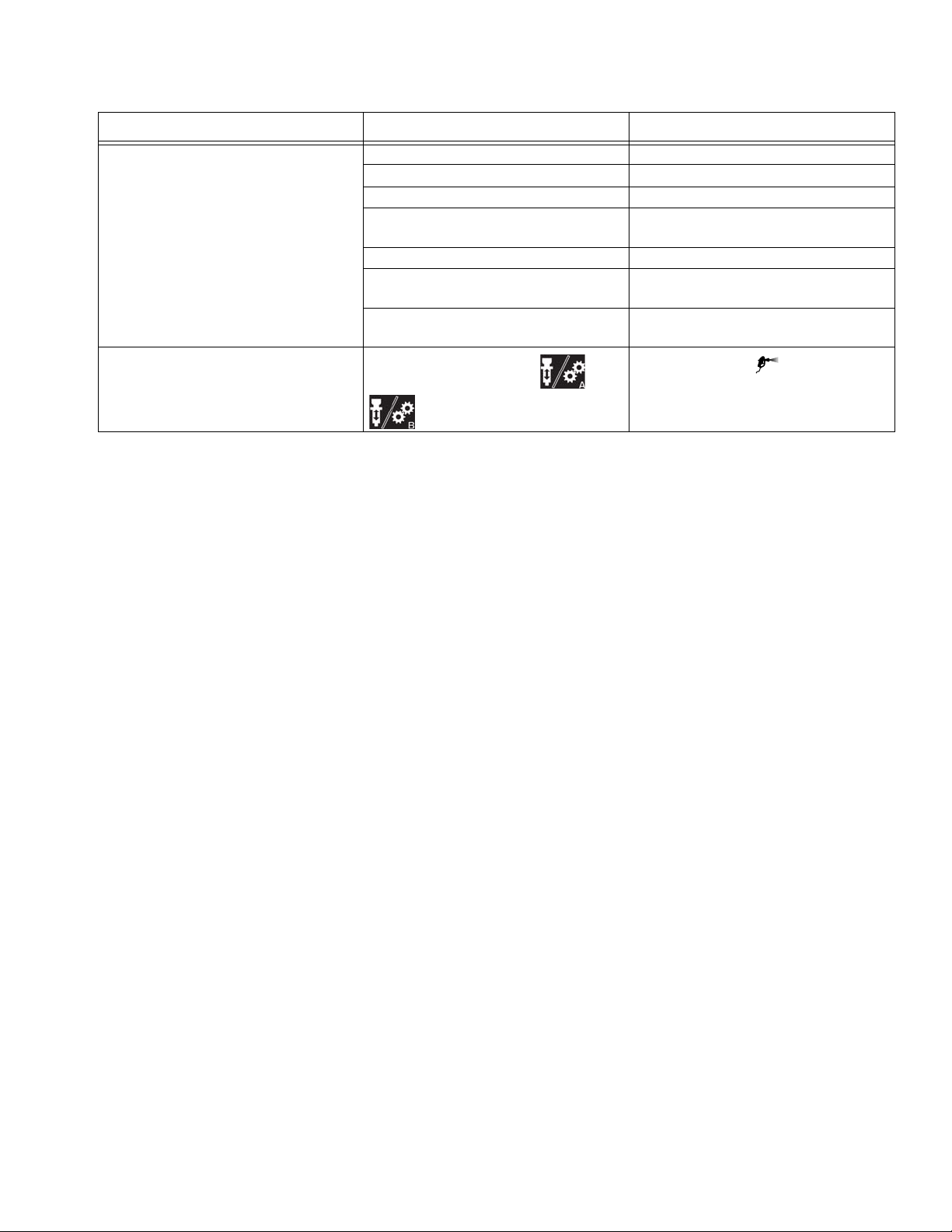

Fluid Manifold to Gun

1. Press .

2. Close all valves at mix manifold.

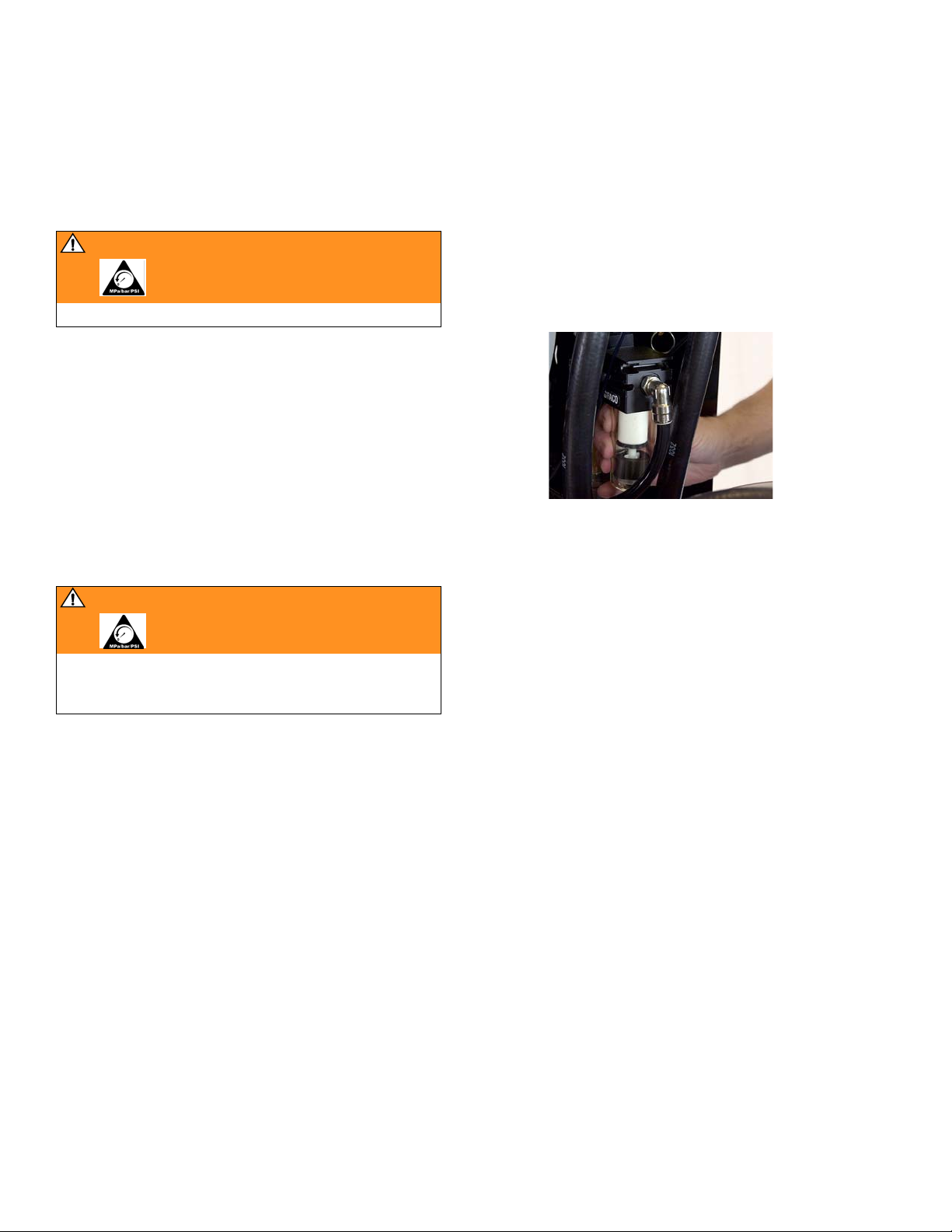

3. Hold a metal part of the gun firmly to a grounded

metal pail. Trigger gun to relieve pressure.

TI4836a

6 311004F

Pressure Relief Procedure (Models 249320 and 249321)

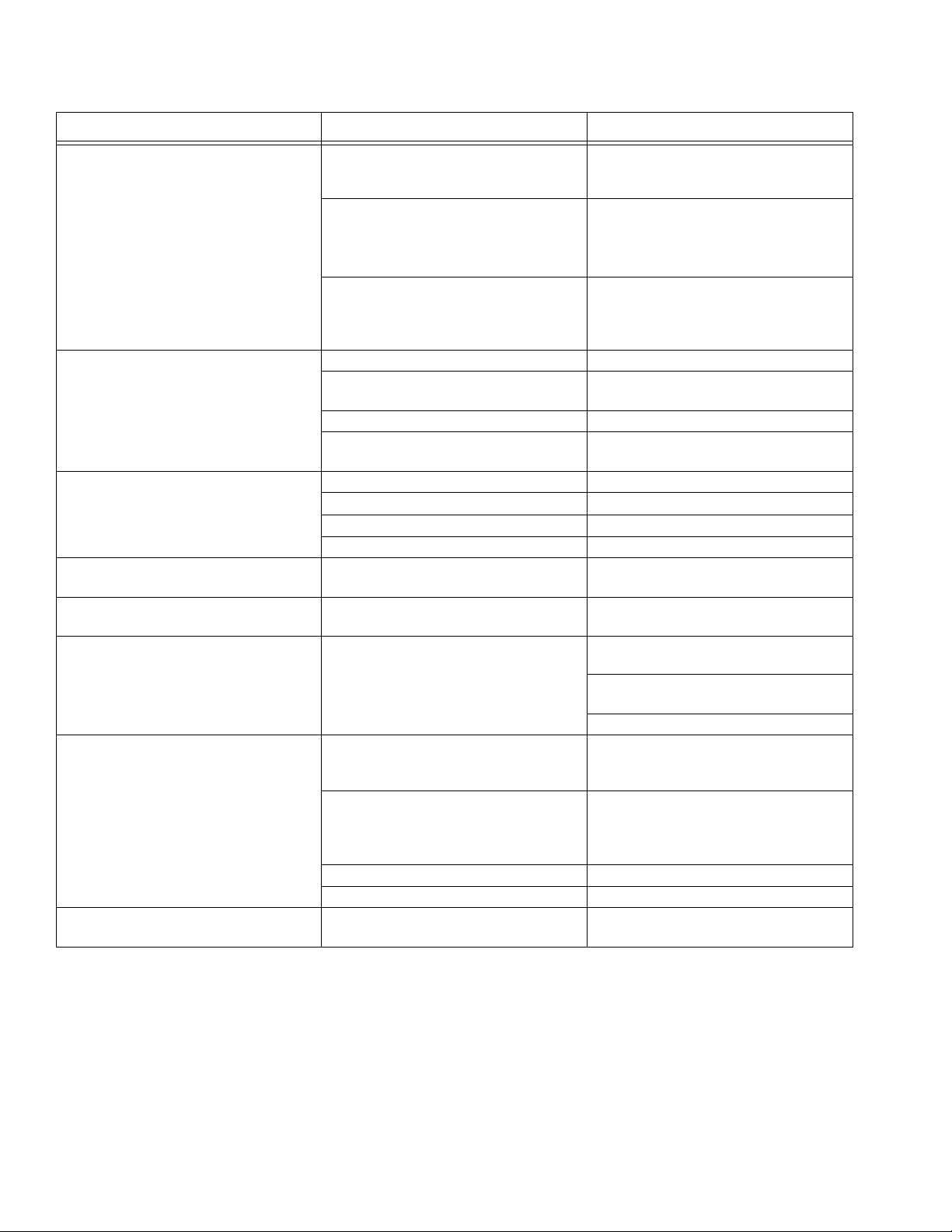

Pump to Fluid Manifold

1. Open all fluid valves at mix manifold. Leave solvent

valve (S2) closed.

TI6424a

S2

2. Open all fluid outlet valves.

3. Turn function knob to pressure relief/park .

5. Hold a metal part of the gun firmly to a grounded

metal pail. Trigger gun to relieve component A pressure. Indicator A will stay on for 5 sec after Pump A

reaches Park position, then go off.

TI4836a

6. Indicator B comes on and Pump B pressurizes.

7. Hold a metal part of the gun firmly to a grounded

metal pail. Trigger gun to relieve component B pressure. Indicator B will stay on for 5 sec after Pump B

reaches Park position, then go off.

4. Press . Indicator A comes on, and Pump A pres-

surizes.

Pump air supply pressure must be sufficient to

cause pumps to stroke to bottom-most position

when function knob to is set to pressure relief/park

.

TI4836a

If both pumps are not parked after 1 min, Alarm

26 will sound.

311004F 7

Pressure Relief Procedure (Model 258961)

Pressure Relief Procedure (Model 258961)

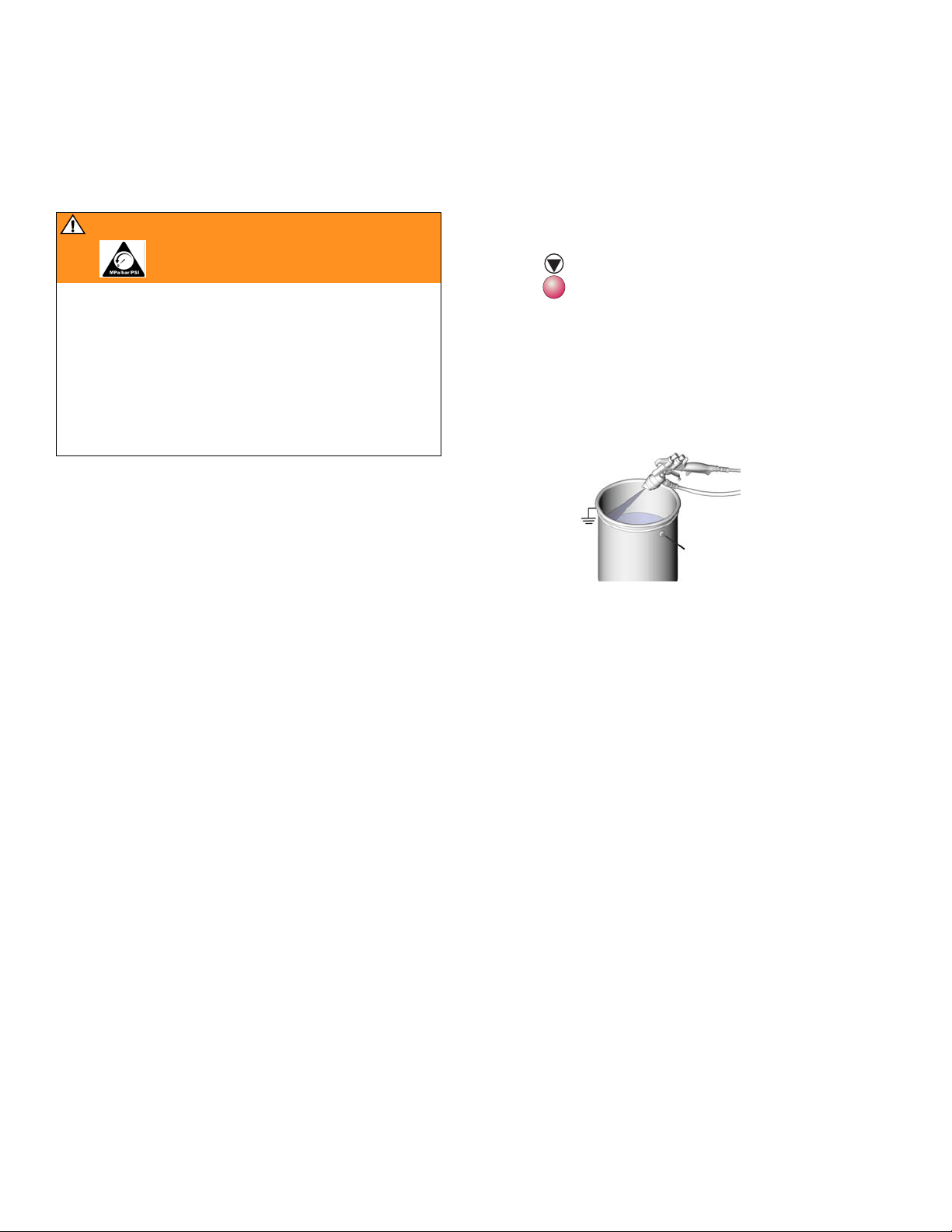

WARNING

Relieve pressure from fluid manifold to gun whenever

you stop spraying and before servicing gun or removing spray tip.

In addition, relieve pressure from pump to fluid manifold at end of day and before cleaning, checking, or

servicing pump, manifold, or fluid line accessories or

transporting equipment.

Read warnings, page 4.

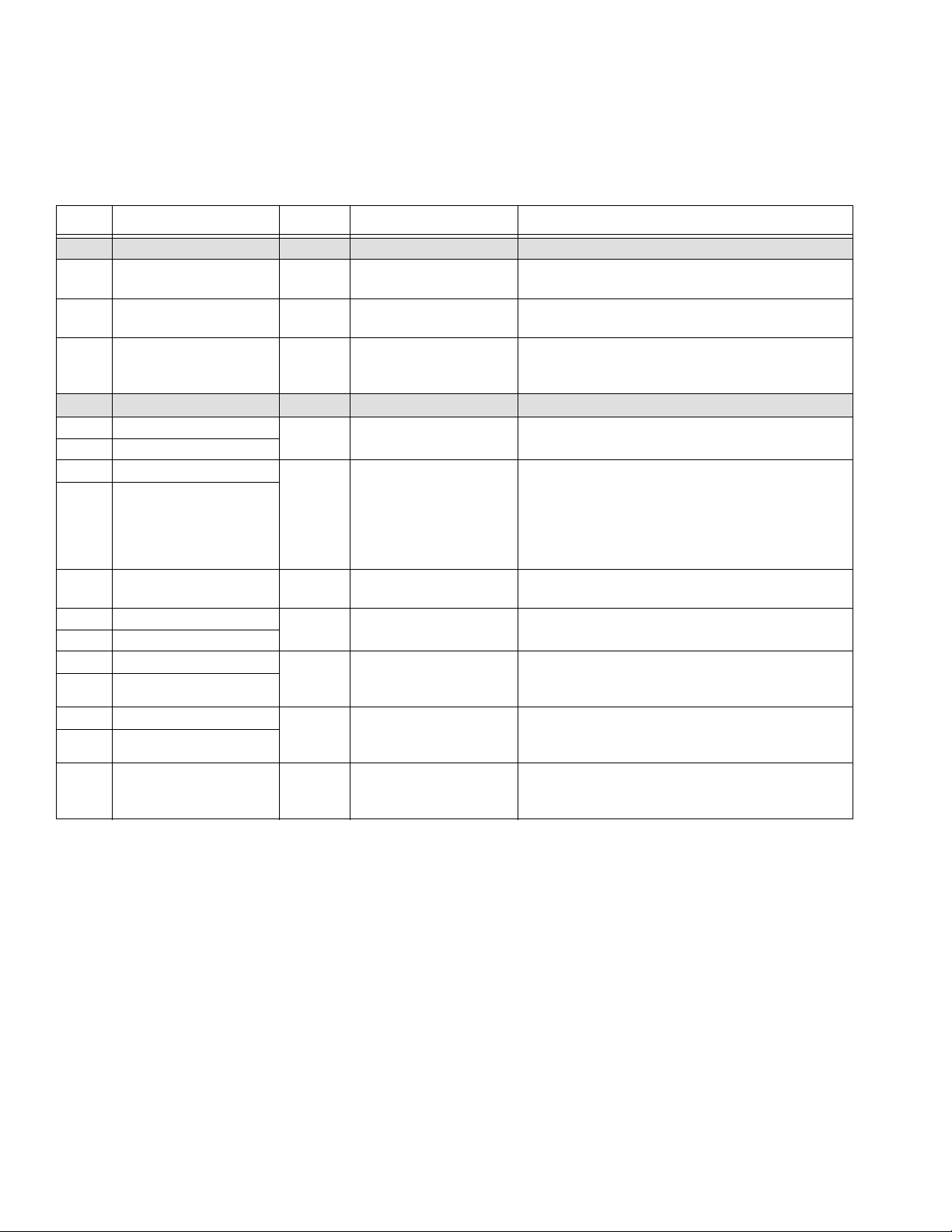

Fluid Manifold to Gun

1. Engage trigger lock.

5. Engage trigger lock.

2. Press .

3. Disengage trigger lock.

4. Hold a metal part of the gun firmly to a grounded

metal pail. Trigger gun to relieve pressure.

8 311004F

Pressure Relief Procedure (Model 258961)

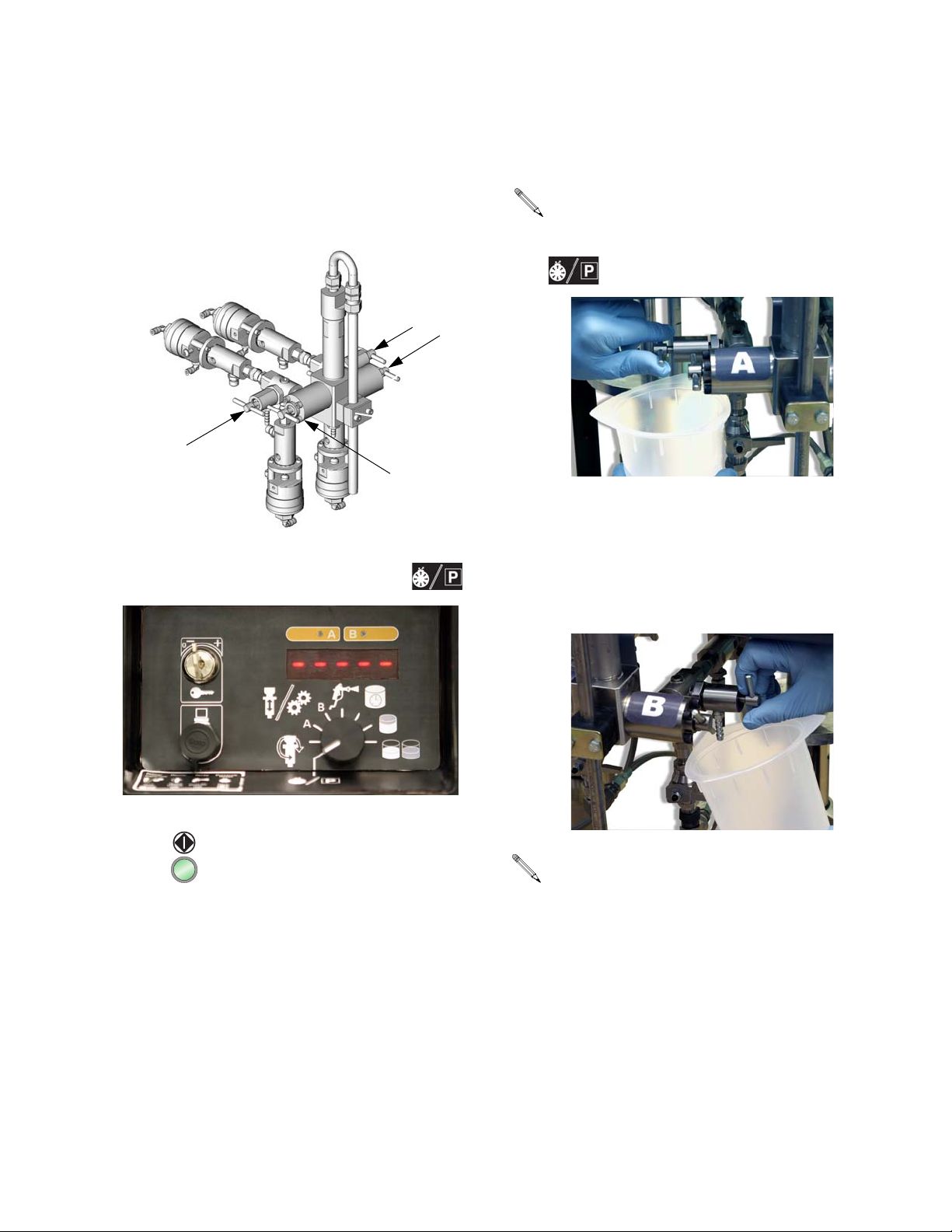

Pump to Fluid Manifold

1. Close shutoff valves G

2. Place waste container under sampling valves H

B

and H

.

A

H

3. Turn function knob to pressure relief/park .

A

and GB.

A

B

B

H

G

A

G

TI5286a

5. Open sampling valve A slowly to bleed off pressure.

Indicator A will stay on for 5 sec after Pump A

reaches Park position, then go off.

Pump air supply pressure must be sufficient to

cause pumps to stroke to bottom-most position

when function knob to is set to pressure relief/park

.

6. Indicator B comes on and Pump B pressurizes.

7. Open sampling valve B slowly to bleed off pressure.

Indicator B will stay on for 5 sec after Pump B

reaches Park position, then go off.

4. Press . Indicator A comes on, and Pump A pres-

surizes.

If both pumps are not parked after 1 min, Alarm

26 will sound.

8. Close sampling valves A and B before restarting

system.

311004F 9

Maintenance

Maintenance

Preventive Maintenance

Schedule

Establish a preventive maintenance schedule, based on

the pump’s repair history.

Dispense Valve

See dispense valve manual 310655.

Pump

See applicable pump manual 310671 or 310662.

Turbine Alternator

Replace bearings every 2000 hours. See page 20.

Air Filters

Drain and clean as necessary. See page 16.

Pump Test

See ProMix Easy Operation manual. If pumps fail test,

see Icing, page 10.

Wet Cup

Check pump wet-cups daily. Keep filled with Graco

Throat Seal Liquid (TSL), Part No. 206995.

Storage

Before storing the pump, always flush it, see ProMix

Easy Operation manual. Relieve the pressure, page 6.

Icing

If you experience icing at the pump air manifold:

• Reduce pump input air pressure below 80 psi (0.56

MPa, 5.6 bar), if required spray pressure allows.

• Reduce moisture in compressed air supply, or use

heated air.

If icing persists, see table below.

Problem Solution

Pump slows on both up

and down stroke.

Pump slows on down

stroke.

Pump slows on up stroke. Turn U port bleed screw 90° (1/4 turn) counter-

Turn D port bleed screw 60° (1/6 turn) counterclockwise, to bleed 1 cfm air to melt ice.

Turn D port bleed screw 60° (1/6 turn) counterclockwise, to bleed 1 cfm air to melt ice. If icing

continues, turn screw to 90° (1/4 turn) to increase

air flow to 2 cfm. If necessary, increase air flow to

3 cfm by turning screw to 270° (3/4 turn). Do not

exceed 3 cfm (3/4 turn maximum).

clockwise, to bleed 1 cfm air to melt ice. If icing

continues, turn screw to 120° (1/3 turn) to

increase air flow to 2 cfm. If necessary, increase

air flow to 3 cfm by turning screw to 180° (1/2

turn). Do not exceed 3 cfm (1/2 turn maximum).

U

D

TI5294a

10 311004F

Troubleshooting

Troubleshooting

WARNING

If an alarm code displays, see page 14.

Read warnings, page 4-5.

Problem Cause Solution

Display not lit.

No electric power.

Pumps do not run. Air pressure to pumps too low. Increase pressure to 50 psi (0.35 MPa,

Pump test volume is not correct. Air pressure to pumps too low Increase pressure to 50 psi (0.35 MPa,

Air valve not turned on. Turn on main air valve to system.

Air supply pressure too low. Increase pressure to 60 psi (0.42 MPa,

4.2 bar) or greater.

Air supply filters plugged. Clean filter bowls; replace filter elements.

Page 16.

Turbine air regulator set too low. Adjust to proper setting.

Turbine alternator failure. Repair or replace turbine. Page 20.

Power supply not connected to main

board.

Main board not connected to display

board.

Display board failure. Replace display board. Page 19.

Solenoid valve stuck. Actuate solenoid manually, if it does not

Dispense valve(s) not opening. Service or replace valve(s). See 310655.

Sensors not functioning properly. Check position of sensors. See ProMix

Pump cavitating excessively. Check for air in siphon lines caused by

Check power connections to main board.

See Electrical Schematic, page 24.

Check electrical connections between

display and main board. See Electrical

Schematic, page 24, and Main Control

Board Schematic, page 25.

3.5 bar).

operate, replace solenoid. Page 21.

3.5 bar).

Easy Operation manual, and applicable

pump manual.

Check board calibration and recalibrate if

necessary. See ProMix Easy Operation

manual.

Replace sensors. See pump manual

310671.

loose fitting or use of agitator.

Material too viscous. Use heater.

311004F 11

Troubleshooting

Problem Cause Solution

Paint does not cure consistently. Ratio not set correctly. Check that correct ratio is set and set by

volume. See ProMix Easy Operation

manual.

Material not mixing correctly. Test pump. Page 10.

Make sure mixer is clean; flush as

needed. See ProMix Easy Operation

manual.

Pump not operating correctly. Observe whether pumps are loading and

checking correctly, if not, clean and repair

pump. See displacement pump manual

310662.

Poor spray pattern. Fluid pressure too low. Increase pump pressure.

Spray tip dirty or worn. Relieve pressure. Clean or replace tip.

Follow gun manual instructions.

Fluid A or B filters plugged. Clean filters on siphon tube in tank.

Mixer or hoses partially plugged. Inspect parts for cured material. Clean or

replace.

System runs erratically. Air filter(s) clogged. Replace elements. Clean. Replace element(s). See page 16.

Air supply hoses undersized. Replace hoses with appropriate size.

Air compressor undersized. Use larger air compressor.

Air supply pressure tank undersized. Use larger pressure tank.

Air supply relief valve opens. Turbine air regulator set too high. Lower setting to 23-25 psi (172-241 kPa,

1.7-2.4 bar).

Turbine alternator makes high-pitched

whining noise.

Display shows 88888 or unit reboots

unexpectedly.

ProMix Easy does not start when start

button is pressed.

Dispense valves leaking. Loose or worn packings. Tighten packing nut. If leak continues,

Turbine bearings worn. (Setting turbine

air regulator too high, wears bearings.)

Turbine is not supplying enough power to

board.

Faulty start switch or wire harness. Check start switch and wiring harness

Faulty stop switch or wiring harness. Check stop switch and wiring harness

Bad I/O port on display board. Replace board. Page 19.

Bad I/O port on main board. Replace board. Page 18.

Replace bearings. Page 20.

Increase turbine regulator setting to

23-25 psi (172-241 kPa, 1.7-2.4 bar).

Check turbine and electrical control

exhaust air for restrictions.

Replace turbine bearings. Page 20.

continuity; switch is normally open circuit.

See Electrical Schematic, page 24.

continuity; stop switch is normally closed

circuit. See Electrical Schematic, page

24.

replace packings. See 310655.

12 311004F

Troubleshooting

Problem Cause Solution

Flow rate too low, or no flow. Inadequate air supply. Use larger CFM compressor.

Air pressure to pumps too low. Increase pressure.

Fluid A or B filters plugged. Clean filters on siphon tube in tank.

Mixer or hoses partially plugged. Inspect parts for cured material. Clean or

replace.

Insufficient dispense valve travel. Increase travel. See 310655.

Shutoff valves are not fully open. Ensure that shutoff valves are fully open

and sampling valves are closed.

Fluid regulator on remote mix manifold is

set to high pressure position.

Set regulator to lower pressure position.

Pump stops after 12 cycles.

Knob is set to Run pump A

independently.

or B

Turn knob to spray

rial.

if spraying mate-

311004F 13

Alarms

Alarms

* Indicates error where audible alarm sounds once briefly. ** Indicates error where audible alarm sound pulses.

Code Alarm Active Problem Cause

Startup Errors

01 Sensor Error A* Always No signal from pump A

sensor

02 Sensor Error B* Always No signal from pump B

sensor

03 Communication Error* Always Loss of communication

between main and display boards

Operating Errors

04 not used

05 not used

06 Pump Error A** Spray

07 Pump Error B**

08 Sensor Code Error Always Sensor values reverted to

09 not used

10 not used

11 Sensor Reading Low A* Spray

12 Sensor Reading Low B*

13 Sensor Reading High A* Spray

14 Sensor Reading High B*

21 Pot Life Error Spray

Te st

Batch

Te st

Batch

Te st

Batch

first, then

Always

Pump does not stall after

top change over

Pump cavitating excessively

default

Pump stroke travels

beyond sensor range at

top change over

Pump stroke travels

beyond sensor range at

bottom change over

Pot life timer timed out Not enough material sprayed after last reset

Loose cable, failed sensor or cable, failed magnet

assembly

Loose cable, failed sensor or cable, failed magnet

assembly

Loose cable, failed board

Intake valve leak

Air in siphon lines caused by loose fitting or use of

agitator

Empty fluid supply

Sensor value data corrupt; board needs replacement

and /or recalibration

Sensor or bracket loose

Sensor magnet dirty

Sensor or bracket loose

Sensor magnet dirty

14 311004F

Code Alarm Active Problem Cause

Operating Errors

(continued)

22 not used

23 not used

24 not used

25 not used

26 Park Timeout Park Pumps not at bottom of

stroke

Testing Error

15 Piston packing/ball A* Test Pump does not com16 Piston packing/ball B*

17 Inlet Ball A* Test Pump does not com18 Inlet Ball B*

19 Dispense Valve A* Test Pump does not com20 Dispense Valve B*

27 Pump Calibration

Timeout A

28 Pump Calibration

Timeout B

Run A Pump doesn’t run

Run B

pletely stall in up stroke

pletely stall in downstroke

pletely stall in both up

and down strokes

through calibration.

Sampling valves closed, or gun not triggered.

Piston packing or ball check failure

Intake valve ball check failure

Throat packing or dispense valve failure

Sampling valves closed.

Alarms

311004F 15

Repair

Repair

Flush before repairing equipment, if possible. See ProMix Easy Operation manual.

WARNING

Read warnings, page 4.

Follow Pressure Relief Procedure (Models 249320

and 249321), page 6, if service time may exceed pot life

time, before servicing fluid components, and before

transporting equipment to a service area.

Replacing Air Filter Element

There are 2 air filters on the unit: the 5 micron air manifold filter (7) and 40 micron pump air filter (9). Replace

element as needed. Order 15D909 5 micron filter and

15D890 40 micron filter.

WARNING

1. Close main air shutoff valve on air supply line and

on unit.

2. Remove left side plate (21).

3. Unlock filter bowl guard and remove.

4. Unscrew filter bowl.

5. Remove and replace element.

6. Screw filter bowl on securely.

7. Reassemble.

Removing the bowl of a pressurized air filter could

cause serious injury. Do not service air filter until air

line is depressurized.

16 311004F

Loading...

Loading...