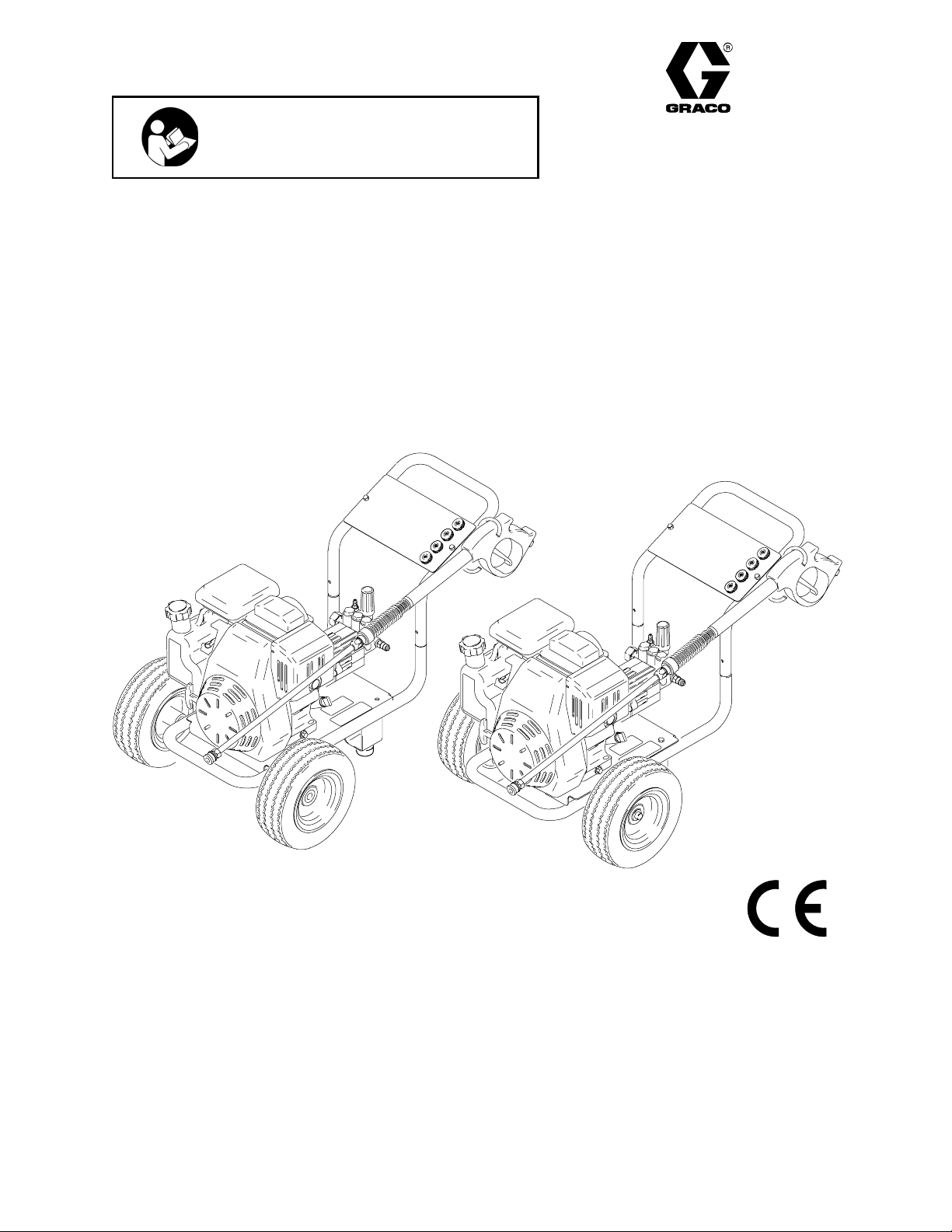

Page 1

309828NINSTRUCTIONS

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

G–Force Direct-Drive Pressure Washer

2525LD

Model 246601, Series A & Series B

2300 psi (159 bar, 15.8 MPa) Maximum Operating Pressure

2500 psi (172 bar, 17.2 MPa) Maximum Working Pressure

2626LD

Model 249065, Series A

2600 psi (179 bar, 17.9 MPa) Maximum Operating Pressure

2750 psi (191 bar, 19.0 MPa) Maximum Working Pressure

2525LD

ti6075a

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

COPYRIGHT 2003 GRACO INC.

Graco Inc. is registered to I.S. EN ISO 9001

2626LD

ti3224b

Page 2

Table of Contents

Symbols 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warnings 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Component Identification 4. . . . . . . . . . . . . . . . . . . . . . . .

Pressure Relief Procedure 7. . . . . . . . . . . . . . . . . . . . . . .

Installing and Changing Spray Tips 12. . . . . . . . . . . . . .

Pump Service 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Drawing 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts List 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Graco Phone Number 28. . . . . . . . . . . . . . . . . . . . . . . . . .

Warning Symbol

WARNING

This symbol alerts you to the possibility of serious

injury or death if you do not follow instructions.

Caution Symbol

CAUTION

This symbol alerts you to the possibility of damage to

or destruction of equipment if you do not follow instructions.

2 309828

Page 3

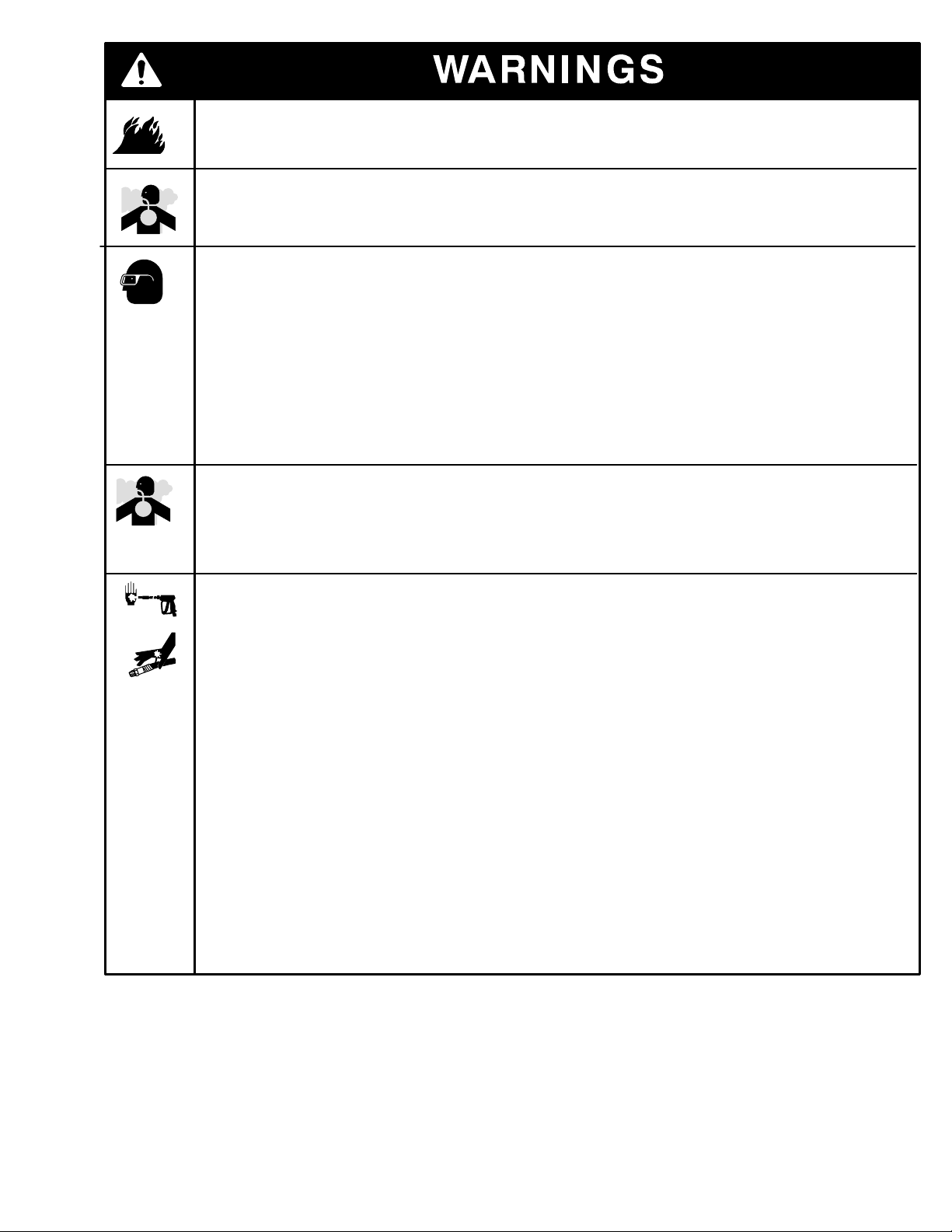

FUEL HAZARD:

Fuel is combustible. When spilled on a hot surface it can ignite and cause a fire.

Do not fill fuel tank while engine is running or hot.

EXHAUST HAZARD:

Exhaust contains poisonous carbon monoxide, which is colorless and odorless. Do not operate this

equipment in a closed building.

EQUIPMENT MISUSE HAZARD:

Misuse of pressure washer or accessories can cause the equipment to rupture or malfunction and

result in serious injury.

Do not alter or modify any part or factory–setting

Check equipment daily. Repair or replace worn or damaged parts immediately.

Do not exceed maximum working pressure (MWPR) of the lowest–rated system component

Use fluids and solvents that are compatible with the equipment wetted parts. See Specifications

page for this information.

Wear hearing protection when operating this equipment.

Do not “blow back” fluid; this is not an air spray system

Follow Pressure Relief, page 7 before cleaning, checking or servicing equipment.

TOXIC FLUID HAZARD:

Hazardous fluid or toxi fumes can cause serious injury or death if splashed in eyes or on skin,

inhaled, or swallowed.

Know specific hazards of fluids you are using and take protective measures as recommended by

the fluid and solvent manufacturer.

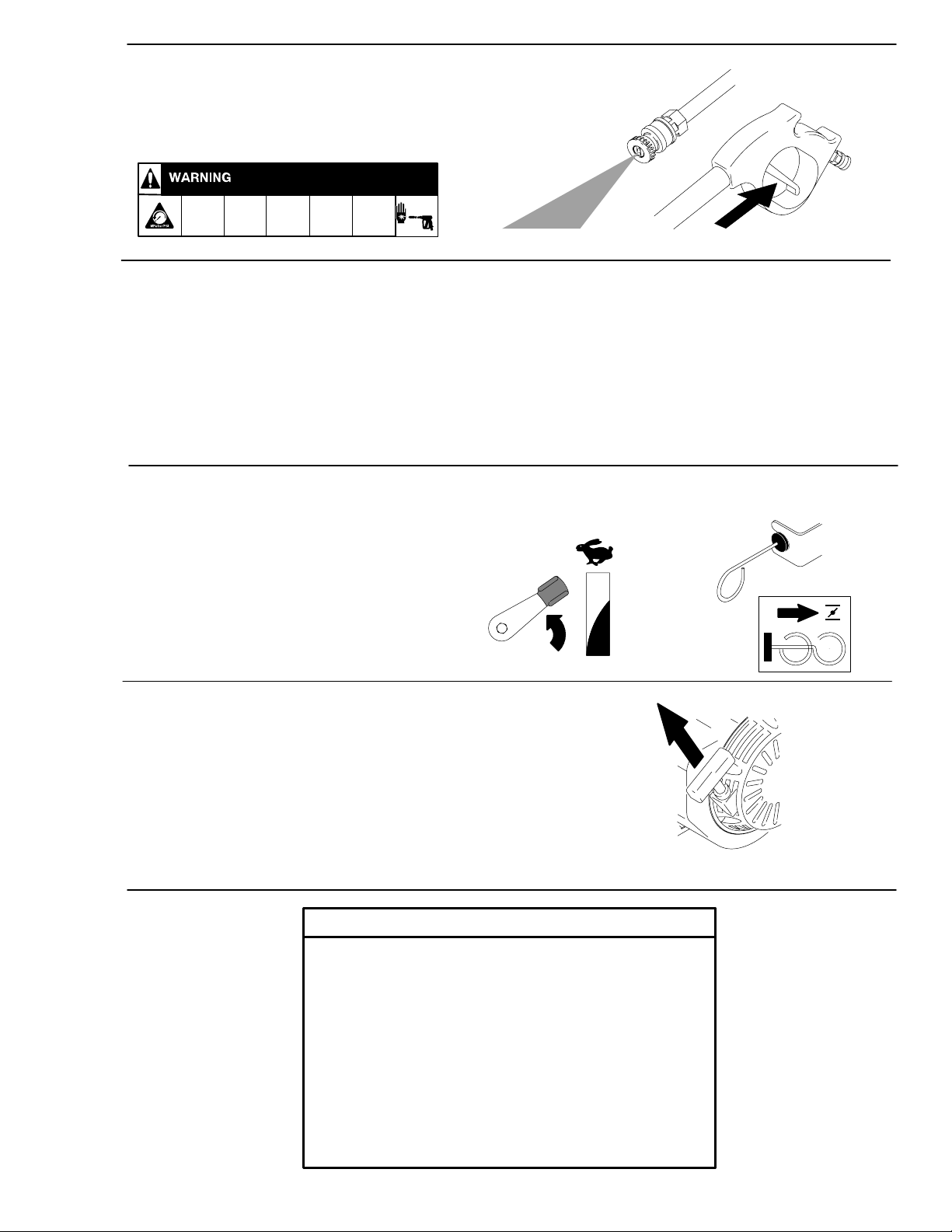

SKIN INJECTION HAZARD:

Spray from gun, leaks or ruptured components can inject fluid into your body and cause serious

injury. Fluid splashed in eyes or on skin can also cause serious injury.

Fluid injected into skin might look like just a cut, but it is a serious injury. Get immediate

surgical treatment.

Do not point gun at anyone or any part of the body.

Do not stop or deflect leaks with hand, body, glove, or rag.

Do not put your hand or fingers over the spray tip.

TIghten fluid connections before you start this equipment.

Engage the gun safety whenever you stop spraying.

Follow Pressure Relief Procedure, page 7 if the spray tip clogs and before you clean, check

or service this equipment.

Repair or replace worn or damaged parts immediately.

Check hoses, tubes, and couplings daily. Do not repair high–pressure couplings. Replace entire

hose. Fluid hoses must have spring guards on both ends to prevent kinks and rupture.

3309828

Page 4

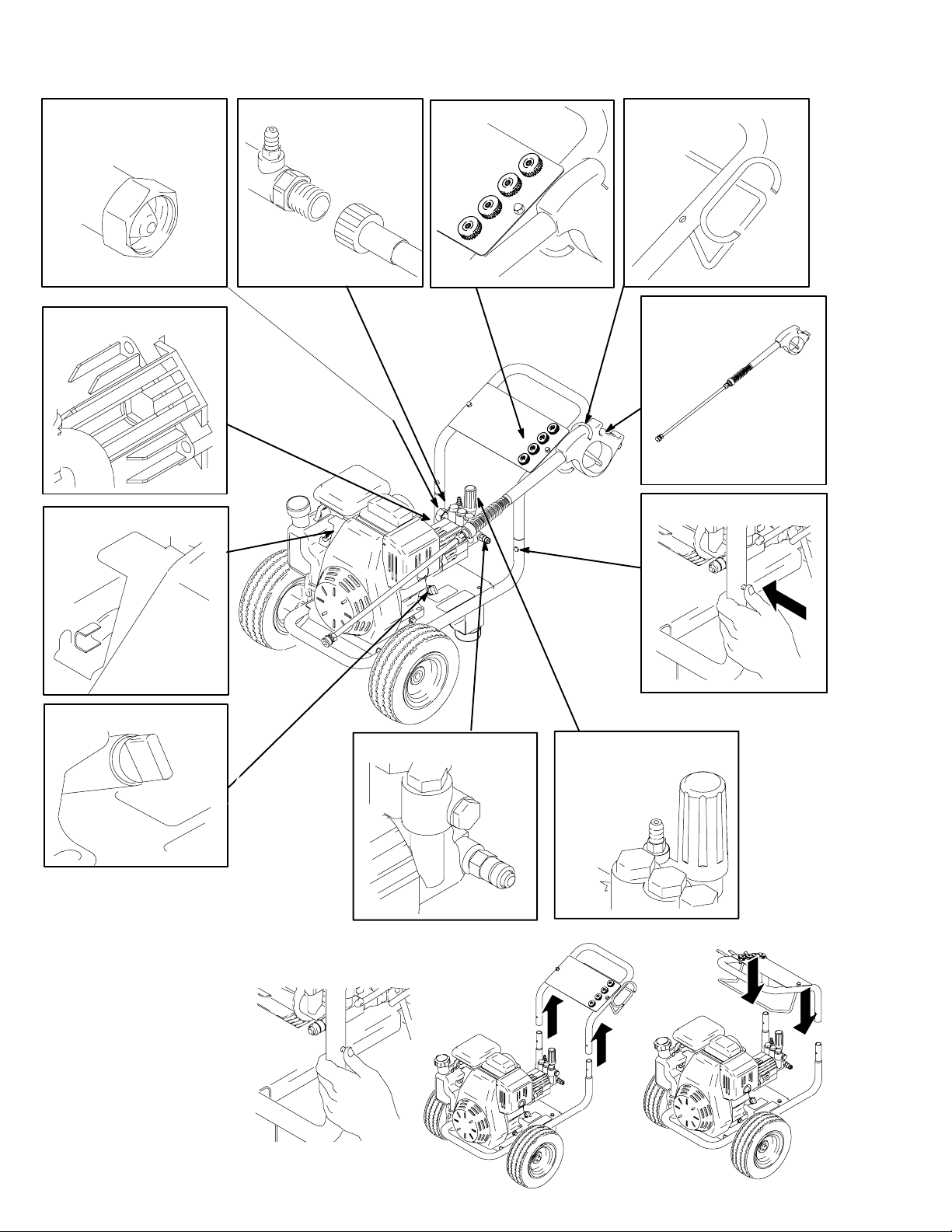

Component Identification

Garden Hose

Connection

Water Pump Oil Fill

On/Off Engine Switch (side)

High Pressure

Hose Connection

Tip Storage

Hose Rack (a) /

Gun Holder (b)

(b)

Gun and Wand

Handle Release Button*

(a)

Engine Oil Fill

*Cart handle can be removed to create a compact profile for storage

and transporting. Push

in release button on

each side of handle.

(Fig. 1) Pull handle off

lower frame. (Fig. 2).

Rotate handle 180 and

reposition over lower

frame. (Fig. 3) Push

down on handle until until release buttons engage.

4 309828

Fig. 1

ti3226a

Thermal Valve

Fig. 2

Pressure Unloader

Adjustment Knob

Fig. 3

ti6079a

ti6077a

Page 5

Initial Setup

Shipping Damage

Check pressure washer for shipping damage. Notify carrier immediately if there is any damage.

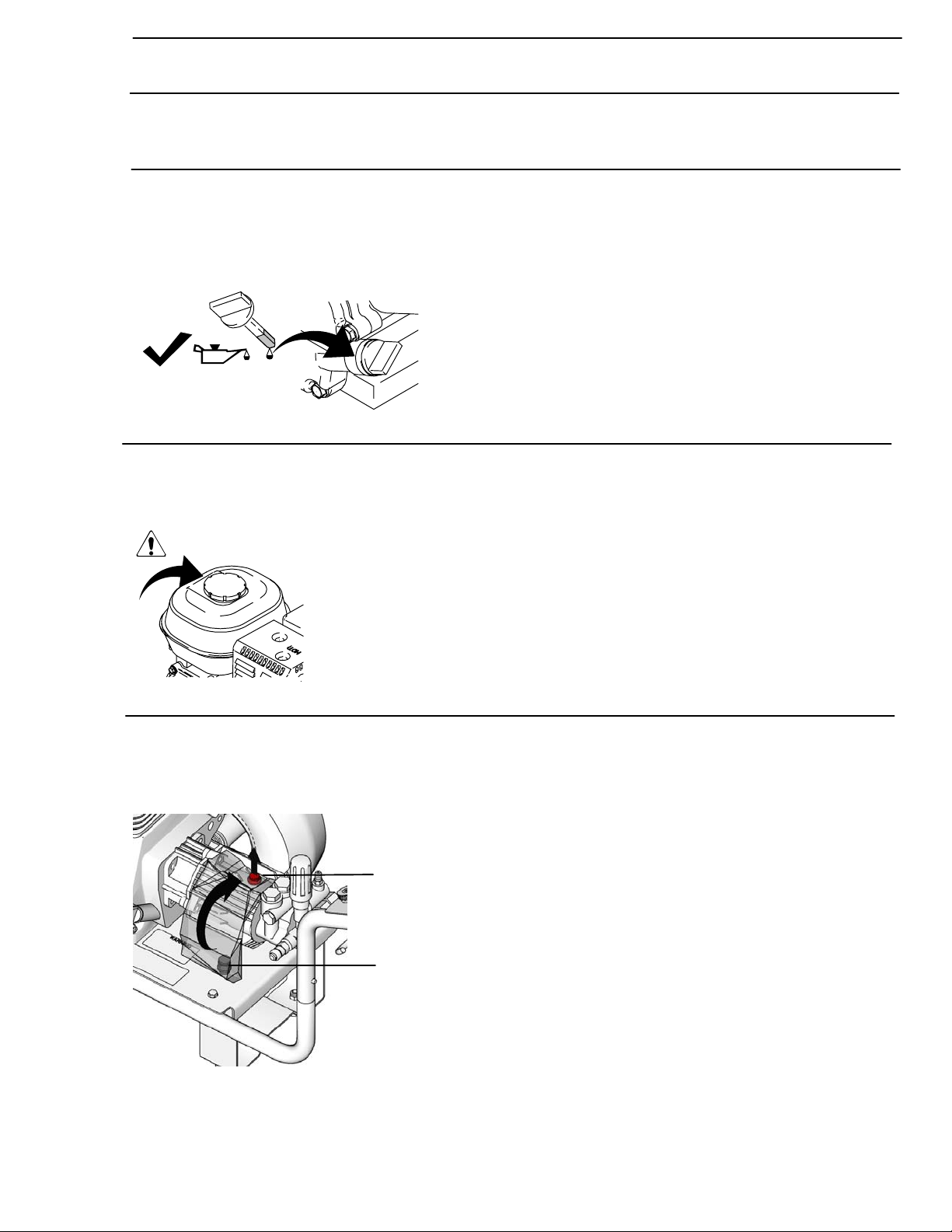

Oil

Engine is shipped without engine oil. Add Graco SAE 10W–30 engine oil (included) and confirm oil level is within

an acceptable range according to the Honda Owner’s Manual (included).

(cold)

ti5952a

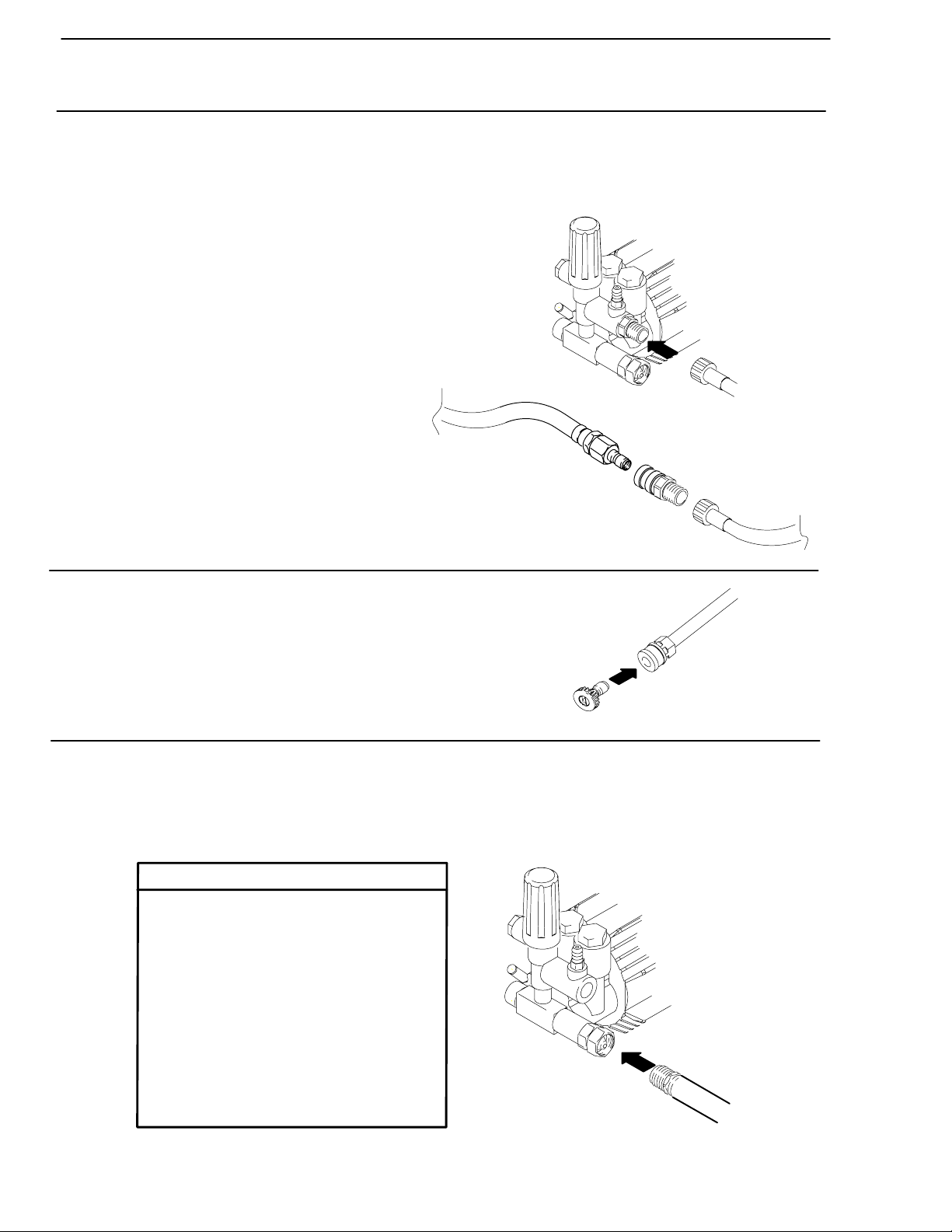

Fuel

Fill fuel tank.

ti5953a

Pump plug

Remove red water pump plug (A) and replace with attached black vented pump plug (B).

TI10675A

Red water pump plug

Black vented pump plug

5309828

Page 6

Installation

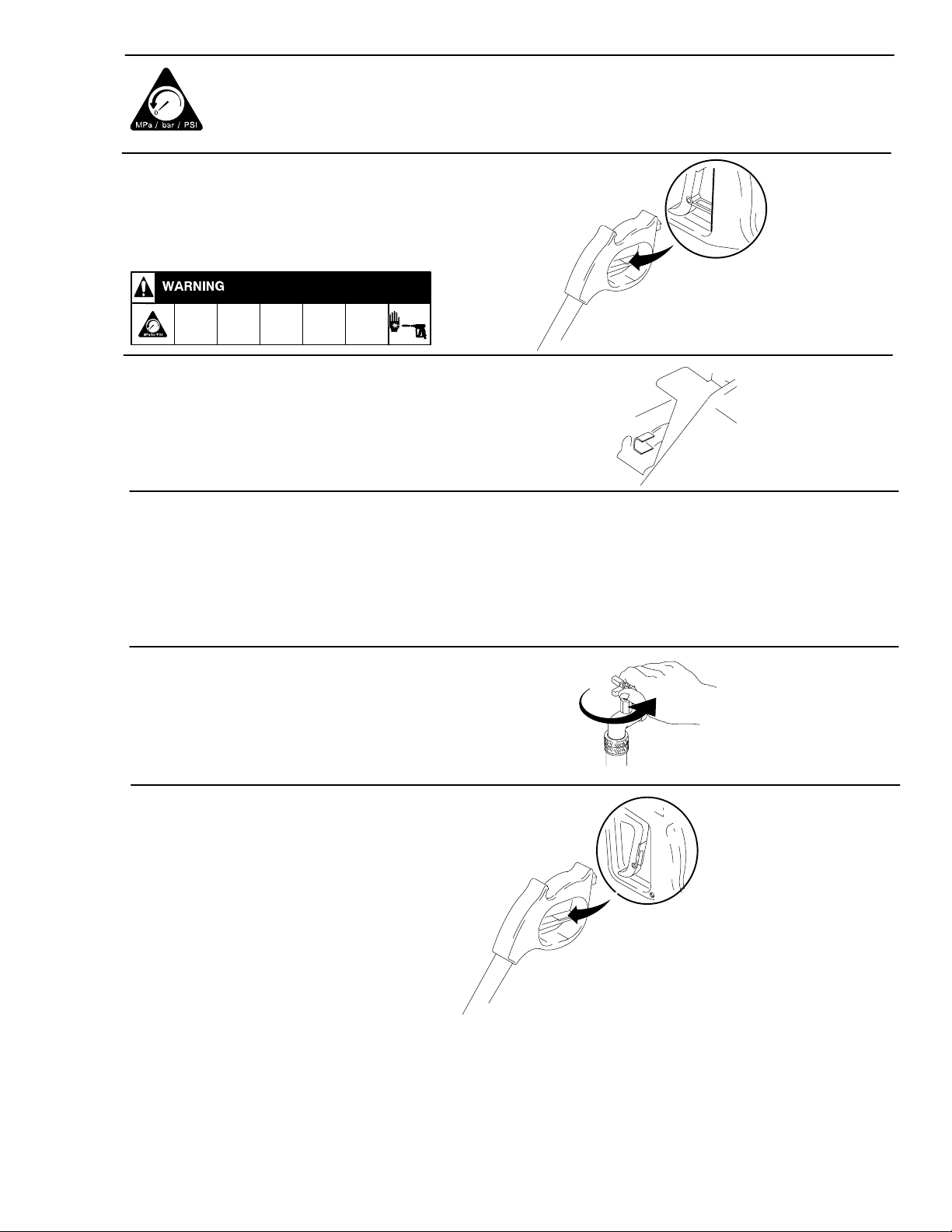

Connect High–Pressure Hose and Gun

Connect high–pressure hose between the pump outlet and gun inlet.

Both of these connections are made with quick couplers.

Note: Adapter kit 249101 can be used to connect

two high pressure hoses together.

Install Spray Tip

Install spray tip on wand. Installing and Changing Spray Tips,

page 12). If you are using a Sandblasting Kit, see its separate

manual for installation instructions.

Connect to Water Supply

Connect hose with at least a 3/4 in. (19 mm) ID from water supply

to 3/4 in. garden hose inlet on the pressure washer. The supply

hose should not be more than 50 ft (15 m) long.

ti3457a

ti7345a

ti3228a

CAUTION

Before you connect garden hose to pressure washer, check local plumbing codes

regarding cross–connection to water

supply. If required, install backflow preventer.

If inlet water pressure is over 60 psi (4.1

bar), a regulating water valve must be

installed at garden hose connection.

Do not exceed 104° F (40° C) inlet water

temperature.

Note: Water source must have a minimum flow rate equal to that of pressure washer.

ti3229a

6 309828

Page 7

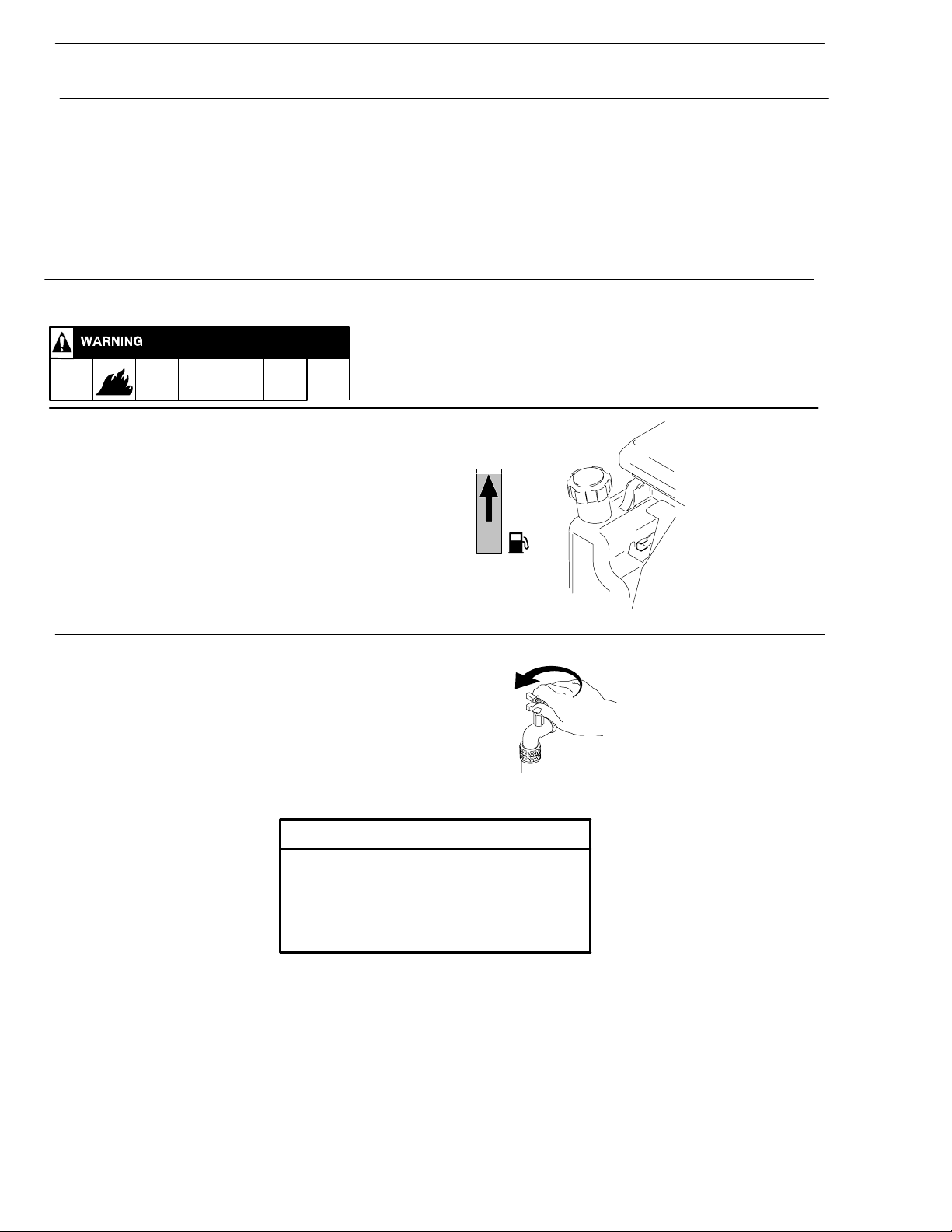

PRESSURE RELIEF

Follow these instructions whenever you are instructed to relieve pressure, stop spraying for

more than 10 minutes, check or service the equipment, or install or clean the spray nozzle.

1. Engage trigger safety latch

2. Turn pressure washer off

3. Remove ignition cable from spark plug.

TI3233A

4. Shut off water supply. Disconnect from water.

5. Disengage trigger safety latch. Trigger gun to relieve

pressure. Then re–engage the safety latch.

TI3234a

Note: If you suspect that the spray tip or hose is clogged or that pressure has not been fully relieved after

following the steps above, disengage the trigger safety latch and trigger the gun to relieve pressure.

7309828

Page 8

Operation

Startup

Always use this startup procedure to ensure that the pressure washer is started

safely and properly.

Always engage gun trigger safety latch when you stop spraying. This reduces the risk of fluid injection or

splashing in eyes or on skin if gun is bumped or accidentally triggered.

Always observe the CAUTIONS in this section to avoid costly damage to pressure washer.

If you use the Sandblaster Kit, see Sandblaster Kit Manual for detailed cleaning information.

1. Check oil level of engine.

2. Check fuel level.

3. Turn on water supply.

.

8 309828

CAUTION

Never run pressure washer without water. Costly pump damage will result.

Always be sure water supply is completely turned on before you run pressure

washer.

Page 9

4. Trigger gun until a constant stream of water sprays from tip indicating air is purged from the system.

5. Be sure spark plug ignition cable is pushed firmly onto spark plug.

6. For Model 2525LD ONLY, move

throttle to Rabbit (fast) position first.

All models

Model 2525 Only

For all models, (then) move choke to

CHOKE position.

ti3242a

7. Pull the starter rope quickly to start the engine. Pull and return the

rope until the engine starts. HINT: Placing one foot on the pressure washer as a brace provides better leverage.

NOTE: For easier starting, have one person start pressure washer while another triggers gun.

CAUTION

Do not allow pressure washer to idle more than 10

minutes. This causes circulating water to overheat and

serious damage to the pump. The pump is equipped

with a thermal valve to help prevent severe damage if

circulating water is overheating.

Turn off pressure washer if it will not be spraying at

least every 10 minutes or if thermal valve activates. If

heated inlet water is used, reduce this time.

Do not operate pressure washer with inlet water

screen removed. This screen helps keep abrasive

sediment which could clog pump or damage cylinders,

out of pump.

Do not pump caustic materials.

ti3240a

9309828

Page 10

Trigger Safety Latch

Always engage the safety latch when you stop spraying.

Always engage trigger safety latch when you stop spraying even for a moment. The engaged

safety latch prevents the gun from being triggered accidentally by hand or when dropped or

bumped. Be sure latch is pushed fully down or it will not prevent the gun from being triggered.

Safety ON

TI3233A

Safety OFF

TI3234a

10 309828

Page 11

Chemical Injector Operation

1. Follow Pressure Relief Procedure, page 7.

2. Push end of chemical injector hose over chemical injector fitting on

pump. Place other end in container of chemical solution.

3. Install the black, large–orifice, chemical tip. (Installing and Changing Spray Tips page 12).

4. Trigger gun for a few seconds. Chemical solution will begin mixing in spray pattern.

ti3237b

The large orifice of the chemical tip causes a drop in pressure that actuates the chemical injector.

Changing back to a small orifice spray tip deactivates the chemical injector and produces high pressure

for rinsing. The chemical filter can be left in the chemical container during high–pressure use.

11309828

Page 12

Installing and Changing Spray Tips

Spray tips have 4– or 5–digit numbers on them.

The first two digits are the spray angle. Tip

holding holes are provided on the chassis.

Spray Tip

Number

00XXX

15XXX

25XXX

Spray Pattern Fan Angle

0 blaster (red)

15 (yellow)

25 (green)

40XXX

Chemical

NOTE: The chemical injector tip is brass and has a large opening and a black plastic cap.

1. Perform Pressure Relief Procedure, page 7.

2. Point the gun and wand away from you and anyone else.

3. Without holding your hand over spray tip (A), pull back quick

coupler ring (B). Remove current tip. Install a different one.

Then push the ring back on.

40 (white)

XX (black)

B

A

12 309828

CAUTION

To avoid blowing the o–ring out of the

quick coupler due to the high pressure in

the system, never operate pressure

washer without a tip securely mounted in

quick coupler.

Page 13

Shutdown, Flushing, and Storage

1. Remove chemical injector hose from pump, if attached.

2. Trigger gun for one minute to flush pump with clear water.

3. Engage trigger safety.

TI3233A

4. For model 2525LD, adjust throttle to STOP position. Engine

should turn off.

For model 2626LD, turn OFF power switch.

13309828

Page 14

5. Shut off water supply. Disconnect water supply hose from pump.

6. Remove trigger safety latch and trigger gun to relieve pressure.

7. Remove high pressure hose from pump. Drain water from all components.

ti3231a

TI3234a

After each use, wipe all surfaces of pressure washer with a clean, damp cloth.

ti3247b

ti3245b

14 309828

Page 15

Long Term (more than 30 days)/Winter Storage

Do not store unit outside where it can be exposed to rain, dirt or adverse weather conditions.

Do not expose pressure washer to freezing temperatures or allow water to freeze in pressure washer

components, causing the pump to lock–up. If this happens let pump thaw naturally in WARM ENVIRONMENT. DO NOT attempt to to speed up this process by pouring warm water on pump. This could

cause further damage.

ENGINE:

1. Run engine until gas is gone or stabilize the fuel and run it through the fuel system and carburetor.

2. Drain water out of pressure washer hose.

3. Turn fuel system to OFF position.

Pump:

1. Attach one end of a 4 or 5–foot section of hose to pump inlet and other end in an antifreeze solution approximately 1–foot off the ground.

2. Pull pull–cord on engine until antifreeze comes out of pump outlet.

Storage Location:

1. Store pressure washer in garage, basement or other area where it is protected from freezing temperatures.

15309828

Page 16

Maintenance Chart

Perform Pressure Relief Procedure (page 7).

Interval What to do

Daily Clean water inlet screen and filter. Check engine and pump oil levels. Fill as necessary. Check

gasoline level. Fill as necessary.

After first

5 hours of

operation

Every 3

months or

25 hours of

operation

Change engine break-in oil. Drain oil when warm. Use SAE 30 or 10W–30 detergent oil.

Clean and remove air cleaner foam. Wash with water and detergent. Dry thoroughly. Rub with

oil, and squeeze to distribute oil.

Every 6

months or

50 hours of

operation

After every

100 hours of

operation, or

every 3 months

NOTE: It is not necessary to change pump oil during the life of the pump. If pump oil is drained for repair, use part

number 117784 replacement oil only.

Change engine oil. Use approved SAE30 or 10W30 detergent oil.

Check/adjust spark plug and idle speed. Clean fuel tank and filter..

16 309828

Page 17

Troubleshooting

roughly

Perform Pressure Relief Procedure (page 7).

Problem Cause Solution

Engine will not start or

is hard to start.

Engine misses or

lacks power

Pressure is too low

and/or pump runs

Water leaks from

under pump manifold

Water on oil side of Worn packings Install new packings.

pump

No gasoline in fuel tank or carburetor Fill tank with gasoline, open fuel shutoff valve.

Check fuel line and carburetor.

Low oil Add oil to proper level.

Throttle in STOP position (model

2525LD only)

Water in fuel or old fuel Drain fuel tank and carburetor. Use new fuel

Engine flooded or improperly choked Open choke, pull engine starter rope several

Dirty air cleaner filter Remove and clean.

Spark plug dirty, wrong gap, or wrong

type

Gun not triggered Trigger gun while starting engine.

Partially plugged air cleaner filter Remove and clean.

Spark plug dirty, wrong gap, or wrong

type

Worn or wrong size tip Replace with tip of proper size.

Inlet filter clogged Clean. Check more frequently.

Worn packings, abrasives in water, or

natural wear

Inadequate water supply Check water flow rate to pump.

Fouled or dirty inlet or discharge valves Clean inlet and discharge valve assemblies.

Restricted inlet Garden hose might be collapsed or kinked.

Worn inlet or discharge valves Replace worn valves.

Leaking high–pressure hose Replace high–pressure hose.

Worn packings Install new packings.

Loose fitting connections Check all fitting connections. TIghten if loose.

Oil seals leaking Install new oil seals.

Move throttle to FAST (rabbit) position

andmake sure spark plug is dry.

times to clear out fuel. Make sure spark plug

is dry.

Clean, adjust gap or replace.

Clean, adjust gap or replace.

Check filter. Replace packing.

Check filter.

17309828

Page 18

Problem

prematurely

prematurely

Packings are failing

frequently or

Strong surging at inlet

and low pressure on

discharge side

Water spitting out of

thermal valve

Note: For complete pump repair and design information see website: www.ARNORTHAMERICA.com

Scored, damaged, or worn plungers Install new plungers.

Abrasive material in fluid being pumped Install proper filtration on pump inlet plumbing.

Inlet water temperature too high Check water temperature. It should not

Overpressurizing pump Do not modify any factory–set adjustments.

Excessive pressure due to partially

plugged or damaged tip

Pump running too long without spraying Never run pump more than 10 minutes without

Running pump dry Do not run pump without water.

Foreign particles in inlet or discharge

valve or worn inlet and/or discharge

valves

Pump running too long without spraying Trigger gun to get fresh, cooler water in pump.

Cause Solution

exceed 160F (70C).

Clean or replace tip. See Installing and

Changing Spray Tips (page 12).

spraying.

Clean or replace valves.

18 309828

Page 19

Pump Service

Repair kits are available. See the Parts Lists (page 21). For the best results, use all parts in the kits.

Perform Pressure Relief Procedure (page 7).

Servicing Valves

Discharge Valves:

Disassembly

1. Remove valve cap.

2. Inspect valve cap o–ring for damage. Replace if

necessary.

3. Using a needle nose pliers, remove valve.

4. Use a small probe to move the poppet up and down

to assure it is functioning properly.

5. Inspect for any debris that may be lodged between

poppet and seal.

6. Remove valve seat o–ring and inspect for damage.

Assembly

Inlet Valves

Disassembly

1. Remove manifold.

2. Remove low–pressure seals by inserting a flat

screwdriver under seal lip and lifting up.

3. Using a reversible pliers, carefully remove packing

retainers (plunger guides).

Note: Packing retainers can be reused if not worn.

4. Remove high–pressure packing by pulling straight

out with your finger.

5. Pull out valve cage/head ring assembly, valve

poppet, spring and o–ring.

6. Inspect for debris and/or damage.

7. Remove valve o–ring.

Assembly

1. Install valve seat o–ring squarely into bottom of

manifold.

2. Insert valve assembly and push squarely into

o–ring.

3. Install high–pressure packing by placing it into

cylinder at an angle and then pushing into place.

Note: The point of the “v” or flat side of packing is

pointed at you.

4. Lubricate packing retainer o–ring with a light film of

oil and install it into cylinder.

1. Install valve seat o–ring squarely into bottom of

manifold.

2. Insert valve assembly squarely into port, pushing it

into o–ring.

3. Install valve cap and torque to 443 in.–lbs (37

ft–lbs).

5. Push it completely into place.

Note: O–ring will seat just inside manifold and you will

hear a slight pop.

6. Insert low–pressure seal by placing it into cylinder

at an angle and pushing it into place.

7. Put a thin coat of oil on plungers and packings.

8. Carefully install manifold and torque bolt to 443

in.–lbs (37 ft–lbs).

Note: Valve life is dependant on many variables.

Hard water, cavitation, corrosion, chemicals and

equipment care. The valves are a wear item and need

periodic replacement. Worn o–rings or damaged

valves will cause pressure loss and pulsations.

19309828

Page 20

Packings

Disassembly

1. To access water seals for inspection or replacement, remove head of pump.

Assembly

1. Install high–pressure seal into head.

Note: It is important to note the order in which the

components of the packing stack are arranged and

facing during disassembly.

2. Remove head bolts.

3. Insert a small pry bar between head and body at

opposite corners and apply pressure down on one

pry bar and up on the other pry bar.

4. Lift head up and away from body.

Note: Packing stack will not always stay in head of

pump when it is removed. Sometimes one or more

components of the packing stack will come out of the

head and stay on the plunger.

5. To remove any components that stay on plungers

twist back and forth while pulling up.

6. Remove low–pressure seals by inserting a flat

screwdriver under seal lip and lifting up.

7. Remove piston guides from head by using a reverse pliers (preferably rubber coated) inserted

into center of piston guide.

8. Use back and forth twisting motion while pulling up

(clockwise and counter–clockwise).

Note: It should fit snugly. The packing support is part

of the valve cage.

2. Place high–pressure seal at an angle and work it

into cylinder.

Note: The point of the “v” or flat side of packing is

pointed at you.

3. Lubricate packing retainer o–ring with a light film of

oil and install it into cylinder.

4. Push it completely into place.

Note: O–ring will seat just inside manifold and you will

hear a slight pop.

5. Insert low–pressure seal by placing it into cylinder

at an angle and pushing it into place.

6. Put a thin coat of oil on plungers and packings.

7. Carefully install manifold and torque bolt to 443

in.–lbs (37 ft–lbs).

9. Another method is to use a two–prong slide hammer puller. Insert prongs into piston guide allowing

prongs to grab under support ring, then use slide

hammer to pull packing stack up and out of head.

Note: Damage to piston guides and or seals may

occur during removal. Inspect carefully before reusing

any components of packing stack.

10. Remove high–pressure packing by pulling straight

out with your finger.

Note: Valve life is dependant on many variables.

Hard water, cavitation, corrosion, chemicals and

equipment care. The valves are a wear item and need

periodic replacement. Worn o–rings or damaged

valves will cause pressure loss and pulsations.

Water seals are wear items. Lift of seals is dependent

on many factors. Water seals should be replaced

when water leak or loss of performance is noticed.

Prompt replacement of worn seals will insure peak

operating performance and trouble–free operation.

20 309828

Page 21

Parts

Model 2525LD

20 23

45

22

24

43,44

25

40

21

33

31

4

2

26

35

10

12

32

34

5

9

6

7

8

27

3

1

29

30

28

56

13

14

22

ti7343a

15

36

16

17

21309828

Page 22

Parts

Model 2525LD

Ref.

Part

No.

No.

1 15C311 HANDLE, cart 1

2 15B880 FRAME, placard 1

3 15C307 RACK, hose 1

4 115651 NUT, acorn 2

5 805535 TIP, 0°, red 1

6 805536 TIP, 15°, yellow 1

7 805538 TIP, 40°, white 1

8 805634 TIP, chemical, black 1

9 801012 GROMMET 4

10 112827 BUTTON, snap 2

12 15C309 FRAME, cart, Series A 1

287611 FRAME, cart, Series B 1

13 116968 WHEEL 2

14 101242 RING, retaining 2

15 15C305 FRAME, leg. Series A 1

287609 FRAME, leg. Series B 1

16 113817 FOOT, base, rubber 2

17 100057 SCREW, hex, cap 2

Description Qty.

Ref.

Part

No.

No.

20 118000 ENGINE, 5 hp, Honda 1

21 110837 SCREW, hex hd 4

22 111040 NUT, nylon 6

23 197792 KEY, motor shaft 1

24 287137 PUMP (with bolts) 1

25 117758 ADAPTER, garden hose 1

26 117759 VALVE, thermal 1

27 117760 HOSE, injector 1

28 118125 HOSE 1

29 246674 GUN 1

30 118124 EXTENSION, gun 1

31 116477 WASHER 2

32 290013 LABEL, warning 1

33 290131 LABEL, warning 1

34 802363 LABEL, caution 1

35 100270 SCREW, cap, hex hd 2

36 102040 NUT, lock 2

40 116411 SPRING 2

45 100527 WASHER 4

55 249101 KIT, coupling, hose (see

56 113418 O–RING 1

Y Additional danger and warning tags and labels

available free.

Description Qty.

page NO TAG)

1

22 309828

Repair parts for Honda Engine model GC160, 5

hp, can be identified and purchased by following the

links on our website: www.graco.com.

Page 23

SJV2.5G25D–F7

(Use with model 2525LD)

1

2

3

5

6

8

9

10

11

12

13

14

15

16

17

18

19

21

23

4

6

7

5

26

24

25

Repair Kits

57

48

30

31

32

27

28

40

33

34

35

36

47

46

49

62

44

43

45

41

37

38

55

63

66

ti6080c

SJV2.5G25D–F7 Repair Kits

287572 KIT, repair, water seals

includes 41, 43, 44, 45, 62

287132 KIT, repair, valves

includes 12, 28, 40

287133 KIT, repair, pistons

includes 55

287134 KIT, repair, oil seals

includes 46, 57, 66

287135 KIT, repair, o–rings

includes, 9, 10, 12, 13, 14,

15, 16, 19, 21, 27, 30, 31,

32, 33, 36, 37, 49, 63

287874 KIT, chemical injector, 33,

1

34, 35, 36, 37, 38

287136 KIT, repair, unloader

1

includes 1–19

1

1

287137 PUMP (complete pump) 1

1

1

Additional repair parts for AR North American

117784 OIL, pump 1

pump model SJV2.5G25D–F7, can be identified and

1

purchased by following the links on our website:

www.graco.com.

23309828

Page 24

Parts

Model 2626LD

20 23

45

22

24

43,44

25

21

33

4

2

26

35

10

12

32

34

5

9

6

7

8

27

3

1

29

30

28

56

13

22

40

14

31

ti7344a

15

36

16

17

24 309828

Page 25

Parts

Model 2626LD

Ref.

Part

No.

No.

1 15C311 HANDLE, cart 1

2 15F136 FRAME, placard 1

3 15C307 RACK, hose 1

4 115651 NUT, acorn 2

5 805535 TIP, 0°, red 1

6 805536 TIP, 15°, yellow 1

7 805538 TIP, 40°, white 1

8 805634 TIP, chemical, black 1

9 801012 GROMMET 4

10 112827 BUTTON, snap 2

12 287611 FRAME, cart 1

13 116968 WHEEL 2

14 101242 RING, retaining 2

15 287609 FRAME, leg 1

16 113817 FOOT, base, rubber 2

17 100057 SCREW, hex, cap 2

Description Qty.

Ref.

Part

No.

No.

20 119587 ENGINE, 6 hp, Honda 1

21 110837 SCREW, hex hd 4

22 111040 NUT, nylon 6

23 197792 KEY, motor shaft 1

24 287574 PUMP (with bolts) 1

25 117758 ADAPTER, garden hose 1

26 117759 VALVE, thermal 1

27 117760 HOSE, injector 1

28 118125 HOSE 1

29 246674 GUN 1

30 118124 EXTENSION, gun 1

31 116477 WASHER 2

32 290013 LABEL, warning 1

33 290131 LABEL, warning 1

34 802363 LABEL, caution 1

35 100270 SCREW, cap, hex hd 2

36 102040 NUT, lock 2

40 116411 SPRING 2

45 100527 WASHER 4

55 249101 KIT, coupling, hose (see

56 113418 O–RING 1

Y Additional danger and warning tags and labels

available free.

Description Qty.

page NO TAG)

1

Repair parts for Honda Engine model GC190, 6

hp, can be identified and purchased by following the

links on our website: www.graco.com.

25309828

Page 26

SJV2.5G27–D105

(Use with Model 2626LD)

1

2

3

5

6

8

9

10

11

12

13

14

15

16

17

18

19

21

23

4

6

7

5

26

27

28

24

33

25

34

Repair Kits

48

30

31

32

41

40

35

36

37

47

46

49

62

44

43

45

38

55

63

66

ti6163b

SJV2.5G27–D2105 Repair Kits

287572 KIT, repair, water seals

includes 41, 43, 44, 45, 62

287132 KIT, repair, valves

includes 12, 28, 40

287133 KIT, repair, pistons

includes 55

287573 KIT, repair, oil seals

includes 46, 47, 66

287135 KIT, repair, o–rings

includes, 9, 10, 12, 13, 14,

15, 16, 19, 21, 27, 30, 31,

32, 33, 36, 37, 49, 63

287874 KIT, chemical injector, 33,

1

34, 35, 36, 37, 38

287136 KIT, repair, unloader

1

includes 1–19

1

1

287574 PUMP (complete pump) 1

1

1

Additional repair parts for AR North American

117784 OIL, pump 1

pump model SJV2.5G27–D2105, can be identified and

1

purchased by following the links on our website:

www.graco.com.

26 309828

Page 27

Technical Data

Model 2525LD

Working pressure range

Operating Pressure 2300 psi (159 bar, 15.8 MPa)

Maximum Working Pressure 2500 psi (172 bar, 17.2 MPa)

Engine horsepower 5.0

Maximum delivery (with nozzle) 2.5 gpm

High pressure hose 30 ft x 5/16 in. supplied

Chemical injector hose 4 ft ( m) 1/4 in. ID

Weight, pressure washer only 60 lb (27.22 kg)

Weight: sprayer, hose and gun 73 lb (33.11 kg)

Dimensions

23.5 in. (59.69 cm) Length

22.0 in. (55.88 cm) Width

22.0 (55.88 cm) Height

Pump inlet fitting 3/4 in. internal thread (standard garden hose thread)

Storage temperature range* –30 to 160F (–35 to 71C)

Operating temperature range 40 to 115F (4 to 46C)

Sound data Sound pressure: 92.5 dB(A)

Sound level: 106.8 dB(A)

*When pump is stored with non–freezing fluid.

Model 2626LD

Working pressure range

Operating Pressure 2600 psi (179 bar, 17.9 MPa)

Maximum Working Pressure 2750 psi (190 bar, 19.0 MPa)

Engine horsepower 6.0

Maximum delivery (with nozzle) 2.6 gpm

High pressure hose 30 ft x 5/16 in. supplied

Chemical injector hose 4 ft ( m) 1/4 in. ID

Weight, pressure washer only 63 lb (28.58 kg)

Weight: sprayer, hose and gun 70 lb (31.75 kg)

Dimensions

23.5 in. (59.69 cm) Length

22.0 in. (55.88 cm) Width

22.0 (55.88 cm) Height

Pump inlet fitting 3/4 in. internal thread (standard garden hose thread)

Storage temperature range* –30 to 160F (–35 to 71C)

Operating temperature range 40 to 115F (4 to 46C)

Sound data Sound pressure: 95.2 dB(A)

Sound level: 109 dB(A)

*When pump is stored with non–freezing fluid.

27309828

Page 28

Graco Standard Warranty

Graco warrants all equipment listed in this manual which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. Graco will, for a period of twelve months from the date of

sale, repair or replace any part of the equipment determined by Graco to be defective. This warranty applies only when the equipment

is installed, operated and maintained in accordance with Graco’s written recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by

faulty installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or

substitution of non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of

Graco equipment with structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture,

installation, operation or maintenance or structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for

verification of the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The

equipment will be returned to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect

in material or workmanship, repairs will be made at a reasonable charge, which charges may include the costs of parts, labor, and

transportation.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other

remedy (including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any

other incidental or consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the

date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR

A PARTICULAR PURPOSE IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT

NOT MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, gas engines,

switches, hose, etc.), are subject to the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance

in making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment

hereunder, or the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract,

breach of warranty, the negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings

entered into, given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties

reconnaissent avoir convenu que la rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures

judiciaires exécutés, donnés ou intentés à la suite de ou en rapport, directement ou indirectement, avec les procédures concernées.

ADDITIONAL WARRANTY COVERAGE

Graco does provide extended warranty and wear warranty for products described in the “Graco Contractor Equipment Warranty

Program”.

Graco Phone Number

TO PLACE AN ORDER, contact your Graco distributor, or call this number to identify the distributor closest to you:

1–800–690–2894 Toll Free

All written and visual data contained in this document reflect the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

MM 309828

International Offices: Belgium, China, Japan, Korea

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

Graco Headquarters: Minneapolis

www.graco.com

2/2003, Rev 1/2008

28 309828

Loading...

Loading...