Page 1

INSTRUCTIONS

309368

This manual contains important

warnings and information.

READ AND KEEP FOR REFERENCE.

INSTRUCTIONS

Direct-Drive Pressure Washers

2730

Model 244811, Series B with Briggs & Stratton 6.5 HP Motor

2700 psi (186 bar, 18.6 MPa) Operating Pressure

3000 psi (210 bar, 21.0 MPa) Maximum Working Pressure

2730

Model 244812, Series B with Honda 6.5 HP Motor

2700 psi (186 bar, 18.6 MPa) Operating Pressure

3000 psi (210 bar, 21.0 MPa) Maximum Working Pressure

3030

Model 244813, Series B

3000 psi (210 bar, 21.0 MPa) Operating Pressure

3300 psi (227.5 bar, 22.75 MPa) Maximum Working Pressure

Rev. H

First choice when

quality counts.t

3340

Model 244814, Series B

3300 psi (227.5 bar, 22.75 MPa) Operating Pressure

3600 psi (248 bar, 24.8 MPa) Maximum Working Pressure

3540

Model 244815, Series B

3500 psi (241 bar, 24.1 MPa) Operating Pressure

3800 psi (262 bar, 26.2 MPa) Maximum Working Pressure

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440 --1441

3300 Pressure Washer

Model 244814 Shown

ECOPYRIGHT 2001 GRACO INC.

Graco Inc. is registered to I.S. EN ISO 9001

Page 2

Table of Contents

Symbols 2......................................

Warnings 3......................................

Component Identification 4........................

Pressure Relief Procedure 7.......................

Installing and Changing Spray Tips 13..............

Parts Drawing 16.................................

Parts List 17.....................................

Warning Symbol

WARNING

This symbol alerts you to the possibility of serious

injury or death if you do not follow instructions.

Caution Symbol

CAUTION

This symbol alerts you to the possibility of damage to

or destruction of equipment if you do not follow instructions.

2 309368

Page 3

WARNINGS

Fuel Hazard:

Fuel is combustible. When spilled on a hot surface it can ignite and cause a fire.

Do not fill fuel tank while engine is running or hot.

Exhaust Hazard:

Exhaust contains poisonous carbon monoxide, which is colorless and odorless. Do not operate this

equipment in a closed building.

Equipment Misuse Hazard:

Misuse of pressure washer or accessories can cause the equipment to rupture or malfunction and

result in serious injury.

DDo not alter or modify any part or factory--setting.

DCheck equipment daily. Repair or replace worn or damaged parts immediately.

DDo not exceed maximum working pressure (MWPR) of the lowest--rated system component.

DUse fluids and solvents that are compatible with the equipment wetted parts. See Specifications page

for this information.

DWear hearing protection when operating this equipment.

DDo not “blow back” fluid; this is not an air spray system.

DFollow Pressure Relief, page 7 before cleaning, checking or servicing equipment.

TOXIC FLUID HAZARD:

Hazardous fluid or toxi fumes can cause serious injury or death if splashed in eyes or on skin,

inhaled, or swallowed.

DKnow specific hazards of fluids you are using and take protective measures as recommended by

the fluid and solvent manufacturer.

Injection Hazard:

Spray from gun, leaks or ruptured components can inject fluid into your body and cause serious

injury. Fluid splashed in eyes or on skin can also cause serious injury.

DFluid injected into skin might look like just a cut, but it is a serious injury. Seek immediate surgical

treatment.

DDo not point gun at anyone or any part of the body.

DDo not stop or deflect leaks with hand, body, glove, or rag.

DDo not put your hand or fingers over the spray tip.

DTIghten fluid connections before you start this equipment.

DEngage the gun safety whenever you stop spraying.

DFollow Pressure Relief Procedure, page 7 if the spray tip clogs and before you clean, check or

service this equipment.

DRepair or replace worn or damaged parts immediately.

DCheck hoses, tubes, and couplings daily. Do not repair high--pressure couplings. Replace entire

hose. Fluid hoses must have spring guards on both ends to prevent kinks and rupture.

3309368

Page 4

Component Identification

Hose

On/Off Engine Switch (side)

Pressure Gauge (not

shown)

Hose Rack (a)/Gun Holder (b)

(b)

(a)

Gun and wand

Tip Storage

High Pressure Hose

Connection

Garden Hose

Connection

Pressure Unloader

Adjustment Knob

4 309368

Oil Level Site Gauge

Engine Oil Fill

Water Pump Oil Fill

Page 5

Setup

Shipping Damage

Check the pressure washer for shipping damage. Notify the carrier immediately if there is any damage.

Connect High--Pressure Hose and Gun

Connect the high--pressure hose between the pump outlet and gun inlet.

Both of these connections are made with quick couplers.

CAUTION

Up to 100 ft (30 m) of 3/8” high--pressure hose may be used. Longer hoses could affect pressure

washer and chemical injector performance balance.

Install Spray Tip

Install the spray tip on the wand. (Installing and Changing Spray Tips, page 13). If you are using a Sandblasting Kit, see its separate manual for installation instructions.

Connect to Water Supply

Connect hose with at least a 3/4--in (19 mm) ID from the water supply to the 3/4--in garden hose inlet

on the pressure washer. The supply hose should not be more than 50 ft (15 m) long.

5309368

Page 6

CAUTION

Before you connect the garden hose to the pressure washer, check your local plumbing code regarding

cross--connection to the water supply. If required, install a backflow preventer.

If the inlet water pressure is over 60 psi (4.1 bar), a regulating water valve must be installed at the garden

hose connection.

Do not exceed 160_F(70_C) inlet water temperature.

NOTE: The water source must have a minimum flow rate equal to that of the pressure washer.

6 309368

Page 7

PRESSURE RELIEF

Follow these instructions whenever you are instructed to relieve pressure, stop spraying for more than 10 minutes, check or service the

equipment, or install or clean the spray nozzle.

1. Engage trigger safety latch.

2. Turn pressure washer off.

3. Remove ignition cable from spark plug.

4. Shut off water supply. Disconnect from water.

5. Disengage trigger safety latch and trigger the gun to

relieve pressure. Then re--engage the safety latch.

Note: If you suspect that the spray tip or hose is clogged or that pressure has not been fully relieved after

following the steps above, disengage the trigger safety latch and trigger the gun to relieve pressure.

7309368

Page 8

Operation

Startup

Always use this startup procedure to ensure that the pressure washer is started safely and properly.

D Always engage the gun trigger safety latch when you stop spraying. This reduces the risk of fluid

injection or splashing in the eyes or on the skin if the gun is bumped or triggered accidentally.

D Always observe the CAUTIONS in this section to avoid costly damage to the pressure washer.

D If you use the Sandblaster Kit, see the Sandblaster Kit Manual for detailed cleaning information.

.

. Check the oil level of the engine and pump.

1

Oil level

NOTE: All Honda engine powered pressure washers are equipped with an engine low-oil sensor that shuts the

engine off if the oil level falls below a certain level. If the engine stops unexpectedly, check the oil and the fuel

levels. Check the oil level each time you add fuel.

WARNING

FIRE HAZARD

Do not refuel a hot engine. Refueling a hot engine could cause a fire. Use only fresh, clean,

regular or unleaded gasoline. Close the fuel shutoff valve during refueling.

2. Check fuel level.

3. Check oil level in pump. It should be half way up the sight

glass located on the front of the pump. Add pump oil as

necessary . The system is equipped with a thermal overload to help prevent severe damage.

Fuel level

Oil level

NOTE: It is important to drain and refill the pump oil after the first 50 hours of operation.

8 309368

Page 9

4

. Turn on water supply.

CAUTION

Never run pressure washer without water. Costly damage to the pump will result. Always be sure the water

supply is completely turned on before you run the pressure washer.

5

. Trigger the gun until a constant stream of water sprays from the tip indicating

the air is purged from the system.

6. Open fuel shutoff valve. Be sure the spark plug ignition

cable is pushed firmly onto the spark plug.

7. Put the switch in the ON position and the throttle at HALF

throttle.

9309368

Page 10

CAUTION

Do not allow pressure washer to idle for more than 10 minutes. This causes the recirculating water to

overheat and serious damage to pump. Turn off pressure washer if it will not be spraying at least every 10

minutes. If heated inlet water is used, reduce this time more. Do not operate pressure washer with inlet

water screen removed. This screen helps keep abrasive sediment out of pump, which could clog pump or

damage cylinders. Keep screen clean. Do not pump caustic materials; such materials could corrode pump

components.

8. Pull the starter rope quickly to start the engine.

Pull and return the rope until the engine starts.

HINT: Placing one foot on the pressure washer

as a brace provides better leverage.

NOTE: For easier starting, have one person start pressure washer while another triggers gun.

D If engine is cold, start engine with choke completely closed. In cool weather, you might have to let engine

run with choke closed for first 10--30 seconds. In warm weather, open choke completely as soon as engine starts.

D If engine is warm, start engine with choke completely open or partially closed. When engine starts open

choke completely.

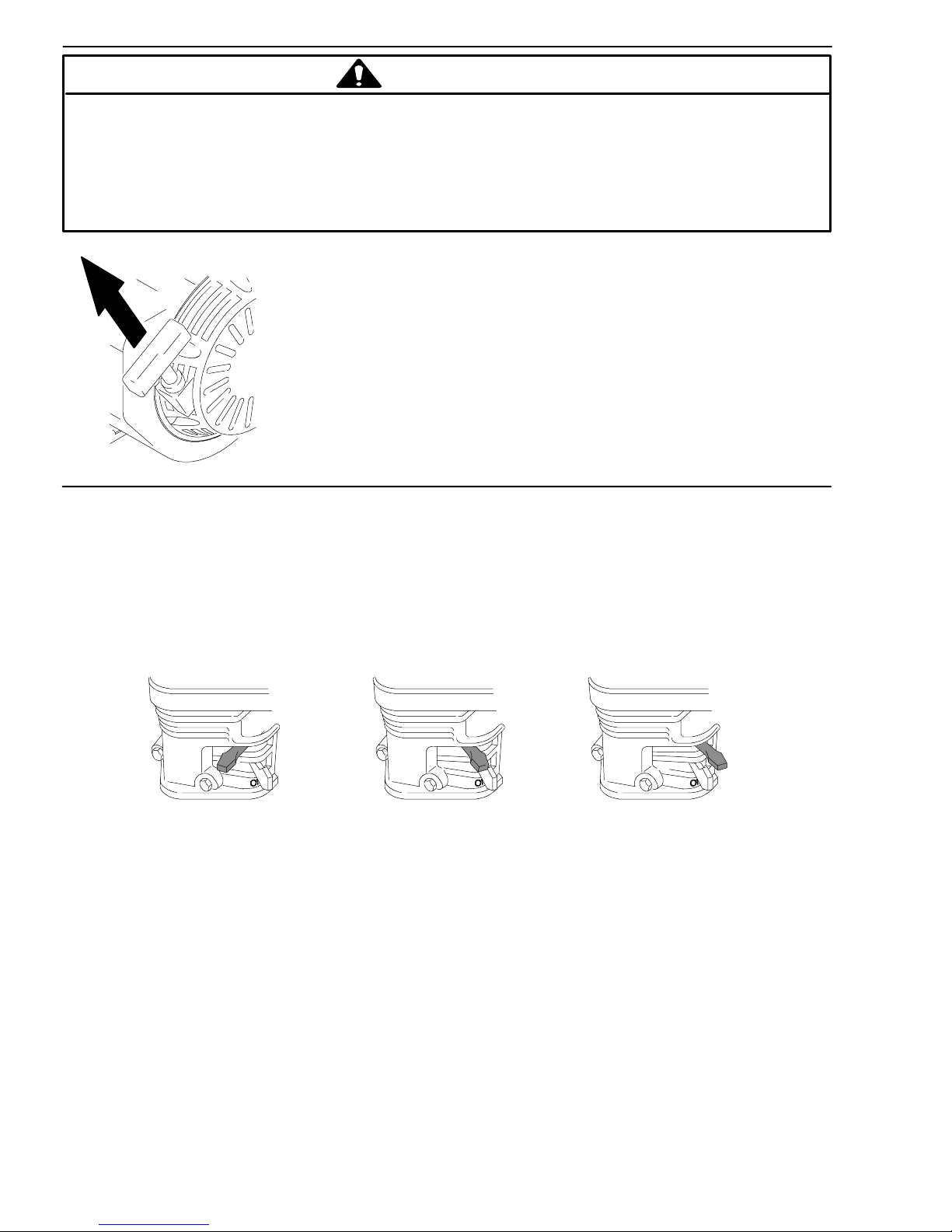

CLOSED

HALF

OPEN

10 309368

Page 11

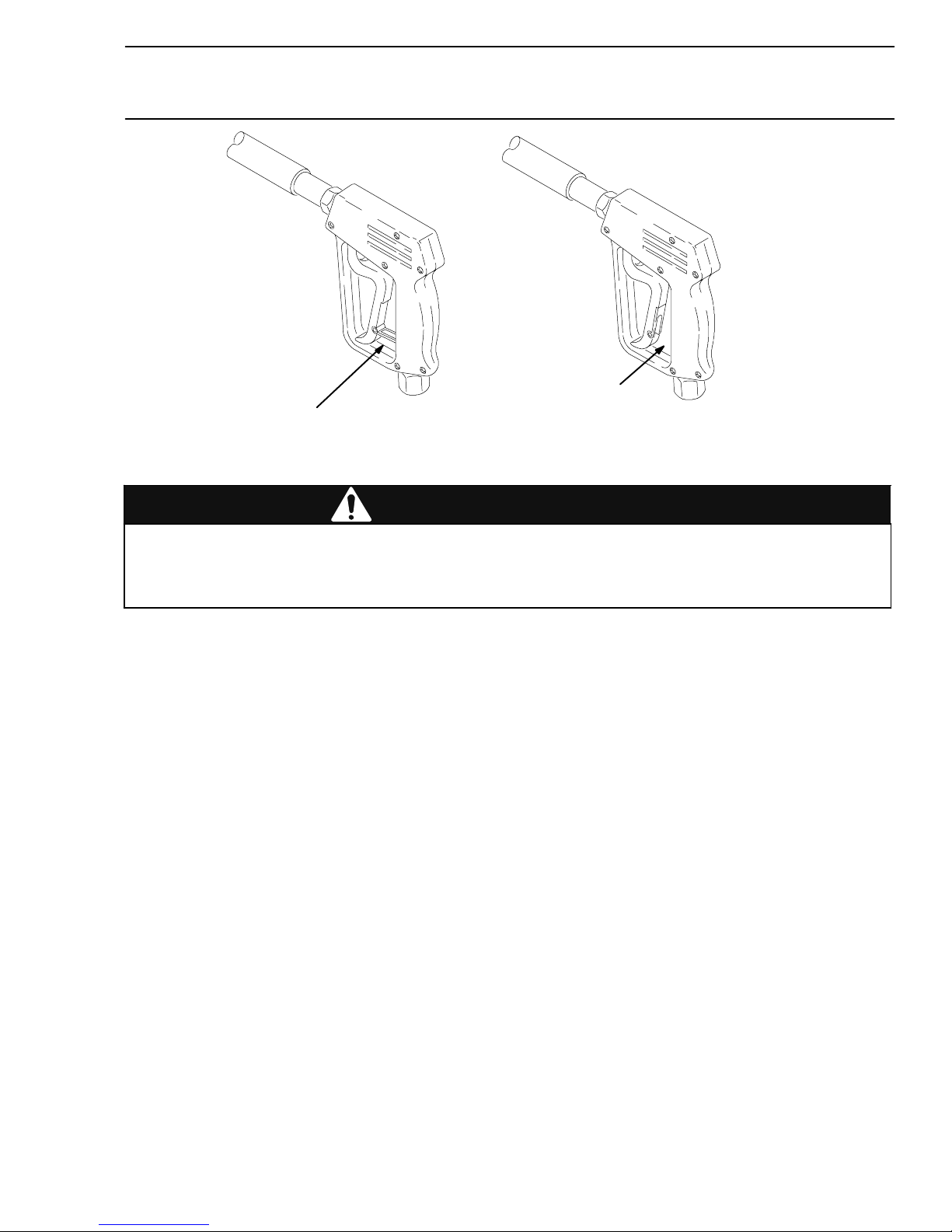

Trigger Safety Latch

Always engage the safety latch when you stop spraying.

disengaged

engaged

WARNING

Always engage the trigger safety latch when you stop spraying even for a moment. The

engaged, safety latch prevents the fun from being triggered accidentally by hand or when

dropped or bumped. Be sure the latch is pushed fully down, or it will not prevent the gun from

being triggered.

WARNING

11309368

Page 12

Chemical Injector Operation

1

. Follow Pressure Relief Procedure (page 7).

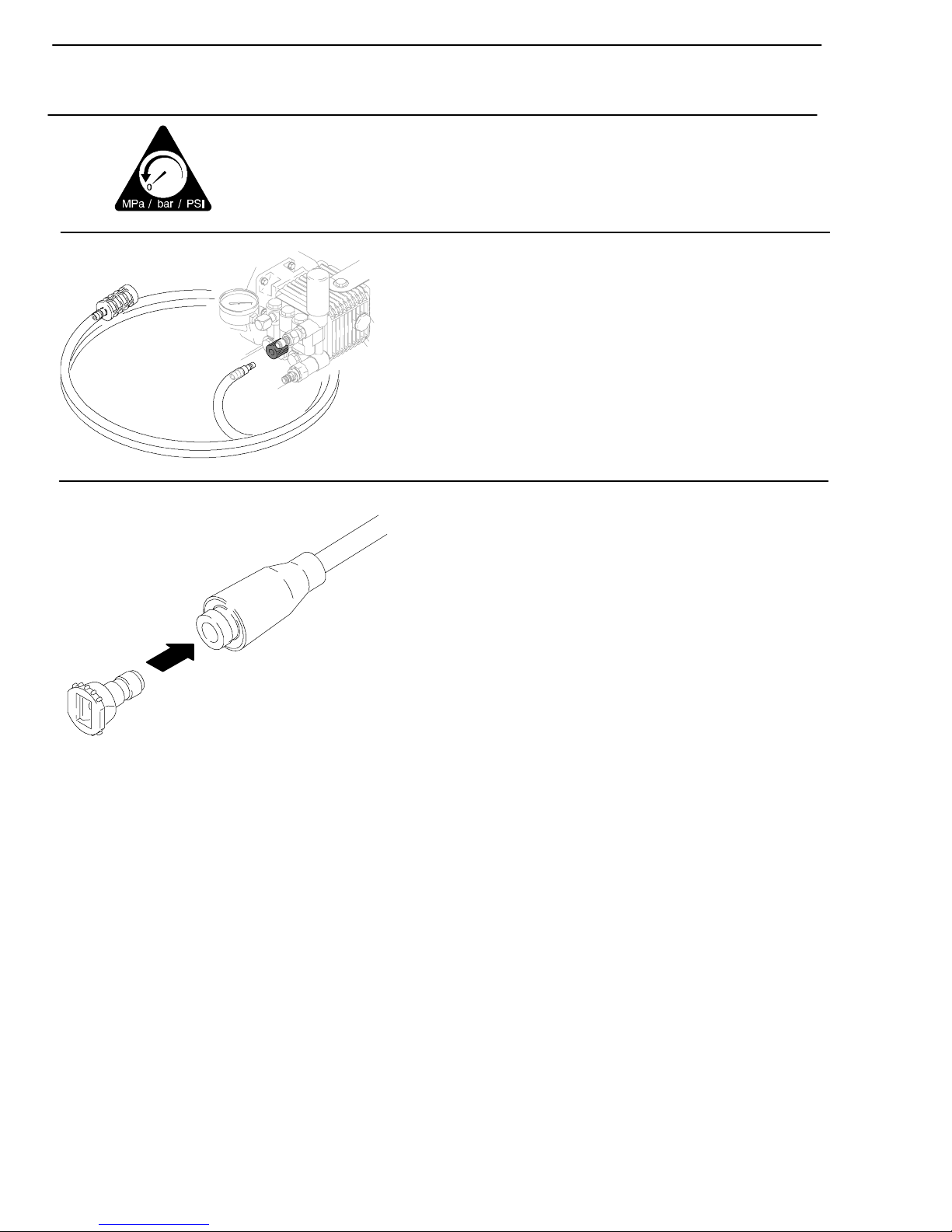

2. Insert chemical filter (attached with clear tubing to

chemical injector) into the container of chemical.

Insert brass coupler into chemical injector.

3. Install the black, large--orifice, chemical tip. (Instal-

ling and Changing Spray Tips page 13).

The large orifice of the chemical tip causes a drop in

pressure that actuates the chemical injector. Changing

back to a small orifice spray tip deactivates the chemical injector and produces high pressure for rinsing.

The chemical filter can be left in the chemical container

during high--pressure use. To regulate the flow rate of

the chemical, turn the chemical adjustment knob on the

injector.

12 309368

Page 13

Installing and Changing Spray Tips

Spray tips have 4-- or 5--digit numbers on them.

The first two digits are the spray angle. Tip

holding holes are provided on the chassis.

NOTE: The chemical injector tip is brass and has a large opening and a black plastic cap.

. Perform Pressure Relief Procedure (page 7).

1

2. Point the gun and wand away from you and anyone else.

Spray Tip

Number

00XXX

15XXX

25XXX

40XXX

Chemical

Spray Pattern Fan Angle

0_ blaster (red)

15_ (yellow)

25_ (green)

40_ (white)

XX_ (black)

3. Without holding your hand over the spray tip (A), pull back the

quick coupler ring (B). Remove the current tip, install a different one. Then push the ring back on.

A

B

CAUTION

To avoid blowing the O-ring out of the quick coupler due to the high pressure in the system, never operate

the pressure washer without a tip securely mounted in the quick coupler.

13309368

Page 14

Shutdown, Flushing, and Storage

D Before you store the pressure washer

overnight or transport it, disconnect the water

supply, and turn off the fuel supply valve.

D After each use, wipe all surfaces of the

pressure washer with a clean, damp cloth.

14 309368

Page 15

Long T erm (more than 30 days)/Winter Storage

S Do not store unit outside where it can be exposed to rain, dirt or adverse weather condi-

tions.

S Do not expose pressure washer to freezing temperatures or allow water to freeze in

pressure washer components, causing the pump to lock--up. If this happens let pump

thaw naturally in WARM ENVIRONMENT. DO NOT attempt to to speed up this process

by pouring warm water on pump. This could cause further damage.

ENGINE:

1. Run engine until gas is gone or stabilize the fuel and run it through the fuel system and carburetor.

2. Drain water out of pressure washer hose.

3. Turn fuel system to OFF position.

Pump:

1. Attach one end of a 4 or 5--foot section of hose to pump inlet and other end in an antifreeze

solution approximately 1--foot off the ground.

2. Pull pull--cord on engine until antifreeze comes out of pump outlet.

Storage Location:

1. Store pressure washer in garage, basement or other area where it is protected from freezing

temperatures.

15309368

Page 16

Parts for 2730 Pressure Washer

Model 244811, Series A

40

14

4

5

8--12

1

45

29*

41

42

44

31

43

18

27

34*

39

2

33*

35*

30

32*

28

23

25

3

20

21

22

16

ti1309B

17

19

7

26

38, 15

16 309368

Page 17

Parts for 2730 Pressure Washer

Model 244811, Series A with 6.5 HP Briggs & Stratton motor

Ref.

Ref.

Part

No.

No.

1 1 16299 1

2 244749 1

3 244767 1

4 244779 1

5 244782 1

7 80451 1 2

8 805535 1

9 805536 1

10 805537 1

1 1 805538 1

244768 1

12 805634 1

14 804275 1

15 1 16342 2

16 1 10837 4

17 1 11040 4

18 197428 1

19 1 16411 2

20 801546 2

Description Qty.

Part

No.

No.

21 100132 2

22 101566 2

23 801504 2

25 197792 1

26 1 16477 2

27 244803 1

28 1 16460 1

29 244741 1

30 1 16557 1

31 1 16558 1

32 804037 1

33 804402 1

34 80401 1 1

35 804033 1

38 1 16563 2

39 244821 1

40 198012 1

41 804582 1

42 15B910 1

43 244746 1

44 801 112 1

45 287643 1

Description Qty.

17309368

Page 18

Parts for 2730 Pressure Washer

Model 244812, Series A, with Honda 6.5 HP Motor

4

40

41

*34

*33

2

31

39

18

42

29*

45

44

* internal replacement parts

27

43

30

*35

*32

5

25

1

16

19

26

22

20

17

7

38, 15

14

28

3

23

21

8--12

18 309368

Page 19

Parts for 2730 Pressure Washer

Model 244812, Series A with Honda 6.5 HP Motor

Ref.

No.

1 1 16298 1

2 244749 1

3 244767 1

4 244779 1

5 244782 1

7 80451 1 2

8 805535 1

9 805536 1

10 805537 1

1 1 805538 1

12 805634 1

14 804275 1

15 116342 2

16 110837 4

17 111040 4

18 197428 1

19 116411 2

20 801546 2

Part No. Description Qty.

244768 1

Ref.

No.

21 100132 2

22 101566 2

23 801504 2

25 197792 1

26 116477 2

27 244803 1

28 116460 1

29 244741 1

30 116557 1

31 116558 1

32 804037 1

33 804402 1

34 804011 1

35 804033 1

38 116563 2

39 244821 1

40 198012 1

41 804582 1

42 15B910 1

43 244746 1

44 801112 1

45 287643 1

Part No. Description Qty.

19309368

Page 20

Parts for 3030/3340/3540 Pressure Washer

Model 244813, Series A with Honda 9 HP Motor†

Model 244814, Series A, with Honda 11 HP Motor

Model 244815, Series A, with Honda 13 HP Motor

4

41

3

42

31

40

18

43

29*

46

45

44

* internal replacement parts

*33

27

*34

2

30

*35

*32

28

14

5

8--12

1

25

16

19

26

23

21

20

22

17

38

39, 15

7

20 309368

Page 21

Parts for 3030/3340/3540 Pressure Washer

Model 244813, Series A with Honda 9 HP Motor†

Model 244814, Series A with Honda 11 HP MotorG

Model 244815, Series A with Honda 13 HP Motorn

Ref.

No.

1

2

3 244767 1

4 244779 1

5

7

8

9

10

11

12 805634 1

14 804275 1

15 1 16342 2

16 1 10837 4

17 1 11040 4

Part No. Description Qty.

803900

803158G 1

1 14703n 1

244750

244751G 1

244752n 1

244782

244783Gn 1

80451 1

1 16478Gn 2

805539

805543

805540

805544

805541

805545

805542

805546

244769

800708

†

†

†

†

†G

n 1

†G

n 1

†G

n 1

†G

n 1

†G

n 1

Ref.

No.

1

1

1

2

1

1

1

1

1

18 197428 1

19 116411 2

20 801546 2

21 100132 2

22 101566 2

23 801504 2

25 801137 1

26 116477 2

27 244804 1

28 116461 1

29 244741 1

30 116559 1

31 116558 1

32 804404 1

33 804402 1

34 804415 1

35 804033 1

38 198055 2

39 116563 2

40 244821 1

41 198012 1

42 804582 1

43 15B910 1

44 244746 1

45 801112 1

46 287643 1

Part No. Description Qty.

244805 1

244806 1

21309368

Page 22

Notes

22 309368

Page 23

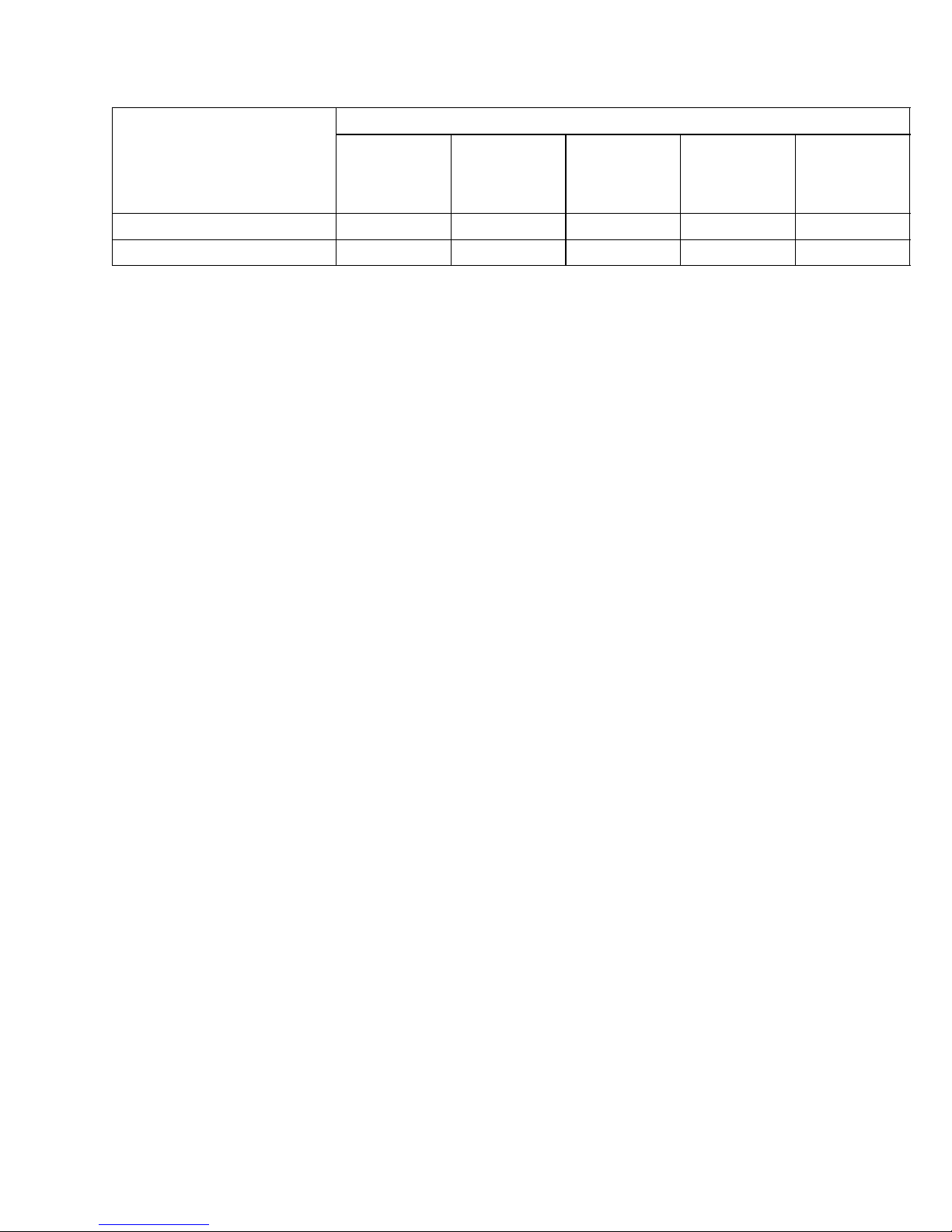

Sound Data

Direct Drive Pressure Washer Models

Sound Data

Sound Pressure 92.5 dB(A) 89.0 dB(A) 93.3 dB(A) 90.4 dB(A) 90.7 dB(A)

Sound Level 106.8 dB(A) 103.3 dB(A) 107.6 dB(A) 104.7 dB(A) 105.0 dB(A)

2730

Briggs &

Stratton

Motor

2730

Honda Motor

3030 3340 3540

23309368

Page 24

Graco Standard Warranty

Graco warrants allequipment manufactured byGraco andbearing its nameto be free fromdefects in material andworkmanship onthe

date of sale by an authorized Gracodistributor tothe original purchaser foruse. With the exception ofany special,extended, orlimited

warrantypublished byGraco, Graco will, for a period oftwelve months from the dateof sale,repair or replace any part of the equipment

determined by Graco to be defective. This warranty applies only when the equipment is installed,operated and maintained in accordance with Graco’s written recommendations.

This warranty does not cover, and Gracoshall not be liable for general wear and tear, or any malfunction,damage or wear caused by

faultyinstallation, misapplication,abrasion, corrosion, inadequate orimproper maintenance, negligence, accident, tampering, orsubstitution of non--Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of

Graco equipment with structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture,

installation, operation or maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for

verification of the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The

equipmentwill bereturned to theoriginal purchaser transportationprepaid. If inspection ofthe equipmentdoes notdisclose any defect

in material or workmanship, repairs will be made at a reasonable charge, which charges may include the costs of parts, labor, and

transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT

NOT LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’ssole obligationand buyer’ssole remedyfor anybreach ofwarrantyshall be as set forth above. The buyer agrees thatno other

remedy (including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property,or any

other incidental or consequential loss) shall be available. Any actionfor breachof warrantymust be brought withintwo (2) years of the

date of sale.

Graco makes no warranty, and disclaims all implied warranties of merchantability and fitness for a particular purpose in connection

with accessories, equipment, materials or components sold but not manufactured by Graco. These items sold, but not manufactured

by Graco (such as electric motors, switches, hose, etc.), are subject to the warranty, if any, of their manufacturer. Graco will provide

purchaser with reasonable assistance in making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment

hereunder, or the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract,

breach of warranty, the negligence of Graco, or otherwise.

FOR GRACO CANADA CUST

The parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings

entered into, given orinstituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoirconvenu que la rédaction du présente document sera en Anglais, ainsique tous documents, aviset procédures judiciaires

exécutés, donnés ou intentés à la suite de ou en rapport, directement ou indirectement, avec les procedures concernées.

OMERS

TO PLACE AN ORDER OR FOR SERVICE, contact your Graco distributor, or call this number to identify the

distributor near you:1--800--690--2894 Toll Free

mm 309368

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

International Offices: Belgium, China, Japan, Korea

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440 --1441

24 309368

Graco Headquarters: Minneapolis

www.graco.com

Printed in USA 309368F

8/2001 Rev. 07/2008

Loading...

Loading...