Page 1

Instructions-Parts

ProDispense™

Used to meter and dispense paints, coatings, solvents, water, and lubrication fluids.

For Professional Use Only.

Not for use in explosive atmospheres.

309301G

Part No. 244561 Electronic Preset Dispense System

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

See page 4 for maximum working fluid pressure

and system component information.

ENG

Conforms to ANSI/UL

standard 3121-1

CAN/CSA C22.2 No 1010-1-92

Page 2

Contents

ProDispense System Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

WARNING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

How the ProDispense System Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Main Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Install the Fluid Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Mount the Fluid Panel(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Connect the Air and Fluid Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Install the Remote Operator Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Mount the Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Connect the Cables and Power Cord . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Ground the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Check the Resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Connect a Printer (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Connect to a PC or Alarm (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Before Beginning Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Startup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Setup Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Screen Navigation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

System Setup Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Fluid Setup Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Recipe Setup Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Calibrate Meter Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Dispense Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Screen Navigation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Run Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Fluid Totals Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Alarm History Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Operation Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Loading Fluid Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Manual Dispense. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Automatic Dispense. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Purging Fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Emergency Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Removing and Installing Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

2 309301G

Page 3

Replacing Display Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Replacing Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Replacing Membrane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Replacing Main Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Replacing Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Replacing Fluid Panel Junction Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Servicing Fluid Panel 244599. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Servicing Fluid Panel 244600. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Servicing Fluid Panel 244601 and 246837. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Servicing Fluid Panel 246838. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Servicing Fluid Panel 246839. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Wiring Charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Part No. 244561, Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Part No. 244599, Fluid Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Part No. 244600, Fluid Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Part No. 244601, Fluid Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Part No. 246837, Fluid Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Part No. 246838, Fluid Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Part No. 246839, Fluid Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Technical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Accessories and Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Graco Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

309301G 3

Page 4

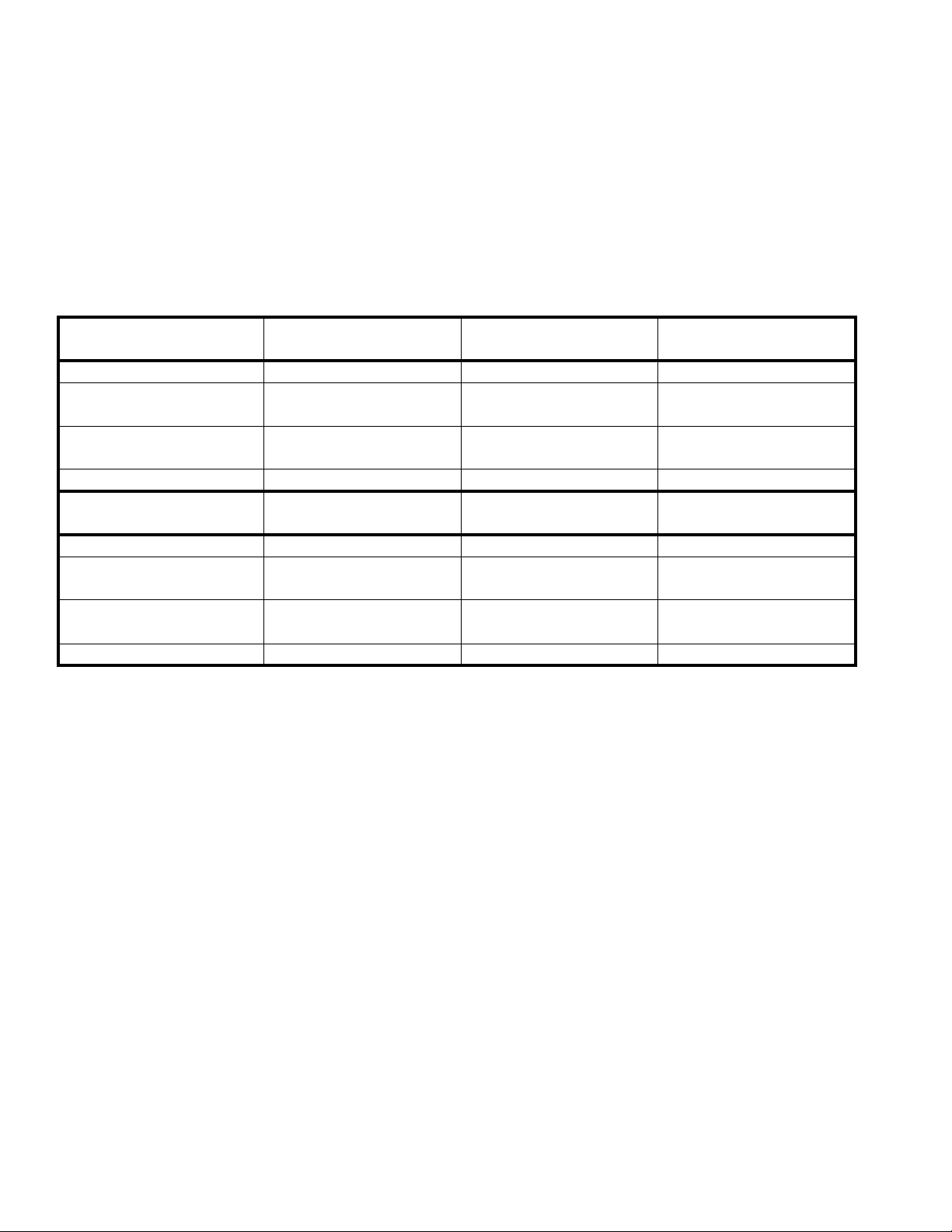

ProDispense System Components

ProDispense System Components

Follow the instructions in this manual (309301) and refer to the component manuals for additional warning, operation, service, and parts information. See the table below for:

• maximum working pressure of the fluid panels

• component part numbers and manual numbers

• parts list page numbers

Fluid Panels Part No. 244599

Oil/Lubricant

Maximum Working Pressure 1500 psi (10 MPa, 103 bar) 250 psi (1.7 MPa, 17 bar) 3000 psi (21 MPa, 207 bar)

Fluid Meter Part No. 238618 513891 239716

Manual No. 308245 — 308778

Dispense Valve Part No. — — 205612

Manual No. — — 306715

Parts List Page No. 64 65 66

Fluid Panels Part No. 246837

Grease/Paint

Maximum Working Pressure 3000 psi (21 MPa, 207 bar) 3000 psi (21 MPa, 207 bar) 3000 psi (21 MPa, 207 bar)

Fluid Meter Part No. 244292 — 246190

Manual No. 308778 — 309834

Dispense Valve Part No. 205612 205612 205612

Manual No. 306715 306715 306715

Parts List Page No. 69 70 71

ProDispense Controller Part No. 244561

Parts List Page No. 62

244600

Water/Antifreeze

246838

Meterless

244601

Grease/Paint

246839

Sealants

Remote Operator Station Part No. 116669

4 309301G

Page 5

Conventions

The following conventions are used in this manual to help guide you through the information.

Warning Symbols

The warning symbol alerts you to the possibility of serious injury or death if you do not follow

the instructions.

Symbols, such as fire, explosion, or electric shock hazard (shown at left), alert you to the specific hazard. Read the main Warnings on pages 6-7 for detailed information about the hazard

indicated.

Caution Symbol

The caution symbol alerts you to the possibility of equipment or property damage or to operation errors if you do not follow the instructions.

Note Symbol

The note symbol is used to call your attention to additional helpful information.

Conventions

Amount 20 qts

Recipe#

ID#

1. Enter the ID

number.

• Italicized text in a screen diagram indicates the text may vary according to how the sys-

tem parameters have been configured. For example, the units of measure shown in the

manual may be qts (quarts). The units you see on your screen may be pounds, kilograms,

quarts, gallons, or liters.

• A shaded box is used to indicate a value/field that can be edited on the controller

screen.

1

• A circled number in a screen diagram relates a field on the screen to a step in a proce-

dure.

1

• Numbers and letters in parentheses in the text, such as (A) or (7), refer to reference num-

bers and letters in the figures.

• When you need to press a key during a procedure, the key is indicated by an icon as

shown in the following example: Press Start to begin the dispense.

309301G 5

Page 6

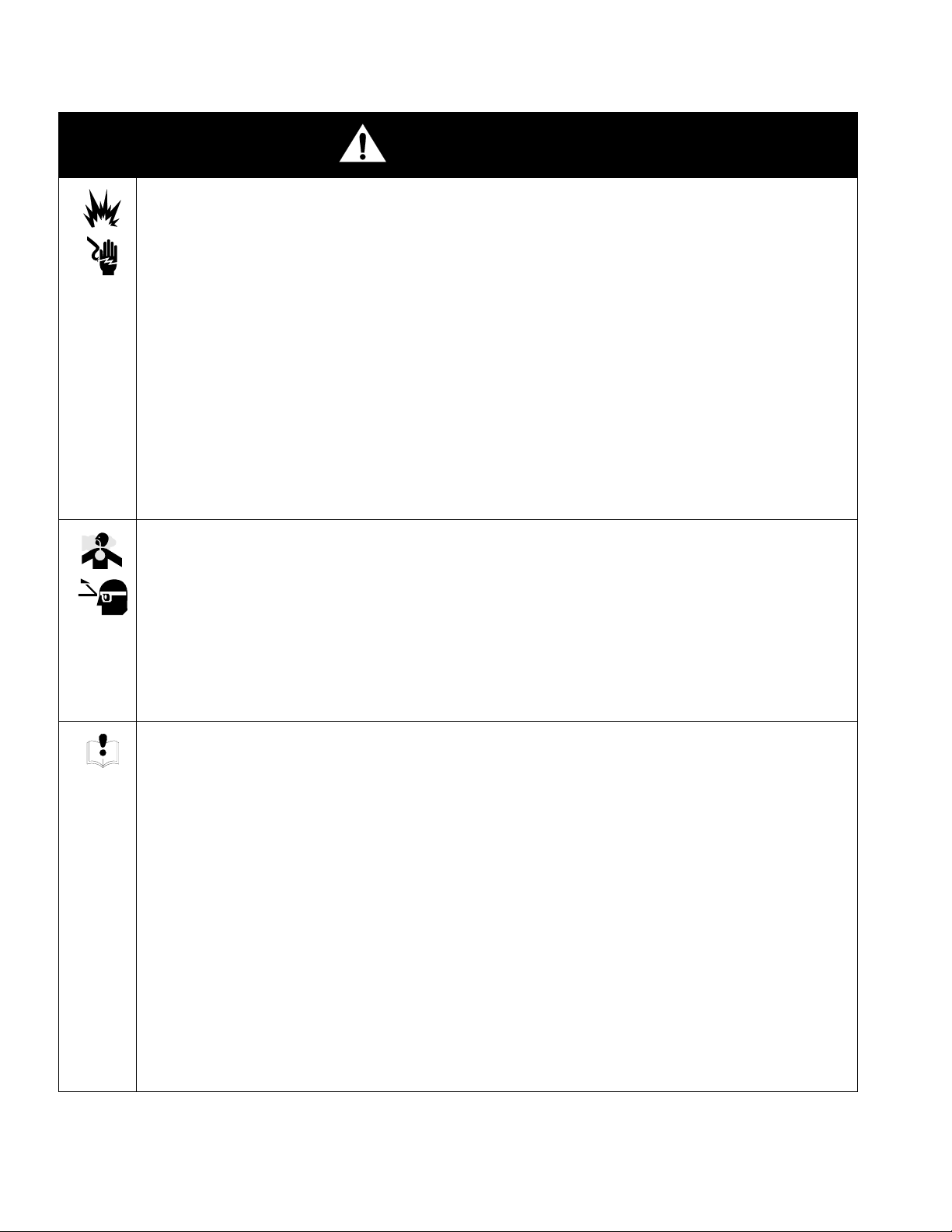

WARNING

WARNING

FIRE, EXPLOSION, AND ELECTRIC SHOCK HAZARD

Improper grounding, poor ventilation, open flames or sparks can cause a hazardous condition and result

in fire, explosion or electric shock.

• Installation and service of electrical components must be completed by a qualified electrician.

• Do not install the ProDispense controller, fluid panels, or remote operator station in a hazardous

location.

• Ground the equipment. See Ground the System, page 20.

• If there is any static sparking while using equipment, stop dispensing immediately. Identify and

correct the problem.

• Provide fresh air ventilation to avoid buildup of flammable fumes.

• Eliminate all ignition sources, such as cigarettes.

• Avoid spilling fluids onto electrical components.

• Turn off the ProDispense controller power switch before servicing equipment.

TOXIC FLUID HAZARD

Hazardous fluid or toxic fumes can cause serious injury or death if splashed in the eyes or on the skin,

inhaled, or swallowed.

• Always wear protective eyewear, gloves, clothing and respirator as recommended by the fluid and

solvent manufacturer.

• Know the specific hazards of the fluid you are using.

• Store hazardous fluid in an approved container. Dispose of hazardous fluid according to all local,

state and national guidelines.

EQUIPMENT MISUSE HAZARD

Equipment misuse can cause the equipment to rupture or malfunction and result in serious injury.

• This equipment is for professional use only.

• Read all instruction manuals, tags, and labels before operating the equipment.

• Use the equipment only for its intended purpose. If you are not sure, call your Graco distributor.

• Do not alter or modify this equipment.

• Check equipment daily. Repair or replace worn or damaged parts immediately.

• Do not exceed the maximum working pressure stated on the equipment or in the Technical Data,

page 71.

• Use fluids and solvents which are compatible with the equipment wetted parts. Refer to the Techni-

cal Data in all equipment manuals and the fluid manufacturer warnings.

• Route hoses away from traffic areas, sharp edges, moving parts, and hot surfaces. Do not expose

Graco hoses to temperatures above 180° F (82° C) or below -40° F (-40° C).

• Comply with all applicable local, state, and national fire, electrical, and safety regulations.

6 309301G

Page 7

WARNING

WARNING

HIGH PRESSURE FLUID HAZARD/SKIN INJECTION HAZARD

Fluid Panels 244599 and 244601 can be operated at very high fluid pressure (see page 4). High pressure spray from dispense valves, hoses, or ruptured components can inject fluid into your body and

cause an extremely serious injury, including the need for amputation. Splashing fluid in the eyes or on

the skin can also cause a serious injury.

The following precautions should be taken for high pressure fluid dispensing:

• Fluid injected into the skin might look like just a cut, but it is a serious injury. Get immediate surgi-

cal treatment.

• Do not place a rag over the end of the nozzle and “blow back” fluid to clear the nozzle.

• Follow the additional precautions under LOW PRESSURE FLUID HAZARD.

LOW PRESSURE FLUID HAZARD

Fluid Panel 244600 is for low pressure use only (see page 4). Fluid coming from the dispense valves,

leaks or ruptured components can splash in the eyes or on the skin and cause serious injury.

The following precautions should be taken for either high or low pressure fluid dispensing:

• Wear protective eyewear.

• Do not put your hand or fingers over the valve nozzle or hose.

• Do not point the dispense valve or hose at anyone or at any part of the body.

• Do not stop or deflect leaks with your hand, body, glove or rag.

• Follow the Pressure Relief Procedure on page 24 before cleaning, checking, or servicing the

equipment or installing or cleaning the dispense valve nozzle.

• Tighten all fluid connections before operating the equipment.

• Check the hoses, tubes, and couplings daily. Replace worn, damaged, or loose parts immediately.

309301G 7

Page 8

Overview

Overview

How the ProDispense System Works

Usage

The ProDispense system enables you to accurately dispense preset amounts of up to three

different fluids or to manually dispense fluid as desired. The fluid meters provide accurate fluid

flow readings to the controller. Controller totalizers use the meter flow readings to calculate

fluid volume and usage and display the information on the screen. The controller can store the

parameters for up to 250 recipe dispenses.

Fluid Supply

The ProDispense system can dispense fluids supplied from pressure tanks or feed pumps.

Each fluid is supplied separately to the ProDispense fluid panels.

Choice of Recipe Dispense or Fluid Dispense

You can choose Fluid Dispense mode to individually enter a fluid preset volume and dispense

the fluid. Or you can choose Recipe Dispense mode to dispense a preset recipe. A recipe

allows you to select or set up to three preset fluid volumes simultaneously.

Regardless of which dispense mode you choose, a dispense tolerance must be entered for

each fluid. The controller monitors the Target and Actual dispense values and reports an error

if the tolerance is not maintained.

8 309301G

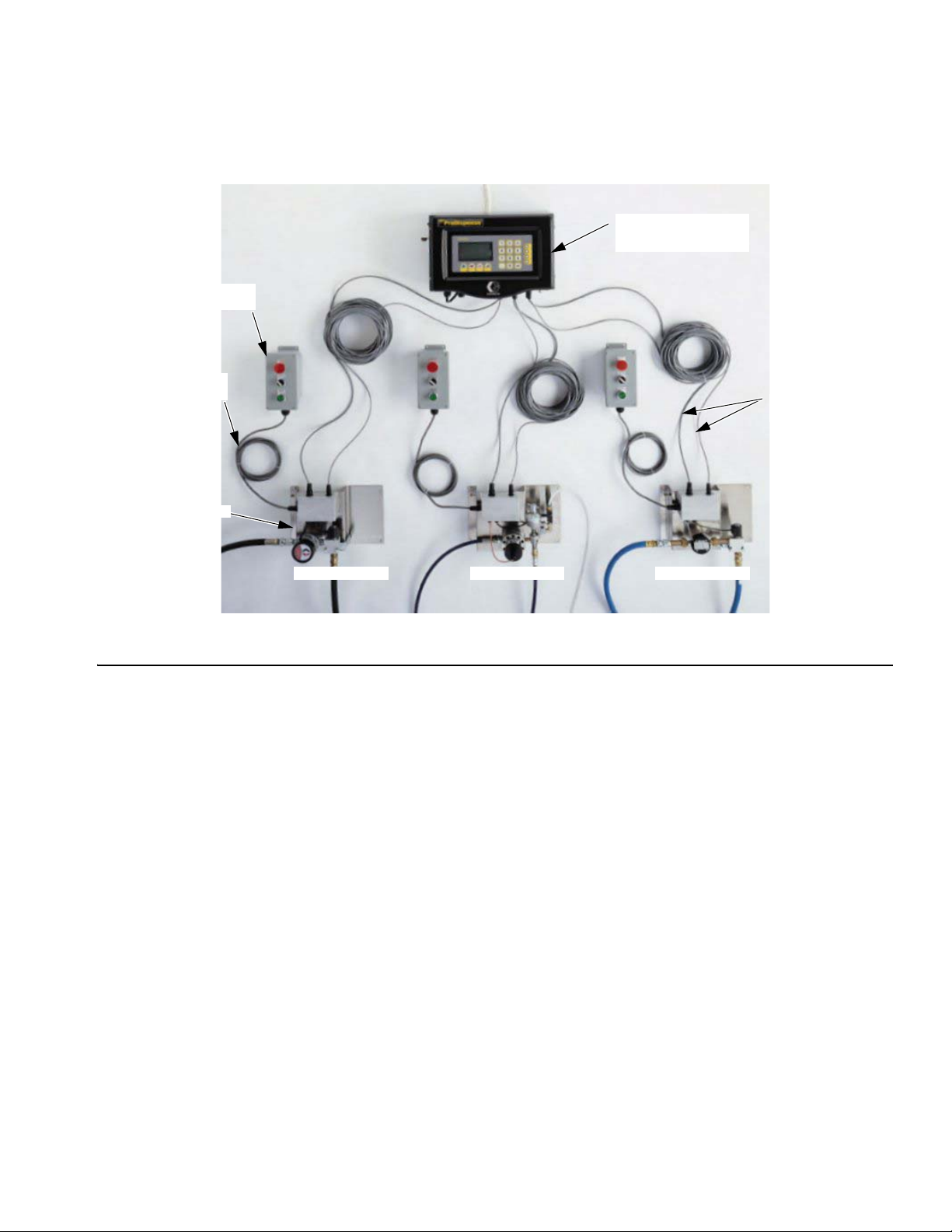

Page 9

Remote

Operator Station

10’ (3.05 m) station

cable standard*

Fluid Panel

Overview

Main Components

ProDispense Controller

with display and

EasyKey™ pad

50’ (15.24 m) meter &

solenoid cables

FIG. 1

Oil/Lubricant Grease/Paint Water/Antifreeze

*20’ (6.1 m) station cable extension 198456 is available.

ProDispense Controller

The controller is used to setup the ProDispense system, fluids, and recipes, calibrate the

meters, and select a recipe or preset a dispense. The controller totalizers enable you to view

fluid dispense information and print the following reports:

• Alarm history report

• Totals report

• Configuration Setup report

• Fluid Setup report

• Recipe Setup report

• Run report

Display and EasyKey™ Pad

The EasyKey™ pad is the operator interface for the ProDispense system. The keypad consists of number keys, enter key, scrolling (arrow) keys, and operation (start, stop, clear, and

print) keys.

The graphic LCD screen displays system status, setup information, and operation options that

can be selected using the keypad.

309301G 9

Page 10

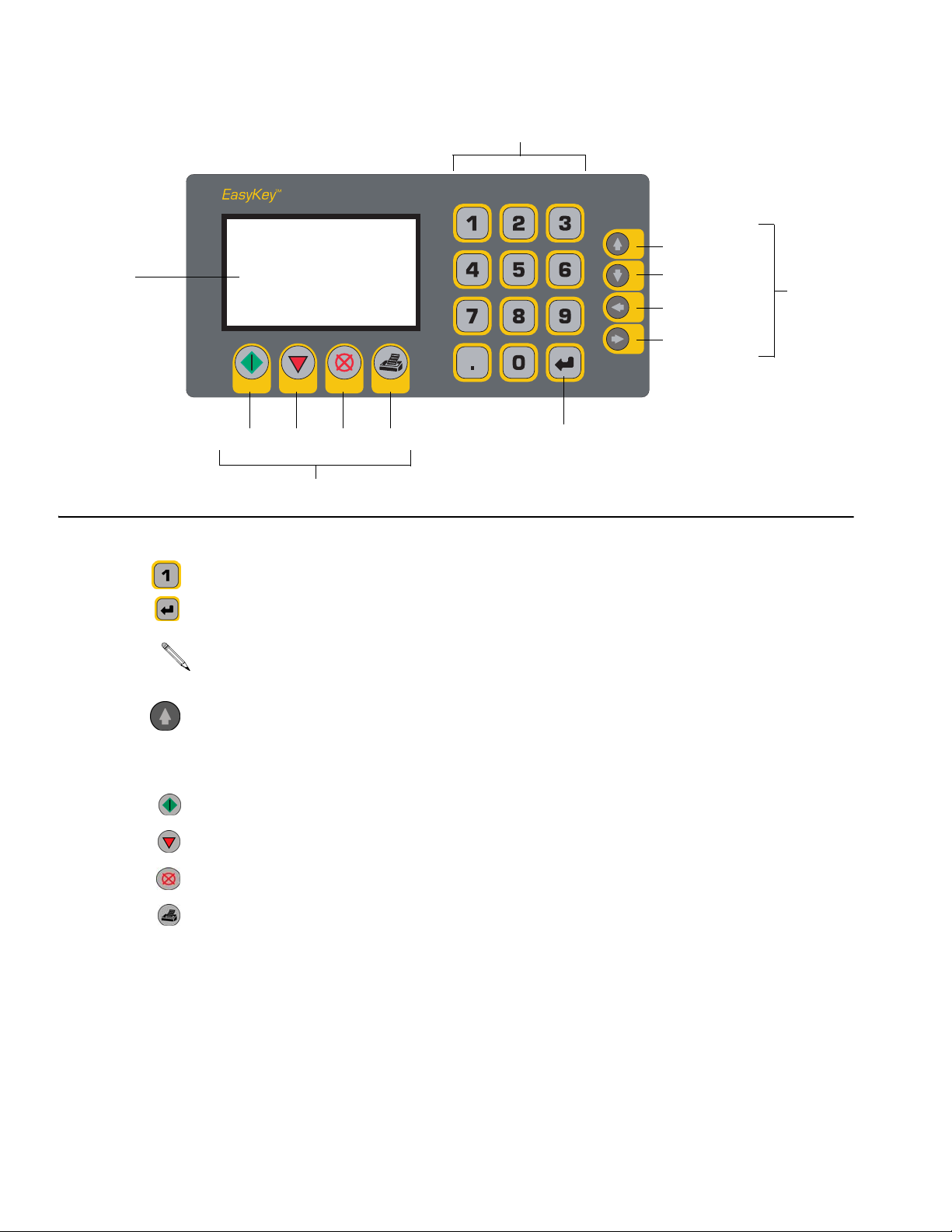

Number Keys

Overview

Previous Field

FIG. 2

Display

Start Stop Clear Print

Operation Keys

Next Field

Previous Screen

Next Screen

Enter

Key

Scrolling

Keys

Number Keys — type in setup or operation data.

Enter Key — press to accept and enter data.

If you press a scrolling key without pressing Enter, the cursor will move to the next field and

the information you typed will reset back to the previous data.

Scrolling Keys — press the up or down arrows to move between fields on the screen. Use the

left or right arrows to move between screens.

Operation Keys — use to operate the ProDispense system functions.

Start — press to start the current recipe dispense.

Stop — press to stop the current process.

Clear — press to clear an entry in an input field.

Print — press to print a report.

10 309301G

Page 11

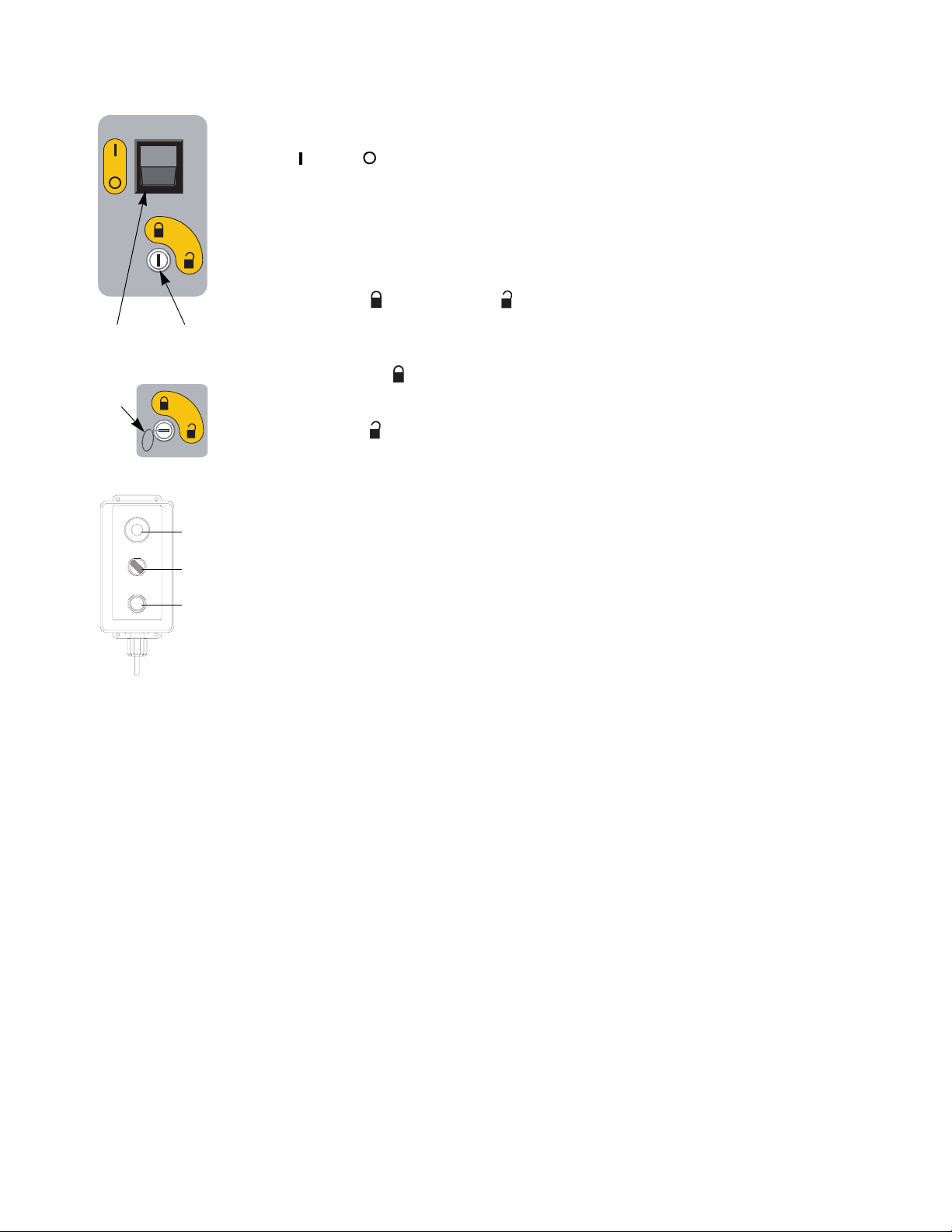

Overview

Power Switch (A)

On = Off = .

(On side of controller)

Operation Mode Switch (B) and Key (C)

The position of the switch (B) determines which mode of operation you are in:

Dispense Mode or Setup Mode . A key (C) supplied with the ProDispense system is

A

B

C

inserted into the switch and turned to change operation modes. The key cannot be removed

while the system is in Setup Mode.

Dispense Mode is used to dispense a recipe, fluid, check fluid totals, and to view the

alarms log.

Setup Mode is used to configure the system, fluid, and recipe parameters, and to cali-

brate the meters.

STOP

DISPENSE

AUTO ON

DISPENSE

START

ti1359a

Stop

button

Dispense

switch

Start

button

Remote Operator Stations

A cable connects the operator station to the fluid panel junction box. A separate operator station is needed for each fluid panel installed on the system. The dispense switch can be set to

dispense automatically (AUTO) or manually (ON).

If set to AUTO, the fluid panel will dispense when a recipe or fluid dispense is selected with

the controller and the start button is pressed either on the controller or the operator station.

The dispense will stop when the preset amount is reached or when the stop button is pressed

on either the controller or the operator station.

If set to ON, the fluid panel will begin dispensing immediately or when the dispense valve is

triggered. The dispense is stopped by releasing the trigger or turning the dispense switch to

AUTO or pressing the STOP button on the operator station.

309301G 11

Page 12

Overview

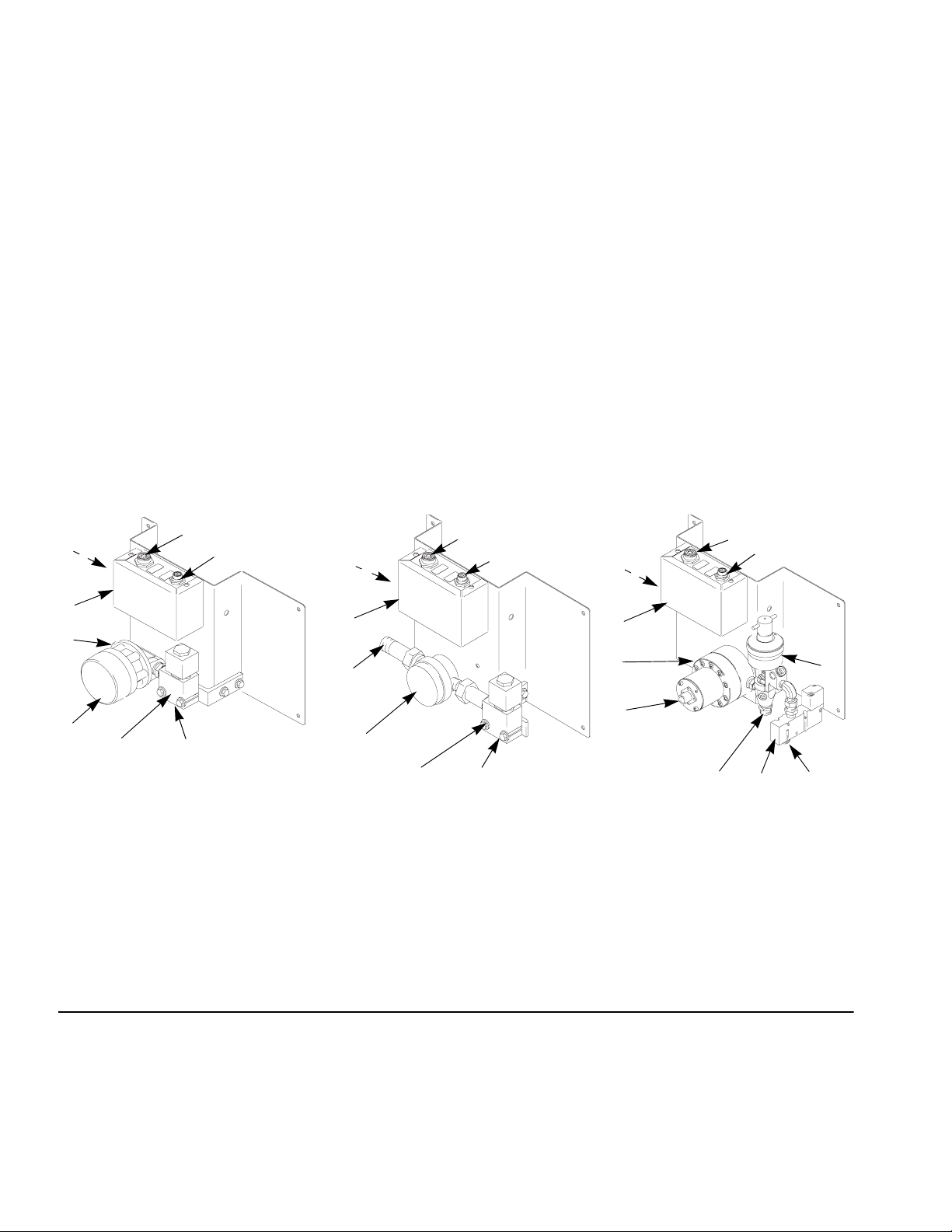

Fluid Panels

There are six types of fluid panels available:

• 244599 — Oil and Lubricant Fluid Panel

• 244600 — Water and Antifreeze Fluid Panel

• 244601 — Grease and Paint Fluid Panel

• 246837 — Grease and Paint Fluid Panel

• 246838 — Meterless Fluid Panel (meter supplied by user)

• 246839 — Grease and Paint Fluid Panel

There are three cable connections on the fluid panel junction box for connecting:

• operator station to the solenoid connection

• controller to solenoid connection

• controller to meter connection

Signals from the controller and operator station communicate to the fluid panel(s) when to

start and stop dispensing. Signals from the fluid panel’s fluid meter communicate to the controller how much fluid has been dispensed.

A

C

244599 244601

A

B

C

244600

B

A

B

C

D

E

D

E

F

G

H

ti1433a

F

G

H

ti1434a

D

E

F

H

G

J

ti1435a

I

Key

A Controller Solenoid Connection

B Controller Meter Connection

C Operator Station Connection

D Junction Box

E Fluid Inlet

F Meter

G Solenoid

H Fluid Outlet

I Air Inlet

J Fluid Valve

FIG. 3

12 309301G

Page 13

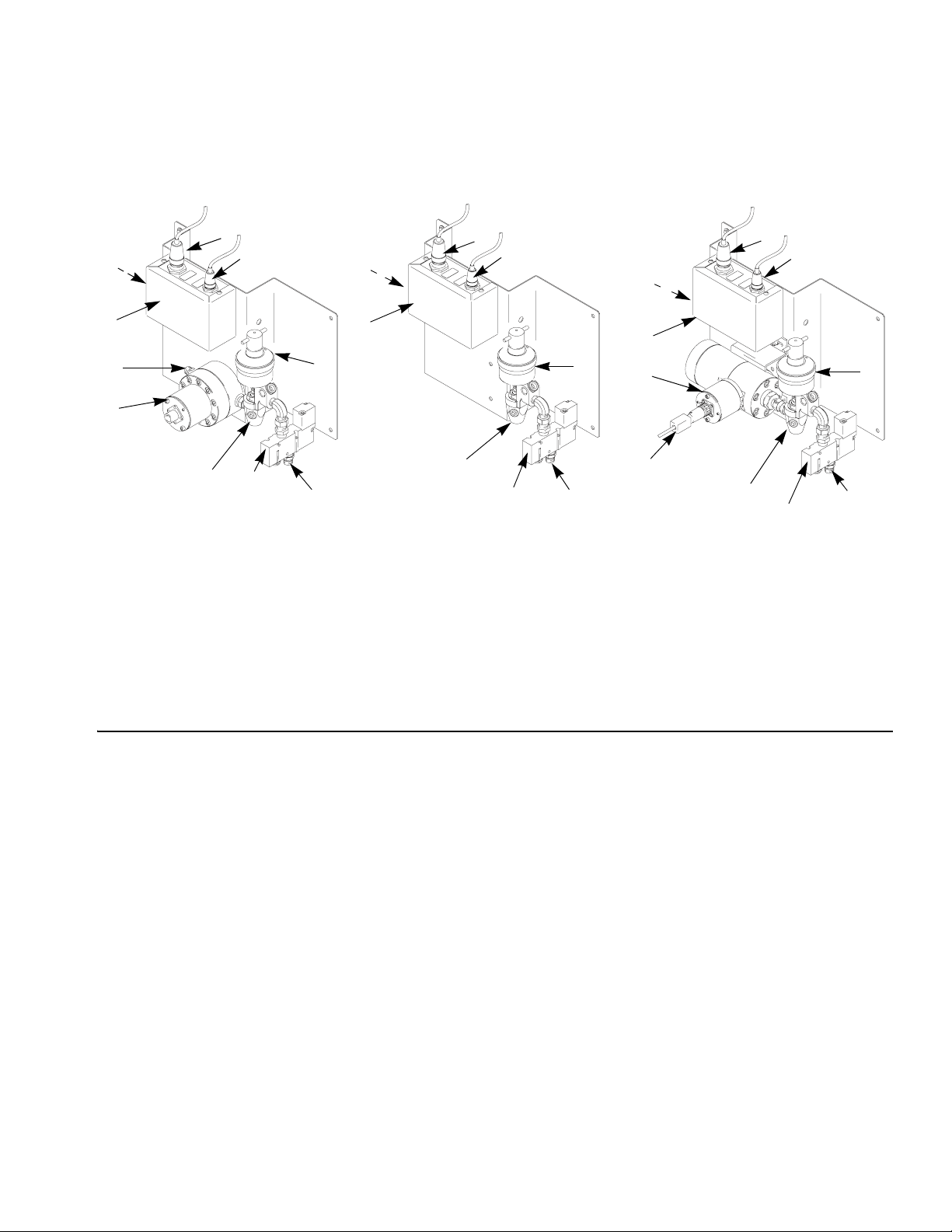

Overview

C

D

E

F

FIG. 4

B

246838

A

B

C

246837 246839

A

B

C

A

D

D

J

H

H

G

I

G

Key

A Controller Solenoid Connection

B Controller Meter Connection

C Operator Station Connection

D Junction Box

E Fluid Inlet

F Meter

G Solenoid

H Fluid Outlet

I Air Inlet

J Fluid Valve

J

E

J

F

I

H

I

G

309301G 13

Page 14

Installation

Do not install or service this equipment unless you are trained and qualified.

Do not install the ProDispense controller, fluid panels, or remote operator station in a

hazardous location.

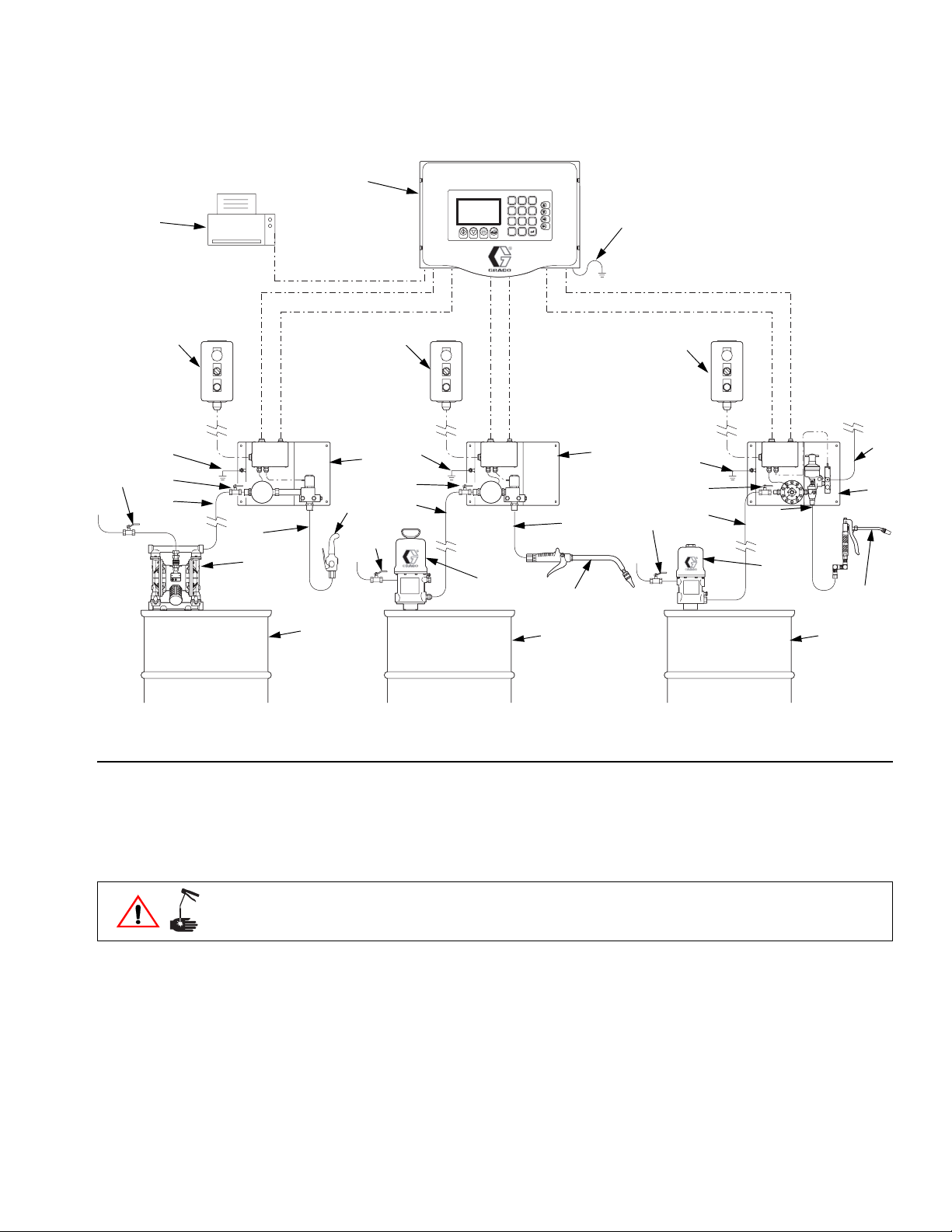

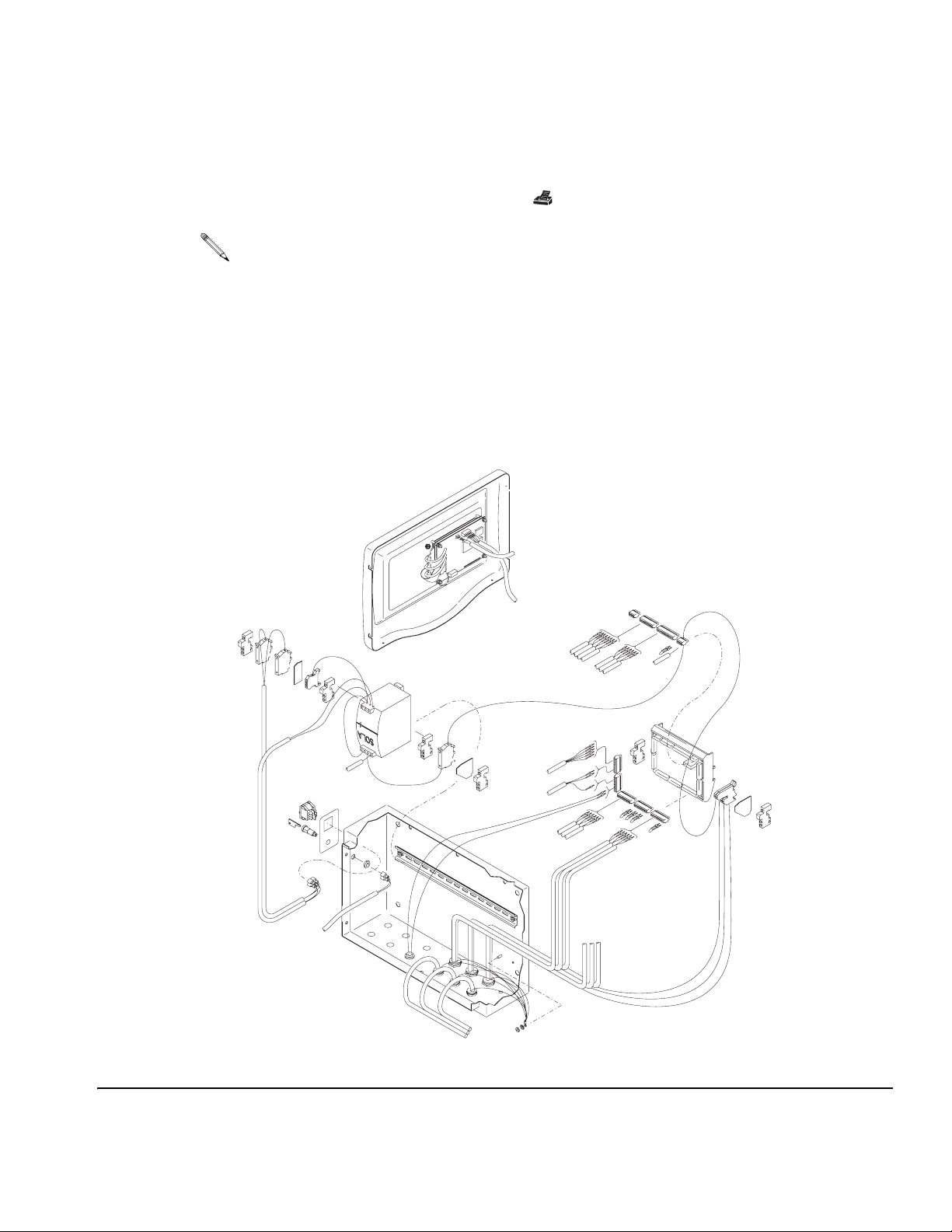

• FIG. 5 is not an actual system design. Contact your Graco distributor for assistance in

• See detailed installation instructions, beginning on page 18.

• Be sure all accessories are adequately sized and pressure rated to meet the system

• Be sure mounted surfaces and fasteners can support the weight of the equipment; hose,

Installation

designing your system.

requirements.

tubing and cable attachments; and fluid.

Key for F

1 ProDispense Controller with EasyKey™ Pad

2 Remote Operator Station

3 Oil/Lubricant Fluid Panel (244599)

4 Water/Antifreeze Fluid Panel (244600)

5 Grease/Paint Fluid Panel (244601)

6 Fluid Supply Pump

7 Fluid Supply

8 Air Supply Line

9 Dispense Valve

10 Ground Wire to true earth ground

11 Fluid Supply Line

12 Fluid Dispense Line

13 Fluid Shutoff Valve

14 Bleed-type Air Shutoff Valve

15 Optional Printer

IG. 5

14 309301G

Page 15

Installation

14

15

10

13

11

1

EasyKey

TM

123

456

789

0

.

2

2

10

4

13

9

12

11

12

14

6

6

9

10

2

3

10

13

14

11

12

8

5

6

9

7

FIG. 5: ProDispense System - Typical Installation

Install the Fluid Supplies

For maintenance and safety, you must install:

• a fluid shutoff valve between each fluid supply line and the ProDispense fluid panel.

• a bleed-type air shutoff valve on the air supply line to the fluid supplies.

The ProDispense fluid panels can be supplied by pressure tanks, pail or drum pumps, or central recirculating lines.

The fluid supply must be free of pressure spikes, commonly caused by a pump stroke

changeover. If necessary, install pressure regulators or a surge tank on the fluid supply outlets. Note that this will also reduce the fluid supply pressure.

7 7

ti1361a

309301G 15

Page 16

Installation

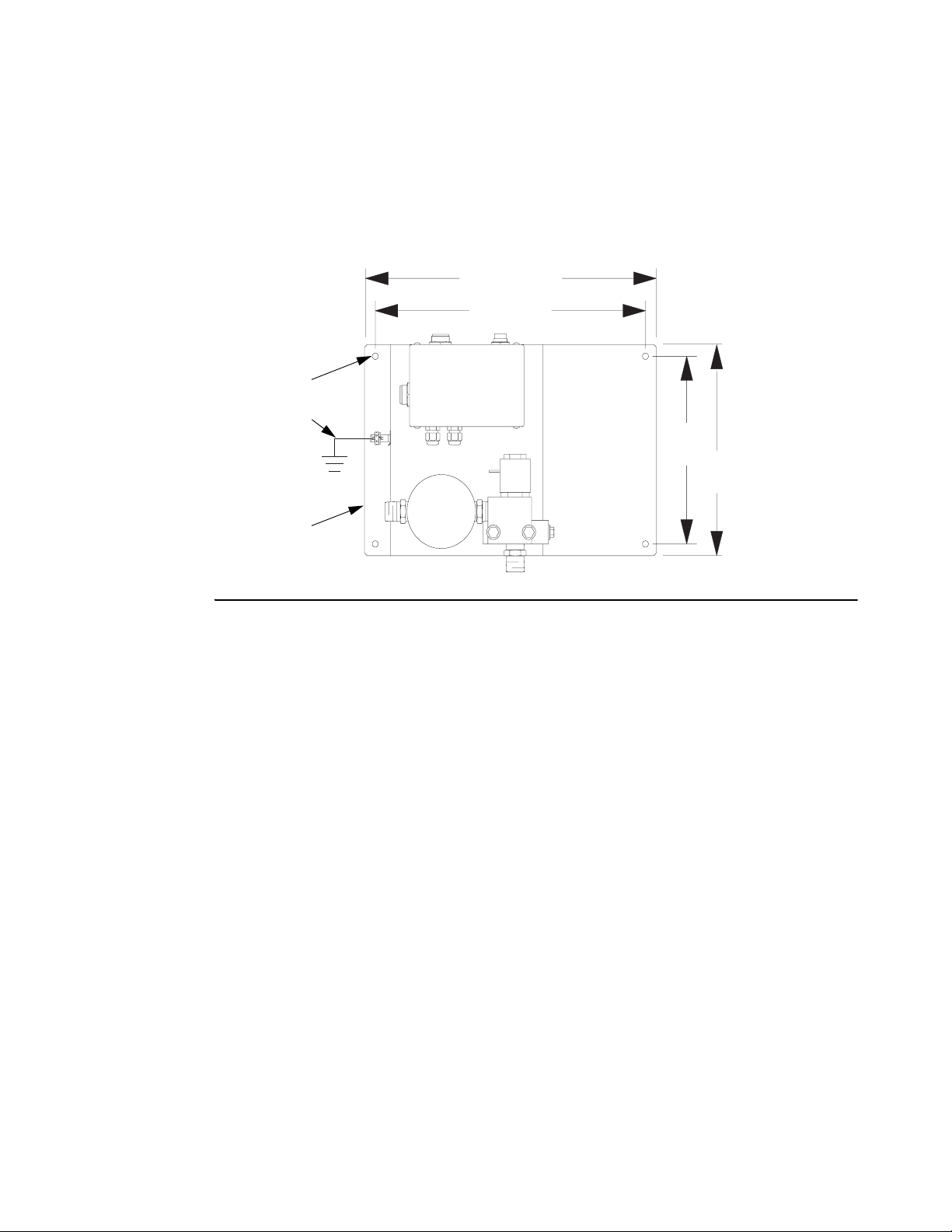

Mount the Fluid Panel(s)

Mount the fluid panel(s) on a flat, sturdy surface. Install 1/4” or M6 fasteners in the four 0.28”

mounting holes (C1) and secure the fluid panel (C) to the mounting surface. Connect a

ground wire (G) as instructed on page 20.

13.4”

(315 mm)

12.4”

(340 mm)

C1

G

8”

(203 mm)

9”

(229 mm)

C

ti1357a

FIG. 6

Connect the Air and Fluid Lines

Fluid Panel 244599 and 244600

Connect the fluid supply line (11) to the 1/2” npt(f) meter inlet. See FIG. 5. Connect a fluid dis-

pense line (12) to the 1/2” npt(f) solenoid outlet. Connect the other end to the dispense valve

(9).

Fluid Panel 244601 and 246837

Connect an air supply line (8) to the 1/4” npt(f) solenoid valve port. The air supply must be filtered to 10 micron to lengthen solenoid valve life.

Connect the fluid supply line (11) to the 1/4” npt(f) meter inlet. Connect a fluid dispense line

(12) to the 3/8” npt(m) outlet of the dispense valve on the fluid panel. Connect the other end to

the dispense valve (9).

16 309301G

Page 17

Installation

Fluid Panel 246838

Connect an air supply line (8) to the 1/4” npt(f) solenoid valve port. The air supply must be filtered to 10 micron to lengthen solenoid valve life.

Connect the fluid supply line (11) to the meter inlet. Connect a fluid dispense line (12) to the

3/8” npt(m) outlet of the dispense valve on the fluid panel. Connect the other end to the dispense valve (9).

Fluid Panel 246839

Connect an air supply line (8) to the 1/4” npt(f) solenoid valve port. The air supply must be filtered to 10 micron to lengthen solenoid valve life.

Connect the fluid supply line (11) to the 3/4” npt(f) meter inlet. Connect a fluid dispense line

(12) to the 3/8” npt(m) outlet of the dispense valve on the fluid panel. Connect the other end to

the dispense valve (9).

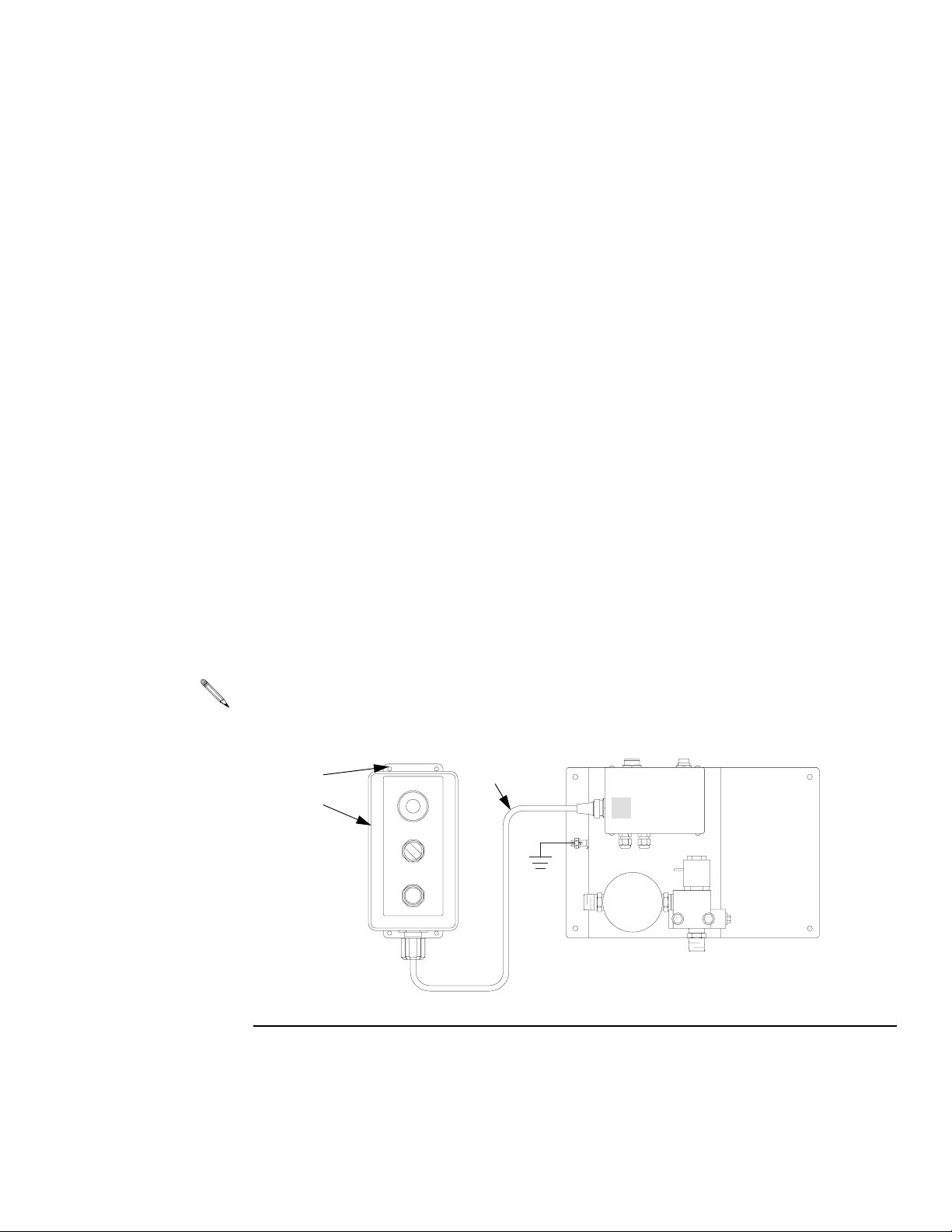

Install the Remote Operator Station

Mount the operator station (D) in a convenient location for the operator. Secure it with No. 10

or M5 fasteners through the four 0.22” mounting holes (D1). Connect the cable (D2) to the

fluid panel junction box connector marked

20 ft. (6.1 m) station cable extension 198456 is available.

D1

D

D2

C.

C

ti1451a

FIG. 7

309301G 17

Page 18

Installation

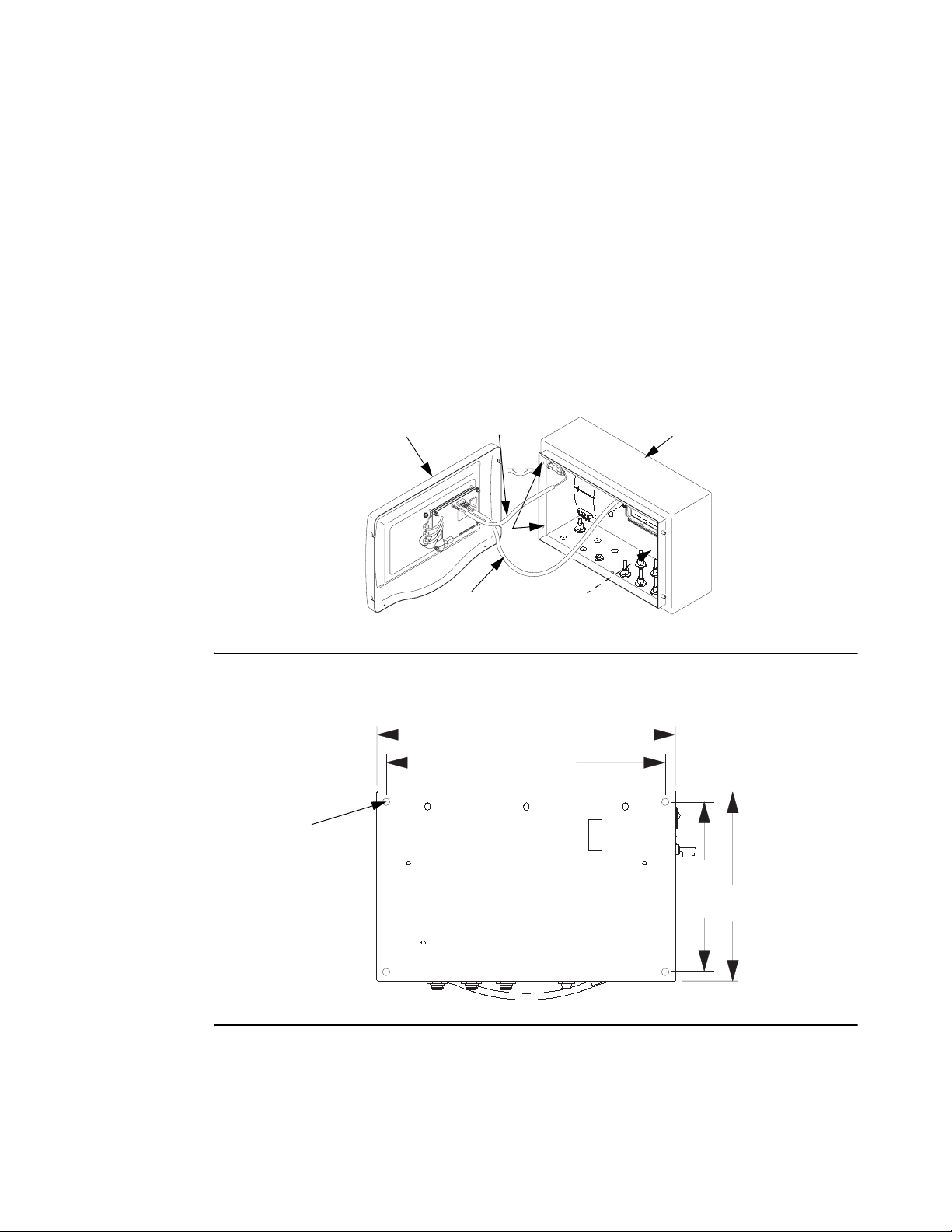

Mount the Controller

Mount the controller on a flat, sturdy surface as instructed below.

1. Loosen the four screws (A1), disconnect the two cables (A2, A3) and remove the controller cover (A).

2. Install 0.44” or M11 fasteners in the four 0.51” mounting knockouts (B1) and secure the

controller (B) to the mounting surface.

3. Reconnect the cables (A2, A3).

4. Install the controller cover (A) and secure it with the screws (A1).

FIG. 8

B1

A2

A3

A1

(441 mm)

(368 mm)

17.38”

14.5”

B1

B

TI1436a

8.5”

(216 mm)

11.3”

(287 mm)

A

TI1453A

FIG. 9

18 309301G

Page 19

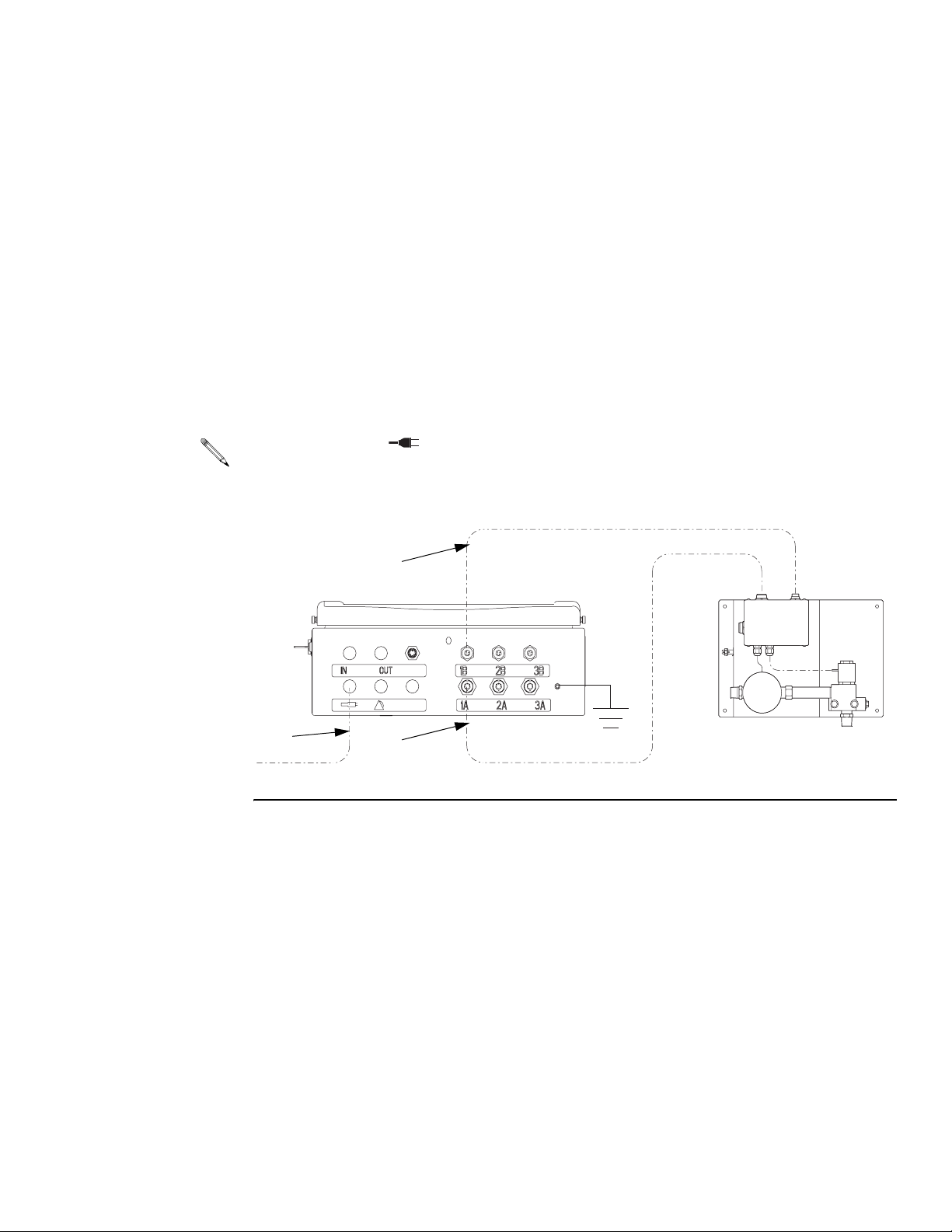

Installation

Connect the Cables and Power Cord

On the bottom of the controller, there are meter and solenoid cable connectors for three Fluid

panels. The row of connectors marked

row of connectors marked

cables as instructed below.

1B, 2B, and 3B are for meter cable connections. Connect the

1A, 2A, and 3A are for solenoid cable connections. The

1. Connect the solenoid cable (E) between controller connector

first fluid panel.

2. Connect the meter cable (F) between controller connector

fluid panel.

3. Repeat the cable connection for each of the fluid panels installed in the system (

1A and connector A on the

1B and connector B on the first

2A to A,

2B to B, etc.).

A knockout, marked , is provided for a customer supplied power input (P) cable with strain

relief or for wire conduit.

F

P

FIG. 10

309301G 19

E

TI1438a

Page 20

Installation

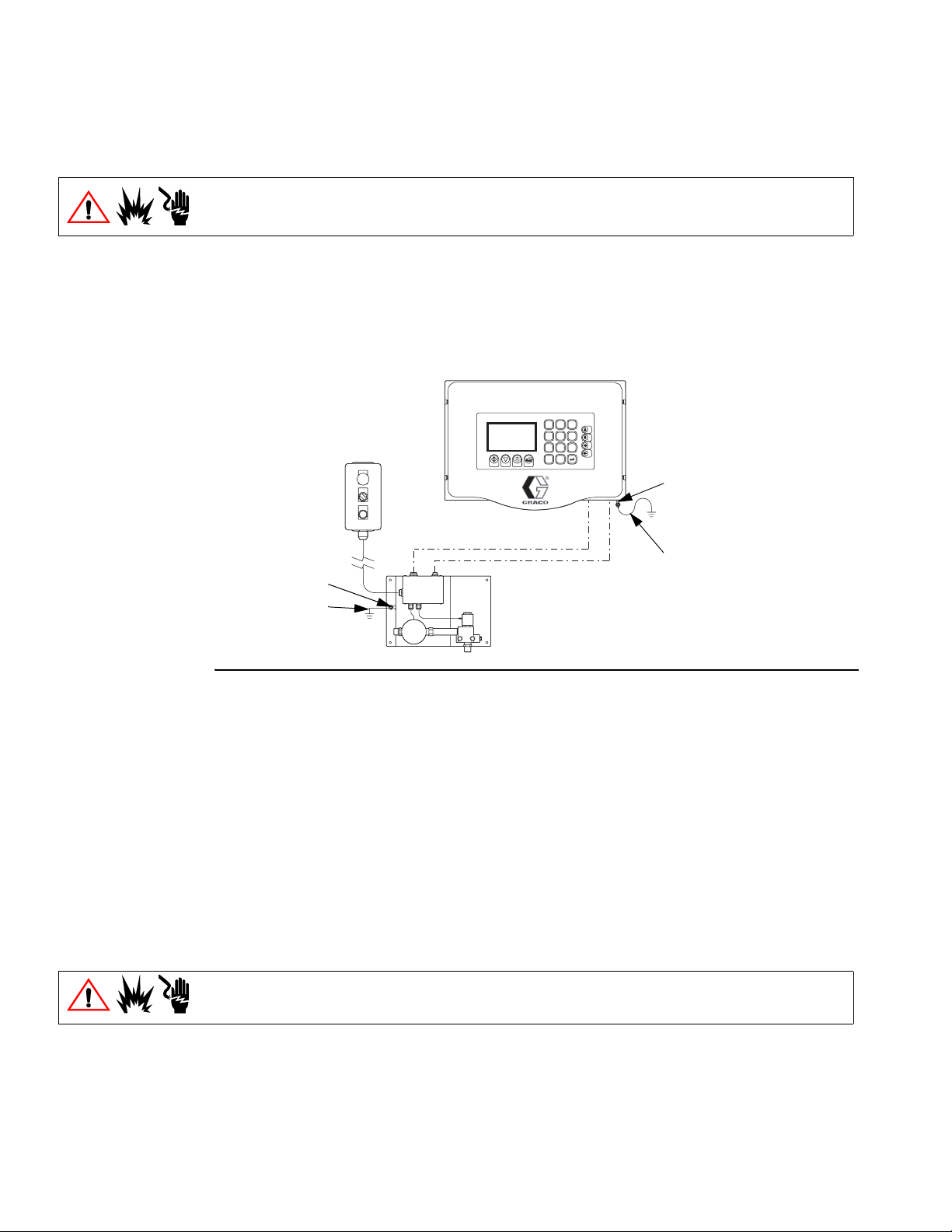

Ground the System

The system must be properly grounded. Follow the instructions here and on page 6.

ProDispense Controller: Connect a ground wire (G1) to the grounding lug (H1) on the bottom

of the controller. Connect the other end of the ground wire to a true earth ground.

Fluid Panels: Connect a ground wire (G) to the grounding lug (H) on the junction box bracket.

Connect the other end of the ground wire to a true earth ground.

EasyKey

TM

123

456

789

0

.

H1

G1

H

G

TI1439a

FIG. 11

Feed Pumps or Pressure Pots: See your separate pump or pressure pot manual.

Air and Fluid Hoses: Use only grounded hose.

Fluid Supply Container: Ground the container according to your local code.

Solvent Pails Used when Purging: Ground pails according to your local code. Use conductive,

metal pails, placed on a grounded surface. Do not place pails on nonconductive surfaces,

such as paper or cardboard.

Check the Resistance

To reduce the risk of fire, explosion, or electric shock, the resistance between the ProBatch

components and true earth ground must be less than 1 ohm.

Have a qualified electrician check the resistance between each ProDispense component and

true earth ground. If the resistance is 1 ohm or greater, a different ground site may be

required. Do not operate the system until the problem has been corrected.

20 309301G

Page 21

Installation

Connect a Printer (optional)

Connect the 5 ft. (1.52 m) printer cable (provided with printer kit 239873) between the printer

and controller printer connector marked . See F

Accessory Printer Cable 198669, 50 ft. (15.24 m) long, is available. Do not use longer cables.

IG. 5, page 15.

Connect to a PC or Alarm (optional)

The ProDispense system can be connected to a PC via Modbus RTU network protocol (6)

and/or audible alarms (7) as shown in F

instructions on page 26 to setup modbus station number and recipe selection. Contact your

Graco distributor for Modbus address mapping list.

IG. 12. Refer to field wiring chart, page 60. Follow

5

4

7

1

3

1

4

6

2

5

3

TI1454A

2

FIG. 12

309301G 21

Page 22

Before Beginning Operation

• Check all fluid and air connections for correctness and tightness.

• Follow the Startup procedure on page 23.

Installation

22 309301G

Page 23

Startup

Startup

Follow this procedure to start the ProDispense system for the first time (initial startup) or after

the system has been shut down.

1. Turn on the power. The ProDispense system startup screen will display while the system

is starting, then the Run screen (page 30) or System Setup screen (page 26) will appear,

depending on the mode of operation the system is in. For an explanation of operation

modes, see page 11.

FloSync

Startup screen

ProDispense: Rev. X.XX

2. If this is the initial startup, change to Setup Mode (page 25) and complete the setup procedures.

3. Change to the Dispense Mode Run screen if you are not there already (page 29).

4. Make sure the dispense lines run into the proper reservoir.

5. Load the fluids (page 34).

Software revision

309301G 23

Page 24

Pressure Relief Procedure

Follow this procedure to relieve pressure in the fluid panel and dispense line before cleaning,

checking, or servicing the equipment or installing or cleaning a dispense valve nozzle.

Follow the additional instructions in brackets if a dispense valve is installed on the

dispense line.

1. Shut off the fluid supply to the ProDispense fluid panel. Follow the Pressure Relief Proce-

STOP

dure for the fluid supply system.

Pressure Relief Procedure

DISPENSE

AUTO ON

DISPENSE

START

Dispense

Switch ON

2. Place the dispense line [or direct the dispense valve] into a waste container.

3. To begin dispensing, turn the Operator Station dispense switch to ON [and trigger the

ti1360a

4. When fluid stops flowing and pressure is relieved, [release the dispense valve trigger and]

STOP

DISPENSE

AUTO ON

DISPENSE

START

Dispense

Switch AUTO

ti1359a

5. Repeat the process for each fluid panel as needed.

Shutdown

Follow this procedure before servicing the equipment and to avoid having fluid dry in the

equipment and fluid lines when the equipment is not being operated.

dispense valve].

turn the dispense switch to AUTO to stop dispensing.

1. Purge the system until it is clean (page 35).

2. Relieve the pressure as instructed above.

3. Turn off the ProDispense controller power switch.

24 309301G

Page 25

Setup Mode

Screen Navigation

To enter Setup Mode:

Setup

Mode

You must have the key supplied with the system. Insert the key into the switch and turn it to

Setup Mode . The System Setup screen appears.

Do not turn the key to Setup Mode while the ProDispense is dispensing or the system will

abort the dispense.

Setup Mode

SYSTEM SETUP

Day/Month/Year: Dispense Mode:

1=Fluid Station

Hour:Minute 2=Recipe

Language:

1=English 2=Spanish 2=Network

3=German 4=French

5=Japanese Station Number:

System Fluids Recipes Meters

current screen

The name of the screen that is currently displayed is highlighted.

Press the left or right arrow keys on the keypad to move through the screens.

Press the up or down arrow keys to move through data fields on the screen.

Recipe Selection:

1=User Interface

System Setup Screen

4 screen selections

To exit Setup Mode:

Turn the key to Dispense Mode. The Run screen appears. Refer to page 30.

309301G 25

Page 26

Setup Mode

System

Day/Month/Year: Dispense Mode:

Hour:Minute 2=Recipe

Language:

1=English 2=Spanish 2=Network

3=German 4=French

5=Japanese Station Number:

System Fluids Recipes Meters

System Setup Screen

Use system setup to enter the date, time, language to display, dispense mode, means of recipe selection and station number.

SYSTEM SETUP

1=Fluid Station

Recipe Selection:

1=User Interface

To setup the system:

1. Type the current date: day (1-31) ,

month (1-12) , year (2000-2099) .

2. Type the current time: hour (0-23) ,

minute (0-59) .

The ProDispense clock is a 24 hour clock. The date

and time are used for date/time stamps on alarms

and reports.

3. Type the desired language number (1-5).

Power must be cycled before the language change

will take affect.

4. Type the number for the desired dispense mode

(1-2).

Fluid Station: use this mode to select individual

fluid stations when dispensing.

Recipe: use this mode to select a recipe when dispensing. Dispensing by recipe will signal all fluid stations included in the recipe to dispense

simultaneously.

5. Type the number for the desired recipe selection

(1-2).

User Interface: use to select recipes from the

EasyKey pad.

Network: use to select recipes from a networked

source.

6. Type the station number (1-99).

This number is used for network communications to

identify the station. Each station must have a

unique number.

7. Press the right arrow key to go to the Fluid Setup

screen.

26 309301G

Page 27

Setup Mode

Fluids

Units of Measure

1=cc 2=oz 3=Qt

4=Ltr 5=Gal

Tolerance %

Timeout Value (min)

K-factor (cc/pulse)

System Fluids Recipes Meters

Fluid Setup Screen

Use fluid setup to designate the parameters for each fluid you will dispense.

Fluid parameters must be set before the fluid can be used in a recipe.

FLUID SETUP

Fluid 1 Fluid 2 Fluid 3

To set up the fluids:

You can have 1-3 fluid panels connected to the ProDispense controller. Setup the fluids for each of your fluid

panels as follows:

1. Type the number for the desired units of measure

(1-5).

2. Type the dispense tolerance percentage (1-99).

3. Type the timeout value in minutes (1-99).

If a dispense does not complete by the end of the

entered value, a Dispense Timeout alarm occurs.

See page 33.

4. Type the fluid meter’s K-factor (cc/pulse).

Fluid Panel

part no.

244599 oil/lubricant 4.73

244600 water/antifreeze 25

244601 grease/coating 0.119

246837 grease/coating .061

246838 grease/coating n/a

246839 grease/coating 0.286

The K-factors in the table are a starting point. You

can calibrate the meter as instructed on page 28.

5. Repeat steps 1-4 for each additional fluid panel.

6. Press the right arrow key to go to the Recipe

Setup screen.

Meter Type K-factor

(cc/pulse)

309301G 27

Page 28

Setup Mode

Recipes

Target Amount

Type in 0 for Target Amount if Fluid

System Fluids Recipes Meters

Meters

Recipe Setup Screen

Use recipe setup to configure your recipes by assigning a recipe number and designating Target Amounts for each fluid in the recipe.

RECIPE SETUP

Fluid 1 Fluid 2 Fluid 3

ltr ltr ltr

is not used in this Recipe.

*

Calibrate Meter Screen

Use this screen to calibrate your fluid panel meters. All values are in cubic centimeters (cc).

Follow the additional instructions in brackets if a dispense valve is installed on the

dispense line.

To setup the recipes:

1. Type a recipe number (1-250).

2. Type the Target Amount for each fluid used in the

recipe (0-999.99).

Type in 0 if a fluid is not used in the recipe. The

units of measure are set in Fluid Setup (page 27).

3. Press the right arrow key to go to the Calibrate

Meter screen.

CALIBRATE METER

K-factor

(cc/pulse)

Fluid 1 04.730 0

Fluid 2 00.119 0

Fluid 3 25.000 0

1) Manually dispense fluid into a calibrated container

(minimum of 300 cc).

2) Type in Actual Value and Press ENTER.

System Fluids Recipes Meters

Dispensed

(cc)

Actual

(cc)

To calibrate a meter:

1. Dispense fluid into a calibrated container (minimum

300 cc) by turning the Operator Station dispense

switch to ON [and triggering the dispense valve].

2. Stop dispensing by [releasing the dispense valve

trigger and] turning the dispense switch to AUTO.

3. The amount the controller detected was dispensed

appears on the screen in the Dispensed column. If

the value in the column differs from the measured

amount in the container, enter the measured value

(in cc) in the Actual column.

If nothing is entered in the Actual column, the K-factor remains unchanged.

4. The controller will calculate the meter K-factor and

display the new value in the K-factor column.

5. Repeat the process for each of your fluid panels.

28 309301G

Page 29

Dispense Mode

Screen Navigation

Dispense Mode is used to dispense a fluid or recipe, check fluid dispense totals, and view

Dispense

Mode

the alarms log.

Target 005.00 ltr 050.00 ltr 010.10 ltr

Actual 5.00 ltr 51.00 ltr 10.00 ltr

Tolerance % 555

Difference % 0+2-1

RECIPE DISPENSE ID#

Fluid 1 Fluid 2 Fluid 3

Idle Idle Idle

Dispense Mode

Recipe Dispense screen

AUTO

Run Totals Alarms

current screen

The name of the screen that is currently displayed is highlighted.

The Operator Station dispense switch must be set to AUTO to dispense using the controller.

Press the left or right arrow keys on the keypad to move through the screens.

Press the up or down arrow keys to move through data fields on the Run screen.

3 screen selections

309301G 29

Page 30

Dispense Mode

Run

Run Screen

Use the Run screen to dispense a recipe or individual fluids. The Run screen displays either

Recipe Dispense or Fluid Dispense, depending on which Dispense Mode was selected in

System setup.

Idle, Dispense, and Alarm Status

In each of the fluid columns, under the Fluid panel number, is a status line, which shows the

status of the associated fluid panel. The three possible statuses are:

Idle — fluid panel is idle (not dispensing).

Dispense — fluid panel is dispensing.

Alarm — controller has detected the fluid panel has an alarm condition. To view alarm

information, press the right arrow key twice to move to Alarm screen. Refer to page 33.

Status line

RECIPE DISPENSE

Fluid 1 Fluid 2 Fluid 3

Idle Idle Idle

Target 005.00 ltr 050.00 ltr 010.10 ltr

Actual 5.00 ltr 51.00 ltr 10.00 ltr

Tolerance % 555

Difference % 0+2-1

ID#

Recipe Dispense

Recipe Dispense displays in the Run screen if “Recipe”

is selected as the Dispense Mode. Recipe Dispense is

used to dispense a set amount of fluid, typically from

more than one fluid panel simultaneously.

1. Place the dispense lines into the receptacle(s) you

2. Set the Operator Station dispense switch to AUTO.

want to dispense into.

Run Totals Alarms

Start

STOP

DISPENSE

AUTO ON

DISPENSE

START

ti1359a

Dispense

Switch AUTO

START

3. Type the desired recipe number (1-250).

The Target value is set in Recipe Setup. You cannot

change it in the Run screen.

4. Type a 4 digit ID# if desired.

5. Press the Start button on the Controller or on the

Remote Operator Station to begin dispensing the

recipe.

6. As the fluids dispense, their statuses on the screen

change from Idle to Dispense and the amounts dispensed appear in the Actual row.

7. Each fluid panel stops dispensing when its individual

Target is reached.

30 309301G

Page 31

Dispense Mode

Target

Status line

FLUID DISPENSE ID#

Fluid 1 Fluid 2 Fluid 3

Idle Idle Idle

005.00 ltr 050.00 ltr 010.10 ltr

Fluid Dispense

Fluid Dispense displays in the Run screen if “Fluid Station” is selected as the Dispense Mode. Fluid Dispense

allows you to select a fluid panel and the amount to dispense on an individual basis.

Actual 5.00 ltr 51.00 ltr 10.00 ltr

1. Place the fluid panel dispense line into the recepta-

Tolerance % 555

Difference % 0+2-1

Run Totals Alarms

2. Type a 4 digit ID# if desired.

3. In the column for the fluid you want to dispense, type

4. Press the Start button on the Remote Operator Sta-

5. As the fluid dispenses, the status on the screen

STOP

DISPENSE

AUTO ON

DISPENSE

START

ti1359a

Dispense

Switch AUTO

START

6. The fluid panel stops dispensing when its Target is

cle.

the desired amount of fluid in the Target field.

tion to begin dispensing the fluid.

changes from Idle to Dispense and the amount dispensed appears in the Actual row.

reached.

309301G 31

Page 32

Dispense Mode

Totals

Fluid Totals Screen

Press the left or right arrow key to select Totals. The Fluid Totals screen shows how

much of each of the fluids has been dispensed overall. Two totals are shown. Grand totals are

tracked from the time the system is first started up and they are not resettable. Resettable

totals show the total amount of each fluid dispensed since the last reset.

FLUID TOTALS

Fluid# Resettable Grand

1 00005.1 ltr 00312.1 ltr

2 00005.2 ltr 00582.8 ltr

3 00004.8 ltr 00468.2 ltr

Press ENTER and CLEAR to reset totals

Run

To tal s A l ar m s

Clear Print

Last Reset

Date:23/04/01

Time: 07:35

Press Print key to print Fluid Totals Report.

Press Clear and Enter keys simultaneously to reset all

resettable totals.

All resettable totals are reset when Clear and

!

Enter are pressed. Fluid totals cannot be reset

+

individually.

32 309301G

Page 33

Dispense Mode

Alarms

Date Time Description Recipe Fluid

03/09 9:39 Invalid K-factor 10 1

03/08 14:32 Out of Tolerance 0 1

03/05 15:01 Timeout 6 2

03/05 8:12 Out of Tolerance 62

03/02 10:59 Invalid K-factor 0 3

Run Totals

Alarm History Screen

Press the left or right arrow key to select Alarms. This screen summarizes the last five

alarms that have occurred.

ALARMS

Alarms

Print

Press Print key to print an Alarms Report.

Out of Tolerance Alarm

This alarm occurs when the current actual dispense is either less than target – tolerance or

greater than target + tolerance.

Dispense Timeout Alarm

The controller stops an active dispense and initiates this alarm when the current dispense is

not finished by the end of the Timeout. Timeout is a value entered during Fluid Setup (page

27).

Invalid K-factor Alarm

This alarm occurs if the meter K-factor is set to zero (00.000).

Memory Failure Alarm

This alarm occurs when the memory has been replaced but not programmed or when the

memory has become corrupt.

See page 36 for alarm troubleshooting information.

309301G 33

Page 34

Operation Procedures

Wear eye protection whenever you are dispensing fluid.

Follow the additional instructions in brackets if a dispense valve is installed on the

dispense line.

Loading Fluid Lines

Follow this procedure to load the fluid lines and purge out any air:

1. Place the dispense line [or direct the dispense valve] into a waste container.

1. To begin loading fluid, turn the Operator Station dispense switch to ON [and trigger the

dispense valve].

Operation Procedures

DISPENSE

AUTO ON

DISPENSE

START

2. Continue dispensing until all air is purged from the fluid line and fluid flows steadily from

the valve.

3. Turn the dispense switch to AUTO to stop dispensing.

Manual Dispense

1. Place the dispense line [or direct the dispense valve] into the reservoir.

STOP

ti1360a

STOP

Dispense

Switch ON

START

2. To begin dispensing, turn the Operator Station dispense switch to ON [and trigger the dispense valve].

3. Turn the dispense switch to AUTO [or release the dispense valve trigger] to stop dispensing.

Automatic Dispense

Refer to page 30 for instructions on dispensing a recipe or page 31 to dispense individual

fluids.

34 309301G

Page 35

Operation Procedures

Purging Fluid

Follow this procedure to purge the fluid lines:

1. Connect the fluid supply line to a solvent supply. Set the fluid supply pressure as low as

possible to avoid splashing.

2. To begin purging the lines, direct the fluid outlet into a grounded metal pail, turn the Operator Station dispense switch to ON [and trigger the dispense valve].

3. Continue dispensing until fluid lines are clean.

4. Turn the dispense switch to AUTO or [release the dispense valve trigger] to stop dispensing.

5. If you are loading a new material, connect the fluid supply line to the new fluid supply, and

follow the procedure for Loading Fluid Lines.

Emergency Stop

RECIPE DISPENSE

ID#

To stop fluid flow at all the fluid panels connected to the

controller, press the Stop button on the controller.

Fluid 1 Fluid 2 Fluid 3

Idle Idle Idle

Target 005.00 ltr 050.00 ltr 010.10 ltr

Actual 000.00 ltr 000.00 ltr 000.00 ltr

Tolerance % 555

Difference % -98 -99 -97

Run Totals Alarms

Stop

To stop fluid flow at an individual fluid panel, press the

STOP

DISPENSE

AUTO ON

DISPENSE

START

STOP

ti1359a

STOP button on the Operator Station connected to the

fluid panel.

309301G 35

Page 36

Troubleshooting

Problem Cause Solution

Troubleshooting

Out of Tolerance Alarm Dispense is under or over tolerance

limit set for the fluid.

Dispense Timeout Alarm The dispense did not complete within

set Dispense Timeout value.

Run screen shows tolerance difference for last

dispense. Use the value to determine whether

you should:

• Increase the tolerance value

• Model 244601 only — increase fluid flow

by further opening the dispense valve

(turn the t-handle clockwise).

• Increase or decrease fluid flow rate of the

fluid supply.

Check the following:

• Fluid supply container is not empty.

• Fluid supply equipment is not faulty.

• Fluid flow rate is sufficient.

• Timeout value is too low and needs

increase.

• Fluid line is not clogged.

• Solenoids are operating.

• Model 244601 only — solenoid is receiv-

ing air and dispense valve is open.

• Cables are properly connected.

• Meters are operating and communicating

with controller.

• Dispense valves are operating.

Service equipment as needed.

Invalid K-factor Alarm Meter K-factor is set to zero (00.000). Set valid meter K-factor (page 27).

Memory Failure Alarm The system is not configured. Enter setup values (page 25).

The memory is corrupt. Replace flash EPROM.

No display No power Turn on or reconnect power.

Faulty cable(s) Replace cable(s).

Blown fuse(s) Replace fuse(s).

36 309301G

Page 37

Service

Service

Removing and Installing Controller

Wear a grounding strap when replacing any of the controller boards to avoid shorting them

out.

Check with your Graco distributor periodically to see if circuit board or software updates are

available.

To remove controller:

1. Turn off controller power switch.

2. Disconnect meter (F), solenoid (E), and power (P) cables and ground wire (G) from the

bottom of the controller (B). See F

IG. 13.

.

F

F

G

B

P

P

FIG. 13

3. Loosen the four screws (A1) and carefully remove the controller cover (A). See FIG. 14.

4. Disconnect cable connectors (A2, A3) from the display board.

5. Remove the four bolts (B1) and remove the control box. (B).

E

TI1438a

309301G 37

Page 38

To install controller:

6. Secure controller (B) to the mounting surface with four bolts (B1).

Service

7. Plug two connectors (A2, A3) into the display board. See F

IG. 14.

8. Install controller cover (A) and secure it with four screws (A1).

9. Reconnect ground wire (G) and power (P), meter (F), and solenoid (E) cables to the controller. See F

IG. 13.

A3

B

A

A1

A2

B1

TI1436a

FIG. 14

38 309301G

Page 39

Service

Replacing Display Board

1. Turn off controller power switch.

2. Remove controller cover (A). See page 37, steps 1-4.

3. Unplug keypad (D) ribbon cable from the display board. Note position of cable in connector. Arrow indicates pin #1, reconnect with pin #1 engaged.

4. Remove four nuts (C1) from the board. See F

IG. 15.

5. Disconnect ground wire.

6. Unplug three fiber optic connectors (C3) from the diodes, then remove display board (F).

7. Install parts in reverse order of disassembly.

• If replacing software chip, use a chip puller to remove it.

• Spacers (G) must be used in correct positions to protect the display and board.

C

F

C1

G

D

C3

A

TI1056A

FIG. 15

309301G 39

Page 40

Replacing Display

1. Follow steps 1 through 6 in the procedure for replacing the display board.

Service

2. Remove the display (C). See F

3. Install the parts in reverse order of disassembly.

• Make sure the keypad ribbon cable does not interfere with the display.

• Spacers (G) must be used in correct positions to protect the display and board.

IG. 15.

Replacing Membrane

1. Follow steps 1-6 in the procedure for replacing the display board, page 39.

2. Remove display (C). See F

3. Peel the membrane (D) off the controller cover.

4. Remove adhesive liner from the new membrane. Align the membrane with recessed area

on the panel (A), and press it into place.

5. Install parts in reverse order of disassembly.

Spacers (G) must be used in correct positions to protect the display and board.

IG. 15.

40 309301G

Page 41

Replacing Main Board

1. Turn off controller power switch.

2. Remove controller cover. See page 37, steps 1-4.

Service

3. Unplug all wire connectors (G) from the main board (H). See F

4. Squeeze release clips and pull the main board (H) away from the din rail (J).

5. Install parts in reverse order of disassembly.

If replacing software chip, use a chip puller to remove it.

IG. 16.

5

G

4

1

3

H

1

5

4

J

2

3

TI1441A

2

FIG. 16

309301G 41

Page 42

Replacing Power Supply

1. Turn off controller power switch.

2. Remove controller cover. See page 37, steps 1-4.

3. Unplug all wire connectors from the power supply.

Service

4. Pull the tab up with a screw driver and remove the power supply from the din rail. See F

17.

5. Install parts in reverse order of disassembly.

TI1455a

FIG. 17

IG.

42 309301G

Page 43

Replacing Fluid Panel Junction Box

1. Turn off controller power switch.

2. Disconnect three cables (C) from the junction box (J). See FIG. 18.

3. Remove four screws (K) and remove junction box cover (L).

4. Disconnect meter and solenoid wires (M) from the terminal block.

5. Loosen two strain relief connectors (N) to pull out the wires.

C

Service

FIG. 18

J

N

K

M

M

L

L

ti1403a

309301G 43

Page 44

FIG. 19

Service

P

M

J

ti1404a

6. Remove the two screws (P) and remove the junction box (J). See F

7. Secure the new junction box with the two screws (P).

IG. 19.

44 309301G

Page 45

Service

8. Connect meter and solenoid wires (M) to the terminal block. Connect as shown for the

specific fluid panel in F

IG. 20.

FIG. 20

9. Tighten two strain relief connectors (N). See F

IG. 18.

10. Secure the cover (L) with four screws (K).

11. Reconnect three cables (C).

309301G 45

Page 46

Service

Servicing Fluid Panel 244599

Replacing Fluid Meter or Solenoid

1. If necessary, purge ProDispense system (page 35).

2. Relieve pressure (page 24) and turn off controller power switch.

3. Follow steps 3–5 on page 43 to disconnect meter and solenoid cables from the terminal

block.

4. Disconnect fluid lines from the meter and solenoid.

5. Remove two bolts (6) and washers (7) from the solenoid (3), and remove solenoid and

meter assembly. See F

6. Place flats of the solenoid (3) in a vice and unscrew the meter (4).

IG. 21.

7. Install new meter or solenoid.

8. Secure the assembly to the fluid panel with solenoid washers (7) and bolts (6).

9. Follow steps 8–10 on page 45 to connect meter and solenoid cables to the terminal block.

10. Connect fluid lines to the meter and solenoid.

11. Load fluid at low pressure and check for leaks. Tighten fittings as needed.

46 309301G

Page 47

ti1413a

Service

4

FIG. 21

5

7

6

3

309301G 47

Page 48

Service

Servicing Fluid Panel 244600

Replacing Fluid Meter or Solenoid

1. If necessary, purge ProDispense system (page 35).

2. Relieve pressure (page 24) and turn off controller power switch.

3. Follow steps 3–5 on page 43 to disconnect meter cable from the terminal block. If replacing the solenoid, also disconnect solenoid cable.

4. If replacing meter (4):

a. Disconnect fluid line from the meter. Loosen two nuts (A) holding the meter and

remove meter. See F

b. Secure new meter (4) with the nuts (A). Continue with step 6.

IG. 22.

5. If replacing solenoid (3):

a. Disconnect fluid lines from meter and solenoid.

b. Remove two bolts (6) and washers (7) from the solenoid (3), and remove solenoid

and meter assembly. See F

c. Place flats of the solenoid (3) in a vice and unscrew the meter (4).

d. Secure new solenoid (3) to the meter with the nut (A).

e. Secure meter and solenoid assembly to the fluid panel with solenoid washers (7) and

bolts (6).

6. Follow steps 8–10 on page 45 to connect meter cable (and solenoid cable if it was disconnected) to the terminal block.

7. Connect fluid line(s).

8. Load fluid at low pressure and check for leaks. Tighten fittings as needed.

IG. 22.

48 309301G

Page 49

Service

ti1412a

A

4

A

FIG. 22

7

6

3

309301G 49

Page 50

Service

Servicing Fluid Panel 244601 and 246837

Replacing Fluid Meter, Solenoid, or Dispense Valve

1. If necessary, purge ProDispense system (page 35).

2. Relieve pressure (page 24) and turn off controller power switch.

3. Follow steps 3–5 on page 43 to disconnect meter and solenoid cables from the terminal

block.

4. Disconnect fluid lines from the meter and dispense valve. Disconnect air line from the

solenoid.

5. Remove screw (20) and washer (21) from the meter (4). Remove meter, dispense valve

and solenoid assembly from the fluid panel.

Remove fittings from old components and reinstall in new components as needed.

6. If replacing meter (4):

a. Place flats of the solenoid (3) in a vice and unscrew the meter (4).

b. Screw new meter into connector (A).

7. If replacing dispense valve (19):

a. Place flats of the solenoid (3) in a vice and unscrew the meter (4).

b. Unscrew dispense valve (19) from the solenoid (3).

c. Screw new dispense valve into connector (C).

d. Screw the meter into the connector (A).

8. If replacing solenoid (3):

a. Place flats of the solenoid (3) in a vice and unscrew dispense valve and meter

assembly.

b. Screw new solenoid (3) into connector (B).

9. Secure the assembly to the fluid panel with screw (20) and washer (21).

10. Follow steps 8–10 on page 45 to connect meter and solenoid cables to the terminal block.

11. Connect fluid lines to the meter and dispense valve. Connect air line to the solenoid.

50 309301G

Page 51

12. Load fluid at low pressure and check for leaks. Tighten fittings as needed.

21

Service

20

4

FIG. 23

ti1411a

Show meter removal

3

A

19

C

B

309301G 51

Page 52

Service

Servicing Fluid Panel 246838

Replacing Solenoid or Dispense Valve

1. If necessary, purge ProDispense system (page 35).

2. Relieve pressure (page 24) and turn off controller power switch.

3. Follow steps 3–5 on page 43 to disconnect meter and solenoid cables from the terminal

block.

4. Disconnect fluid lines from the meter and dispense valve. Disconnect air line from the

solenoid.

5. Remove dispense valve and solenoid assembly from the fluid panel.

Remove fittings from old components and reinstall in new components as needed.

6. If replacing dispense valve (19):

a. Place flats of the solenoid (3) in a vice.

b. Unscrew dispense valve (19) from the solenoid (3).

c. Screw new dispense valve into connector (C).

7. If replacing solenoid (3):

a. Place flats of the solenoid (3) in a vice and unscrew dispense valve.

b. Screw new solenoid (3) into connector (B).

8. Follow steps 8–10 on page 45 to connect meter and solenoid cables to the terminal block.

9. Connect fluid lines to the meter and dispense valve. Connect air line to the solenoid.

10. Load fluid at low pressure and check for leaks. Tighten fittings as needed.

52 309301G

Page 53

Service

FIG. 24

3

A

19

C

B

309301G 53

Page 54

Service

Servicing Fluid Panel 246839

Replacing Fluid Meter, Solenoid, or Dispense Valve

1. If necessary, purge ProDispense system (page 35).

2. Relieve pressure (page 24) and turn off controller power switch.

3. Follow steps 3–5 on page 43 to disconnect meter and solenoid cables from the terminal

block.

4. Disconnect fluid lines from the meter and dispense valve. Disconnect air line from the

solenoid.

5. Remove screw (20) and washer (21) from the meter (4). Remove meter, dispense valve

and solenoid assembly from the fluid panel.

Remove fittings from old components and reinstall in new components as needed.

6. If replacing meter (4):

a. Place flats of the solenoid (3) in a vice and unscrew the meter (4).

b. Screw new meter into connector (A).

7. If replacing dispense valve (19):

a. Place flats of the solenoid (3) in a vice and unscrew the meter (4).

b. Unscrew dispense valve (19) from the solenoid (3).

c. Screw new dispense valve into connector (C).

d. Screw the meter into the connector (A).

8. If replacing solenoid (3):

a. Place flats of the solenoid (3) in a vice and unscrew dispense valve and meter

assembly.

b. Screw new solenoid (3) into connector (B).

9. Secure the assembly to the fluid panel with screw (20) and washer (21).

10. Follow steps 8–10 on page 45 to connect meter and solenoid cables to the terminal block.

11. Connect fluid lines to the meter and dispense valve. Connect air line to the solenoid.

54 309301G

Page 55

12. Load fluid at low pressure and check for leaks. Tighten fittings as needed.

21

Service

20

4

FIG. 25

ti1411a

Show meter removal

3

A

19

C

B

309301G 55

Page 56

Wiring Charts

Service

Control Box Wiring Chart

Wire / Harness

Internal Wiring

198556

Main PCB to 7 pin

bulkhead (1A)

198556

Main PCB to 7 pin

Bulkhead (2A)

Connection

(Connector-Pin)

Fuse 1 PWR SW 1A black

Fuse 2 PWR SW 2A black

PWR SW 1 P Supply L black

PWR SW 2 P Supply N black

GND TB P Supply G green/yellow

P Supply G P Supply - green/yellow

P Supply - J7-3 blue ground

P Supply + Fuse 3 blue

Fuse 3 J7-4 blue

J7-4 J7-1 blue jumper

J7-1 terminal block red 24 VDC power

J9-9 J9-10 blue jumper

J10-1 J10-2 blue jumper

J10-2 J10-3 blue jumper

J10-3 J10-4 blue jumper

terminal block P-1 red 24 VDC power

J9-5 P-2 red stop PB

P-3 open

J9-6 P-4 black start PB

J6-2 P-5 red solenoid

J6-1 P-6 black ground

ring terminal P-7 green ground

terminal block P-1 red 24 VDC power

J9-3 P-2 red stop PB

P-3 open

J9-4 P-4 black start PB

J6-4 P-5 red solenoid

J6-3 P-6 black ground

ring terminal P-7 green ground

Color Function

56 309301G

Page 57

Control Box Wiring Chart

Service

Wire / Harness

198556

Main PCB to 7 pin

bulkhead (3A)

198557

Main PCB to 4 pin

bulkhead (1B)

198557

Main PCB to 4 pin

bulkhead (2B)

198557

Main PCB to 4 pin

bulkhead (3B)

116726

Main PCB to 3 pin

bulkhead

197827

Main board to

front panel

197835

Front panel to

key switch

Connection

(Connector-Pin)

terminal block P-1 red 24 VDC power

J9-1 P-2 red stop PB

P-3 open

J9-2 P-4 black start PB

J6-6 P-5 red solenoid

J6-5 P-6 black ground

ring terminal P-7 green ground

J11-7 P-1 red 24 VDC power

J11-8 P-2 black ground

J11-9 P-3 clear meter signal

ring terminal P-4 drain ground

J11-4 P-1 red 24 VDC power

J11-5 P-2 black ground

J11-6 P-3 clear meter signal

ring terminal P-4 drain ground

J11-1 P-1 red 24 VDC power

J11-2 P-2 black ground

J11-3 P-3 clear meter signal

ring terminal P-4 drain ground

J2-6 P-1 black ground

J2-7 P-2 clear printer

P-3 shield

J3-1 J4-1 brown RS485_B

J3-2 J4-2 white RS485_A

J3-3 J4-5 black ground

J3-5 J4-3 green DSRI

J3-10 J4-4 red VCC

J1-1 SW1 black key switch

J1-2 SW2 red key switch

Color Function

309301G 57

Page 58

Fluid Panel Wiring Chart

Service

Harness

198426

Control box to fluid

panel (1A, 2A, 3A)

198427

Control box to fluid

panel (1B, 2B, 3B)

116669

Remote operator

station

Connection

(Connector-Pin)

Pin-1 Pin-1 orange

Pin-2 Pin-2 white

Pin-3 Pin-3 green

Pin-4 Pin-4 blue

Pin-5 Pin-5 black

Pin-6 Pin-6 red

Pin-7 Pin-7 shield

Pin-1 Pin-1 red

Pin-2 Pin-2 black

Pin-3 Pin-3 white

Pin-4 Pin-4 shield

F1 2POS SW NC 2 orange

F2 2POS SW NO 3 orange

F3 Start PB X1 orange

F4 Start PB NO 4 brown

F5 2POS SW NO 4 brown

F6 Stop PB NC 1 brown/green

F7 Start PB NO 3 white

F8 Start PB X2 black/green

F9 Ground Lug green

F10 Stop PB NC 2 red

F11 Stop PB NC 1 blue

F12 Ground Lug shield

stop PB NC 2 2POS SW NC 1 blue jumper

Color Function

58 309301G

Page 59

Fluid Panel Wiring Chart

Service

Harness

244660

Fluid panel

junction box

Terminal block 5 & 6

are bridged

Terminal block 7 & 8

are bridged

Used for 244599,

244600, 244601

fluid panels

244599

Fluid panel (oil)

244600

Fluid panel (water)

246837

246839

244601

Fluid panel (grease)

Connection

(Connector-Pin)

T Block 1 Pin-1 orange

T Block 2 Pin-2 white

T Block 3 Pin-5 black

T Block 4 Pin-4 blue

T Block 7 Pin-6 red

ground Pin-7 green/yellow

T Block 1 Pin-1 orange

T Block 2 Pin-2 white

T Block 3 Pin-6 red

T Block 4 Pin-4 blue

T Block 5 Pin-5 black

ring terminal Pin-7 green/yellow

T Block 9 Pin-1 red

T Block 10 Jumper

T Block 11 Pin-2 black

T Block 12 Pin-3 white

T Block 13 Pin-4 G/Y & shield

TB 10 red

TB 12 white

TB 6 black

TB 8 black

TB 10 brown

TB 12 green

TB 6 black

TB 8 black

TB 10 red

TB 11 black

TB 12 white

TB13 green/shield

TB 6 black

TB 8 black

Color Function

197573

6 pin bulkhead

operator station

197574

7 pin bulkhead (A)

cable connection

197575

4 pin bulkhead (B)

cable connection

meter wiresTB 11 black

solenoid wires

meter wiresTB 11 white

solenoid wires

meter wires

solenoid wires

309301G 59

Page 60

Fluid Panel Wiring Chart

Service

Harness

246838

Fluid Panel

(Grease)

Harness

197458

(5 ft., 1.52 m)

198669

(50 ft. 15.24 m)

Printer Cable

Connection

(Connector-Pin)

TB 6 black

TB 8 black

Color Function

Accessories Wiring Chart

Connection

(Connector-Pin)

2 1 shield

3 3 clear

15black

4

6

Color Function

jumper

Field Wiring Chart - Output

solenoid wires

Harness

Connection

(Connector-Pin)

J5-1 ground

J5-2 General Alarm (24 VDC)

J5-3 ground

J5-4 Fluid 1 Alarm (24 VDC)

J5-5 ground

J5-6 Fluid 2 Alarm (24 VDC)

J5-7 ground

J5-8 Fluid 3 Alarm (24 VDC)

J3-8 Modbus B

J3-9 Modbus A

J2-6 ground

Color Function

60 309301G

Page 61

Notes:

Service

309301G 61

Page 62

Parts

Part No. 244561, Controller

32

Parts

E

48

46

D

4a

12

31

33

5

A

3

24

C

D

B

4

E

16

20

B

C

49

A

47

19

TI1462A

50

Ref. # Part # Description Qty.

3 197386 LABEL, power switch 1

4 116368 SWITCH, key, 2-position, includes item 4a 1

4a 116370 • KEY PACKAGE (2 duplicate keys) 1

5 116320 SWITCH, power 1

12 196975 POWER SUPPLY, 24 VDC 1

13 244952 BOARD, circuit, main control 1

16 197835 HARNESS, wire 1

18 245222 COVER ASSEMBLY, electrical section, includes items 18a-18h 1

18a 197431 • COVER, enclosure 1

18b 116371 • SPACER, 0.151” ID 4

18c 197281 • SWITCH, membrane 1

18d 198573 • DISPLAY, graphic 1

13

62 309301G

Page 63

Ref. # Part # Description Qty.

18e 116374 • SPACER, 0.14” ID 4

18f 244407 • BOARD, circuit, display 1

18g 103181 • WASHER, lock, external, #6 4

18h 100072 • NUT, hex, 6-32 UNC-2B 4

19 198556 WIRE HARNESS, solenoid 3

20 198557 WIRE HARNESS, meter 3

22 194741 LABEL, warning (not shown) 1

24 116726 WIRE HARNESS, printer 1

31 114835 FUSE, time lag, 4 A, 250 V 1

32 120614 FUSE, time lag, 1.6 A, 250 V 2

33 197827 WIRE HARNESS 1

46 116772 CONNECTOR, plug, 3.81 mm, 4 position 1

47 116773 CONNECTOR, plug, 3.81 mm, 10 position 3

48 116774 CONNECTOR, plug, 3.81 mm, 13 position 1

49 116343 SCREW, ground 1

50 222011 CLAMP, grounding 1

Parts

Item 18 Cover Assembly

Part No. 245222

18f

18d

18h

18g

18e

18b

18a

TI1056A

18c

309301G 63

Page 64

Part No. 244599, Fluid Panel

Parts

21

9, 10, 11, 12, 20

54

22

14, 15

23

1

ti1323a

26, 7

Ref. # Part # Description Qty.

1 116421 PANEL, fluid dispense 1

2 197576 BLOCK, solenoid mount 1

3 110025 VALVE, solenoid 1

4 238618 METER, electronic pulse, see Manual 308245 for parts 1

5 158491 FITTING, nipple, 1/2-14 npt 1

6 102313 SCREW, cap, 1/4-20 UNC-2A x 1.75” 2

7 110755 WASHER, plain, 0.281” ID 6

8 102040 NUT, lock, hex, 1/4-20 UNC-3B 2

9 104029 CLAMP, ground 1

10 104582 WASHER, tab, 5.3 mm ID 1

11 100718 WASHER, lock, #10 1

12 105332 NUT, lock, hex, M5 x 0.8 1

13 244660 JUNCTION BOX, electrical 1

14 101577 SCREW, cap, hex hd., 10-24 UNC-2A x 0.375” 2

15 C38163 WASHER, lock, star, #10 2

16 100021 SCREW, cap, hex hd., 1/4-20 UNC-2A x 1” 2

17 112514 FERRULE, wire, AWG 18 (not shown) 2

18 112512 FERRULE, wire, AWG 26-22 (not shown) 3

20 237569 WIRE ASSY., 25 ft. (7.6 m) 1

21 116669 OPERATOR STATION, remote 1

22 198426 HARNESS, wire 1

23 198427 HARNESS, wire 1

13

3

7, 8, 16

64 309301G

Page 65

Part No. 244600, Fluid Panel

Parts

21

9, 10, 11, 12

4

6, 7

, 20

22

14, 15

23

1

13

7, 8, 16

3

ti1322a

2

Ref. # Part # Description Qty.

1 116421 PANEL, fluid dispense 1

2 197576 BLOCK, solenoid mount 1

3 110025 VALVE, solenoid 1

4 513891 METER, pulse, water 1

6 102313 SCREW, cap, 1/4-20 UNC-2A x 1.75” 2

7 110755 WASHER, plain, 0.281” ID 6

8 102040 NUT, lock, hex, 1/4-20 UNC-3B 2

9 104029 CLAMP, ground 1

10 104582 WASHER, tab, 5.3 mm ID 1

11 100718 WASHER, lock, #10 1

12 105332 NUT, lock, hex, M5 x 0.8 1

13 244660 JUNCTION BOX, electrical 1

14 101577 SCREW, cap, hex hd., 10-24 UNC-2A x 0.375” 2

15 C38163 WASHER, lock, star, #10 2

16 100021 SCREW, cap, hex hd., 1/4-20 UNC-2A x 1” 2

17 112514 FERRULE, wire, AWG 18 (not shown) 2

18 112512 FERRULE, wire, AWG 26-22 (not shown) 3

20 237569 WIRE ASSY., 25 ft. (7.6 m) 1

21 116669 OPERATOR STATION, remote 1

22 198426 HARNESS, wire 1

23 198427 HARNESS, wire 1

309301G 65

Page 66

Part No. 244601, Fluid Panel

9, 10, 11, 12, 25

Parts

26

20, 21

4

2

27

14, 15

28

13

ti1324b

3

Ref. # Part # Description Qty.

1 116421 PANEL, fluid dispense 1

2 156971 NIPPLE, short, 1/4-18 npt 1

3 116463 VALVE, solenoid 1

4 239716 METER, gear, G3000, see Manual 308778 for parts 1

6 112173 MUFFLER, 1/4-18 npt 1

7 181256 NEEDLE, fluid 1

8 110249 ADAPTER, male, 90° elbow, 1/4-18 npt 1