Page 1

Instructions/Instrucciones

309319

Rev. E

Important Safety Instructions

D Read all warnings and instructions in this manual.

Save these instructions.

D Lisez tous les avertissements et instructions en ce

manuel. Économiser ces instructions.

D Lea todas las advertencias e instrucciones en este

manual. Excepto estas instrucciones.

t

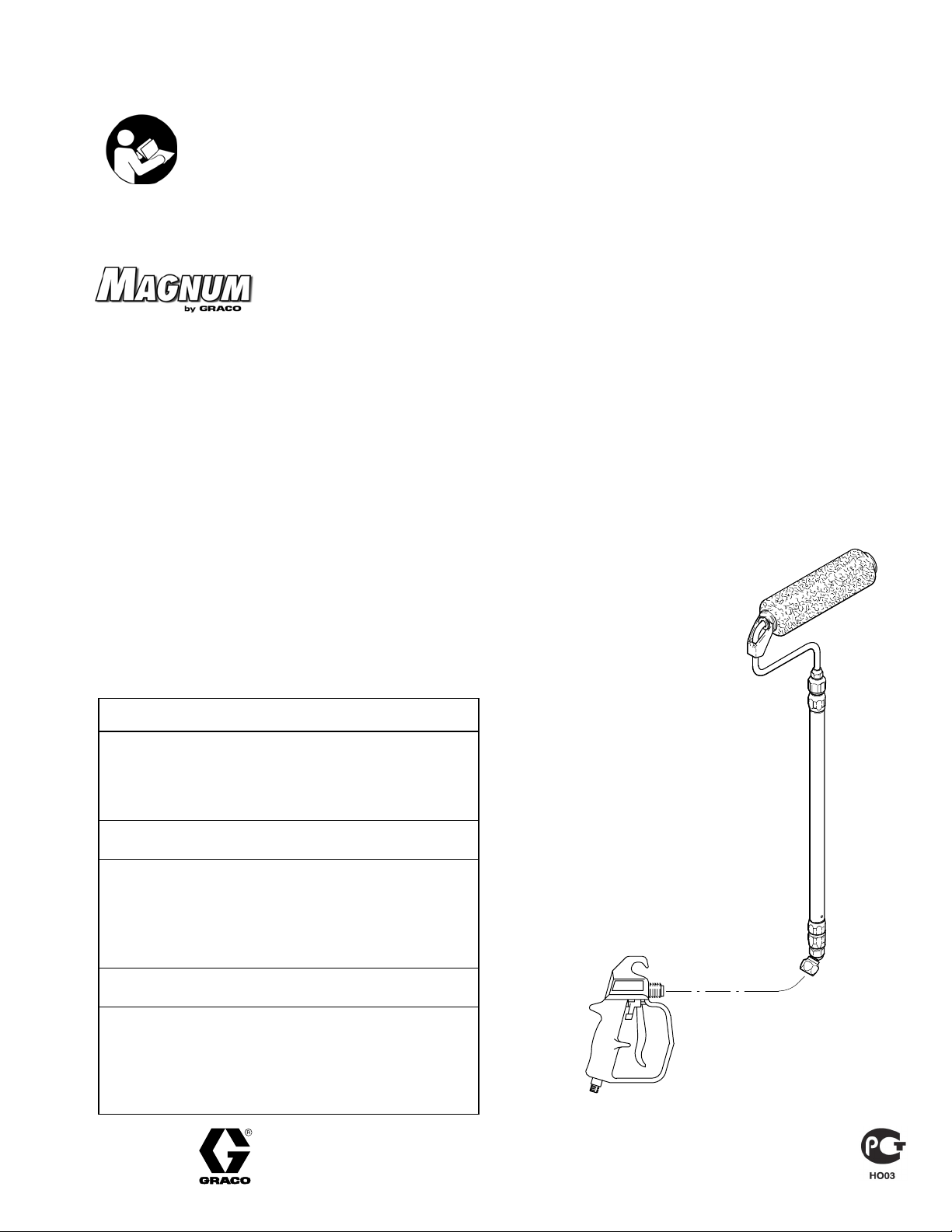

Pressure Roller

To find your local Graco/M

service center

D 1–888–541–9788

D Magnum.Graco.com

D Graco/MAGNUM Authorized Service Centers list 302367

AGNUM authorized

Rouleau à peinture sous pression

Rodillo a presión

Model 244512, Series C

D 20 in. (50 cm) heavy-duty extension / Rallonge robuste / Extensión para trabajos pesados

D 45_ swivel adapter / Adaptateur à pivot / Adaptador giratorio

D 9 in. (23 cm) roller frame / Armature de rouleau / Soporte del rodillo

D 1/2 in. (13 mm) nap roller cover / gaine / Cubierta de lanilla del rodillo

3600 psi (24.8 MPa, 248 bar) Maximum Fluid Inlet Pressure/* / Pression maximale d’admission de fluide*

PresIón de entrada de fluido máxima*

Use the lowest pressure that provides an even paint supply to the roller;

*

typically less than 300 psi (2.1 MPa, 21 bar).

Employez la plus basse pression qui fournit une offre égale de peinture au

*

rouleau ; en général moins de 300 psi (2.1 MPa, 21 bar).

Utilice la presión más baja que proporciona una fuente uniforme de la pintura

*

al rodillo; típicamente menos de 300 psi (2.1 MPa, 21 bar).

CAUTION

Never leave water in the pump, gun, or pressure roller.

Doing so could cause corrosion and damage from freezing.

For storage, flush the system with Graco Pump Armort or

mineral spirits/paint thinner.

ATTENTION

Ne jamais laisser d’eau dans la pompe, le pistolet ou le

rouleau à peinture sous pression. Cela pourrait causer de

la corrosion et des dommages dus à la congélation. Pour

l’entreposage, vidanger le système avec du Pump Armort

de Graco, de l’essence minérale ou du solvant à peinture.

PRECAUCION

Nunca deje agua en la bomba, en la pistola ni en el rodillo

a presión. Esto podría provocar corrosión y daños por

congelamiento. Para su almacenamiento, lave el sistema

con Pump Armort de Graco o solución alcohólica mineral

o disolvente de pinturas.

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

ECOPYRIGHT 2001, GRACO INC.

Graco Inc. is registered to I.S. EN ISO 9001

Page 2

English

Warnings

WARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause the equipment to rupture or

malfunction and result in serious injury.

To help prevent injury

D Do not modify the extension tube or roller

frame or use parts not designed for this

equipment.

D Do not use 1,1,1–trichloroethane, methylene

chloride, other halogenated hydrocarbon solvents or fluids containing such solvents in this

or any other pressurized aluminum equipment.

Such use could result in a chemical reaction,

with the possibility of explosion.

FIRE AND EXPLOSION HAZARD

Improper grounding, poor ventilation, open

flames or sparks can cause a hazardous condition and result in a fire or explosion and serious

injury.

To help prevent injury from fire or explosion

D Provide fresh air ventilation to avoid the

buildup of flammable fumes from flushing fluids

or the coating being applied.

D Keep the application area free of debris,

including solvent, rags, and gasoline.

Installation

Assemble the pressure roller as shown in the Parts

Drawing on page 3. Attach pressure roller assembly

to spray gun.

Pressure Relief Procedure

WARNING

To help prevent injection injuries,

follow this procedure whenever

psi/MPa/bar

1. Put gun trigger safety in SAFETY ON position.

2. Shut off power to pump.

3. Turn prime/spray valve to the PRIME position to

relieve pressure in system.

4. Put gun trigger safety in SAFETY OFF position,

and trigger gun to relieve any pressure in hose.

5. Put gun trigger safety in SAFETY ON position, and

keep pump prime/spray valve in PRIME position

until you paint again.

you stop painting.

FLUID INJECTION HAZARD

If high-pressure fluid pierces your skin, the injury might look like “just a cut”. But it is a serious

wound. Get immediate surgical treatment.

To help prevent injection

D Keep your hands and body away form the

roller frame when flushing. High pressure

fluid emitted from the holes in the frame

could cause an injection injury.

D Always relieve pressure before you check or

repair leaks and when you turn off pump or stop

painting.

D Never use components rated less than

system Maximum Working Pressure.

ELECTROCUTION HAZARD

Failure to observe the electrical hazards

described below could result in serious injury,

including burns or electrocution.

To help prevent harmful electrical shock

D Avoid contact with power lines.

D Follow all grounding instructions in your

separate pump and gun instruction manual,

and comply with all local, state, and national

fire, electrical, and safety regulations.

D Use only MAGNUM or Graco paint hoses.

Additional Roller Covers

Operation

1. Follow pump priming instructions using lowest

pressure setting at which pump primes.

2. Turn prime/spray valve to SPRAY position.

3. Disengage gun safety latch, trigger the gun, and

roll the surface until paint comes to roller.

NOTE: Trigger the gun briefly only when you need

more paint. Determine how often you must trigger

the gun to maintain an even paint supply to the

roller.

4. Increase pump pressure only if triggering gun

cannot supply enough paint for your rolling speed.

See Pressure Relief

Procedure on page 2.

5. Whenever you stop painting, relieve the

pressure, and elevate roller end of extension tube

to prevent paint from draining out.

Flush the pump, gun, and pressure roller immediately

after each use to prevent paint from drying in the

pressure roller and damaging it. See Cleaning on

page 2.

The following MAGNUM pressure roller covers are

available at your local distributor:

243063 9 in. (23 cm); 1/2 in. (13 mm) nap

243064 9 in. (23 cm); 3/4 in. (19 mm) nap

243065 9 in. (23 cm); 1-1/4 in. (32 mm) nap

2 309319

Cleaning

This is the procedure for flushing the pressure roller.

The pump and gun you are using may have additional

flushing steps, such as cleaning filters and screens.

See the pump and gun flushing instructions.

Page 3

NOTE: Leave the pressure roller attached to the gun

for this procedure.

See Pressure Relief

Procedure on page 2.

MAGNUM Pressure Roller,

Model 244512, Series C

4

23

1. Relieve the pressure.

2. Remove roller cover (19) and diffuser (23) from

roller frame as follows (see Parts Drawing):

a. Using your thumb, press down on clip (5) to

release end caps (2 &4), diffuser (23) and

roller cover (19) into a pail.

b. Remove roller cover (19) from diffuser (23).

c. Pull end caps (2 & 4) off diffuser (23).

Disassemble.

3. Clean roller cover (19), caps (2 & 4) and diffuser

(19) with water or a compatible fluid for oil–based

materials.

4. Place roller frame (1) in paint pail. Be sure the

holes in roller frame (1) are facing inside the paint

pail.

5. Prime pump with water or flushing fluid for

oil–based materials. Use the lowest pump priming

pressure setting.

6. Turn prime/spray valve to SPRAY.

NOTE: Perform Step 7 at the lowest pressure

possible.

7. Trigger gun until flushing fluid begins to dilute the

paint.

8. Place roller frame (1) in another bucket and

continue flushing until fluid coming out of the roller

frame (1) is clear.

9. Shut off the pump. Turn prime/spray valve to

PRIME.

Storage

If you are going to store the airless equipment for an

extended period of time after flushing with water-base

fluid, flush again with Graco Pump Armor or mineral

spirits/paint thinner. Leave the fluid in the system

during storage.

1

5

2

ti10641a

7*

12

14

7

17

19

Parts List

Ref.

No. Part No. Description Qty.

1 FRAME, roller 1

2 245999 CAP, end (includes seal and retainer) 1

4 246277 CAP, end (includes seal, retainer, and

o–ring) 1

5 197106 CLIP, roller 1

7 15H622 GASKET 2

12 115524 GASKET 1

14 243051 EXTENSION, 20 in. (50 cm) 1

17 243057 SWIVEL, 45_ 1

19 243063 ROLLER, cover, 9 inch,

1/2 in. (13 mm) nap 1

23 15B065 DIFFUSER 2

309319 3

Page 4

Français

Mise en garde

MISE EN GARDE

Risque dû au mauvais usage

Un mauvais usage peut entraîner le bris ou la

défaillance de l’équipement et causer des

blessures graves.

Pour éviter les risques de blessures

D Ne pas modifier le tube rallonge ou l’armature

du rouleau et n’utilisez pas des pièces non

prévues pour cet équipement.

D Ne pas utiliser de trichloroéthane-1,1,1, de

chlorure de méthylène, d’autres solvants à

base d’hydrocarbures halogénés ni de fluides

contenant de tels solvants dans cet appareil ou

tout autre appareil sous pression en aluminium.

Cela pourrait provoquer une réaction chimique

avec risque d’explosion

DANGER D’INCENDIE ET D’EXPLOSION

Un mise à la terre erronée, une ventilation

insuffisante, des flammes nues ou des étincelles peuvent créer une condition dangereuse et

provoquer un incendie, une explosion ou des

blessures graves.

Pour éviter les risques de blessures

provoqués par un incendie ou une explosion

D Assurer un apport d’air neuf pour dissiper

l’accumulation de gaz inflammables émanant

de la vidange de fluides ou de l’application de

l’enduit.

D Garder l’aire de travail libre de débris, solvants,

chiffons et gazoline.

DANGER D’INJECTION DE FLUIDE

Si un fluide haute pression perce la peau, la blessure

peut présenter l’aspect d’une simple «coupure».

Mais il s’agit bien d’une lésion grave. Consulter immédiatement un médecin.

Pour éviter les risques d’injection

D Éloigner corps et mains de l’armature du rouleau

durant la vidange. Le fluide haute pression qui

sort des orifices de l’armature peut causer des

blessures par injection.

D Décharger toujours la pression avant de vérifier ou

réparer une fuite, arrêter la pompe, ou arrêter de

peindre.

D Ne jamais utiliser des accessoires dont la pression

nominale est inférieure à la pression maximale de

service du système.

DANGER D’ÉLECTROCUTION

La non-observation des mesures préventives

contre les dangers reliés à l’électricité décrites

ci-dessous peut entraîner des blessures graves, y

compris des brûlures ou l’électrocution.

Pour éviter les risques de chocs électriques

dangereux

D Éviter tout contact avec les lignes de haute

tension.

D Observer toutes les directives de mises à la

terre décrites dans les guides techniques

afférents à la pompe et le pistolet, aussi, se

conformer à tous les règlements locaux,

provinciaux et nationaux de protection

incendie, d’électricité et de sécurité.

D Utiliser uniquement les flexibles à peinture

MAGNUM ou Graco.

.

Manchons additionnels

Les manchons MAGNUM suivants sont disponibles chez

un revendeur près de chez vous :

243063 Gaine 9 po (23 cm) ; 1/2 po (13 mm) ép.

243064 Gaine 9 po (23 cm) ; 3/4 po (19 mm) ép.

243065 Gaine 9 po (23 cm) ; 1-1/4 po (32 mm) ép.

Installation

Assembler les pièces du rouleau à peinture sous pression

selon le Diagramme de montage illustré à la page 5.

Procédure de décharge de la

pression

MISE EN GARDE

Pour éviter les blessures par

injection, suivre cette procédure

lb/po2 / MPa / bar

1. Toujours mettre le loquet de sécurité du pistolet en

position SAFETY ON.

2. Mettre la pompe hors tension.

3. Mettre le robinet d’amorçage/pulvérisation à la

position PRIME pour décharger la pression du

système.

4. Mettre le loquet de sécurité du pistolet en position

SAFETY OFF ensuite, actionner le pistolet pour

décharger la pression qui pourrait se trouver dans

le flexible.

5. Mettre le loquet de sécurité du pistolet en position

SAFETY ON et laisser le robinet

d’amorçage/pulvérisation à la position PRIME

jusqu’à reprise suivante de la peinture.

chaque fois qu’on arrête de peindre.

Fonctionnement

1. Suivre les instructions d’amorçage de la pompe en

utilisant la plus basse pression d’amorçage.

2. Mettre le robinet d’amorçage/pulvérisation à la

position SPRAY.

3. Dégager le loquet de sécurité et actionner le

pistolet brièvement jusqu’à l’arrivée de la peinture

dans le rouleau.

REMARQUE : Actionner le pistolet brièvement au

besoin seulement pour assurer un débit uniforme

de peinture au rouleau.

4. Augmenter uniquement la pression si l’action du

pistolet ne peut fournir assez de peinture pour la

vitesse d’application.

Voir Procédure de décharge

de la pression à la page 4.

5. À la fin du cycle de peinture, décharger la

pression et redresser le tube rallonge, rouleau en

tête, pour empêcher l’évacuation de la peinture.

Vidanger pompe, pistolet et rouleau immédiatement

après chaque usage pour empêcher la peinture de

sécher dans le rouleau et l’endommager. Voir

Nettoyage à la page 5.

4 309319

Page 5

Nettoyage

Cette procédure vise la vidange du rouleau à peinture

sous pression. Des instructions de vidange

additionnelles, telles que nettoyage de filtres et tamis,

peuvent s’appliquer à la pompe et au pistolet utilisés.

Consulter les instructions de vidange pertinentes à la

pompe et au pistolet.

REMARQUE : Pour cette procédure, garder

l’ensemble du rouleau couplé au pistolet.

Voir Procédure de

décharge de la pression à

la page 4.

1. Décharger la pression.

2. Retirer le manchon (19) et le diffuseur (23) de

l’armature comme suit (voir le Diagramme de

montage) :

a. Appuyer avec le pouce sur le collier de

serrage (5) pour relâcher les embouts (2 et 4),

le diffuseur (23) et le manchon (19) dans un

seau.

b. Séparer le manchon (19) du diffuseur (23).

c. Séparer les embouts (2 et 4) du diffuseur (23).

Démonter le tout.

3. Nettoyer le manchon (19), les embouts (2 et 4) et

le diffuseur (19) avec de l’eau ou un fluide

compatible aux enduits à base d’huile.

4. Placer l’armature (1) dans un seau vide. S’assurer

que les orifices de l’armature du rouleau (1) font

fasse à la paroi intérieure du seau.

5. Amorcer la pompe à la plus basse pression

d’amorçage en utilisant de l’eau ou un fluide de

vidange pour enduits à base d’huile.

6. Mettre le robinet d’amorçage/pulvérisation de la

pompe à la position SPRAY.

REMARQUE : Effectuer l’étape 7 à la plus basse

pression possible.

7. Actionner le pistolet jusqu’à ce que le fluide de

vidange commence à diluer la peinture.

8. Placer l’armature du rouleau (1) dans un autre

seau et poursuivre la vidange jusqu’à la sortie d’un

fluide clair de l’armature du rouleau (1).

9. Arrêter la pompe. Mettre le robinet

d’amorçage/pulvérisation à la position PRIME.

Entreposage

S’il faut entreposer l’équipement sans air pour une

longue période après une vidange avec de l’eau, refaire

une vidange du système avec le Pump Armor de Graco,

à l’essence minérale ou au diluant pour peintures.

Laisser le fluide dans le système pendant l’entreposage.

MAGNUM Pressure Roller,

Model 244512, Series C

4

1

5

ti10641a

7*

14

7

17

12

23

2

19

Liste des pièces

No

réf. No pièce Description Nbr

1 ARMATURE de rouleau 1

2 245999 EMBOUT (joint étanche et collier

compris) 1

4 246277 EMBOUT (joint étanche, collier et

joint torique compris) 1

5 197106 COLLIER DE SERRAGE 1

7 15H622 JOINT D’ÉTANCHÉITÉ 2

12 115524 JOINT D’ÉTANCHÉITÉ 1

14 243051 RALLONGE, 20 po (50 cm) 1

17 243057 PIVOT, 45_ 1

19 243063 MANCHON, 9 po,

gaine feutrée 1/2 po (13 mm) 1

23 15B065 DIFFUSEUR 2

309319 5

Page 6

Español

Advertencias

ADVERTENCIA

PELIGRO POR MAL USO DE LOS EQUIPOS

El mal uso de los equipos puede causar su rotura

o mal funcionamiento y provocar lesiones graves.

Para evitar lesiones

D No modifique el tubo de extensión ni el soporte

del rodillo ni utilice piezas que no hayan sido

diseñadas para este equipo.

D No utilice nunca 1,1,1-tricloroetano, cloruro de me-

tileno, otros disolventes de hidrocarburos halogenados ni fluidos que contengan tales disolventes

en éste u otros equipos a presión de aluminio. El

uso de estas sustancias puede provocar una

reacción química con riesgo de explosión.

PELIGRO DE INCENDIO Y DE EXPLOSIÓN

La conexión deficiente a tierra, la mala ventilación, las llamas o las chispas pueden causar

una situación peligrosa y provocar un incendio

o explosión y lesiones graves.

Para evitar lesiones por incendios o

explosiones

D Asegúrese de que haya buena ventilación

para evitar la formación de gases

inflamables a partir de los fluidos para el

lavado o por el recubrimiento que se esté

aplicando.

D Mantenga el área de aplicación libre de

desechos, incluyendo disolventes, trapos y

gasolina

PELIGRO DE INYECCIÓN DE FLUIDO

Si penetra en la piel fluido a alta presión, la herida

podría parecer “simplemente un corte”. Sin embargo, se trata de una herida grave. Consulte de inmediato al médico.

Para prevenir la inyección

D Mantenga las manos y el cuerpo alejados del

soporte del rodillo al lavar. El fluido emitido a

alta presión desde los orificios del soporte

podría provocar una lesión de tipo inyección.

D Alivie siempre la presión antes de verificar o reparar

pérdidas y cuando apague la bomba o deje de

pintar.

D No utilice componentes de presión nominal menor

que la Presión de trabajo máxima del sistema.

PELIGRO DE ELECTROCUCIÓN

Si no se previenen los peligros eléctricos

descritos a continuación se pueden producir

lesiones graves, incluso quemaduras o

electrocución.

Para evitar la descarga eléctrica dañina

D Evite el contacto con líneas de energía

eléctrica.

D Siga todas las instrucciones de puesta a tierra

de los correspondientes manuales de

instrucciones para la bomba y la pistola y

cumpla con todas las reglamentaciones

municipales, provinciales y nacionales contra

incendios, eléctricas y de seguridad.

D Use sólo mangueras para pintura MAGNUM o

Graco.

Cubiertas para rodillo adicionales

Las siguientes cubiertas para rodillos a presión

MAGNUM están disponibles en su distribuidor local:

243063 23 cm. (9 pulgadas); lanilla de 13 mm. (1/2 pulgada)

243064 23 cm. (9 pulgadas); lanilla de 19 mm. (3/4 pulgada)

243065 23 cm. (9 pulgadas); lanilla de 32 mm. (1 pulgada y 1/4)

6 309319

.

Instalación

Arme el rodillo a presión tal como se muestra en la Lista de Partes de la página 7. Conecte el sistema de rodillo a presión con la pistola pulverizadora.

Procedimiento de alivio de

presión

ADVERTENCIA

Para evitar lesiones por inyección,

siga los pasos de este procedimiento

psi/MPa/bar

1. Ponga la palanca de seguridad de la pistola en la

posición SAFETY ON.

2. Desconecte el suministro de energía eléctrica a la

bomba.

3. Ponga la válvula de cebado/pulverización en la

posición PRIME para aliviar la presión del sistema.

4. Ponga la palanca de seguridad de la pistola en la

posición SAFETY OFF y dispare la pistola para

aliviar la presión de la manguera.

5. Ponga la palanca de seguridad de la pistola en la

posición SAFETY ON y mantenga la válvula de

cebado/pulverización en la posición PRIME hasta

que vuelva a pintar.

cuando no esté pintando.

Operación

1. Siga las instrucciones de cebado de la bomba

utilizando la configuración de presión más baja

para el cebado de la bomba.

2. Gire la válvula de cebado/pulverización a la

posición SPRAY.

3. Desenganche la palanca de seguridad de la

pistola, dispárela y haga rolar la superficie hasta

que la pintura llegue al rodillo.

NOTA: Dispare la pistola brevemente sólo cuando

necesite más pintura. Determine con qué

frecuencia debe disparar la pistola para mantener

un suministro parejo de pintura al rodillo.

4. Suba la presión de la bomba si el disparo de la

pistola no suministra suficiente pintura para su

velocidad con el rodillo.

Consulte el Procedimiento de

alivio de presión en la página 6.

5. Cuando no esté pintando, alivie la presión y

eleve el extremo del rodillo del tubo de extensión

para que la pintura no se chorree.

Lave la bomba, la pistola y el rodillo de presión

inmediatamente después de cada uso para que la

pintura no se seque en el rodillo y lo dañe. Consulte la

sección sobre Limpieza de la página 7.

Page 7

Limpieza

Éste es el procedimiento para lavar el rodillo a presión.

La bomba y la pistola que está utilizando pueden tener

pasos de limpieza adicionales, como la limpieza de

filtros. Consulte las instrucciones de lavado de la

bomba y la pistola.

NOTA: Deje el rodillo a presión conectado con la

pistola para este procedimiento.

MAGNUM Pressure Roller,

Model 244512, Series C

4

1

23

Consulte el Procedimiento

de alivio de presión de la

página 6.

1. Alivie la presión.

2. Quite la cubierta del rodillo (19) y el difusor (23)

del soporte del rodillo tal como se describe a

continuación (vea la Ilustración de piezas):

a. Utilizando el pulgar, presione hacia abajo el

sujetador (5) para soltar las tapas del extremo

(2 y 4), el difusor (23) y la cubierta del rodillo

(19) en un cubo.

b. Extraiga la cubierta del rodillo (19) del

difusor (23).

c. Quite las tapas del extremo (2 y 4) del

difusor (23). Desarme.

3. Limpie la cubierta del rodillo (19), las tapas (2 y 4)

y el difusor (19) con agua o un fluido compatible

con materiales a base de aceite.

4. Coloque el soporte del rodillo (1) en un cubo de

pintura. Asegúrese de que los orificios del soporte

del rodillo (1) estén mirando hacia dentro del cubo

de pintura.

5. Cebe la bomba con agua o líquido de lavado para

materiales a base de aceite. Utilice la

configuración de presión más baja para el cebado

de bomba.

6. Ponga la válvula de cebado/pulverización en la

posición SPRAY.

NOTA: Realice el paso 7 a la presión más baja

posible.

7. Dispare la pistola hasta que el líquido de lavado

empiece a diluir la pintura.

8. Ponga el soporte del rodillo (1) en otro balde y

continúe lavando hasta que el líquido que salga

del mismo (1) sea transparente.

9. Cierre la bomba. Ponga la válvula de

cebado/pulverización en la posición PRIME.

Almacenamiento

Si va a guardar el equipo sin aire por un periodo largo,

después de lavar con líquido a base de agua, lave

nuevamente con Graco Pump Armor o solución

alcohólica mineral o disolvente de pinturas. Deje el

líquido en el sistema durante el almacenamiento.

5

2

ti10641a

7*

12

14

7

17

19

Lista de partes

No. No.

Ref. de parte Descripción Cantidad

1 SOPORTE, rodillo 1

2 245999 TAPA, extremo (incluye sello y retén) 1

4 246277 TAPA, extremo (incluye sello, retén y

aro tórico) 1

5 197106 SUJETADOR, rodillo 1

7 15H622 EMPAQUETADURA 2

12 115524 EMPAQUETADURA 1

14 243051 EXTENSIÓN, 50 cm. (20 pulgadas) 1

17 243057 ADAPTADOR GIRATORIO, 45_ 1

19 243063 RODILLO, cubierta, 9 pulgadas,

Lanilla de 13 mm. (1/2 pulgada) 1

23 15B065 DIFUSOR 2

309319 7

Page 8

Limited Warranty

Graco Inc. warrants to the original retail purchaser (other than for purposes of resale or rental) all equipment

manufactured by Graco and bearing its name to be free from defects in material and workmanship if operated

in accordance with Graco’s printed recommendations and instructions. This warranty applies for one year from

the date of purchase.

This warranty does not cover and Graco shall not be liable for general wear and tear, or any malfunction,

damage or wear caused by improper use, accidents, user negligence, use of non-Graco component parts or

service or repair performed by anyone other than a Graco authorized service center.

IMPLIED WARRANTIES, INCLUDING THOSE OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE, ARE LIMITED TO ONE YEAR FROM THE DATE OF ORIGINAL PURCHASE.

GRACO SHALL NOT IN ANY EVENT BE LIABLE FOR ANY INCIDENTAL, INDIRECT, OR CONSEQUENTIAL

LOSS, DAMAGE OR EXPENSE OF ANY KIND, WHETHER FROM BREACH OF THIS WARRANTY OR ANY

OTHER REASON. Some states do not allow the exclusion or limitation of incidental or consequential damages,

so the above limitation or exclusion may not apply to you.

To make a claim under this warranty, return the product with proof of purchase, transportation prepaid, to any

Authorized Graco Service Center. Graco’s Authorized Service Center, at its option, will either repair or replace

the product and return it to you, postage prepaid. A listing of Authorized Graco Service Centers is enclosed

with this product. You may also find the nearest Authorized Graco Service Center by calling 1–888–541–9788

or by visiting our website at www.graco.com.

This warranty gives you specific legal rights and you may also have other rights which may vary from state to

state.

POUR LES CLIENTS PARLANT FRANCAIS

Les parties reconnaissent avoir convenu que la rédaction du présent document ainsi que de tous les

documents, avis et procédures judiciaires exécutés, donnés ou intentés à la suite de ou en rapport,

directement ou indirectement, avec les procédures concernées, sera en anglais.

PARA LOS CLIENTES QUE HABLAN ESPAÑOL

Las partes reconocen haber convenido que el presente documento, así como todos los documentos,

notificaciones y procedimientos judiciales emprendidos, presentados o establecidos que tengan que ver con

estas garantías directa o indirectamente, estarán redactados en inglés.

All written and visual data contained in this document reflect the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

This manual contains English, French, Spanish; MM 309319

International Offices: Belgium, Korea, China, Japan

Graco Headquarters: Minneapolis

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

www.graco.com

3/2001, Revised 9/2007

8 309319

Loading...

Loading...