Page 1

Instructions–Parts List

1:1 RATIO

TRITONR 308

Diaphragm Pump

Used to pump waterborne and solvent–based paints and catalysts. For

professional use only.

115 psi (0.8 MPa, 8 bar) Maximum Fluid Working Pressure

115 psi (0.8 MPa, 8 bar) Maximum Air Input Pressure

Part No. 233500 Aluminum Pump, Series D, npt threads

Part No. 233501 Stainless Steel Pump, Series C, npt threads

Part No. 233776 Aluminum Pump, Series C, BSPP threads

Part No. 233777 Stainless Steel, Series C, BSPP threads

U.S. and Foreign Patents Pending

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

309303V

ENG

Part No. 233501 Shown

ti1029a

Page 2

Table of Contents

Safety Warnings 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service

Remove the Fluid and Side Covers 14. . . . . . . . . . .

Ball Check Repair 16. . . . . . . . . . . . . . . . . . . . . . . . . .

Diaphragm Repair 17. . . . . . . . . . . . . . . . . . . . . . . . . .

Air Valve Repair 18. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shaft Repair 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Data 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dimensions 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Graco Standard Warranty 26. . . . . . . . . . . . . . . . . . . . . .

Graco Information 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Symbols

Warning Symbol

WARNING

This symbol alerts you to the possibility of serious

injury or death if you do not follow the instructions.

Caution Symbol

CAUTION

This symbol alerts you to the possibility of damage to

or destruction of equipment if you do not follow the

instructions.

2 309303

Page 3

WARNING

EQUIPMENT MISUSE HAZARD

INSTRUCTIONS

Equipment misuse can cause the equipment to rupture, malfunction, or start unexpectedly and result

in a serious injury.

This equipment is for professional use only.

Read all instruction manuals, tags, and labels before operating the equipment.

Use the equipment only for its intended purpose. If you are not sure, call your Graco distributor.

Do not alter or modify this equipment. Use only genuine Graco parts and accessories.

Check equipment daily. Repair or replace worn or damaged parts immediately.

Do not exceed the maximum working pressure of the lowest rated component in your system. This

equipment has a 115 psi (0.8 MPa, 8 bar) maximum working pressure at 115 psi (0.8 MPa, 8

bar) maximum incoming air pressure.

Use fluids and solvents which are compatible with the equipment wetted parts. Refer to the Tech-

nical Data section of all equipment manuals. Read the fluid and solvent manufacturer’s warnings.

Aluminum pumps only: Never use 1.1.1–trichloroethane, methylene chloride, other halogenated

hydrocarbon solvents or fluids containing such solvents in pressurized aluminum equipment. Such

use could result in a chemical reaction, with the possibility of explosion.

Do not use hoses to pull equipment.

Route hoses away from traffic areas, sharp edges, moving parts, and hot surfaces. Do not expose

Graco hoses to temperatures above 180F (82C) or below –40F (–40C).

Wear hearing protection when operating this equipment.

Comply with all applicable local, state, and national fire, electrical, and safety regulations.

309303 3

Page 4

WARNING

FIRE AND EXPLOSION HAZARD

Improper grounding, poor air ventilation, open flames, or sparks can cause a hazardous condition and

result in fire or explosion and serious injury.

Ground the equipment. Refer to Grounding on page 7.

If there is any static sparking or you feel an electric shock while using this equipment, stop pump-

ing immediately. Do not use the equipment until you identify and correct the problem.

Provide fresh air ventilation to avoid the buildup of flammable fumes from solvents or the fluid

being pumped.

Keep the work area free of debris, including solvent, rags, and gasoline.

Electrically disconnect all equipment in the work area.

Extinguish all open flames or pilot lights in the work area.

Do not smoke in the work area.

Do not turn on or off any light switch in the work area while operating or if fumes are present.

Do not operate a gasoline engine in the work area.

4 309303

Page 5

WARNING

PRESSURIZED FLUID HAZARD

Spray from the gun, hose leaks, or ruptured components can splash fluid in the eyes or on the skin

and cause serious injury.

Do not stop or deflect fluid leaks with your hand, glove, or rag.

Follow the Pressure Relief Procedure on page 11 before cleaning, checking, or servicing the

equipment.

Tighten all fluid connections before each use.

Check the hoses, tubes, and couplings daily. Replace parts immediately if worn, damaged, or

loose. Permanently coupled hoses cannot be repaired.

TOXIC FLUID HAZARD

Hazardous fluids or toxic fumes can cause a serious injury or death if splashed in the eyes or on the

skin, swallowed, or inhaled.

Know the specific hazards of the fluid you are using. Read the fluid manufacturer’s warnings.

Store hazardous fluid in an approved container. Dispose of the hazardous fluid according to all

local, state, and national guidelines.

Wear appropriate protective clothing, gloves, eyewear, and respirator.

If the diaphragm fails, the fluid is exhausted along with the air.

309303 5

Page 6

Installation

General Information

Fig. 2 shows a wall mounted HVLP spray applica-

tion. It is only a guide for selecting and installing

system components. Contact your Graco distributor

for assistance in planning a system to suit your

needs.

Always use Genuine Graco Parts and Accessories,

available from your Graco distributor. If you supply

your own accessories, be sure they are adequately

sized and pressure rated for your system.

WARNING

FIRE AND EXPLOSION HAZARD

To prevent hazardous concentrations of

toxic and/or flammable vapors, spray

only in a properly ventilated spray booth.

Never operate the spray gun unless

ventilation fans are operating.

Check and follow all of the national,

state, and local codes regarding air

exhaust velocity requirements.

Use a compatible, liquid thread sealant on all male

threads. Tighten all connections firmly to avoid air

or fluid leaks.

NOTE: On all npt threads, tighten to 2–3 turns past

finger tight.

Reference numbers and letters in parentheses refer

to the callouts in the figures and the parts lists on

pages 23–22.

In a spray system, ventilate the spray booth.

Tightening Threaded Fasteners Before

First Use

NOTE: Before using pump, loosen fluid cover screws

(38) 1–2 turns and then retorque to 13.6 Nm

(10 ft–lb).

See the Service section for torque specifications.

After unpacking the pump, and before using it for

the first time, check and retorque all external fas-

teners.

WARNING

TOXIC FLUID HAZARD

Hazardous fluid or toxic fumes can

cause serious injury or death if splashed

in the eyes or on the skin, inhaled, or

swallowed.

1. Read TOXIC FLUID HAZARD on page 5.

2. Use fluids and solvents which are compatible

with the equipment wetted parts. Refer to the

Technical Data section of all equipment manuals. Read the fluid and solvent manufacturer’s

warnings.

Mounting the Pump

Mount the pump in a well-ventilated area, with

sufficient clearance on all sides for operator access

and servicing.

Be sure the mounting can support the weight of the

pump, hoses, and accessories, as well as the

stress caused during operation.

The pump may be mounted vertically or horizontal-

ly. Be sure the pump is level in all directions.

After the first day of operation, retorque the fasten-

ers.

As a general guideline, retorque fasteners every

two months.

6 309303

Wall, pail, stand, or portable cart mounting kits are

available from Graco. For other mountings, be sure

the pump is adequately secured. The pump has

two mounting holes for 0.35 in. (9 mm) screws. See

the Dimension drawing on page 25.

Page 7

Grounding

Installation

WARNING

FIRE AND EXPLOSION HAZARD

This pump must be grounded. Before

operating the pump, ground the system

as explained below. Also read the section FIRE AND EXPLOSION HAZARD

on page 4.

35

Y

To reduce the risk of static sparking, ground the pump

and all other equipment used or located in the pumping

area. Check your local electrical code for detailed

grounding instructions for your area and type of equipment.

Ground all of this equipment:

Pump: Attach a ground wire (Y) to the pump’s

grounding screw (35) and secure with the screw, as

shown in Fig. 1. Connect the clamp end of the

ground wire to a true earth ground. Order Part No.

238909 Ground Wire and Clamp.

ti1030b

Fig. 1

Air and fluid hoses: Use only electrically conductive

hoses.

Air compressor: Follow the manufacturer’s recom-

mendations.

Solvent pails used when flushing: Follow your local

code. Use only metal pails, which are conductive.

Do not place the pail on a non-conductive surface,

such as paper or cardboard, which interrupts the

grounding continuity.

Fluid supply container: Follow your local code.

309303 7

Page 8

Installation

Air Line

WARNING

A bleed-type master air valve (B) is required in your

system to relieve air trapped between this valve

and the pump. See Fig. 2. Trapped air can cause

the pump to cycle unexpectedly, which could result

in serious injury, including splashing in the eyes or

on the skin, injury from moving parts, or contamination from hazardous fluids.

1. Install the air line accessories as shown in Fig. 2.

Mount these accessories on the wall or on a

bracket. Be sure the air line supplying the accessories is electrically conductive.

a. The fluid pressure can be controlled in two

ways, either by controlling the air into the

pump with the air regulator (F) or the fluid out

of the pump with the fluid regulator (H).

b. Locate a bleed-type master air valve (B) close

to the pump, to relieve trapped air. See the

WARNING at left. Locate another air valve (E)

upstream from all air line accessories, to

isolate them during cleaning and repair.

c. Install an air line filter (D) to remove harmful

contaminants such as dirt, moisture, and oil

from the compressed air supply.

2. The air valve does not require lubrication.

3. Install an electrically conductive, flexible air hose

(C) between the accessories and the pump air inlet

(T). Use a minimum 1/4” (6.3 mm) ID air hose.

Screw an air line quick disconnect coupler (V) onto

the end of the air hose and screw the mating fitting

into the pump air inlet snugly. Do not connect the

coupler to the fitting yet.

8 309303

Page 9

Installation

Wall Mount HVLP Spray Installation Shown

KEY

A TRITON 308 Pump

B Bleed-type master air valve

(required for pump)

C Air supply line

D Air line filter

E Air line shutoff valve

F Pump air regulator

G Gun air regulator (used in spray system only)

H Fluid pressure regulator (used in spray

system only)

J Drain/circulation valve

K Drain tube

L Suction tube

M Pump fluid inlet

N Pump fluid outlet

P Fluid hose (shown connected to gun in spray

system)

R Gun air hose (used in spray system only)

S Spray gun (used in spray system only)

T Pump air inlet

U Agitator (used in spray system only)

V Air line quick disconnect

Y Ground wire

B

V

C

S

H

DE

J

R

Y

P

L

U

Y

K

J

H

N

ti1020a

K

G

T

F

A

M

Fig. 2

L

B

ti1007a

309303 9

Page 10

Installation

Fluid Suction Line

Screw the suction line (L) into the pump inlet (M)

snugly. Use a compatible liquid thread sealant on

connections to prevent air from getting into the fluid

line.

Do not pressure feed this pump.

See the Technical Data on page 24 for maximum

suction lift.

Use an agitator (U) to prevent fluid from settling

out. Part No. 245081 Agitator Kit (accessory) is

available.

Fluid Outlet Line

WARNING

A fluid drain valve (J) is required in your system to

relieve pressure in the hose if it is plugged. See

Fig. 2. The drain valve reduces the risk of serious

injury, including splashing in the eyes or on the

skin, or contamination from hazardous fluids when

relieving pressure. Install the valve close to the

pump fluid outlet. To use the valve as a circulation

valve, connect a tube (K) between the valve and

pail.

CAUTION

Some systems may require installation of a pressure

relief valve at the pump outlet to prevent overpressurization and rupture of the pump or hose.

Thermal expansion of fluid in the outlet line can

cause overpressurization. This can occur when using

long fluid lines exposed to sunlight or ambient heat,

or when pumping from a cool to a warm area (for

example, from an underground tank).

Overpressurization can also occur if the pump is

being used to feed fluid to a piston pump, and the

intake valve of the piston pump does not close,

causing fluid to back up in the outlet line.

Use electrically conductive fluid hoses (P). Screw

the fluid fitting into the pump outlet (N) snugly.

Install a fluid regulator (H) at the pump fluid outlet

to control fluid pressure, if desired. See Air Line,

step 1a, for another method of controlling pressure.

Install a fluid drain valve (J) near the fluid outlet.

See the WARNING at left.

Flush the Pump Before First Use

The pump was tested in lightweight oil. If the oil could

contaminate the fluid you are pumping, flush the pump

thoroughly with a compatible solvent. Follow the steps

under Starting and Adjusting the Pump on page 11.

10 309303

Page 11

Operation

Pressure Relief Procedure

WARNING

The system remains pressurized until pressure is

manually relieved. To reduce the risk of serious

injury from pressurized fluid, accidental spray from

the gun, or splashing of any fluid, follow this procedure whenever you

Stop spraying

Are instructed to relieve pressure

Check or service any system equipment

Install, clean, or change spray nozzles

1. Shut off the bleed-type air valve (B).

2. In a spray system, hold the gun (S) firmly against a

grounded metal pail and trigger the gun to relieve

the fluid pressure.

3. Place the drain tube (K) in a waste pail. Open the

drain/circulation valve (J) to relieve any fluid pressure trapped in the system.

Starting and Adjusting the Pump

1.

Read Toxic Fluid Hazard

on page 5.

4. Check all fittings to be sure they are tight. Use a

compatible liquid thread sealant on all male

threads. Tighten the fluid inlet and outlet fittings

snugly. Do not overtighten the fittings.

NOTE: Before using he pump, re–torque fluid

cover screws (38) to 10 ft–lb (13.6 Nm).

5. Place the suction tube (L, if used) in the fluid to be

pumped.

6. Place the fluid hose (P) in a container.

7. Close the drain/circulation valve (J).

8. Close the pump air regulator (F). Open all bleedtype master air valves (B, E).

9. If the fluid hose has a dispensing device, hold it

open while continuing with the following step.

Slowly open the air regulator (F) until the pump

starts to cycle. Allow the pump to cycle slowly until

all air is pushed out of the lines and the pump is

primed.

If you are flushing, run the pump long enough to

thoroughly clean the pump and hoses. Close the

air regulator. Remove the suction tube from the

solvent and place it in the fluid to be pumped.

Pump Shutdown

2.

3.

If lifting the pump, follow the Pres-

sure Relief Procedure above.

Be sure the pump is

properly grounded.

Read Fire and

Explosion Hazard

on page 4.

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure at left.

At the end of the work shift, flush the pump and relieve

pressure.

309303 11

Page 12

Maintenance

Tightening Threaded Connections

Before each use, check all hoses for wear or damage.

Replace as necessary. Check that all threaded connections are tight and leak-free.

NOTE: Periodically, re–torque fluid cover screws (38)

to 10 ft–lb (13.6 Nm).

Cleaning

Clean the outside of the equipment daily, using a soft

cloth and compatible solvent.

Clean the suction tube (L) and inlet strainer daily, using

a compatible solvent.

Clean the air filter (D) in your main air line at least

once a week.

Troubleshooting

WARNING

Storage

Before storing the pump, always flush it and relieve

pressure.

Preventive Maintenance Schedule

Establish a preventive maintenance schedule, based

on the pump’s service history. This is especially important for prevention of spills or leakage due to diaphragm failure.

1. Relieve the pressure before checking or servicing

the equipment.

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 11.

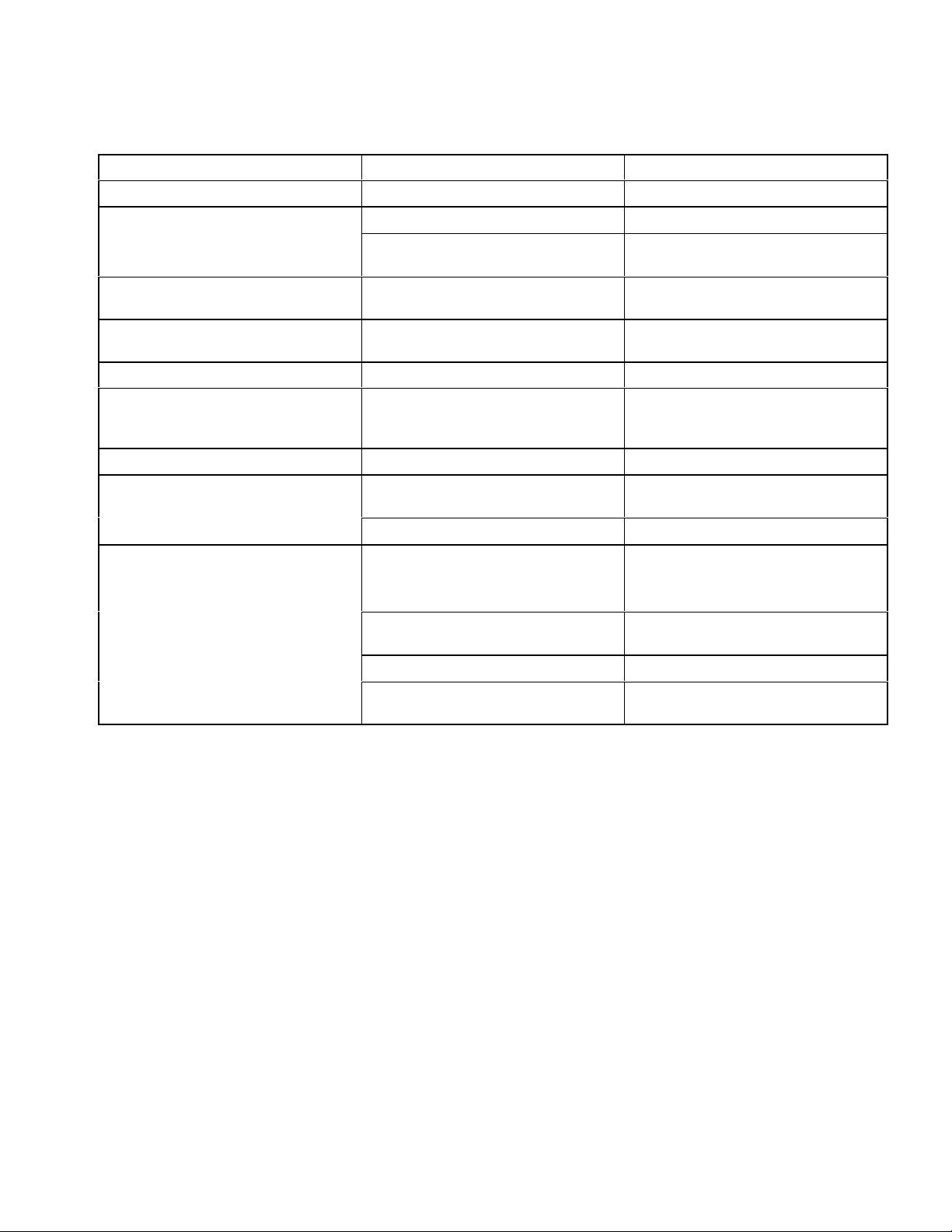

PROBLEM CAUSE SOLUTION

Pump will not run.

Closed air line valve. Open valve.

Inadequate air supply, or clogged/

restricted air line.

Clogged pump, fluid line, or spray

gun.

Stuck or damaged pump air valve. Disassemble and clean air valve.

Ruptured diaphragm. Replace diaphragms. See page 17.

Air valve plate installed incorrectly. Align plate with center housing. See

2. Check all possible problems and causes before

disassembling the pump.

Increase air supply. Do not exceed

maximum air inlet pressure.

Open or clear air line.

Clean air filter.

Clear, service. Flush regularly. Do

not allow fluid to set up in the pump

and lines.

Replace worn parts. See page 18.

Use filtered air.

page 19.

12 309303

Page 13

Troubleshooting

PROBLEM CAUSE SOLUTION

Pump runs sluggishly. Worn or damaged carriage o-rings. Service air valve. See page 18.

Pump runs erratically.

Clogged suction line or inlet strainer. Clear.

Sticking or leaking ball check

valves.

Pump runs too fast. Exhausted fluid supply. Refill fluid supply and prime pump.

Pump cycles at stall or fails to hold

pressure at stall.

Audible air leak. Worn air valve cup or plate. Service air valve. See page 18.

Air exhausting from the mounting

holes.

Fluid in the exhaust air. Ruptured diaphragm. Replace diaphragms. See page 17.

Air bubbles in fluid.

Poor finish or irregular spray pattern.

Worn ball check valves. Disassemble and clean ball checks.

Fluid covers are installed incorrectly. Align mounting holes in fluid covers

Loose suction line. Tighten. Use a compatible liquid

Ruptured diaphragm. Replace diaphragms. See page 17.

Incorrect fluid or air pressure at gun. See gun manual; read fluid

Fluid is too thin or too thick. Adjust fluid viscosity; read fluid

Dirty, worn, or damaged spray gun. Service gun.

Fluid is settling out. Use agitator. Order Part No. 245081

Disassemble and clean ball checks.

Replace worn parts. See page 16.

Replace worn parts. See page 16.

with holes in center housing. See

page 14.

thread sealant on connections.

manufacturer’s recommendations.

Use fluid regulator.

manufacturer’s recommendations.

Agitator Kit.

309303 13

Page 14

Service

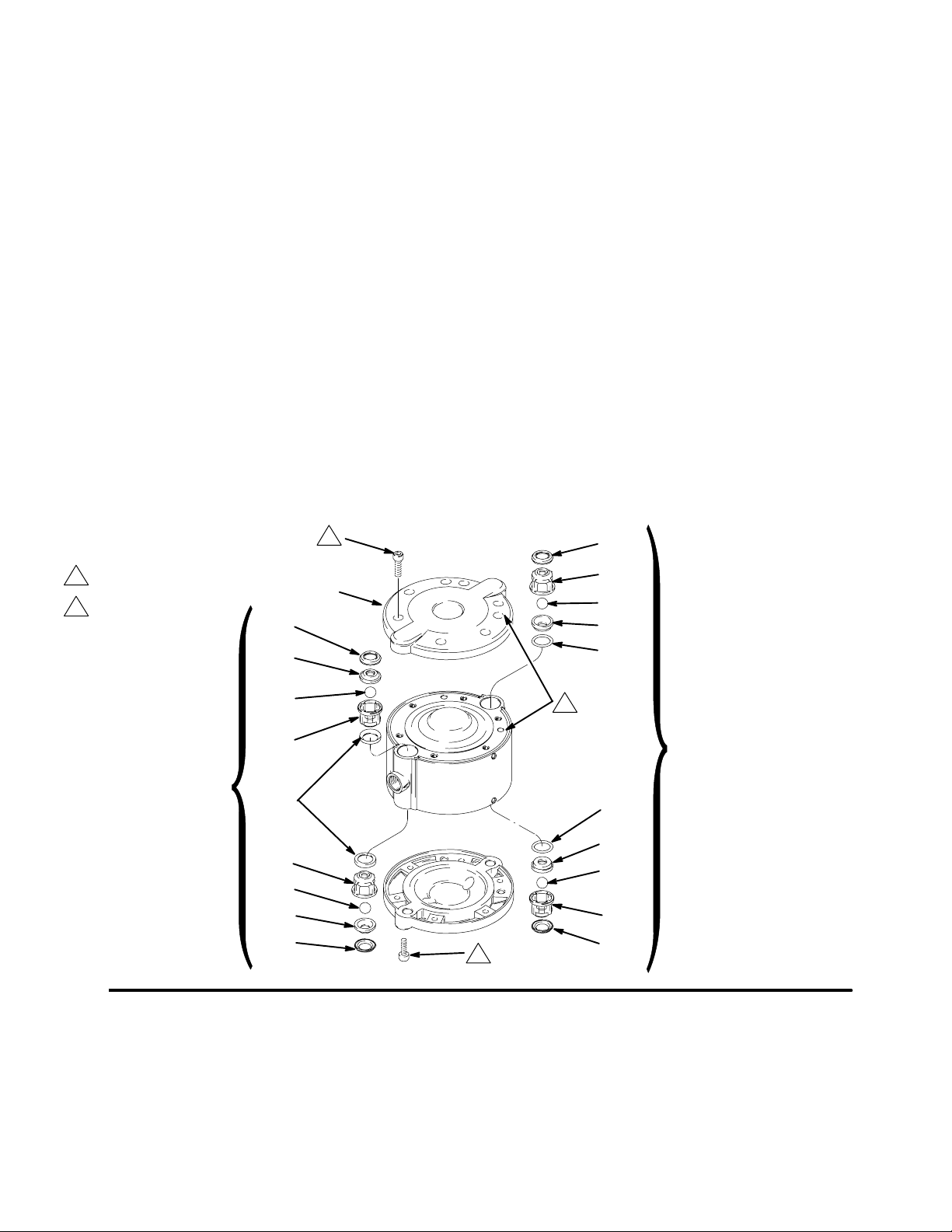

Remove the Fluid and Side Covers

Tools Required

Torque wrench

2.5 mm allen wrench

6 mm allen wrench

Adjustable wrench

Disassembly

WARNING

To reduce the risk of serious injury whenever you

are instructed to relieve pressure, always follow the

Pressure Relief Procedure on page 11.

1. Relieve the pressure.

2. Disconnect the hoses and ground wire.

3. Remove the pump from its mounting.

CAUTION

Be careful that the ball checks do not fall out when

you remove the fluid covers (32).

4. Remove the six screws (38) and top cover (32)

from the center housing (1). Remove the ball

check seals (24). Remove the bottom cover and

seals.

NOTE: Always replace the ball check seals (24) whenever the fluid covers (32) are removed. These seals

are included in the four repair kits.

NOTE: Perform step 5 only if you are servicing the air

valve or the diaphragm shaft.

5. Remove the two screws (39) and take off the side

cover (31) and felt dampener (29).

14 309303

Page 15

Service

Remove the Fluid and Side Covers

(continued)

Reassembly

1. Clean all parts and inspect for wear or damage.

Replace parts as needed.

2. If necessary, reinstall the felt dampener (29) and

side cover (31). Torque the screws (39) to 28 in-lb

(3.1 Nm).

3. Install new ball check seals (24).

4. Place the fluid covers (32) on the housing (1).

Align the mounting holes (H) in the fluid covers

with the holes in the housing. Install the screws

(38) loosely, then torque oppositely and evenly to

10 ft-lb (13.6 Nm).

5. Reinstall the pump on its mounting.

6. Reconnect the ground wire and hoses.

1 3

28 in-lb (3.1 Nm)

2

38

3

32

1

24

4

10 ft-lb (13.6 Nm)Align

4 Replace seals whenever

cover (32) is removed.

H

1

24

4

H

1

39

2

31, 29

Fig. 3

38

H

1

32

3

ti1031a

309303 15

Page 16

Service

Ball Check Repair

Tools Required

O-ring pick

Disassembly

NOTE: Ball Check Repair Kit 245067 is available.

Parts included in the kit are marked with a double

dagger, for example (21). Use all the parts in the kit

for the best results.

1. Remove the fluid covers. See page 14.

2. Remove the inlet and outlet ball checks. Note that

the orientation of the inlet check parts is different

from the outlet check parts. See Fig. 4.

NOTE: If the inlet seats (26) are difficult to remove,

drive them out from the opposite side using a brass

rod and hammer.

3. Clean all parts and inspect for wear or damage.

Replace parts as needed.

1

Reassembly

1. Reinstall the inlet and outlet ball checks on one

side of the pump. The inlet and outlet checks are

assembled differently. Install the parts exactly as

shown in Fig. 4.

2. Install one cover (32) loosely, to prevent the ball

checks from falling out. See page 14.

3. Turn the pump over and install the ball checks on

the opposite side, exactly as shown.

4. Reinstall the fluid covers. See page 14.

24

10 ft-lb (13.6 Nm)

1

Align

2

Outlet Ball Checks

Fig. 4

24

23

21

27

22

27

21

23

24

32

27

21

26

25

2

Inlet Ball Checks

25

26

21

27

1

24

ti1032a

16 309303

Page 17

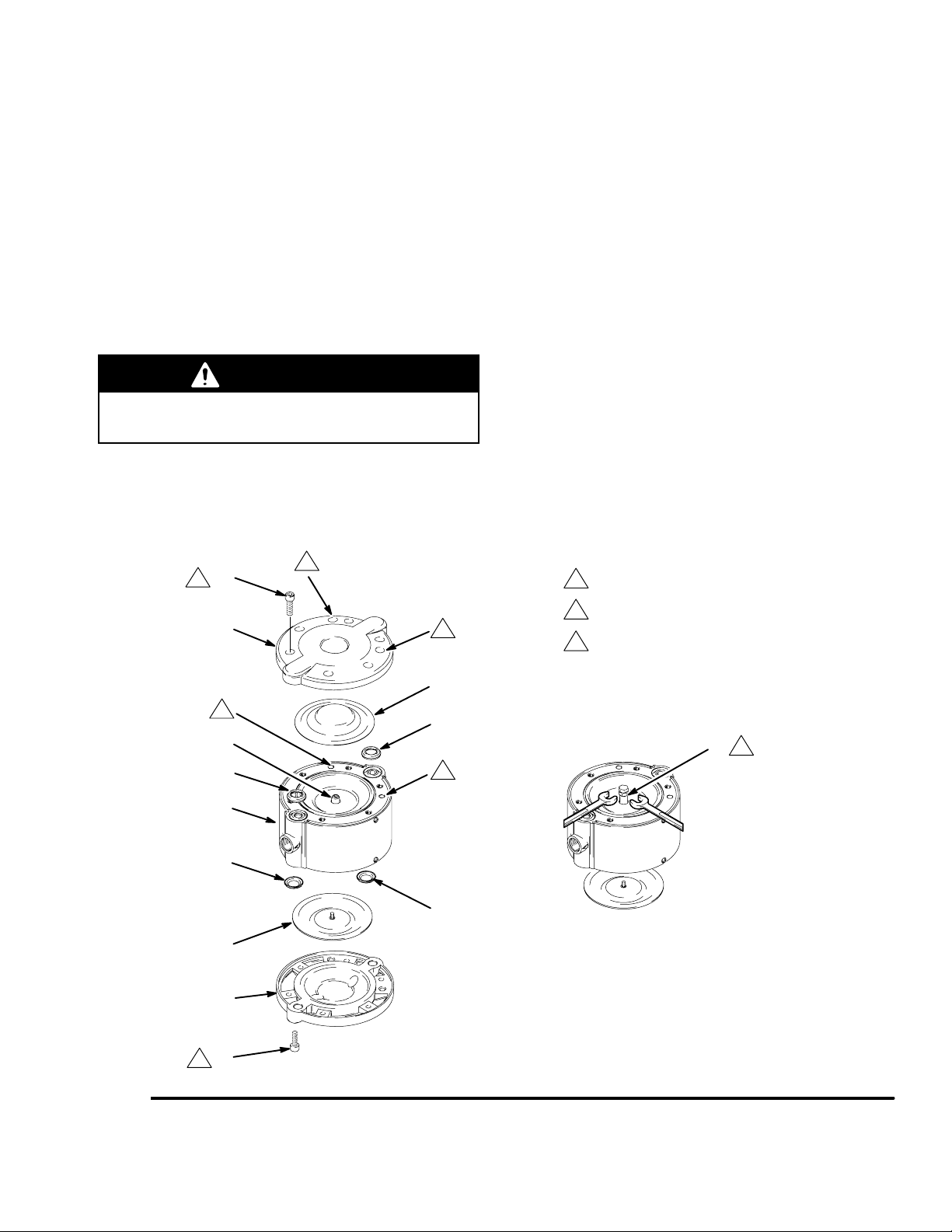

Service

Diaphragm Repair

Tools Required

M8 bolt

M8 hexnut

Adjustable wrench, or vise

NOTE: Diaphragm Repair Kit 245065 is available.

Parts included in the kit are marked with an asterisk,

for example (6*). Always replace both diaphragms for

the best results.

1. Remove the fluid covers. See page 14.

WARNING

Wear gloves when removing the diaphragms to

reduce the risk of cuts.

2. Unscrew one diaphragm (6) from the shaft (5) by

hand. See Fig. 5.

3. Thread an M8 hexnut (A) onto an M8 bolt. Screw

the bolt into the shaft (5) until it bottoms out.

Thread the nut down to the shaft to lock it.

4. Hold the nut with a wrench or vise to keep the

shaft from turning. Unscrew the other diaphragm

(6) by hand.

NOTE: If you cannot remove the second diaphragm,

refer to Shaft Repair Disassembly on page 20.

Reassembly

1. Screw the new diaphragms (6*) into the shaft (5)

handtight.

2. Replace the ball check seals (24*) with the new

seals in the kit.

3. Reinstall the fluid covers. See page 14.

38

1

32

2

2

10 ft-lb (13.6 Nm)

1

Align

2

3

Use M8 bolt and nut to keep shaft from turning.

6*

2

24*

*24

5

2

A 3

1

*24

24*

*6

32

Fig. 5

38

1

ti1033a

309303 17

Page 18

Service

Air Valve Repair

Tools Required

3 mm allen wrench

Needlenose pliers

Retaining ring removal tool

O-ring pick

Disassembly

NOTE: Air Valve Repair Kit 245066 is available. Parts

included in the kit are marked with a dagger, for example (8). Use all the parts in the kit for the best results.

1. Remove the side cover (31) and felt dampener

(29).

2. Remove the four screws (36), air valve cover (17),

and gasket (16). See Fig. 7.

3. See Fig. 6. Note the orientation of the air valve

plate (13) relative to the fluid outlet arrow, with

“POM” marking up. Pull the plate out of the center

housing (1). Remove the three o-rings (14, 15) and

the two o–rings (43) from the plate. See Fig. 7.

4. Remove the air valve cup (12) from the center

housing (1).

5. Remove the retaining rings (11) and plug (9) from

both sides, and slide the carriage (7) from the

center housing (1). Remove the o-rings (8, 10)

from the carriage and the plug.

6. Clean all parts and inspect for wear or damage.

Replace parts as needed.

Orient “POM” marking on air

1

valve plate as shown in

relation to fluid outlet arrow.

1

“POM”

marking

fluid outlet

arrow

1

13

ti15226a

Fig. 6

18 309303

Page 19

Service

Air Valve Repair (continued)

Reassembly

1. Lubricate the o-rings (8) and install them on the

carriage (7). Slide the carriage into the center

housing (1) so the notch faces out, as shown in

Fig. 7.

2. Lubricate each o-ring (10) and install them on the

plugs (9). Insert a plug in each side to secure the

carriage (7). Install the retaining rings (11) to hold

these parts in place.

3. Install the air valve cup (12) in the notch of the

carriage (7) so the open side faces out.

4. Install two o–rings (43) in the counterbore of the air

motor.

1

5. Lubricate the large o-ring (15) and the two small

o-rings (14) and install them on the air valve plate

(13). Align the point on the plate with the arrow

on the center housing (1) as shown in Fig. 6.

Install the plate in the housing.

6. Install the gasket (16). Note the orientation.

7. Reinstall the air valve cover (17) and screws (36).

Torque the screws to 28 in-lb (3.1 Nm).

8. Replace the ball check seals (24) with the new

seals in the kit.

9. Reinstall the felt dampener (29) and side cover

(31). See page 14.

Lubricate

2

210

9

11

28 in-lb (3.1 Nm)

4

Align. See Fig. 6.

5

2

11

Fig. 7

8

9

7

10

12

8

2

14

2

15

2

13

5

16

17

36

4

29

31

4

39

2

43

ti1044d

309303 19

Page 20

Service

Shaft Repair

Tools Required

Needlenose pliers

O-ring pick

Retaining ring removal tool

Vise with soft jaws

Disassembly

NOTE: Shaft Repair Kit 24A155 is available. Parts

included in the kit are marked with a star, for example

(5). Use all the parts in the kit for the best results.

NOTE: Shaft and Bearing Repair Kit is available. Parts

included in the kit are marked with a symbol, for example (44). Use all the parts in the kit for the best

results.

1. Remove the fluid covers. See page 14. Remove

the side cover (31) and felt dampener (29).

2. Disassemble the air valve. See page 18.

3. Remove the diaphragms (6). See page 17.

7. If you could not remove one diaphragm from the

shaft, place the shaft in a vise with soft jaws.

Unscrew the remaining diaphragm (6) from the

shaft (5) by hand.

8. Clean all parts and inspect for wear or damage.

Replace parts as needed.

Reassembly

1. Screw one diaphragm (6) into the shaft (5)

handtight.

2. Lubricate the o–rings (45, 46) and install on the

bearings (44). Install the bearings in the center

housing (1) and secure with the retaining rings

(47).

3. Place the valve carriage (3) in the center housing

(1). Grease the shaft (5) and slide it through the

center housing and valve carriage.

4. Install the retaining rings (4) on the shaft (5).

4. Remove the retaining rings (4) from the shaft (5).

See Fig. 8.

5. Slide the shaft (5) out of the center housing (1).

Remove the valve carriage (3) from the housing.

6. Remove the retaining rings (47) and bearings (44).

Remove the o–rings (45, 46) from the bearings.

CAUTION

Do not grip the shaft with tools that can scratch or

damage the shaft, such as wrenches or pliers.

5. Screw the second diaphragm (6) into the shaft

(5) handtight.

6. Reassemble the air valve and carriage (see page

18), using the new o-rings (8, 10, 14, 15)

and gasket (16) included in the shaft repair kit.

7. Replace the ball check seals (24) with the new

seals in the kit.

8. Reinstall the fluid covers. See page 14.

20 309303

Page 21

Shaft Repair (continued)

38

1

32

47

46

2

5

2

Service

3

6

44

45

2

24

10 ft-lb (13.6 Nm).

1

Lubricate.

2

Align.

3

28 in-lb (3.1 Nm).

4

Align. See Fig. 6.

5

10

2

11

Fig. 8

24

3

1

8

2

8

2

7

9

45

24

2

46

44

47

32

38

1

3

4

12

14

2

15

2

13

5

4

17

36

29

2

16

24

31

6

43

3

39

4

ti1035E

309303 21

Page 22

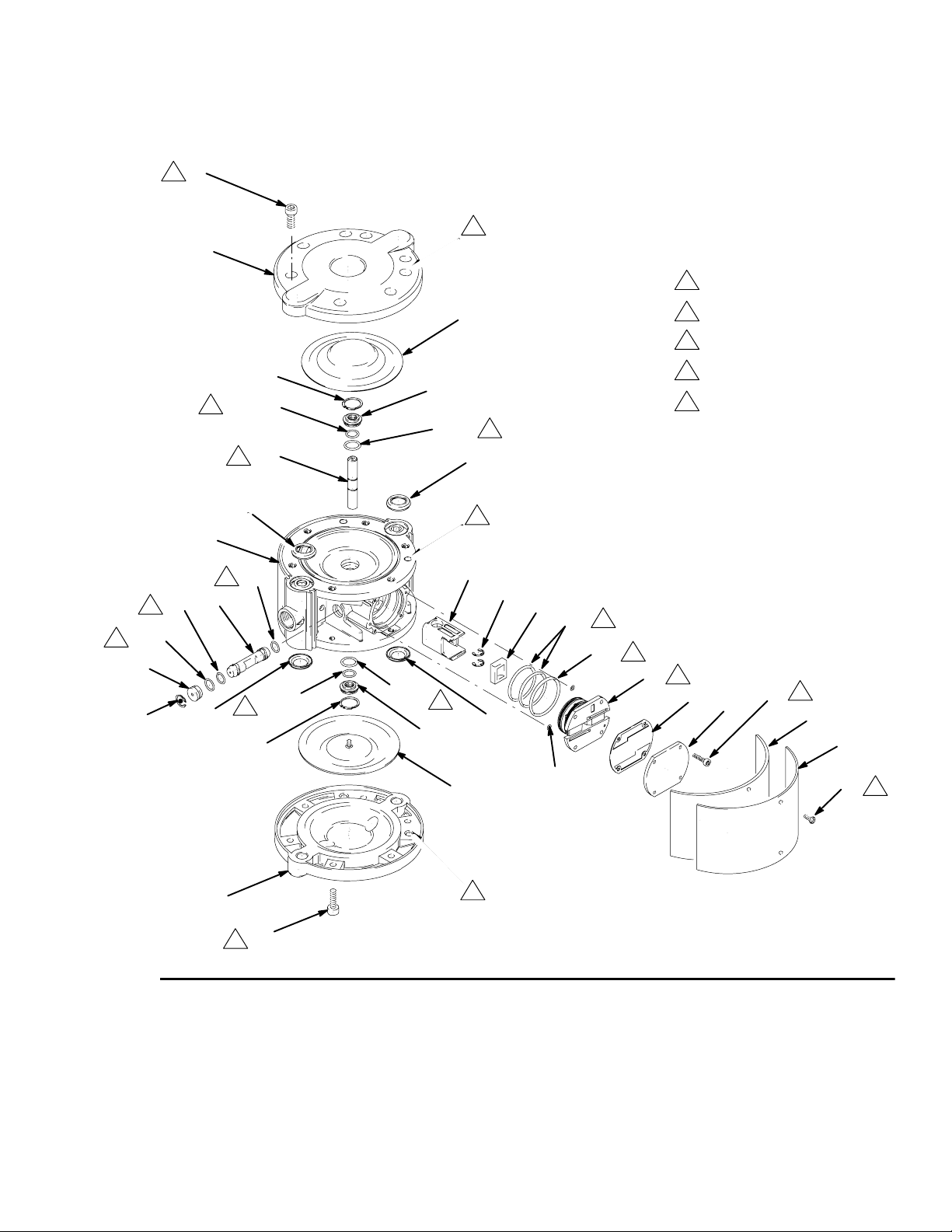

Parts

Part No. 233500 Aluminum Pump, Series D, npt threads

Part No. 233501 Stainless Steel Pump, Series C, npt threads (Shown)

Part No. 233776 Aluminum Pump, Series C, BSPP threads

Part No. 233777 Stainless Steel Pump, Series C, BSPP threads

38

32

Detail of Grounding Screw

*6

33

30

40

37

20

19

47

5

44

24*

27

21

26

25

35

28

10

11

8

9

*24

18

7

22

27

21

23

32

45

46

47

46

45

44

ti1030b

1

3

4

12

14

15

13

16

17

36

43

29

31

6*

39

ti1036F

22 309303

Page 23

NOTE: Purchase items 36–39 locally.

Parts

Ref.

No. Part No. Description Qty.

1 15J732 HOUSING, center;

for Part No. 233500; aluminum 1

198894 HOUSING, center;

for Part No. 233501;

stainless steel 1

198892 HOUSING, center;

for Part No. 233776; aluminum 1

197679 HOUSING, center;

for Part No. 233777;

stainless steel 1

3 197645 CARRIAGE, valve 1

4 197646 RING, retaining, shaft 2

5 n/a SHAFT, diaphragm 1

6* 197648 DIAPHRAGM; PTFE

composite 2

7 197649 CARRIAGE 1

8 197650 O-RING, carriage 2

9 197651 PLUG, carriage 2

10 197652 O-RING, plug 2

11 197653 RING, retaining, carriage 2

12 197654 CUP, valve, air 1

13 197655 PLATE, valve, air 1

14 197656 O-RING, valve, air 2

15 197657 O-RING, valve, air 1

16 197658 GASKET, valve, air 1

17 197659 COVER, valve, air 1

18 197660 VALVE, safety, air 1

19 197661 PLATE, dampener; neoprene 1

20 197662 DAMPENER; steel 1

21 197663 BALL; acetal 4

22 197664 SEAL, valve, outlet; acetal 2

23 197665 SEAT, valve, outlet;

stainless steel 2

24* 197666 SEAL, ball check; nylon 4

25 197667 O-RING, valve, inlet;

fluoroelastomer 2

26 197668 SEAT, valve, inlet;

stainless steel 2

27 197669 GUIDE, ball; acetal 4

28 197670 DAMPENER, felt, air inlet side 1

29 197671 DAMPENER, felt, side 1

30 16A659 COVER, air inlet side 1

31 16A661 COVER, side 1

Ref.

No. Part No. Description Qty.

32 197674 COVER, housing;

for Part Nos. 233500 and 233776;

aluminum 2

197680 COVER, housing;

for Part Nos. 233501 and 233777;

stainless steel 2

33 198832 FITTING, air inlet; for Part Nos.

233500 and 233501 1

198831 FITTING, air inlet; for Part Nos.

233776 and 233777 1

35 116343 SCREW, grounding; M5 x 10 1

36 116474 SCREW, cap, socket-hd;

M4 x 20 4

37 116475 SCREW, cap, socket-hd;

M4 x 12 2

38 117367 SCREW, cap, socket-hd;

M8 x 18; for Part Nos.

233500 and 233776 12

15D128 SCREW, same as above; for

Part Nos. 233501 and 233777 12

39 116595 SCREW, button-hd; M4 x 12 2

40 188621 LABEL, warning 1

43 157628 O–RING 2

44 n/a BEARING 2

45 n/a O–RING, nitrile 2

46 n/a O–RING, nitrile 2

47 n/a RING, retaining 2

* These parts are only available by purchasing Dia-

phragm Repair Kit 245065.

These parts are only available by purchasing Air

Valve Repair Kit 245066.

These parts are only available by purchasing Ball

Check Repair Kit 245067.

These parts are only available by purchasing Shaft

and Bearing Repair Kit 24A155.

Replacement Danger and Warning labels, tags and

cards are available at no cost.

This part available in 10–pack kit 15D564 or in Ball

Check Repair kit 245067

309303 23

Page 24

Technical Data

Category Data

Maximum fluid working

pressure

Air pressure operating range 12 to 115 psi (.08 to 0.8 MPa, 0.8 to 8.0 bar)

Ratio 1:1

Maximum free flow delivery 8.5 gal./min (32 l/min)

Operating fluid temperature

range

Maximum suction lift 16 ft (4.8 m) dry; 22 ft (6.5 m) wet

Weight Part Nos. 233500, 233776: 9 lb (4 kg)

Wetted parts Part Nos. 233500, 233776: Aluminum, Stainless Steel, Acetal, Nylon, PTFE,

115 psi (0.8 MPa, 8.0 bar)

50 to 176 C (10 to 80 C)

Part Nos. 233501, 233777: 14 lb (6.4 kg)

fluoroelastomer

Part Nos. 233501, 233777: Stainless Steel, Acetal, Nylon, PTFE, fluoroelastomer

Sound Pressure Levels in dB(A)*

(measured at 1 m from unit)

Input Air Pressures Sound Pressure

40 psi (0.28 MPa, 2.8 bar) 69.1

60 psi (0.42 MPa, 4.2 bar) 72.1

Performance Chart

To find Fluid Outlet Pressure (psi/MPa/bar) at a specific fluid flow

(lpm/gpm) and operating air pressure (psi/MPa/bar):

1. Locate desired flow along bottom of chart.

2. Follow vertical line up to intersection with selected fluid outlet

pressure curve (black). Follow left to scale to read fluid outlet

pressure.

A 115 psi (0.8 MPa, 8 bar) air pressure

B 90 psi (0.6 MPa, 6 bar) air pressure

C 60 psi (0.4 MPa, 4 bar) air pressure

D 30 psi (0.2 MPa, 2 bar) air pressure

Test Fluid: No. 10 Weight Oil

Fluid Outlet Pressure

psi

MPa, bar

120

0.8, 8.0

0.7, 7.0

0.6, 6.0

0.4, 4.0

0.3, 3.0

FLUID PRESSURE

0.14, 1.4

gpm

l/min

A

100

B

80

60

C

40

D

20

0

012345678

cycles per minute

24

47 71

3.8 15.2 19.0 26.6

94

118

141 165 188

22.87.6 11.4

30.4

Sound Power Levels in dB(A)*

(tested in accordance with ISO 3744)

Input Air Pressures Sound Power

40 psi (0.28 MPa, 2.8 bar) 80.8

60 psi (0.42 MPa, 4.2 bar) 83.7

To find Pump Air Consumption (l/min or scfm) at a specific fluid flow

(lpm/gpm) and air pressure (psi/MPa/bar):

1. Locate desired flow along bottom of chart.

2. Read vertical line up to intersection with selected air consumption

curve (dashes). Follow left to scale to read air consumption.

Air Consumption

scfm

l/min

224

196

168

140

112

84

56

AIR CONSUMPTION

28

gpm

l/min

24

8

7

6

5

4

3

2

1

0

012345678

cycles per minute

47 71

3.8 15.2 19.0 26.6

118

94 141 165 188

A

B

C

D

22.87.6 11.4

30.4

24 309303

Page 25

Dimensions

BOTTOM VIEW

1/4 npt or 1/4 BSPP Air Inlet

4.53 in.

(115 mm)

3/8 npt or 3/8 BSPP Fluid Outlet

Two 0.35 in. (9 mm) diameter

holes, for mounting pump

3/4 npt or M26 x 1.5

Fluid Inlet

SIDE VIEW

Aluminum

8.2 in.

(208 mm)

ti1037a

4.1 in.

(104 mm)

SIDE VIEW

SST

4.88 in.

(124 mm)

9.1 in.

(231.5 mm)

TI3265A

309303 25

Page 26

Graco Standard Warranty

Graco warrants all equipment manufactured by Graco and bearing its name to be free from defects in material and workmanship on the

date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty published by Graco,

Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be

defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by

faulty installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of non–Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of

Graco equipment with structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture,

installation, operation or maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for

verification of the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The

equipment will be returned to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect

in material or workmanship, repairs will be made at a reasonable charge, which charges may include the costs of parts, labor, and

transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT

NOT LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other

remedy (including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any

other incidental or consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the

date of sale.

Graco makes no warranty, and disclaims all implied warranties of merchantability and fitness for a particular purpose in connection

with accessories, equipment, materials or components sold but not manufactured by Graco. These items sold, but not manufactured

by Graco (such as electric motors, switches, hose, etc.), are subject to the warranty, if any, of their manufacturer. Graco will provide

purchaser with reasonable assistance in making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment

hereunder, or the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract,

breach of warranty, the negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings

entered into, given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires

exécutés, donnés ou intentés à la suite de ou en rapport, directement ou indirectement, avec les procedures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor, or call one of these numbers

to identify the distributor closest to you:

1–800–328–0211 Toll Free

612–623–6921

612–378–3505 Fax

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

Original instructions. This manual contains English. MM 309303

26 309303

International Offices: Belgium, China, Japan, Korea

Graco Headquarters: Minneapolis

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

Copyright 2001, Graco Inc. is registered to ISO 9001

www.graco.com

Revised 02/2011

Loading...

Loading...