Page 1

Instructions–Parts List

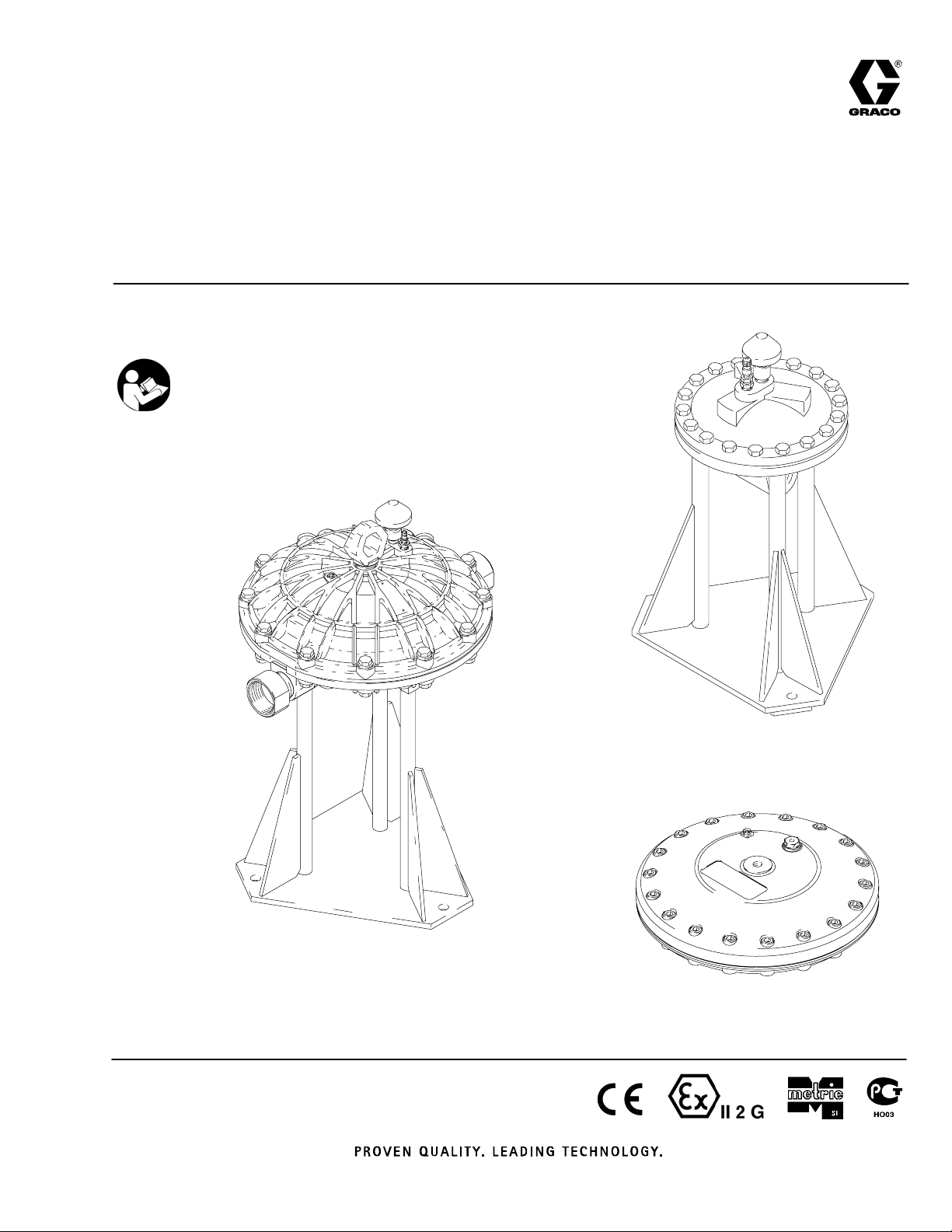

HIGH–FLO SERIES

307707ZAN

Surge Tanks

These tanks reduce fluid surging in a high– or medium–volume, low–pressure

fluid system. For professional use only.

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

ENG

Model 238983, Series C

on Surge Tank Stand Kit 218742

7287B

Model 220157, Series E

on Surge Tank Stand Kit 218742

7139A

Model 233736, Series A

TI1898B

Page 2

Table of Contents

Warnings 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation

All Models 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Models 238983, 238984, 238985,

238986, 238987, 238988, 218509, and 220157 6. .

Model 233736 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation

All Models 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Models 238983, 238984, 238985, 218509,

238985, 238986, 238987, 238988, and 220157 10.

Model 233736 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service

Models 218509, 220157 14. . . . . . . . . . . . . . . . . . . . .

Models 238983, 238984, 238985 15. . . . . . . . . . . . .

Model 233736 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

List of Models

Parts Drawings and Lists

Model 218509 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Model 220157 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Models 238983, 238984, 238985, 238986,

238987, 238988 19. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Model 233736 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dimensional Drawings 21. . . . . . . . . . . . . . . . . . . . . . . . .

Stand Mounting Hole Layout 22. . . . . . . . . . . . . . . . . . . .

Technical Data 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warranty 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Graco Information 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum Fluid

Part No. Series Description

238983,

238986

238984,

238987

238985,

238988

233736 A High volume, stainless steel, 1/4 bspp(f) air port, 3/4

218509 E High volume, carbon steel, 2 npt(f) inlet and outlet 600 psi (4.2 MPa, 42 bar)

220157 E Medium volume, electropolished stainless steel, 1.25

Accessory

218742 A Surge Tank Stand Kit (not used with Part No. 233736) n/a

C High volume, electropolished stainless steel, 2 npt(f) inlet

and outlet

C High volume, electropolished stainless steel, 2 in. sanitary

inlet and outlet (Tri–Clamp compatible)

C High volume, electropolished stainless steel, 1.5 in. sani-

tary inlet and outlet (Tri–Clamp compatible)

bspp(f) fluid port

npt(f) inlet, 1.25 npt(f) outlet

Working Pressure

300 psi (2.1 MPa, 21 bar)

300 psi (2.1 MPa, 21 bar)

300 psi (2.1 MPa, 21 bar)

360 psi (2.5 MPa, 25 bar)

600 psi (4.2 MPa, 42 bar)

2 307707

Page 3

Symbols

Warning Symbol

WARNING

This symbol alerts you to the possibility of serious

injury or death if you do not follow the instructions.

WARNING

EQUIPMENT MISUSE HAZARD

Equipment misuse can cause the equipment to rupture or malfunction and result in serious injury.

INSTRUCTIONS

This equipment is for professional use only.

Read all instruction manuals, tags, and labels before operating the equipment.

Use the equipment only for its intended purpose. If you are not sure, call your Graco distributor.

Do not alter or modify this equipment. Use only genuine Graco parts and accessories.

Check equipment daily. Repair or replace worn or damaged parts immediately.

Caution Symbol

CAUTION

This symbol alerts you to the possibility of damage to

or destruction of equipment if you do not follow the

instructions.

Do not exceed the maximum working pressure of the lowest rated component in your system. See

Technical Data on page 23.

Use fluids and solvents that are compatible with the equipment wetted parts. Refer to the

Technical Data section of all equipment manuals. Read the fluid and solvent manufacturer’s

warnings.

Route hoses away from traffic areas, sharp edges, moving parts, and hot surfaces. Do not expose

Graco hoses to temperatures above 82C (180F) or below –40C (–40F).

Wear hearing protection when operating this equipment.

Do not lift pressurized equipment.

Comply with all applicable local, state, and national fire, electrical, and safety regulations.

PRESSURIZED EQUIPMENT HAZARD

Spray from the gun, hose leaks or ruptured components can splash fluid in the eyes or on the skin and

cause serious injury.

Do not stop or deflect fluid leaks with your hand, body, glove or rag.

Follow the Pressure Relief Procedure on page 9 when: you are instructed to relieve pressure;

stop spraying; clean, check or service the equipment; and install or clean fluid nozzles.

Do not point the spray gun at anyone or at any part of the body.

Tighten all fluid connections before operating the equipment.

Check the hoses, tubes and couplings daily. Replace worn, damaged or loose parts immediately.

Permanently coupled hoses cannot be repaired; replace the entire hose.

3307707

Page 4

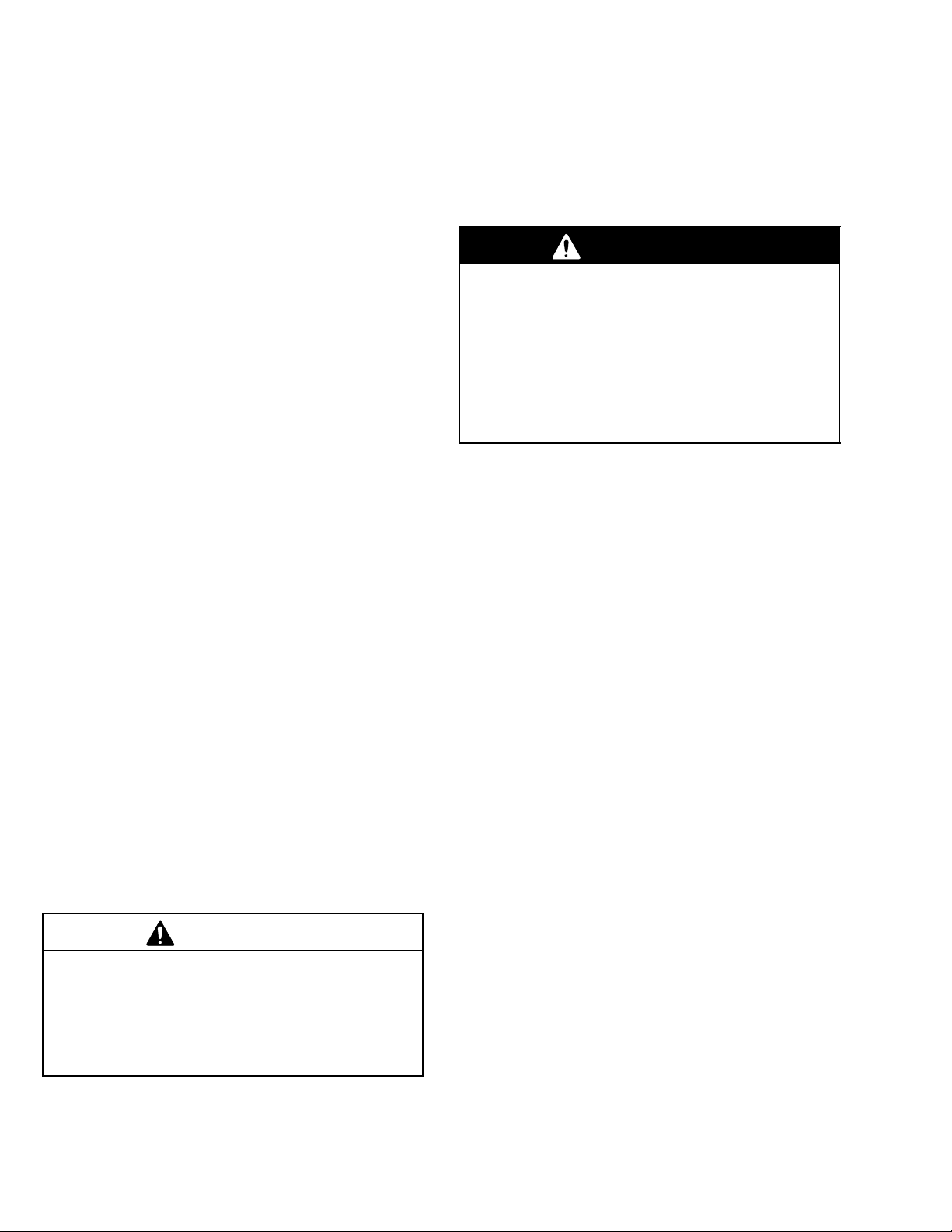

WARNING

FIRE AND EXPLOSION HAZARD

Improper grounding, poor ventilation, open flames or sparks can cause a hazardous condition and

result in a fire or explosion and serious injury.

Ground the equipment. See Grounding on page 5.

If there is any static sparking or you feel an electric shock while using this equipment, stop pump-

ing immediately. Do not use the equipment until you identify and correct the problem.

Provide fresh air ventilation to avoid the buildup of flammable fumes from solvents or the fluid

being pumped.

Keep the work area free of debris, including solvent, rags, and gasoline.

Electrically disconnect all equipment in the work area.

Extinguish all open flames or pilot lights in the work area.

Do not smoke in the work area.

Do not turn on or off any light switch in the work area while operating or if fumes are present.

Do not operate a gasoline engine in the work area.

Never use 1.1.1–trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or

fluids containing such solvents in pressurized aluminum equipment. Such use could result in a

chemical reaction, with the possibility of explosion.

TOXIC FLUID HAZARD

Hazardous fluid or toxic fumes can cause serious injury or death if splashed in the eyes or on the skin,

inhaled, or swallowed.

Know the specific hazards of the fluid you are using.

Store hazardous fluid in an approved container. Dispose of hazardous fluid according to all local,

state and national guidelines.

Always wear protective eyewear, gloves, clothing and respirator as recommended by the fluid and

solvent manufacturer.

Graco does not manufacture or supply the reactive chemical components that may be used in this

equipment and is not responsible for injury or property loss, damage, expense or claims (direct or

consequential) that arise from the use of such chemical components.

MOVING PARTS HAZARD

Moving parts, such as the air motor piston in the pump, can pinch or amputate your fingers.

Keep clear of all moving parts when starting or operating the pump.

Before servicing this surge tank, follow the Pressure Relief Procedure on page 9 to prevent the

4 307707

equipment from starting accidentally.

Page 5

Installation

All Models

Grounding

Ground the tank and the rest of your system. See Fire

and Explosion Hazard on page 4.

Static electricity is generated by the flow of fluid

through the pump and hose, but it is dissipated

through proper grounding. If every part of the spray

system is not properly grounded, sparking may occur,

and the system may become hazardous. Sparking

may also occur when plugging in or unplugging a

power supply cord. Sparks can ignite fumes from

solvents and the fluid being sprayed, dust particles and

other flammable substances, and can cause a fire or

explosion and serious injury and property damage.

If you experience any static sparking or feel even a

slight shock while using this equipment, stop spraying

immediately. Check for proper grounding of the entire

system. Be sure you have corrected the problem

before starting to spray again.

Ground the pump and all other spray equipment used

or located in the spray area. The following are

minimum requirements for grounding a basic spray

system. Your system may include other equipment or

objects which must also be grounded. Always check

your local electrical code for detailed grounding

instructions. Be sure your system is connected to a

true earth ground.

Object being sprayed: Ground according to local

code.

Fluid supply container: Ground according to local

code.

All solvent pails used when flushing must be

grounded according to local code. Use only

grounded metal pails, which are conductive. Do not

place the pail on any non-conductive surface, such

as cardboard or paper, which would interrupt

grounding continuity.

To maintain grounding continuity when flushing or

relieving pressure, always hold a metal part of the

gun firmly to the side of a grounded metal pail, then

trigger the gun.

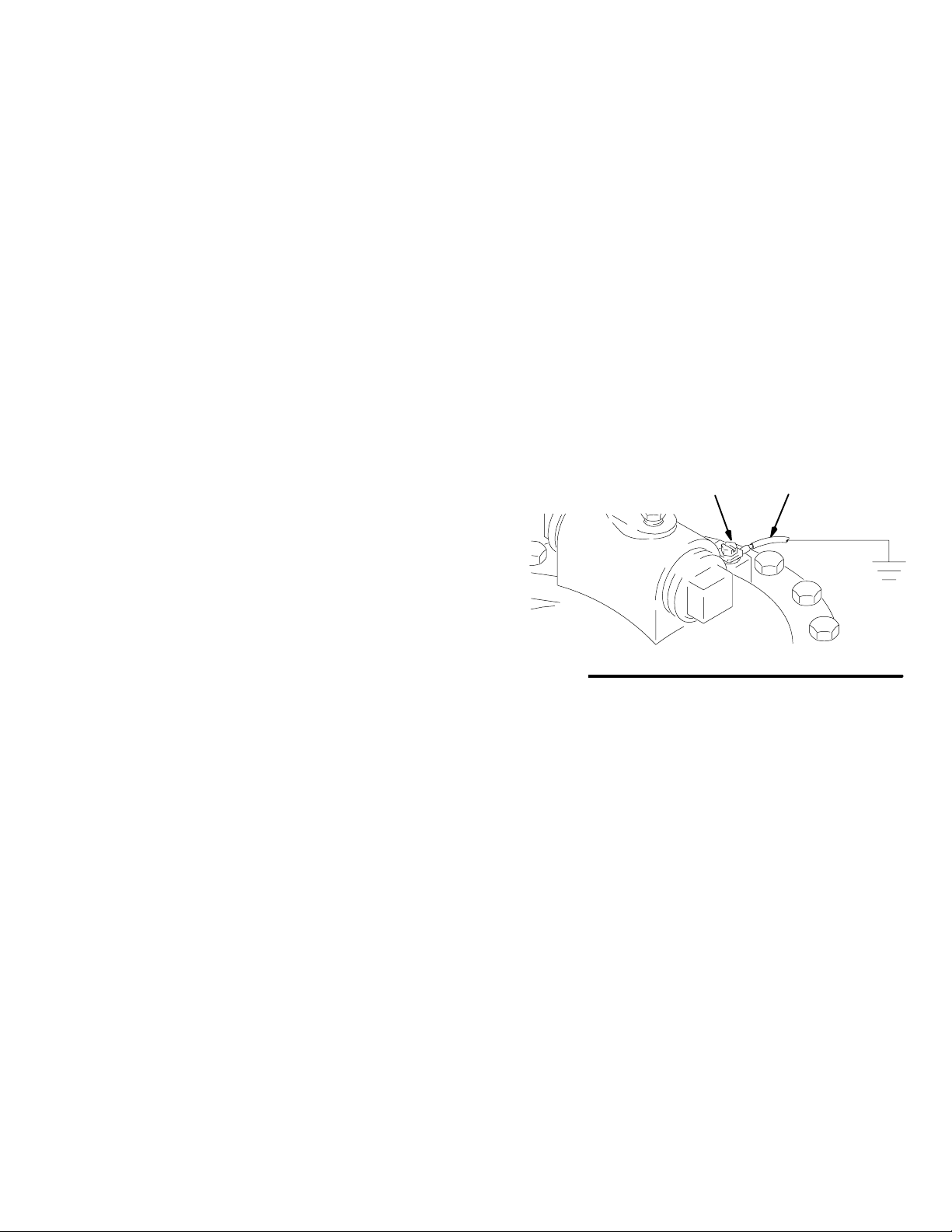

W

Fig. 1

Y

Pump: Ground by using a ground wire and clamp

as described in your separate pump instruction

manual.

Air compressors and hydraulic power supplies:

Follow the manufacturer’s recommendations.

All air and fluid lines: Use only grounded hoses with

a maximum of 150 m (500 ft) combined hose length

to ensure grounding continuity. See Hose

Grounding Continuity on page 5.

Surge tank: Connect a ground wire and clamp as

shown in Fig. 1. Loosen the grounding screw (W).

Insert one end of a 1.5 mm2 (12 ga.) minimum

ground wire (Y) behind the grounding screw and

tighten the screw securely. Connect the clamp end

of the ground wire to a true earth ground. Order

Part No. 222011 Ground Wire and Clamp.

Spray gun: Obtain grounding through connection to

a properly grounded fluid hose and pump.

Hose Grounding Continuity

Proper hose grounding continuity is essential to

maintaining a grounded spray system. Check the

electrical resistance of your air and fluid hoses at least

once a week. If your hose does not have a tag on it

which specifies the maximum electrical resistance,

contact the hose supplier or manufacturer for the

maximum resistance limits. Use a resistance meter in

the appropriate range for your hose to check the

resistance. If the resistance exceeds the

recommended limits, replace the hose immediately. An

ungrounded or poorly grounded hose can make your

system hazardous.

Flushing Safety

Before flushing, be sure the entire system and flushing

pails are properly grounded, and be sure that pressure

is relieved. See Grounding and Pressure Relief

Procedure on page 9.

5307707

Page 6

Installation

Models 238983, 238984, 238985, 238986, 238987, 238988, 218509, and 220157

NOTE: Refer to page 8 to install Model 233736.

Installing the Tank

Use Stand Kit 218742 to mount the tank to the floor.

See the Stand Mounting Hole Layout on page 22.

Secure the stand (B) to the floor with M19 (5/8 in.)

bolts that engage at least 152 mm (6 in.) into the

concrete floor to prevent the tank from tipping.

Horizontal / Vertical Mounting

All surge tanks can by mounted horizontally or

vertically.

NOTE: Model 220157 can be mounted vertically with

the fluid direction flowing upward (with the fluid inlet at

the bottom).

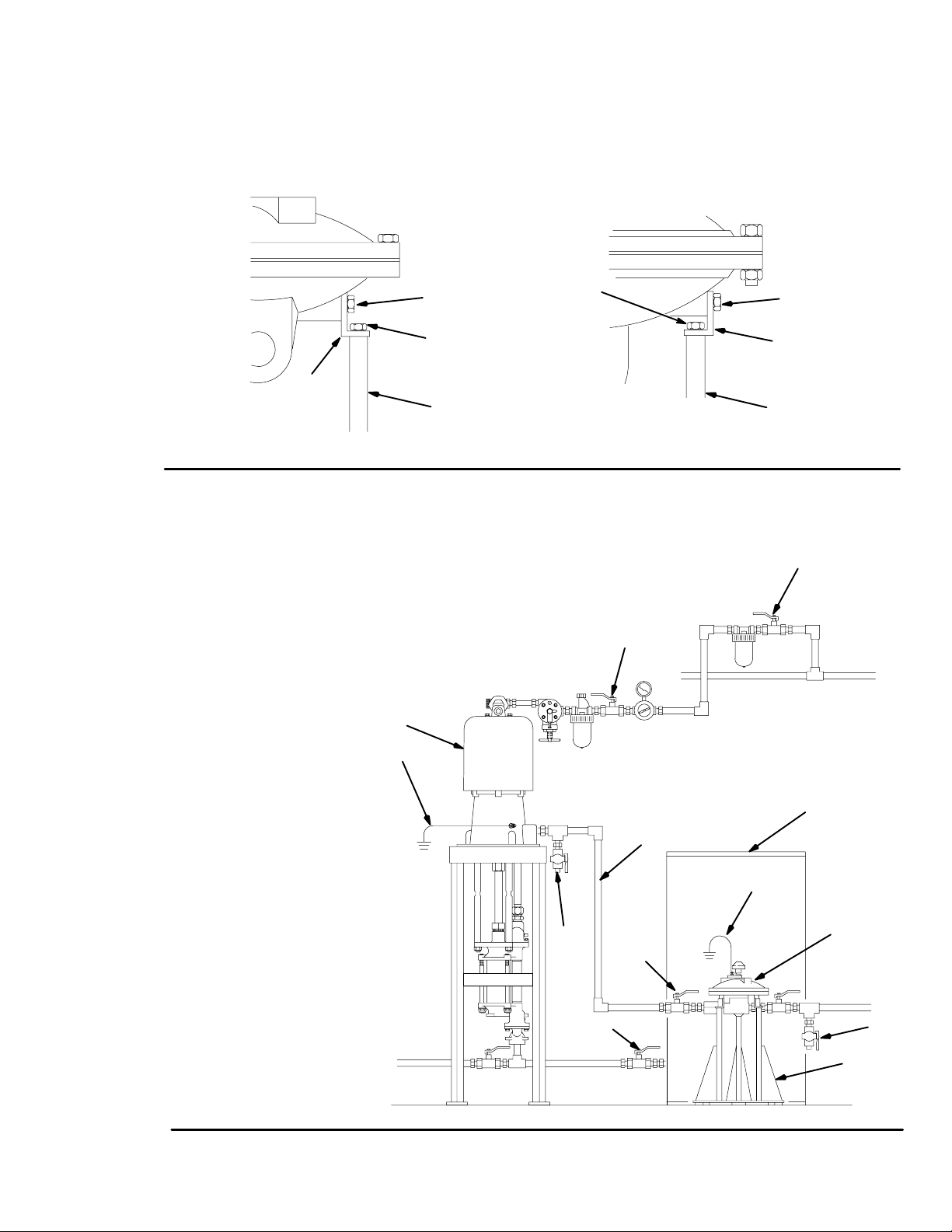

Stand Kit

(See Fig. 2.)

Items J, K, and L (mentioned in the text below) are

supplied with Stand Kit 218742.

Secure the bracket (J) to the leg of the stand (B) with a

screw (K). Notice the different bracket positions for the

three tank sizes.

Turn the bracket (J) with a wrench to align it with the

bosses on the surge tank. Then secure the bracket to

the tank with the screws (L).

Fluid Lines and Accessories

(See Fig. 3.)

Install a fluid drain valve (H) near the surge tank outlet.

WARNING

A fluid drain valve (H) is required in your system to

help reduce the risk of serious injury, including

splashing fluid in the eyes or on the skin and injury

from moving parts.

Opening the fluid drain valve helps relieve pressure

in the surge tank, pumps, hose and gun after

shutting off the system. Triggering the gun to

relieve pressure may not be sufficient.

Install a fluid shutoff valve (C) before and after the

surge tank to isolate it when servicing the tank. See

Fig. 3.

Proper line sizing is an important part of the system.

Contact your Graco distributor if you need assistance.

To obtain proper flow through the system, use the

proper size plumbing from the following list:

Models 238983, 238984, 238985, 238986, 238987,

238988: Use a minimum 51 mm (2 in.) diameter

pipe and plumbing.

Model 218509: Use a minimum 51 mm (2 in.)

diameter pipe and plumbing.

Fluid Inlet / Outlet Ports

On high-volume models (218509, 238983, 238984,

238985, 238986, 238987, and 238988), either port

may be used as the fluid inlet. The direction of fluid

flow through these models does not affect the

performance. See the Dimensional Drawings on

page 21.

CAUTION

The inlet and outlet adapter fittings on Models

238983, 238984, and 238985 (Ref. No. 3 on page

20) use a non-standard thread to fit into the fluid

cover (Ref. No. 1 on page 20). You must use Gracoapproved fittings to prevent thread damage. Contact

your Graco distributor for optional fittings.

Model 220157: Use a minimum 25 mm (1 in.)

diameter flexible hose between the pump and tank

and a hard or flexible pipe after the tank.

6 307707

Page 7

Installation

Models 238983, 238984, 238985, 238986, 238987, 238988, 218509, and 220157

Stand Kit

Model 220157

Fig. 2

KEY

A Surge tank

B Stand

C Fluid shutoff valve

D Fluid line

E Mix tank

F High-Flo pump

G Ground wire*

H Fluid drain valve*

J Bleed-type master air valve*

* Required for safe operation.

Must be purchase separately.

J

Typical Installation

F

G*

L

K

B

K

Models 218509,

238983, 238984,

238985, 238986,

238987, 238988

L

J

B

7140B

J*

J*

E

D

NOTE: This installation is only a

guide for selecting and installing a

system; it is not an actual system

design. Contact your Graco

distributor for assistance in

designing a system to suit your

needs.

Fig. 3

H*

G*

A

C

C

H*

B

7141B

7307707

Page 8

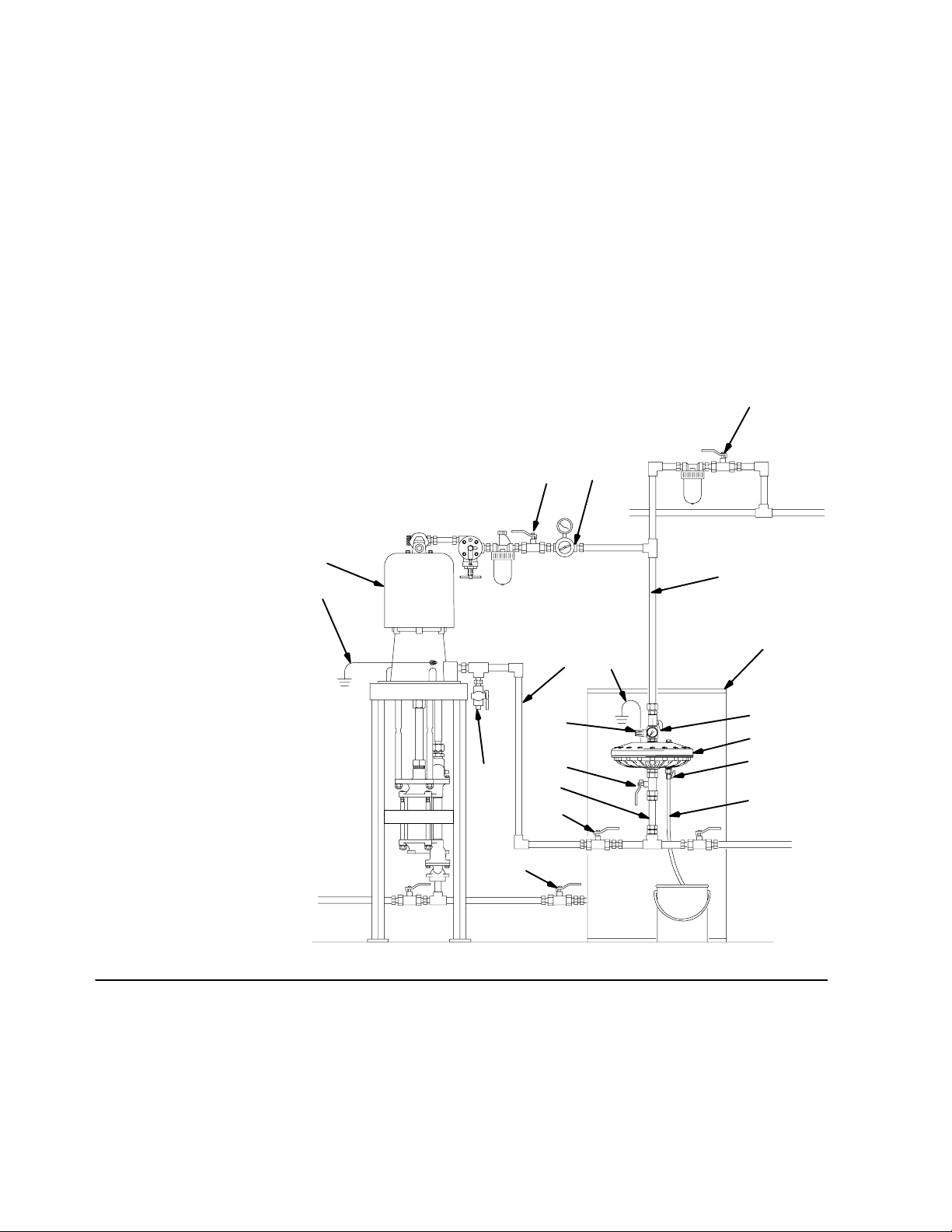

Installation

Model 233736

Model 233736 surge tank (A) must be installed

horizontally (see Fig. 4).

Install the surge tank on a short riser tube (B) off the

fluid supply line (D). The air inlet must face up.

Install an air pressure regulator (M) and a ball valve

(N) on the air supply line (P) to the surge tank. The air

regulator controls the air pressure in the tank. The ball

valve prevents air from escaping from the tank during

operation.

Typical Installation

KEY

A Surge tank

B Riser tube

C Fluid shutoff valve

D Fluid line

E Mix tank

F High-Flo pump

G Ground wire*

H Fluid drain valve*

J Bleed-type master air valve*

M Air regulator

N Air shutoff valve

P Air line to surge tank

R Priming valve

S Fluid drain line

T Fluid valve

U Pump air regulator

* Required for safe operation.

Must be purchased separately.

NOTE: This installation is only a

guide for selecting and installing a

system; it is not an actual system

design. Contact your Graco

distributor for assistance in

designing a system to suit your

needs.

Fig. 4

F

G*

Install a fluid valve (T) on the riser tube (B). Close this

valve to allow maintenance of the surge tank while fluid

continues to flow in the main fluid supply line.

Remove the plug (12) and install a fluid priming valve

(R) and drain line (S), for use in bleeding air from the

fluid section.

J*

U

J*

P

E

D

G*

M

N

A

H*

T

B

C

R

S

C

TI1913B

8 307707

Page 9

Operation

All Models

Pressure Relief Procedure

WARNING

To reduce the risk of an injury from splashing fluid

or moving parts, follow the Pressure Relief Proce-

dure whenever you

Are instructed to relieve the pressure

Stop dispensing

Check or service any of the system equipment

Install or clean any system components

1. Turn off the power to the pump.

2. In a hydraulic system, close the hydraulic shutoff

valves.

3. In an air-powered system, close the pump air

regulator, and close the bleed-type master air

valve (required in your system).

4. Close the fluid shutoff valves from the supply

tanks.

5. Hold a metal part of the gun firmly to the side of a

grounded metal pail and trigger the gun to relieve

fluid pressure.

6. Open the fluid drain valve (required in your

system), having a container ready to catch the

drainage. Keep hands away from the end of the

drain valve when opening it.

7. Leave the drain valve open until you are ready to

use the system again.

8. For Models 238983, 238984, 238985, 238986,

238987, 238988, 218509, and 220157: To relieve

the gas charge pressure in the surge tank, remove

the cap on the charge valve (6), and press down

on the valve stem until all pressure is relieved.

NOTE: Relieving all gas pressure takes several

minutes.

For Model 233736: Back out the plug (11) to

relieve air pressure in the surge tank.

9307707

Page 10

Operation

Models 238983, 238984, 238985, 238986, 238987, 238988, 218509, and 220157

3. Up to a charging pressure of 120 psi (0.84 MPa,

WARNING

Always follow the Pressure Relief Procedure

on page 9 before you remove the surge tank

for any reason.

Tighten all fluid connections securely before

each use.

Never try to stop or deflect leaks with your hand

or body.

Be sure the drain valve connected to the surge

tank is closed before you start the system.

Always keep hands away from the end of the

drain valve when opening it.

NOTE: Always re-torque all of the M12 cap screws

and hex nuts using a star-pattern sequence before you

charge or operate the surge tank to ensure against

fluid or gas leakage. For torque specifications for your

Model No., see the Parts Drawings on pages 17, 18,

and 19.

8.4 bar) compressed air or bottled nitrogen may be

used. For higher pressures, use only nitrogen. For

optimum performance, charge the tank to 2/3

of the anticipated fluid line operating pressure

(see table below). This pressure allows the tank

diaphragm to store enough energy for efficient

operation. Charging takes several minutes.

FLUID LINE PRESSURE TANK CHARGE PRESSURE

600 psi (4.2 MPa, 41 bar) 400 psi (2.8 MPa, 28 bar)

500 psi (3.5 MPa, 35 bar) 334 psi (2.2 MPa, 22 bar)

400 psi (2.8 MPa, 28 bar) 268 psi (1.8 MPa, 18 bar)

300 psi (2.1 MPa, 21 bar) 200 psi (1.4 MPa, 14 bar)

200 psi (1.4 MPa, 14 bar) 134 psi (0.9 MPa, 9 bar)

100 psi (0.7 MPa, 7 bar) 67 psi (0.5 MPa, 5 bar)

CAUTION

Charging the Tank

1. The fluid line pressure must be at zero before you

charge the tank. Pressure in the fluid line prevents

the tank from accepting a full charge.

2. Remove the relief valve cap and the tank charge

valve cap from the tank charge valve. See Fig. 5.

WARNING

To reduce the risk of fire or explosion, which could

result in serious injury and property damage,

always use an inert gas, such as nitrogen or

compressed air, to charge the tank. Never use

pure oxygen.

NOTE: Do not install a continuously fed gas charge

supply to the surge tank. Doing so will adversely affect

the surge tank performance.

The maximum working pressure for surge tank

Models 238983, 238984, and 238985 is 300 psi (2.1

MPa, 21 bar). For these Models, do not exceed this

fluid line pressure or the associated charge pressure

as shown in the table above.

4. Replace the two caps hand-tight.

Relieving Gas Pressure in the Tank

This tank has a pressure relief valve that

automatically relieves gas pressure (only) in the

tank if it overpressurizes while charging.

To manually relieve gas pressure in the tank,

remove the cap from the charge valve (6). Press

down the stem of the valve until all gas pressure is

relieved.

NOTE: Relieving all gas pressure takes several

minutes.

Flushing Procedure

For the best flushing results, alternate the gas charge

pressure between 2/3 of the fluid pressure (normal

operating condition) and zero pressure. This allows the

flushing solvent to reach all areas of the fluid

containing vessel.

10 307707

Page 11

Operation

Models 238983, 238984, 238985, 238986, 238987, 238988, 218509, and 220157

relief valve cap

Model 218509 shown

tank charge valve cap

tank charge valve

Fig. 5

7142B

11307707

Page 12

Operation

Model 233736

WARNING

Always follow the Pressure Relief Procedure

on page 9 before you remove the surge tank

for any reason.

Tighten all fluid connections securely before

each use.

Never try to stop or deflect leaks with your hand

or body.

NOTE: Always re-torque all of the cap screws using a

star-pattern sequence before you charge or operate

the surge tank to ensure against fluid or air leakage.

For torque specifications, see the Parts Drawing on

page 20.

Charging the Tank with Air

The fluid line pressure must be at zero before you

charge the tank. Pressure in the fluid line prevents the

tank from accepting a full charge.

1. See Fig. 4 on page 8. Close the fluid valve (T).

Open the priming valve (R).

2. Open the air valve (N) and set the air regulator (M)

to the desired pressure. When the tank is charged

with air, close the air valve (N) to prevent air from

escaping when fluid is introduced.

Relieving Air Pressure in the Tank

To manually relieve air pressure in the tank, back out

the plug (11).

Fill the Tank with Fluid

1. Charge the surge tank with air, as described at left.

2. Open the fluid valve (T). Ensure that the priming

valve (R) is open.

3. Start the pump and slowly increase the fluid

pressure. When fluid flows from the priming valve,

close the valve. The surge tank is ready for use.

CAUTION

The maximum working pressure for Model 233736 is

360 psi (2.5 MPa, 25 bar). Do not exceed this fluid

line pressure.

Flush Before First Use

The surge tank is tested with oil in production. Oil

residue remains in the tank to protect it from corrosion.

Before using, flush the tank thoroughly with a

compatible solvent.

For the best results, set the air pressure to 15 psi

(0.1 MPa, 1 bar) below the fluid pressure. Do not

exceed the maximum air pressure of 218 psi (1.5

MPa, 15 bar). For fluid pressures of 232 psi (1.6

MPa, 16 bar) and above, set the air pressure to

218 psi (1.5 MPa, 15 bar).

WARNING

To reduce the risk of fire or explosion, which could

result in serious injury and property damage,

always use compressed air to charge the tank.

Never use pure oxygen.

12 307707

Page 13

Troubleshooting

WARNING

To reduce the risk of serious injury, including

splashing fluid in the eyes or on the skin, always

follow the Pressure Relief Procedure on page 9

before you check or service the surge tank or

remove the surge tank from the system.

Problem Cause Solution

Surge tank will not accept a

gas charge.

Poor pulsation reduction.

Plugged restrictor in charge valve

(not applicable for Model 233736)

Incorrect gas charge pressure Charge the surge tank to recom-

Surge tank undersized for application

CAUTION

If you replace the diaphragm, do not attempt to make

a new one yourself. Use only genuine Graco parts.

Other materials may not stand up to the pressures

developed in the tank or to the fluid being pumped. A

ruptured diaphragm will release gas into the paint

line.

The restrictor is a safety device that

prevents overpressurization during

charging of the tank. Clean or replace

the restrictor bushing:

Ref. No. 25 on page 17.

Ref. No. 25 on page 18.

Ref. No. 13 on page 20.

mended air pressure (see Operation

section).

Reduce working fluid pressure and/or

flow rate.

Surge tank gas charge bleeds

off.

Install a larger surge tank model.

Install a surge regulator (SR200)

Extended pump change-over time

due to worn or held open check

valves

Ruptured diaphragm Replace diaphragm.

Relaxed diaphragm seal Check flange bolt torques. Re-torque

Damaged diaphragm seal Replace.

Leaking charge valve or relief valve Replace charge valve or relief valve.

Repair the piston pump.

as necessary. See Parts Drawings

for torque specifications.

13307707

Page 14

Service

(Models 218509 and 220157)

Installing Diaphragm and Seal Repair Kit

Diaphragm and Seal Repair Kits are available and can

be ordered separately as follows:

Kit 218799, for Model 218509 surge tank

Kit 234118, for Model 220157 surge tank

WARNING

Follow the Pressure Relief Procedure on page 9

before you check or service the surge tank or

remove the surge tank from the system. All fluid

and gas charge pressure must be relieved completely before you attempt any service.

See the Parts Drawings on pages 17 and 18.

Disassembly

1. To manually relieve gas pressure in the tank,

remove the relief valve cap (27) and the cap from

the charge valve (6). Press down the valve stem

until all gas pressure is relieved.

NOTE: Relieving all gas pressure takes several

minutes.

2. Disassemble the surge tank by removing the M12

cap screws (2), lock washers (3), and hex nuts (4).

Reassembly

1. Carefully and thoroughly clean all housing flange

and o-ring sealing surfaces. Clean and dry an area

at least 12 mm (0.5 in.) inside the o-ring diameter

on the upper air housing (7) for application of the

special gasket joint sealant (38).

2. Install the new o-rings (1b), and lay the diaphragm

(1a) in place on the lower fluid housing (8).

3. Remove the printed release paper from the gasket

joint sealant (38) adhesive strip.

NOTE: Be careful not to remove the adhesive with

the release paper. Check to be sure that the

adhesive stays on the joint sealant. If the adhesive

sticks to the release paper and begins to lift off the

joint sealant, stop and trim to a new length, or start

from the opposite end and try again.

4. Place the gasket joint sealant (38) on the upper air

housing (7) within 3 mm (1/8 in.) of the internal

diameter of the o-ring groove as follows. Be careful

that you do not twist or damage the joint sealant

during installation.

a. Begin and finish the sealant ends directly

inward from a bolt hole. See Detail in Parts

Drawings.

NOTE: Model 220157 does not contain

lockwashers (3) or hex nuts (4).

3. Separate the air section (7) from the fluid section

(8). Be careful that you do not damage the

machined flange surfaces or components attached

to either housing.

4. Remove and discard the diaphragm (1a) and the

two o-rings (1b).

b. Overlap the ends of the sealant by at least

10 mm (3/8 in.) as shown. Point the ends

inward.

c. Trim off excess length of joint sealant as

necessary.

5. Reassemble the housings carefully, making sure

the joint sealant remains in place.

6. Torque the M12 cap screws (2) using a star

pattern sequence, in three successive steps, to a

final torque of 63 to 73 N-m (46 to 54 ft-lb).

7. Follow the instructions for Charging the Tank on

page 10, and see Operation on page 9 to return

the surge tank to service.

14 307707

Page 15

Service

(Models 238983, 238984, 238985, 238986, 238987, 238988)

Installing Diaphragm Repair Kit

Diaphragm and Seal Repair Kit 248079 is available

and can be ordered separately.

WARNING

Follow the Pressure Relief Procedure on page 9

before you check or service the surge tank or

remove the surge tank from the system. All fluid

and gas charge pressure must be relieved completely before you attempt any service.

See the Parts Drawing on page 19.

Disassembly

1. To manually relieve gas pressure in the tank,

remove the relief valve cap (17) and the cap from

the charge valve (15). Press down the valve stem

until all gas pressure is relieved.

NOTE: Relieving all gas pressure takes several

minutes.

2. Disassemble the surge tank by removing the M12

cap screws (8), plain washers (11), lock washers

(10), and hex nuts (9).

Reassembly

1. Carefully and thoroughly clean all housing flange

and diaphragm bead sealing surfaces.

2. Lay the diaphragm (7a,b) in place on the lower

fluid housing (1) with the center contour (the

convex side) facing upward.

3. Lay the cream-colored TPE backing diaphragm (6)

over the diaphragm (7a, b). The diaphragms

should fit closely together.

4. Reassemble the air housing (2) and the fluid

housing (1) carefully. Make sure the diaphragms

remain in the grooves and are not pinched.

5. Replace the flange hardware with the capscrews,

nuts, and washers that are provided with the

Diaphragm Repair Kit.

6. Torque the M12 cap screws (8) using a

star-pattern sequence in two successive steps to a

final torque of 68 to 81 N-m (50 to 60 ft-lb).

7. Follow the Charging the Tank instructions on

page 10. See the rest of the Operation section on

page 10 to return the surge tank to service.

3. Separate the air housing (2) from the fluid housing

(1). Be careful that you do not damage the

machined flange surfaces or components attached

to either housing.

4. Remove and discard the diaphragms (6 and 7).

15307707

Page 16

Service

(Model 233736)

Diaphragm Repair

WARNING

Follow the Pressure Relief Procedure on page 9

before you check or service the surge tank or

remove the surge tank from the system. All fluid

and gas charge pressure must be relieved completely before you attempt any service.

See the Parts Drawing on page 20.

Disassembly

1. To manually relieve air pressure in the tank, back

out the plug (11).

2. Disassemble the surge tank by removing the cap

screws (8).

3. Separate the air housing (2) from the fluid housing

(1). Be careful that you do not damage the

machined flange surfaces or components attached

to either housing.

Reassembly

1. Carefully and thoroughly clean all housing flange

and diaphragm sealing surfaces.

2. Apply thread sealant to the screw (10). Assemble

the air side plate (6), diaphragm (7), fluid side plate

(5), and screw (10) as shown in the parts drawing.

Torque the screw to 2 to 3 N-m (1.5 to 2.2 ft-lb).

Lay the diaphragm (7) in the lower fluid housing (1)

with the smaller air side plate facing upward.

3. Reassemble the air housing (2) and the fluid

housing (1) carefully. Make sure the diaphragm is

not pinched.

4. Replace the capscrews (8) loosely, then torque the

screws (8) to 18 to 22 N-m (13 to 16 ft-lb), using a

star-pattern sequence.

5. Follow the Charging the Tank with Air

instructions on page 12. See the rest of the

Operation section on page 12 to return the surge

tank to service.

4. Remove the screw (10) and diaphragm plates (5,

6). Discard the diaphragm (7).

16 307707

Page 17

Model 218509, Series E

carbon steel,

2 npt(f) inlet/outlet

Parts

29

2

27

28

6

26

25

31

2

2

1

Detail

38

1b

1

Torque to 63 to 73 N-m (46 to 54 ft-lb).

Apply thread sealant and thread tape to

2

pipe threads before reassembling.

7143A

38

see detail

1b

1a

1b

3

4

1

7

8

7138b

Ref Part

No. No. Description Qty.

1 218799 REPAIR KIT, surge tank; includes

items 1a, 1b, and 38 1

1a . DIAPHRAGM 1

1b . O–RING 2

2 107596 . CAPSCREW, hex hd; M12 x 50 24

3 107541 . LOCKWASHER, spring 24

4 107539 . NUT, hex; M12 24

6 104031 VALVE, charge, tank 1

7 180667 HOUSING, diaphragm 1

8 180557 HOUSING, diaphragm

(Model 218509 only) 1

25 180969 BUSHING, air valve 1

26 108147 ELEMENT, filter 1

Ref Part

No. No. Description Qty.

27 180942 CAP, relief valve 1

28 108519 O–RING; fluoroelastomer 1

29 102042 PLUG, pipe 2

31 116343 SCREW, grounding 1

33* 181068 TAG, warning (not shown) 1

38 192258 GASKET JOINT SEALANT 1

These parts are available in Diaphragm and Seal

Repair Kit 218799, which can be ordered separately.

* Extra warning tags are available at no charge.

17307707

Page 18

Model 220157, Series E

electropolished stainless steel,

1.25 npt(f) inlet, 1.25 npt(f) outlet

2

6

Parts

27

28

Detail

38

7143A

1b

1

Torque to 63 to 73 N-m (46 to 54 ft-lb).

Apply thread sealant and thread tape to

2

pipe threads before reassembling.

26

25

31

1

2

7

17

38

see detail

1b

1a

1b

8

Ref Part

No. No. Description Qty.

1 234118 REPAIR KIT, surge tank; includes

items 1a, 1b, 2, and 38 1

1a . DIAPHRAGM 1

. O–RING 2

1b

117638 . CAPSCREW, hex hd; M12 x 50 18

2

6 104031 VALVE, charge, tank 1

7 181408 HOUSING, diaphragm 1

8 181410 HOUSING, diaphragm 1

18 307707

7137C

Ref Part

No. No. Description Qty.

17 107541 WASHER, lock, spring 18

25 180969 BUSHING, air valve 1

26 108147 ELEMENT, filter 1

27 180942 CAP, relief valve 1

28 108519 O–RING; fluoroelastomer 1

31 116343 SCREW, grounding 1

33* 181068 TAG, warning (not shown) 1

38 192258 GASKET JOINT SEALANT 1

These parts are available in Diaphragm and Seal

Repair Kit 234118, which can be ordered separately.

* Extra warning tags are available at no charge.

Page 19

Parts

Models

238983, 238986 Series C

electropolished stainless steel, 2 npt(f) inlet/outlet

238984, 238987 Series C

electropolished stainless steel, 2-in. sanitary inlet/outlet

238985, 238988 Series C

electropolished stainless steel, 1.5-in. sanitary inlet/outlet

Ref Part

No. No. Description Qty.

1 15D038 COVER, fluid; electro-

polished SST 1

2 191768 COVER, air; cast aluminum 1

3a 191771 FITTING, 2 npt(f)

Used on Models

238983, 238986 2

3b 187004 FITTING, 2-in. sanitary

Used on Models

238984, 238987 2

3c 188286 FITTING, 1.5-in. sanitary

Used on Models

238985, 238988 2

5 107078 PACKING, o-ring 2

6

191407 DIAPHRAGM, backing, TPE 1

118357 DIAPHRAGM, PTFE; Used on

7a

Models 238983, 238984, 238985 1

7b 15F232 DIAPHRAGM, PTFE; Used on

Models 238986, 238987, 238988 1

15W044 SCREW, M12, cap, hex head 12

8

15W043 NUT, hex; M12 12

9

107541 LOCKWASHER, spring; M12 12

10

11 109570 WASHER, plain 12

12 180952 RING, lift 1

13 180969 BUSHING, air valve 1

14 108147 ELEMENT, filter 1

15 104031 VALVE, charge, tank 1

16 238876 VALVE, relief 1

17 180942 CAP, relief valve 1

18 108519 O–RING; fluoroelastomer 1

19 116343 SCREW, grounding 1

21* 181068 TAG, warning (not shown) 1

These parts are available in Diaphragm Repair

Kit 248079, which can be ordered separately.

* Extra warning tags are available at no charge.

Included in repair kit 249141.

19

12

17

18

16

15

14

13

4

4

4

8

11

2

6

7a, 7b

3a

2

5

1

3b, 3c

2

5

3

Torque to 68 to 81 N-m (50 to 60 ft-lb).

1

Torque to 136 to 149 N-m

2

(100 to 110 ft-lb).

Apply lubricant to o-ring

3

surface before reassembling.

Apply thread sealant and

4

thread tape to pipe threads

before reassembling.

Non-standard thread. Use

5

Graco-approved fittings only.

2

3b, 3c

5

10

3

5

2

3a

1

9

1

7286C

19307707

Page 20

Parts

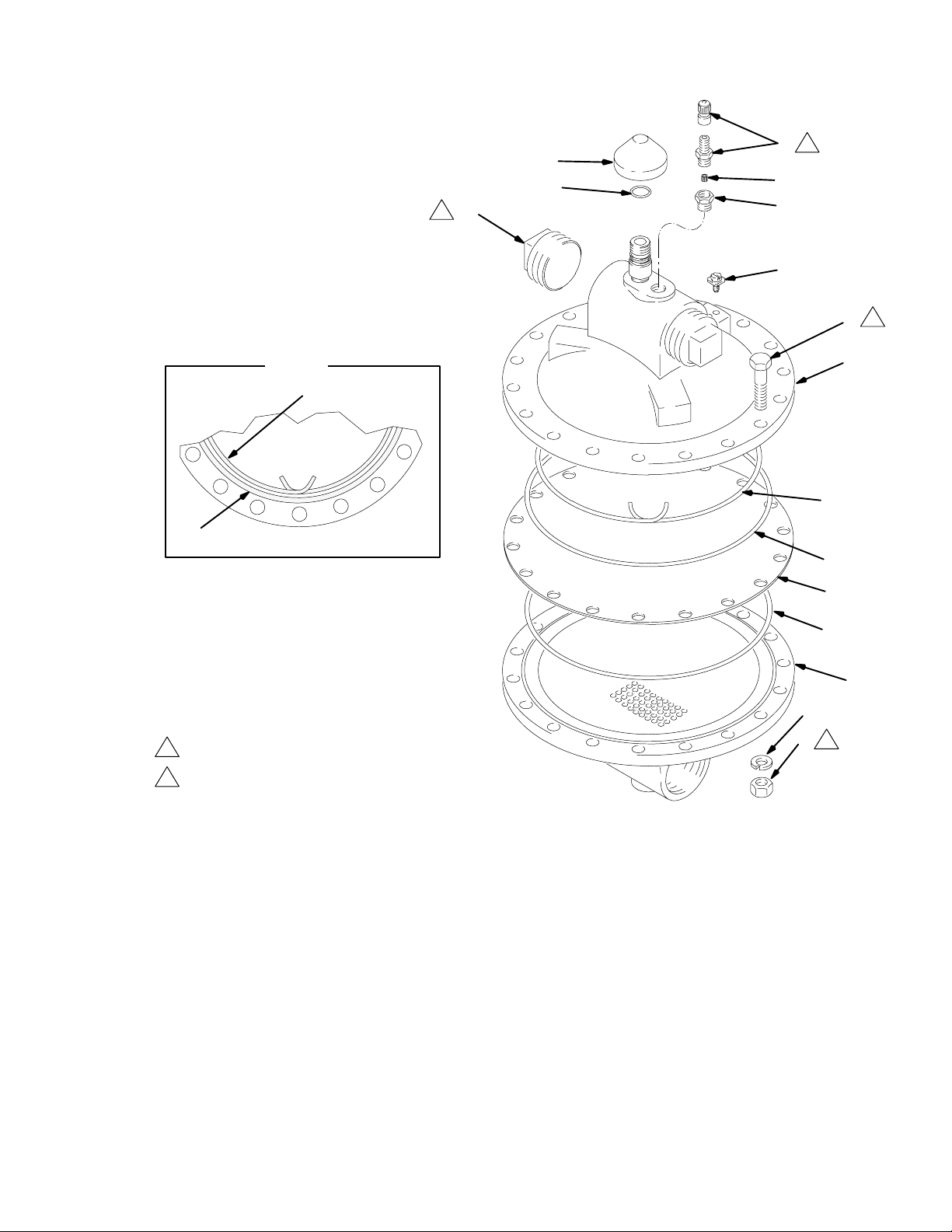

Model 233736, Series A

stainless steel, 1/4 bspp(f) air port, 3/4 bspp(f) fluid port

Ref Part

No. No. Description Qty.

1 198776 COVER, fluid;SST 1

2 198775 COVER, air; cast aluminum 1

5 198779 PLATE, diaphragm, fluid side 1

6 198778 PLATE, diaphragm, air side 1

7 198777 DIAPHRAGM, PTFE 1

8 117033 SCREW, M10, cap, socket head 18

9 116898 WASHER 1

10 116899 SCREW, cap, socket head 1

11 116901 PLUG, hex head 1

12 116902 PLUG, socket head 1

19 116343 SCREW, grounding 1

20 15F749 WASHER, seal 1

Keep this part on hand to reduce down time.

11

19

8

3

5

20

2

6

7

Apply thread sealant.

1

2

Torque to 2 to 3 N-m (1.5 to 2.2 ft-lb).

3

Torque to 18 to 22 N-m (13 to 16 ft-lb).

4

Torque to 47 to 55 N-m (35 to 40 ft-lb).

5

Torque to 43.4 N-m (32 ft-lb).

10

5

1 2

9

12

1

4

TI1899B

20 307707

Page 21

Dimensional Drawings

334 mm

(13.1 in.)

268 mm

(10.6.in.)

2 – 11.5

pt(f) fluid

port,

inlet /

outlet

Model 218509

648 mm

(25.5 in.)

383 mm

(15.1 in.)

1.25 – 11.5

npt(f) fluid inlet

2 – 11.5

npt(f) fluid

port,

inlet /

outlet

7144A

1.25 – 11.5

npt(f) fluid

outlet

284 mm

(11.2.in.)

383 mm

(15.1.in.)

7139A

Model 220157

fluid inlet / outlet:

Models 238984, 238987 2 npt(f)

Models 238984, 238987 2-in.

sanitary

(Tri-Clamp compatible)

Models 238985, 238988 1.5-in.

sanitary

(Tri-Clamp compatible)

2 npt(f) shown

480 mm

18.9 in.

highest

point

409 mm

(16.1 in.)

fluid inlet / outlet:

Models 238984, 238987 2 npt(f)

Models 238984, 238987 2-in.

sanitary

(Tri-Clamp compatible)

Model 238985, 238988 1.5-in.

sanitary

(Tri-Clamp compatible)

2 npt(f) shown

465 mm

18.3 in.

(all models)

693 mm

27.3 in.

Models 238983, 238984, 238985, 238986, 238987, 238988

7287B

21307707

Page 22

Dimensional Drawings

Height:

102 mm

(4.0 in.)

Model 233736

1/4 bspp(f) air port

300 mm

(11.8 in.)

3/4 bspp(f) fluid port

TI1898B

397 mm

(15.6 in.)

Stand Mounting Hole Layout

(Stand is not used with Model 233736)

350 mm

(13.8 in.)

278 mm

(10.9 in.)

3 holes

17.5 mm

(0.69 in.)

320 mm

(12.6 in.)

22 307707

160 mm

(6.3 in.)

7144A

Page 23

Technical Data

Category Data

Maximum fluid working pressure Models 238983, 238984, 238985, 238986, 238987, 238988: 300

psi (2.1 MPa, 21 bar)

Model 233736: 360 psi (2.5 MPa, 25 bar)

Models 218509, 220157: 600 psi (4.2 MPa, 42 bar)

Maximum gas charge pressure

(maximum air inlet pressure for Model 233736)

Maximum flow rate* Models 238983, 238984, 238985,238986, 238987, 238988

Maximum operating temperature Model 233736: 80 C (176 F)

Models 238983, 238984, 238985, 238986, 238987, 238988: 300

psi (2.1 MPa, 21 bar)

Model 233736 (air inlet pressure): 218 psi (1.5 MPa, 15 bar)

Models 218509, 220157: 600 psi (4.2 MPa, 42 bar)

218509: 76 lpm (20 gpm)

Model 233736: tank volume is 1.5 liters (0.4 gal.); fluid does not

flow through tank

Model: 220157: 57 lpm (15 gpm)

All other models: 50 C (120 F)

Wetted parts Models 238983, 238984, 238985, 238986, 238987, 238988: 304

& 316 stainless steel, PTFE.

Model 233736: stainless steel, PTFE

Model 218509, 220157: carbon steel, electroless

nickel-plated steel, UHMW polyethylene, fluoroelastomer, PTFE

Model 220157: 304 and 17–4 PH stainless steel, UHMW polyethylene, fluoroelastomer, PTFE, tungsten carbide

* Maximum flow rates are recommended maximums for peak performance. Exceeding these values reduces

the surge tank’s ability to dampen pulsation.

Tri-Clamp is a registered trademark of Tri-Clover Inc.

Canadian Registration Number (CRN)

Model Alberta Ontario

218509 0C4155.2 0C4874.5

220157 0C4155.2 0C4874.5

23307707

Page 24

Graco Standard Warranty

Graco warrants all equipment manufactured by Graco and bearing its name to be free from defects in material and workmanship on the

date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty published by Graco,

Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be

defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by

faulty installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or

substitution of non–Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of

Graco equipment with structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture,

installation, operation or maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for

verification of the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The

equipment will be returned to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect

in material or workmanship, repairs will be made at a reasonable charge, which charges may include the costs of parts, labor, and

transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT

NOT LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other

remedy (including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any

other incidental or consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the

date of sale.

Graco makes no warranty, and disclaims all implied warranties of merchantability and fitness for a particular purpose in connection

with accessories, equipment, materials or components sold but not manufactured by Graco. These items sold, but not manufactured

by Graco (such as electric motors, switches, hose, etc.), are subject to the warranty, if any, of their manufacturer. Graco will provide

purchaser with reasonable assistance in making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment

hereunder, or the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract,

breach of warranty, the negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings

entered into, given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties

reconnaissent avoir convenu que la rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures

judiciaires exécutés, donnés ou intentés à la suite de ou en rapport, directement ou indirectement, avec les procedures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER, contact your Graco distributor, or call one of the following numbers

to identify the distributor closest to you:

1–800–328–0211 Toll Free

612–623–6921

612–378–3505 Fax

All written and visual data contained in this document reflect the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

This manual contains English. MM 307707

International Offices: Belgium, China, Japan, Korea

Graco Headquarters: Minneapolis

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

Copyright 1984, Graco Inc. is registered to ISO 9001

www.graco.com

Revised 11/2009

24 307707

Loading...

Loading...