Page 1

Instructions-Parts List

3:1 Ratio Bulldog

®

Transfer Pump

- For use in lubrication applications only -

Model: 205028

With inductor, guide bars and release bar

Model: 205148, Series E

Without inductor, guide bars and release bar

300 psi (2.1 MPa, 21 bar) Maximum Working Pressure

100 psi (0.7 MPa, 7 bar) Maximum Air Input Pressure

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

306642F

Use with lubrication applications only! This pump is

designed to be used for pumping non-corrosive and

non-abrasive lubricants and greases only. Any other use of

the pump can cause unsafe operating conditions and result

in component rupture, fire or explosion, which can cause

serious bodily injury.

Priming Piston Hazard

This pump has a priming piston which extends below the

foot valve during operation. This piston could pinch or

amputate your fingers or hands as it moves up, into the cylinder. To reduce the risk of injury, keep your fingers and

hands and all tools away from the priming piston during

operation and whenever the air and fluid pressure in the

pump is not fully relieved.

ti10550a

Graco Inc. P.O. Box 1441 Minneapolis, MN 55440-1441

Copyright 1958, Graco Inc. is registered to I.S. EN ISO 9001

Page 2

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific risk. Refer back to these warnings. Additional, product-specific warnings may be found throughout the body of this manual where applicable.

WARNING

FIRE AND EXPLOSION HAZARD

When flammable fluids are present in the work area, such as gasoline and windshield wiper fluid, be aware that

flammable fumes can ignite or explode. To help prevent fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources, such as cigarettes and portable electric lamps.

• Keep work area free of debris, including rags and spilled or open containers of solvent and gasoline.

• Do not plug or unplug power cords or turn lights on or off when flammable fumes are present.

• Ground all equipment in the work area.

• Use only grounded hoses.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment until you

identify and correct the problem.

• Keep a working fire extinguisher in the work area.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system component.

See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all equipment

manuals. Read fluid and solvent manufacturer’s warnings. For complete information about your material,

request MSDS forms from distributor or retailer.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s

replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

ELECTRIC SHOCK HAZARD

Improper grounding, setup, or usage of the system can cause electric shock.

• Turn off and disconnect power at main switch before disconnecting any cables and before servicing

equipment.

• Connect only to grounded power source.

• All electrical wiring must be done by a qualified electrician and comply with all local codes and

regulations.

PRESSURIZED EQUIPMENT HAZARD

Fluid from the gun/dispense valve, leaks, or ruptured components can splash in the eyes or on skin and cause serious injury.

• Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning, checking, or

servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses, tubes, and couplings daily. Replace worn or damaged parts immediately.

MOVING PARTS HAZARD

Moving parts can pinch or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment, follow the

Pressure Relief Procedure in this manual. Disconnect power or air supply.

2 306642F

Page 3

Installation

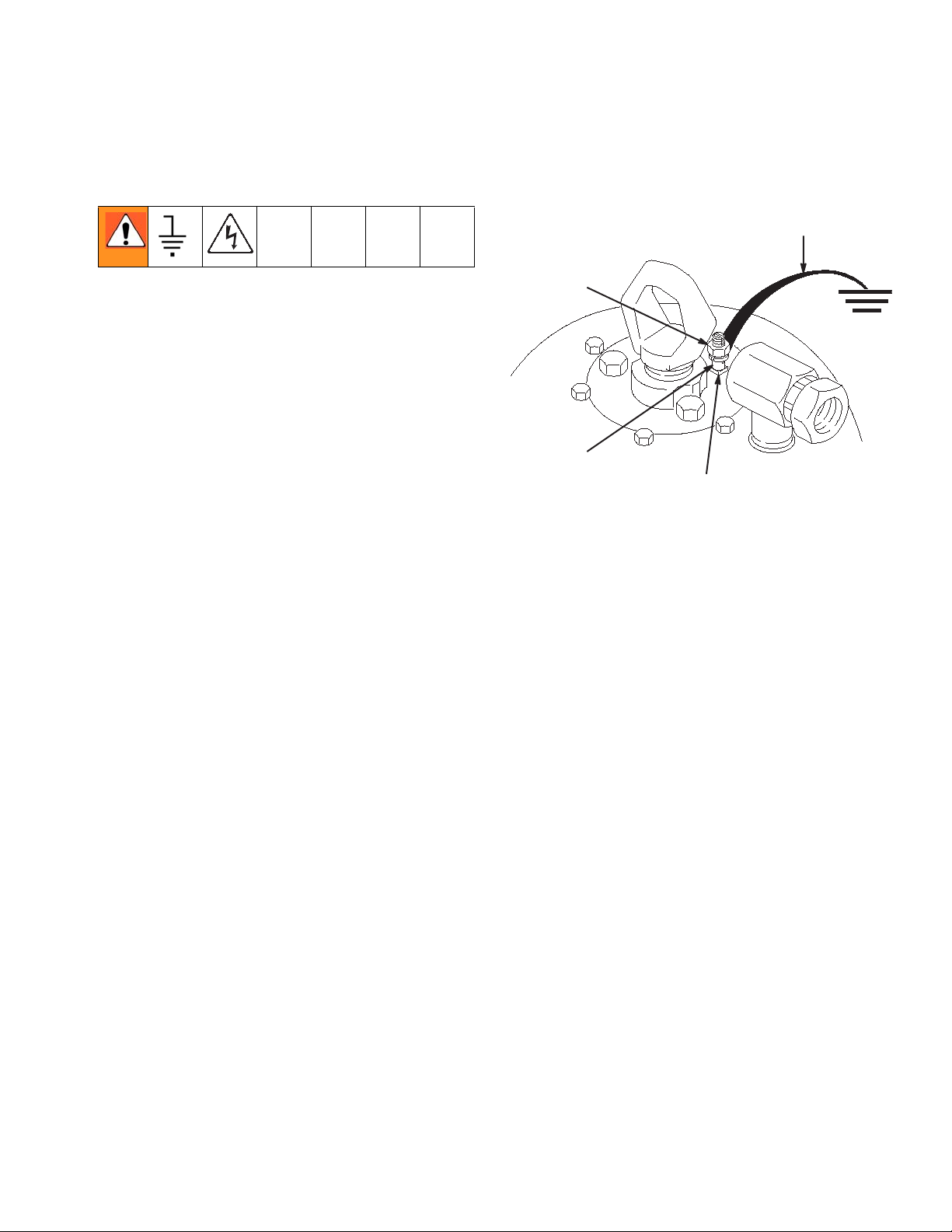

Grounding

In a low pressure air spray system, static sparking is

generally not a problem; however some simple precautions should be taken to reduce the risk. Check your

local code for detailed grounding instructions for your

area and type of equipment. Ground all equipment.

Grounding reduces the risk of static and electric shock

by providing an escape wire for the electrical current

due to static build up or in the event of a short circuit.

Installation

(c)

(a)

(b)

• Pump: (F

plied). Loosen grounding lug locknut (a) and washer

(b). Insert one end of ground wire (c) into the slot in

the lug (d). Tighten locknut securely. Connect other

end of wire to a true earth ground.

IG. 1) Use ground wire and clamp (sup-

(d)

F

IG. 1

• Air Compressor: according to manufacturer’s recommendations.

• Object being sprayed: according to local code.

• Fluid supply container: according to local code.

• All solvent pails used when flushing: according to

local code.

Only use conductive, metal pails. Do not place the

pail on a non-conductive surface such as paper or

cardboard, which interrupts the grounding continuity.

• To maintain grounding continuity when flushing or

relieving pressure, always hold metal part of the dispenser firmly to the side of a grounded metal pail,

then squeeze trigger.

306642F 3

Page 4

Installation

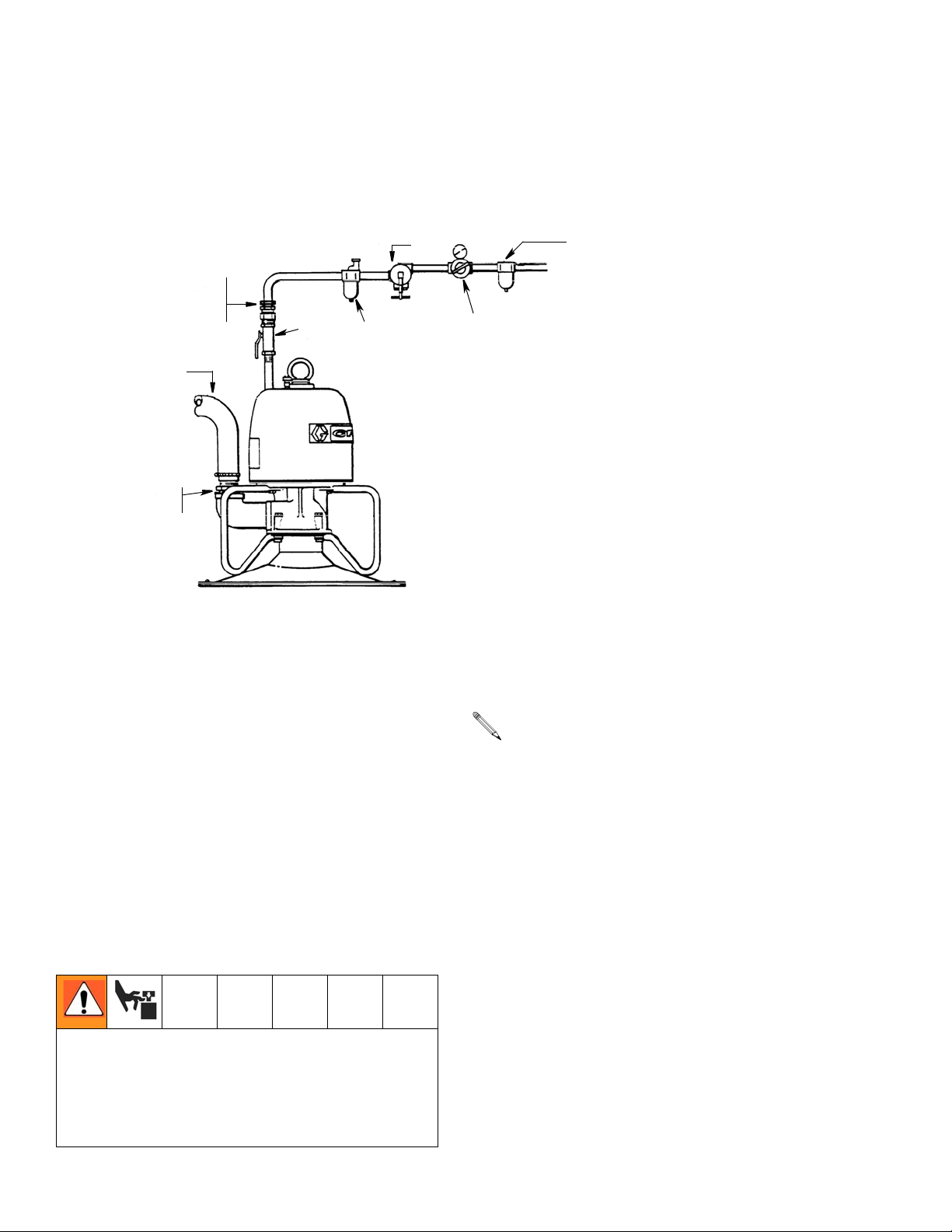

Air and Transfer Lines (FIG. 2)

The typical installation shown in FIG. 2 is only provided as a guide for selecting and installing required and optional

accessories. Be sure all air and fluid accessories are properly sized for your system and are compatible with the fluid

you are pumping. Contact your Graco representative for assistance in designing a transfer system to suit your specific needs.

Air inlet

3/4 npsm(f)

swivel

F

2” npt

outlet

ti0551a

F

IG. 2

• 3/4 in. ID Air Supply Line

• 3/4 npt(f) Air Inlet Swivel

C

E

D

B

A

Key:

A Air Line Filter

B Air Regulator

C Air Runaway Valve

D Air Line Oiler

E Bleed-type Master Air Valve

F Outlet Hose

• Install Transfer Hose (F) to the 2 in. npt(f) pump

outlet and tighten securely.

• On the Air Supply Line install:

• Air Filter (A) to remove harmful dirt and mois-

ture from the compressed air supply

• Air Regulator (B) to control pump speed

• Air Runaway Valve (C) to stop the pump auto-

matically if the supply container is empty.

• Air Line Oiler (D) for automatic air motor lubri-

cation

• Bleed-type master air valve (E): required in your

system to relieve air trapped between it and the air

motor when the valve is closed.

Never operate this pump with the bleed-type master air

valve (E) (supplied with the air motor) removed. When

closed, this valve relieves air trapped between it and

the air motor. Trapped air can cause the pump to cycle

unexpectedly and cause serious bodily injury from

moving parts.

For air requirements and additional Technical Data

see page 10.

Install the Pump

1. Remove cover from a full, open head drum of lubricant.

2. To help eliminate air pockets, which is essential for

good priming, smooth surface of the lubricant with a

straight edge until it is level.

3. Lift pump from the inductor plate and wipe bottom of

plate clean.

4. Press inductor plate down onto the lubricant. Rock

plate back and forth to firmly seat it and to exhaust

air trapped under the plate. Continue with this

motion until some lubricant is forced up into the

neck of the inductor plate.

5. Place pump on the inductor plate.

4 306642F

Page 5

Operation

Operation

Pressure Relief Procedure

The system pressure must be manually relieved to prevent the system from starting accidentally, which could

cause moving parts to pinch or amputate your fingers.

To reduce the risk for injury, always follow this procedure whenever you:

• are instructed to relieve the pressure

• check or service any part of the pump or system.

1. Shut off main air supply.

2. Close the air regulator and bleed-type master air

valve.

3. Loosen a fluid fitting near the pump outlet to relieve

fluid pressure.

Clearing Obstructions

KEEP YOUR FINGERS AND HANDS AWAY FROM

THE PRIMING PISTON! The priming piston, located

at the pump intake, could pinch or amputate your fingers as it moves into the intake cylinder.

1. Always relieve pressure, page 5, before attempting

to clear any obstructions.

2. Disconnect Air Hose. Grip 1-3/4 inch hex in the center of the piston to unscrew it.

Removing Inductor Plate from Drum

Reference numbers and letters in parentheses in

the text refer to the callouts in F

IG. 3.

Startup

Reference numbers and letters in parentheses in

the text refer to the callouts in the F

1. Turn on the main air supply.

2. Open Air Valve (E) and slowly open the Air Regulator (B) until the pump is running smoothly. Always

use the lowest pressure necessary to deliver lubricant at the desired quantity.

CAUTION

Do not let the pump run dry. A dry pump quickly

speeds up and may damage itself. If the pump is running erratically or speeds up suddenly, relieve pump

pressure following Pressure Relief Procedure

(page 5) and change the lubricant drum. Use an Air

Runaway Valve (D) to shut off the pump automatically

when the drum is empty.

3. Shut off the pump and relieve pressure, page 5,

when the pump is not in use.

IG. 2.

16

ti0552a

FIG. 3

1. Relieve pressure, page 5.

2. Lift pump off inductor plate.

3. Insert the release bar (15) into the neck of the plate

and position it so that by applying leverage, the vacuum seal which formed beneath the plate, is broken.

4. Remove the plate.

306642F 5

Page 6

Troubleshooting

Troubleshooting

L

Problem Cause Solution

Pump doesn’t operate Insufficient air supply Be sure adequate volume of air is

supplied to pump. See Technical

Data on back cover.

Check for restriction in air line or

closed valves or regulators.

Check valve plate held closed by

obstruction

Damaged air motor See motor manual 307049, supplied.

Air motor operates but lubricant flow

is low

Erratic pump operation Worn, damaged or obstructed check

Leakage from weep hole Worn or damage throat packings Replace v-packings and glands. See

Empty lubricant drum Change drums.

Insufficient air supply Increase air pressure. Do not exceed

valve plate

Follow the Pressure Relief Procedure

above. Remove pump from inductor

plate and clean pump intake.

100 psi (.7 MPa, 7 bar)

Follow the Pressure Relief Proce-

dure, page 5. Remove pump from

inductor plate and clean and/or repair

intake.

page 7.

6 306642F

Page 7

Repair

Repair

Throat Packing Repair (FIG. 4)

V-Packin g

Must Face

Lips of

V-Packin gs

Must Face

FIG. 4

E

Lips of

L

Down

Up

P

B

• The throat packings are actually located in the

base of the air motor, but function as the throat

packings for the pump. To identify part numbers

and order repair parts, refer to parts list page

for air motor 208357 in instruction manual

307049, supplied.

C

• Reference numbers and letters in parentheses

in the text refer to the callouts in F

IG. 4 and

Parts List page 9.

F

H

J

D

17

4, 2

19

14

A

13

Weep

Hole

K

M

N

G

1. Relieve pressure, page 5.

2. Disconnect air hose and transfer hose. Remove air

inlet fittings.

3. Remove pump from inductor plate (20).

4. Unscrew priming piston (13) from connecting tube

(A). The priming piston has a 1-3/4 in. hex in the

center.

5. Remove nuts and lock washers (4, 2) holding pump

guides (12) and collars (17). Remove these parts.

6. Pull intake cylinder (19) straight down.

7. Remove screws (P) and air motor shield (B).

8. Remove screws and washers holding air motor cylinder (C) to base (D). Pull base straight off, being

careful not to damage smooth surfaces of connecting tube and cylinder.

9. Inspect v-packing (E) in base. If it is worn or damaged, remove it. Grease new packing and carefully

tuck it into base. Be sure washer (F) is in place in

base.

10. Unscrew packing retainer (G) and remove the

spring and packings.

11. Clean all parts thoroughly and inspect for wear or

damage. Replace all packings and glads and other

parts as necessary.

12. Grease all parts thoroughly with light, waterproof

grease.

306642F 7

Page 8

Repair

13. One at a time, install a washer (H), bearing (J),

female gland (K), four leather v-packings (L) with

lips of the v-packings facing out of the base, male

gland (M), spring (N) and retainer (G).

14. Turn retainer in about 3 times.

15. Lubricate connecting tube (A) with light, waterproof

grease.

16. Carefully push base onto tube and secure it to the

cylinder with screws and washer. Then tighten packing retainer (G) snugly.

17. Inspect o-ring (18) in air motor base. Replace it if it

is damaged. Grease new o-ring before installing it.

18. Install air motor shield and screws.

19. Install check valve plate (14), cylinder (19) collars

(17), and pump guides (12). Secure with lock washers (2) and nuts (4) on screws (5).

20. Screw priming piston (13) onto connecting tube (A).

Pump Intake Repair (FIG. 4)

1. Relieve pressure, page 5.

2. Disconnect air hose from motor.

3. Remove pump from inductor plate.

4. Remove nuts and lock washers (4, 2) holding pump

guides (12). Remove collars (17).

5. Pull cylinder (19) straight down.

6. Unscrews priming piston (13) from connecting tube

(A). The priming piston has a 1-3/4 in. hex in the

center.

7. Remove check valve plate (14).

8. Clean all parts thoroughly and inspect for wear or

damage. Replace parts as necessary and

reassemble.

8 306642F

Page 9

Parts

21

2” npt(f)

fluid outlet

11

18

10

Parts

Model 205148

3/4” npt air inlet

8

1, 3

5

Pump, 3:1 Bulldog

Ref.

No. Part No. Description Qty.

2 100133 LOCKWASHER, spring, 3/8” 4

4 100340 NUT, hex; 3/8-16 4

5 100454 CAPSCREW, hex hd; 3/8-16x3” 4

8 101864 CAPSCREW, soc hd; 5/16-18 x 1” 4

10 162841 O-RING 1

11 162842 ADAPTER 1

13 162844 PLATE, priming shovel 1

14 162846 PLATE, check valve 1

17 162933 COLLAR, cylinder mounting 2

18 162934* O-RING 1

19 162936 CYLINDER, pump intake 1

21 208357 AIR MOTOR (see manual 307049

for parts)

* Recommended “tool box” spare parts. Keep on

hand.

1

ti10555a

FIG. 5

12

17

14

16 Follow Plate Release Bar

6

9

20

13

19

4, 2

15

Model 205028

Pump, 3:1 Bulldog with inductor

Ref.

No. Part No. Description Qty.

1 100057 SCREW, hex hd cap; 5/16-18 x 3/4” 4

3 100214 LOCKWASHER, spring 5/16 4

6 100799 SCREW, rd hd mach; 1/4-20 x 1/2” 18

9 161288 SEGMENT, full barrel, 400 lb 6

12 162843 GUIDE, pump 4

15 162852* WIPER, follow plate 1

16 162853 BAR, follow plate release 1

20 205144 PLATE, follow 1

* Recommended “tool box” spare parts. Keep on

hand.

306642F 9

Page 10

Technical Data

Technical Data

Fluid Pressure Ratio. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3:1

Air Pressure Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40 - 100 psi (0.28 - 0.7 MPa, 2.8 - 7 bar)

Maximum Working Fluid Pressure . . . . . . . . . . . . . . . . . . 300 psi (2.1 MPa, 21 bar)

Maximum Recommended Pump Speed . . . . . . . . . . . . . 60 cycles/minute

Air Motor Effective Diameter . . . . . . . . . . . . . . . . . . . . . . 7 in. (178 mm)

Stroke. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3/4 in. (120 mm)

Air Inlet Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3/4 npsm(f) swivel

Fluid Outlet Size. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 in. npt(f)

Fluid Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Priming Piston

Height. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28.25 in. (718 mm)

Inductor Diameter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22.5 in. (570 mm)

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121 lb (53 Kg) approximate

Wetted Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Aluminum, steel, Buna-N, Leather, Brass, neoprene/duck

10 306642F

Page 11

Notes

Notes

306642F 11

Page 12

Graco Warranty and Disclaimers

Graco Warranty and Disclaimers

Warranty

Graco warrants all equipment manufactured by it and bearing its name to be free from defects in material and workmanship on the date of sale by an authorized Graco distributor to the original purchaser for use. As purchaser’s sole

remedy for breach of this warranty, Graco will, for a period of twelve months from the date of sale, repair or replace

any part of the equipment proven defective. This warranty applies only when the equipment is installed, operated and

maintained in accordance with Graco’s written recommendations.

This warranty does not cover, and Graco shall not be liable for, any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused

by incompatibility with Graco equipment of structures, accessories, equipment or materials not supplied by Graco, or

improper design, manufacture, installation, operation or maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco

distributor for verification of the claim. If the claimed defect is verified, Graco will repair or replace free of charge any

defective parts. The equipment will be returned to the original purchaser transportation prepaid. If inspection of the

equipment does not disclose any defect in material or workmanship, repairs will be made at a reasonable charge,

which charges may include the costs of parts, labor and transportation.

Disclaimers and Limitations

The terms of this warranty constitute purchaser’s sole and exclusive remedy and are in lieu of any other warranties

(express or implied), including warranty of merchantability or warranty of fitness for a particular purpose, and of any

non-contractual liabilities, including product liabilities, based on negligence or strict liability. Every form of liability for

direct, special or consequential damages or loss is expressly excluded and denied. In no case shall Graco’s liability

exceed the amount of the purchase price. Any action for breach of warranty must be brought within two (2) years of

the date of sale.

Equipment Not Covered by Graco Warranty

Graco makes no warranty, and disclaims all implied warranties of merchantability and fitness for a particular purpose,

with respect to accessories, equipment, materials, or components sold but not manufactured by Graco. These items

sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.) are subject to the warranty, if any,

of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of

these warranties.

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

This manual contains English. MM 306642

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

12 306642F

www.graco.com

12/1958, Revised 6/2007

Loading...

Loading...