Page 1

Repair and Parts

™

GTX

- For Water-Based Materials Only-

Model: 257030

Sprayer with Graco Trigger Gun

120 psi (8.27 bar) Maximum Working Air Pressure

120 psi (8.27 bar) Maximum Working Fluid Pressure

Important Safety Instructions

Read all warnings and instructions in this

manual. Save these instructions.

2000EX

313385B

Related Manuals

Operation: 313384

Gun: 310616

Pump: 309915

ti13066a

Page 2

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific risk. Refer back

to these warnings. Additional, product-specific warnings may be found throughout the body of this manual where

applicable.

WARNING

WARNINGWARNINGWARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes

are present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information

about your material, request MSDS forms from distributor or retailer.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

PRESSURIZED EQUIPMENT HAZARD

Fluid from the gun/dispense valve, leaks, or ruptured components can splash in the eyes or on skin and

cause serious injury.

• Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning,

checking, or servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses, tubes, and couplings daily. Replace worn or damaged parts immediately.

2 313385B

Page 3

PLASTIC PARTS CLEANING SOLVENT HAZARD

Use only compatible water-based solvents to clean plastic structural or pressure-containing parts. Many

solvents can degrade plastic parts and cause them to fail, which could cause serious injury or property

damage. See Technical Data in this and all other equipment instruction manuals. Read fluid and solvent

manufacturer’s warnings.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, including eye injury, inhalation of toxic

fumes, burns, and hearing loss. This equipment includes but is not limited to:

• Protective eye wear

• Clothing and respirator as recommended by the fluid and solvent manufacturer

•Gloves

• Hearing protection

NOTICE

Water or material remaining in unit when temperatures are below freezing can damage pump and/or delay startup.

To insure water and material are completely drained out of unit:

1. Remove material line from sprayer.

2. Tip sprayer to allow material (water) to flow out of pump inlet.

Before adding material or starting unit in cold weather, run warm water through pump.

313385B 3

Page 4

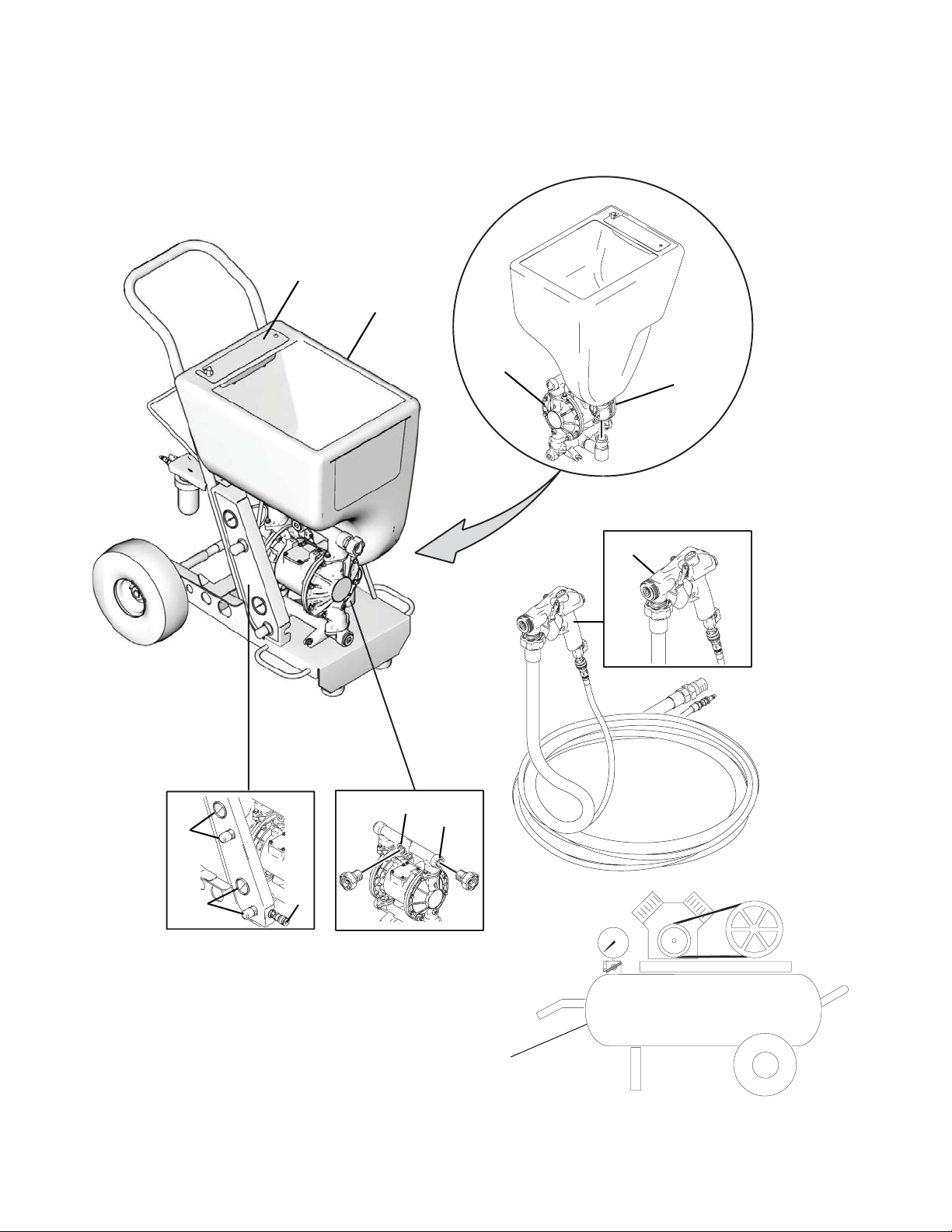

Component Identification

Component Identification

A

B

D

C

ti13066a

K

E

H

J

G

F

L

4 313385B

Page 5

Component Identification

Component Identification List

A Nozzle Storage

B Hopper

C Hopper Quick Connect

D Diaphragm Pump

E Material Outlet Option 1

F Material Outlet Option 2

G Gun Air Outlet Quick Connect

H Material (Pump) Air Pressure Gauge and Control Knob

J Gun Air Pressure Gauge and Control Knob

K Gun (see manual 308878)*

L Air Compressor (not supplied by Graco)

* Reference numbers used in gun illustrations coincide with reference numbers shown in gun manual 310616

313385B 5

Page 6

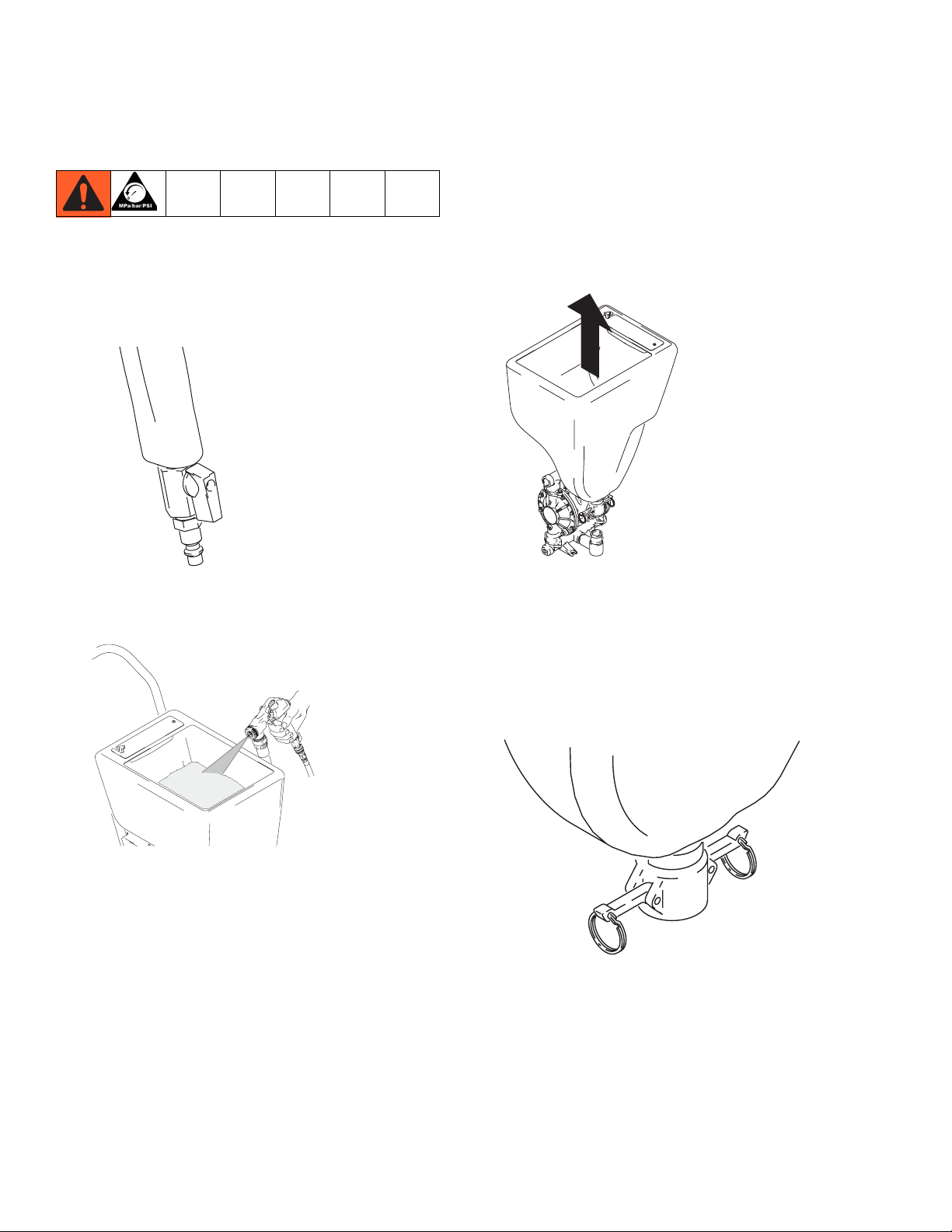

Preparation

Preparation

Hopper Removal

1. To remove hopper (G), release the latches on each

side of coupler (H).

Pressure Relief

1. Disconnect air inlet.

2. Open gun air valve (23).

ti4000b

3. Trigger gun, and spray material back into hopper.

2. Lift hopper straight up, off unit.

ti3900a

Install Hopper

1. To install hopper, position coupler over material outlet and slide it straight down, over the fitting, as far

as it will go.

2. Secure latches by pushing each one up and firmly

into locked position.

ti3899a

ti3900a

Hopper Removal and Installation

The hopper (G) can be removed from the cart for cleaning and servicing equipment.

NOTE: Before removing hopper, allow unit to cool down

and/or remove compressor power pack from cart.

6 313385B

Page 7

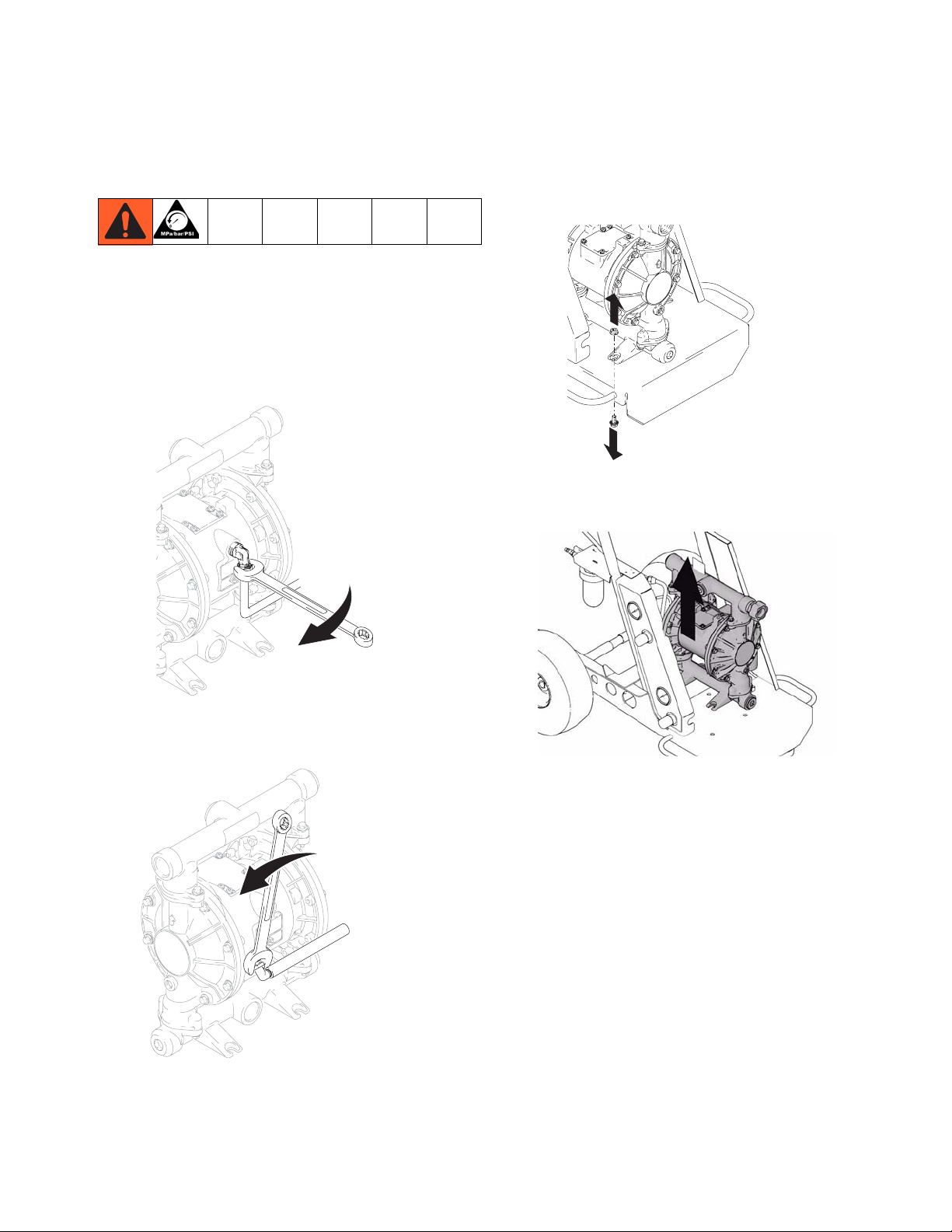

Pump Removal and Installation

5. Remove four bolts holding pump to cart.

Pump Removal

1. Relieve Pressure, page 6.

2. Remove hopper, page 6.

Pump Removal and Installation

3. Disconnect air lines.

4. Disconnect exhaust tube.

ti3824a

6. Lift pump straight up off cart.

ti3888a

ti3825c

Pump Installation

1. Lower pump on cart.

2. Replace four bolts holding pump to cart.

3. Reconnect exhaust tube.

4. Reconnect air lines.

5. Replace hopper, page 6.

ti3889a

313385B 7

Page 8

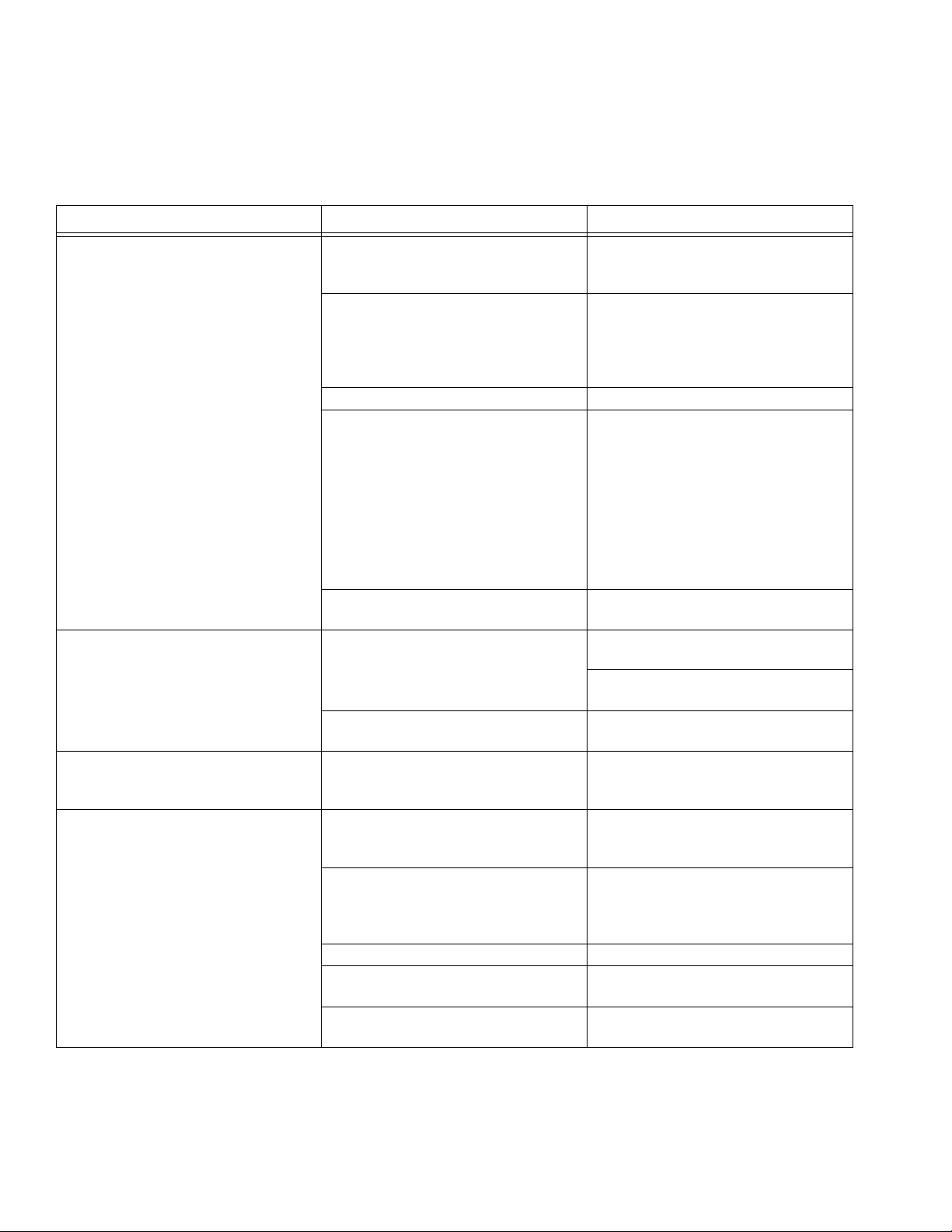

Troubleshooting

Troubleshooting

Before performing any Troubleshooting procedures, follow Pressure Relief procedure on page 6.

PROBLEM CAUSE SOLUTION

No material output from pump Not enough air pressure to pump Shut off air at the gun, and increase air

pressure to the pump to maximum.

Turn regulator clockwise to increase.

Material too thick Thin the material. Material must be

mixed thoroughly to a consistency that

immediately folds back in as you draw

your finger through the surface of the

material.

Damaged checkballs or seats Replace checkballs or seats.

Plugged gun or nozzle Relieve Pressure, page 6. Remove

gun from material hose, and cycle

pump.

NOTE: A plugged gun or nozzle may

cause the hose and pump to plug. If

necessary, flush hose and pump with

clean water before cycling material

through the hose with the gun

removed.

Plugged hose, or hose too small Relieve pressure, page 6. Flush hose

with clean water, or try a 1-1/4 in. hose.

Pump stops pumping Stalled pump Shut down system. Relieve Pressure,

page 6. Restart.

Contact an authorized Graco service

center.

Pump in need of repair See texture pump instruction manual

308479.

Pulsing or surging material Triggering too fast Slowly squeeze trigger to fully open

position while moving gun quickly in a

circular motion.

Speed of application too slow Not enough air pressure to pump Shut off air at the gun, and increase air

pressure to the pump to maximum.

Turn regulator clockwise to increase.

Material too thick Material must be mixed thoroughly to a

consistency that immediately folds

back in as you draw your finger through

the surface of the material.

Nozzle too small Increase nozzle size.

Hose plugged or too small. Relieve Pressure, page 6. Clean hose,

or try a 1-1/4 in. hose.

Pump in need of repair See texture pump instruction manual

308479.

8 313385B

Page 9

Troubleshooting

PROBLEM CAUSE SOLUTION

Pattern too fine or too much overspray Material too thin Thicken material. Material must be

mixed thoroughly to a consistency that

immediately folds back in as you draw

your finger through the surface of the

material.

Air pressure at gun too high Decrease air to gun at gun fitting and/or

regulator.

Fluid delivery too low Increase nozzle size.

Increase air pressure to pump, or

decrease air to gun at gun fitting and/or

regulator.

Turn fluid knob out on gun. See Spray

Techniques in Operation Manual

309915.

Pattern too coarse Material too thick Thin material. Material must be mixed

thoroughly to a consistency that immediately folds back in as you draw your

finger through the surface of the material.

Air pressure at gun too low Increase air to gun at gun fitting and/or

regulator.

Fluid delivery too high Decrease nozzle size.

Decrease air pressure to pump, or

increase air to gun at gun fitting and/or

regulator.

Turn fluid knob in on gun. See Spray

Techniques in Operation Manual

309915.

313385B 9

Page 10

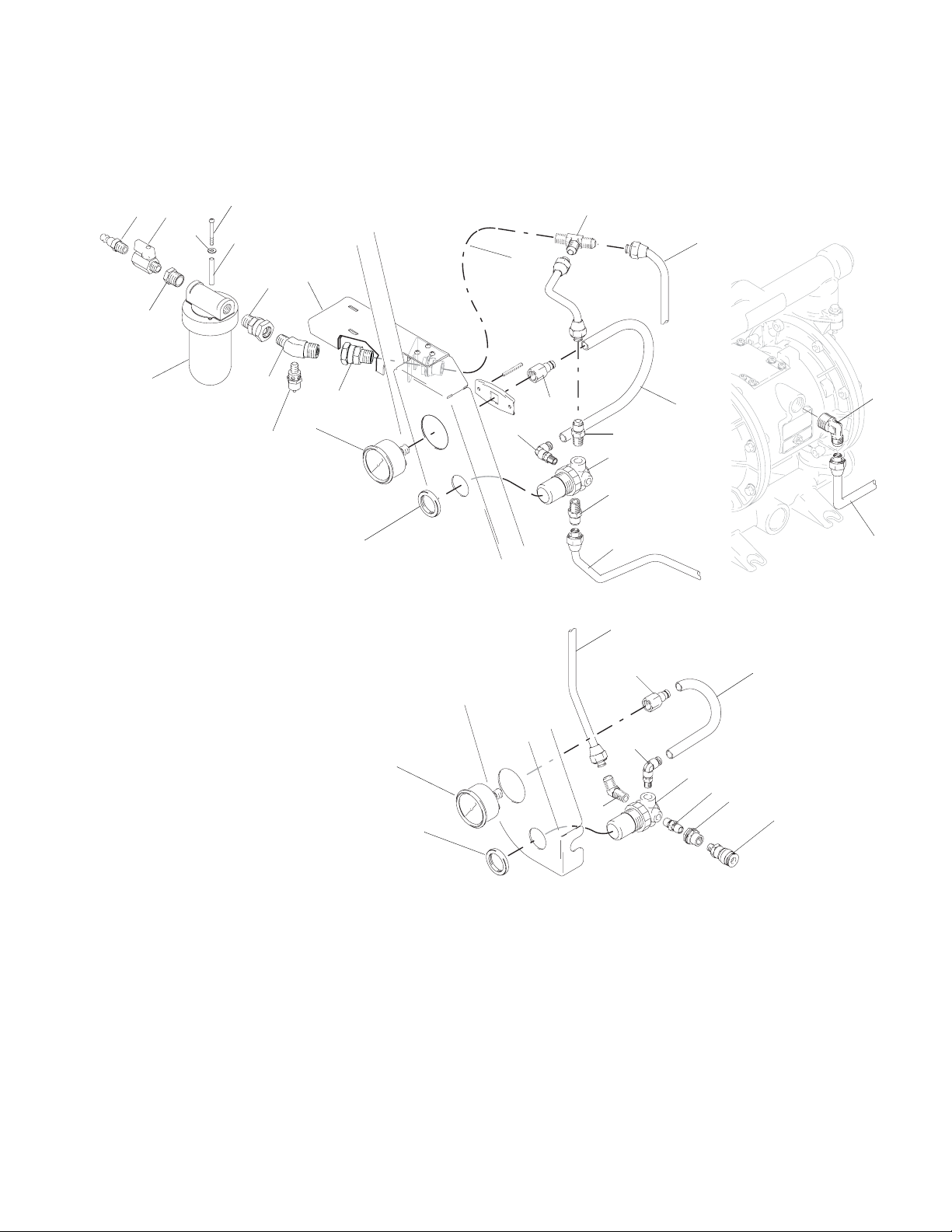

Parts Drawing

Parts Drawing

58

32

43

44

33

3

72

1

30

36

4

5

6

7

31

38

40

2

39

42

8

9

29

ti3953c

10 313385B

28

Page 11

Parts Drawing

Parts Drawing

11

69

65

12

75

66

67

70

68

76

71

10

13

16

19

25

18 22

17

A

15

26

22

26

21

20

A

23

B

21

B

10

16

ti3954c

24

18

17

15

14

22

13

27

313385B 11

Page 12

Parts Drawing

Parts Drawing

45

35

34

ti3956a

ti3955a

41

38

12 313385B

Page 13

Parts List

Parts Drawing

Ref. Part Description Qty.

1 15C878 FRAME, texture, blue 1

2 801504 FOOT, rubber 2

3 15C843 HOPPER, texture, gas 1

4 116478 WHEEL, pneumatic 2

5 101242 RING, retaining, ext. 2

6 111841 WASHER, plain 5/8 2

7 246887 PUMP, diaphragm, 1040, texture 1

8 15C759 COUPLING, pump 1

9 15D985 FITTING, adapter, swivel 1

10 118457 GAUGE, panel, mount 2

11 169970 FITTING, line air 1

12 15B565 VALVE, ball 1

13 104641 FITTING, bulkhead 2

14 156971 FITTING, nipple, short 1

15 115242 REGULATOR, air, 1/4 npt 2

16 115244 NUT, regulator 2

17 118486 FITTING, elbow, push 2

18 118481 FITTING, push 2

19 15C970 TUBE, air, pump, regulator 1

20 15C971 TUBE, air, regulator 1

21 15C969 TUBE, air, pump 1

22 15C968 TUBE, air 2

23 118458 FITTING, elbow, male 1

24 118482 FITTING, elbow, 45 1

25 118472 FITTING, tee 1

26 118484 FITTING, connector 2

27 116720 COUPLER, quick disconnect 1

28 287304 HOSE, texture, twin line 1

29 15W898 LABEL, brand, GTX2000 front 1

30 15W900 LABEL, brand, GTX2000 righT 1

31 15W899 LABEL, brand, GTX2000 left 1

32▲ 15C996 LABEL, warning, sprayer 1

33 15C844 COVER, holder, nozzle 1

34 118465 FITTING, elbow, nylon, hose 1

35 15C948 HOSE, exhaust 1

36 15D094 FILTER, hopper 1

37 110996 NUT, hex, flange head 4

Ref. Part Description Qty.

38 111800 SCREW, cap, hex hd 5

39 100132 WASHER, flat 2

40 101566 NUT, lock 2

41 112717 WASHER 1

42 100004 SCREW, cap, hex hd 2

43 114966 KNOB, pronged 1

44 111831 SCREW, cap, skt, button hd 1

45 103473 STRAP, tie, wire 2

58 15D366 PAD, isolator, hopper bracket 1

59 248515 BALL, sponge, 30mm (5 pk) 1

60 15C090 GAUGE, thickness, fluid 1

65 106148 FILTER, air, 3/8npt 1

66 122544 SCREW, self tap, pnhd 2

67 15W881 SPACER, standoff, GTX 1

68 15X997 VALVE, check 1/8 120 psi 1

69 100176 BUSHING, hex 1

70 15W375 FITTING, 30 deg, 3/8 x 1/4 npt 1

71 15X567 BRACKET, compressorless 1

72 248093 GUN, spray, texture, bleeder 1

75 WASHER, #8, plain, flat 1

76 235208 FITTING, union, swivel 1

▲ Replacement Danger and Warning labels, tags, and

cards are available at no cost.

Accessories:

248112 KIT, suction (allows sprayer to

pump texture material directly out

of large container or trash can)

248117 HOSE, 3/8 in. x 50 ft. with quick dis-

connect (allows compressor to stay

outside while sprayer is used

inside. Can use up to three 50 ft.

sections with minimal performance

loss)

1

1

313385B 13

Page 14

Pump Parts Drawing

Pump Parts Drawing

3

20

17†

11

16

18†

12

6†

7†

16

5

9†

8

17†

10†

2

4†

11

23

25

113

104

▲110

113

106

103

301*

202*

10†

3

15

*402

19

22

401*

105

113

108*

107

ti12959a

101

106

201*

202*

106

301*

202*

201

202*

102

113

14 313385B

Page 15

Pump Parts List

Pump Parts Drawing

Ref. Part Description Qty.

1 188838 HOUSING, center, aluminum 1

2 188854 COVER, air valve, aluminum 1

3 116344 SCREW, mach, hex flange hd;

M5 X 0.8; 12 mm (0.47 in.)

4 188618 GASKET, molded Santoprene 1

5 188855 CARRIAGE, aluminum 1

6† 108730 O-RING, nitrile 1

7† 188616 BLOCK, air valve, acetal 1

8 188615 PLATE, air valve, sst 1

9† 188617 SEAL, valve plate, buna-N 1

10† 112181 PACKING, u-cup, nitrile 2

11 188612 PISTON, actuator, acetal 2

12 188613 BEARING, piston, acetal 2

15 188611 BEARING, pin, acetal 2

16 188610 PIN, pilot, stainless steel 2

17† 157628 O-RING, buna-N 2

18† 188614 BLOCK, pilot, acetal 1

19 188609 BEARING, shaft, acetal 2

20 116343 SCREW, grounding 1

22 188603 GASKET, air cover, foam 2

23 188839 COVER, air, aluminum 2

24 188608 SHAFT, diaphragm, sst 1

25 115643 SCREW, M8 X 1.25;

25 mm (1 in.)

101 188840 COVER, fluid, aluminum 2

12

Ref. Part Description Qty.

102 188841 MANIFOLD, inlet, aluminum 1

103 188842 MANIFOLD, outlet, aluminum 1

104 188607 PLATE, air side, aluminum 2

9

105 188607 PLATE, fluid side, aluminum 2

106 115643 SCREW, M8 X 1.25;

25 mm (1 in.)

107 189044 BOLT, M12 X 1.75;

35 mm (1.38 in.) sst

108* 104319 O-RING, PTFE 2

110▲ 188621 LABEL, warning 1

113 121497 PLUG, 1 in. npt, cst 4

201* 194211

202* 109205 O-RING, PTFE 8

301* 114751 BALL, Geolast[, 1-1/4 in. 4

401* 15B499 DIAPHRAGM, buna-N 2

402* 112181 PACKING, u-cup, nitrile 2

† These parts are included in Air Valve Repair Kit

236273, which may be purchased separately.

* These parts are included in Pump Repair Kit

D07GG7 which may be purchased separately.

▲ Replacement Danger and Warning labels, tags

and cards are available at no cost.

SEAT, Geolast

®

24

2

4

313385B 15

Page 16

Technical Data

Technical Data

Maximum air working pressure. . . . . . . . . . . .120 psi (8.27 bar)

Maximum working fluid pressure . . . . . . . . . .120 psi (8.27 bar)

Compressor (not supplied)

AIr Delivery . . . . . . . . . . . . . . . . . . . . . . .12 cfm @ 100 psi

(340 lpm @ 6.9 bar)

Hopper capacity

Maximum. . . . . . . . . . . . . . . . . . . . . . .17 gallons (64 liters)

Maximum delivery with texture material . . 4.0 gpm (15.14 lpm)

Maximum delivery with water . . . . . . . . . . 40.0 gpm (151.4 lpm) at 12 CFM @ 100 psi (340 lpm @ 6.9 bar)

Dimensions

Length . . . . . . . . . . . . . . . . . . .38 in. (965 mm) with handle

Width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 in. (610 mm)

Height . . . . . . . . . . . . . . . . . . . . . . . . . . . 40 in. (1016 mm)

Weight

With hoses, gun. . . . . . . . . . . . . . . . . . . . . 110 lb (49.9 kg)

Wetted parts . . . . . . . . . . . . . . . . . . . . . . . . PVC, zinc plate CS,

buna-N, aluminum, brass, polyethylene

sst, UHMW, acetal

Sound . . . . . . . . . . . . . . . . . . .Reference pump manual 308479

at 12 CFM @ 100 psi (340 lpm @ 6.9 bar)

16 313385B

Page 17

Notes

Notes

313385B 17

Page 18

Graco Warranty

Graco warrants all equipment manufactured by Graco and bearing its name to be free from defects in material and workmanship on the date of

sale to the original purchaser for use. With the exception of any special, extended, or limited warranty published by Graco, Graco will, for a period

of twelve months from the date of sale, repair or replace any part of the equipment determined by Graco to be defective. This warranty applies only

when the equipment is installed, operated and maintained in accordance with Graco's written recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of non-Graco

component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with structures,

accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs will

be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT LIMITED

TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco's sole obligation and buyer's sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

Graco makes no warranty, and disclaims all implied warranties of merchantability and fitness for a particular purpose in connection with accessories, equipment, materials or components sold but not manufactured by Graco. These items sold, but not manufactured by Graco (such as electric

motors, switches, hose, etc.), are subject to the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in

making any claim for breach of these warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés à la suite

de ou en rapport, directement ou indirectement, avec les procedures concernées.

ADDITIONAL WARRANTY COVERAGE

Graco does provide extended warranty and wear warranty for products described in the "Graco Contractor Equipment Warranty Program".

Graco Phone Number

TO PLACE AN ORDER, contact your Graco distributor, or call this number to identify the distributor closest to you:

1-800-690-2894 Toll Free

All written and visual data contained in this document reflects the latest product information available at the time of publication.

Graco reserves the right to make changes at any time without notice.

This manual contains English. MM 313385

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

Copyright 2008, Graco Inc. is registered to I.S. EN ISO 9001

www.graco.com

12/2008

Loading...

Loading...