Page 1

Instructions-Parts

Pneumatic

Pneumatic Pneumatic

User

Interface

User User

Interface Interface

For

professional

For For

professional professional

19Y486

19Y486 19Y486

The19Y486PumpControlModuleuses

the25B475AdvancedDisplayControl

Module(ADCM).Seemanual332013

(supplied)forcompletewarningsand

approvalsforthe25B475ADCM.

—

Pneumatic

— —

Pneumatic Pneumatic

Important

Important Important

Readallwarningsandinstructionsinthismanual,thesupplied

ADCMmanual,andtheIPKmanualsbeforeusingtheequipment.

Save

these

Save Save

these these

Pump

Pump Pump

for

controlling

for for

controlling controlling

use

only.

use use

only. only.

Pump

Pump Pump

Safety

Safety Safety

Instructions

Instructions Instructions

instructions.

instructions. instructions.

Control

Control Control

Module

Module Module

3A7709B

EN

and

monitoring

and and

monitoring monitoring

Control

Control Control

Module

Module Module

Graco

Graco Graco

Intelligent

Intelligent Intelligent

Paint

Kitchen

Paint Paint

Kitchen Kitchen

(IPK)

Pneumatic

(IPK) (IPK)

Pneumatic Pneumatic

Pumps.

Pumps. Pumps.

PROVENQUALITY.LEADINGTECHNOLOGY.

Page 2

Contents

Contents Contents

RelatedManuals................................................2

Warnings...........................................................3

PumpControlModule.........................................7

Installation..........................................................7

HazardousLocations....................................7

Grounding...................................................9

CableConnection........................................11

TypicalInstallation.......................................13

Operation...........................................................14

PressureReliefProcedure............................14

ModesofOperation......................................14

Display........................................................15

ModuleScreens...........................................16

ModuleMenuBar.........................................16

ModuleKeys................................................16

RunScreens......................................................17

PumpControlChapter..................................17

TotalizerChapter.........................................19

AgitatorChapter...........................................20

EventLogChapter.......................................21

SetupScreens....................................................22

ProleChapter.............................................22

PressureTransducerChapter.......................27

PumpSetupChapter....................................29

DiagnosticChapter......................................30

TotalizerChapter.........................................30

ModbusChapter..........................................31

MiscellaneousChapter.................................32

ErrorCodeTroubleshooting................................35

Parts..................................................................38

25B234PneumaticADCMDisplay

EnclosureAssembly.......................39

AccessoriesandKits...........................................41

AutomaticAirControlKit19Y482..................41

NXTAirControlKit19Y996..........................42

TransducerI/PKit24V001............................43

PressureTransducerKitfor4-ballPumps

24R050PressureTransducerKit

for2-ballPumps24Y245.................43

PressureTransducerKitforSanitary

Pumps24X089...............................44

CaliforniaProposition65.....................................44

Notes................................................................45

AppendixA-ModbusVariableMap.....................45

AppendixB-ControlModuleProgramming...........58

GracoStandardWarranty....................................60

Related

Related Related

Manual

Manual Manual

332013

332196

3A1244

3A3382High-Flo

3A3452

333015Endura-Flo™3D150,3D350,4D150,and4D350DiaphragmPump,Instructions

307843

No.

No. No.

Manuals

Manuals Manuals

Description

Description Description

AdvancedDisplayControlModule(ADCM),Instructions-Parts

ISPowerSupplyModules,Instructions-Parts

GracoControlArchitectureModuleProgramming,Instructions

®

4–BallPumps,Instructions-Parts

4–BallLowerswithOpenWetCup,Repair-Parts

Air-PoweredGlutton

®

Pumps,Instructions-Installation

2

3A7709B

Page 3

Warnings

Warnings Warnings

Thefollowingwarningsareforthesetup,use,grounding,maintenanceandrepairofthisequipment.The

exclamationpointsymbolalertsyoutoageneralwarningandthehazardsymbolreferstoprocedure-specic

risks.Whenthesesymbolsappearinthebodyofthismanualoronwarninglabels,referbacktothese

Warnings.Product-specichazardsymbolsandwarningsnotcoveredinthissectionmayappearthroughout

thebodyofthismanualwhereapplicable.

WARNING

WARNING WARNING

FIRE

AND

FIRE FIRE

Flammablefumes,suchassolventandpaintfumes,inwork work

orsolventowingthroughtheequipmentcancausestaticsparking.Tohelppreventreand

explosion:

•Useequipmentonlyinwellventilatedarea.

•Eliminateallignitionsources;suchaspilotlights,cigarettes,portableelectriclamps,and

plasticdropcloths(potentialstaticarc).

•Keepworkareafreeofdebris,includingsolvent,ragsandgasoline.

•Donotplugorunplugpowercords,orturnpowerorlightswitchesonoroffwhenammable

fumesarepresent.

•Groundallequipmentintheworkarea.SeeGrounding Grounding

•Useonlygroundedhoses.

Stop

•Stop Stop

equipmentuntilyouidentifyandcorrecttheproblem.

•Keepaworkingreextinguisherintheworkarea.

EXPLOSION

AND AND

EXPLOSION EXPLOSION

operation

operation operation

immediately

immediately immediately

HAZARD

HAZARD HAZARD

work

area

area area

canigniteorexplode.Paint

Grounding

ifstaticsparkingoccursoryoufeelashock.Donotuse

instructions.

Warnings

Staticchargemaybuilduponplasticpartsduringcleaningandcoulddischargeandignite

ammablevapors.Topreventreandexplosion:

•Cleanplasticpartsonlyinawell-ventilatedarea.

•Donotcleanwithadrycloth.

3A7709B3

Page 4

Warnings

WARNING

WARNING WARNING

INTRINSIC

INTRINSIC INTRINSIC

Intrinsicallysafeequipmentthatisinstalledimproperlyorconnectedtonon-intrinsicallysafe

equipmentwillcreateahazardousconditionandcancausere,explosion,orelectricshock.

Followlocalregulationsandthefollowingsafetyrequirements.

•InstallationshouldbeinaccordancewithANSI/ISARP12.06.01“InstallationofIntrinsically

SafeSystemsforHazardous(Classied)Locations”andtheNationalElectricalCode®

(ANSI/NFPA70).

•InstallationinCanadashouldbeinaccordancewiththeCanadianElectricalCode,CSA

C22.1,Part1,AppendixF.

•ForATEX,installperEN60079–14andapplicablelocalandnationalcodes.

•Equipmentthatcomesincontactwithintrinsicallysafeterminalsmustmeettheentity

parameterrequirementsspeciedinControlDrawing16M169.SeeAppendixAinManual

332013.Thisincludessafetybarriers,DCvoltagemeters,ohmmeters,cables,and

connections.Removetheunitfromthehazardousareawhenservicing.

•Withoutthesafetybarrier,theequipmentisnolongerintrinsicallysafeandmustnotbe

operatedinhazardouslocations,asdenedinarticle500oftheNationalElectricalCode

(USA)oryourlocalelectricalcode.

•Donotinstallequipmentapprovedonlyfornon-hazardouslocationinahazardousarea.See

theIDlabelfortheintrinsicsafetyratingforyourmodel.

•Donotuseintrinsicallysafeequipmentwithapowersupplythathasnobarrier.Intrinsic

safetymaybecompromised.

•Groundthepowersupply.Avoltagelimitingsafetybarriermustbeproperlygroundedtobe

effective.Forpropergrounding,usea12gaugeminimumgroundwire.Thebarrier’sground

mustbewithin1ohmoftrueearthground.

•Donotremoveanycoveruntilpowerhasbeenremoved.

•Donotsubstitutesystemcomponentsasthismayimpairintrinsicsafety.

SAFETY

SAFETY SAFETY

4

3A7709B

Page 5

WARNING

WARNING WARNING

SKIN

INJECTION

SKIN SKIN

INJECTION INJECTION

High-pressureuidfromgun,hoseleaks,orrupturedcomponentswillpierceskin.Thismay

looklikejustacut,butitisaseriousinjurythatcanresultinamputation.Get Get

treatment.

treatment. treatment.

•Donotspraywithouttipguardandtriggerguardinstalled.

•Engagetriggerlockwhennotspraying.

•Donotpointgunatanyoneoratanypartofthebody.

•Donotputyourhandoverthespraytip.

•Donotstopordeectleakswithyourhand,body,glove,orrag.

•FollowthePressure Pressure

orservicingequipment.

•Tightenalluidconnectionsbeforeoperatingtheequipment.

•Checkhosesandcouplingsdaily.Replacewornordamagedpartsimmediately.

HAZARD

HAZARD HAZARD

Get

immediate

immediate immediate

Pressure

Relief

Procedure

Relief Relief

Procedure Procedure

whenyoustopsprayingandbeforecleaning,checking,

Warnings

surgical

surgical surgical

EQUIPMENT

EQUIPMENT EQUIPMENT

Misusecancausedeathorseriousinjury.

•Donotoperatetheunitwhenfatiguedorundertheinuenceofdrugsoralcohol.

•Donotexceedthemaximumworkingpressureortemperatureratingofthelowestrated

systemcomponent.SeeTechnical Technical

•Useuidsandsolventsthatarecompatiblewithequipmentwettedparts.SeeTechnical Technical

Specications

Specications Specications

Forcompleteinformationaboutyourmaterial,requestSafetyDataSheets(SDSs)from

distributororretailer.

•Donotleavetheworkareawhileequipmentisenergizedorunderpressure.

•TurnoffallequipmentandfollowthePressure Pressure

•Checkequipmentdaily.Repairorreplacewornordamagedpartsimmediatelywithgenuine

manufacturer’sreplacementpartsonly.

•Donotalterormodifyequipment.Alterationsormodicationsmayvoidagencyapprovals

andcreatesafetyhazards.

•Makesureallequipmentisratedandapprovedfortheenvironmentinwhichyouareusingit.

•Useequipmentonlyforitsintendedpurpose.Callyourdistributorforinformation.

•Routehosesandcablesawayfromtrafcareas,sharpedges,movingparts,andhotsurfaces.

•Donotkinkoroverbendhosesorusehosestopullequipment.

•Keepchildrenandanimalsawayfromworkarea.

•Complywithallapplicablesafetyregulations.

MISUSE

MISUSE MISUSE

HAZARD

HAZARD HAZARD

Technical

inallequipmentmanuals.Readuidandsolventmanufacturer’swarnings.

Specications

Specications Specications

Pressure

Relief

Relief Relief

inallequipmentmanuals.

Procedure

Procedure Procedure

Technical

whenequipmentisnotinuse.

3A7709B5

Page 6

Warnings

WARNING

WARNING WARNING

PERSONAL

PERSONAL PERSONAL

Wearappropriateprotectiveequipmentwhenintheworkareatohelppreventseriousinjury,

includingeyeinjury,hearingloss,inhalationoftoxicfumes,andburns.Protectiveequipment

includesbutisnotlimitedto:

•Protectiveeyewear,andhearingprotection.

•Respirators,protectiveclothing,andglovesasrecommendedbytheuidandsolvent

manufacturer.

PROTECTIVE

PROTECTIVE PROTECTIVE

EQUIPMENT

EQUIPMENT EQUIPMENT

63A7709B

Page 7

PumpControlModule

Pump

Pump Pump

ThePumpControlModuleisauserinterfaceforthesetupandcontrolofpneumaticpumps.ItisanAdvanced

DisplayControlModule(ADCM)thatusesspecializedsoftwaretoallowtheusertoremotelysetthemode

ofpumpoperation,andtomonitorandcontrolpressureandowrate.

Thescreenbacklightisfactorysettoremainon,evenwithoutscreenactivity.See

SetupMiscellaneous1,page32,tosetthebrightnessandbacklighttimer.Pressanykeytorestorethesettings.

Keysareusedtoinputnumericaldata,entersetupscreens,navigatewithinascreen,scrollthroughscreens,

andselectsetupvalues.

Installation

Installation Installation

Forinstallationandsetupinstructions,seethe

AdvancedDisplayControlModule(ADCM)manual

332013.

Hazardous

Hazardous Hazardous

Donotsubstituteormodifysystemcomponents

asthismayimpairintrinsicsafety.Forinstallation,

maintenance,oroperationinstructions,read

theinstructionmanualsprovided:3A7709and

332013.Donotinstallequipmentapprovedonly

fornon-hazardouslocationinahazardouslocation.

Seetheidenticationlabelfortheintrinsicsafety

ratingforyourmodel.

Intrinsicallysafeequipmentshouldnotbeusedwith

apowersupplythathasnoISbarrier.Donotmove

unitsfromanon-ISinstallationtoanISinstallation.IS

equipmentthathasbeenusedwithanon-ISpower

Control

Control Control

Locations

Locations Locations

Module

Module Module

supplymustnotbereturnedtoahazardouslocation.

AlwaysuseanISbarrierwithISequipment.

•InstallaccordingtoControlDrawingNumber

16M169.SeeAppendixAintheAdvancedDisplay

ControlModule(ADCM)manual332013.

•InstallationintheUSshouldbeinaccordancewith

ANSI/ISARP12.06.01,“InstallationofIntrinsically

SafeSystemsforHazardous(Classied)

Locations,”andtheNationalElectricalCode®

(ANSI/NFPA70).

•InstallationinCanadashouldbeinaccordance

withtheCanadianElectricalCode,CSAC22.1,

Part1,AppendixF.

•ForATEX,installperEN60079-14andapplicable

localandnationalcodes.

•Multipleearthingofcomponentsisallowedonly

ifahighintegrityequipotentialsystemisrealized

betweenthepointsofbonding.

•Donotremoveanycoveruntilpowerhasbeen

removed.

3A7709B

7

Page 8

Installation

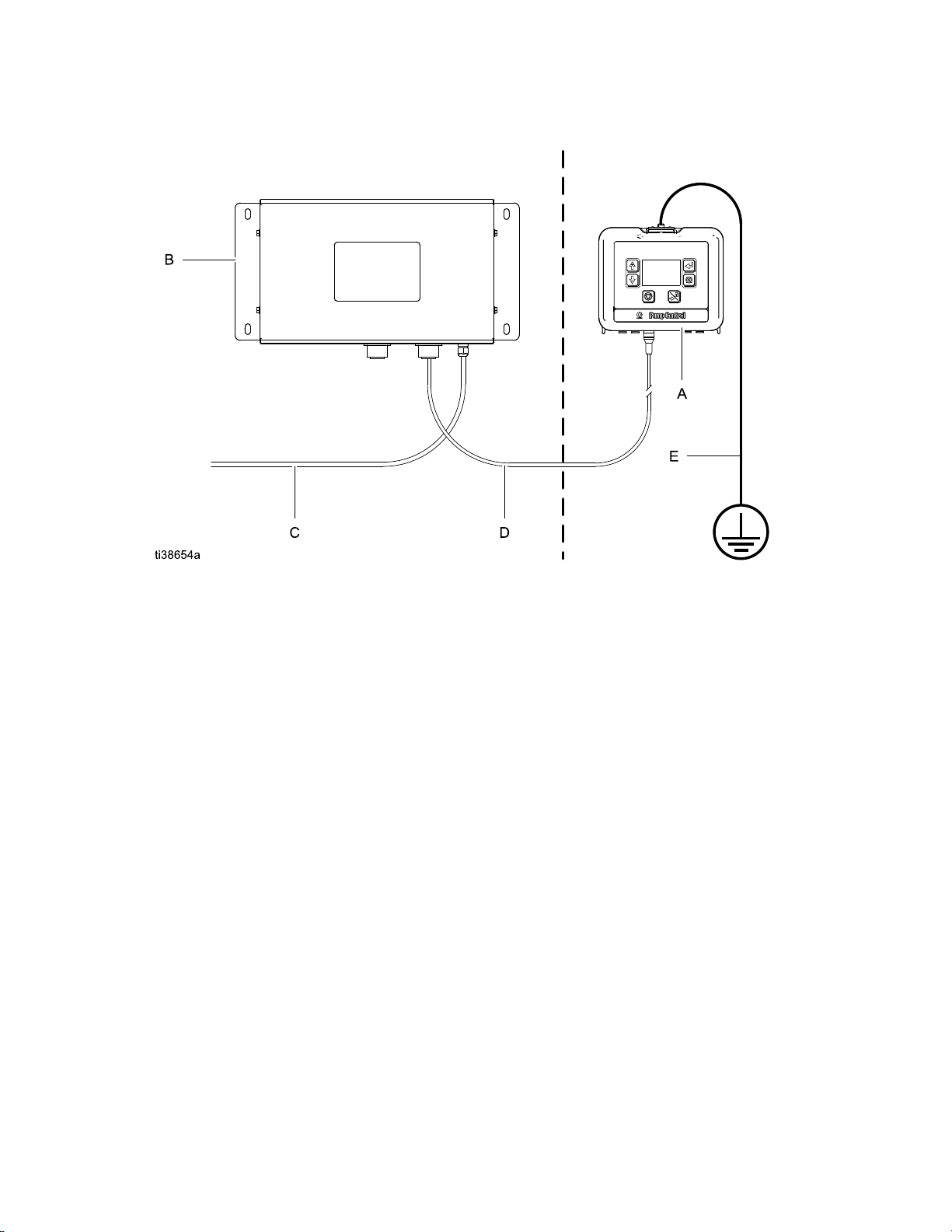

Non

Hazardous

Non Non

- --Hazardous Hazardous

Location

Location Location

Hazardous

Hazardous Hazardous

Location

Location Location

Figure1InstallationinaHazardousLocation

KEY:

KEY: KEY:

A

A A

B

B B

C

C C

D

D D

E

E E

PumpControlModule

PowerSupplyModule

PowerAccessoryCable

ISPowerCable(50ft.,15m),toterminal3.SeeCableConnection,page11.

GroundwireandclampforPumpControlModule.PN223547isnotsupplied.

83A7709B

Page 9

Installation

Grounding

Grounding Grounding

Theequipmentmustbegroundedtoreducethe

riskofstaticsparking.Staticsparkingcancause

fumestoigniteorexplode.Groundingprovidesan

escapewirefortheelectriccurrent.

Non-

Hazardous

Location

B

1

Hazardous

Location

A

Pump

Pump Pump

Control

Control Control

Module:

Module: Module:

Groundedthrough

theISPowerCable(34)totheISbarrier

(29)inthePowerSupplyModule.(See

PowerSupplyModuleGrounding,page10.)Ifthe

mountingbracketisused,connectagroundwire(E)

tothescrewatthetopofthebrackettoatrueearth

ground.(SeeFigure1.)

Power

Power Power

Supply

Supply Supply

Module:

Module: Module:

Followthegrounding

instructionsinthePowerSupplyModulemanual

332196.

NonHazardous

Location

Hazardous

Location

B

2

A

ti20264a

PowerSupplyModuleLocatedin

Non-HazardousLocation

KEY

KEY KEY

A

A A

B

B B

PumpControlModule

PowerSupplyModuleandBarrier

PowerSupplyModuleLocatedinHaz-

ardousLocation

ti20217a

ThepowercableCANNOThavethecableshieldtiedtothecouplingnut.500VACisolation

1

isrequired.ThepowercableandcircuitboardareisolatedfromthePumpControlModule

enclosure.TheyhaveconductivepathstoSEPARATE SEPARATE

SEPARATE

grounds

grounds grounds

.

ThepowercableCANhavethecableshieldtiedtothecouplingnut.Thepowercablecoupling

2

nutandPumpControlModulehaveconductivepathstoaCOMMON COMMON

COMMON

ground

ground ground

.

3A7709B9

Page 10

Installation

Power

Power Power

NOTE:

NOTE: NOTE:

(332196),andareincludedhereonlyforreferenceandforconsistencywithmanual332196.

Supply

Supply Supply

ThecalloutsandidenticationsonthispagereectthoseusedintheISPowerSupplyModulesmanual

Module

Module Module

Grounding

Grounding Grounding

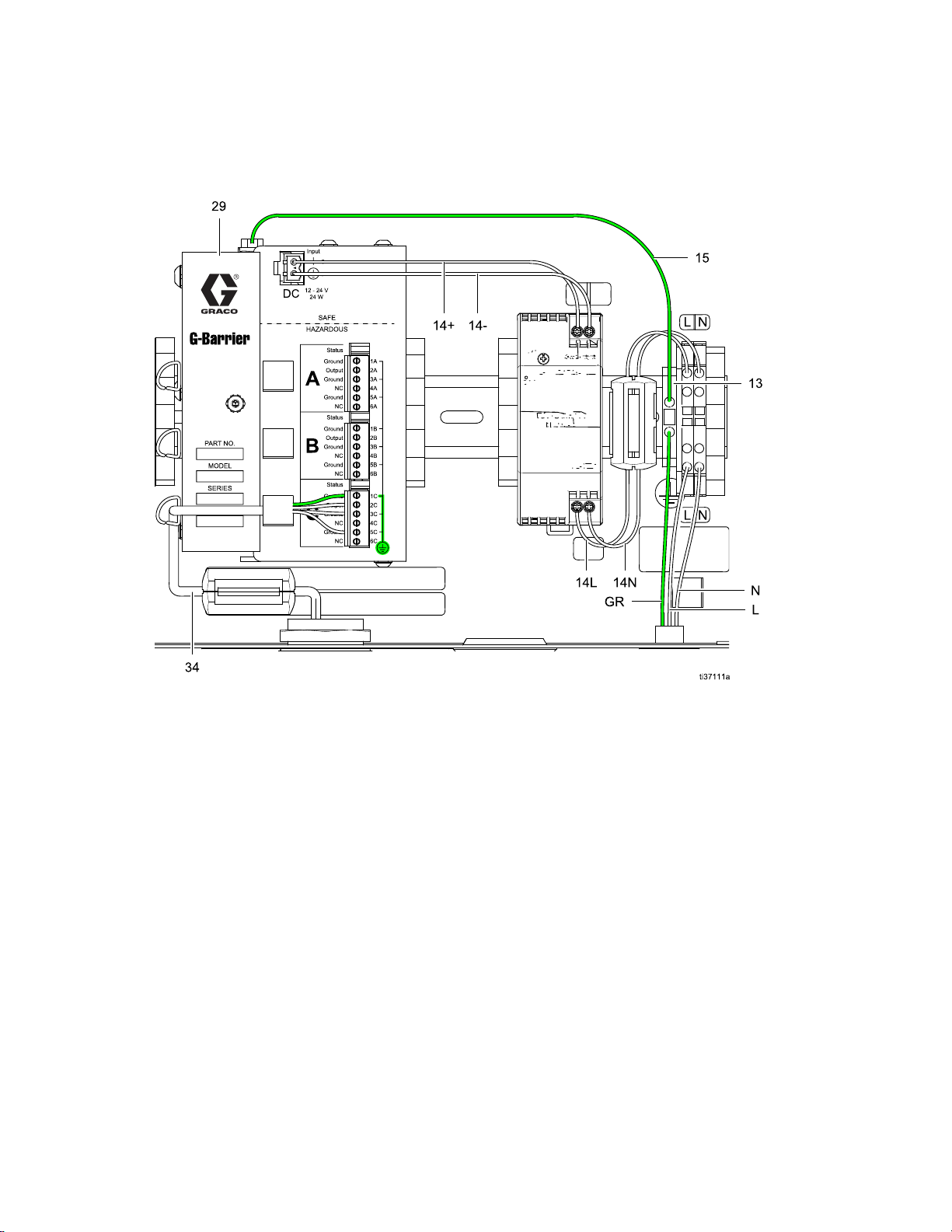

Figure2PowerSupplyModuleGrounding

KEY:

KEY: KEY:

GR

GR GR

L

L L

N

N N

13

13 13

14+

14+ 14+

14–

14– 14–

14L

14L 14L

14N

14N 14N

15

15 15

29

29 29

34

34 34

SupplyGroundWire

SupplyLineWire

SupplyNeutralWire

GroundTerminalBlock

PowerSupplyoutputpower

PowerSupplyinputpower

Ground(fromtheGroundTerminalBlock(13)totheG-Barrier(29))

G-Barrier

ISPowerCable(fromtheG-Barrier(29)tothePumpControlModule(A,seeFigure1);

installedinfactory)

103A7709B

Page 11

Installation

Cable

Cable Cable

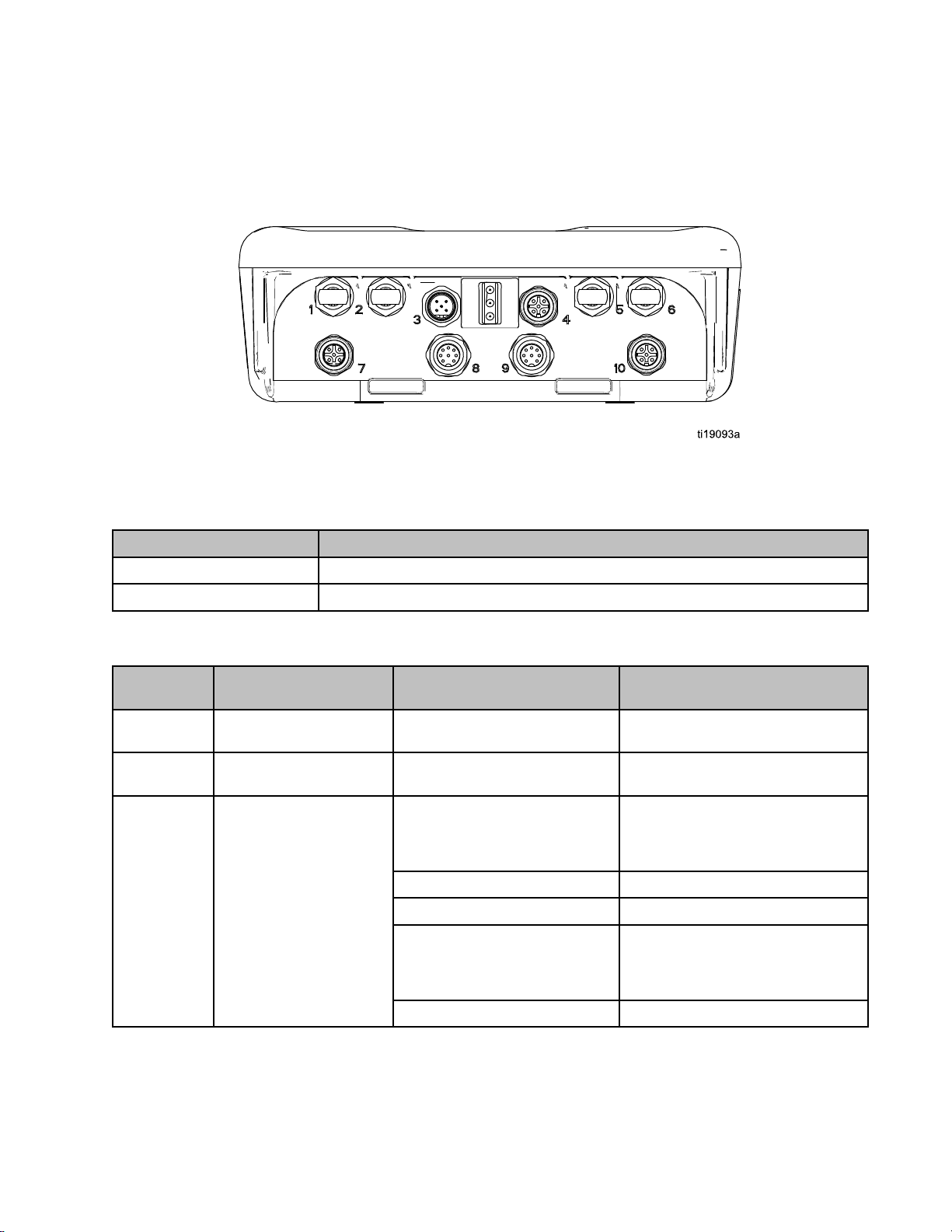

Orderapoweraccessorycable(C)fromTable1.ConnectthecabletoPort3onthebottomofthecontrol

module(seeFigure3).Connecttheotherendtothepowerbarrier(seeFigure1).Connectothercables

asdescribedinTable2.

Figure3PumpControlModuleConnectors

Table

Table Table

Cable

Cable Cable

16K509

Connection

Connection Connection

Power

1 11Power Power

Part

Part Part

Accessory

Accessory Accessory

No.

No. No.

Cable

Cable Cable

Description

Description Description

Intrinsicallysafepowercable,52ft(16m)

16K615

Table

Table Table

ADCM

ADCM ADCM

Number

Number Number

1

2

3PowerInput

ADCM

2 22ADCM ADCM

Port

Port Port

Cable

Cable Cable

Connector

Connector Connector

FiberOpticReceive

FiberOpticTransmit

Intrinsicallysafepowercable,105ft(32m)

Connections

Connections Connections

Purpose

Purpose Purpose

Connection

Connection Connection

Pin1–CANLowCANdatalowlineforGCA

Pin2–PowerPowersupplyvoltage

Pin3–Common

Pin4–CANHigh

Pin5–ShieldCableshield

Notes

Notes Notes

Fiberopticreceivelineusedfor

Modbuscommunications

Fiberoptictransmitlineusedfor

Modbuscommunications

communication.CAN

communicationisnotused

onthisproduct.

Powersupplycommon

CANdatahighlinefor

GCAcommunication.CAN

communicationisnotusedonthis

product.

3A7709B

11

Page 12

Installation

Pin1–Voltage

Pin2–ReedSwitch1InputDownstrokeinputforreedswitch.

Pin3–AuxiliaryOutput

4

5

6

7

8

AuxiliaryIO

FiberOpticReceiveMirrorofberopticreceiveport1

FiberOpticTransmitMirrorofberoptictransmitport2

PressureTransducer1

4–20mAOutput1

Pin4–ReedSwitch2InputUpstrokeinputforreedswitch.

Pin5–CommonConnectedtothesysteminput

Connectedtothesysteminput

voltage(PowerInputPin2)

Inputcanbecongured

Notusedatthistime

Potentialtobeconguredas

inputcapture,butcurrentlynot

supportedincomponentlibrary.

voltagecommon(PowerInputPin

3)

Adifferentialvoltageinput.This

portcansupportmultiplepressure

transducerranges(seePressure

TransducerChapter,page27).

Monitorspumpoutletpressure.

Usedtocontroltheairinletto

thepumptoregulatethesystem

uidpressure.TheI2Pprovides

aresponsecorrelatedtotheinlet

airpressure,witha0–100%drive

signalcontrollingpressuretoa

boostvalue.

4–20mAOutput2

9

PressureTransducer2

10

Usedtocontrolanybackpressure

regulator(BPR).At4mA(0%)the

BPRiscompletelyopen,andat

20mA(100%)theBPRisfully

closed.

Adifferentialvoltageinput.This

portcansupportmultiplepressure

transducerranges.Monitorsthe

pressureattheBPR,butcanbe

usedanywhereinthesystem

(includingairinletpressure).

12

3A7709B

Page 13

Installation

Typical

Typical Typical

Installation

Installation Installation

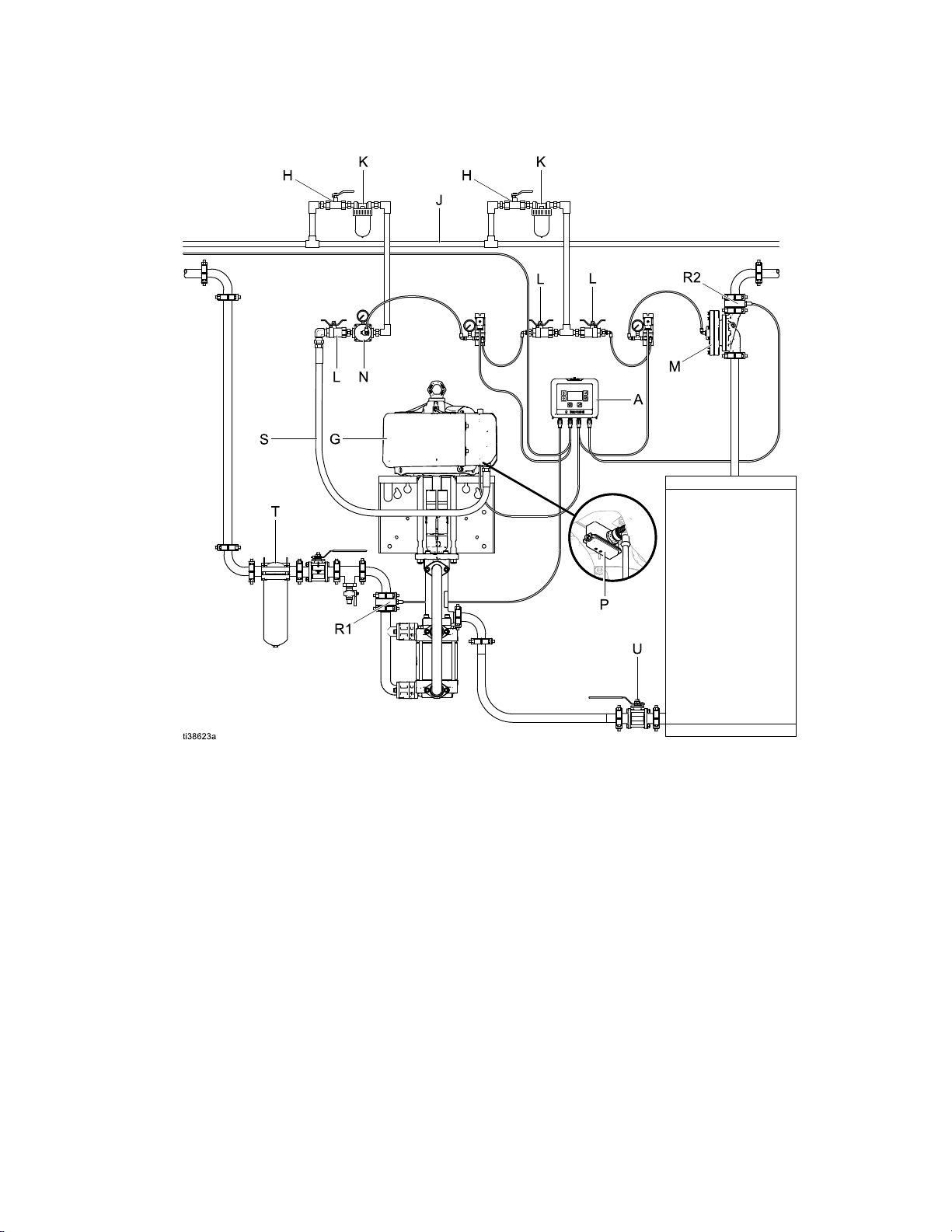

Figure4TypicalInstallation

KEY:

KEY: KEY:

A

A A

G

G G

H

H H

J

J J

K

K K

L

L L

M

M M

N

N N

P

P P

R1

R1 R1

R2

R2 R2

S

S S

T

T T

U

U U

Pumpcontrolmodule

Airmotor

Airlineshutoffvalve

Airsupplyline

Airlinelter

Bleed-typemasterairvalve

Back-pressureregulator(BPR)

Self-relievingpilotedairregulator

Reedswitches

Pressuretransduceratoutletofpump

PressuretransduceratBPR

Pumpinlethose

Fluidlter

Fluidinletshutoffvalve

3A7709B13

Page 14

Operation

Operation

Operation Operation

Pressure

Pressure Pressure

Unexpectedactivationofthepumpcouldresult

inseriousinjuryfrompressurizeduid,suchas

skininjection,splashinguidandmovingparts.

FollowthePressureReliefProcedurewhenyou

stopsprayingandbeforecleaning,checking,or

servicingtheequipment.

1.Ensurethepumpisoffbypressingthepump

shutdownbuttononthepumpcontrolmodule(A).

2.Closethebleed-typemasterairvalve(L).

3.Openalluiddrainvalvesinthesystem,havinga

wastecontainerreadytocatchdrainage.Leave

drainvalvesopenuntilyouarereadytospray

again.

Relief

Relief Relief

FollowthePressureReliefProcedure

wheneveryouseethissymbol.

Procedure

Procedure Procedure

Modes

Modes Modes

Pressure

Pressure Pressure

Whenthesystemisinpressurecontrolmode,the

pumpcontrolsthepressureprovidedattheoutletof

thepumpwithclosed-loopcontrol.Theunitcontrols

theairintothepumpusinganI2Pwhilemonitoring

theoutletpressurewithadifferentialpressuresensor.

Thecontrolloopupdatesatthetopofthecycle.The

pressuretargetshouldbereachedwithinvecycles.

Flow

Flow Flow

Whenthesystemisinowcontrolmode,the

pumpcontrolstoaowrateusingpressure.Flow

rateisestimatedoncycles/minuteandvolume

displacement.Thecontrolloopupdatesatthetopof

thecyclefortraditionalairmotorsandattheleftcycle

ofanAODDorGlutton

bereachedwithinvecycles.

Hybrid

Hybrid Hybrid

Whenthesystemisincontrolpumpmode,thepump

controlstoapressuretargetwhilealsoupdatingthe

BPRsetpointtocontroltheowrate.Theuseris

requiredtoenterapressuretarget,owratetarget,

andamaximumowratevalue.Thesystemrst

achievesthepressuretarget.Next,ifthesystemis

runningtoofastorslowbasedontheowratetarget,

thesystemadjuststheBPRtargettoachievetheow

ratetarget.IftheBPRtargetisateither100%or0%,

theowratetargetmaynotbeachieved.

of

Operation

of of

Operation Operation

Control

Control Control

Control

Control Control

®

.Theowratetargetshould

Open

Open Open

Whenthesystemisinopenloopmode,axedair

pressureisappliedtothepumpinlet.Thesystemwill

operatesimilarlytoamanualairregulator.Changing

thepercentagesetpointupordownadjuststheair

appliedtotheairmotorinlet.

NOTE:

NOTE: NOTE:

iftheothermodescannotbeused,butthepumpstill

needstooperate.Totroubleshooterrorcodessee

ErrorCodeTroubleshooting,page35.

14

Loop

Loop Loop

Thismodeofoperationisonlyrecommended

3A7709B

Page 15

Operation

Display

Display Display

Overlay

Overlay Overlay

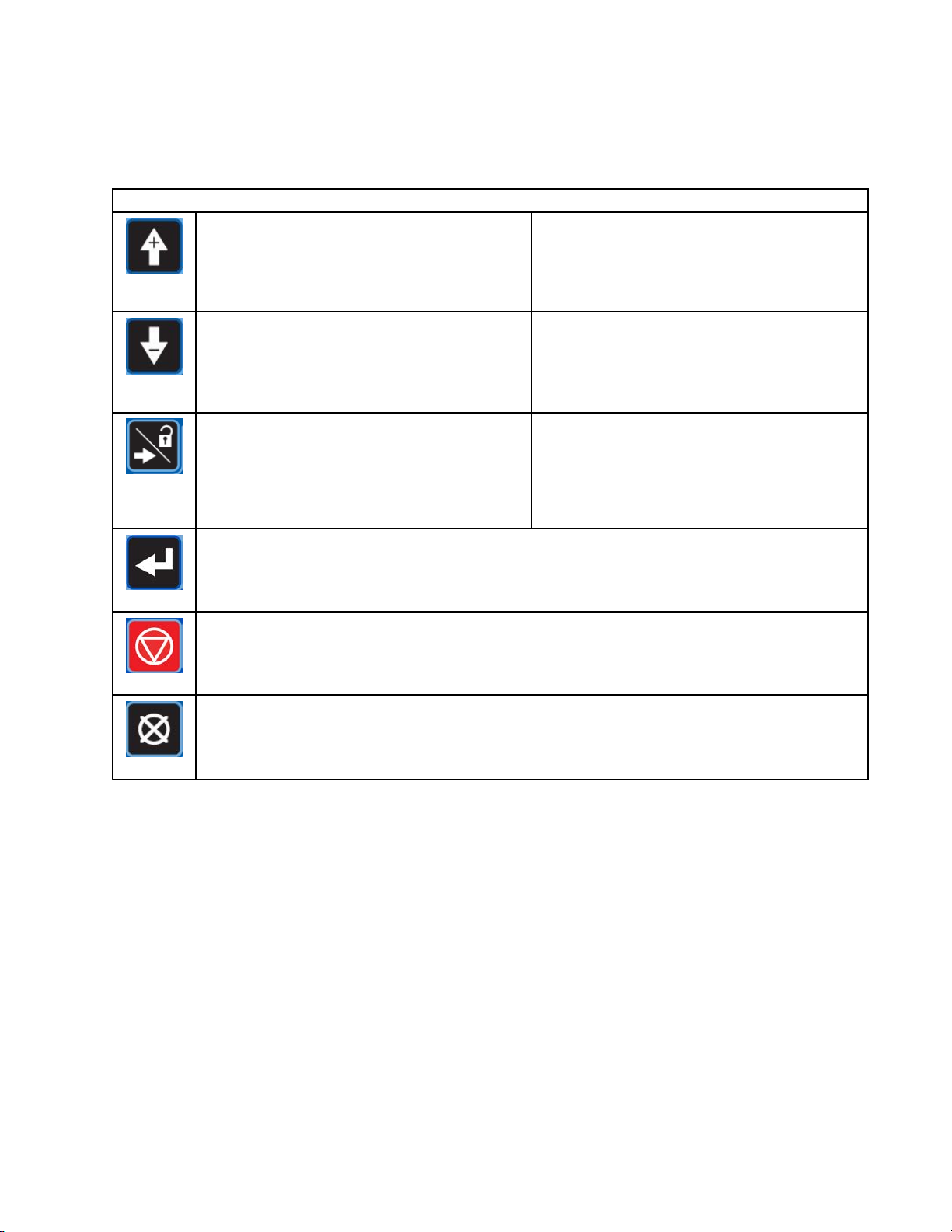

UpArrow

Down

Arrow

Right

Arrow/

Setup

Enter

Overlay

Overlay Overlay

Page

Navigation

Page Page

Navigation Navigation

Theuparrowisusedtomovetotheprevious

page.IftheuserisatPage1,pressingtheup

arrowcausesthepagestorollovertothelast

page.

Page

Navigation

Page Page

Navigation Navigation

Thedownarrowisusedtomovetothenext

page.Iftheuserisatthelastpage,pressing

thedownarrowcausesthepagestooverow

anddisplaytherstpage.

Chapter

Chapter Chapter

Therightarrowisusedtomovetothenext

chapter.Iftheuserisatthelastchapter,

pressingtherightarrowwillwraparoundtothe

rstchapter.

Field

Field Field

Pressingtheenterkeyactivatesaeldforediting,activatesthechangesinahighlightedeld,

selectsahighlightedoptioninamenu,andselectsorunselectsacheckbox.

Stop

Stop Stop

Pressingtheshutdownkeywillstopthepump.

Navigation

Navigation Navigation

Entry

Entry Entry

Pump

Pump Pump

Keys

Keys Keys

Setpoint

Setpoint Setpoint

Whentheuserisinanentryeld,theuparrow

isusedtoincrementthevalue.Ifthevalueisat

“9”,pressingtheuparrowwillcausethevalue

torolloverto“0”.

Setpoint

Setpoint Setpoint

Whentheuserisinanentryeld,thedown

arrowisusedtodecrementthevalue.Ifthe

valueisat“0”,pressingthedownarrowwill

causethevaluetorolloverto“9”.

Setup

Setup Setup

ToenterorexitSetup,theuserwillpressand

holdtherightarrowkeyforthreeseconds.

Incrementation

Incrementation Incrementation

Decrementation

Decrementation Decrementation

Shutdown

Field

Entry

Field Field

Entry Entry

Whentheuserisinamenuoranumericeld,pressingthecancelkeycausesthedisplayto

exiteldentrymodeandrevertbacktothepreviousscreen.

Cancel

3A7709B15

Page 16

Operation

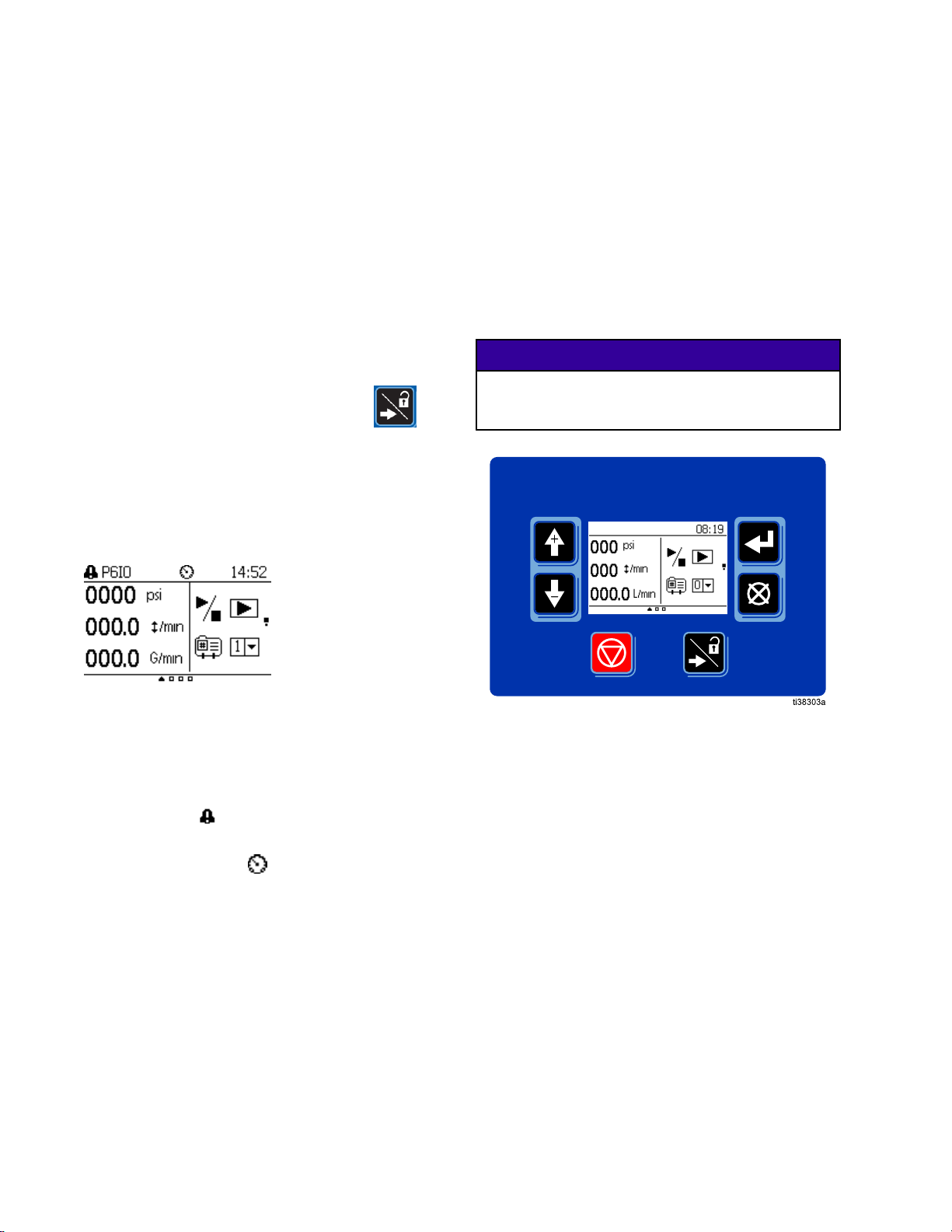

Module

Module Module

Therearetwosetsofscreens(Books):Runand

Setup.RunandSetupbookscontainchapters,

andeverychaptercontainspages.Chaptersare

accessedbyusingtherightarrowkey.Atthebottom

ofthescreentherearedotstoindicatethenumberof

chaptersandtohighlightthecurrentchapter.Ifyou

navigatepastthechapteryouwanttodisplay,you

needtocontinuepressingrightarrowkeytowrap

backtothechapteryouwouldliketoupdate.

Pagesareaccessedusingtheupanddownarrows.

Attherightsideofthescreentherearedotsto

indicatethenumberofpagesinthischapterandto

highlightthecurrentpage.

Pressandholdtherightarrow/lockicon(

threesecondstoenterorexitSetup.

NOTE:

NOTE: NOTE:

loadrequirements.

Example:ThissetofRunScreenshasthreechapters

(indicatedbythebottomofthescreen)andtwo

pages(indicatedbythesquaresontherightsideof

thescreen).

Screens

Screens Screens

Thescreenautomaticallydimsbasedonthe

Module

Module Module

Thegurebelowisaviewofthecontrolmodule

displayandkeys.Overlay,page15,explains

thefunctionofthemembranekeysonthecontrol

module.Asyoumovethroughthescreens,you

willnoticethatmostinformationiscommunicated

usingiconsratherthanwordstosimplifyglobal

communication.Thedetailedscreendescriptionsin

RunScreens,page17,andSetupScreens,page22,

explainwhateachiconrepresents.Thetwokeysare

membranebuttonswhosefunctioncorrelateswith

thescreencontenttotheimmediateleftofthebutton.

Topreventdamagetothebuttons,donotpressthe

buttonswithsharpobjectssuchaspens,plastic

)for

cards,orngernails.

Keys

Keys Keys

NOTICE

NOTICE NOTICE

Module

Module Module

TheModuleTopMenuonlydisplayson

RunScreens,page17andshowsthefollowing:

Error

•Error Error

ErrorCodeTroubleshooting,page35.

Current

•Current Current

SeeProleCongurationPage,page22.

Time

•Time Time

163A7709B

Menu

Menu Menu

Codes

Codes Codes

Prole

Prole Prole

Bar

Bar Bar

See

Mode

Mode Mode

(PressureModeshown).

Figure5ControlModuleKeypadandDisplay

Page 17

RunScreens

Run

Run Run

Unexpectedactivationofthepumpcouldresult

inseriousinjuryfrompressurizeduid,suchas

skininjection,splashinguidandmovingparts.

FollowthePressureReliefProcedurewhenyou

stopsprayingandbeforecleaning,checking,or

servicingtheequipment.

Pump

Pump Pump

Pump

Pump Pump

Screens

Screens Screens

Control

Control Control

Control

Control Control

Chapter

Chapter Chapter

Page

Page Page

1

1 1

RunScreensarecomprisedoftheruntime

informationthatthesystemismonitoringand

controlling,suchas:CurrentFlowRate,Cycle

PerMinute,Pressure,ActiveProle,etc.See

Overlay,page15,forinformationonhowtomake

selectionsandenterdata.

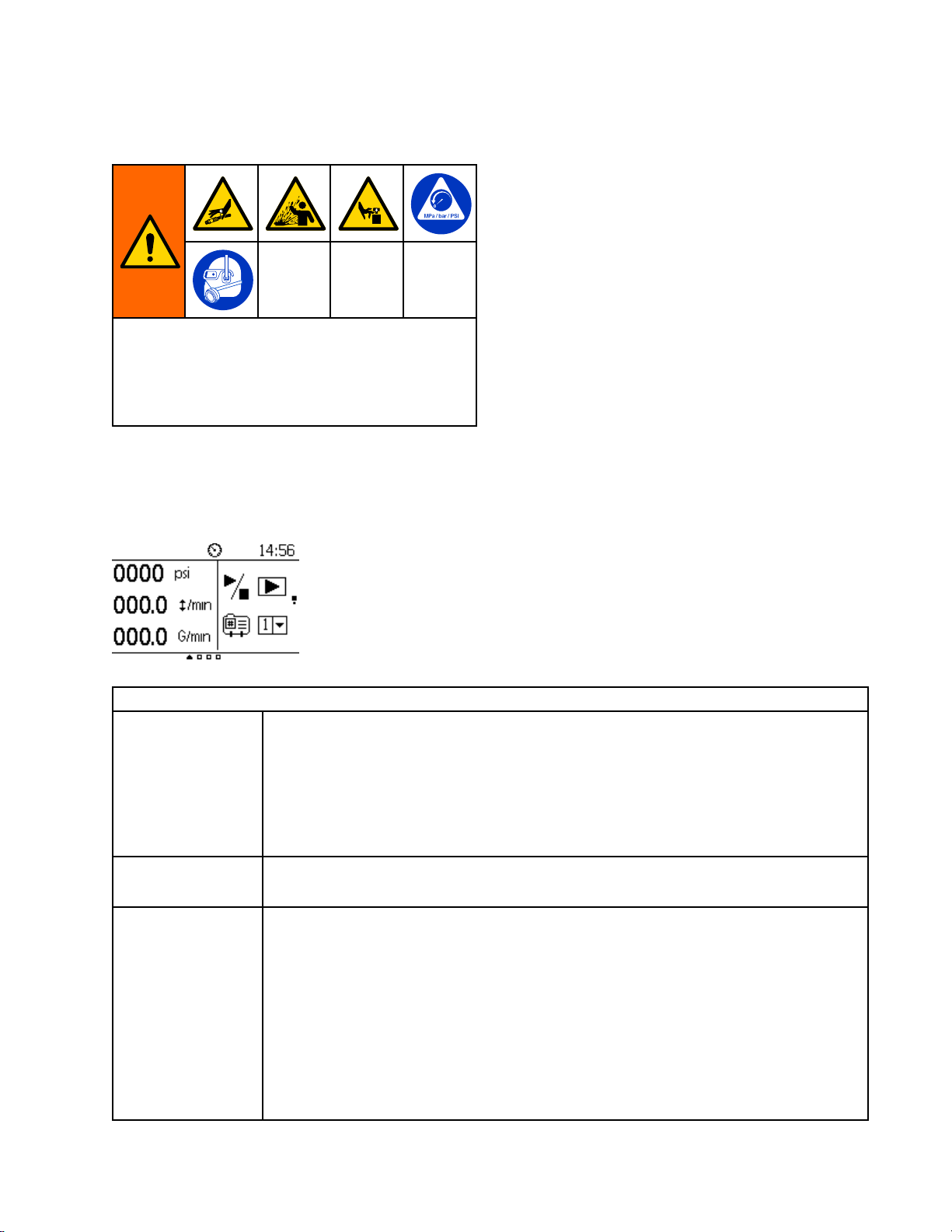

Figure6PumpControlPage1

Displaysthecurrentaveragepressureattheoutletofthepumpinpressureunits

selectedinsetup.

Range:

Current

Current Current

Cycles

Cycles Cycles

Current

Current Current

Pressure

Pressure Pressure

Per

Minute

Per Per

Minute Minute

Flow

Rate

Flow Flow

Rate Rate

•PSI:0–9999

•Bar:0.0–999.9

•MPa:0.00–99.99

Displaysthecurrentaveragecyclesrateofthepumpincyclesperminute.

Range:00.0–99.9CPM

Displaythecurrentowrateofthepump.Numberiscalculatedbasedoncycles

perminuteanddisplacement.Thevalueisdisplayedintheowrateunitsspecied

insetup.

Range:

•Gallons/min:0.0–999.9

•Liters/min:0.0–999.9

•CC/min:0–99999

•Oz/min:0–99999

•CPM:0.0–99.9

Pump

Pump Pump

Control

Control Control

Page

Page Page

Key

1 11Key Key

3A7709B

17

Page 18

RunScreens

Commandthepumptostartorstop,asindicatedbyaplayorpauseicon.Pressto

togglebetweenthetwoicons.

Run/Stop

Run/Stop Run/Stop

Prole

Prole Prole

Pump

Pump Pump

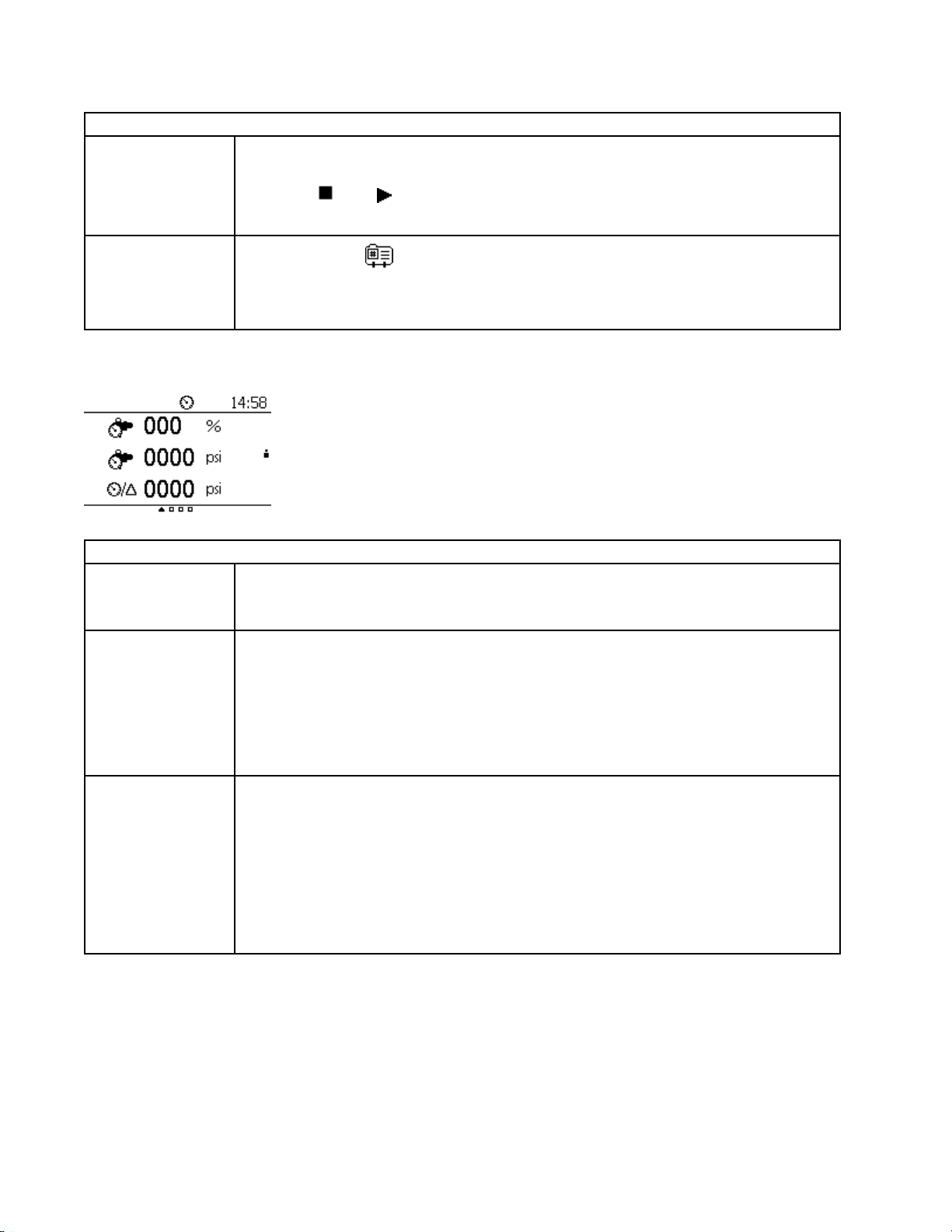

Figure7PumpControlPage2

Back

Back Back

Regulator

Regulator Regulator

Select

Select Select

Control

Control Control

Pressure

Pressure Pressure

Percent

Percent Percent

Output

Output Output

Range:0(

Default:0(Pause)

Selecttheprole(

Range:1–4

Default:Lastvaluethepumpwasrunning

Page

Page Page

2

2 2

Displaysthecurrentpercentoutputbeingappliedtothebackpressureregulator.0%

indicatesfullyopen,while100%indicatesfullyclosed.

Range:0–100%

Displaystheaveragepressureindicatedbypressuresensor2.Acommonapplication

isthepressureattheBackPressureRegulator.

Pump

Pump Pump

)–1( )

Pump

Pump Pump

Control

Control Control

)torunonthepump.ProlesareconguredinSetup.

Control

Control Control

Page

Page Page

Page

Page Page

Key

1 11Key Key

Key

2 22Key Key

Back

Pressure

Back Back

Pressure Pressure

Regulator

Regulator Regulator

Delta

Delta Delta

Pressure

Pressure Pressure

Pressure

Pressure Pressure

Range:

•PSI:0–999

•Bar:0.0–99.9

•MPa:0.00–9.99

Displaysthedifferenceinpressurebetweentheoutletofthepumpandthesecond

pressuretransducer.Commonapplicationistomonitorpressuredropacrossthe

circulationline.Inthatapplicationthesecondpressuretransducerisinstalledatthe

BPR.

Range:

•PSI:0–999

•Bar:0.0–99.9

•MPa:0.00–9.99

183A7709B

Page 19

RunScreens

Totalizer

Totalizer Totalizer

Totalizer

Totalizer Totalizer

Figure8TotalizerPage

Pump

Pump Pump

Batch

Batch Batch

Maintenance

Maintenance Maintenance

Page

Page Page

Totalizer

Totalizer Totalizer

Totalizer

Totalizer Totalizer

Totalizer

Totalizer Totalizer

Chapter

Chapter Chapter

Totalizer

Totalizer Totalizer

Thepumptotalizerdisplaysthetotalcycles/volumethatthepumphasdisplaced.

Thiseldisnotresettable.

Thebatchtotalizerdisplaysthetotalvolumethatthepumphasdisplacedfora

particularjob.Batchtotalizercanberesetinsetup.

Themaintenancetotalizerdisplaysthecurrentvolumethatthepumphasdisplaced

sincethelasttimemaintenancewasperformed.Maintenancetotalizerhastobereset

insetupaftereachmaintenancecycle.

Page

Key

Page Page

Key Key

NOTE:

NOTE: NOTE:

Allcounterscountup.

3A7709B19

Page 20

RunScreens

Agitator

Agitator Agitator

Thisscreendisplaysinformationforcontrollingan

electricagitatorusingthesupervisortopasson

thecontrolsetpointtoaVariableFrequencyDrive

(VFD),alsoknownasaninverter.

Figure9AgitatorChapter

Enable/Disable

Enable/Disable Enable/Disable

Speed

Speed Speed

Local

Local Local

Chapter

Chapter Chapter

Selecttheboxtoenableordisabletheagitator.

Agitator

Agitator Agitator

Setpoint

Setpoint Setpoint

Mode

Mode Mode

Setthespeedsetpointfortheagitatorfrom0–100%.

Selectthisboxtoputagitatorcontrolinlocalonlymode.SetpointandEnable/Disable

requestsfromPLC/Supervisorwillbeignored.

Run

Screen

Run Run

Screen Screen

Key

2 22Key Key

203A7709B

Page 21

RunScreens

Event

Event Event

Theerrorsscreenisutilizedtoshowanysystem

errorsthathaveoccurred.Theerrorswillbe

displayedwithoneerrorperrow.Theprevious20

errorscanbedisplayedatanytimeoverthefourerror

screens.Alackofanerrorisshownwithhyphens‘-‘.

Theerrorsaredisplayedmostrecentrst.

Figure10EventLogChapter

Log

Chapter

Log Log

Chapter Chapter

Event

Log

1

Event Event

Log Log

1 1

Event

Log

Event Event

Log Log

2 2

Event

Log

Event Event

Log Log

3 3

Event

Log

Event Event

Log Log

4 4

Displaysthelast1–5Events.

2

Displaysthelast6–10Events.

3

Displaysthelast11–15Events.

4

Displaysthelast16–20Events.

Event

Log

Event Event

Key

Log Log

Key Key

3A7709B

21

Page 22

SetupScreens

Setup

Setup Setup

UsetheSetupscreensforpumpsettingsandaccessoryfeatures.SeeOverlay,page15,forinformationon

howtomakeselectionsandenterdata.

Inactiveeldsaregrayedoutonascreen.

Prole

Prole Prole

Prole

Prole Prole

PressureModeFlowModeHybridMode

Prole

Prole Prole

Screens

Screens Screens

Chapter

Chapter Chapter

Conguration

Conguration Conguration

Number

Number Number

Page

Page Page

Prole

Prole Prole

Selectthenumberofthedesiredprolesfromthemenu:1–4.

Selecttheoperatingmodeoftheprole.

Conguration

Conguration Conguration

Page

Key

Page Page

Key Key

OpenLoopMode

Range:

•Pressure(

owratelimitedbythemaximumvalue.

Prole

Prole Prole

Mode

Mode Mode

Target

Target Target

•Flow()—Whenselected,theunitwilloperateontheowsetpointwithapressure

limitedbythemaximumvalue.

•Hybrid(

automaticallyadjusttheBPRtocontroltheow.

•OpenLoop—Whenselectedtheunitwilloperateonapercentagesetpointfrom0100%.Thisdirectlycorrelatestotheinletairtothepump.

Targetelds(seethefollowingPressure,Flow,andBackPressureRegulatorelds)

areupdatedbasedontheProleMode.

•PressureMode:

–TargetPressure( )

–BPRSetpoint()

•FlowMode:

–TargetFlow(

–BPRSetpoint( )

•HybridMode:

)—Whenselected,theunitwilloperateonthepressuresetpointwitha

)—Whenselected,theunitwilloperateonthepressuresetpoint,and

)

–TargetPressure( )

–TargetFlow()

22

3A7709B

Page 23

SetupScreens

Prole

Prole Prole

SetsthetargetpressurewhentheProleModeeldissettoPressure(

(

).

Range:

Pressure

Pressure Pressure

Flow

Flow Flow

•PSI:0–9999

•Bar:0.0–999.9

•MPa:0.00–99.99

Default:0.0

SetsthetargetowratewhentheProleModeeldissettoFlow(

().

Range:

•Gallons/min:0.0–999.9

•Liters/min:0.0–999.9

•CC/min:0–99999

•Oz/min:0–99999

•CPM:0.0–99.9

Default:0.0

SetstheBackPressureRegulatorpercentagewhenProleModeeldissetto

Pressure(

)orFlow( ).

Conguration

Conguration Conguration

Page

Key

Page Page

Key Key

)orHybrid

)orHybrid

TorunHybridMode(

Back

Pressure

Back Back

Pressure Pressure

Regulator

Regulator Regulator

(BPR)

(BPR) (BPR)

thesystemisstable.AftertheHybridmodeprolestarts,thesystemwillautomatically

adjusttheBPRpercentbasedonthestartingpercentagevalue.Ifthesystemstallsfor

15seconds,thentheBPRpercentagewillautomaticallydecrease.

Range:

•BPR:0–100%

Default:0

),enterastartingBPRpressure.Thisisrequiredtoensure

3A7709B23

Page 24

SetupScreens

Limit

Conguration

Limit Limit

Conguration Conguration

Figure11LimitCongurationPage

Page

Page Page

NOTE:

NOTE: NOTE:

conguredonProlePage3(see

EventCongurationPage,page26).

Limit,Deviation,orAlarmare

Prole

Prole Prole

ThiseldisactivewhentheproleisinPressuremode,anddisabledwheninFlowor

Hybridmode.

NOTE:

NOTE: NOTE:

stalls,thenthesystemwillkeepincreasingthepressureevery15secondstomovethe

pumporuntilitreachesthespeciedHighPressurelimit.

Thiseldcanhavethreedifferenteventtypes:

•Limit:Limitsthemaximumpressurethemotorcangenerate.

Pressure

Pressure Pressure

Pressure

Pressure Pressure

High

High High

Low

Limit

Low Low

Limit Limit

•Deviation:Generatesadeviationwhenthemotorpressureexceedsthelimit.

Limit

Limit Limit

•Alarm:Generatesanalarmandshutsdownthemotorafterthelimitisexceeded

Thiseldcanhavethreedifferenteventtypes:

•Limit:Limitstheminimumpressurethemotorcangenerate.

•Deviation:Generatesadeviationwhenthemotorpressuredropsbelowthelimit.

•Alarm:Generatesanalarmandshutsdownthemotorwhentheforcedropsbelow

HighPressurelimitshouldbespeciedwheninFlowmode.Ifthesystem

fortwocycles.

–Range:

♦PSI:0–9999

♦Bar:0.0–999.9

♦MPa:0.00–99.99

–Default:0.0

thelimitfortwocycles.

–Range:

Conguration

Conguration Conguration

Page

Key

Page Page

Key Key

♦PSI:0–9999

♦Bar:0.0–999.9

♦MPa:0.00–99.99

–Default:0.0

24

3A7709B

Page 25

SetupScreens

Prole

Prole Prole

ThiseldisactivewhentheproleisinFlowmode,andisdisabledwheninPressure

orHybridmode.

Thiseldcanhavethreedifferenteventtypes:

•Limit:Limitsthemaximumowratethesystemcangenerate.

•Deviation:Generatesadeviationwhenthesystemowrateexceedsthelimit.

•Alarm:Generatesanalarmandshutsdownthemotorwhenthelimitisexceeded

Flow

Rate

Flow Flow

High

Rate Rate

High High

Limit

Limit Limit

fortwocycles.

–Range:

♦Gallons/min:0.0–999.9

♦Liters/min:0.0–999.9

♦CC/min:0–99999

♦Oz/min:0–99999

♦CPM:0.0–999.9

–Default:0.0

Thiseldcanhavethreedifferenteventtypes:

•Limit:Limitstheminimumowratethesystemcangenerate.

•Deviation:Generatesadeviationwhenthesystemowratedropsbelowthelimit.

•Alarm:Generatesanalarmandshutsdownthemotorwhentheowratedrops

belowlimitfortwocycles.

Conguration

Conguration Conguration

Page

Key

Page Page

Key Key

–Range:

Flow

Rate

Low

Flow Flow

Rate Rate

Limit

Low Low

Limit Limit

♦Gallons/min:0.0–999.9

♦Liters/min:0.0–999.9

♦CC/min:0–99999

♦Oz/min:0–99999

♦CPM:0.0–999.9

–Default:0.0

3A7709B25

Page 26

SetupScreens

Event

Event Event

Figure12EventCongurationPage

Conguration

Conguration Conguration

Limit:Limitsthemaximumpressureorforcethemotorcangenerate.

Deviation:Generatesadeviationwhenthemotorpressureexceedsthelimit.

Pressure/Force

Pressure/Force Pressure/Force

High

Event

High High

Pressure/Force

Pressure/Force Pressure/Force

Low

Low Low

Event Event

Type

Event Event

Type Type

Event

Type

Type Type

Alarm:Generatesanalarmandshutsdownthemotorwhenthelimitisexceeded.

•Range:Limit,Deviation,Alarm

•Default:Limit

Limit:Limitstheminimumpressureorforcethemotorcangenerate.

Deviation:Generatesadeviationwhenthemotorpressuredropsbelowthelimit.

Alarm:Generatesanalarmandshutsdownthemotorwhentheforcedropsbelow

thelimit.

•Range:Limit,Deviation,Alarm

•Default:Limit

Limit:Limitsthemaximumowratethesystemcangenerate.

Page

Page Page

Prole

Prole Prole

Conguration

Conguration Conguration

Page

Key

Page Page

Key Key

Deviation:Generatesadeviationwhenthesystemowrateexceedsthelimit.

Flow

High

Flow Flow

Flow

Flow Flow

Event

High High

Event Event

Type

Type Type

Low

Event

Low Low

Event Event

Type

Type Type

Alarm:Generatesanalarmandshutsdownthemotorwhenthelimitisexceeded.

•Range:Limit,Deviation,Alarm

•Default:Limit

Limit:Limitstheminimumowratethesystemcangenerate.

Deviation:Generatesadeviationwhenthesystemowratedropsbelowthelimit.

Alarm:Generatesanalarmandshutsdownthemotorwhentheowratedropsbelow

thelimit.

•Range:Limit,Deviation,Alarm

•Default:Limit

263A7709B

Page 27

SetupScreens

Pressure

Pressure Pressure

Setup

Setup Setup

Figure13SetupPressureSensor1

Pressure

Pressure Pressure

Transducer

Transducer Transducer

Sensor

Sensor Sensor

Offset

Offset Offset

Transducer

Transducer Transducer

Pressure

Pressure Pressure

Sensitivity

Sensitivity Sensitivity

Voltage

Voltage Voltage

Sensor

Sensor Sensor

Usethemenutoselecttheattachedtransduceroption.Thedefaultvalueistheno

transducericon( ).

Range:Notransducer,500psi,or7500psi.

Default:500psi

Enterthecalibrationscalefactorintothiseld.Eachpressuretransducerhasaunique

calibrationscalefactor.

Range:00.0000–99.9999mV/V

Default:00.0000mV/V

Entertheoffsetfactorintothiseld.Eachpressuretransducerhasauniqueoffset

voltagefactor.

Range:0.00–9.99mV/V

Chapter

Chapter Chapter

1

1 1

Setup

Setup Setup

Pressure

Pressure Pressure

Sensor

Sensor Sensor

Key

1 11Key Key

Default:0.00mV/V

3A7709B

27

Page 28

SetupScreens

Setup

Setup Setup

Figure14SetupPressureSensor2

Pressure

Pressure Pressure

Pressure

Pressure Pressure

Transducer

Transducer Transducer

Sensor

Sensor Sensor

Sensitivity

Sensitivity Sensitivity

Offset

Voltage

Offset Offset

Voltage Voltage

Sensor

Sensor Sensor

2

2 2

Usethemenutoselecttheattachedtransduceroption.Thedefaultvalueistheno

transducericon( ).When100psiisselected,thedeltapressurefeatureis

disabled.Itisassumedthattheairinlettothepumpismonitored.

Range:Notransducer,500psi,or7500psi.

Default:Notransducer

Enterthecalibrationscalefactorintothiseld.Eachpressuretransducerhasaunique

calibrationscalefactor.

Range:00.0000–99.9999mV/V

Default:00.0000mV/V

Entertheoffsetfactorintothiseld.Eachpressuretransducerhasauniqueoffset

voltagefactor.

Range:0.00–9.99mV/V

Setup

Setup Setup

Pressure

Pressure Pressure

Sensor

Sensor Sensor

Key

2 22Key Key

Default:0.00mV/V

283A7709B

Page 29

SetupScreens

Pump

Pump Pump

Pump

Pump Pump

Pump

Pump Pump

Setup

Setup Setup

Setup

Setup Setup

Pump

Pump Pump

Lower

Lower Lower

Setup

Setup Setup

Chapter

Chapter Chapter

Screen

Screen Screen

Screen

Screen Screen

1

1 1

Pump

Pump Pump

Ratio

Ratio Ratio

Size

Size Size

2

2 2

Enterthepumpratio.Referencetheproductmanualifthevalueisnotknown.

ChecktheboxtolockouttheagitatoreldintheRunscreens.

Setup

Setup Setup

Screen

Screen Screen

Key

1 11Key Key

Pump

Pump Pump

Pressure

Pressure Pressure

Volume

Volume Volume

Flow

Flow Flow

Units

Units Units

Units

Units Units

Rate

Units

Rate Rate

Units Units

Selectthepressureunits:

•psi

•bar(default)

•MPa

Selectthevolumeunits:

•liters(default)

•gallons

•cc

Selecttheowrateunits:

•L/min(default)

•gpm

•cc/min

•oz/min

•cycles/min

Setup

Setup Setup

Key

Key Key

3A7709B29

Page 30

SetupScreens

Diagnostic

Diagnostic Diagnostic

Setup

Setup Setup

Figure15SetupDiagnostic

Current

Current Current

Current

Current Current

Totalizer

Totalizer Totalizer

Setup

Setup Setup

Chapter

Chapter Chapter

Diagnostic

Diagnostic Diagnostic

Setup

Setup Setup

Readback

Readback Readback

—

Port

— —

—

— —

8

Port Port

8 8

Readback

Readback Readback

Port

9

Port Port

9 9

Chapter

Chapter Chapter

Totalizer

Totalizer Totalizer

Thisnon-editableeldreadstheinstantaneousoutputcurrentinmAformotorinlet

I2Poutput.

Thisnon-editableeldreadstheinstantaneousoutputcurrentinmAforBackPressure

RegulatorI2Poutput.

Diagnostic

Diagnostic Diagnostic

Outputs

Outputs Outputs

Key

Key Key

Figure16SetupTotalizer

Maintenance

Maintenance Maintenance

Maintenance

Maintenance Maintenance

Setpoint

Setpoint Setpoint

Set

Totalizer

Set Set

Totalizer Totalizer

Countsdownthenumberofcyclesbeforeamaintenanceeventistriggered.A

Cycles

Cycles Cycles

maintenanceeventistriggeredwhenthevaluehitszero.Thiseldisresettable.

Range:0–9999999cycles

Default:0

Setstheamountofcyclesinamaintenancecycle.

Range:0–9999999cycles

Default:0

Key

Key Key

303A7709B

Page 31

SetupScreens

Modbus

Modbus Modbus

UsethisscreentosettheModbuspreferences.

NOTE:

NOTE: NOTE:

Modbus

Modbus Modbus

Serial

Serial Serial

Chapter

Chapter Chapter

ThefollowingarexedModbussettings,whichcannotbesetorchangedbytheuser:

DataBits:8

StopBits:2

Parity:None

Modbus

Modbus Modbus

Location

Location Location

Node

ID

Node Node

ID ID

Port

Baud

Port Port

Baud Baud

Rate

Rate Rate

Setup:

Setup: Setup:

Selectlocal orremote fromthemenu.Thissettingappliestotheselected

pumponly.

LocalmodeallowsyoutoviewchangesovertheModbusnetwork,butyoucannot

makechangesovertheModbusnetwork.Remotemodeallowsyoutobothviewand

changeinformationovertheModbusnetwork.

EnterorchangetheModbusnodeID.Thevalueisbetween1and246.Eachpump

requiresauniquenodeID,whichidentiesthatpumpifmorethanonepumpis

connectedtothedisplay.

Selecttheserialportbaudratefromthemenu.Thisisasystem-widesetting.

•38400kbps

•57600kbps(default)

•115200kbps

SelecttheModbuseventtype:

Screen

Screen Screen

1

1 1

Modbus

Modbus Modbus

Setup

Setup Setup

Key

Key Key

Modbus

Modbus Modbus

Setup:

Setup: Setup:

Screen

Screen Screen

2

2 2

Modbus

Modbus Modbus

Event

Event Event

None

Deviation

Alarm

3A7709B31

Page 32

SetupScreens

Miscellaneous

Miscellaneous Miscellaneous

Setup

Setup Setup

Figure17SetupMiscellaneous1

Off

Off Off

Miscellaneous

Miscellaneous Miscellaneous

Auto

Restart

Auto Auto

Restart Restart

Production

Production Production

Backlight

Backlight Backlight

Time

Time Time

Chapter

Chapter Chapter

1

1 1

Whenenabledifthepumplossespoweritwillautomaticallyresumeoperationinthe

lastproleitwasrunningbeforepowerloss.

Range:0–1

Default:0

Mode

Mode Mode

- --out out

Enabletheoffproductionprolemode.Thisfeatureturnsprole4intotheoff

productionprole..

Specifythebacklighttimeoutinminutes.Ifthedisplayisinactiveforxamountoftime

out

thedisplaybacklightwillturnoff.Ifvalueis0thenbacklightwillalwaysremainon.

Setup

Setup Setup

Maintenance

Maintenance Maintenance

Key

1 11Key Key

Range:0–99

Default:10

323A7709B

Page 33

SetupScreens

Setup

Setup Setup

Figure18SetupMiscellaneous2

Miscellaneous

Miscellaneous Miscellaneous

Date

Order

Date Date

Order Order

Set

Date

Set Set

Date Date

Set

Time

Set Set

Time Time

2

2 2

Usethedropdownmenutoselectthedesireddateorientation.

Range:MM/DD/YY,DD/MM/YY,orYY/MM/DD

Default:MM/DD/YY

Usetheeldtosetthecurrentdate.

MonthRange:01-12

DayRange:01-31

YearRange:00-99

Usetheeldtosetthecurrenttime.

HourRange:01-23

MinuteRange:01-59

Setup

Setup Setup

Maintenance

Maintenance Maintenance

Key

2 22Key Key

3A7709B33

Page 34

SetupScreens

Setup

Setup Setup

Figure19SetupMiscellaneous3

Miscellaneous

Miscellaneous Miscellaneous

Passcode

Passcode Passcode

Passcode

Passcode Passcode

Prole

Prole Prole

Enable

Enable Enable

Lock

Lock Lock

3

3 3

Enablespasscodeentrywhenuserenterssetup.

Range:Enable/Disable

Default:Disable

Checktheboxnexttothelockicontoenableapasscodeonthedevice.Enterthe

desiredpasscodeintheeldbelowthebox.Uponacceptingthesechanges,pressing

thelocksoftkeywilllocktheaccesstothesettingsofthedevice.Apasswordof0000

isinvalidandwillnotlockthesettingsofthedevice.

Range:0000–9999

Default:0000

Checktheboxnexttoprolelockicon( )tolockouttheuserfrommodifying

thecurrentproleontheRunscreens.

Setup

Setup Setup

Maintenance

Maintenance Maintenance

Key

3 33Key Key

Range:Enable/Disable

Default:Disable

343A7709B

Page 35

ErrorCodeTroubleshooting

Error

Error Error

Errorcodescantakethreeforms:

•Alarm

downthepump.

•Deviation

maycontinuetorunpastthesetlimitsuntilthe

system’sabsolutelimitsarereached.

•Advisory

tooperate.

NOTE:

NOTE: NOTE:

pressure(Pcodes)canbedesignatedasalarmsor

deviations.SeeEventCongurationPage,page26.

Event

Event Event

Code

Code Code

C3G1

C3G1 C3G1

Code

Code Code

:alertsyoutothealarmcauseandshuts

:alertsyoutotheproblem,butpump

:informationonly.Pumpwillcontinue

OnAdvancedmotors,ow(Kcodes)and

ModbusCommunication

Troubleshooting

Troubleshooting Troubleshooting

Event

Event Event

Deviation

NOTE:

NOTE: NOTE:

thecodeisassociatedwiththedisplayonly.

NOTE:

NOTE: NOTE:

codeisaplaceholderforthenumberofthepump

wheretheeventoccurred.

NOTE:

NOTE: NOTE:

indicatoronthemotor.Theblinkcodegivenbelow

indicatesthesequence.Forexample,blinkcode1–2

indicates1blink,then2blinks;thesequencethen

repeats.

NOTE:

NOTE: NOTE:

indicatorofwhichpumpisactive.

Event

Event Event

Deviation

Intheerrorcodeslistedbelow,an“X”means

Intheerrorcodeslistedbelow,a“_”inthe

Theblinkcodeisdisplayedusingthepower

Ablinkcodeof9isnotanerrorcode,butan

Type

Type Type

Displaydetectsalossof

Modbuscommunicationwhen

Modbuseventtypeissetupto

beadeviation.Triggereventif

therehasnotbeenaModbus

readeventwithin1second.

Description

Description Description

C4G1

C4G1 C4G1

DD90

DD90 DD90

DK61

DK61 DK61

DK62

DK62 DK62

K1D1

K1D1 K1D1

K2D1

K2D1 K2D1

ModbusCommunicationAlarm

ReedSwitchFailure

PumpDivingDownStroke

PumpCavitationUpStroke

MinimumFlowRateAlarmAlarm

MinimumFlowRateDeviationDeviation

Alarm

Deviation

DeviationThetimetocompleteadown

DeviationThetimetocompleteanup

Displaydetectsalossof

Modbuscommunicationwhen

Modbuseventtypeissetupto

beanalarm.Triggereventif

therehasnotbeenaModbus

readeventwithin1second.

Systemisnotdetectingareed

switch.

strokeissignicantlyshorterto

completethananupstroke.

strokeissignicantlyshorter

thantocompleteadown

stroke.

Averageowratehasdropped

belowminimumowrate

thresholdspeciedforactive

prole.Eventwilltriggerif

minimumowrateeventis

conguredforalarm.

Averageowratehasdropped

belowminimumowrate

thresholdspeciedforactive

prole.Eventwilltriggerif

minimumowrateeventis

conguredfordeviation.

3A7709B35

Page 36

ErrorCodeTroubleshooting

Event

Event Event

Code

Code Code

K3D1

K3D1 K3D1

K4D1

K4D1 K4D1

P1I1

P1I1 P1I1

P2I1

P2I1 P2I1

MaximumFlowRateDeviationDeviation

MaximumFlowRateAlarmAlarm

MinimumPressure1AlarmAlarmAveragepumpoutletpressure

MinimumPressure1DeviationDeviationAveragepumpoutletpressure

Event

Event Event

Event

Type

Event Event

Type Type

Averageowratehasrisen

abovemaximumowrate

thresholdspeciedforactive

prole.Eventwilltriggerif

maximumowrateeventis

conguredfordeviation.

Averageowratehasrisen

abovemaximumowrate

thresholdspeciedforactive

prole.Eventwilltriggerif

maximumowrateeventis

conguredforalarm.

hasdroppedbelowminimum

pressurethresholdspecied

foractiveprole.Eventwill

triggerifminimumpressure

eventisconguredforalarm.

hasdroppedbelowminimum

pressurethresholdspeciedfor

activeprole.Eventwilltrigger

ifminimumpressureeventis

conguredfordeviation.

Description

Description Description

P3I1

P3I1 P3I1

P4I1

P4I1 P4I1

P6I1

P6I1 P6I1

P1CB

P1CB P1CB

P2CB

P2CB P2CB

MaximumPressure1DeviationDeviationAveragepumpoutletpressure

hasrisenabovemaximum

pressurethresholdspeciedfor

activeprole.Eventwilltrigger

ifmaximumpressureeventis

conguredfordeviation.

MaximumPressure1AlarmAlarmAveragepumpoutletpressure

hasrisenabovemaximum

pressurethresholdspecied

foractiveprole.Eventwill

triggerifmaximumpressure

eventisconguredforalarm.

PressureTransducer1FaultAlarmForunitswithoutclosedloop

pressurecontrol:Transducer1

isenabledbutnotdetected.

MinimumPressure2AlarmAlarmAveragepressureattransducer

2hasdroppedbelowminimum

pressurethreshold.Eventwill

triggerifminimumpressure

eventisconguredforalarm.

MinimumPressure2DeviationAlarmAveragepressureattransducer

2hasdroppedbelowminimum

pressurethreshold.Event

willtriggerifminimum

pressureeventiscongured

fordeviation.

363A7709B

Page 37

ErrorCodeTroubleshooting

Event

Event Event

Code

Code Code

P3CB

P3CB P3CB

P4CB

P4CB P4CB

P6CB

P6CB P6CB

P6D1

P6D1 P6D1

P6P1

P6P1 P6P1

MaximumPressure2DeviationAlarmAveragepressureattransducer

MaximumPressure2AlarmAlarmAveragepressureattransducer

PressureTransducer2FaultAlarmTransducer2isopencircuit.

MotorInletI2PisdisconnectedAlarmPort8isenabledandthe

BackPressureRegulator

I2Pisdisconnected

Event

Event Event

Event

Event Event

Type

Type Type

2hasrisenabovemaximum

pressurethreshold.Event

willtriggerifmaximum

pressureeventiscongured

fordeviation.

2hasrisenabovemaximum

pressurethreshold.Eventwill

triggerifmaximumpressure

eventisconguredforalarm.

currentdrawislessthan4mA.

Themotorairinletdriveris

requestingavaluegreaterthan

0%.Verifythatthedeviceis

connected.

AlarmPort9isenabledandthe

currentdrawislessthan4mA.

TheBPRisrequestingavalue

greaterthan0%.Verifythe

deviceisconnected.

Description

Description Description

WSC1

WSC1 WSC1

WSC2

WSC2 WSC2

WSD1

WSD1 WSD1

WSD2

WSD2 WSD2

PressureTargetis0Alarm

FlowRateTargetis0Alarm

InvalidLowerSize

InvalidPumpRatioAlarm

Alarm

Proleissetto0pressure.

Proleissetto0ow.

Invalidlowersize;occursifthe

unitisoperatedbeforesetting

upthelowersize.

Invalidpumpratio;occursifthe

unitisoperatedbeforesetting

upthepumpratio.

3A7709B37

Page 38

Parts

Parts

Parts Parts

19Y486

19Y486 19Y486

Pump

Pump Pump

Control

Control Control

Module

Module Module

Part

Ref

Part Part

Ref Ref

119Y486

1a▲16P265LABEL,warning,

1b▲16P265LABEL,warning,

1c▲16P265LABEL,warning,

Description

Description Description

DISPLAYKIT,control

module;includes

item1a,1b,and

1c;seemanual

332013forapprovals

informationaboutthe

bareADCMmodule

English

French

Spanish(shipped

loose)

Qty

Qty Qty

1

1

1

1

▲Replacementsafetylabels,tags,andcardsare

availableatnocost.

Itemsmarked———arenotavailableseparately.

Part

Ref

Part Part

Ref Ref

———

2

———

3

———

4

Description

Description Description

BRACKET,control

module

LABEL,product1

TOKEN,GCA,

upgrade,IPK

pneumatic

Qty

Qty Qty

1

1

383A7709B

Page 39

Parts

25B234

25B234 25B234

Pneumatic

Pneumatic Pneumatic

ADCM

ADCM ADCM

Display

Display Display

Enclosure

Enclosure Enclosure

Assembly

Assembly Assembly

3A7709B39

Page 40

Parts

Part

Ref

Part Part

Ref Ref

———

1

2114225

———

3

———

4

5

277853

6258475

———

7

8117026

———

10

12102478

———

13

Description

Description Description

ENCLOSURE,

ADCM

TRIM,EDGE

PROTECTION

BRACKET,

MOUNTING,AOCM,

PAINTED

NUT,FLANGE,

SERRATED,#10-32,

SS

BRACKET,

MOUNTING,BOOTH

CONTROL

MODULE,GCA,

ADCM,IS

WASHER,LOCK,

EXTERNAL

SCREW,SHCS

M5XU

HOLDER,TIE

USTRAP,TIE

WIRING

WIRE,GROUNDING

PANEL

Qty

Qty Qty

1

1

1

5

1

1

2

2

1

1

1

Itemsmarked———arenotavailableseparately.

Part

Ref

Part Part

Ref Ref

———

14

1615T500

17

18104176BULKHEAD,1/4TX

———

19

———

20

21U5415

———

22

2354757

———

24

———

25

Description

Description Description

SCREW,GROUND

GAUGE,

PRESSURE,AIR,

PLMNT,1/8

TRANSDUCER,

I/P,PRESSURE

SWITCH

1/4T

FITTING,TEE,5/32

TUBE,1/8NPT

BULKHEAD,TUBE,

5/32

FITTING,UNION,

TEE1/4TUBE

TUBE,

POLYURETHANE,

RD

TUBE,NYLON,RND

SCREW,GROUND,

10-32

NUT,LOCK,HEX

Qty

Qty Qty

1

2

2

1

2

2

1

1

1

3

4

403A7709B

Page 41

AccessoriesandKits

Accessories

Accessories Accessories

Automatic

Automatic Automatic

Theairregulator(106)isusedtocontrolairintothe

AirMotor(G,seeTypicalInstallation,page13).The

reedswitchassembly(102)monitorspumpoperation

andprovidescontroltothetransducerI2P(101).The

reedswitchcable(105)connectsthereedswitch

assembly(102)tothe19Y486PumpControlModule

(A).

Part

Ref

Part Part

Ref Ref

10224X220

———

103

104102360

10519Y480

10619Y479

Air

Air Air

and

and and

Control

Control Control

Description

Description Description

SWITCH,reed,

assembly

SCREW,panhead,

#8-32X1.5in.

WASHER,at

SWITCH,M12harness

connect

REGULATOR,remote

piloted,3/4in.

Kits

Kits Kits

Kit

19Y482

Kit Kit

19Y482 19Y482

Qty

Qty Qty

1

1

1

1

1

Technical

Technical Technical

Reed

Reed Reed

Electrical

Electrical Electrical

Voltage

Current

Power10Wmaximum

AmbientTemperature

EX

Ratings:

EX EX

Ratings: Ratings:

Classication"SimpleApparatus"inaccordance

Specications

Specications Specications

Switch

Switch Switch

24X220

24X220 24X220

Ratings:

Ratings: Ratings:

for

19Y482

for for

19Y482 19Y482

US

US US

24VDC

400mA

-22°F–158°F-30°C–70°C

withUL/EN/IEC60079-11,clause5.7

ClassI,Div1:GroupDT4

II IIII1 1

ExiaIICT4Ga

ParametersUi=17.9V

Ii=400mA

Pi=1.2W

Ci=1.2nF

Li=6.0μH

Li/Ri=5.9μH/Ω

Metric

Metric Metric

1

G

G G

3A7709B

41

Page 42

AccessoriesandKits

NXT

NXT NXT

Theairregulator(206)isusedtocontrolairintothe

AirMotor(G,seeTypicalInstallation,page13).The

NXTreedswitchassembly(203)monitorspump

operationandprovidescontroltothetransducerI2P

(201).Thereedswitchcable(205)connectstheNXT

reedswitchassembly(203)tothe19Y486Pump

ControlModule(A).TheNXTreedswitchconversion

cable(202)allowstheM12reedswitchcable(205)

toconnecttoconnecttothestandardNXTairmotor

reedswitch(203).

Air

Control

Air Air

Control Control

Part

Ref

Part Part

Ref Ref

20219Y997

203119700

204102730

20519Y480

20619Y479

207118605

Kit

19Y996

Kit Kit

19Y996 19Y996

Description

Description Description

SWITCH,reed,NXT,

assembly

SENSOR,reedswitch

SCREW,machine,hex

washerhead

SWITCH,M12harness

connect

REGULATOR,remote

piloted,3/4in.

O-RING

Qty

Qty Qty

1

1

1

1

1

1

Technical

Technical Technical

Reed

Reed Reed

Electrical

Electrical Electrical

Voltage

Current

Power10Wmaximum

AmbientTemperature

EX

Ratings:

EX EX

Ratings: Ratings:

Classication"SimpleApparatus"inaccordance

Specications

Specications Specications

Switch

Switch Switch

119700

119700 119700

Ratings:

Ratings: Ratings:

for

19Y996

for for

19Y996 19Y996

US

US US

24VDC

500mA

-40°F–221°F-40°C–105°C

withUL/EN/IEC60079-11,clause5.7

ClassI,Div1:GroupDT4

II IIII1 1

ExiaIICT4Ga

ParametersUi=17.9V

Ii=500mA

Pi=1.2W

Ci=1.2nF

Li=6.0μH

Li/Ri=5.65μH/Ω

Metric

Metric Metric

1

G

G G

42

3A7709B

Page 43

AccessoriesandKits

Transducer

Transducer Transducer

UsedforAirMotorairinletcontrolandBack

PressureRegulatorcontrol.FortheAirMotor(G,

seeTypicalInstallation,page13),thecable(302)

connectstoPort8onthe19Y486PumpControl

Module(A).FortheBackPressureRegulator(M),

thecable(302)connectstoPort9onthe19Y486

PumpControlModule(A).

Part

Ref

Part Part

Ref Ref

———

301

———

302

303110436

304100030

305198178

306110207

307

C19466

308198171

———

Partsnotsoldseparately.

I/P

Kit

I/P I/P

24V001

Kit Kit

24V001 24V001

Description

Description Description

TRANSDUCER,

miniature

CABLE,F/C,I.S.,8M

GAUGE,pressure,air

BUSHING

ELBOW

ELBOW

TEE1

ELBOW

Qty

Qty Qty

1

1

1

1

1

1

1

Pressure

Pressure Pressure

Pressure

Pressure Pressure

Pressuretransducerkitsareusedtomonitorthepump

outletpressure(R1,seeTypicalInstallation,page13)

andpressureattheBackPressureRegulator(R2,

M).Formonitoringpumpoutletpressure(R1),the

cable(403)connectstoPort7onthe19Y486Pump

ControlModule(A).Forthepressuretransducer(R2)

attheBackPressureRegulator(M),thecable(403)

connectstoPort10onthe19Y486PumpControl

Module(A).

Ref

Ref Ref

401ADAPTER,

402

403

Description

Description Description

tting,

pressure

sensor

PACKING,

o-ring

SENSOR,

pressure,uid

outlet

Transducer

Transducer Transducer

Transducer

Transducer Transducer

Kit

for

Kit Kit

for for

Kit

for

Kit Kit

for for

24R050

24R050 24R050

Part

Part Part

16U4401

1193481

16P28915M6691

ball

4 44- --ball ball

ball

2 22- --ball ball

24Y245

24Y245 24Y245

Part

Part Part

Pumps

Pumps Pumps

Pumps

Pumps Pumps

Qty

Qty Qty

24R050

24R050 24R050

24Y245

24Y245 24Y245

3A7709B43

Page 44

CaliforniaProposition65

Pressure

Pressure Pressure

Ref

Ref Ref

501

502

503

504

505

Technical

Technical Technical

Pressure

Pressure Pressure

24X089

24X089 24X089

Electrical

Electrical Electrical

Transducer

Transducer Transducer

Description

Description Description

MANIFOLD,1.5in.

sanitary,transducer

SENSOR,pressure,

uidoutlet

PACKING,o–ring

CLAMP,sanitary,1.5

in.

GASKET,sanitary

Specications

Specications Specications

Transducer

Transducer Transducer

Ratings:

Ratings: Ratings:

Kit

for

Kit Kit

Part

Part Part

for

for for

Kits

24R050,

Kits Kits

24R050, 24R050,

Sanitary

for for

Sanitary Sanitary

17D2331

16P2891

1193481

1185981

1203511

24R050,

24R050, 24R050,

24Y245,

24Y245, 24Y245,

24Y245,

24Y245, 24Y245,

Pumps

Pumps Pumps

Qty

Qty Qty

and

and and

and

and and

24X089

24X089 24X089

24X089

24X089 24X089

US

US US

Metric

Metric Metric

Voltage

FullScalesensitivity

SpanAtMaxpressure

AmbientTemperature

EX

Ratings:

EX EX

Ratings: Ratings:

Classication"SimpleApparatus"inaccordance

32°F–140°F0°C–60°C

withUL/EN/IEC60079-11,clause5.7

ClassI,Div1:GroupDT4

5VDC

20.00mV/V

100mV

II IIII1 1

ExiaIIAT4Ga

ParametersUi=17.9V

Ii=73mA

Pi=1.3W

Ci=900pF

Li=1.7μH

Li/Ri=6.6μH/Ohm

California

California California

CALIFORNIA

CALIFORNIA CALIFORNIA

Proposition

Proposition Proposition

RESIDENTS

RESIDENTS RESIDENTS

65

65 65

1

G

G G

WARNING:

WARNING: WARNING:

44

Cancerandreproductiveharm—www.P65warnings.ca.gov.

3A7709B

Page 45

Notes

Notes

Notes Notes

Appendix

Appendix Appendix

TocommunicatethroughberopticswiththeE-Flo

DCControlModule,referencetheappropriate

3A7709B45

A

A A

Modbus

- --Modbus Modbus

Variable

Variable Variable

Map

Map Map

hardwareasshowninmanual332356.That

manualindicatesvariousoptionsforconnecting

Page 46

AppendixA-ModbusVariableMap

beropticcablesfromthecontrolmoduletothe

non-hazardousarea.Thefollowingtableslist

ModbusregistersavailabletoaPCorPLClocatedin

thenon-hazardousarea.

Table

Table Table

ADCM

ADCM ADCM

Modbus

Modbus Modbus

Register

Register Register

403100timeHour_u80–23Read

403101timeMinute_u80–59Read

403102

403103dateYear_u80–99Read

403104dateMonth_u81–12Read

403105dateDay_u81–31Read

403106ActiveAlarmsUpper

403107ActiveAlarmsLower

403200timeHour_u80–23Read/Write

Pump

3 33Pump Pump

Conguration

Conguration Conguration

Parameter

Parameter Parameter

timeSecond_u8

Registers

Registers Registers

Name

Name Name

Table3showstheregistersneededforbasic

operation,monitoring,andalarmcontrolfeatures.

Tables4and5providebitdenitionsasneededfor

certainregisters.Table6showstheunitsandhowto

converttheregistervaluetoaunitvalue.

Range

Range Range

0–59Read

SeeEventTable

SeeEventTable

Register

Register Register

Access

Access Access

Read

Read

403201timeMinute_u80–59Read/Write

403202

403203dateYear_u80–99Read/Write

403204dateMonth_u81–12Read/Write

403205dateDay_u81–31Read/Write

403206displayPassword_u320-9999Read/Write

403207displayDateFormat_enum0=MMDDYY

403208PressureUnits

403209VolumeUnits

403210FlowUnits0=Liter/min

403211

timeSecond_u8

ProleLock

0–59Read/Write

1=DDMMYY

2=YYMMDD

0=PSI

1=BAR

2=MPA

0=Gallons

1=Liters

1=Gallons/min

2=cc/min

3=oz/min

4=cycles/min

0=unlocked

1=locked

Read/Write

Read/Write

Read/Write

Read/Write

Read/Write

403212Tranducer_1_type0=None

1=500psi

403213Reserved

403214

Transducer_1_ScaleUpper

0-65535Read

463A7709B

Read/Write

Page 47

AppendixA-ModbusVariableMap

ADCM

ADCM ADCM

Modbus

Modbus Modbus

Register

Register Register

403215

403216

403217

403218Transducer_2_type0=None

403219Reserved

403220

403221

403222

403223

403224

Table

Table Table

ADCM

ADCM ADCM

Modbus

Modbus Modbus

Register

Register Register

Pump

4 44Pump Pump

Parameter

Parameter Parameter

Transducer_1_ScaleLower

Transducer_1_OffsetUpper

Transducer_1_OffsetLower

Transducer_2_ScaleUpper

Transducer_2_ScaleLower

Transducer_2_OffsetUpper

Transducer_2_OffsetLower

DisableRemoteStart_bool0=RemoteStartEnabled

Run

Registers

Run Run

Registers Registers

Parameter

Parameter Parameter

Name

Name Name

Name

Name Name

Range

Range Range

0-65535Read

0-65535Read

0-65535Read

1=500psi

0-65535Read

0-65535Read

0-65535Read

0-65535Read

1=RemoteStartDisabled

Range

Range Range

Register

Register Register

Access

Access Access

Read/Write

Read/Write

Register

Register Register

Access

Access Access

404100

404101

404102ActualPumpFlowRate10=1.0L/min

404103EstimatedPumpForceorPressure0–100Read

404104Transducer1Pressure1=1psi

404105Transducer2Pressure1=1psi

PumpStatusBits

ActualPumpSpeed

bit0=Pumptryingtomove

bit1=Pumpactuallymoving

bit2=ActiveAlarm

bit3=ActiveDeviation

bit4=ActiveAdvisory

bit5=SetupModied

(Registers6141-6159)

bit6=PumpDirection

bit7=RunStatus

bit8=Prole1Modied

bit9=Prole2Modied

bit10=Prole3Modied

bit11=Prole4Modied

10=1.0cycle/minRead

10=1.0Gal/min

1=1cc/min

1=1oz/min

10=1.0cycle/min

10=1.0Bar

100=1.00Mpa

10=1.0Bar

100=1.00Mpa

Read

Read

Read

Read

404106BatchTotalHighWord0-65535Read

404107BatchTotalLowWord0-65535Read

3A7709B

47

Page 48

AppendixA-ModbusVariableMap

ADCM

ADCM ADCM

Modbus

Modbus Modbus

Register

Register Register

404108

404109

404110MaintenanceTotalHighWord0-65535Read

404111MaintenanceTotalLowWord0-65535Read

404112PumpAlarmsHighWord

404113PumpAlarmsLowWord

404114Reserved

404115Reserved

404116Reserved

404117Reserved

404118Reserved

404119Reserved

404120DisplayVersionMajor0–99Read

404121DisplayVersionMinor0–99Read

404122DisplayVersionBuild0–99Read

Parameter

Parameter Parameter

GrandTotalHighWordPump1

GrandTotalLowWordPump1

Name

Name Name

Range

Range Range

0-65535Read

0-65535Read

SeeEventTable

SeeEventTable

Register

Register Register

Access

Access Access

Read

Read

404150

404151

404152

404153

404154

404155

404156

404157

404158ActivePressureMinimumEventType0=Limit

404159ActivePressureMaximumEventType0=Limit

ActiveProlePressureMinimum0tomaximumpressureforpump

ActiveProlePressure0tomaximumpressureforpump

ActiveProlePressure0tomaximumpressureforpump

ActiveProleFlow0tomaximumpressureforpump

ActiveProleFlow0tomaximumpressureforpump

ActiveProleFlow0tomaximumpressureforpump

ActiveProleMode

ActiveBPR%Closed

type

type

type

type

type

type

0=Pressure

1=Flow

2=Hybrid

0-100Read

1=Deviation

2=Alarm

1=Deviation

2=Alarm

Read

Read

Read

Read

Read

Read

Read

Read

Read