Page 1

Instructions - Parts

®

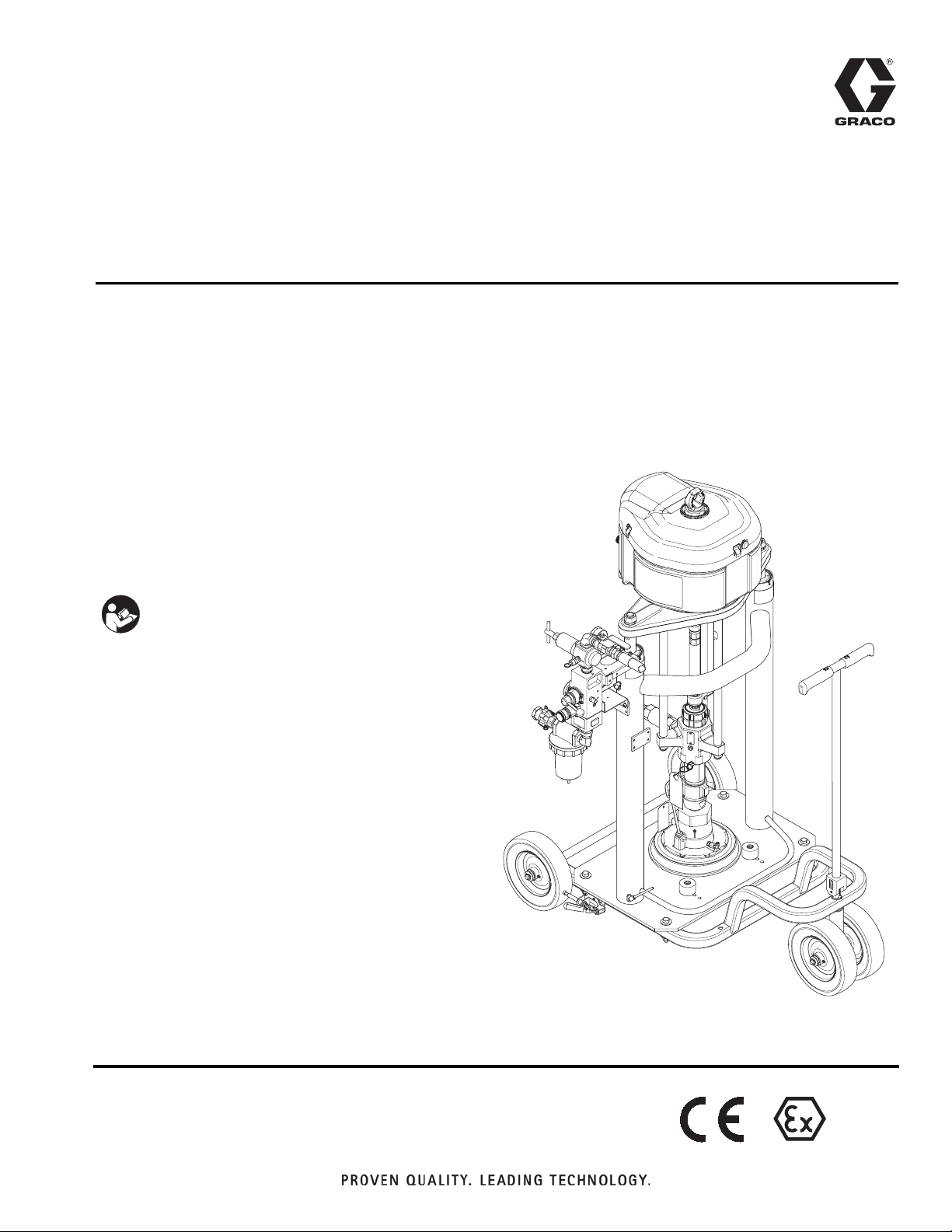

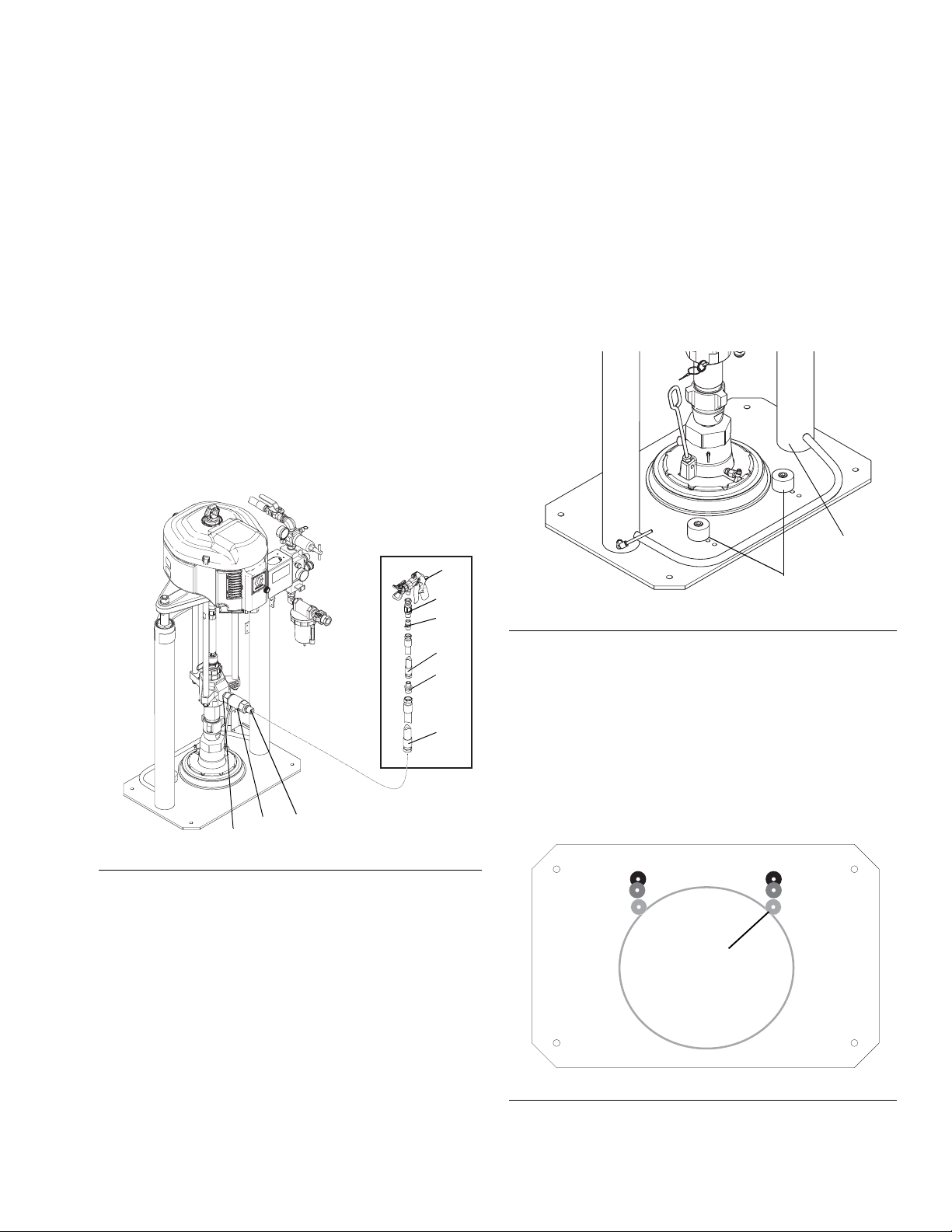

Xtreme

For use with bulk supply of medium to high viscosity sealants and adhesive materials. For

professional use only.

6500 psi (45 MPa, 448 bar) Maximum Fluid Working Pressure

90 psi (620 kPa, 6.2 bar) Maximum Air Working Pressure

100 psi (0.7 kPa, 7 bar) Maximum Air Inlet Pressure

Model 16T311

5 gallon (20 liter), with cart

Model 16P957

5 gallon (20 liter), no cart

Important Safety Instructions

Read all warnings and instructions in this manual. Save these instructions.

PFP

3A2798D

EN

Model 16T311 shown

WLE

II 2 G c T2

Page 2

Related Manuals

Contents

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Component Identification . . . . . . . . . . . . . . . . . . . . 5

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

General Information . . . . . . . . . . . . . . . . . . . . . . 8

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Connect Mix Line and Gun . . . . . . . . . . . . . . . . . 9

Mechanical Setup . . . . . . . . . . . . . . . . . . . . . . . . 9

Attach Drum Stops . . . . . . . . . . . . . . . . . . . . . . . 9

Supply System Operation . . . . . . . . . . . . . . . . . . . 10

Before Operating . . . . . . . . . . . . . . . . . . . . . . . . 10

Pressure Relief Procedure . . . . . . . . . . . . . . . . 10

Flush Before Using Equipment . . . . . . . . . . . . . 10

Start and Adjust Ram . . . . . . . . . . . . . . . . . . . . 11

Start and Adjust Pump . . . . . . . . . . . . . . . . . . . 11

Change Drums . . . . . . . . . . . . . . . . . . . . . . . . . 12

Flush . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Shutdown and Care of the Pump . . . . . . . . . . . 12

Replace Throat Seals . . . . . . . . . . . . . . . . . . . . 12

Remove Quick Coupler . . . . . . . . . . . . . . . . . . . 12

Before Beginning Repair . . . . . . . . . . . . . . . . . . . 13

Maintenance Procedures . . . . . . . . . . . . . . . . . . . 13

Platen Maintenance . . . . . . . . . . . . . . . . . . . . . 13

Adjust Spacers . . . . . . . . . . . . . . . . . . . . . . . . . 13

Remove and Reinstall Wiper . . . . . . . . . . . . . . 14

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Disconnect Pump from Platen . . . . . . . . . . . . . . 17

Connect Platen to Pump . . . . . . . . . . . . . . . . . . 17

Remove Wipers . . . . . . . . . . . . . . . . . . . . . . . . . 17

Install Wipers . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Disconnect Displacement Pump . . . . . . . . . . . . 18

Remove Displacement Pump . . . . . . . . . . . . . . 18

Install Displacement Pump . . . . . . . . . . . . . . . . 18

Connect Displacement Pump . . . . . . . . . . . . . . 18

Remove Air Motor . . . . . . . . . . . . . . . . . . . . . . . 19

Install Air Motor . . . . . . . . . . . . . . . . . . . . . . . . . 19

Supply Unit Repair . . . . . . . . . . . . . . . . . . . . . . . 20

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Check Valve (16T481) . . . . . . . . . . . . . . . . . . . . 29

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Static Mixer Kit, 16T316 . . . . . . . . . . . . . . . . . . 30

Static Mixer (16T316) . . . . . . . . . . . . . . . . . . . . 30

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 34

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 34

Related Manuals

The following manuals are available at www.graco.com.

Component Manuals in English:

Manual Description

311762

311238

2 3A2798D

Xtreme Lowers Instructions-Parts

®

NXT

Air Motor Instructions-Parts

Page 3

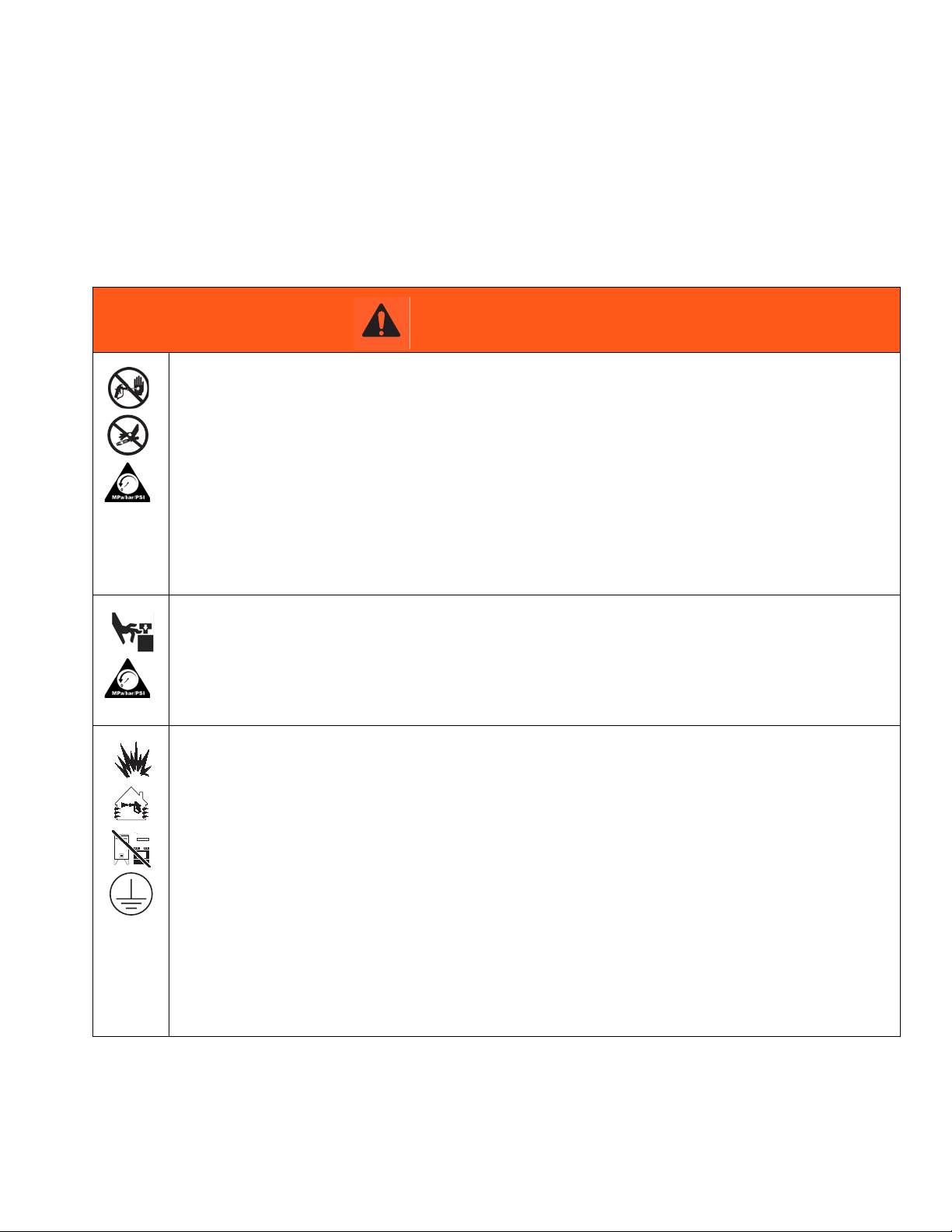

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. When

these symbols appear in the body of this manual or on warning labels, refer back to these Warnings. Product-specific

hazard symbols and warnings not covered in this section may appear throughout the body of this manual where

applicable.

WARNING

SKIN INJECTION HAZARD

High-pressure fluid from gun, hose leaks, or ruptured components will pierce skin. This may look like just

a cut, but it is a serious injury that can result in amputation. Get immediate surgical treatment.

• Do not spray without tip guard and trigger guard installed.

• Engage trigger lock when not spraying.

• Do not point gun at anyone or at any part of the body.

• Do not put your hand over the spray tip.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

•Follow the Pressure Relief Procedure when you stop spraying and before cleaning, checking, or

servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses and couplings daily. Replace worn or damaged parts immediately.

MOVING PARTS HAZARD

Moving parts can pinch, cut or amputate fingers and other body parts.

• Keep clear of moving parts.

• Do not operate equipment with protective guards or covers removed.

• Pressurized equipment can start without warning. Before checking, moving, or servicing equipment,

follow the Pressure Relief Procedure and disconnect all power sources.

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes

are present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail. Do not use pail liners unless they

are antistatic or conductive.

• Stop operation immediately if static sparking occurs or you feel a shock. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

3A2798D 3

Page 4

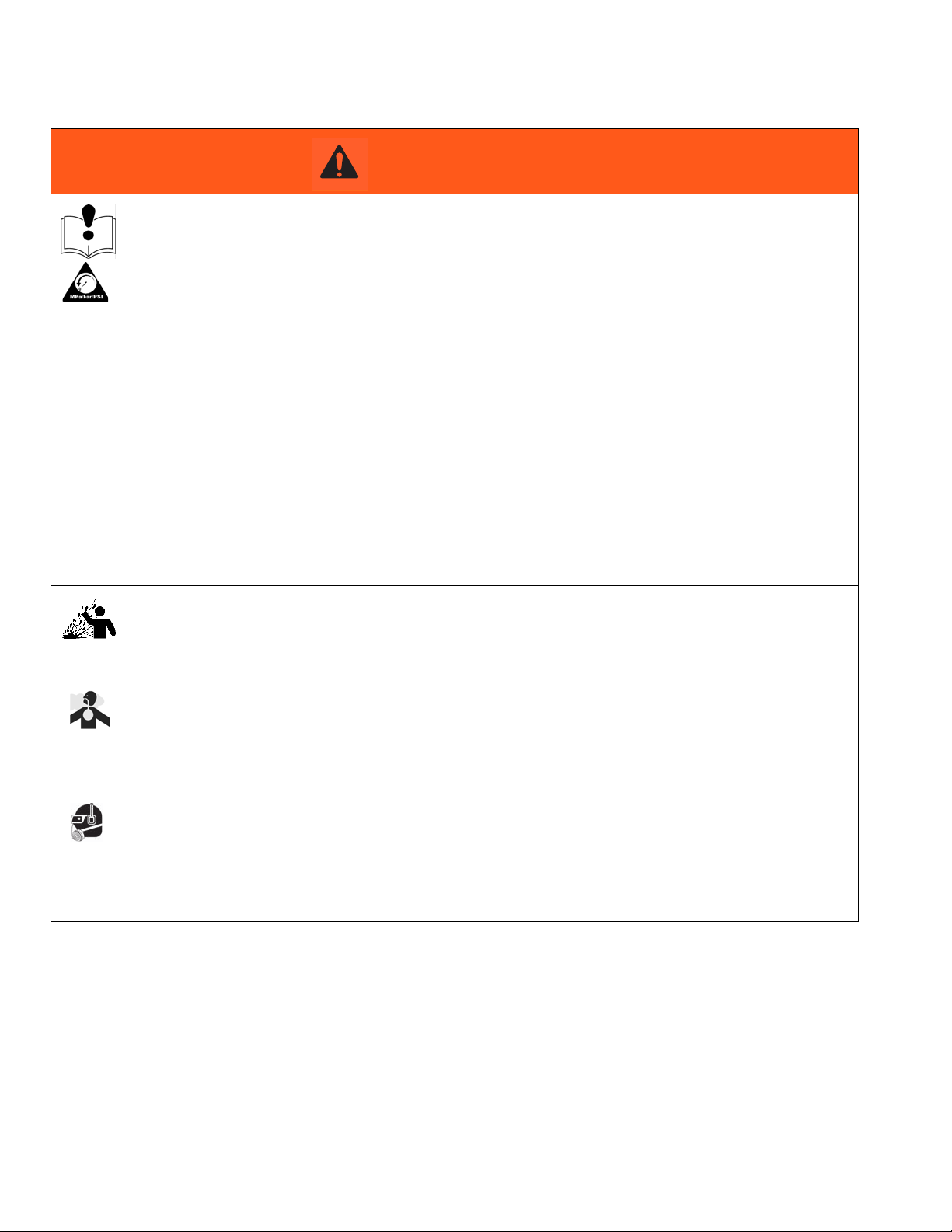

Warnings

WARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information

about your material, request MSDS from distributor or retailer.

• Do not leave the work area while equipment is energized or under pressure.

• Turn off all equipment and follow the Pressure Relief Procedure when equipment is not in use.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment. Alterations or modifications may void agency approvals and create

safety hazards.

• Make sure all equipment is rated and approved for the environment in which you are using it.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

SPLATTER HAZARD

Hot or toxic fluid can cause serious injury if splashed in the eyes or on skin. During blow off of platen,

splatter may occur.

• Use minimum air pressure when removing platen from drum.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read MSDSs to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

PERSONAL PROTECTIVE EQUIPMENT

Wear appropriate protective equipment when in the work area to help prevent serious injury, including

eye injury, hearing loss, inhalation of toxic fumes, and burns. This protective equipment includes but is

not limited to:

• Protective eyewear, and hearing protection.

• Respirators, protective clothing, and gloves as recommended by the fluid and solvent manufacturer

4 3A2798D

Page 5

Component Identification

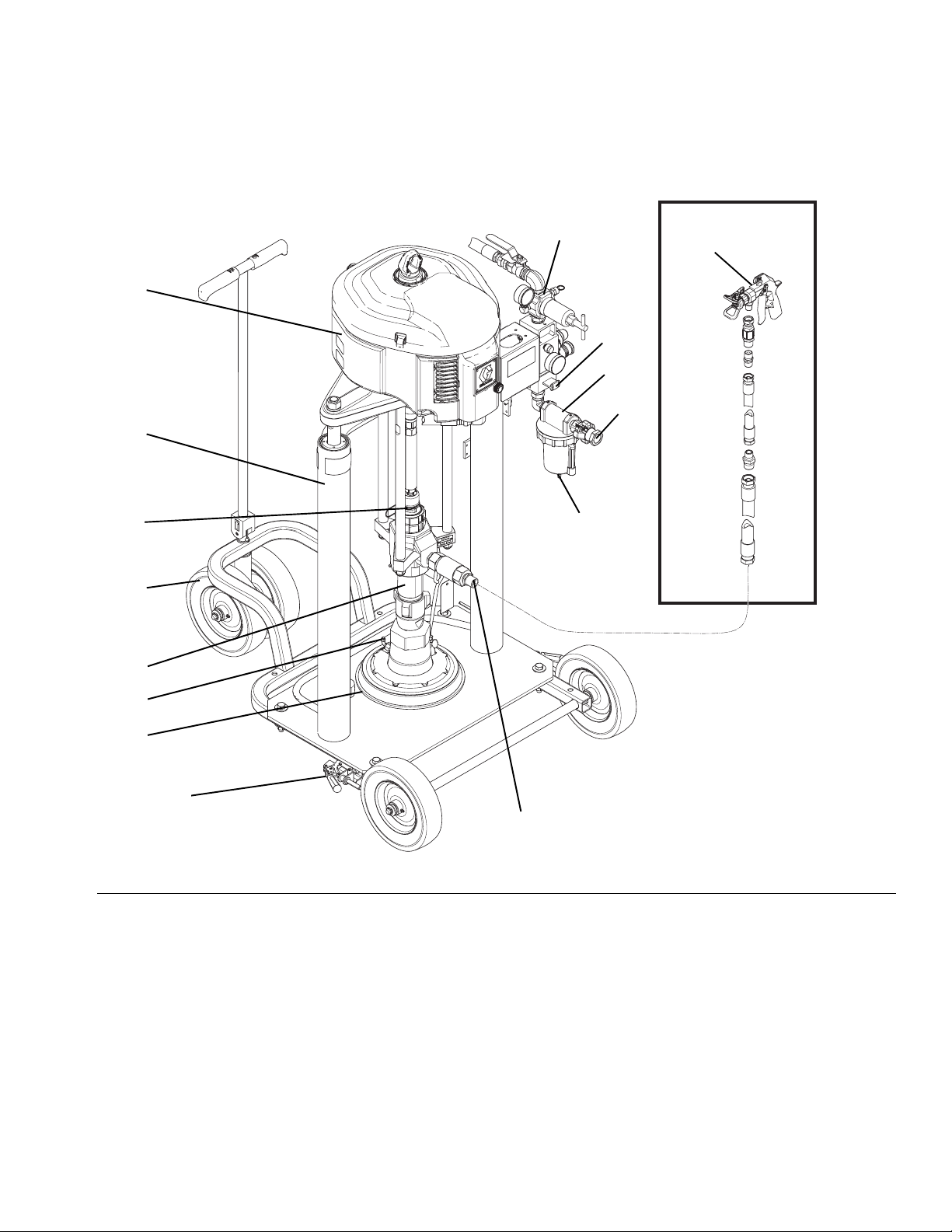

Component Identification

Model 16T311 shown

G (see F

IG

. 2 on

page 6)

H

B

V

U

T

A

R

W

E

C

M

D

F

FIG. 1

Key:

ARam Assembly

B Air Motor

C Displacement Pump

IG

D Platen (see F

ECart

F Cart Brake

G Integrated Air Controls (see F

HSpray Gun

M Blowoff Air Supply Line

RWet Cup

S Fluid Outlet

T Main Air Inlet

. 3 on page 7)

IG

. 2 on page 6)

S

U Air Filter and Water Separator

V Bleed Type Air Shutoff Valve

W Air Line Drain Valve

ti20228b

3A2798D 5

Page 6

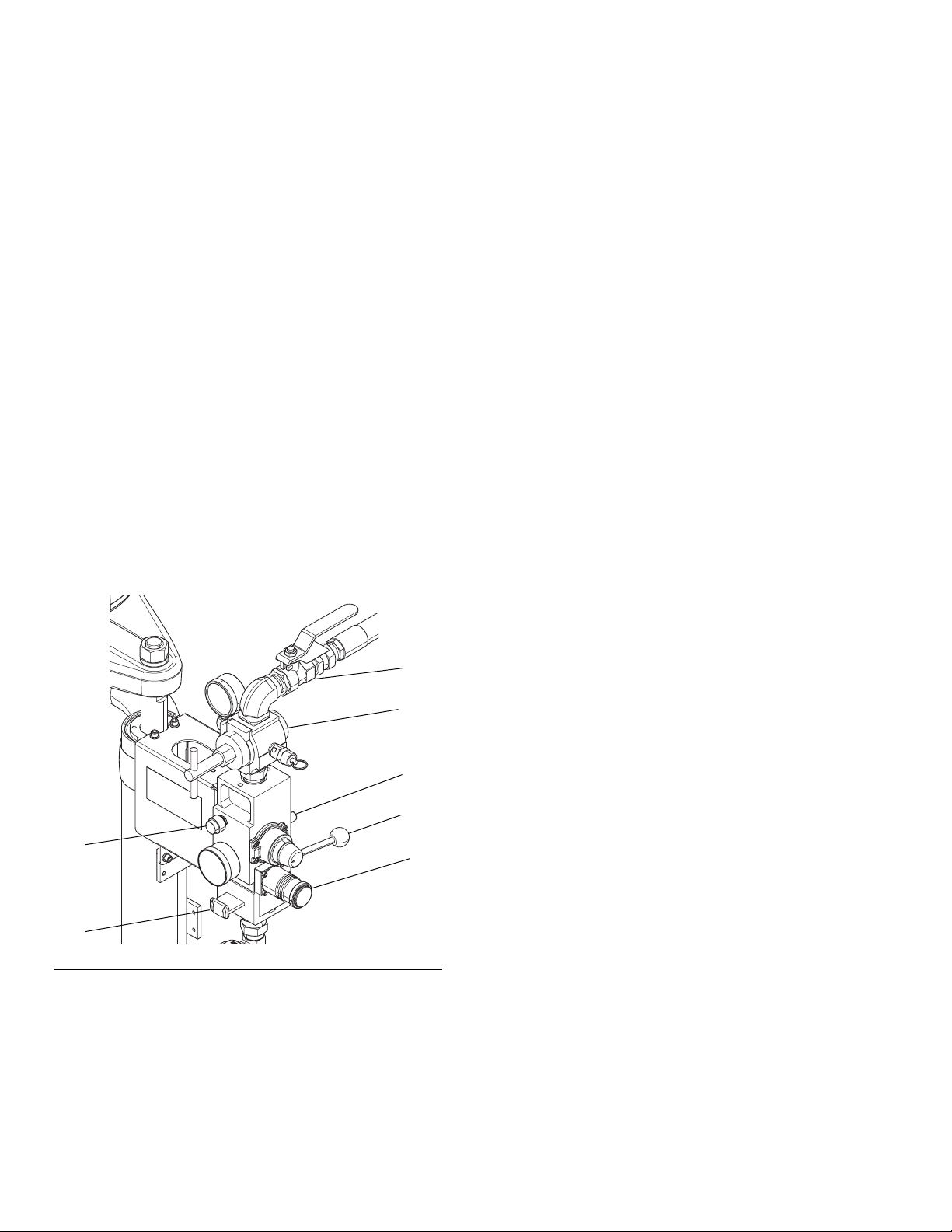

Component Identification

Integrated Air Controls

The integrated air controls include:

• Main air slider valve (BA): turns air on and off to

the system. When closed, the valve relieves pressure downstream.

• Ram air regulator (BB): controls ram up and down

pressure and blowoff pressure.

• Ram director valve (BC): controls ram direction.

• Exhaust port with muffler (BD)

• Air motor regulator (BE): Controls air pressure to

motor.

• Air motor ball valve (BF): turns air on and off to

the air motor. When closed, the valve relieves air

trapped between it and the air motor.

• Blowoff button (BG): turns air on and off to push

the platen out of an empty drum.

Air Line Accessories

See FIG. 1 on page 5.

• Air line drain valve (W)

• Air line 40 micron filter (U): removes harmful dirt

and moisture from compressed air supply.

• Air relief valve (attached to ram air regulator, not

visible): automatically relieves excessive pressure.

BG

BA

FIG. 2. Integrated Air Controls

BF

BE

BD

BC

BB

ti20246a

6 3A2798D

Page 7

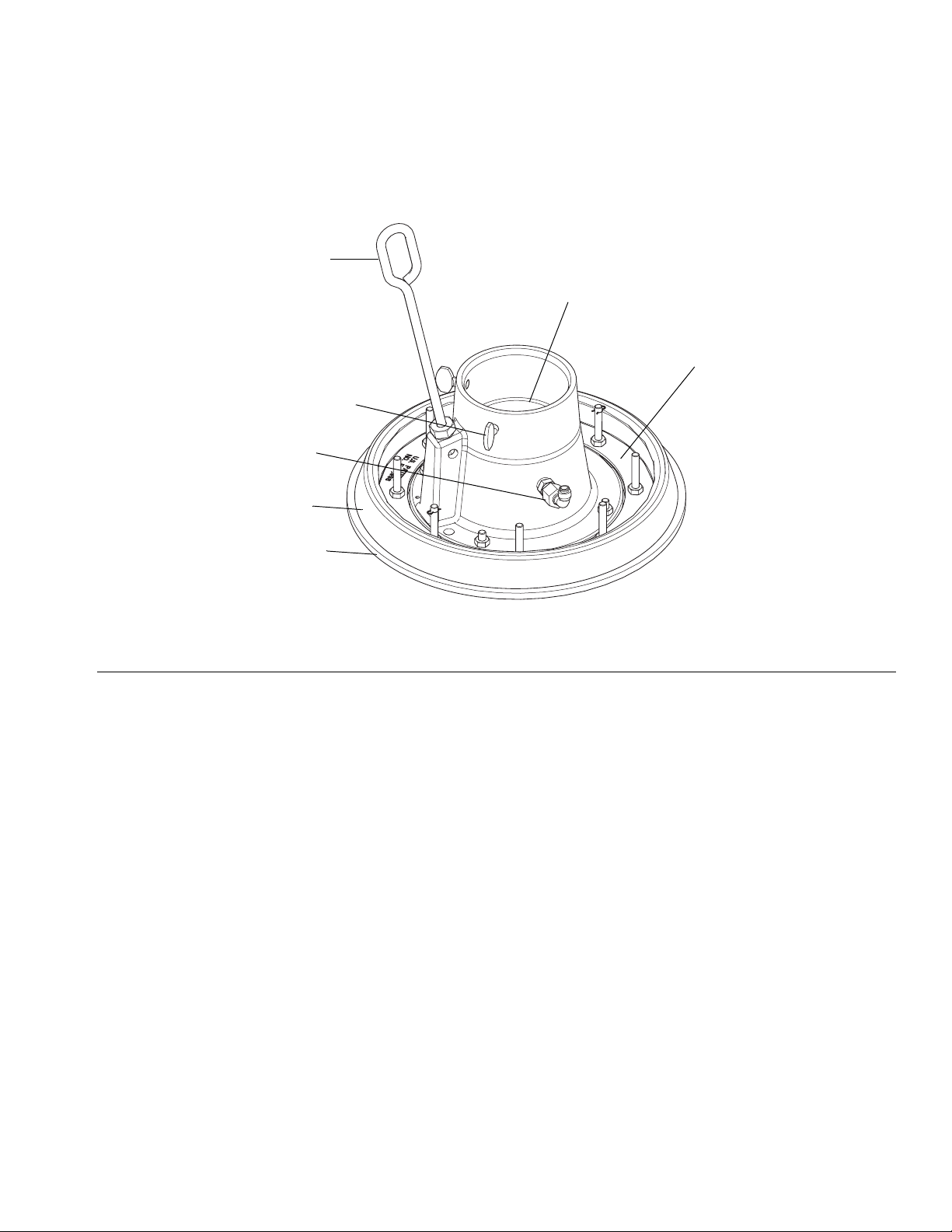

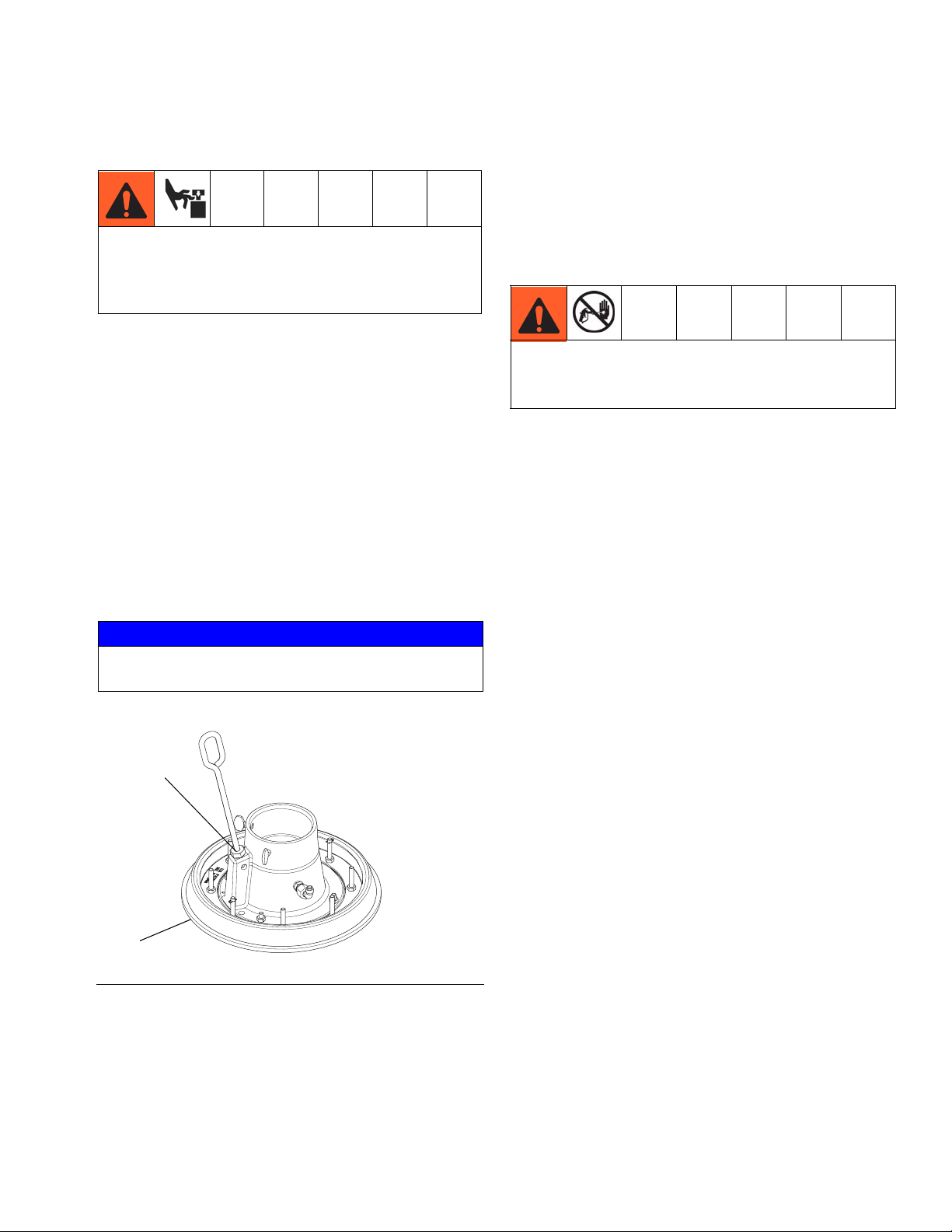

Platen Component Identification

Model 16U676, 20 liter (5 gallon)

EK

EH

EM

EG

Component Identification

EP

EA

EB

FIG. 3

Key:

EA Retainer Clamp

EB Wiper

EG Spacer

EH Thumb Screws

EK Bleed Stick

EM Air Assist Body Check Valve

EP O-ring Seal (assembles to platen adapter, not shown)

ti20247b

3A2798D 7

Page 8

Installation

Installation

General Information

NOTE: Reference numbers and letters in parentheses

in the text refer to the callouts in the figures.

Accessories are available from Graco. Make certain all

accessories are adequately sized and pressure-rated to

meet the system’s requirements.

Location

Lift location

Floor

mounting

location

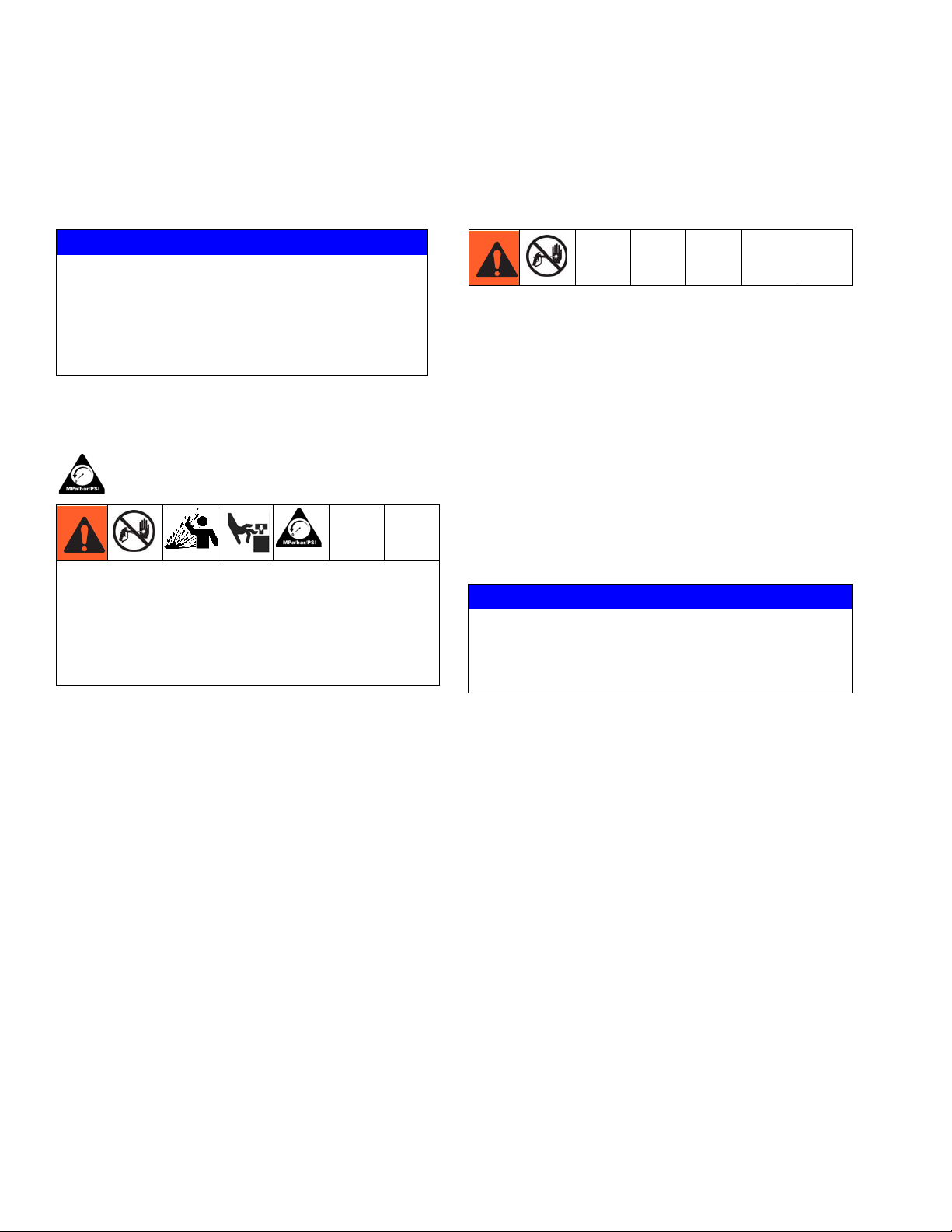

FIG. 4

Attach a lifting sling at the proper lift spots. Lift off the

pallet using a crane or a forklift.

Position the ram so the air controls are easily accessible. Ensure that there is enough space overhead for the

ram to raise fully. See Dimensions, page 31.

Set the brake on the cart before using the system.

Model 16P957 only:

a guide, drill holes for 1/2 in. (13 mm) anchors.

Model 16P957 only:

all directions. If necessary, level the base using metal

shims. Secure the base to the floor using 1/2 in. (13

mm) anchors that are long enough to prevent the ram

from tipping.

Lift location

Floor

mounting

location

ti20230b

Using the holes in the ram base as

Ensure that the ram base is level in

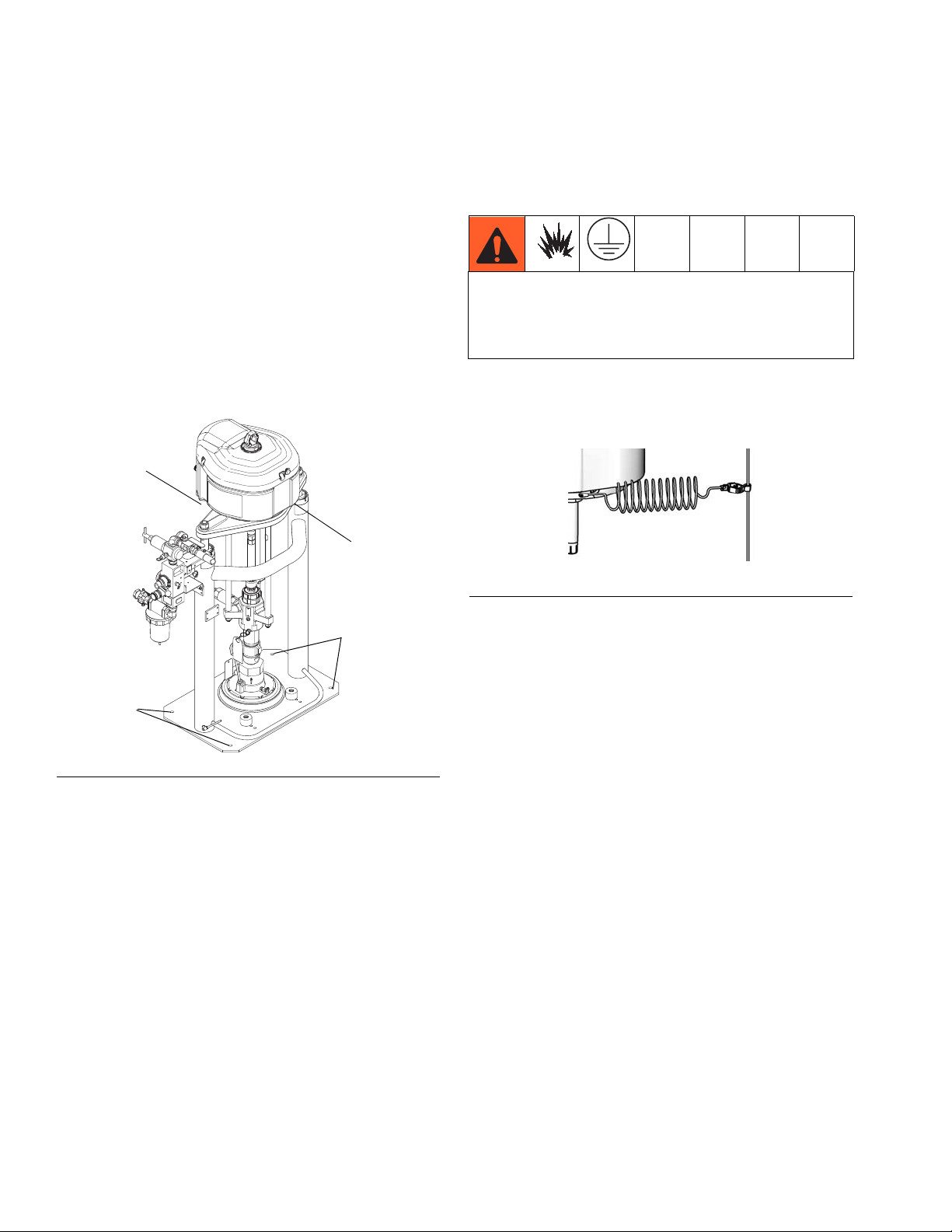

Grounding

The equipment must be grounded to reduce the risk

of static sparking. Static sparking can cause fumes

to ignite or explode. Grounding provides an escape

wire for the electric current.

Pump: use the supplied ground wire and clamp. Connect other end of wire to a true earth ground. See F

ti8250a

FIG. 5

Air and fluid hoses: use only electrically conductive

hoses with a maximum of 500 ft. (150 m) combined

hose length to ensure grounding continuity. Check electrical resistance of hoses. If total resistance to ground

exceeds 25 megohms, replace hose immediately.

Air compressor: follow manufacturer’s recommendations.

Spray gun/dispense valve: ground through connection

to a properly grounded fluid hose and pump.

Fluid supply container: follow local code.

Object being sprayed: follow local code.

Solvent pails used when flushing: follow local code.

Use only conductive metal pails that are properly

grounded.

To maintain grounding continuity when flushing or

relieving pressure: hold metal part of the dispense

valve firmly to the side of a grounded metal pail, then

trigger the valve.

IG

. 5.

8 3A2798D

Page 9

Installation

Connect Mix Line and Gun

NOTE: Kit 24P832 includes items 5, 6, and 11-16 in FIG.

6.

1.

If installing mix line and gun kit 24P832,

nipple (5), check valve (6), and second nipple (5)

onto the pump outlet as shown in F

2. Connect the supplied 3/4 in. hose (11) to the

nipple (5). See F

3. Use reducing nipple (12) to connect the supplied

1/2 in. whip hose (13) to the 3/4 in. hose (11).

4. Use nipple (14) to connect gun swivel (15) to whip

hose (13).

5. Connect gun (16) to gun swivel (15).

IG

. 6.

IG

install

. 6.

16

15

14

NOTE: Quick disconnects restrict flow for large air

motors.

Attach Drum Stops

This unit is shipped with drum stops in place to help

position the drum on the ram. For replacement parts,

order Kit 255477. The kit includes 2 each of capscrews

(FA), lock washers (not shown), and drum stops (FB).

FA

ti20248b

FIG. 7

FB

13

12

11

5

FIG. 6

6

5

ti20229b

Mechanical Setup

1. Fill displacement pump wet cup 2/3 full with Graco

™

Throat Seal Liquid (TSL

2. Back-off air regulators to their full counterclockwise

position and close all shutoff valves.

3. Connect air line from an air source to the system air

inlet. See F

meeting the required flow.

IG

. 1. Use a supply hose capable of

).

1. Locate the correct set of mounting holes on the ram

base.

2. Using the capscrews (FA) and lock washers (not

shown), attach the drum stops (FB) to the ram base.

NOTE: Only use the 5 gallon drum stop position shown

in F

IG

. 8.

5 gal (20 L)

FIG. 8: Ram Base

3A2798D 9

Page 10

Supply System Operation

Supply System Operation

Before Operating

NOTICE

To prevent mixed material from fully curing in the

system requiring replacement of all parts containing

cured material, always be prepared to immediately

begin flushing at the first sign of material curing in the

system and immediately after spraying stops. See

Flush on page 12.

Pressure Relief Procedure

Follow the Pressure Relief Procedure whenever

you see this symbol.

This equipment stays pressurized until pressure is

manually relieved. To help prevent serious injury

from pressurized fluid, such as skin injection,

splashing fluid and moving parts, follow the Pressure

Relief Procedure when you stop spraying and before

cleaning, checking, or servicing the equipment.

5. Lock the gun/valve trigger.

If you suspect that the spray tip/nozzle or hose is completely clogged, or that pressure has not been fully

relieved after following the steps above,

loosen the tip guard retaining nut or hose end coupling

and relieve pressure gradually, then loosen completely.

Now clear the tip/nozzle or hose.

very slowly

Flush Before Using Equipment

The pump was tested with lightweight oil, which is left in

the fluid passages to protect parts. To avoid contaminating fluid with oil, flush the pump with a compatible solvent before use. See Flush on page 12.

NOTICE

Prolonged exposure to solvent will reduce the life of

the wiper. For maximum performance, do NOT soak

platen soft parts in solvent. Instead, gently wipe down

soft parts with solvent.

1. Lock the gun/valve trigger.

2. See F

3. Unlock the gun/valve trigger.

4. Hold a metal part of the gun/valve firmly to the side

IG

. 2, page 6.

a. Close the air motor ball valve (BF) and the main

air slider valve (BA).

b.

If the RAM is in a raised position,

director valve (BC) to DOWN. The ram will

slowly drop.

c. Jog the director valve up and down to bleed air

from ram cylinders.

of a grounded metal pail, and trigger the gun/valve

to relieve pressure.

set the ram

10 3A2798D

Page 11

Supply System Operation

Start and Adjust Ram

Moving parts can pinch or amputate fingers. When

the pump is operating and when raising or lowering

the ram, keep fingers and hands away from the

pump intake, platen, and lip of the drum.

1. Set platen configuration based on pail type (see

Adjust Spacers, page 13).

IG

2. Refer to F

and air valves.

3. Open main air slider valve (BA) and set ram air regulator (BB) to 45 psi (0.31 MPa, 3.1 bar). Set director valve handle (BC) to UP and let the ram rise to

its full height.

4. Remove the drum cover.

5. Put a full drum of fluid on the ram base, slide it back

against the drum stops, and center it under the

platen (D). See F

To avoid damage to the platen seals, do not use a

drum that is dented or damaged.

. 1 and FIG. 2. Close all air regulators

IG

. 9.

NOTICE

7. Set the director valve (BC) to DOWN and lower the

ram until fluid appears at the top of the platen bleed

port (J). Adjust ram air regulator (BB) as needed.

Set the director valve (BC) to neutral and close the

platen bleed port (J).

Start and Adjust Pump

To prevent equipment rupture, be sure all

components are adequately sized and pressure rated

to meet the system’s requirements.

1. Start and Adjust Ram, page 11. Keep the director

valve (BC) set to DOWN while pump is operating.

2. Be sure the main air slider valve (BA) is closed.

Then set the ram air regulator (BB) to about

40-45 psi (0.28-3.1 MPa, 2.8-3.1 bar). Set the director valve (BC) to DOWN.

3. Open main air slider valve (BA). Use air motor

regulator (BE) to slowly increase pressure until

pump operates at desired flow rate.

NOTE: Increase air pressure to the ram if the pump

does not prime properly with heavier fluids.

Decrease Ram air pressure if fluid is forced out

around the top seal or platen.

J

D

FIG. 9

6. Remove bleed stick from platen bleed port (J).

NOTE: Some pails may require the spacer (EG) to

be flipped upside down so the smaller diameter side

is on the bottom. If unable to get ram into the pail,

see Remove and Reinstall Wiper on page 14 to

re-install the spacer upside down.

3A2798D 11

ti20247b

Page 12

Supply System Operation

Change Drums

Excessive air pressure in the material drum could

cause the drum to rupture, causing serious injury.

The platen must be free to move out of the drum.

Never use drum blowoff air with a damaged drum.

1. Close the air motor ball valve (BF) to stop the pump.

2. Press and hold the blowoff air button (BG) then set

ram director valve (BC) to UP to raise the platen (D)

until the platen (D) is completely out of drum. When

the ram exits the pail, release the blowoff air button

to allow the ram to rise to its full height. Use minimum amount of air pressure necessary to push the

platen out of the drum.

3. Remove empty drum.

4. Inspect platen and, if necessary, remove any

remaining material or material build-up.

5. Place full drum on ram base.

Shutdown and Care of the Pump

1. Set the ram director valve (BC) to DOWN.

2. Follow the Pressure Relief Procedure on page 10.

3. Follow the pump shutdown instructions in Xtreme

lowers manual. See Related Manuals on page 2.

Replace Throat Seals

Remove wet cup from displacement pump while

attached to the ram to replace throat seals.

1. Follow the Pressure Relief Procedure on page 10.

2. Remove Quick Coupler.

3. Remove wet cup and packing cartridge according to

instructions in Xtreme lowers manual. See Related

Manuals on page 2.

6. Lower the ram and adjust the position of the drum

relative to the platen. See Start and Adjust Ram on

page 11.

NOTICE

To prevent material from curing in the system, immediately flush the system when a pressure drop is

noticed during spraying and when done spraying.

Flush

1. Remove platen from pump, then submerge pump

into solvent. To clean platen, gently wipe with solvent. NOTE: Read notice table in Flush Before

Using Equipment section, page 10.

2. Perform Start and Adjust Ram on page 11 to pres-

surize the pump with solvent.

3. Hold gun firmly against a grounded pail and trigger

gun into pail until clean solvent dispenses.

Remove Quick Coupler

1. Ensure displacement pump is at bottom of stroke.

2. Follow the Pressure Relief Procedure on page 10.

3. Remove clip (GC), and slide coupling cover (GB) up

to remove coupling (GA).

GB

GA

GC

ti20249a

12 3A2798D

Page 13

Before Beginning Repair

Before Beginning Repair

Maintenance Procedures

To reduce the risk of serious injury whenever you are

instructed to relieve pressure, always follow the

Pressure Relief procedure.

Platen Maintenance

See FIG. 10. If the platen does not come out of the pail

easily when the pump is being raised, the air assist

tube (EF) or air assist check valve may be plugged, or

the bleed stick (J) may not be tightened. A plugged air

assist check valve prevents air from reaching the underside of the plate to assist in raising it from the pail. If the

bleed stick is not tightened no pressure will build.

1. Follow the Pressure Relief Procedure on page 10.

Refer to platen parts illustration on page 28 and disassemble air assist check valve (414) as shown.

Adjust Spacers

Use Platen with Tapered and Straight Sided

Pails

Use platen with tapered pails

1.

Working from the bottom

spacer (EG) loose. Work spacer upward completely

above the flange of the platen. See F

2. By hand, angle spacer (EG) and work it off the plate,

pulling it down over the flange. See F

3. Save spacer (EG), as it is required for other applications.

, use screwdriver to pry

IG

. 11.

IG

. 12.

EG

2. Clear air assist tube (EF) in platen. Clean all parts of

air assist check valve (414) and reassemble.

3. Remove bleed stick (J) from platen. Push bleed

stick through bleed relieve ports to remove material

residue.

EK

EF

EG

ti20250b

FIG. 10

FIG. 11

EB

ti20251b

3A2798D 13

Page 14

Maintenance Procedures

Use platen with straight sided pail

1. Ensure large diameter of spacer (EG) is facing

down. Work spacer (EG) up over the platen by

hand completely above the flange of the platen. See

F

IG

. 12.

Working from the top

2.

, use screwdriver to position

spacer (EG) between flange and wiper (EB). See

F

IG

. 13.

EB

ti20251b

FIG. 12: Sliding spacer

c. See Reassemble 20 Liter Wiper Assembly to

change wiper styles or a complete wiper assembly.

2. Remove eight nuts (409) on wiper assembly.

3. Separate top plate (407), spacer (402), wiper (403),

and bottom plate (405).

4. Clean, inspect, and replace worn components.

Reassemble 20 Liter Wiper Assembly

1. Place bottom plate (405) on flat surface. Place wiper

(403), spacer (402), and top plate (407) on bottom

plate (405).

EG

2. Install eight nuts (409) on outer ring. Torque to

40-50 in-lb (4.5-5.6 N•m).

3. Replace o-ring (406), or install new o-ring under

platen casting (401). Use lubricant to hold in place.

4. Install platen casting (401). Tighten with four

nuts (409). Torque to 40-50 in-lb (4.5-5.6 N•m).

EG

EB

ti20252b

FIG. 13: Installing Spacer

Remove and Reinstall Wiper

1. Remove wiper assembly; see FIG. 14:

a. Remove two clips (420) with needle nose pliers

and remove platen cover (419).

b. Remove four nuts (409) that hold wiper assem-

bly to platen casting (407) and remove wiper

assembly.

14 3A2798D

Page 15

420

419

Maintenance Procedures

6

411

418

412

409

6 4

401

414

415

406

409

6 4

407

402

5

5

3

403

405

ti20253b

3

Apply grease to hold ring (406) in place during assembly.

4

Torque to 40-50 in-lb (4.5-5.6 N•m).

5

Apply pipe sealant to all non-swiveling pipe threads.

6

Apply thread lubricant to threads.

FIG. 14: Platen Assembly

3A2798D 15

Page 16

Troubleshooting

Troubleshooting

Check all possible problems before disassembling the ram, pump, or platen. Refer to Xtreme Pump Packages manual 311762 for pump troubleshooting.

Ram

Problem Cause Solution

Decreasing spraying pressure or

poor spray pattern.

Ram will not raise or lower. Closed air valve or clogged air line. Open, clear.

Ram raises and lowers too fast. Air pressure is too high. Decrease.

Air leaks around cylinder rod. Worn rod seal. Replace. See Supply Unit Repair

Fluid squeezes past ram plate wipers.

Pump will not prime properly or

pumps air.

Material beginning to cure in lines. Flush immediately.

Not enough air pressure. Increase.

Worn or damaged piston. Replace. See Supply Unit Repair

on page 20.

Hand valve closed or clogged. Open, clear.

on page 20.

Air pressure too high. Decrease.

Worn or damaged wipers. Replace. See Remove and Rein-

stall Wiper on page 14.

Closed air valve or clogged air line. Open, clear.

Not enough air pressure. Increase.

Worn or damaged piston. Replace. See pump manual.

Hand valve closed or clogged. Open, clear. See Platen Mainte-

nance on page 13.

Hand valve is dirty, worn, or damaged.

Air assist valve will not hold drum

down or push plate up.

16 3A2798D

Closed air valve or clogged air line. Open, clear. See Platen Mainte-

Not enough air pressure. Increase.

Valve passage clogged. Clean. See Platen Maintenance on

Clean, service.

nance on page 13.

page 13.

Page 17

Repair

Disconnect Pump from Platen

1. Loosen two thumb screws (412) from platen.

2. Carefully pull pump away to prevent damage to

pump inlet. Remove adapter (421) and o-ring (406)

from platen adapter (421).

421

Repair

406

412

ti20254b

FIG. 15

Connect Platen to Pump

1. Apply grease to o-ring (406) then install the o-ring

on platen adapter (421). See F

2. Apply pipe sealant to pump inlet thread then thread

onto adapter (421).

3. Loosen thumb screws (412) then carefully lower

pump onto platen.

4. Tighten thumb screws (412) to secure platen to

adapter.

IG

. 15.

Remove Wipers

See Remove and Reinstall Wipers on page 13.

Install Wipers

See Remove and Reinstall Wipers on page 13.

3A2798D 17

Page 18

Repair

Disconnect Displacement Pump

1. Remove Quick Coupler, page 12.

2. Remove tie rod nuts (206).

206

ti20255a

FIG. 16

Install Displacement Pump

1. Raise ram to install displacement pump to platen.

2. Connect Platen to Pump, page 17.

3. Connect Displacement Pump, page 18.

Connect Displacement Pump

1. Install tie rod nuts (206). Torque to 50-60 ft-lb

(68-81 N•m).

2. Install quick coupler.

3. Lift air motor rod to bring rod to top of stroke.

Remove Displacement Pump

Refer to your Xtreme Displacement Pump 311762 manual to repair the displacement pump.

If the air motor does not require servicing, leave it

attached to its mounting. If the air motor does need to

be removed, see page 19.

1. Follow the Pressure Relief Procedure on page 10.

2. Disconnect Displacement Pump, page 18.

3. Disconnect Pump from Platen, page 17 to disconnect the platen from the displacement pump.

4. Raise the ram assembly to lift the air motor away

from the displacement pump.

5. Remove displacement pump and service as

needed.

18 3A2798D

Page 19

Repair

Remove Air Motor

1. Follow the Pressure Relief Procedure on page 10.

2. Disconnect Displacement Pump, page 18.

3. Disconnect air hose from air motor fitting (7). See

page 22.

4. Remove Quick Coupler, page 12.

5. Remove screws (3) and washers (2) that secure air

motor to mounting plate (320).

Install Air Motor

1. Using a secure hoist, attach motor to mounting

plate (320) with screws (3) and washers (2). See

F

IG

. 17.

2. Connect Displacement Pump, page 18.

3. Connect air hose to air motor fitting (7). See

page 22.

320

2

3

ti20255b

FIG. 17

6. Using a capable hoist connected to air motor lift

ring, secure air motor to hoist and remove air motor.

3A2798D 19

Page 20

Repair

Supply Unit Repair

To reduce the risk of serious injury whenever you are

instructed to relieve pressure always follow the

Pressure Relief Procedure on page 10. Do not use

pressurized air to remove the guide sleeve or the

piston.

Ram Piston Rods

Always service both cylinders at the same time. When

you service the piston rod always install new o-rings in

the piston rod seal and ram piston.

Repair Parts:

Piston Repair Kit 257622. See Ram Frame on page 26

for parts included in kit.

Disassemble Piston Rod Seal and Bearing

1. Relieve pressure.

NOTE: Do not reinstall end cap assembly if the ram piston (302f) needs to be removed from the piston rod. See

the next page for ram piston repair instructions.

302d

302b

302k

302m

302a

FIG. 18: 3 in. Piston Rod Seal

303

302e

302c

302l

ti10520a

2. Access piston rod seal and bearing.

a. Ensure ram is in lowest position.

b. Remove nuts (333) and lockwashers (332) from

piston rods (302a).

c. Remove entire pump package, including the

mounting plate (331) off of the piston

rods (302a). Use a fork-truck to lift the assembly

from the mounting plate.

d. Secure pump package so pump and platen will

not fall.

3. Remove retaining ring (303).

4. Remove piston rod seal and bearing. Slide end cap

(302b), pin (302c), o-ring (302d), and spring (302m)

up off of the piston rod (302a). Remove retaining

ring (302l) and bearing (302k) from end cap (302b)

and remove o-ring (302e).

5. Inspect parts for wear or damage. Replace as necessary.

20 3A2798D

Page 21

Assemble Piston Rod Seal and Bearing

See F

IG

. 18 on page 20.

1. Lubricate o-ring (302e) and bottom bearing (302k).

a. Install o-ring (302e), bottom bearing (302j), and

retaining ring (302l) into end cap (302b).

Repair

302a

302d

b. Install new o-ring (302d) and pin (302c) on end

cap (302b). Lubricate o-ring (302d) and end

cap (302b).

c. Slide spring (302m) and end cap (302b) on pis-

ton rod (302a).

2. Install retaining ring (303).

3. Remount mounting plate (331) and attach nuts

(333) and lockwashers (332). Torque to 40 ft-lb

(54 N•m).

Disassemble Ram Piston

1. Complete steps 1-4 from Disassemble Piston Rod

Seal and Bearing to remove the end cap (302b)

from the piston rod (302a).

NOTICE

Do not tilt the piston rod to one side when removing it

from the base or when installing it. Such movement

can damage the piston or inside surface of the base

cylinder.

2. Carefully lay piston (302f) and rod (302a) down so

piston rod will not be bent. Remove nut (302g),

washer (302h), piston (302f), outer o-ring (302d),

and inner o-ring (302j). See F

IG

. 19.

302f

302j

302h

302g

TI10521A

FIG. 19: 3 in. Ram Piston

Assemble Ram Piston

1. Install new o-rings (302d, 302j) and lubricate

piston (302f) and o-rings.

2. Apply medium strength thread sealant. Install

piston (302f), washer (302h), and nut (302g) on piston rod (302a).

3. Carefully insert piston (302f) into cylinder and push

piston rod (302a) straight down into cylinder.

4. Slide spring (302m) and end cap (302b) onto piston

rod (302a).

5. Install retaining ring (303).

6. Remount mounting plate (331) and attach nuts

(333) and lockwashers (332). Torque to 40 ft-lb

(54 N•m).

3. Inspect parts for wear or damage. Replace as necessary.

3A2798D 21

Page 22

Parts

Parts

Xtreme PFP, 16P957 and 16T311

27

8

4

20

21

19

1

15

14

13

12

11

16

1

1

18

1

26

1

26

7

1

5

1

6

1

5

2, 3

1

5

1

22

24

1

Apply sealant (8) to all non-swiveling pipe threads.

5

Assemble o-ring from platen to platen adapter (22) then

assemble platen to adapter.

8

Install grounding wire (27) to ground screw on motor (4).

25

ti20231b

22 3A2798D

Page 23

Ref Part Description Qty

1 --- RAM, dual post, motor regulator

2 100133 WASHER, lock, 3/8

3 --- SCREW, cap, hex head

4 --- PUMP, Xtreme, PFP

5◆ 160032 FITTING, nipple

6◆ 16T481 VALVE, check

7 160327 FITTING, union adapter, 90 degree

8 --- SEALANT, pipe, stainless steel

10❄ 206994 FLUID, TSL, 8 oz bottle

11◆ H67550 HOSE, coupled, 3/4 in. ID, 6500 psi

12◆ 16R883 FITTING, nipple, reducing, 3/4 x 1/2

13◆ H75025 HOSE, coupled, 7250 psi, 0.50 in. ID,

25 ft

14◆ 158491 FITTING, nipple

15◆ 24P834 SWIVEL, straight

16◆ 262854 GUN, spray, XHF

18 113429 COUPLING, universal, 3/4-14 npt

male

19 117628 FILTER, air, 3/4 (auto drain)

20 157785 FITTING, swivel

21 295847 FITTING, elbow, 90, 3/4 mpt

22 --- ADAPTER, platen

24 --- LABEL, identification

25 16P434 CART, ram

(Model 16T311 only)

26 113430 COUPLING, universal, 3/4-14 npt

female

27 238909 WIRE, grounding

Parts

1

4

4

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

--- Not for sale.

❄

Not shown.

◆

Included in mix line and gun kit 24P832. See Connect Mix Line and Gun on page 9 for kit installation.

3A2798D 23

Page 24

Parts

Cart, 16P434

120

110

2

109

2

121

21

101

109

1

3

21

108

107

3

104

103

1

Insert axle (8) into cart (101) then press pin (109)

into axle (108).

2

Place handle (110) on top of axle (108) then press

pin (109) into handle (110)

3

Apply grease to axles (102, 107, 108).

5

Apply anaerobic sealant to threads.

102

3

104

103

111

112

5

113

104

105

106

ti20233a

104

105

106

Ref Part Description Qty

101 --- CART 1

102 --- AXLE 1

103 113807 WHEEL, flat free, urethane 4

104 191824 WASHER, space 8

105 111841 WASHER, plain 5/8 4

106 101242 RING, retaining, external 4

107 15A913 AXLE 1

108 --- AXLE 1

109 124291 PIN, spring 2

110 258982 HANDLE, cart 1

111 --- BRAKE 2

112 112788 SCREW, cap, socket head 8

113 102962 SCREW, cap, socket head 2

114 --- LUBRICANT, grease 1

115◆ 101147 SCREW, cap, hex head 4

116◆ 101044 WASHER, plain 8

117◆ 100018 WASHER, lock, spring 4

118◆ 100321 NUT 4

119 --- SEALANT, anaerobic 1

120 116139 GRIP, handle 2

121 --- LABEL, arrow 2

--- Not for sale.

◆

Not shown.

24 3A2798D

Page 25

Pumpline

Parts

201,

212

215

7

202

1

Ref Part Description

201 N65DN0 MOTOR, 6500

202 --- ROD, tie

203 197340 COVER, coupler

204 244819 COUPLING, assembly

205 L180C7 LOWER, Xtreme

206 101712 NUT, lock

207 244820 CLIP, hairpin; with lanyard

208 --- SEALANT, anaerobic

212 --- LABEL, Xtreme PFP

214 --- LUBRICANT, thread

215 15J277 CONTROL, de-ice

216 15H392 ADAPTER, rod, Xtreme

229 --- ROD, adapter

Qty

1

3

1

1

1

3

1

1

1

1

1

1

1

--- Not for sale.

229

2 3

2 3

4

216

207

ti20241a

1

Torque to 50-60 ft-lb (68-81 N•m).

2

Torque together to 145-155 ft-lb (196-210 N•m).

3

Apply sealant.

4

Insert lanyard from locking pin onto tie rod (2).

5

Apply thread lubricant to threads, o-rings, and seals. Do not

apply to rod adapter (216) or rod (229).

7

Push in de-ice control (15) fully. Symbols must be upright.

203

204

1

206

205

3A2798D 25

Page 26

Parts

b

o

Ram Frame

2

328

319

323

322

302d

302e

302b

302c

302k

302l

302a

302m

302f

302j

302d

302h

302g

96

333

332

331

303

302

310

335

315

314

313

320, 327

305, 306

321

318

4

326

307

308

312

324

304, 310

305, 306

3

6 9

301

308

334

ti20257a

ti20240b

1

Apply pipe sealant to all non-swiveling pipe threads.

2

Apply electrical tape and protective sleeve (316) to hose (315)

at motor end with blow-off assist air hose. Double-back the

sleeve over itself. Tape the air control end last.

3

Attach strap (323) and hose-tube routing over rear cross bar.

26 3A2798D

4

Arrow on air regulator (304) must point towards el

fitting (308).

6

Apply grease to all packings and cavity of RAM cy

9

Add oil to cylinder (301) wall before and after pist

assembly (302) is installed.

Page 27

Parts

Ram Frame Parts

Ref Part Description

301 --- RAM, dp, weldment

302◆ --- PISTON, ram, subassembly

(includes items 302a-302p)

302a◆ --- ROD, piston, ram

302b◆ 15M295 BEARING, ram end cap

302c◆ 15U979 PIN, spring, straight

302d◆ 160258 PACKING, o-ring, buna-n

302e◆ 156698 PACKING, o-ring

302f◆ 183943 PISTON

302g◆ 101535 NUT, full hex

302h◆ 101533 WASHER, spring lock

302j◆ 156401 PACKING, o-ring

302k◆ --- BEARING, ram end cap

302l◆ 15F453 RETAINER, retaining ring

302m◆ 160138 SPRING, compression

302n◆ --- LUBRICANT, grease

302p◆ --- SEALANT, thread, medium

strength

303◆ --- RING, retaining

304 255296 BRACKET, mounted

305 100016 WASHER, lock

306 101682 SCREW, socket cap head

307 24C824 CONTROL, air, ram, hydraulic

driver

308 597151 FITTING, elbow

309 --- LUBRICANT, grease

310▲ 15J074 LABEL, safety, crush and pinch

311 --- SEALANT, pipe, sst

312 --- LABEL, valve, shutoff, air con-

trol

313 C32467 STOP, drum

314 C38185 WASHER, lock

315 C19853 SCREW, cap, socket head

316 C12509 TUBE, nylon, round

317 --- LUBRICANT, oil

318 16F014 REGULATOR, air, t-handle

319 157785 FITTING, swivel

320 100960 GAUGE, pressure, air

321 103347 VALVE, safety, 100 psi

322 --- FITTING, elbow, street, 3/4-14

323 113218 VALVE, ball, vented, 0.750

324 101689 GAUGE, press, air

326 C20487 FITTING, nipple, hex

327 100840 FITTING, elbow, street

328 C12034 HOSE, coupled 72 in.

329 552071 SLEEVE, protective

330 --- TAPE, electrical

Qty

14

15

Ref Part Description

331 --- BRACKET, shelf, D60, 3400 /

1

332 101533 WASHER, spring lock

2

6500

333 101535 NUT, full hex

334 198442 STRAP, retaining mix manifold

1

335 16U676 PLATE, 20 L single wiper

1

1

--- Not for sale.

2

▲

1

1

1

Replacement Danger and Warning labels, tags and

cards are available at no cost.

◆

Included in kit 257622.

1

1

1

1

1

1

1

2

1

8

8

1

2

1

4

1

1

2

2

2

1

1

1

1

1

1

1

1

1

1

1

1

Qty

1

2

2

1

1

3A2798D 27

Page 28

Parts

20L Platen, 16U676

6

411

418

412

420

419

409

6 4

401

414

415

406

409

6 4

407

Ref Part Description

401 --- BASE, platen, 20L

402 276049 SPACER

403 262936 WIPER, main

405 --- PLATE, bottom, platen

406 121829 O-RING, packing, -162

407 --- CLAMP, retainer

409 --- NUT, keps, hex head, 1/4-20

411 257697 HANDLE, bleed, stainless steel

5

5

412 --- SCREW, thumb, 5/16-18 x 1/2,

carbon steel

413◆ 112358 PACKING, o-ring

414 122056 VALVE, check

3

415 C20350 FITTING, elbow 90 degree

416 --- LUBRICANT, grease

417 --- SEALANT, pipe, stainless steel

418 --- TAG, instruction

419 15W184 COVER, 20L, shroud

Qty

1

1

1

1

1

1

12

1

2

1

1

1

1

1

1

1

420 16U740 PIN, hairpin, cotter; pack of 10

421 --- LUBRICANT, thread

1

--- Not for sale.

ti20253b

3

Apply grease to hold ring (406) in place during assembly.

4

Torque to 40-50 in-lb (4.5-5.6 N•m).

5

Apply pipe sealant to all non-swiveling pipe threads.

6

Apply thread lubricant to threads.

402

403

405

◆

Not shown. Item is not assembled. Items installs

onto platen adapter.

28 3A2798D

Page 29

Check Valve (16T481)

Parts

1205

1206

1204

1207

1

Torque to 75-80 ft-lb (102-108 N•m).

Ref. Part Description Qty.

1201 --- NUT, seat 1

1202 102595 PACKING, o-ring 1

1203 100279 BALL, metallic 1

1204 108361 SPRING, compression 1

1205 --- HOUSING, ball check 1

1206 181492 GUIDE, ball 3

1207 181535 RETAINER, spring 1

1202

1203

1201

1

--- Not for sale.

3A2798D 29

Page 30

Accessories

Accessories

Static Mixer Kit, 16T316

This is a 12 element, stainless steel, static mixer used to

thoroughly mix the materials. The static mixer kit is

installed between DD and EE.

Static Mixer Kit Installation:

BB

AA

Static Mixer (16T316)

1303

1301

ti20731b

FIG. 20

See FIG. 20.

1. Remove bushings (AA) on each end of static mixer

assembly and discard.

2. Disconnect 3/4 in. ID hose (EE) from pump outlet

check valve then remove and discard the

nipple (BB) used to connect the check valve to the

hose.

3. Install static mixer (CC) onto pump outlet check

valve (DD).

4. Install 3/4 in. ID hose (EE) onto the static

mixer (CC) outlet.

DD

CC

EE

1302

1303

1

Apply pipe sealant to all non-swiveling pipe threads.

Ref. Part Description Qty.

1301 --- TUBE, mixer 1

1302 24P886 MIXER, 12 element, stainless steel 1

1303 16T315 BUSHING, reducing 3/4 nptf x

1/2 npt

1304 --- SEALANT, pipe, stainless steel 1

---Not for sale.

ti20224a

2

30 3A2798D

Page 31

Dimensions

A

(ram up)

B

(ram down)

Dimensions

Model

Xtreme PFP,

no cart

(16P957)

Xtreme PFP,

with cart

(16T311)

A

in. (m)

81.43

(2.07)

87.18

(2.21)

C

D

B

in. (m)

54-7/8

(1.39)

60-5/8

(1.54)

C

in. (m);

Mounting Holes

14

(0.36)

14

(0.36)

D

in. (m)

20-3/4

(0.53)

47-5/8

(1.21)

WLE

E

E

in. (m);

Mounting Holes

24

(0.61)

24.0

(0.61)

F

F

in. (m)

37

(0.94)

39-3/4

(1.01)

3A2798D 31

Page 32

Technical Data

Technical Data

Maximum fluid working pressure . . . . . . . . . . . . . . . . . . 6500 psi (45, 448 bar)

Max working air pressure . . . . . . . . . . . . . . . . . . . . . . . . 90 psi (620 kPa, 6.2 bar)

Max air inlet pressure. . . . . . . . . . . . . . . . . . . . . . . . . . . 100 psi (0.7 MPa, 7 bar)

Air inlet size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3/4 npt(f)

System Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pump Wetted parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . See Xtreme lowers manual 311762.

System Wetted parts . . . . . . . . . . . . . . . . . . . . . . . . . . . Electroless nickel, polyurethane, PTFE-coated nitrile, poly-

Ambient operating temperature range (supply system) 32-120 °F (0- 49°C)

Sound data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . See NXT air motor manual 311238.

16P957:

16T311:

ethylene, PTFE, carbon steel, buna, 316 stainless steel,

17-4 stainless steel

325 lb (147 kg)

392 lb (178 kg)

32 3A2798D

Page 33

Notes

Notes

3A2798D 33

Page 34

Graco Standard Warranty

Graco warrants all equipment referenced in this document which is manufactured by Graco and bearing its name to be free from defects in

material and workmanship on the date of sale to the original purchaser for use. With the exception of any special, extended, or limited warranty

published by Graco, Graco will, for a period of twelve months from the date of sale, repair or replace any part of the equipment determined by

Graco to be defective. This warranty applies only when the equipment is installed, operated and maintained in accordance with Graco’s written

recommendations.

This warranty does not cover, and Graco shall not be liable for general wear and tear, or any malfunction, damage or wear caused by faulty

installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident, tampering, or substitution of

non-Graco component parts. Nor shall Graco be liable for malfunction, damage or wear caused by the incompatibility of Graco equipment with

structures, accessories, equipment or materials not supplied by Graco, or the improper design, manufacture, installation, operation or

maintenance of structures, accessories, equipment or materials not supplied by Graco.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized Graco distributor for verification of

the claimed defect. If the claimed defect is verified, Graco will repair or replace free of charge any defective parts. The equipment will be returned

to the original purchaser transportation prepaid. If inspection of the equipment does not disclose any defect in material or workmanship, repairs

will be made at a reasonable charge, which charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT

LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

Graco’s sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees that no other remedy

(including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to person or property, or any other incidental or

consequential loss) shall be available. Any action for breach of warranty must be brought within two (2) years of the date of sale.

GRACO MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IN CONNECTION WITH ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD BUT NOT

MANUFACTURED BY GRACO. These items sold, but not manufactured by Graco (such as electric motors, switches, hose, etc.), are subject to

the warranty, if any, of their manufacturer. Graco will provide purchaser with reasonable assistance in making any claim for breach of these

warranties.

In no event will Graco be liable for indirect, incidental, special or consequential damages resulting from Graco supplying equipment hereunder, or

the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of contract, breach of warranty, the

negligence of Graco, or otherwise.

FOR GRACO CANADA CUSTOMERS

The Parties acknowledge that they have required that the present document, as well as all documents, notices and legal proceedings entered into,

given or instituted pursuant hereto or relating directly or indirectly hereto, be drawn up in English. Les parties reconnaissent avoir convenu que la

rédaction du présente document sera en Anglais, ainsi que tous documents, avis et procédures judiciaires exécutés, donnés ou intentés, à la suite

de ou en rapport, directement ou indirectement, avec les procédures concernées.

Graco Information

For the latest information about Graco products, visit www.graco.com.

TO PLACE AN ORDER,

Phone: 612-623-6921 or Toll Free: 1-800-328-0211 Fax: 612-378-3505

All written and visual data contained in this document reflects the latest product information available at the time of publication.

GRACO INC. AND SUBSIDIARIES • P.O. BOX 1441 • MINNEAPOLIS MN 55440-1441 • USA

Copyright 2012, Graco Inc. All Graco manufacturing locations are registered to ISO 9001.

contact your Graco distributor or call to identify the nearest distributor.

Graco reserves the right to make changes at any time without notice.

For patent information, see www.graco.com/patents.

Original instructions.

Graco Headquarters: Minneapolis

International Offices: Belgium, China, Japan, Korea

This manual contains English. MM 3A2798

www.graco.com

Revised May 2014

Loading...

Loading...