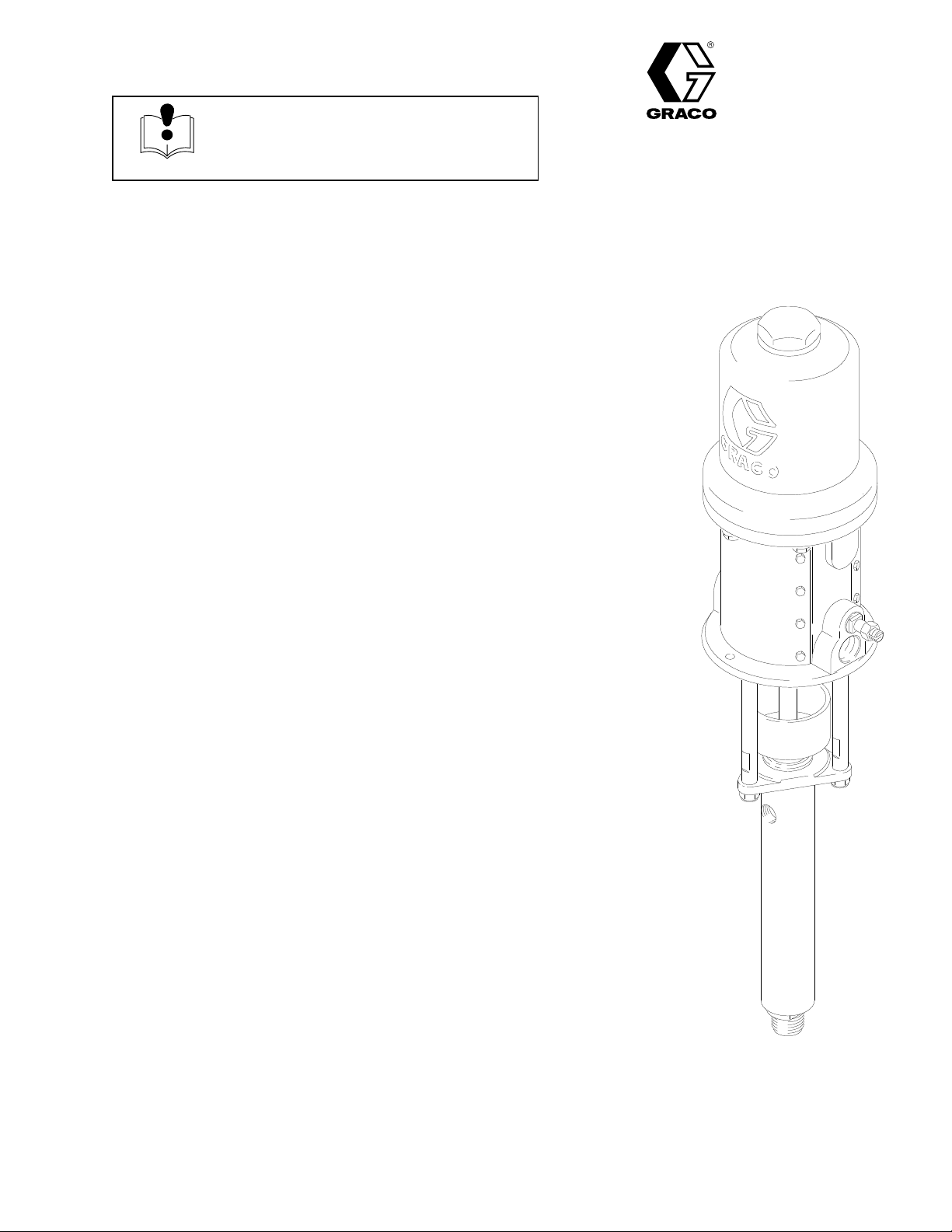

Graco 239-327, А Series User Manual

INSTRUCTIONS-PARTS

LIST

308–739

This

manual contains important

warnings and information.

READ AND KEEP IT FOR REFERENCE.

INSTRUCTIONS

STUBBY SIZE

15:1

Part No. 239–327, Series A

105

bar (10.5 MPa, 1500 psi) Maximum Fluid Working Pressure

7 bar (0.7 MPa, 100 psi) Maximum Air Input Pressure

Refer to page 2 for the T

Ratio Monark Pump

able of Contents.

First

choice when

quality counts.

Rev. A

GRACO INC. P.O. BOX 1441

http://www.graco.com

COPYRIGHT

Graco

Inc. is registered to I.S. EN ISO 9001

MINNEAPOLIS, MN

1997, GRACO INC.

07196

55440–1441

Table

of Contents

Symbols

Warnings 2.

Installation 5

Operation 8

Troubleshooting 10

Service 11

Parts 12

Dimensions 13

Mounting

Technical

Warranty 16

Graco

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hole Layout

Data

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Phone Number

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

13.

14.

16.

WARNING

EQUIPMENT MISUSE HAZARD

INSTRUCTIONS

Equipment

This equipment is for professional use only

Read all instruction manuals, tags, and labels before operating the equipment.

misuse can cause the equipment to rupture or malfunction and result in serious injury

Warning Symbol

WARNING

This

symbol alerts you to the possibility of serious

injury or death if you do not follow the instructions.

Caution Symbol

CAUTION

This

symbol alerts you to the possibility of damage to

or destruction of equipment if you do not follow the

corresponding instructions.

.

.

Use the equipment only for its intended purpose. If you are uncertain about usage, call your Graco

distributor.

Do not alter or modify this equipment. Use only genuine Graco parts and accessories.

Check equipment daily

Do not exceed the maximum working pressure of the lowest rated system component. Refer to the

T

echnical Data

Use fluids and solvents which are compatible with the equipment wetted parts. Refer to the

nical Data

Do not use hoses to pull equipment.

Route hoses away from traffic areas, sharp edges, moving parts, and hot surfaces. Do not expose

Graco hoses to temperatures above 82C (180F) or below –40C (–40

W

ear hearing protection when operating this equipment.

Do not lift pressurized equipment.

Comply with all applicable local, state, and national fire, electrical, and safety regulations.

on page 14 for the maximum working pressure of this equipment.

section of all equipment manuals. Read the fluid and solvent manufacturer’s warnings.

. Repair or replace worn or damaged parts immediately

F).

.

Tech-

WARNING

INJECTION HAZARD

Spray

from the gun, hose leaks, or ruptured components can inject fluid into your body and cause

extremely serious injury

can also cause serious injury

Fluid injected into the skin might look like just a cut, but it is a serious injury. Get immediate medi

cal attention.

Do not point the gun at anyone or at any part of the body

Do not put your hand or fingers over the spray tip.

Do not stop or deflect leaks with your hand, body

Do not “blow back” fluid; this is not an air spray system.

Always have the tip guard and the trigger guard on the gun when spraying.

Check the gun dif

Be sure the gun trigger safety operates before spraying.

Lock the gun trigger safety when you stop spraying.

, including the need for amputation. Fluid splashed in the eyes or on the skin

.

.

, glove or rag.

fuser operation weekly

. Refer to the gun manual.

-

Follow the

sure; stop spraying; clean, check, or service the equipment; and install or clean the spray tip.

T

ighten all fluid connections before operating the equipment.

Check the hoses, tubes, and couplings daily

Permanently coupled hoses cannot be repaired; replace the entire hose.

Use only Graco approved hoses. Do not remove any spring guard that is used to help protect the

hose from rupture caused by kinks or bends near the couplings.

Pressure Relief Procedure

on page 8 whenever you: are instructed to relieve pres

. Replace worn, damaged, or loose parts immediately

MOVING PARTS HAZARD

Moving

parts, such as the air motor piston, can pinch or amputate your fingers.

Keep clear of all moving parts when starting or operating the pump.

Before servicing the equipment, follow the

equipment from starting unexpectedly

Pressure Relief Procedure

.

on page 8 to prevent the

-

.

WARNING

FIRE AND EXPLOSION HAZARD

Improper

result in a fire or explosion and serious injury

grounding, poor ventilation, open flames or sparks can cause a hazardous condition and

.

Ground the equipment and the object being sprayed. Refer to

If there is any static sparking or you feel an electric shock while using this equipment,

ing immediately. Do not use the equipment until you identify and correct the problem.

Provide fresh air ventilation to avoid the buildup of flammable fumes from solvents or the fluid

being sprayed.

Keep the spray area free of debris, including solvent, rags, and gasoline.

Electrically disconnect all equipment in the spray area.

Extinguish all open flames or pilot lights in the spray area.

Do not smoke in the spray area.

Do not turn on or of

Do not operate a gasoline engine in the spray area.

f any light switch in the spray area while operating or if fumes are present.

Grounding

on page 5.

TOXIC FLUID HAZARD

stop spray-

Hazardous

inhaled, or swallowed.

Know the specific hazards of the fluid you are using.

Store hazardous fluid in an approved container

state and national guidelines.

Always wear protective eyewear

solvent manufacturer

fluid or toxic fumes can cause serious injury or death if splashed in the eyes or on the skin,

, gloves, clothing and respirator as recommended by the fluid and

.

. Dispose of hazardous fluid according to all local,

4 308-739

Installation

NOTES:

Reference numbers and letters in parentheses in

the text refer to the callouts in the figures and

drawings.

Always use Genuine Graco Parts and Accessories,

available from your Graco distributor

your own accessories, be sure they are adequately

sized and pressure-rated to meet the system’

requirements.

Fig. 2 is only a guide for selecting and installing

system components and accessories. Contact your

Graco distributor for assistance in designing a

system to suit your particular needs.

. If you supply

s

Prepare the Operator

All

persons who operate the equipment must be

trained in the safe, ef

components as well as the proper handling of all fluids.

All operators must thoroughly read all instruction

manuals, tags, and labels before operating the

equipment.

ficient operation of all system

Prepare the Site

Ensure

supply

find the air consumption of your pump.

that you have an adequate compressed air

. Refer to the performance chart on page 15 to

Pump:

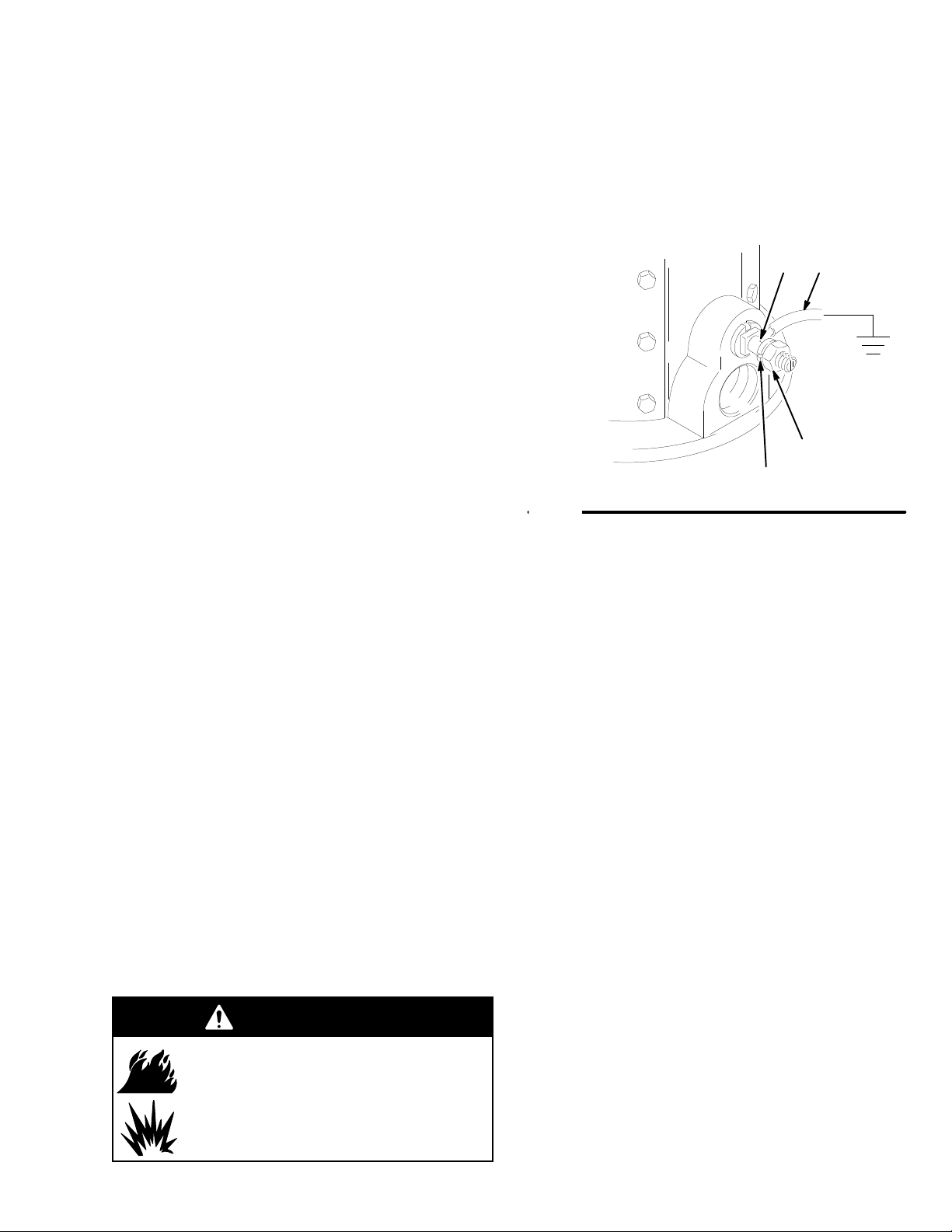

Loosen the grounding lug locknut (W) and washer

(X). Insert one end of a 12 ga (1.5 mm

ground wire (Y) into the slot in lug (Z) and tighten

the locknut securely

wire to a true earth ground. For a ground wire and

clamp, order Part No. 237–569.

Fig. 1

Air and fluid hoses:

hoses with 150 m (500 ft) maximum combined hose

length to ensure grounding continuity

Air compressor:

recommendations.

Use a ground wire and clamp. See Fig.1.

) minimum

. Connect the other end of the

Y

Z

W

X

Use only electrically conductive

.

Follow manufacturer

’s

Keep the site clear of any obstacles or debris that

could interfere with the operator’s movement.

Have a grounded, metal pail available for use when

flushing the system.

Mounting the Pump

Mount

the pump (A) to suit the type of installation

planned. The pump dimensions and mounting hole

layout are shown on page 13. If you are using a wall

bracket (B), check that the wall is strong enough to

support the weight of the equipment, hoses, fluid, and

stress caused when the pump is in operation. Mount

the wall bracket 1.5 m (5 ft) above the floor

.

Grounding

WARNING

FIRE AND EXPLOSION HAZARD

Before operating the pump, ground the

system as explained below

the section

HAZARD

FIRE AND EXPLOSION

on page 4.

. Also read

Spray gun or dispensing valve:

properly grounded fluid hose and pump.

Object being sprayed:

Fluid supply container:

Solvent pails used when flushing:

code. Use only metal pails, which are conductive,

placed on a grounded surface. Do not place the

pail on a nonconductive surface, such as paper or

cardboard, which interrupts the grounding

continuity.

T

o maintain proper grounding continuity when

flushing or relieving pressure,

part of the spray gun firmly to the side of a

grounded

metal

pail, then trigger the gun.

Follow your local code.

Follow your local code.

Connect to a

Follow your local

always hold the metal

308-739 5

Loading...

Loading...