Page 1

Interface description

R2600 / R2601

DIN Draft 19244 Interface

3-348-815-15

6/11.03

Page 2

Page 3

CONTENTS Page Page

1 General ...................................................................................... 4

1.1 Interface hardware ............................................................. 4

1.2 Communications protocol ................................................... 4

1.3 How to connect the interface .............................................. 5

1.4 Principal function ............................................................... 6

1.5 Time action ....................................................................... 7

2 Telegram structure ..................................................................... 8

2.1 Short set ........................................................................... 8

2.2 Control set ........................................................................ 9

2.3 Long set .......................................................................... 10

2.4 Function and value range of the format characters ............. 11

2.5 Criteria for the validity of a request telegram ...................... 14

3 Telegram contents R2600/01 .................................................... 15

3.1 Equipment reset .............................................................. 15

3.2 Interrogation: Equipment OK? ........................................... 15

3.3 Request for cycle data ...................................................... 16

3.4 Request for event data ..................................................... 17

3.5 Request data from R2600/01 ........................................... 20

3.6 Send data to R2600/01 ................................................... 22

GOSSEN METRAWATT GMBH 3

4 Parameter indices of the equipment parameters ........................ 24

4.1 Temperature parameters ................................................. 24

4.2 Control parameters ......................................................... 28

4.3 Control instructions ......................................................... 29

4.4 Equipment specifications ................................................. 32

4.5 Heating current monitor ................................................... 37

5 Storage operations ................................................................... 38

5.1 Request a record ............................................................ 38

5.2 Send a record ................................................................. 39

Page 4

GOSSEN METRAWATT GMBH 4

1 General

1.1 Interface hardware

To communicate with a host computer, an SPS, etc., the controllers R2600 / 01 must be equipped with marking F1. In this case, the controllers are

equipped with a serial interface having the following data:

• Level types RS-232 and RS-485 (two-wire)

• Baud rate 9600 bd

• Character format 8 data bits, 1 parity bit, 1 stop bit

• Parity Even

• Maximum number of equipment on the bus: 32

• With RS-485 bus operation, each connected R2600/01 must

have a different interface address (Addr = 0 ... 250)

(see operating instructions 3-348-778-15).

1.2 Communications protocol

The transmission protocol used complies with DIN draft 19244. The R2600 / 01 uses only a partial amount of the defined functions which are

described below.

in the unit selectable

2

3

2

-

S

5

8

4

-

S

R

R

Page 5

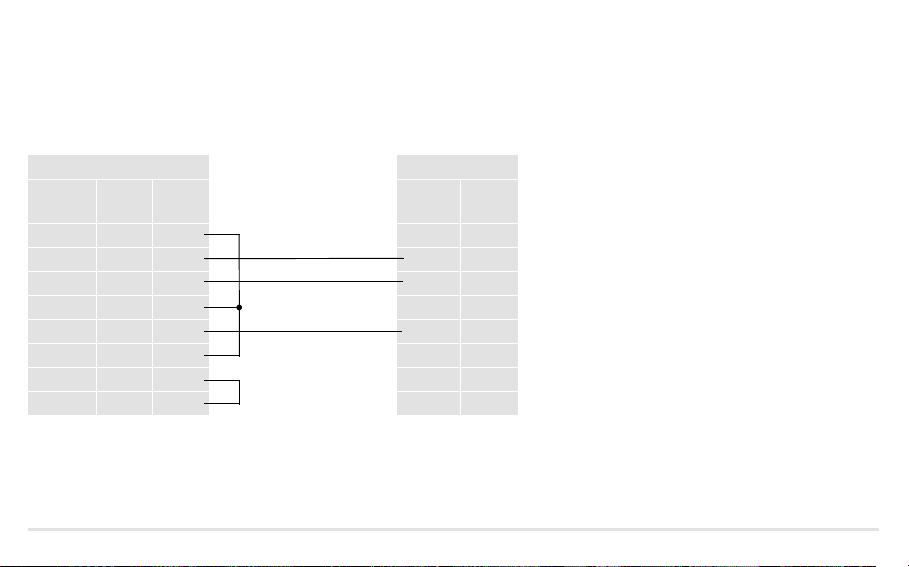

1.3 How to connect the interface

1.3.1 RS-232 connection

When using the a RS-232 interface, only one R2600/01 can be connected to a master (e.g. PC), for example, for pre-loading the unit with user-specific

data.

Sub-D socket R2600/01

Number

of pins:

DCD 8 1

RxD 3 2 20 TxD

TxD 2 3 21 RxD

DTR 20 4

Gnd 7 5 19 Gnd

DSR 6 6

RTS 4 7

CTS 5 8

Depending upon the driver software, the jumpers on the master side can be omitted and/or can be different.

GOSSEN METRAWATT GMBH 5

25 9

Page 6

GOSSEN METRAWATT GMBH 6

1.3.2 RS-485 connection

When using a RS-485 interface, as many as 32 equipment (R2600/01 and others) can be connected to the bus.

Thereby, all terminals A, B and/or C are interconnected in parallel. The wiring must be made from equipment to equipment and must not be a star connection. With longer bus lines (longer than about 5 m) the bus should be terminated at both ends with the characteristic impedance

(e.g. 200 Ω between A and B).

Master R2600/01 R2600/01

A 21 21

B 20 20

C 19 19

When using the 1799-V5040 interface converter on the master, the following pins are connected on the Sub-D plug:

A = 3 B = 8 C = 5

1.4 Principal function

Involved is a master/slave protocol with a fixedly assigned master (e.g. SPS) and as many as 255 slaves (equipment e.g. R2600/01).

Communication is in half-duplex mode.

An equipment connected to the master becomes active (responds) only, when

– it receives a valid telegram addressed to itself and

– the minimum specified response delay time (t

av) has elapsed so that the host computer has time to get ready to receive data.

Page 7

Following, the master may only become active again, when

– it receives a reply telegram from the addressed equipment and the specified wait time after a reply telegram (t aw) has elapsed, or

– the maximum specified response delay time (t

av) has elapsed.

Within a telegram, pauses of limited duration (t zv = character delay time) may occur between 2 character transmissions.

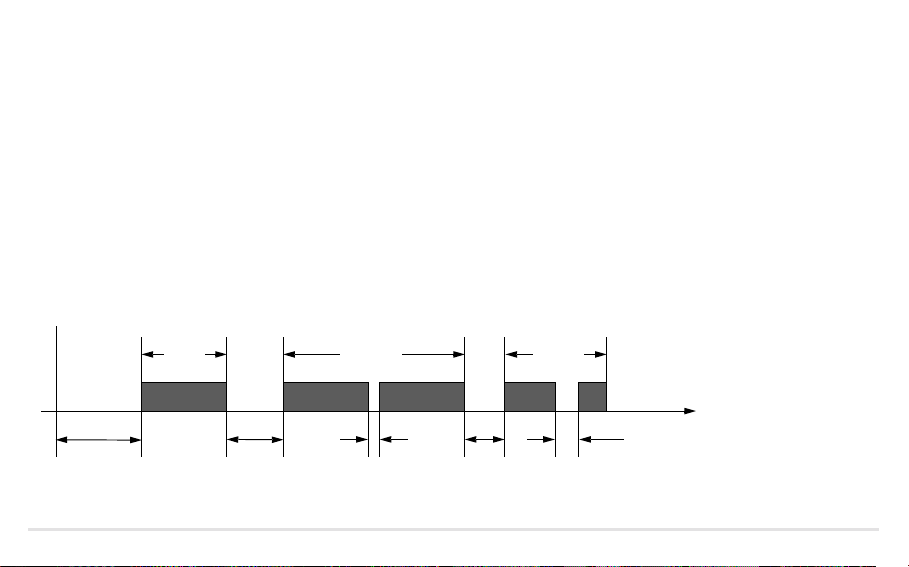

1.5 Time action

Ready to send/receive after turn-on t ber approx. 5 s

Character delay time (R2600 transmitter) t

Character delay time (master) t

Response delay time (R2600 transmitter) 10 ms < t

Wait time after R2600 response (master) t

zvs <3ms

zvm < 500 ms

av < 100 ms

aw > 10 ms

ber

t

approx. 5 s

Master

sends

t

av

10 ...

100 ms

Equipment

responds

tzvs

< 3 ms

taw

> 10 ms

Master

sends

t

zvm

< 500 ms

Time

GOSSEN METRAWATT GMBH 7

Page 8

GOSSEN METRAWATT GMBH 8

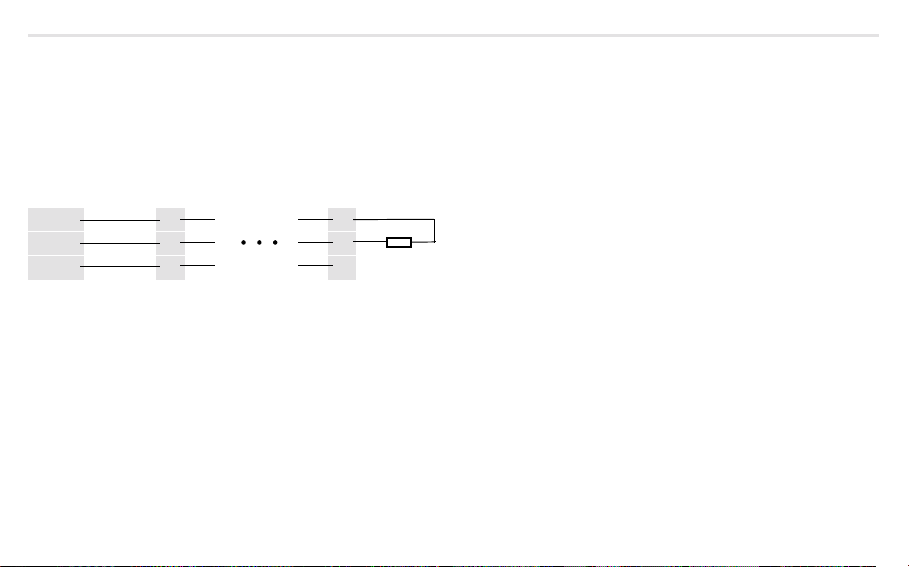

2 Telegram structure

All telegrams consist of one of 3 sets in both request and reply direction, they differ in their principal structure.

Their use is fixed for each interface function of the R2600/01.

Structure and use of the set types are described as follows.

2.1 Short set

Short sets are used on the request side (from the master)

• for transmission of short instructions to the equipment (e.g. Reset)

• for short requests of important data from the equipment (e.g. event data)

Short sets are used on the reply side (from the R2600/01)

• for acknowledgement of requests that require no reply data.

Principal construction short set

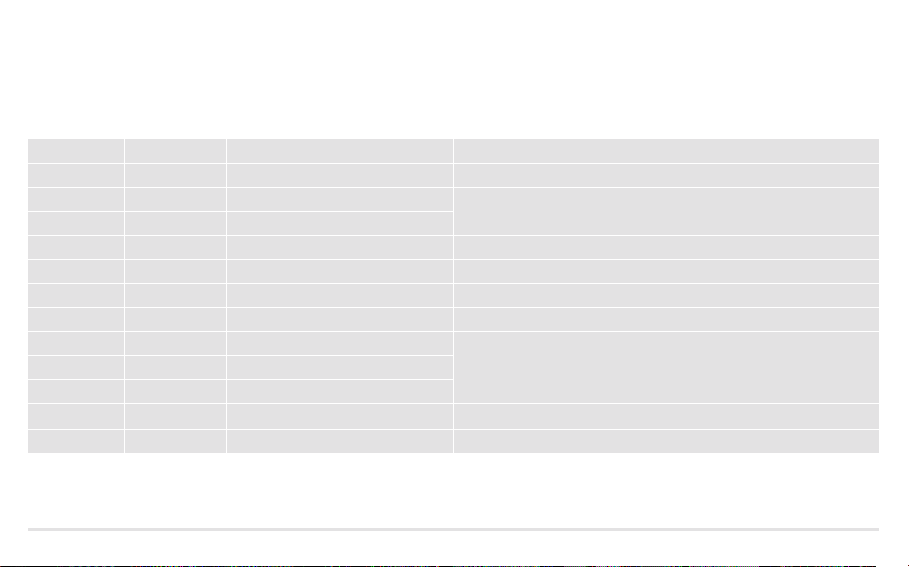

Character No. Contents Meaning Remarks

1 10h Start character Especially for short set

2 0 ... FAh, FFh Equipment address Addr and/or 255 (see 2.4.1)

3 Function field (FF) see 2.4.2

4 Checksum (PS) = Equipment address + FFh

5 16h End character Common to all set types

Page 9

2.2 Control set

The R2600/01 uses control sets on the request side only. They serve to request all equipment data that cannot be requested via a short set because a

detailed specification is required for them.

Principal construction control set

Character No. Contents Meaning Remarks

1 68h Start character

2 3 and/or 6 Length Number of characters from equipment address to checksum exclusive

3 3 and/or 6 Length (repeat)

4 68h Start character (repeat)

5 0 ... FAh, FFh Equipment address Addr and/or 255 (see 2.4.1)

6 Function field (FF) see 2.4.2

7 Parameter index (PI) see 2.4.3

8 1 From channel For reasons of compatibility with multi-channel controllers these charac9 1 To channel

10 0 Receipt number

8 and/or 11

Checksum (PS)

9 and/or 12 16h End character

1) For the set types, the checksum is formed by bytewise summation without overflow summation over all characters from the equipment address to checksum exclusive.

GOSSEN METRAWATT GMBH 9

ters must be available, omitted for parameter index 30h ... 3Fh.

1)

Page 10

GOSSEN METRAWATT GMBH 10

2.3 Long set

The R2600/01 uses long sets to transmit instructions and parameters to the equipment and to receive data from the equipment.

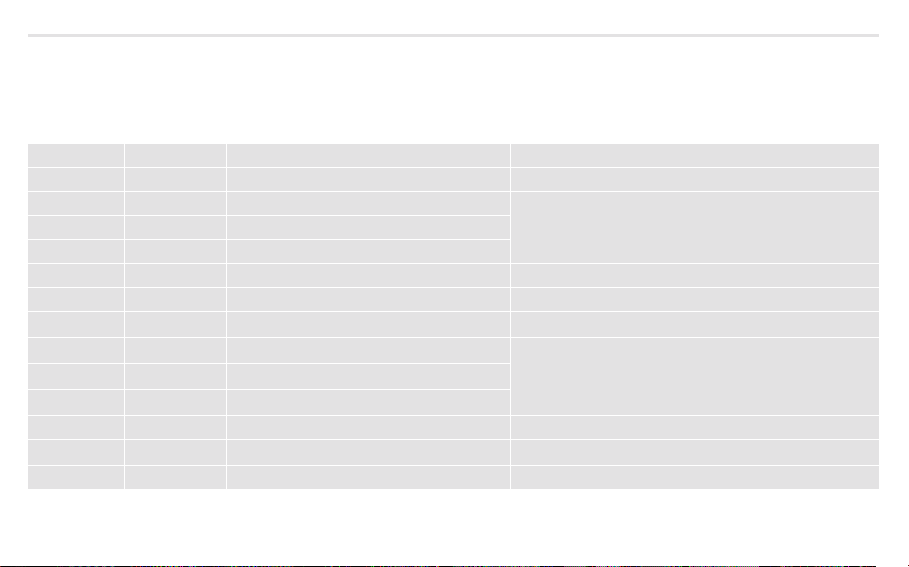

Principal construction long set

Character No. Contents Meaning Remark

1 68h Start character

2 Length Number of characters from equipment address to checksum

3 Length (repeat)

4 68h Start character (repeat)

5 0 ... FAh, FFh Equipment address Addr and/or 255 (see 2.4.1)

6 Function field (FF) see 2.4.2.

7

8 1

9

10

Parameter index (PI)

From channel

1

0

To c h a nnel

Receipt number

1)

1)

1)

1)

. . . n character data block see 2.4.4.

Length + 5

Checksum (PS)

Length + 6 16h End character

1) Omitted for reply cycle data and event data.

2) For the set types, the checksum is formed by bytewise summation without overflow summation over all characters from the equipment address to checksum exclusive.

exclusive

see 2.4.3.

Omitted for parameter index 30h ... 3Fh

2)

Page 11

2.4 Function and value range of the format characters

2.4.1 Equipment address

• 0 ... 250 Range for individual equipment addresses = interface address Addr

• 255 All equipment connected to a bus can simultaneously be addressed under this address. Data and instructions entered with this address

are accepted by all equipment, but there is no acknowledgement made to the master.

2.4.2 Function field (FF)

The function field contains

• with the short set the proper user information, predefined by bits and different in request and response direction

• with the control and long set the direction and control information for the transmitted data block

2.4.2.1 Function coding of the function field in request direction

Request check Code Set Remark

Reset equipment 09h

Interrogation: Equipment OK? 29h Short set

Request cycle data from equipment 89h The R2600/01 evaluates the given codes only; an error acknowledgement is

Request event data from equipment A9h

Send data to R2600/01 69h Long set

Request data from R2600/01 89h

GOSSEN METRAWATT GMBH 11

issued for invalid ones

Page 12

GOSSEN METRAWATT GMBH 12

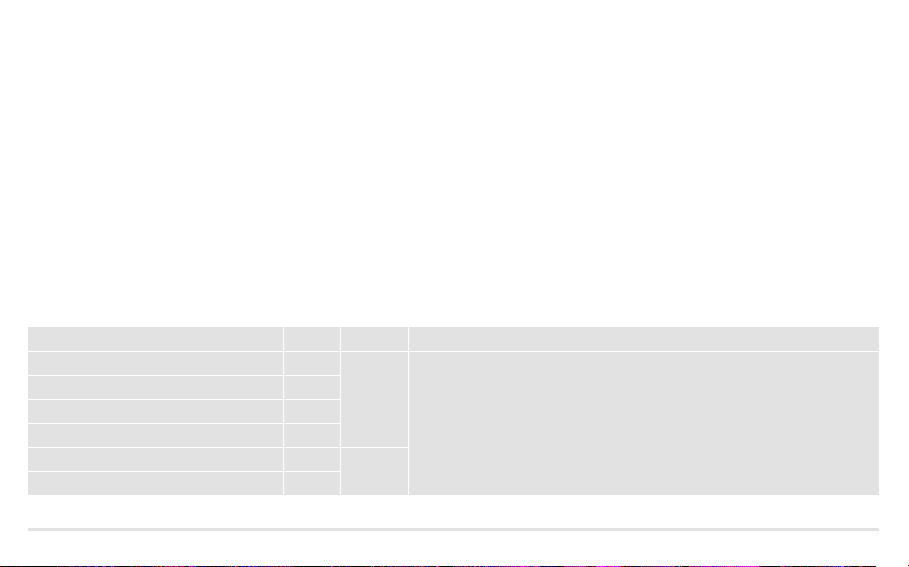

2.4.2.2 Function coding of the function field (FF) in response direction

Bit No. Function Value Meaning

0 ... 2 Reserved 0, 0, 0 (fixed)

3 Request disable 01Instruction executed, equipment ready

4 Instruction acknowledgement 01Instruction executed, equipment ready

5 Transmission error 01Request telegram correct

6 Not used 0

7 Service request 01None of the errors contained in error status words 1 and 2 occurred

Equipment not ready for this instruction, eventually repeat instruction

Instruction could not be executed, equipment ready

Request telegram incorrect

One or more errors occurred, request error status for exact identification!

Page 13

2.4.3 Parameter index (PI)

The type of the data to be transmitted is defined via the parameter index. The "PI" character is interpreted as follows:

Bit 7-4 Bit 3-0

0 ... Fh 0 ... Fh

Selection number for main parameter group Selection number for a special parameter in the main group

Functionally used data and/or setting parameters of an equipment are combined in the main parameter groups. Only those parameter indices documented in section 4 can be addressed in the R2600/01, an error message is issued for all others.

2.4.4 Length and format of the data block

Length and format of the data block are variable and a function of PI and FF.

The transmitted values can have byte or word format:

8 Bit

± 7 Bit 2's complement presentation

16 Bit LS byte first

± 15 Bit LS byte first, 2's complement presentation

8/16 Bit LS byte first

GOSSEN METRAWATT GMBH 13

Number without sign

Number with sign

Number without sign

Number with sign

Bit field

Page 14

GOSSEN METRAWATT GMBH 14

2.5 Criteria for the validity of a request telegram

The R2600/01 checks the characters of the telegrams received in accordance with the following tables:

For short set: For control and long set:

Character No. Criterion Character No. Criterion

1 10h 1 68h

2 Interface address Addr or 255 (see 2.4.2) 2 Note length for PS and end character

3 FF = valid function coding 3 Character 3 = character 2

4 PS = Addr or 255 + FF 4 68h

5 16h 5 Interface address Addr or 255

6 FF = 69h oder 89h

7 PI = valid parameter index (see section 4)

. . . (data block)

Length + 5

Length + 6 16h

1) Bytewise sum without overflow over all characters from equipment address (Addr or 255) to checksum exclusive

If incorrect values are received for FF, PI and PS, the R2600/01 responds with a short set with set transmission error bit. If the user data is entered

beyond its specific value ranges, the R2600/01 responds with a short set with set service request bit. The bit "impermissible value" is set in the error

status word 2.

If there are other deviations or a parity error, the telegram is invalid, the R2600/01 does not respond.

PS =

1)

Page 15

3 Telegram contents R2600/01

3.1 Equipment reset

The addressed equipment performs a hardware reset same as in the case of a short interruption of the auxiliary voltage.

Example: Equipment address = 2

Request from master (short set):

R2600/01 response:

3.2 Interrogation: Equipment OK?

The addressed equipment shows the function field only:

Example: Equipment address = 3

Request from master (short set): 10h 03h 29h 2Ch 16h

R2600/01 response (short set):

See 2.4.2.2 for contents of the function field.

GOSSEN METRAWATT GMBH 15

10h 02h 09h 0Bh 16h

FF PS

None

FF PS

10h 03h „FF“ „FF“+3 16h

Page 16

GOSSEN METRAWATT GMBH 16

3.3 Request for cycle data

You will get the most important measuring and output values of the controller in one data package.

Cyclic requests of these values are thus made possible in compact form (short set request.

Example: Equipment address = 2

Request from master (short set):

R2600/01 response (long set, see 2.3):

See 2.4.2.2 for contents of the function field (FF)

The 7 characters of the cycle data block have the following format:

Character No. Contents, e.g. Format Unit of measure Remark Condition

7, 8

9, 10 36h, 01h ± 15 bits 1 ° / 0.1 ° / 1 2nd measured value (e.g. 310 °) B3, B4, B5

11

12, 13 28h, 00h ± 15 bits 0.1 A Meas. val. of the heating curr. (e.g. 4,0 A)

2Ch, 01h ± 15 bits 1 ° / 0.1 ° / 1

0, 0 B1, B2

CEh ± 7 bits 1%

10h 02h 89h 8Bh 16h

FF PS

68h 09h 09h 68h 02h „FF“ Data block „PS“ 16h

7 characters

1st measured value (e.g. 300 °)

Actual ON time (e.g. –50 %)

A1, A2, A3

1% Position readback (e.g. 40 %)

A4

Page 17

3.4 Request for event data

The event date, combined in 2 words, contain all error messages and alarms of the equipment.

They can be called up via short set to identify a special error.

This request can be made asynchronous, for example, if the service request bit (collected errors) was set before in any random response telegram in

the function field (FF).

Example: Equipment address = 5

Request from master (short set):

R2600/01 response (long set, see 2.3):

See 2.4.2.2 for contents of the function field (FF)

The 4 characters of the event data block are bit fields which are combined to form the error status words 1 and 2.

These 4 characters can also be read by data request with parameter index 21h.

See the operating instructions for more explanations and information on error elimination.

GOSSEN METRAWATT GMBH 17

10h 05h A9h AEh 16h

68h 06h 06h 68h 05h „FF“ Data block „PS“ 16h

4 characters

Page 18

GOSSEN METRAWATT GMBH 18

Character Bit No. Meaning Display on equipment Remark

0 Sensor breakage measuring circuit 2

1 Wrong polarity measuring circuit 2

2 Analog error

1.

3 Sensor breakage measuring circuit 1

4 Wrong polarity measuring circuit 1

5 Low limit 1 fallen below

6 Low limit 2 fallen below

7 High limit 1 exceeded

8 High limit 2 exceeded

9

Impermissible parameter, see 2.5

Associated

data

display

flashes

1)

Status error

word 1

(control loop)

10

11

2.

Error in heating circuit

12

Error at start of self-optimizing

13

Error during self-optimizing + stop

1)

1)

1)

14

15

Page 19

0 Sensor error position readback

1 Sensor error heating current

2

3

3.

4 Heating current not "off" with positioning signal switched off

Heating current < 80 % of the set point of the heating current with

5

active positioning signal

6

7

8

EEPROM error

2)

9

Current display

flashes

Error status

word 2

(heating

current

monitor,

equipment)

10 Function error of rotary button

4.

11 Error of measured value calibration

12

13 Invalid combination of markings

14

15

1) These error bits are deleted after reading. With LE and/or tE , the control function is reactivated.

2) EEPROM error reset by setting the standard parameters with PI = 32h.

GOSSEN METRAWATT GMBH 19

Page 20

GOSSEN METRAWATT GMBH 20

3.5 Request data from R2600/01

This communication makes it possible to request all values, parameters, configurations, states and equipment markings.

Thereby, the data is individually addressed per parameter index. See section 4 for the complete list of all parameter indices.

3.5.1 Request an equipment specification

The parameter index lies between 30h and 3Fh. Thus the characters "from/to channel" and "receipt No." in the control and long set are omitted.

Example: Request for equipment marking having the address = 33 = 21h (see 4.4)

Request from master (control set, see 2.2):

68h 03h 03h 68h 21h 89 30h DAh 16h

FF PI PS

Equipment response (long set, see 2.3):

68h 04h 04h 68h 21h „FF“ 30h 26h „PS“ 16h

PI

Data block

See 2.4.2.2 for the contents of the function field (FF).

The "data block" consists of a character 26h as marking for the R2600/01 (see 4.4).

Page 21

3.5.2 Request for a temperature parameter, for example

The parameter index is not 3xh, thus the characters "from/to channel" and "receipt No." = 1, 1, 0 are contained in the control and long set.

Example: Request for the maximum selectable set point (SP H ) of the R2600/01 with address = 33 = 21h (see 4.1)

Request from master (control set, see 2.2):

68h 06h 06h 68h 21h 89 07h 01h 01h 00h B3h 16h

FF PI PS

Equipment response (long set, see 2.3):

68h 08h 08h 68h 21h „FF“ 07h 01h 01h 00h 52h 03h „PS“ 16h

PI

See 2.4.2.2 for the contents of the function field (FF)

According to 4.1 and 2.4.4, the two characters of the data block (52h, 03h) result in:

SP H = 0352h = 850

If it is an equipment with marking B1 and configuration "sensor type" = 0 ... 6 and "sensor unit" = even number, the unit is °C

(the configuration could be requested with PI = 32h and 33h).

GOSSEN METRAWATT GMBH 21

2 characters

Data block

Page 22

GOSSEN METRAWATT GMBH 22

3.6 Send data to R2600/01

This communication makes it possible to set all parameters, configurations and operating states which can be changed via operation. Thereby, the data

is individually addressed per parameter index. See section 4 for the complete list of all parameter indices. There is no protection against overwriting.

The settings of the DIP switches for disabling of the configuration and/or parameter setting are of no importance. Also the start of optimizing cannot be

disabled.

The R2600/01 checks the transmitted value for its setting range. Should it be beyond its permissible range, it is not stored, the bit "impermissible

value" is set in error status word 1, and the "service request" bit is set in the acknowledgement short set.

Same as with manual operation of the equipment, it must be noted, that a complete configuration must be made before parameters are set: That is, the

"control instructions" and "equipment specifications" must first be transmitted which influence the presentation of the "temperature parameters" (see

4.3 and 4.4).

3.6.1 Sending an equipment specification

The parameter index lies between 30h and 3Fh. Thus the characters "from/to channel" and "receipt No." are omitted in the long set.

Example: Setting the thermocouple type "K" on the equipment having the address = 0 (see 4.4).

Request from master (long set, see 2.3):

68h 05h 05h 68h 00h 69 33h 02h 00h 9Eh 16h

FF PI PS

Data block

Page 23

Acknowledgement from equipment (short set):

See 2.4.2.2 for the contents of the function field (FF)

The first character of the data block is the configuration "sensor type". The second character (B marking) cannot be stored, but a character (any, e.g.

00h) must be sent.

10h 00h „FF“ „FF“ 16h

PS

3.6.2 Send a control parameter, for example

The parameter index (PI) is not 3xh, thus the characters "from/to channel" and "receipt No." = 1, 1, 0 are contained in the long set.

Example: Send the Heat proportional band Pb I = 2.3% to R2600/01 with the address = 1 (see 4.2).

Transmission from master (long set, see 2.3):

68h 08h 08h 68h 01h 69 10h 01h 01h 00h 17h 00h 93h 16h

FF PI PS

Data block

Acknowledgement from equipment (short set):

See 2.4.2.2 for the contents of the function field (FF)

According to 4.2 and 2.4.4, the two characters of the data block (17h, 00h) are calculated to be: Pb I in 0.1% = 23 = 0017h

GOSSEN METRAWATT GMBH 23

10h 01h „FF“ „FF“ + 1 16h

PS

Page 24

GOSSEN METRAWATT GMBH 24

4 Parameter indices of the equipment parameters

For a request and/or transmission of data from and/or to the R2600/01, not only the parameter index for the individual data but also the format and

thus the length of the data block in the long set are of interest. From the column "Format" of the parameter tables and section 2.4.4, the number, order

and contents of the characters of the data block can be found.

See the operating instructions for detailed information on the function of the data.

4.1 Temperature parameters

The temperature parameters are combined in the main parameter group 0.

In the R2600/01, they are stored in standardized form to the measuring range so that other values result when the sensor type or the unit of measure

is re-configured, or when a change is made from fixed value or slave controller to differential controller.

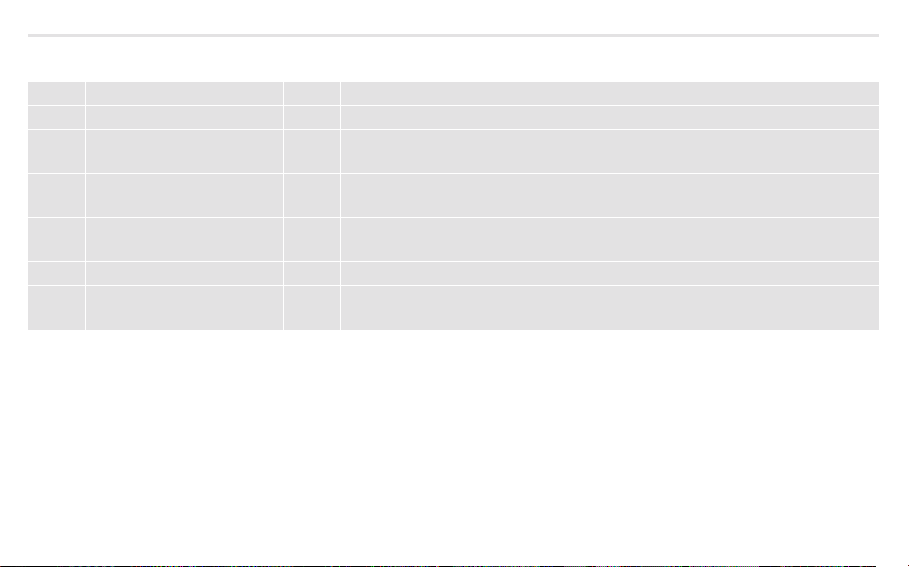

4.1.1 Table of temperature parameters

X1 = range span, X2 = upper range limit, MBU = X2 - X1, see 4.1.3

PI Parameter Display Format Unit Setting range Remarks

00h Set point ± 15 bits (4.1.2) SP L... SP H

01h High limit for relay A1 ± 15 bits (4.1.2) 0 = oFF, 1... MBU At rel. limit

X1 = oFF, X1 + 1 ... X2 At abs. limit and

fixed value controller

–MBU/2 = oFF,

–MBU/2 + 1 ... +MBU/2

02h Low limit for relay A1 ± 15 bits (4.1.2) Same as PI = 01h Same as PI = 01h

At abs. limit and

differential controller

Page 25

03h Second set point ± 15 bits (4.1.2) SP L ... SP H

04h High limit for relay A2 ± 15 bits (4.1.2) Same as PI = 01h Same as PI = 01h

05h Low limit for relay A2 ± 15 bits (4.1.2) Same as PI = 01h Same as PI = 01h

06h Low set point ± 15 bits (4.1.2) X1 ... SP H For fixed value controller,

slave controller

–MBU/2 ... SP H For differential controller

07h High set point ± 15 bits (4.1.2) SP L ... X2 For fixed value controller,

slave controller

SP L ... MBU/2 For differential controller

08h Lower range limit standard signal ± 15 bits –1500 ... rn H For B2, B4, B5

09h Upper limit standard signal ± 15 bits rn L....9999 For B2, B4, B5

0Ch Calibration actual value ± 15 bits (4.1.2) –MBU/4 ... +MBU/4 For B1, B3, B4 and TC

–MBU/4 = Auto,

For B1, B3, B4 and Pt100

–MBU/4 + 1 ... MBU/4

0Dh Location of decimal point 8 bits

1)

0, 1 = 9.999, 2 = 99.99,

For B2, B5

3 = 999.9, 4 = none

0Eh Ramp for rising set points ± 15 bits

0Fh Ramp for falling set points ± 15 bits

1) The decimal point is for the display on the R2600/01 only, not for the parameter values.

2) Unit per minute, see 4.1.2 for units

2)

0 = oFF, 1 ... MBU

2)

0 = oFF, 1 ... MBU

GOSSEN METRAWATT GMBH 25

Page 26

GOSSEN METRAWATT GMBH 26

4.1.2 Unit of the temperature parameters

The unit of the temperature parameters depends upon

– the range marking B1 ... B5 of the equipment (see PI = 33h),

– the configured sensor type (see PI = 33h) and

– the configured unit of the sensor (see PI = 32h).

Marking

B1, B3, B4 1°C / 1°F 0.1°C / 0.1°F

B2, B5 1, 0.1, 0.01, 0.001

With standard signal (B2, B5) and Pt100 with 0.1° display, the decimal point only serves for the display on the R26900/01, not for the parameter values. That is, a value of 234.5 in the display, for example, is to be transmitted as 2345 = 0929. The two characters of the data block then are 29h, 09h.

Sensor type

0 ... 7 8

Page 27

4.1.3 Table of measuring ranges

Sensor type Lower range limit X1 Upper range limit X2 Range span MBU

Code Kind Ty pe in °C in °F in °C in °F in °C in °F

0

1 L –18 0 850 1562 868 1562

2 K –18 0 1200 2192 1218 2192

TC

3 B 0 32 1820 3308 1820 3276

4 S –18 0 1770 3218 1788 3218

5 R –18 0 1770 3218 1788 3218

6 N –18 0 1300 2372 1318 2372

7

Pt100

8 0.1° display –100.0 –148.0 500.0 932.0 600.0 1080.0

0

Standard

signal

1 4 ... 20 mA / 2 ... 10 V

GOSSEN METRAWATT GMBH 27

J –18 0 850 1562 868 1562

1° display –100 –148 500 932 600 1080

0 ... 20 mA / 0 ... 10 V

rn L rn H rn H – rn L

Page 28

GOSSEN METRAWATT GMBH 28

4.2 Control parameters

The control parameters are listed in the main parameter index group 1.

4.2.1 Table of the control parameters

PI Parameter Display Format Unit Setting range Remarks

10h Proportional band Heat 16 bits 0.1 % 1 ... 9999

11h Proportional band Cool 16 bits 0.1% 1 ... 9999

12h Deadband 16 bits (4.1.2) 0 ... MBU

14h Delay time of the controlled system 16 bits 1s 0 ... 9999

15h Output cycle time 16 bits 0.5 s 1 ... 1200

16h Regulation ratio for positioner mode ± 7 bits 1% –100 ... 100 For A2, A3, A4

0 ... 100 For A1

18h Motor running time 16 bits 1s 5 ... 5000

1Dh Maximum regulation ratio ± 7 bits 1% –100 ... 100 For A2, A3, A4

0 ... 100 For A1

1Eh Regulation ratio with sensor error ± 7 bits 1% –100 ... 100 For A2, A3, A4

0 ... 100 For A1

1Fh Switching hysteresis for alarms

and limit monitor

8 bits (4.1.2) 0 ... 1.5 % MBU

Page 29

4.3 Control instructions

The control instructions in main group 2 of the parameter index define the control action of the equipment

4.3.1 Table of the control instructions

PI Parameter Format Unit Setting range Remarks Contents

20h Control status control channel 16 bits Bit field See 4.3.2 Controller type (= CnF1,

21h Error status

Control loop / HÜ (htg. current

monitor) / equipment

22h Configuration

2nd signal input

23h Automatic mode

Off and/or manual mode

28h Manual regulation ratio

with manual mode

GOSSEN METRAWATT GMBH 29

2x16 bits Bit field See 3.4

event data

8 bits See 4.3.3 In fluences the display

8 bits AAh = Automatic,

manual via

binary input 2

55h = Off / manual

± 7 bits 1% –100 ... 100 For A2, A3, A4 Writing only permitted in

0 ... 100 For A1

Read only Summary of all error messages

of the temperature

parameters

2nd digit), SP 2 active?

Start/Stop self-optimizing

CnF2, 2nd digit

Fixed value, differential,

slave controller

input range with standard signal

manual mode

Page 30

GOSSEN METRAWATT GMBH 30

4.3.2 Control status controller channel (PI = 20h):

Bit No. Value Meaning Remarks

Controller type =

Limit monitor

000

Positioner

001

Two-state controller Heat / continuous controller falling characteristic

010

Two-state controller Cool / continuous controller rising characteristic

2 - 0

3 - 6 0

12 - 15 0

1) Otherwise bit 12 "Error at start of self-optimizing" will be set in error status word 1 (see 3.4)

2) Standard: switch-over automatic / manual mode

011

100

Three-state controller / split range controller

101

Three-state controller Water cooling

110

Step controller

Not for marking A1

111 Impermissible

7 0 / 1 SP active / SP 2 active Read only

8 0

9 0 / 1

Self-optimizing Stop / Start

Not for controller types 000, 001

10 0

11 0 / 1

Binary input 2 open / closed

2)

Read only

1)

Page 31

4.3.3 Configuration of the 2nd signal input (PI = 22)

Function signal input 2 Standard signal 2

Code B3 B4 B5 B4, B5

0 Fixed value controller (internal set point)

1 Differential controller Fixed value controller Differential controller

2 –

3 –

4 – Fixed value controller

5 – Fixed value controller Differential controller

6 –

7 –

GOSSEN METRAWATT GMBH 31

Slave controller

Slave controller

0 ... 20 mA

0 ... 10 V

4 ... 20 mA

2 ... 10 V

Page 32

GOSSEN METRAWATT GMBH 32

4.4 Equipment specifications

The equipment specifications in main group 3 of the parameter index among others include marking identification, software version and some configurations.

4.4.1 Table of equipment specifications

PI Parameter Format Unit Setting range Remarks

30h Equipment marking 8 bits 26h Read only

31h Marking identification 8 bits Bit field (4.4.2) Read only

32h Configuration

Sensor unit, continuous output

33h Sensor type, B marking 2x8 bits (4.4.4) CnF1, 3rd digit

35h Software version 8 bits e.g. 18h = version 1.8 Read only

36h Configuration of alarms 1 / 2 8 bits Bit field (4.4.5) CnF1, 1st digit

39h Configuration of

switching outputs I / II

3Ah Continuous signal Cont 8 bits 0 = actual set point

3Fh OEM version number 8 Bit 0 = no OEM version Read only

8 bits (4.4.3) CnF1, 4th digit

CnF2, 1st digit

8 bits Bit field Value I II Read only

00h

Transistor

08h

Relay

10h

Transistor

18h

Relay

1 = Cool reg. ratio (instead of II)

Transistor

Transistor

Relay

Relay

(DIP switch)

Only active, if PI = 32h

set to ≥ 8

Page 33

4.4.2 Marking identifications (PI = 31h)

Bit No. Value Meaning Remark

001

A4

100

2 ... 0

5 ... 3

6 0

7

GOSSEN METRAWATT GMBH 33

A1

101

A2

111

A3

010

B2

011

B1

100

B5

101

B4

111

B3

01Series version

OEM version of hardware and software

Different from PI = 33h

Page 34

GOSSEN METRAWATT GMBH 34

4.4.3 Configuration: Sensor unit, continuous output (PI = 32h)

Code

Sensor unit

0 °C

1 °F

°C

2

3 °F

4 °C

5 °F

6 °C

7 °F

8 °C

9 °F

0Ah °C

0Bh °F

0Fh

1) When switching-over, the physical quantity of the temperature parameter is preserved

2) Configuration digits and all parameters except for the interface address Addr.

1)

Continuous output

Output range Output quantity

0 ... 20 mA

0 ... 10 V

4 ... 20 mA

Actual value

(switching controller)

2 ... 10 V

0 ... 20 mA

0 ... 10 V

4 ... 20 mA

Regulation ratio

(continuous controller)

2 ... 10 V

0 ... 20 mA

0 ... 10 V

4 ... 20 mA

2 ... 10 V

Select

output quantity

with Cont (PI = 3Ah)

Activate default configuration + default parameters

Code Function

The current setting2) is

stored as a user defined

0Dh

default setting.

The user defined default

2)

setting

is uploaded.

If a setting has never been

previously stored with d, the

0Eh

factory default setting or the

configuration in accordance

with customer specific ations

(K9) is uploaded.

The factory default setting2)

0Fh

is uploaded.

Note

Configuration in accordance with customer specifications (K9) is stored at

this location and is thus

overwritten.

All entries are overwritten,

including the results of selfoptimization and calibration.

Page 35

4.4.4 Sensor type, B marking (PI = 33h)

1st character = sensor type: 2nd character = B marking:

Pt 100

1)

For both signal inputs

For signal input 1

at marking B1, B4

at marking B3

For signal input 1

at marking B2, B5

Value Meaning Remarks

1 B4

Read only,

different from

PI = 31h

Code

Sensor type

Typ e Kind Condition 0 B5

0 J

1 L 3 B3

2 K 6 B2

3 B 7 B1

Thermocouple

4 S

5 R

6 N

7 1° display

8 0,1° display

0 0 ... 20 mA / 0 ... 10 V

1 4 ... 20 mA / 2 ... 10 V

1) A change influences the presentation of the temperature parameters

Standard signal

GOSSEN METRAWATT GMBH 35

Page 36

GOSSEN METRAWATT GMBH 36

4.4.5 Configuration of alarms 1 / 2 (PI = 36h)

Bit No. Alarms 1

3 ... 0

1)

Code

0 Relative

1 Absolute

2 Relative

3 Absolute

4 Relative

5 Absolute

6 Relative

7 Absolute

8 Relative

9 Absolute

0Ah Relative

0Bh Absolute

0Ch Relative

0Dh Absolute

0Eh Relative

0Fh Absolute

Start-up suppression Contact Heating circuit monitor

Inactive

NOC

Active

Inactive

Inactive

NCC

Active

Inactive

NOC

Active

Active

Inactive

NCC

Active

Page 37

6 ... 4 Alarms 2

0 Relative

1 Absolute

2 Relative

3 Absolute

4 Relative

5 Absolute

6 Relative

7 Absolute

7 0

1) A change between relative and absolute changes the numeric values of the high and low limits.

Inactive

NOC

Active

Inactive

NCC

Active

4.5 Heating current monitor

Main group 6 of the parameter index includes the parameters for heating current monitoring.

4.5.1 Table of the parameters for the heating current monitor

PI Parameter Display Format Unit Setting range Remarks

60h Set point of the heating current ± 15 bits 0.1 A 0 = Off, 1 ... A H

64h Upper range limit for

heating current

GOSSEN METRAWATT GMBH 37

± 15 bits 0.1 A 10 ... 999 Current value at which 10 V

DC are applied to the input

Page 38

GOSSEN METRAWATT GMBH 38

5 Storage operations

To store all parameter and configuration data of an equipment, it is not required to address all data individually via parameter indices. It is possible

instead to directly read and/or write all data stored in the non-volatile data memory (EEPROM) in one record.

This function serves to save the data, to quickly load or duplicate user-specific settings to the R2600/01. Length and format of the data block depends

upon the EEPROM allocation which can change with the software version of the R2600/01. That is why no information is given about it. Loading of a

record to the R2600/01 can, therefore, only be made for the same software version.

5.1 Request a record

Make the request as described in 3.5, the parameter index = D8h.

Example: Equipment address = 4

Request from master (control set, see 2.2):

68h 06h 06h 68h 04h 89h D8h 01h 01h 00h 67h 16h

FF PI PS

Response from R2600/01 (long set):

68h L + 6 L + 6 68h 04h „FF“ D8h 01h 01h 18h Data block „PS“ 16h

PI

Software version

L character

Page 39

5.2 Send a record

The long set for sending to the R2600/01 can practically only be generated from the received long set at the request of a record. The function field (6th

character) in 69h (write data) must be changed for that purpose. When copying to another R2600/01, the equipment address must be adapted (5th

character). Following, the checksum (last but one character) must be corrected.

Send from master (control set, e.g. equipment address = 4):

68h L + 6 L + 6 68h 04h 69h D8h 01h 01h 18h Data block „PS“ 16h

FF PI

Reply from R2600/01 (short set):

10h 04h „FF“ „FF“ + 4 16h

The record will only be accepted by the equipment, when the software version (12th character) and the length of the data block agree with the equipment. The content of the data block is not checked as it is correct in itself when it comes from a R2600/01.

It must be noted to send a record only to an equipment having the same A and B markings as the equipment from which the record comes. If this is not

observed (e.g. by impermissible configuration data) an unreasonable action of the R2600/01 may result which can be dangerous to the system.

GOSSEN METRAWATT GMBH 39

L character

Page 40

Edited in Germany • Subject to change without notice • A pdf version is available on the internet

Phone +49-(0)-911-8602-0

GOSSEN METRAWATT GMBH

Thomas-Mann-Str. 16-20

90471 Nürnberg, Germany

Fax +49-(0)-911-8602-669

E-Mail: info@gmc-instruments.com

www.gmc-instruments.com

Loading...

Loading...