Page 1

ACE

OM−02817-02

September 11, 2000

Rev. A 11-15-08

INSTALLATION, OPERATION,

AND MAINTENANCE MANUAL

WITH PARTS LIST

VG SERIES PUMP

MODEL

VG6D3−B

THE GORMAN-RUPP COMPANY MANSFIELD, OHIO

www.grpumps.com

GORMAN-RUPP OF CANADA LIMITED ST. THOMAS, ONTARIO, CANADA Printed in U.S.A.

2000 The Gorman-Rupp Company

Page 2

Register your new

Gorman-Rupp pump online at

www.grpumps.com

Valid serial number and e-mail address required.

RECORD YOUR PUMP MODEL AND SERIAL NUMBER

Please record your pump model and serial number in the

spaces provided below. Your Gorman-Rupp distributor

needs this information when you require parts or service.

Pump Model:

Serial Number:

Page 3

TABLE OF CONTENTS

INTRODUCTION PAGE I − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WARNINGS − SECTION A PAGE A − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INSTALLATION − SECTION B PAGE B − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pump Dimensions PAGE B − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PREINSTALLATION INSPECTION PAGE B − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

POSITIONING PUMP PAGE B − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lifting PAGE B − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mounting PAGE B − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SUCTION AND DISCHARGE PIPING PAGE B − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Materials PAGE B − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Line Configuration PAGE B − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connections to Pump PAGE B − 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gauges PAGE B − 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SUCTION LINES PAGE B − 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fittings PAGE B − 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Strainers PAGE B − 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sealing PAGE B − 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Suction Lines In Sumps PAGE B − 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Suction Line Positioning PAGE B − 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DISCHARGE LINES PAGE B − 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Siphoning PAGE B − 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Valves PAGE B − 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ALIGNMENT PAGE B − 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Coupled Drives PAGE B − 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

V−Belt Drives PAGE B − 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OPERATION − SECTION C PAGE C − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PRIMING PAGE C − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hand Primers Page C − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exhaust Primers Page C − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Auxiliary Ejectors Page C − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Vacuum Pumps Page C − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STARTING PAGE C − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rotation Page C − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OPERATION PAGE C − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Leakage PAGE C − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Liquid Temperature And Overheating PAGE C − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Strainer Check PAGE C − 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pump Vacuum Check PAGE C − 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STOPPING PAGE C − 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cold Weather Preservation PAGE C − 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BEARING TEMPERATURE CHECK PAGE C − 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TROUBLESHOOTING − SECTION D PAGE D − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PREVENTIVE MAINTENANCE PAGE D − 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

i

Page 4

TABLE OF CONTENTS

(continued)

PUMP MAINTENANCE AND REPAIR − SECTION E PAGE E − 1. . . . . . . . . . . . . . . .

STANDARD PERFORMANCE CURVE PAGE E − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PUMP MODEL − PARTS LIST PAGE E − 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PUMP AND SEAL DISASSEMBLY AND REASSEMBLY PAGE E − 4. . . . . . . . . . . . . . . . . . . . . . . . .

Impeller Removal PAGE E − 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Seal Removal PAGE E − 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shaft And Bearing Removal And Disassembly PAGE E − 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shaft And Bearing Reassembly And Installation PAGE E − 6. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Seal Reassembly and Installation PAGE E − 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Impeller Installation PAGE E − 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Final Pump Assembly PAGE E − 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LUBRICATION PAGE E − 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Seal Assembly PAGE E − 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bearings PAGE E − 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Source PAGE E − 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

Page 5

VG SERIES OM−02817

INTRODUCTION

Thank You for purchasing a Gorman-Rupp pump.

Read this manual carefully to learn how to safely

install and operate your pump. Failure to do so

could result in personal injury or damage to the

pump.

This pump is a VG Series, enclosed impeller, centrifugal model with straight-in suction without a

suction check valve. The pump is designed for

high pressure distribution of liquids containing

specified entrained solids. The basic material of

construction for wetted parts is gray iron. Be sure

the liquid being pumped is compatible with this

material.

If there are any questions regarding the pump or

its application which are not covered in this manual or in other literature accompanying this unit,

please contact your Gorman-Rupp distributor, or:

Immediate hazards which WILL result in

severe personal injury or death. These

instructions describe the procedure required and the injury which will result

from failure to follow the procedure.

Hazards or unsafe practices which

COULD result in severe personal injury

or death. These instructions describe

the procedure required and the injury

which could result from failure to follow

the procedure.

The Gorman-Rupp Company

P.O. Box 1217

Mansfield, Ohio 44901−1217

Phone: (419) 755−1011

or:

Gorman-Rupp of Canada Limited

70 Burwell Road

St. Thomas, Ontario N5P 3R7

Phone: (519) 631−2870

For information or technical assistance on the

power source, contact the power source manufacturer’s local dealer or representative.

The following are used to alert maintenance personnel to procedures which require special attention, to those which could damage equipment, and

to those which could be dangerous to personnel:

Hazards or unsafe practices which COULD

result in minor personal injury or product

or property damage. These instructions

describe the requirements and the possible damage which could result from failure

to follow the procedure.

NOTE

Instructions to aid in installation, operation, and

maintenance or which clarify a procedure.

PAGE I − 1INTRODUCTION

Page 6

VG SERIES OM−02817

SAFETY − SECTION A

This information applies to the VG Series basic pumps. Gorman-Rupp has no

control over or particular knowledge of

the power source which will be used.

Refer to the manual accompanying the

power source before attempting to begin operation.

Before attempting to open or service the

pump:

1. Familiarize yourself with this manual.

2. Disconnect or lock out the power

source to ensure that the pump will

remain inoperative.

3. Allow the pump to completely cool

if overheated.

4. Check the temperature before

opening any covers, plates, or

plugs.

5. Close the suction and discharge

valves.

6. Vent the pump slowly and cautiously.

7. Drain the pump.

This pump is designed to handle liquids

containing specified entrained solids.

Do not attempt to pump volatile, corrosive, or flammable materials which may

damage the pump or endanger personnel as a result of pump failure.

After the pump has been positioned,

make certain that the pump and all piping connections are tight, properly supported and secure before operation.

Do not operate the pump without the

guards in place over the rotating parts.

Exposed rotating parts can catch clothing, fingers, or tools, causing severe injury to personnel.

Do not operate the pump against a

closed discharge valve for long periods

of time. If operated against a closed discharge valve, pump components will

deteriorate, and the liquid could come

to a boil, build pressure, and cause the

pump casing to rupture or explode.

Use lifting and moving equipment in

good repair and with adequate capacity

to prevent injuries to personnel or damage to equipment. Suction and discharge hoses and piping must be removed from the pump before lifting.

Do not remove plates, covers, gauges,

pipe plugs, or fittings from an overheated pump. Vapor pressure within the

pump can cause parts being disengaged to be ejected with great force. Allow the pump to completely cool before

servicing.

PAGE A − 1SAFETY

Page 7

INSTALLATION − SECTION B

OM−02817VG SERIES

Review all SAFETY information in Section A.

Since pump installations are seldom identical, this

section offers only general recommendations and

practices required to inspect, position, and arrange the pump and piping.

Most of the information pertains to a standard

static lift application where the pump is posi-

tioned above the free level of liquid to be pumped.

If installed in a flooded suction application where

the liquid is supplied to the pump under pressure,

some of the information such as mounting, line

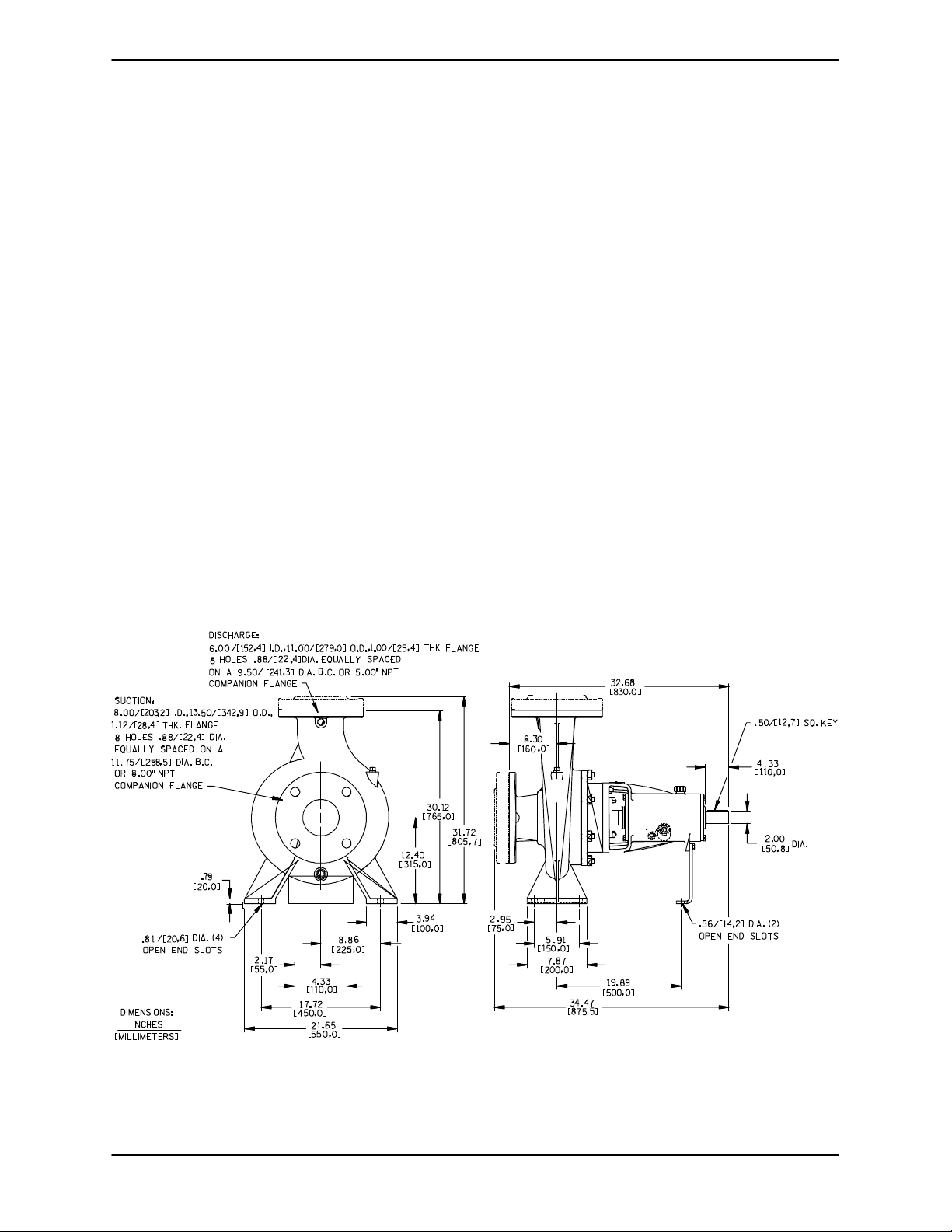

OUTLINE DRAWING

configuration, and priming must be tailored to the

specific application. Since the pressure supplied

to the pump is critical to performance and safety,

be sure to limit the incoming pressure to 50% of

the maximum permissible operating pressure as

shown on the pump performance curve.

For further assistance, contact your Gorman-Rupp

distributor or the Gorman-Rupp Company.

Pump Dimensions

See Figure 1

sions of this pump.

for the approximate physical dimen-

Figure 1. Pump Model VG6D3−B

PAGE B − 1INSTALLATION

Page 8

OM−02817 VG SERIES

PREINSTALLATION INSPECTION

The pump assembly was inspected and tested before shipment from the factory. Before installation,

inspect the pump for damage which may have occurred during shipment. Check as follows:

a. Inspect the pump for cracks, dents, damaged

threads, and other obvious damage.

b. Check for and tighten loose attaching hard-

ware. Since gaskets tend to shrink after drying, check for loose hardware at mating surfaces.

c. Carefully read all warnings and cautions con-

tained in this manual or affixed to the pump,

and perform all duties indicated. Note the direction of rotation indicated on the pump.

Check that the pump shaft rotates counterclockwise when facing the pump suction.

POSITIONING PUMP

Lifting

Pump unit weights will vary depending on the

mounting and drive provided. Check the shipping

tag on the unit packaging for the actual weight, and

use lifting equipment with appropriate capacity.

Drain the pump and remove all customer-installed

equipment such as suction and discharge hoses

or piping before attempting to lift existing, installed

units.

The pump assembly can be seriously

damaged if the cables or chains used to lift

and move the unit are improperly wrapped

around the pump.

Mounting

Only operate this pump in the direction indicated by the arrow on the pump body

and on the accompanying decal. Refer to

ROTATION in OPERATION, Section C.

d. Check all lubricant levels and lubricate as

necessary. Refer to LUBRICATION in the

MAINTENANCE AND REPAIR section of this

manual and perform duties as instructed.

e. If the pump and power source have been

stored for more than 12 months, some of the

components or lubricants may have exceeded their maximum shelf life. These must

be inspected or replaced to ensure maximum pump service.

If the maximum shelf life has been exceeded, or if

anything appears to be abnormal, contact your

Gorman-Rupp distributor or the factory to determine the repair or updating policy. Do not put the

pump into service until appropriate action has

been taken.

Locate the pump in an accessible place as close as

practical to the liquid being pumped. Level mounting is essential for proper operation.

The pump may have to be supported or shimmed

to provide for level operation or to eliminate vibration.

SUCTION AND DISCHARGE PIPING

The size of the system piping is not always determined by the nominal suction and discharge port

diameter. Factors such as suction lift, discharge

elevation, and friction losses for the complete system must be considered to be sure your application allows the pump to operate within the safe operating range shown on page E-1. In any case, the

suction line should never be smaller than the pump

inlet.

Materials

Either pipe or hose maybe used for suction and

discharge lines; however, the materials must be

compatible with the liquid being pumped. If hose is

used in suction lines, it must be the rigid-wall, reinforced type to prevent collapse under suction. Using piping couplings in suction lines is not recommended.

PAGE B − 2 INSTALLATION

Page 9

OM−02817VG SERIES

Line Configuration

Keep suction and discharge lines as straight as

possible to minimize friction losses. Make minimum use of elbows and fittings, which substantially increase friction loss. If elbows are necessary,

use the long-radius type to minimize friction loss.

Connections to Pump

Before tightening a connecting flange, align it exactly with the pump port. Never pull a pipe line into

place by tightening the flange bolts and/or couplings.

Lines near the pump must be independently supported to avoid strain on the pump which could

cause excessive vibration, decreased bearing life,

and increased shaft and seal wear. If hose-type

lines are used, they should have adequate support

to secure them when filled with liquid and under

pressure.

to avoid creating air pockets. Valves are not normally used in suction lines, but if a valve is used,

install it with the stem horizontal to avoid air pockets.

Strainers

If a strainer is furnished with the pump, be certain

to use it; any spherical solids which pass through a

strainer furnished with the pump will also pass

through the pump itself.

If a strainer is not furnished with the pump, but is

installed by the pump user, make certain that the

total area of the openings in the strainer is at least

three or four times the cross section of the suction

line, and that the openings will not permit passage

of solids larger than the solids handling capability

of the pump.

This pump is designed to handle up to 1 1/16 inch

(26,9 mm) diameter spherical solids.

Gauges

Most pumps are drilled and tapped for installing

discharge pressure and vacuum suction gauges.

If these gauges are desired for pumps that are not

tapped, drill and tap the suction and discharge

lines not less than 18 inches (457,2 mm) from the

suction and discharge ports and install the lines.

Installation closer to the pump may result in erratic

readings.

SUCTION LINES

To avoid air pockets which could affect pump priming, the suction line must be as short and direct as

possible. When operation involves a suction lift, the

line must always slope upward to the pump from

the source of the liquid being pumped; if the line

slopes down to the pump at any point along the

suction run, air pockets will be created.

Fittings

Sealing

Since even a slight leak will affect priming, head,

and capacity, especially when operating with a

high suction lift, all connections in the suction line

should be sealed with pipe dope to ensure an airtight seal. Follow the sealant manufacturer’s recommendations when selecting and applying the

pipe dope. The pipe dope should be compatible

with the liquid being pumped.

Suction Lines In Sumps

If a single suction line is installed in a sump, it

should be positioned away from the wall of the

sump at a distance equal to 1 1/2 times the diameter of the suction line.

If there is a liquid flow from an open pipe into the

sump, the flow should be kept away from the suction inlet because the inflow will carry air down into

the sump, and air entering the suction line will reduce pump efficiency.

Suction lines should be the same size as the pump

inlet. If reducers are used in suction lines, they

should be the eccentric type, and should be installed with the flat part of the reducers uppermost

If it is necessary to position inflow close to the suction inlet, install a baffle between the inflow and the

suction inlet at a distance 1 1/2 times the diameter

of the suction pipe. The baffle will allow entrained

PAGE B − 3INSTALLATION

Page 10

OM−02817 VG SERIES

air to escape from the liquid before it is drawn into

the suction inlet.

If two suction lines are installed in a single sump,

the flow paths may interact, reducing the efficiency

of one or both pumps. To avoid this, position the

suction inlets so that they are separated by a distance equal to at least 3 times the diameter of the

suction pipe.

Suction Line Positioning

The depth of submergence of the suction line is

critical to efficient pump operation.

recommended minimum submergence vs. velocity.

Figure 2 shows

NOTE

The pipe submergence required may be reduced

by installing a standard pipe increaser fitting at the

end of the suction line. The larger opening size will

reduce the inlet velocity. Calculate the required

submergence using the following formula based

on the increased opening size (area or diameter).

Figure 2. Recommended Minimum Suction Line Submergence vs. Velocity

DISCHARGE LINES

Siphoning

Do not terminate the discharge line at a level lower

than that of the liquid being pumped unless a siphon breaker is used in the line. Otherwise, a siphoning action causing damage to the pump

could result.

PAGE B − 4 INSTALLATION

Valves

A check valve in the discharge line is normally recommended, but it is not necessary in low discharge head applications.

If a throttling valve is desired in the discharge line,

use a valve as large as the largest pipe to minimize

friction losses. Never install a throttling valve in a

suction line.

With high discharge heads, it is recommended that

a throttling valve and a system check valve be installed in the discharge line to protect the pump

Page 11

OM−02817VG SERIES

from excessive shock pressure and reverse rotation when it is stopped.

If the application involves a high discharge

head, gradually close the discharge

throttling valve before stopping the pump.

ALIGNMENT

The alignment of the pump and its power source is

critical for trouble-free mechanical operation. In

either a flexible coupling or V-belt driven system,

the driver and pump must be mounted so that their

shafts are aligned with and parallel to each other. It

is imperative that alignment be checked after the

pump and piping are installed, and before operation.

Coupled Drives

When using couplings, the axis of the power

source must be aligned to the axis of the pump

shaft in both the horizontal and vertical planes.

Most couplings require a specific gap or clearance

between the driving and the driven shafts. Refer to

the coupling manufacturer’s service literature.

Align spider insert type couplings by using calipers

to measure the dimensions on the circumference

of the outer ends of the coupling hub every 90 degrees. The coupling is in alignment when the hub

ends are the same distance apart at all points (see

Figure 3A).

NOTE

Check Rotation, Section C, before final alignment

of the pump.

When mounted at the Gorman-Rupp factory, driver

and pump are aligned before shipment. Misalignment will occur in transit and handling. Pumps

must be checked and realigned before operation.

Before checking alignment, tighten the foundation

bolts. The pump casing feet and/or pedestal feet,

and the driver mounting bolts should also be tightly

secured.

When checking alignment, disconnect

the power source to ensure that the

pump will remain inoperative.

Figure 3A. Aligning Spider-Type Couplings

Figure 3B. Aligning Non-Spider Type Couplings

Align non-spider type couplings by using a feeler

gauge or taper gauge between the coupling halves

every 90 degrees. The coupling is in alignment

when the hubs are the same distance apart at all

points (see Figure 3B).

Adjusting the alignment in one direction

may alter the alignment in another direction. check each procedure after altering

alignment.

Check parallel adjustment by laying a straightedge

across both coupling rims at the top, bottom, and

side. When the straightedge rests evenly on both

halves of the coupling, the coupling is in horizontal

parallel alignment. If the coupling is misaligned,

use a feeler gauge between the coupling and the

PAGE B − 5INSTALLATION

Page 12

OM−02817 VG SERIES

straightedge to measure the amount of misalignment.

V-Belt Drives

When using V-belt drives, the power source and

the pump must be parallel. Use a straightedge

along the sides of the pulleys to ensure that the pulleys are properly aligned (see Figure 3C). In drive

systems using two or more belts, make certain that

the belts are a matched set; unmatched sets will

cause accelerated belt wear.

Tighten the belts in accordance with the belt manufacturer’s instructions. If the belts are too loose,

they will slip; if the belts are too tight, there will be

excessive power loss and possible bearing failure.

Select pulleys that will match the proper speed ratio; overspeeding the pump may damage both

pump and power source.

Do not operate the pump without the

guard in place over the rotating parts.

exposed rotating parts can catch clothing, fingers, or tools, causing severe injury to personnel.

MISALIGNED:

SHAFTS

NOT PARALLEL

MISALIGNED:

SHAFTS

NOT IN LINE

ALIGNED: SHAFTS

PARALLEL AND

SHEAVES IN LINE

Figure 3C. Alignment of V-Belt Driven Pumps

PAGE B − 6 INSTALLATION

Page 13

VG SERIES

OM−02817

OPERATION − SECTION C

Review all SAFETY information in Section A.

Follow the instructions on all tags, labels and decals attached to the pump.

This pump is designed to handle liquids

containing specified entrained solids.

Do not attempt to pump volatile, corrosive, or flammable liquids which may

damage the pump or endanger personnel as a result of pump failure.

Pump speed and operating conditions

must be within the performance range

shown on page E-1.

PRIMING

Install the pump and piping as described in INSTALLATION. Make sure that the piping connec-

tions are tight, and that the pump is securely

mounted. Check that the pump is properly lubricated (see LUBRICATION in MAINTENANCE

AND REPAIR).

This is not a self-priming pump, so an external

priming device must be used if the pump is installed on a suction lift. A foot valve may be installed at the end of the suction pipe to maintain the

prime; however, this may adversely affect pump

performance due to friction loss. Many standard

centrifugal models are equipped with a hand-operated vacuum pump, exhaust primer, or ejector for

this purpose. If a priming device was not furnished

with the pump, it may be ordered from the factory

as an option. Before attempting to operate the

priming device, close the discharge throttling

valve. (Installation of a spring-loaded check valve

is also recommended to facilitate priming.) Once

the pump is fully primed, close the valve between

the priming device and pump to preserve the

prime. Start the pump and open the discharge

valve slowly to fill the discharge line. When installed

in a flooded suction application, simply open the

system valves and permit the incoming liquid to

evacuate the air. After the pump and piping system

have completely filled, evacuate any remaining air

pockets in the pump or suction line.

Never operate this pump unless there is

liquid in the pump casing. The pump will

not prime when dry. Extended operation of

a dry pump will destroy the seal assembly.

Hand Primers

Hand-operated primers are usually mounted on

the pump and, when operated, draw air out of the

suction line and pump casing. To prime a pump

with a hand vacuum pump, open the cock on the

pump priming line. Operate the hand pump until

liquid flows out of the check valve on the bottom of

the primer pump. Once the pump is primed, close

the valve located between the primer and the

pump so that the prime will not be lost.

HANDLE

DRAIN

COCK

Figure 1. Hand Primer Assembly

Exhaust Primers

Engine driven pumps normally take advantage of

the engine exhaust gases by using them to operate

an exhaust primer. The exhaust is directed through

OPERATION PAGE C − 1

Page 14

VG SERIESOM−02817

a venturi which creates a vacuum in the pump casing in order to fill the suction line and pump casing

with liquid. To prime a pump using an exhaust

primer, open the gas cock in the priming line and

engage the exhaust primer until liquid is thrown out

of the ejector nozzle.

HANDLE

GAS

COCK

Figure 2. Exhaust Primer Assembly

Air can be exhausted to prime a pump by using a

vacuum pump. Either a wet type or a dry type vacuum pump may be used; however, a wet type is

preferred since it will not be damaged if liquid enters it. If a dry vacuum pump is used, provisions

must be made to keep liquid from entering it.

Auxiliary Ejectors

Rotation

The correct direction of pump rotation is counterclockwise when facing the impeller. If the pump is

operated in the wrong direction, pump performance could be adversely affected, and the pump

could be seriously damaged.

Only operate this pump in the direction indicated by the arrow on the pump body

and on the accompanying decal. Otherwise, pump performance could be adversely affected, and the pump could be

seriously damaged.

Consult the operating manual furnished with the

power source before attempting to start the power

source.

If an electric motor is used to drive the pump, remove V-belts, couplings, or otherwise disconnect

the pump from the motor before checking motor

rotation. Operate the motor independently while

observing the direction of the motor shaft, or cooling fan.

Ejectors function much like exhaust primers. They

may be operated by steam, compressed air, water

or exhaust gases. To prime a pump using an ejector, open the gas cock in the priming line and operate the ejector until liquid is thrown out the ejector

nozzle.

Vacuum Pumps

Air can be exhausted to prime a pump by using a

vacuum pump. Either a wet type or a dry type vacuum pump may be used; however, a wet type is

preferred since it will not be damaged if liquid enters it. If a dry vacuum pump is used, provisions

must be made to keep liquid from entering it.

STARTING

Consult the operations manual furnished with the

power source.

If rotation is incorrect on a three-phase motor, have

a qualified electrician interchange any two of the

three-phase wires to change direction. If rotation is

incorrect on a single-phase motor, consult the literature supplied with the motor for specific instructions.

OPERATION

Leakage

No leakage should be visible at pump mating surfaces, or at pump connections or fittings. Keep all

line connections and fittings tight to maintain maximum pump efficiency.

Liquid Temperature And Overheating

The maximum liquid temperature for this pump is

160 F (71,1C). Do not apply it at a higher operating temperature.

Overheating can occur if operated with the valves

in the suction or discharge lines closed. Operating

OPERATIONPAGE C − 2

Page 15

VG SERIES

OM−02817

against closed valves could bring the liquid to a

boil, build pressure, and cause the pump to rupture or explode. If overheating occurs, stop the

pump and allow it to cool before servicing it. Refill

the pump casing with cool liquid.

Allow an over-heated pump to cool before servicing. Do not remove plates,

covers, gauges, or fittings from an overheated pump. Liquid within the pump

can reach boiling temperatures, and vapor pressure within the pump can cause

parts being disengaged to be ejected

with great force. After the pump cools,

drain the liquid from the pump by removing the casing drain plug. Use caution when removing the plug to prevent

injury to personnel from hot liquid.

Strainer Check

inches (508,0 mm) or more of mercury. If it does

not, check for air leaks in the seal, gasket, or discharge valve.

Open the suction line, and read the vacuum gauge

with the pump primed and at operation speed.

Shut off the pump. The vacuum gauge reading will

immediately drop proportionate to static suction

lift, and should then stabilize. If the vacuum reading

falls off rapidly after stabilization, an air leak exists.

Before checking for the source of the leak, check

the point of installation of the vacuum gauge.

STOPPING

Never halt the flow of liquid suddenly. If the liquid

being pumped is stopped abruptly, damaging

shock waves can be transmitted to the pump and

piping system. Close all connecting valves slowly.

On engine driven pumps, reduce the throttle

speed slowly and allow the engine to idle briefly before stopping.

If a suction strainer has been shipped with the

pump or installed by the user, check the strainer

regularly, and clean it as necessary. The strainer

should also be checked if pump flow rate begins to

drop. If a vacuum suction gauge has been installed, monitor and record the readings regularly

to detect strainer blockage.

Never introduce air or steam pressure into the

pump casing or piping to remove a blockage. This

could result in personal injury or damage to the

equipment. If backflushing is absolutely necessary, liquid pressure must be limited to 50% of the

maximum permissible operating pressure shown

on the pump performance curve.

Pump Vacuum Check

Since this pump does not have a suction check

valve, the discharge line must be fitted with a check

valve if a pump vacuum reading is to be taken.

With the pump inoperative, install a vacuum gauge

in the system, using pipe dope on the threads.

Block the suction line and start the pump. At operating speed the pump should pull a vacuum of 20

If the application involves a high discharge

head, gradually close the discharge

throttling valve before stopping the pump.

After stopping the pump, disconnect the power

source to ensure that the pump will remain inoperative.

Cold Weather Preservation

In below freezing conditions, drain the pump to

prevent damage from freezing. Also, clean out any

solids by flushing with a hose. Operate the pump

for approximately one minute; this will remove any

remaining liquid that could freeze the pump rotating parts. If the pump will be idle for more than a

few hours, or if it has been pumping liquids containing a large amount of solids, drain the pump,

and flush it thoroughly with clean water. To prevent

large solids from clogging the drain port and preventing the pump from completely draining, insert

a rod or stiff wire in the drain port, and agitate the

liquid during the draining process. Clean out any

remaining solids by flushing with a hose.

OPERATION PAGE C − 3

Page 16

VG SERIESOM−02817

BEARING TEMPERATURE CHECK

Bearings normally run at higher than ambient temperatures because of heat generated by friction.

Temperatures up to 160F (71,1C) are considered normal for bearings, and they can operate

safely to at least 180F (82,2C).

Checking bearing temperatures by hand is inaccurate. Bearing temperatures can be measured accurately by placing a contact-type thermometer

against the housing. Record this temperature for

future reference.

A sudden increase in bearing temperature is a

warning that the bearings are at the point of failing

to operate properly. Make certain that the bearing

lubricant is of the proper viscosity and at the correct level (see LUBRICATION in MAINTENANCE

AND REPAIR). Bearing overheating can also be

caused by shaft misalignment and/or excessive vibration.

When pumps are first started, the bearings may

seem to run at temperatures above normal. Continued operation should bring the temperatures

down to normal levels.

OPERATIONPAGE C − 4

Page 17

VG-SERIES OM−02817

TROUBLESHOOTING − SECTION D

Review all SAFETY information in Section A.

Before attempting to open or service the

pump:

1. Familiarize yourself with this manual.

2. Lock out or disconnect the power

source to ensure that the pump will

remain inoperative.

3. Allow the pump to completely cool if

overheated.

4. Check the temperature before opening any covers, plates, or plugs.

5. Close the suction and discharge

valves.

6. Vent the pump slowly and cautiously.

7. Drain the pump.

TROUBLE POSSIBLE CAUSE PROBABLE REMEDY

PUMP FAILS TO

PRIME

PUMP STOPS OR

FAILS TO DELIVER

RATED FLOW OR

PRESSURE

Auxiliary priming device faulty or improperly installed.

Discharge check valve open. Check position of handle; close

Strainer clogged. Check strainer and clean if neces-

Air leak in suction line.

Lining of suction hose collapsed.

Leaking or worn seal or pump gasket. Check pump vacuum. Replace

Pump running backwards. Check direction of rotation.

Strainer clogged. Check strainer and clean if neces-

Air leak in suction line. Correct leak.

Suction intake not submerged at

proper level or sump too small.

Repair priming device or check installation.

valve.

sary.

Correct leak.

Replace suction hose.

leaking or worn seal or gasket.

sary.

Check installation and correct submergence as needed.

Impeller or other wearing parts worn

or damaged.

Impeller clogged. Free impeller of debris.

TROUBLESHOOTING PAGE D − 1

Replace worn or damaged parts.

Check that impeller is properly

centered and rotates freely.

Page 18

TROUBLE POSSIBLE CAUSE PROBABLE REMEDY

VG-SERIESOM−02817

PUMP STOPS OR

FAILS TO DELIVER

RATED FLOW OR

PRESSURE (cont.)

PUMP REQUIRES

TOO MUCH

POWER

Discharge throttling valve partially

closed; check that valve is installed improperly.

Pump speed too slow. Check driver output; check belts

Suction lift too high. Measure lift w/vacuum gauge. Re-

Leaking or worn seal or pump gasket. Check pump vacuum. Replace

Liquid solution too thick. Dilute if possible.

Power source too small. Check power requirement for ap-

Pump speed too high. Check driver output; check that

Discharge head too low. Adjust discharge valve.

Impeller jammed due to debris or insufficient clearance.

Open discharge valve fully; check

piping installation.

or couplings for slippage.

duce lift and/or friction losses in

suction line.

leaking or worn seal or gasket.

plication. Install larger power

source.

sheaves or couplings are correctly sized.

Disassemble pump and check impeller.

Liquid solution too thick. Dilute if possible.

Bearing(s) frozen. Disassemble pump and check

PUMP CLOGS

FREQUENTLY

EXCESSIVE NOISE Cavitation in pump.

Discharge flow too slow. Open discharge valve fully to in-

Suction check valve or foot valve

clogged or binding.

Pumping entrained air.

Pump or drive not securely mounted.

Impeller clogged or damaged.

bearing(s).

crease flow rate, and run power

source at maximum governed

speed.

Clean valve.

Reduce suction lift and/or friction

losses in suction line. Record vacuum and pressure gauge readings

and consult local representative or

factory.

Locate and eliminate source of air

bubble.

Secure mounting hardware.

Clean out debris; replace damaged parts.

Suction and discharge lines not properly supported.

Check piping installation for proper

support.

TROUBLESHOOTINGPAGE D − 2

Page 19

VG-SERIES OM−02817

TROUBLE POSSIBLE CAUSE PROBABLE REMEDY

BEARINGS RUN

TOO HOT

Bearing temperature is high, but

within limits.

Low or incorrect lubricant. Check for proper type and level of

Pump speed too high. Reduce speed of power source.

PREVENTIVE MAINTENANCE

Since pump applications are seldom identical, and

pump wear is directly affected by such things as

the abrasive qualities, pressure and temperature

of the liquid being pumped, this section is intended

only to provide general recommendations and

practices for preventive maintenance. Regardless

of the application however, following a routine preventive maintenance schedule will help assure

trouble-free performance and long life from your

Gorman-Rupp pump. For specific questions concerning your application, contact your GormanRupp distributor or the Gorman-Rupp Company.

Record keeping is an essential component of a

good preventive maintenance program. Changes

in suction and discharge gauge readings (if so

Check bearing temperature regularly to monitor any increase.

lubricant.

equipped) between regularly scheduled inspections can indicate problems that can be corrected

before system damage or catastrophic failure occurs. The appearance of wearing parts should also

be documented at each inspection for comparison

as well. Also, if records indicate that a certain part

(such as the seal) fails at approximately the same

duty cycle, the part can be checked and replaced

before failure occurs, reducing unscheduled down

time.

For new applications, a first inspection of wearing

parts at 250 hours will give insight into the wear rate

for your particular application. Subsequent inspections should be performed at the intervals shown

on the chart below. Critical applications should be

inspected more frequently.

TROUBLESHOOTING PAGE D − 3

Page 20

VG-SERIESOM−02817

Preventive Maintenance Schedule

Service Interval*

Item

General Condition (Temperature, Unusual

Noises or Vibrations, Cracks, Leaks,

Loose Hardware, Etc.) I

Pump Performance (Gauges, Speed, Flow) I

Bearing Lubrication I R

Seal Lubrication (And Packing Adjustment,

If So Equipped) I R

V-Belts (If So Equipped) I

Air Release Valve Plunger Rod (If So Equipped) I C

Front Impeller Clearance (Wear Plate) I

Rear Impeller Clearance (Seal Plate) I

Check Valve I

Pressure Relief Valve (If So Equipped) C

Pump and Driver Alignment I

Shaft Deflection I

Bearings I

Bearing Housing I

Piping I

Driver Lubrication − See Mfgr’s Literature

Daily Weekly Monthly Semi-

Annually

Annually

Legend:

I = Inspect, Clean, Adjust, Repair or Replace as Necessary

C = Clean

R = Replace

* Service interval based on an intermittent duty cycle equal to approximately 4000 hours annually.

Adjust schedule as required for lower or higher duty cycles or extreme operating conditions.

TROUBLESHOOTINGPAGE D − 4

Page 21

OM−02817VG SERIES

PUMP MAINTENANCE AND REPAIR − SECTION E

MAINTENANCE AND REPAIR OF THE WEARING PARTS OF THE PUMP WILL MAINTAIN PEAK

OPERATING PERFORMANCE.

STANDARD PERFORMANCE FOR PUMP MODEL VG6D3−B

Based on 70 F (21,1C) clear water at sea level

with minimum suction lift. Since pump installations

are seldom identical, your performance may be different due to such factors as viscosity, specific

gravity, elevation, temperature, and impeller trim.

Contact the Gorman-Rupp Company to verify performance or part numbers.

Pump speed and operating condition

If your pump serial number is followed by an N",

your pump is NOT a standard production model.

MAINTENANCE & REPAIR PAGE E − 1

points must be within the continuous performance range shown on the curve.

Page 22

OM−02817 VG SERIES

SECTION DRAWING

PARTS PAGE

Figure 1. Pump Model VG6D3−B

MAINTENANCE & REPAIRPAGE E − 2

Page 23

OM−02817VG SERIES

PARTS LIST

Pump Model VG6D3−B

(From S/N 1188889 up)

If your pump serial number is followed by an N", your pump is NOT a standard production model. Contact

the Gorman-Rupp Company to verify part numbers.

ITEM

PART NAME PART

NO.

NUMBER

MAT’L

CODE

QTY ITEM

NO.

PART NAME PART

NUMBER

MAT’L

CODE

QTY

1 PUMP CASING 26821−746 −−− 1

2 IMPELLER 26821−109 −−− 1

3 SEAL ASSY 25271−095 −−− 1

4 DISCHARGE STICKER 6588BJ −−− 1

5 SEAL PLATE GSKT 26821−425 −−− 1

6 SEAL PLATE 26821−692 −−− 1

7 SETSCREW 26821−942 −−− 2

8 SEAL COLLAR 26821−034 −−− 1

9 SHAFT SLEEVE O−RING 25154−132 −−− 1

10 SHAFT SLEEVE 26821−224 −−− 1

11 SEAL CAP GSKT 26821−463 −−− 1

12 HEX NUT 26821−935 −−− 20

13 STUD 26821−895 −−− 20

14 STUD 26821−883 −−− 6

15 HEX NUT 26821−933 −−− 6

16 NAME PLATE 38814−043 13990 1

17 DRIVE SCREW BM#04−03 17000 2

18 HEX HD CAPSCREW 22645−162 −−− 4

19 BEARING CAP 26821−074 −−− 1

20 BEARING HOUSING 26821−068 −−− 1

21 BEARING SPACER 26821−321 −−− 1

22 RETAINING RING 26821−384 −−− 1

23 ROTATION DECAL 2613M −−− 1

24 LUBE DECAL 38816−079 −−− 1

25 OIL INLET PLUG 26821−616 −−− 1

26 OUTBRD BALL BRG 23275−012 −−− 1

27 BRG CAP GSKT 26821−404 −−− 1

28 OUTBRD OIL SEAL 26821−634 −−− 1

29 HEX HD CAPSCREW 22645−162 −−− 4

30 BEARING CAP 26821−074 −−− 1

31 SHAFT KEY N0814 15990 1

32 REPAIR IMP SHAFT 26821−174 −−− 1

−INCLUDES ITEMS 31, 48 AND 49

33 HEX HD CAPSCREW 22645−162 −−− 2

34 FLAT WASHER K06 15991 2

35 FOOT 26821−208 −−− 1

36 BEARING SPACER 26821−321 −−− 1

37 BRG RETAINER RING 26821−384 −−− 1

38 OIL LEVEL 26821−611 −−− 1

39 PIPE PLUG P06 15079 1

40 INBRD BALL BRG S1033 −−− 1

41 BRG CAP GSKT 26821−404 −−− 1

42 INBRD OIL SEAL 26821−634 −−− 1

43 DEFLECTOR 26821−494 −−− 1

44 HEX NUT 26821−932 −−− 4

45 STUD 26821−878 −−− 4

46 SEAL CAP 26821−244 −−− 1

47 PIPE PLUG P08 15079 1

48 IMPELLER NUT 26821−135 −−− 1

49 IMPELLER KEY 26821−264 −−− 1

50 SUCTION STICKER 6588AG −−− 1

51 PIPE PLUG P08 15079 1

NOT SHOWN:

INSTRUCTION TAG 38817−011 −−− 1

INSTRUCTION TAG 38817−024 −−− 1

OPTIONAL:

NPT SUCTION FLANGE 1759 10010 1

SUCT FLANGE GSKT 1759G 18000 1

NPT DISCHARGE FLANGE 1758 10010 1

DISCH FLANGE GSKT 1679G 18000 1

STRAINER, STD S2279 −−− 1

STRAINER, IRRIGATION 7531 −−− 1

DISCH CHECK VLV ASSY GRP14−03A −−− 1

HAND PRIMER GRP43−09 −−− 1

VITON SEAL 25271−096 −−− 1

BRONZE IMPELLER 26821−089 −−− 1

INDICATES PARTS RECOMMENDED FOR STOCK

MAINTENANCE & REPAIR PAGE E − 3

Page 24

OM−02817 VG SERIES

PUMP AND SEAL DISASSEMBLY AND REASSEMBLY

Review all SAFETY information in Section A.

Follow the instructions on all tags, label and decals attached to the pump.

This pump requires little service due to its rugged,

minimum-maintenance design. However, if it becomes necessary to inspect or replace the wearing

parts, follow these instructions which are keyed to

the sectional view (see Figure 1) and the accompanying parts list.

This manual will alert personnel to known procedures which require special attention, to those

which could damage equipment, and to those

which could be dangerous to personnel. However,

this manual cannot possibly anticipate and provide

detailed precautions for every situation that might

occur during maintenance of the unit. Therefore, it

is the responsibility of the owner/maintenance personnel to ensure that only safe, established main-

tenance procedures are used, and that any procedures not addressed in this manual are performed

only after establishing that neither personal safety

nor pump integrity are compromised by such practices.

Before attempting to service the pump, disconnect

or lock out the power source and take precautions

to ensure that it will remain inoperative. Close all

valves in the suction and discharge lines.

5. Close the suction and discharge

valves.

6. Vent the pump slowly and cautiously.

7. Drain the pump.

Use lifting and moving equipment in

good repair and with adequate capacity

to prevent injuries to personnel or damage to equipment.

Impeller Removal

For access to the impeller (2) or seal assembly (3),

the pump casing (1) must be separated from the

seal plate (6).

Drain the suction and discharge piping and remove it from the pump. Remove the casing drain

plug (47) and drain the pump. Clean and reinstall

the drain plug.

Remove the hardware securing the pump casing

to the base. Wedge a block of wood under the

bearing housing (20) to support the housing when

the casing is removed.

Remove the nuts (12) and separate the pump casing from the seal plate. Tie and tag any leveling

shims used under the casing mounting feet. Remove the seal plate gasket (5) and clean the mating surfaces.

Before attempting to open or service the

pump:

1. Familiarize yourself with this manual.

2. Disconnect or lock out the power

source to ensure that the pump will

remain inoperative.

3. Allow the pump to completely cool

if overheated.

4. Check the temperature before

opening any covers, plates, or

plugs.

Immobilize the shaft (32). Remove the impeller nut

(48) and use a soft-faced mallet to tap the impeller

from the shaft. Retain the impeller key (49). Inspect

the impeller and replace it if cracked or badly worn.

Seal Removal

To remove the seal assembly (3), disengage the

nuts (15) and slide the seal plate (6), seal cap (46),

seal and shaft sleeve (10) off the shaft as a single

unit. Remove the shaft sleeve O-ring (9).

Disengage the nuts (44) and remove the seal cap

(46) and gasket (11). Remove the stationary element and O-ring from the seal cap.

Pull the sleeve and rotating portion of the seal from

the seal plate. Apply oil to the sleeve and work it up

MAINTENANCE & REPAIRPAGE E − 4

Page 25

OM−02817VG SERIES

under the bellows. Slide the rotating element, retainer and bellows, spring, and spring holder off

the sleeve.

NOTE

It is not necessary to remove the seal collar (8) unless the collar or sleeve requires replacement. DO

NOT remove the collar until the exact location has

been recorded either by scribing or measurement.

The location of the collar is critical to pump operation since it establishes the working length of the

seal. After the dimension has been recorded, or the

location scribed, loosen the setscrews (7) and

slide the collar off the sleeve.

If no further disassembly is required, see Seal Installation.

Shaft And Bearing Removal And Disassembly

Place a block of wood against the drive end of the

shaft and tap the shaft and assembled bearings

(26 and 40) out of the bearing housing.

After removing the shaft and bearings, clean and

inspect the bearings in place as follows.

To prevent damage during removal from

the shaft, it is recommended that bearings

be cleaned and inspected in place. It is

strongly recommended that the bearings

be replaced any time the shaft and bear-

ings are removed.

Clean the bearing housing, shaft and all component parts (except the bearings) with a soft cloth

soaked in cleaning solvent. Inspect the parts for

wear or damage and replace as necessary.

When the pump is properly operated and maintained, the bearing housing should not require disassembly. Disassemble the shaft and bearings

only when there is evidence of wear or damage.

Shaft and bearing disassembly in the field

is not recommended. These operations

should be performed only in a properlyequipped shop by qualified personnel.

Separate the power source from the shaft (32) and

remove the deflector (43) and key (31).

Remove the hardware securing the foot (35) to the

base, and move the bearing housing to a clean,

well-equipped shop for disassembly.

Remove the drain plug (39) and drain the bearing

housing. Clean and reinstall the drain plug.

Most cleaning solvents are toxic and

flammable. Use them only in a well ventilated area free from excessive heat,

sparks, and flame. Read and follow all

precautions printed on solvent containers.

Clean the bearings thoroughly in fresh cleaning

solvent. Dry the bearings with filtered compressed

air and coat with light oil.

Bearings must be kept free of all dirt and

foreign material. Failure to do so will greatly shorten bearing life. Do not spin dry

bearings. This may scratch the balls or

races and cause premature bearing failure.

Disengage the hardware (18 and 29) and remove

the inboard and outboard bearing covers (19 and

30) and gaskets (27 and 41). Inspect the oil seals

(28 and 42) and, if replacement is required, use a

screwdriver or other suitable tool to pry them from

the bearing covers.

MAINTENANCE & REPAIR PAGE E − 5

Rotate the bearings by hand to check for roughness or binding and inspect the bearing balls. If rotation is rough or the bearing balls are discolored,

replace the bearings.

The bearing tolerances provide a tight press fit

onto the shaft and a snug slip fit into the bearing

Page 26

OM−02817 VG SERIES

housing. Replace the bearings, shaft, or bearing

housing if the proper bearing fit is not achieved.

Use a bearing puller to remove the inboard and

outboard bearings from the shaft. Remove the

bearing spacers (21 and 36).

It is not necessary to remove the bearing snap

rings (22 and 37) from the shaft unless replacement is required. If replacement is required, use

snap ring pliers to remove the snap rings from the

impeller shaft.

Shaft And Bearing Reassembly

And Installation

If removed, reinstall the bearing snap rings (22 and

37) in the grooves in the shaft. Replace the bearing

spacers (21 and 36).

Clean and inspect the bearings as indicated in

Shaft and Bearing Removal and Disassembly.

vent the bearings from cooling and sticking on the

shaft.

Use caution when handling hot bearings to prevent burns.

After the bearings have been installed and allowed

to cool, check to ensure that they have not moved

out of position in shrinking. If movement has occurred, use a suitable sized sleeve and a press to

reposition the bearings.

If heating the bearings is not practical, use a suitable sized sleeve and an arbor (or hydraulic) press

to install the bearings on the shaft.

When installing the bearings onto the

shaft, never press or hit against the outer

race, balls, or ball cage. Press only on the

inner race.

To prevent damage during removal from

the shaft, it is recommended that bearings

be cleaned and inspected in place. It is

strongly recommended that the bearings

be replaced any time the shaft and bear-

ings are removed.

The bearings may be heated to ease installation.

An induction heater, hot oil bath, electric oven, or

hot plate may be used to heat the bearings. Bearings should never be heated with a direct flame or

directly on a hot plate.

NOTE

If a hot oil bath is used to heat the bearings, both the

oil and the container must be absolutely clean. If

the oil has been previously used, it must be thor-

oughly filtered.

Heat the bearings to a uniform temperature no

higher than 250F (120C), and slide the bearings

onto the shaft, one at a time, until they are fully

seated against the bearing spacers. This should

be done quickly, in one continuous motion, to pre-

Install the oil seal (28) in the outboard bearing

cover (30). Install the gasket (27), and secure the

bearing cover to the bearing housing (20) with the

capscrews (29).

Slide the shaft and assembled bearings into the

bearing housing until the outboard bearing seats

against the bearing cover. Be careful not to damage the lip of the oil seal (28) on the shaft keyway.

When installing the shaft and bearings into

the bearing bore, push against the outer

race. Never hit the balls or ball cage.

Install the inboard oil seal (42) in the bearing cover

(19). Slide the inboard bearing cover and gasket

(41) over the shaft and secure them with the capscrews (18). Be careful not to damage the oil seal

on the shaft threads.

Install the deflector (43) and shaft key (31).

If removed, secure the foot (35) to the bearing

housing with the hardware (33 and 34), and sup-

MAINTENANCE & REPAIRPAGE E − 6

Page 27

OM−02817VG SERIES

port the bearing housing with a wood block until

the pump is fully reassembled. Lubricate the bearings as indicated in LUBRICATION.

Seal Reassembly and Installation

Clean the seal cavity and shaft with a cloth soaked

in fresh cleaning solvent.

Most cleaning solvents are toxic and

flammable. Use them only in a well ventilated area free from excessive heat,

sparks, and flame. Read and follow all

precautions printed on solvent containers.

The seal is not normally reused because wear patterns on the finished faces cannot be realigned

during reassembly. This could result in premature

failure. If necessary to reuse an old seal in an emergency, carefully wash all metallic parts in fresh

cleaning solvent and allow to dry thoroughly.

Handle the seal parts with extreme care to prevent

damage. Be careful not to contaminate precision

finished faces; even fingerprints on the faces can

shorten seal life. If necessary, clean the faces with a

non-oil based solvent and a clean, lint-free tissue.

Wipe lightly in a concentric pattern to avoid

scratching the faces.

Inspect the seal components for wear, scoring,

grooves, and other damage that might cause leakage. Clean and polish the shaft sleeve, or replace it

if there are nicks or cuts on either end. If any components are worn, replace the complete seal;

never mix old and new seal parts.

If a replacement seal is being used, remove it from

the container and inspect the precision finished

faces to ensure that they are free of any foreign

matter.

To ease installation of the seal, lubricate the shaft

sleeve, O-rings and bellows with water or a very

small amount of oil, and apply a drop of light lubricating oil on the finished faces. Assemble the seal

as follows, (see Figure 2).

SPRING CENTERING

WASHER

SPRING

SHAFT SLEEVE

O-RING

SEAL

COLLAR

SETSCREW

SEAL PLATE

RETAINER

A

BELLOWS

O-RING

STATIONARY

ELEMENT

IMPELLER SHAFT

SEAL CAP

ROTATING

ELEMENT

Figure 2. 25271−095 Seal Assembly

MAINTENANCE & REPAIR PAGE E − 7

Page 28

OM−02817 VG SERIES

until both are fully seated. Install the impeller nut

(48).

Install the seal plate gasket (5). Slide the pump

This seal is not designed for operation at

temperatures above 160

F (71C). Do not

use at higher operating temperatures.

Locate the collar (8) on the shaft sleeve at the

scribed mark or dimension taken before disassembly, and secure with the setscrews (7).

casing (1) over the impeller and secure it to the seal

plate with the nuts (12).

Replace any leveling shims used under the casing

mounting feet and install the hardware securing

the casing and bearing housing foot to the base.

Remove the wood block supporting the bearing

housing.

NOTE

If the dimension is not known, slide the sleeve onto

the shaft until fully seated, and scribe the seal working length on the shaft (dimension A" shown in Figure 2). The designed working length (from the stationary seal face to the collar) for this seal is 2−3/8

inches (60,2 mm). Secure the collar on the sleeve at

this point with the setscrews.

Final Pump Assembly

Be sure the pump is secure to the base and power

source.

Install the suction and discharge lines and open all

valves. Make certain that all piping connections are

tight, properly supported and secure.

Position the seal plate on a flat surface with the impeller side down. Position the sleeve in the seal

plate bore with the chamfered end facing up.

Slide the spring holder and spring over the sleeve

and against the collar. Assemble the drive grooves

of rotating element into the drive lugs of the bellows

retainer, and slide this rotating portion of the seal

over the sleeve until the retainer seats in the spring.

Use thumb pressure to press the stationary seat

and O-ring into the seal cap (46) until fully seated.

Slide the assembled stationary seat, seal cap and

gasket over the shaft sleeve until the seal faces

contact and secure the seal cap and gasket (11) to

the seal plate (6) with the nuts (44).

Install the sleeve O-ring (9) completely against the

shaft shoulder. Be careful not to cut it on the impeller keyway.

Slide the seal plate, shaft sleeve and seal assembly

onto the shaft. Secure the seal plate to the bearing

housing with the nuts (15).

Impeller Installation

Be sure the pump and power source have been

properly lubricated, see LUBRICATION.

Fill the pump casing with clean liquid. Reinstall the

fill plug (51) and tighten it. Refer to OPERATION,

Section C, before putting the pump back into service.

LUBRICATION

Seal Assembly

The seal assembly is lubricated by the medium being pumped and no additional lubrication is required.

Bearings

The bearing housing was fully lubricated when

shipped from the factory. Check the oil level regularly through the sight gauge (38) and maintain it at

the middle of the gauge. When lubrication is required, add SAE No. 30 non-detergent oil through

the oil inlet plug opening (25). Do not over-lubricate. Over-lubrication can cause the bearings to

over-heat, resulting in premature bearing failure.

Inspect the impeller, and replace it if cracked or

badly worn. Install the impeller key (49) and slide

the impeller onto the shaft and against the sleeve

Under normal conditions, drain the bearing housing once each year and refill with clean oil. Change

the oil more frequently if the pump is operated con-

MAINTENANCE & REPAIRPAGE E − 8

Page 29

OM−02817VG SERIES

tinuously or installed in an environment with rapid

temperature change.

Monitor the condition of the bearing lubricant regularly for evidence of rust or moisture condensation. This is especially im-

portant in areas where variable hot and

cold temperatures are common.

For cold weather operation, consult the factory or a

lubricant supplier for the recommended grade of

oil.

Power Source

Consult the literature supplied with the power

source, or contact your local power source representative.

MAINTENANCE & REPAIR PAGE E − 9

Page 30

For U.S. and International Warranty Information,

Please Visit www.grpumps.com/warranty

or call:

U.S.: 419−755−1280

International: +1−419−755−1352

For Canadian Warranty Information,

Please Visit www.grcanada.com/warranty

or call:

519−631−2870

THE GORMAN-RUPP COMPANY D MANSFIELD, OHIO

GORMAN-RUPP OF CANADA LIMITED D ST. THOMAS, ONTARIO, CANADA

Loading...

Loading...