Gorman-Rupp Pumps SM4G1-X30 User Manual

PUBLICATION NUMBER

OM−04417

February 20, 1996

Rev. C 06-23-05

SM SERIES

SUBMERSIBLE PUMPS

THE GORMAN-RUPP COMPANY D MANSFIELD, OHIO

GORMAN-RUPP OF CANADA LIMITED D ST. THOMAS, ONTARIO, CANADA Printed in U.S.A.

eCopyright by the Gorman-Rupp Company

OM−04417 SM SERIES PUMPS

INTRODUCTION

Thank You for purchasing a Gorman-Rupp SM

Series Pump. Read this manual carefully to learn

how to safely install and operate your pump. Failure to do so could result in personal injury or damage to the pump.

A set of three manuals accompanies your pump.

Each set consists of three parts; the Installation/

Operation Manual contains essential information

on installing and operating the pump, and on making electrical connections. However, since pump

installations are seldom identical, some of the information only summarizes general recommendations and practices required to inspect, position,

and arrange the pump and piping.

The Parts List Manual provides performance

curve(s), a pump model cross-section drawing,

and parts list for your pump.

The Maintenance and Repair Manual provides

troubleshooting and maintenance instructions required to properly diagnose operational problems,

and to service the pump hydraulic components.

Pump motor maintenance may be performed only

by a Gorman-Rupp authorized repair facility, or the

factory. Otherwise, the pump warranty will be negated, and damage to the pump, and injury or

death to personnel can result. Contact the factory

for the authorized repair facility closest to you.

The integral electric motor must be operated

through the control box furnished with the pump.

The pump and control comply with MSHA sched-

ule 2G regulations. Control boxes and other control devices are not covered in this manual.

Pump construction may be aluminum or stainless

steel. The pump may be operated fully or partially

submerged, since the integral air-filled electric motor is thermally protected and cooled by the liquid

being pumped.

Because pump installations are seldom identical,

this manual cannot possibly provide detailed instructions and precautions for every aspect of

each specific application. Therefore, it is the responsibility of the owner/installer of the pump to

ensure that applications not addressed in this

manual are performed only after establishing that

neither operator safety nor pump integrity are compromised by the installation. Pumps and related

equipment must be installed and operated according to all national, local and industry standards.

If there are any questions regarding the pump

which are not covered in this manual or in other literature accompanying the unit, please contact

your Gorman-Rupp distributor or the GormanRupp Company:

The Gorman-Rupp Company

P.O. Box 1217

Mansfield, Ohio 44901−1217

or:

Gorman-Rupp of Canada Limited

70 Burwell Road

St. Thomas, Ontario N5P 3R7

CONTENTS

SAFETY − SECTION A

INSTALLATION − SECTION B

GENERAL INFORMATION PAGE B − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GORMAN-RUPP MSHA PUMP INSPECTION FORM PAGE B − 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PREINSTALLATION INSPECTION PAGE B − 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LUBRICATION PAGE B − 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PUMP SPECIFICATIONS PAGE B − 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PUMP INSTALLATION PAGE B − 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PIPING PAGE B − 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ELECTRICAL CONNECTIONS PAGE B − 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OPERATION − SECTION C

GENERAL INFORMATION PAGE C − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PUMP OPERATION PAGE C − 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STARTING, STOPPING, AND OPERATIONAL CHECKS PAGE C − 3. . . . . . . . . . . . . . . . . . . . . . . . . . . .

COLD WEATHER PRESERVATION PAGE C − 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LUBRICATION PAGE C − 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PAGE I − 1INTRODUCTION

OM−04417SM SERIES PUMPS

RECORDING MODEL AND

WARRANTY INFORMATION

SERIAL NUMBERS

Please record the pump model, serial number, voltage, and motor frame size in the spaces provided

below. Your Gorman-Rupp distributor needs this

information when you require parts or service.

Pump Model:

Serial Number:

Voltage:

Phase:

The following are used to alert personnel to procedures which require special attention, to those which

could damage equipment, and to those which could be dangerous to personnel:

Immediate hazards which WILL result in

severe personal injury or death. These

instructions describe the procedure required and the injury which will result

from failure to follow the procedure.

The warranty provided with your pump is part of

Gorman-Rupp’s support program for customers

who operate and maintain their equipment as described in this and the other accompanying literature. Please note that should the equipment be

abused or modified to change its performance beyond the original factory specifications, the warranty will become void and any claim will be denied.

Hazards or unsafe practices which COULD

result in minor personal injury or product or

property damage. These instructions describe the requirements and the possible

damage which could result from failure to

follow the procedure.

Hazards or unsafe practices which

COULD result in severe personal injury

or death. These instructions describe

the procedure required and the injury

which could result from failure to follow

the procedure.

NOTE

Instructions to aid in installation, operation, and

maintenance or which clarify a procedure.

PAGE I − 2 INTRODUCTION

SM SERIES

OM−04417

SAFETY - SECTION A

This information applies to SM Series

Submersible motor driven pumps and

control boxes.

Because pump installations are seldom

identical, this manual cannot possibly

provide detailed instructions and precautions for each specific application.

Therefore, it is the owner/installer’s responsibility to ensure that applications

not addressed in this manual are performed only after establishing that neither operator safety nor pump integrity

are compromised by the installation.

Before attempting to open or service the

pump:

1. Familiarize yourself with this manual.

2. Lock out incoming power to the

control box to ensure that the

pump will remain inoperative.

3. Allow the pump to cool if overheated.

4. Close the discharge valve (if

used).

The pump is designed to be operated

through the control box furnished with

the pump. The control box provides

overload protection and power control.

Do not connect the pump motor directly

to the incoming power lines.

alified electrician to make all electrical

connections. Make certain that the

pump and enclosure are properly

grounded. Be sure the incoming power

matches the voltage and phase of the

pump and control before connecting

the power source. Do not run the pump if

the voltage is not within the limits.

The electrical power used to operate

this pump is high enough to cause injury or death. Make certain the control

handle on the control box is in the off position and locked out, or the power supply to the control box has been otherwise cut off and locked out, before attempting to open or service the pump

assembly. Tag electrical circuits to prevent accidental start-up.

All electrical connections must be in accordance with MSHA Schedule 2G. If

there is a conflict between the instructions provided and MSHA specifications, MSHA specifications shall take

precedence. All electrical equipment

supplied with this pump was in conformance with MSHA requirements in effect on the date of manufacture. Failure

to follow applicable specifications, or

substitution of electrical parts not

supplied or approved by the manufacturer, can result in severe injury or

death.

The electrical power used to operate

this pump is high enough to cause injury or death. Obtain the services of a qu-

This pump is not designed to pump volatile, explosive, or flammable materials.

PAGE A − 1SAFETY

SM SERIESOM−04417

Refer to the chart in Installation, Section

B for the basic materials of construction

for each pump covered in this manual.

Do not attempt to pump any liquids for

which your pump is not approved, or

which may damage the pump or endanger personnel as a result of pump failure. Consult the factory for specific

application data.

After the pump has been installed, make

certain that the pump and all piping or

hose connections are secure before operation.

mal operating temperatures can be high

enough to cause burns. The temperature will be especially high if operated

against a closed discharge valve. Never

operate against a closed discharge

valve for long periods of time.

Do not open the control box in an explosive atmosphere. When sealed, the control box is explosion proof, to prevent

the ignition of combustible gases.

Opening the box in an explosive atmosphere could result in fire or explosion.

Approach the pump cautiously after it

has been running. Although the motor is

cooled by the liquid being pumped, nor-

Pumps and related equipment must be installed and operated according to all national, local and industry standards.

PAGE A − 2 SAFETY

INSTALLATION − SECTION B

OM−04417SM SERIES

Review all SAFETY information in Section A.

Since pump installations are seldom identical, this

section is intended only to summarize recommended installation practices for the pump and

control box. If there are any questions concerning

your specific application, contact your GormanRupp distributor or the Gorman-Rupp Company

All functions performed by the customer on the

pump or control must be done in accordance with

MSHA schedule 2G regulations to ensure the explosion-proof integrity. No alterations of original

design may be made without the consent of the

Gorman-Rupp Company and MSHA.

To retain permissibility" of this equipment,

the following conditions shall be satisfied:

3. FASTENING. All bolts, nuts, screws,

and other means of fastening, and also

threaded covers, shall be in place, properly tightened and secured.

4. RENEWALS AND REPAIRS. Inspec-

tions, repairs, or renewals of electrical

parts shall not be made unless the portable cable is disconnected from the circuit furnishing power, and the cable

shall not be connected again until all

parts are properly reassembled. Special care shall be taken in making renewals or repairs. Leave no parts off. Use replacement parts exactly like those furnished by the manufacturer. When any

lead entrance is disturbed, the original

leads or exact duplicates thereof shall

be used and stuffing boxes shall be repacked in the approved manner.

1. GENERAL SAFETY. Frequent inspec-

tion shall be made. All electrical parts,

including the portable cable and wiring,

shall be kept in a safe condition. There

shall be no openings into the casings of

the electrical parts. A permissible distribution box shall be used for connection

to the power circuit unless connection is

made in fresh intake air. The machine

frame shall be effectively grounded. The

power wires shall not be used for

grounding. The incoming voltage must

match the voltage rating of the motor.

2. SERVICING. Explosion-proof enclosures shall be restored to the state of

original safety with respect to all flame

arresting paths, lead entrances, etc.,

following disassembly for repair or rebuilding, whether by the owner or an independent shop.

5. CABLE REQUIREMENTS. A flame-resistant portable cable bearing a MSHA

assigned identification number, adequately protected by an automatic circuit-interrupting device, shall be used.

Special care shall be taken in handling

the cable to guard against mechanical

injury and wear. Splices in portable

cables shall be made in a workmanlike

manner, mechanically strong, and well

insulated. One temporary splice may be

made in any trailing cable. Such trailing

cable may only be used for the next

24-hour period. No temporary splice

shall be made in a trailing cable within

25 feet of the machine, except cable reel

equipment. Connections and wiring to

the outby end of the cable shall be in accordance with recognized standards of

safety.

PAGE B − 1INSTALLATION

OM−04417 SM SERIES

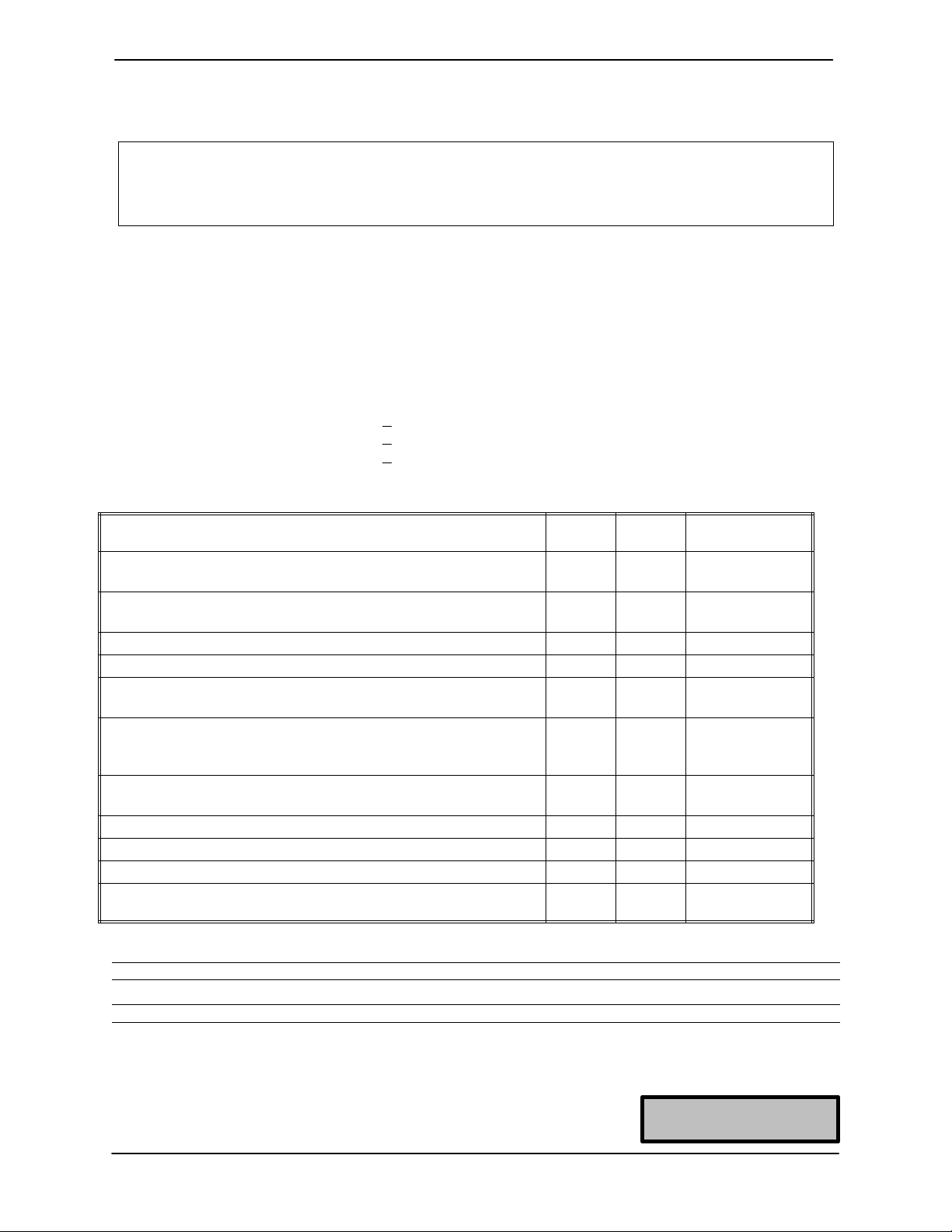

GORMAN−RUPP MSHA PUMP INSPECTION FORM

INSPECTOR____________________________ DATE____________

MODEL NO.____________________________ SERIAL NO.____________

UNIT ELECTRICAL RATING:

H.P.________, VOLTS________, PUMP AMPS________, HERTZ________

STARTER X/P NO: XP3026−1 (CONTROL WITHOUT FLOAT)

OR

18−XPA040007−0 (CONTROL WITH FLOAT)

MOTOR CABLE:

___No. 12; 7 Conductor; Type SPC; .89 + .03 O.D.; Heavy Jacketed; Royal – MSHA 122;

___No. 8; 9 Conductor; Type SPC; 1.05 + .03 O.D.; Heavy Jacketed; Royal – MSHA 122;

___No. 6; 9 Conductor; Type SPC; 1.25 + .04 O.D.; Heavy Jacketed, Royal – MSHA 122;

Length______________________

ITEM AREA OF INSPECTION ACC. REJ. CORRECTED

1. Are lockwashers (or equivalent) provided for all explosion proof enclosure fastenings?

2. Are all plane joints securely fastened so that a .005−inch

feeler gauge cannot be inserted?

3. Is motor plug secured with lock clip?

4. Are all electrical connections secure?

5. Are all electrical connections insulated where necessary

and per appropriate drawing?

6. Are packing glands properly packed so that 1/8−inch

clearance remains between packaging nut and stuffing

box?

7. Are packing nut and cable grip secured with lock wire and

lead seal?

8. Was pump leak tested?

9. Was pump and control electrically tested?

10. Was pump water tested?

11. Are pump, cable, and control assembled together properly

per appropriate drawing?

Comments:

NOTE: Fill out form completely and “rejections” must be corrected and re−inspected. Inspector must

initial and date when corrective action was taken. 10/9/87

Form CD GL−02128 Rev 6/05

Doc# 152708

PAGE B − 2 INSTALLATION

This form not to be revised

without approval of MSHA.

OM−04417SM SERIES

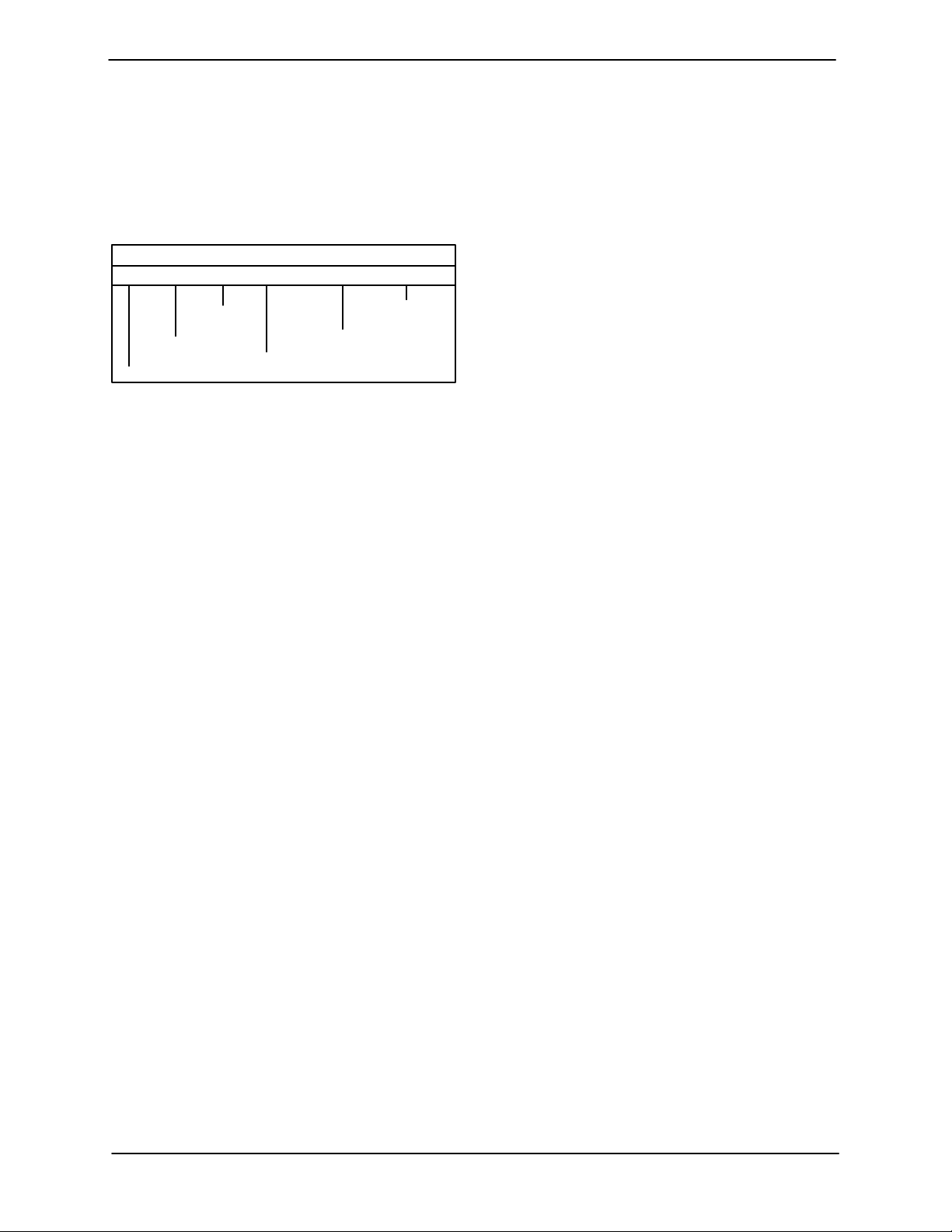

Pump Model Designation

Following is a description of the model numbering

system for SM Series pumps. These submersible

pumps are available in a range of sizes. Refer to the

following chart to identify the size for your specific

pump model.

Pump Model

SM

Series

3 C 1 460/3− X6

Pump

Hydraulics

Discharge

Size

Pump

Construction

Voltage/Phase

H.P.

(If Shown)

PREINSTALLATION INSPECTION

The pump and control box were inspected and

tested before shipment from the factory. Before installation, inspect the pump for damage which may

have occurred during shipment. Check as follows:

h. Check the pump and motor for any oil leaks.

An oil leak may indicate a cut O-ring or other

damage.

i. If the pump and

control box have been stored

for more than 12 months, some of the components or lubricants may have exceeded their

maximum shelf life. These must be inspected

or replaced to ensure maximum pump service.

If the maximum shelf life has been exceeded, or if

anything appears to be abnormal, contact your

Gorman-Rupp distributor or the factory to determine the repair or updating policy. Do not put the

pump into service until appropriate action has

been taken.

LUBRICATION

a. Inspect the pump assembly for cracks, dents,

damaged threads, and other obvious damage.

b. Check for and tighten loose attaching hard-

ware. Since gaskets tend to shrink after drying, check for loose hardware at mating surfaces.

c. The standard pump is furnished with 50 feet of

power cable. Inspect the cable for cuts or

damage.

d. Inspect the control box for cracks, dents, and

other obvious damage.

e. Check that all control box components are se-

curely attached to their mounting surfaces,

and the electrical connections are tight and

free of corrosion.

f. Compare the amperes, phase, voltage and

hertz indicated on the motor nameplate to the

ratings indicated for the control box.

This pump series utilizes one lubrication cavity, located just behind the seal plate. It is filled with premium quality submersible pump oil which lubricates two shaft seals. The motor operates in air

and requires no lubrication.

The lower shaft seal prevents liquid from entering

the lubrication cavity, while the upper shaft seal

prevents oil leakage into the motor. The upper seal

also acts as backup protection in the event of lower

seal failure.

The lubrication cavity was fully lubricated when

shipped from the factory. Check the oil level before

installing the pump (see LUBRICATION in MAIN-

TENANCE AND REPAIR). An additional quart of

oil has been provided with the pump to top off" the

oil cavity. If the oil level is abnormally low, determine the cause before putting the pump into service.

PUMP SPECIFICATIONS

g. Carefully read all tags, decals, and markings

on the pump assembly and the control box,

and perform all duties as indicated.

See Tables B-1 and B-2 for pump specifications

and motor data.

PAGE B − 3INSTALLATION

Loading...

Loading...