Gorenje VLG 300 C1-1G6, VLG 300 B1-1G3, VLG 200 A3-1G3, VLG 300 C1-2G3, VLG 300 B2-1G3 Instructions For Use Manual

...

VLG 200 - 400

NAVODILO ZA UPORABO

INSTRUCTIONS FOR USE

SLEN

www.gorenje.com

OPOZORILA

Aparat lahko uporabljajo otroci stari 8 let in starejši in osebe z zmanjšanimi fizičnimi, čutnimi ali mentalnimi

sposobnostmi ali s pomanjkanjem izkušenj oz. znanjem če so pod nadzorom ali poučeni glede uporabe aparata

SL

na varen način in da razumejo možne nevarnosti.

Otroci se ne smejo igrati z aparatom.

Čiščenje in vzdrževanje aparata ne smejo izvajati otroci brez nadzora.

Vgradnja mora biti izvedena v skladu z veljavnimi predpisi in po navodilih proizvajalca. Izvesti jo mora strokovno

usposobljen monter.

Na dotočno cev hranilnika tople vode je potrebno obvezno vgraditi varnostni ventil z nazivnim tlakom 0,6 MPa

(6 bar), 0,9 MPa (9 bar) ali 1,0 MPa (10 bar) (glejte napisno tablico), ki preprečuje zvišanje tlaka v kotlu za več

kot

0,1 MPa (1 bar) nad nazivnim.

Voda lahko kaplja iz odtočne odprtine varnostnega ventila zato mora biti odtočna odprtina odprta na

atmosferski tlak.

Izpust varnostnega ventila mora biti nameščen v smeri navzdol in v območju, kjer ne zamrzuje.

Za pravilno delovanje varnostnega ventila je potrebno periodično izvajati kontrole, da se odstrani vodni kamen in

se preveri, da varnostni ventil ni blokiran.

Med hranilnik tople vode in varnostni ventil ni dovoljeno vgraditi zapornega ventila, ker s tem onemogočite

tlačno varovanje hranilnika!

Pred električno priključitvijo grelca je potrebno hranilnik obvezno najprej napolniti z vodo!

Hranilnik je zaščiten za primer odpovedi delovnega termostata z dodatno toplotno varovalko. V primeru

odpovedi termostata lahko v skladu z varnostnimi standardi voda v hranilniku doseže temperaturo tudi do

130 °C. Pri izvedbi vodovodnih inštalacij je obvezno potrebno upoštevati, da lahko pride do navedenih

temperaturnih preobremenitev.

Če boste hranilnik iz električnega omrežja izklopili, morate ob nevarnosti zamrznitve vodo iz njega iztočiti.

Voda iz hranilnika se izprazni skozi dotočno cev kotla. V ta namen je priporočljivo med varnostni ventil in

dotočno cev namestiti poseben T-člen z izpustnim ventilom.

Prosimo Vas, da morebitnih okvar na hranilniku ne popravljate sami, ampak o njih obvestite najbližjo

pooblaščeno servisno službo.

518375

Naši izdelki so opremljeni z okolju in zdravju neškodljivimi komponentami in so izdelani tako, da jih lahko v

njihovi zadnji življenjski fazi čim bolj enostavno razstavimo in recikliramo.

Z reciklažo materialov zmanjšujemo količine odpadkov in zmanjšamo potrebo po proizvodnji osnovnih

materialov (na primer kovine), ki zahteva ogromno energije ter povzroča izpuste škodljivih snovi. Z reciklažnimi

postopki tako zmanjšujemo porabo naravnih virov, saj lahko odpadne dele iz plastike in kovin ponovno vrnemo

v različne proizvodne procese.

Za več informacij o sistemu odlaganja odpadkov obiščite svoj center za odlaganje odpadkov, ali trgovca, pri

katerem je bil izdelek kupljen.

2

Cenjeni kupec, zahvaljujemo se Vam za nakup našega izdelka.

øJ

I

PROSIMO, DA PRED VGRADNJO IN PRVO UPORABO HRANILNIKA TOPLE VODE

SKRBNO PREBERETE NAVODILA.

Hranilnik je izdelan v skladu z veljavnimi standardi in uradno preizkušen, zanj pa sta bila izdana varnostni certifikat in certifikat

o elektromagnetni kompatibilnosti. Njegove osnovne tehnične lastnosti so navedene na napisni tablici, nalepljeni na zaščitnem

pokrovu.

Hranilnik sme priključiti na vodovodno in električno omrežje le za to usposobljen strokovnjak. Posege v njegovo notranjost zaradi

popravila, odstranitve vodnega kamna ter preverjanja ali zamenjave protikorozijske zaščitne anode lahko opravi samo pooblaščena

servisna služba.

Hranilnik tople vode je izdelan tako, da lahko preko toplotnega prenosnika uporabljamo sledeče vire ogrevanja in sicer:

• kotel centralnega ogrevanja,

• sončno energijo,

• toplotno črpalko.

VGRADNJA

Hranilnik tople vode postavite v suh prostor, kjer ne zmrzuje, po možnosti v bližino drugih virov ogrevanja (npr. v kurilnico). Pred

postavitvijo privijačite priložene nastavljive nogice. Hranilnik izravnajte vzdolžno in prečno z vrtenjem nastavljivih nogic.

5

4

SL

H

G

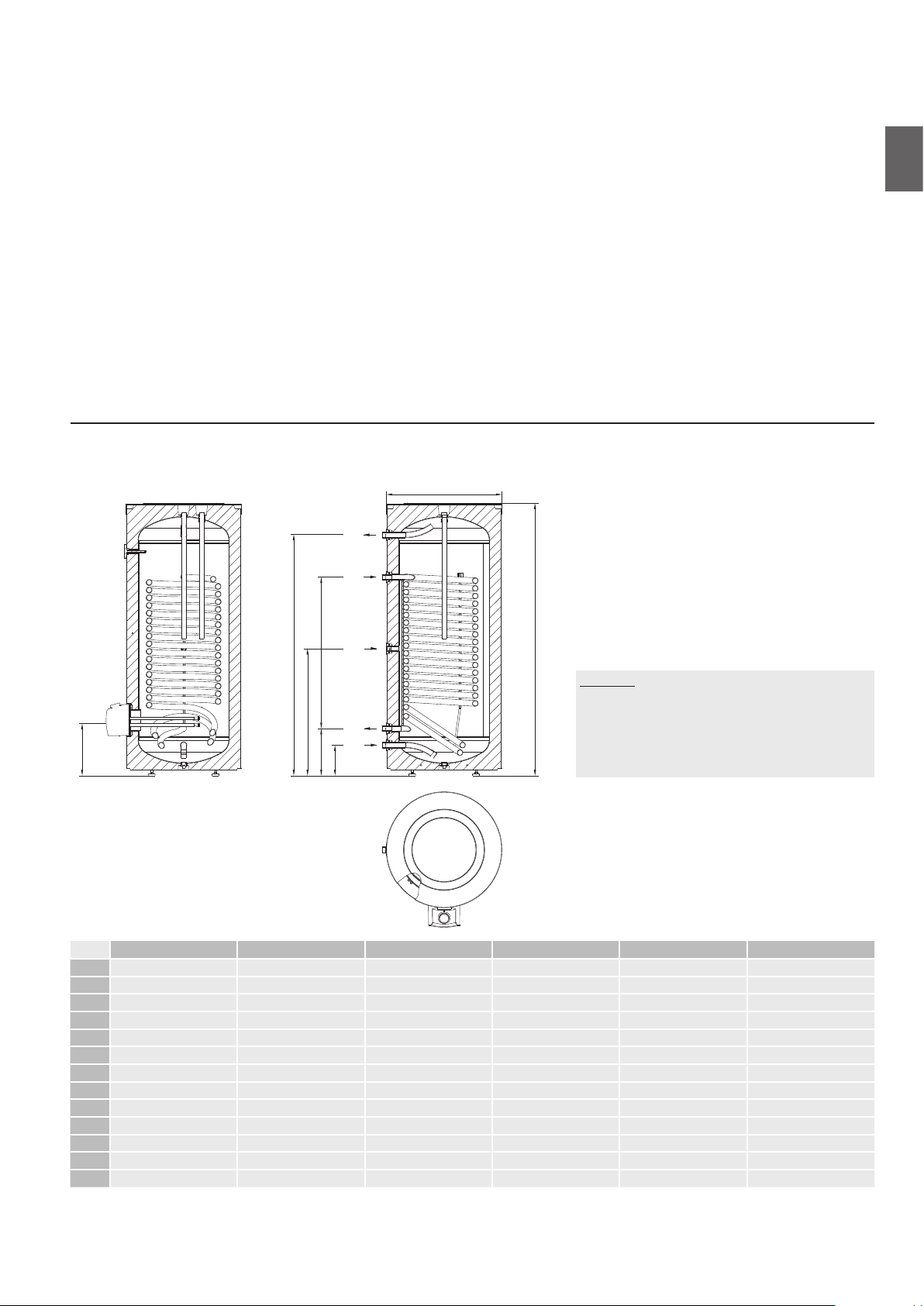

VLG 200 A1-1G VLG 200 A3-1G VLG 300 B1-1G VLG 300 B2-1G VLG 300 C1-1G VLG 400 C1-1G

A 1535 1675 1590 1590 1445 1915

B 180 220 175 175 250 250

C 300 340 270 270 370 370

D 880 1015 890 890 610 1070

G 780 945 740 740 800 990

H 1355 1435 1410 1410 1205 1675

I 365 405 320 340 400 400

J 580 680 680 680 760 760

1 G 3/4 G 3/4 G1 G1 G1 G1

2 G1 G1 G1 G 5/4 G 5/4 G 5/4

3 G 3/4 G 3/4 G 3/4 G 3/4 G 3/4 G 3/4

4 G1 G1 G1 G 5/4 G 5/4 G 5/4

5 G 3/4 G 3/4 G1 G1 G1 G1

Sl. 1: Priključne in montažne mere hranilnika [mm]

3

2

1

C D

B

A

LEGENDA

1 Dotok hladne vode

2 Izstop medija iz prenosnika toplote

3 Cirkulacijski vod

4 Vstop medija v prenosnik toplote

5 Odtok tople vode

3

518375

I

I

SL

øJ

5

4

H

G

C D

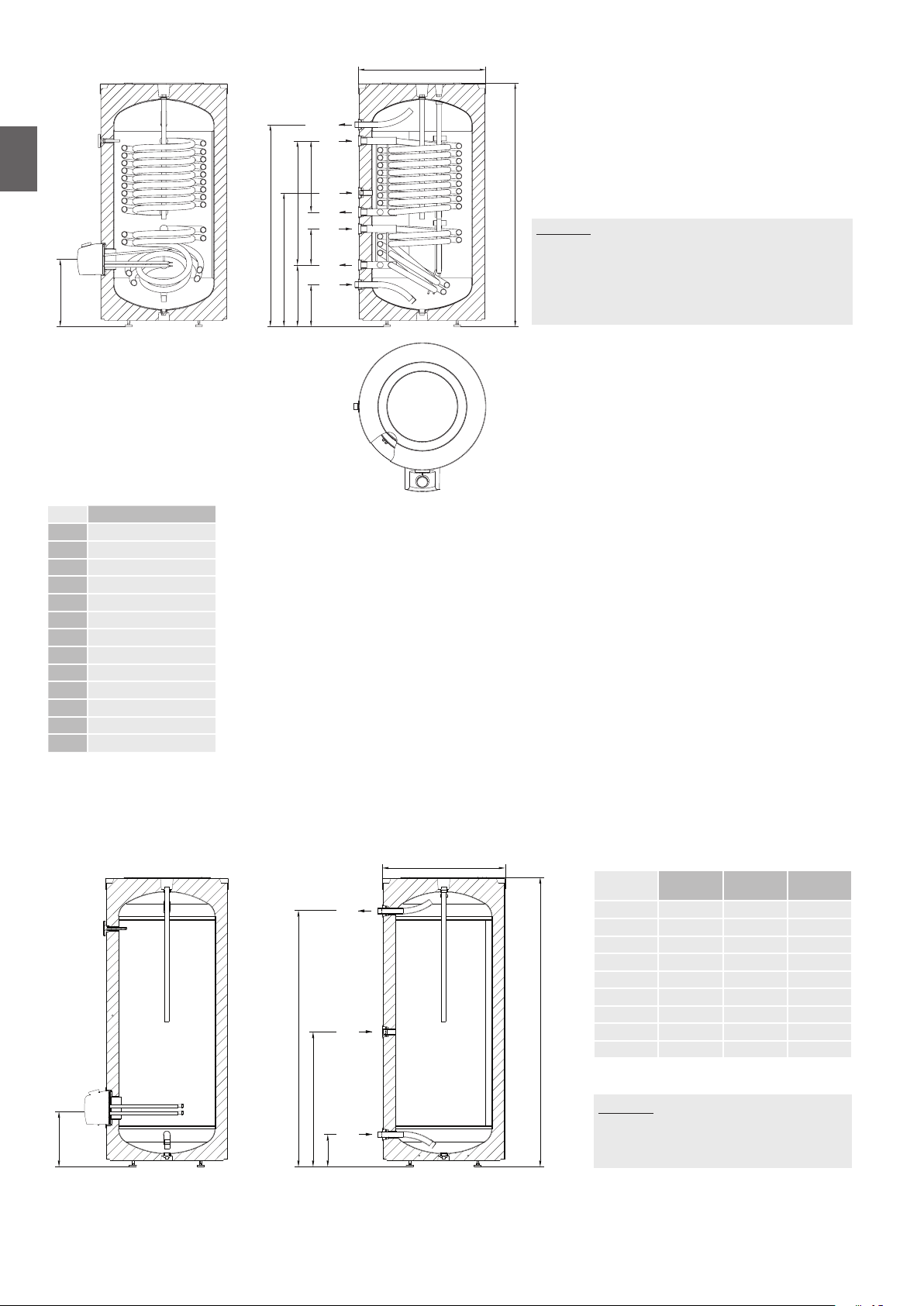

VLG 300 C1-2G

A 1445

B 250

C 370

D 740

G 800

H 1205

I 400

J 760

1 G1

2 G5/4

3 G 3/4

4 G5/4

5 G1

Sl. 2: Priključne in montažne mere hranilnika [mm]

225 425

B

3

2

4

A

LEGENDA

1 Dotok hladne vode

2

1

2 Izstop medija iz prenosnika toplote

3 Cirkulacijski vod

4 Vstop medija v prenosnik toplote

5 Odtok tople vode

518375

øJ

VLG 200

A-G

5

A [mm] 1535 1590 1915

VLG 300

B-G

VLG 400

B-G

B [mm] 180 175 250

G [mm] 780 740 990

H [mm] 1355 1410 1675

I [mm] 365 320 400

J [mm] 580 680 760

H

3

A

1 G 3/4 G1 G1

3 G 3 /4 G 3/4 G 3/4

5 G 3 /4 G1 G1

G

1

B

LEGENDA

1 Dotok hladne vode

3 Cirkulacijski vod

5 Odtok tople vode

4

PRIKLJUČITEV NA VODOVODNO OMREŽJE

765ba43218

Priključitev na vodovodno omrežje napravite po označbah za priključke iz predhodnega poglavja.

Na dotočno cev je zaradi zagotavljanja varnosti pri delovanju hranilnika potrebno vgraditi varnostni ventil ali varnostno grupo,

ki preprečuje zvišanje tlaka v kotlu za več kot 0,1 MPa (1 bar) nad nazivnim. Iztočna odprtina na varnostnem ventilu mora imeti

obvezno izhod na atmosferski tlak. Pri segrevanju vode v hranilniku se tlak vode v kotlu zvišuje do meje, ki je nastavljena v

varnostnem ventilu. Ker je vračanje vode nazaj v vodovodno omrežje preprečeno, lahko pride do kapljanja vode iz odtočne

odprtine varnostnega ventila. Kapljajočo vodo lahko speljete v odtok preko lovilnega nastavka, ki ga namestite pod varnostni ventil.

Odtočna cev nameščena pod izpustom varnostnega ventila mora biti nameščena v smeri naravnost navzdol in v okolju, kjer ne

zmrzuje.

V primeru, da se želite izogniti kapljajoči vodi iz varnostnega ventila, morate na dotočno cev hranilnika vgraditi ekspanzijsko

posodo za sanitarno vodo volumna najmanj 5% volumna hranilnika.

Za pravilno delovanje varnostnega ventila je potrebno periodično izvajati kontrole, da se odstrani vodni kamen in se preveri, da

varnostni ventil ni blokiran. Ob preverjanju morate s premikom ročke ali odvitjem matice ventila (odvisno od tipa ventila) odpreti

iztok iz varnostnega ventila. Pri tem mora skozi iztočno odprtino ventila priteči voda, kar je znak, da je ventil brezhiben.

LEGENDA

1 Izpustni ventil

2 Ekspanzijska posoda

3 Varnostni ventil

a - Preizkusni ventil

b - Nepovratni ventil

4 Lijak s priključkom na odtok

5 Preizkusni nastavek

6 Redukcijski ventil tlaka

T

H

7 Zaporni ventil

8 Tlačne mešalne baterije

SL

H Hladna voda

T Topla voda

Sl. 3: Zaprti (tlačni) sistem

Hranilnik lahko priključite na hišno vodovodno omrežje brez regulatorja tlaka, če je tlak v omrežju nižji od nazivnega tlaka (glejte

napisno tablico). Če tlak v omrežju presega nazivni tlak, je potrebno obvezno vgraditi regulator tlaka.

5

518375

PRIKLJUČITEV NA ELEKTRIČNO OMREŽJE

L

230 V~

3F Y 230 V~

N

2

L3

N

L1

L2

Pred priključitvijo v električno omrežje je potrebno v hranilnik vgraditi priključno vrvico minimalnega preseka vsaj 1,5 mm2

(H05VV-F 3G 1,5 mm2) za 3kW grelo, v primeru 6kW grela (H05VV-F 5G 2,5 mm2), zato morate odstraniti zaščitni pokrov.

To storite tako, da najprej izvlečete gumb, ki je vstavljen na os termostata in odvijete vijaka.

SL

Priprava za ločitev vseh polov mora biti vgrajena v električni inštalaciji v skladu z nacionalnimi inštalacijskimi predpisi.

Sl. 4: Odstranitev pokrova grelca

1

1

Sl. 5: Sheme električnih vezav

STB

TR

ΔT

+°C

+°C

A

B

2

STB

TR

ΔT

+°C

+°C

A1

A2

A3 B3

R1 R2

3

R3

1

2

LEGENDA

R1 R2

1 Priključna sponka

2 Termostat in dvopolna oz. tripolna varovalka

B1

B2

R3 R4 R5 R6

3

3 Grelec

L Fazni vodnik

L1 Fazni vodnik

L2 Fazni vodnik

L3 Fazni vodnik

N Nevtralni vodnik

Zaščitni vodnik

518375

6

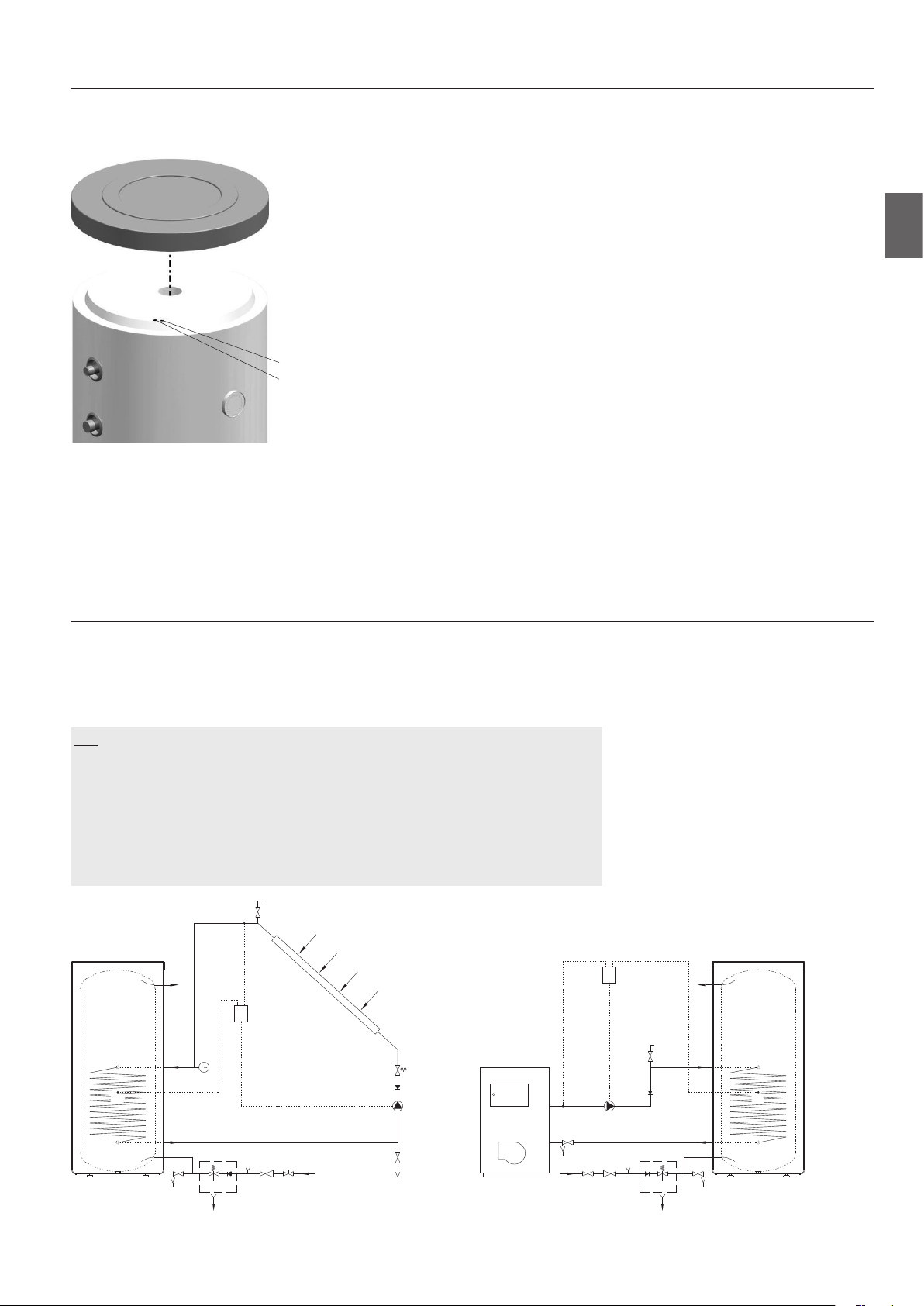

NAMESTITEV TIPAL

Na zgornji strani hranilnika pod pokrovom sta nameščeni dve cevi za tipala, kjer se lahko vstavijo tipala za regulacijo sistemske

povezave hranilnika tople vode z drugimi viri ogrevanja. Maksimalni premer tipal je 8 mm.

Daljša cev za tipalo (spodnja pozicija kotla)

Krajša cev za tipalo (zgornja pozicija kotla)

Sl. 6: Namestitev tipal

OPOZORILO: Pred vsakim posegom v njegovo notranjost morate hranilnik obvezno izključiti iz električnega

omrežja! Poseg lahko izvede le usposobljen strokovnjak!

SL

PRIKLJUČITEV NA DRUGE VIRE OGREVANJA

Hranilnik tople vode omogoča pripravo sanitarne vode preko izmenjevalca toplote z različnimi viri energije (npr. centralno

ogrevanje, sončna energija, ...).

Primera povezave hranilnika tople vode z različnimi viri ogrevanja sta prikazana na skicah.

LEGENDA

1 Hranilnik tople vode

2 Kotel centralnega ogrevanja

3 Sprejemnik sončne energije

4 Diferenčni termostat s tipali

(T1, T2, T3, T4)

5 Obtočna črpalka

6 Ekspanzijska posoda

7 Protipovratni ventil

1

6

T

1

9

T

2

3

4

8 Varnostni ventil

9 Ventil za odzračevanje

10 Ventil za polnjenje in praznjenje sistema

11 Reducirni ventil

12 Izpustni ventil

13 Zaporni ventil

14 Preizkusni nastavek

15 Lijak s priključkom na odtok

8

7

5

2

T

4

9

7

3

12

5

1

T

1

12 8 7

15

14 11 13

10

141113

12

87

15

Sl. 7: Povezava s sprejemniki sončne energije Sl. 8: Povezava s kotlom centralnega ogrevanja

7

518375

UPORABA IN VZDRŽEVANJE

Po priključitvi na vodovodno in električno omrežje ter druge vire ogrevanja je hranilnik tople vode pripravljen za uporabo. Običajno

je osnovni vir za ogrevanje sanitarne vode centralno ogrevanje ali sončna energija, pri čemer je regulacija ogrevanja tople vode

izvedena v sistemu ogrevanja.

SL

Vgradni električni grelec je namenjen le za dodatno ogrevanje vode. Temperaturo nastavljate z vrtenjem gumba v smeri urinega

kazalca na želen temperaturni nivo.

- Zaščita proti zmrzovanju, temperatura približno 10 °C.

- Temperatura vode približno 35 °C.

- Temperatura vode približno 55 °C.

- Temperatura vode približno 85 °C.

Termometer prikazuje temperaturo na mestu vgradnje, medtem ko z vrtenjem gumba na termostatu nastavljate temperaturo vode

v spodnjem delu hranilnika. Zato se ti dve temperaturi lahko razlikujeta.

Kadar obstaja nevarnost, da bo voda v hranilniku zmrznila, jo morate iz njega iztočiti. Voda iz hranilnika se izprazni skozi dotočno

cev hranilnika. V ta namen je priporočljivo ob vgradnji med varnostni ventil in dotočno cev namestiti poseben T-člen z izpustnim

ventilom. Pred praznjenjem je hranilnik potrebno izključiti iz električnega omrežja, zapreti dovod hladne vode v hranilnik, odpreti

ročico za toplo vodo na priključeni mešalni bateriji in počakati da se voda v hranilniku ohladi. Po izpraznitvi vode skozi dotočno cev,

v hranilniku ostane manjša količina vode.

Zunanjost hranilnika čistite z mehko krpo in blagimi tekočimi čistili. Ne uporabljajte čistil, ki vsebujejo alkohol ali abrazivna sredstva.

Z rednimi servisnimi pregledi boste zagotovili brezhibno delovanje in dolgo življenjsko dobo hranilnika. Garancija za prerjavenje

kotla velja le, če ste izvajali predpisane redne preglede izrabljenosti zaščitne anode. Obdobje med posameznimi rednimi pregledi ne

sme biti daljše kot je navedeno v garancijski izjavi. Pregledi morajo biti izvedeni s strani pooblaščenega serviserja, ki Vam pregled

evidentira na garancijskem listu proizvoda. Ob pregledu preveri izrabljenost protikorozijske zaščitne anode in po potrebi očisti

vodni kamen, ki se glede na kakovost, količino in temperaturo porabljene vode nabere v notranjosti hranilnika. Servisna služba vam

bo po pregledu hranilnika glede na ugotovljeno stanje priporočila tudi datum naslednje kontrole.

Prosimo Vas, da morebitnih okvar na hranilniku ne popravljate sami, ampak o njih obvestite najbližjo pooblaščeno

servisno službo.

518375

8

TEHNIČNE LASTNOSTI APARATA

Tip *

Razred energijske učinkovitosti

Lastna izguba S

2)

VLG 200

A1-1G

1)

C B C C B B B

[W] 70,8 58,3 88,8 88,8 68 68 71,9

VLG 200

A3-1G

VLG 300

B1-1G

VLG 300

B2-1G

VLG 300

C1-1G

VLG 300

C1-2G

VLG 400

C1-1G

Prostornina za shranjevanje [l] 184 190,3 275,5 262 283,7 283,7 396

Nazivni tlak [MPa (bar)] 0,6 (6); 0,9 (9); 1,0 (10)

Masa / napolnjen z vodo [kg] 97 / 281 115 / 305 140 / 416 165 / 427 165/449 170/454 230/626

Protikorozijska zaščita kotla

Emajlirano / Mg anoda

• / • • / • • / • • / • • / • • / • • / •

Razred zaščite I

Stopnja zaščite IP24

Površina prenosnika toplote [m2] 2,0 2,3 2,5 4,0 3,45 1,05 + 2,4 6,15

Temperatura grelnega medija v

prenosniku toplote

[°C] < 95

Debelina izolacije [mm] 60 110 67 67 75 75 75

Toplotne izgube

2)

[kWh/24h] 1,7 1,4 2,1 2,1 1,6 1,6 1,7

Maksimalni premer tipal [mm] ø8

* Če v tipski oznaki ni črke G, je aparat brez električnega grelca.

1)

Uredba komisije EU 812/2013

2)

Testirano po EN 12897:2006

Model

VLG 200

A1-1G3

VLG 200

A3-1G3

VLG 300

B1-1G3

VLG 300

B2-1G3

VLG 300

B1-1G6

VLG 300

B2-1G6

Priključna moč [W] 3000 6000

Napetost [V~] 230 400

Model

VLG 300

C1-1G3

VLG 300

C1-2G3

VLG 400

C1-1G3

VLG 300

C1-1G6

VLG 300

C1-2G6

VLG 400

C1-1G6

Priključna moč [W] 3000 6000

Napetost [V~] 230 400

SL

Tip

Profil rabe

Razred energijske učinkovitosti

1)

Energijska učinkovitost ogrevanja vode ƞwh

Letna poraba električne energije

Dnevna poraba električne energije

1)

2)

Nastavitev temperature termostata

Morebitni varnostni ukrepi

(sestava, nameščanje, vzdrževanje)

Vrednost smart

Prostornina za shranjevanje V

Mešana voda pri 40°C V40

2)

Nazivni tlak

Masa / napolnjen z vodo

Protikorozijska zaščita kotla

Emajlirano / Mg anoda

Razred zaščite

Stopnja zaščite

Debelina izolacije

Toplotne izgube

3)

Čas segrevanja od 10 do 65 °C

1)

Uredba komisije EU 812/2013; EN 50440

2)

EN 50440

3)

Testirano po SIST EN 60379:2005

Model

Priključna moč

Napetost

VLG 200 A-G VLG 300 B-G VLG 400 C-G

XL XL XL

C C C

1)

[%] 38,1 38,0 38,1

[kWh] 4399 4412 4400

[kWh] 20,317 20,397 20,328

"eco" "eco" "eco"

Pri tlačni priključitvi obvezna uporaba varnostnega ventila

0 0 0

[l] 203 319 449

[l] 305 508 712

[MPa (bar)] 0,6 (6); 0,9 (9); 1,0 (10)

[kg] 63/265 97/397 230/626

• / • • / • • / •

I

IP24

[mm] 60 67 75

[kWh/24h] 1,7 2,1 1,7

[h] 4

25

56

6

VLG 200 A-G3 VLG 300 B-G3 VLG 400 C-G6

[W] 3000 6000

[V~] 230 400

53

4

PRIDRŽUJEMO SI PRAVICO DO SPREMEMB, KI NE VPLIVAJO NA FUNKCIONALNOST APARATA.

Navodila za uporabo so na voljo tudi na naših spletnih straneh http://www.gorenje.com.

9

518375

WARNINGS

The appliance may be used by children aged 8 and older and persons with physical, sensory or mental

disabilities or lacking experience or knowledge, if they are under supervision or taught about safe use of the

appliance and if they are aware of the potential dangers.

Children should not play with the appliance.

Children should not clean or maintain the appliance without supervision

EN

The installation should be performed in accordance with the valid regulations and the instructions of the

manufacturer. It should be performed by a professionally trained installation expert.

It is obligatory to install a safety valve with a rated pressure of 0.6 MPa (6 bar), 0.9 MPa (9 bar) or 1.0 MPa (10

bar) – see the label - on the inlet pipe of the hot water storage tank to prevent the elevation of pressure in the

tank by more than 0.1 MPa (1 bar) above the rated pressure.

Water may drip from the outlet opening of the safety valve, so the outlet opening should be set to atmospheric

pressure.

The outlet of the safety valve should be installed facing downwards and in a non-freezing area.

To ensure proper functioning of the safety valve, the user should perform regular controls to remove limescale

and make sure the safety valve is not blocked.

Do not install a stop valve between the hot water storage tank and the safety valve, because it will impair the

pressure protection of the storage tank!

Before connecting the heater to the power supply, the storage tank must be filled with water!

The storage tank is protected in case of failure of the operating thermostat with an additional thermal cut-out.

In case of thermostat failure water in the storage tank may reach the temperature of up to 130°C in accordance

with safety standards. The possibility of such temperature overload should be taken into consideration in the

execution of plumbing.

Should you choose to disconnect the power, the storage tank should be drained thoroughly before the onset of

freezing conditions.

Water from the storage tank is drained through the inlet pipe of the tank. For this purpose, a special fitting

(T-fitting) with an outlet valve must be mounted between the safety valve and the inlet pipe.

Please do not try to fix any defects of the storage tank on your own. Call the nearest authorised service provider.

518375

Our products incorporate components that are both environmentally safe and harmless to health, so they can

be disassembled as easily as possible and recycled once they reach their final life stage.

Recycling of materials reduces the quantity of waste and the need for production of raw materials (e.g. metals)

which requires a substantial amount of energy and causes release of harmful substances. Recycling procedures

reduce the consumption of natural resources, as the waste parts made of plastic and metal can be returned to

various production processes.

For more information on waste disposal, please visit your waste collection centre or the store where the

product was purchased

10

øJ

I

Dear buyer, thank you for purchasing our product.

PRIOR TO THE INSTALLATION AND FIRST USE OF THE HOT WATER STORAGE

TANK, PLEASE READ THESE INSTRUCTIONS CAREFULLY.

This storage tank has been manufactured in compliance with the relevant Standards and tested by the relevant authorities as

indicated by the Safety Certificate and the Electromagnetic Compatibility Certificate. The technical characteristics of the product

are listed on the label attached to the protective cover.

The connection of the storage tank to the plumbing and power networks must be carried out by qualified staff only. All repairs

and maintenance work in the interior of the storage tank, as well as limestone removal or testing or replacement of the corrosion

protection anode, may only be carried out by an approved maintenance service provider.

The hot water storage tank is designed in a manner which allows using the following heating sources, via a heat exchanger:

• Central heating hot-water system,

• Solar power,

• Heating pump.

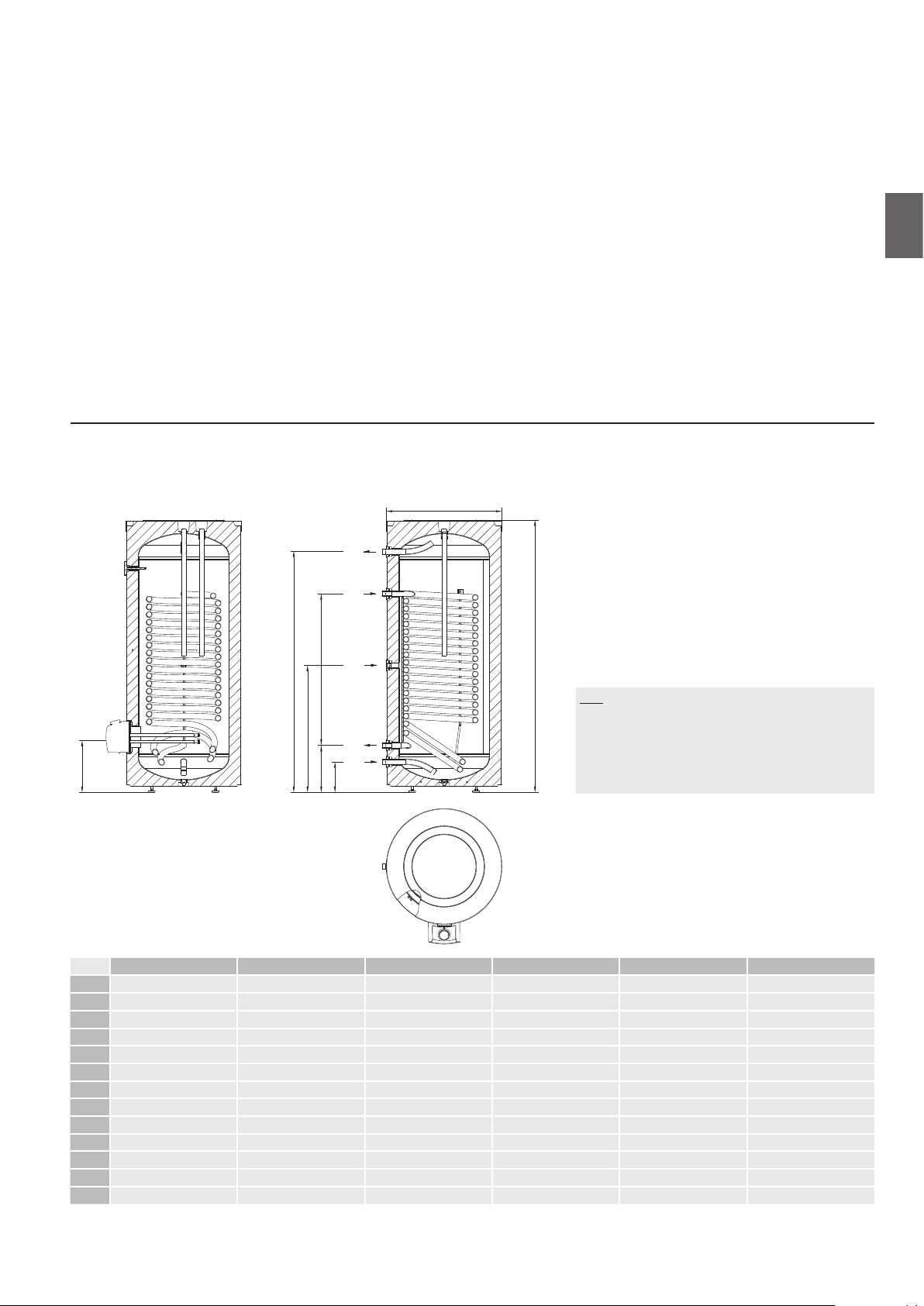

INSTALLATION

The heater should be installed in a dry room that is not subject to freezing conditions, preferably in the vicinity of other sources

of heating (e.g. boiler room). Prior to installation screw on the enclosed adjustable legs. Level the storage tank longitudinally and

transversally by rotating the adjustable legs.

5

4

H

3

A

EN

KEY

G

2

1

C D

B

VLG 200 A1-1G VLG 200 A3-1G VLG 300 B1-1G VLG 300 B2-1G VLG 300 C1-1G VLG 400 C1-1G

A 1535 1675 1590 1590 1445 1915

B 180 220 175 175 250 250

C 300 340 270 270 370 370

D 880 1015 890 890 610 1070

G 780 945 740 740 800 990

H 1355 1435 1410 1410 1205 1675

I 365 405 320 340 400 400

J 580 680 680 680 760 760

1 G 3/4 G 3/4 G1 G1 G1 G1

2 G1 G1 G1 G 5/4 G 5/4 G 5/4

3 G 3/4 G 3/4 G 3/4 G 3/4 G 3/4 G 3/4

4 G1 G1 G1 G 5/4 G 5/4 G 5/4

5 G 3/4 G 3/4 G1 G1 G1 G1

Image 1: Connection and installation dimensions of the storage tank [mm]

1 Cold water inflow

2 Medium outlet from the heat exchanger

3 Circulation conduit

4 Medium inflow into the heat exchanger

5 Hot water outflow

11

518375

øJ

I

I

5

4

3

2

4

225 425

2

1

C D

B

EN

H

G

VLG 300 C1-2G

A 1445

B 250

C 370

D 740

G 800

H 1205

I 400

J 760

1 G1

2 G5/4

3 G 3/4

4 G5/4

5 G1

Image 2: Connection and installation dimensions of the storage tank [mm]

A

KEY

1 Cold water inflow

2 Medium outlet from the heat exchanger

3 Circulation conduit

4 Medium inflow into the heat exchanger

5 Hot water outflow

518375

øJ

VLG 200

A-G

5

A [mm] 1535 1590 1915

VLG 300

B-G

VLG 400

B-G

B [mm] 180 175 250

G [mm] 780 740 990

H [mm] 1355 1410 1675

I [mm] 365 320 400

J [mm] 580 680 760

H

3

A

1 G 3/4 G1 G1

3 G 3 /4 G 3/4 G 3/4

5 G 3 /4 G1 G1

G

1

B

KEY

1 Cold water inflow

3 Circulation conduit

5 Hot water outflow

12

CONNECTION TO THE WATER SUPPLY

765ba43218

Connection to water supply should be made according to the markings for the connections, as defined in the previous Chapter.

For safety reasons the supply pipe must be fitted with a safety valve or, alternatively, a valve of the safety class that prevents the

pressure in the tank from exceeding the nominal pressure by more than 0.1 MPa (1 bar). The outlet opening on the safety valve

must be equipped with an outlet for atmospheric pressure. The heating of water in the storage tank causes the pressure in the tank

to increase to the level set by the safety valve. As the water cannot return to the water supply system, this can result in dripping

from the outlet opening of the safety valve. The drip can be piped to a drain by installing a catching unit just below the safety

valve. The drain installed below the safety valve outlet must be piped down vertically and placed in an environment that is free

from the onset of freezing conditions.

In case you want to avoid water dripping from the safety valve, an expansion tank for domestic water with at least 5 % of the

volume of the storage tank should be installed on the inlet pipe of the storage tank.

To ensure proper functioning of the safety valve, the user should perform regular controls to remove limescale and make sure the

safety valve is not blocked. To check the valve, open the outlet of the safety valve by turning the handle or unscrewing the nut of the

valve (depending on the type of valve). The valve is operating properly if the water comes out of the nozzle when the outlet is open.

KEY

1 Drain valve

2 Expansion tank

3 Safety valve

a - Test valve

b - Non-return valve

4 Funnel outlet to the drain

5 Test unit

6 Pressure-reducing valve

T

H

7 Stop valve

8 Pressure mixer taps

EN

H Cold water

T Hot water

Image 3: Closed (pressure) system

The storage tank can be connected to the domestic water supply network without a pressure regulator if the pressure in the

network is lower than the nominal pressure (see the label). If the pressure in the network exceeds the nominal pressure, a pressure

regulator must be installed.

13

518375

CONNECTION TO THE POWER SUPPLY NETWORK

L

230 V~

3F Y 230 V~

N

2

L3

N

L1

L2

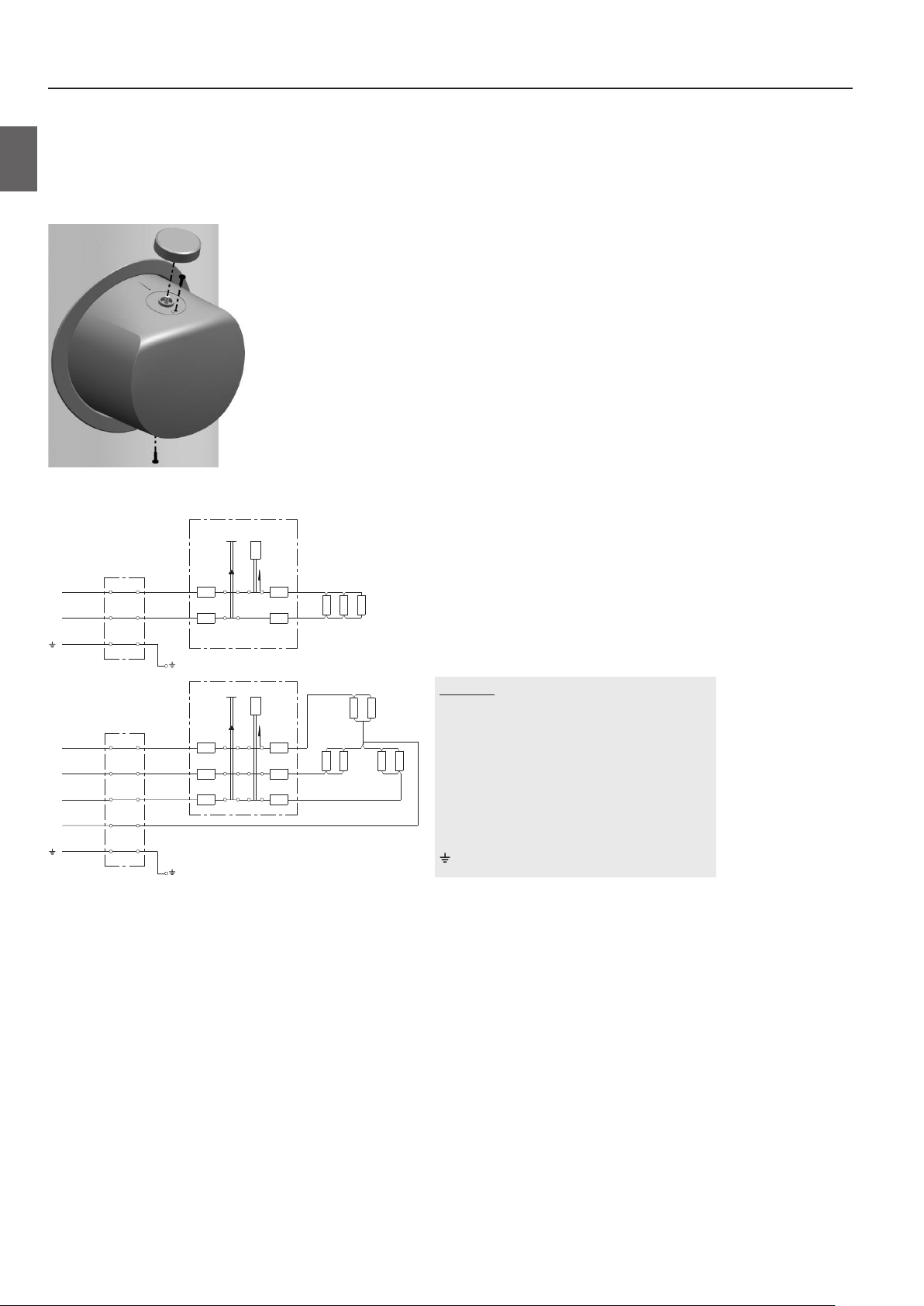

Before connecting the storage tank to the power supply network, a connection cable with a minimum cross-section of at least

1.5 mm2 (H05VV-F 3G 1.5 mm2) for a 3kW-heating element and 2.5 mm2 for a 6kW-heating element (H05VV-F 5G 2,5 mm2) must be

installed in it and the protection cover must be removed.

This is done by pulling out the knob on the thermostat axis and unscrewing two screws.

An all-pole disconnect device must be installed in the electric installation to comply with the National Installation Regulations.

EN

Image 4: Removal of heater cover

STB

ΔT

1

1

+°C

A

B

2

STB

ΔT

+°C

A1

A2

A3 B3

Image 5: Schemes of electric installations

TR

+°C

TR

+°C

R1 R2

3

R3

1

2

KEY

1 Connection terminal

R1 R2

2 A thermostat and a bipolar or tripolar thermal

cut-out

B1

B2

R3 R4 R5 R6

3

3 Heater

L Live conductor

L1 Live conductor

L2 Live conductor

L3 Live conductor

N Neutral conductor

Earthing conductor

518375

14

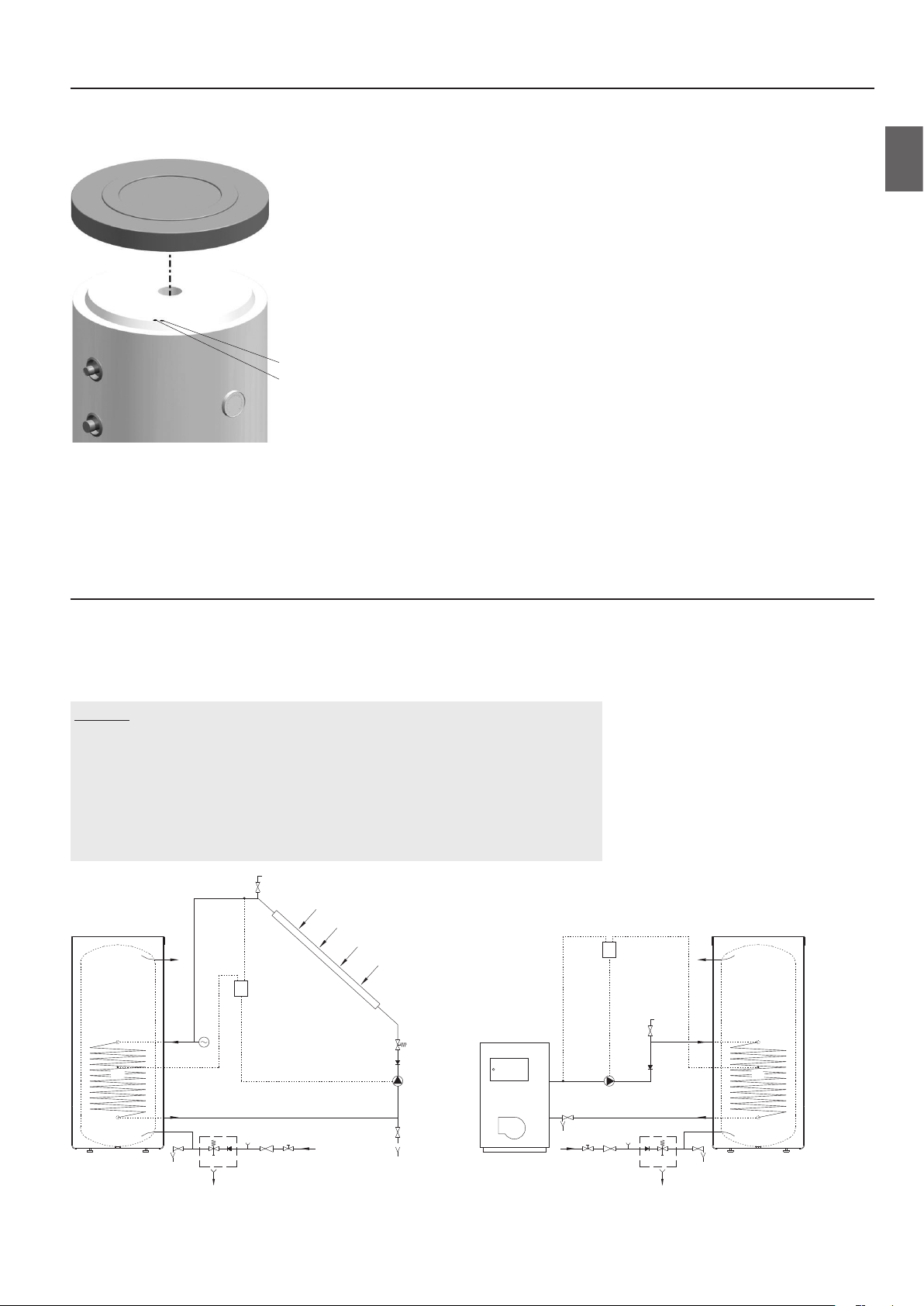

INSTALLATION OF SENSORS

On the upper side of the storage tank there are two sensor tubes for mounting the sensors for regulation of the system connection

of the hot water storage tank to other heating sources. The maximum diameter of the sensors is 8 mm.

Long sensor tube (lower tank position)

Short sensor tube (upper tank position)

Image 6: Installation of sensors

WARNING: Before any intervention into the interior of the storage tank disconnect it from the power supply! All

interventions must be carried out by qualified staff only!

EN

CONNECTION TO ALTERNATIVE

SOURCES OF HEATING

The hot water storage tank enables the water for sanitary use to be heated by alternative sources of energy (e.g. central heating,

solar power etc.) by installing a Heat Exchanger.

Examples of connecting the hot water storage tank to various sources of heating are shown in the drawings below.

KEY

1 Hot water storage tank

2 Central heating hot-water system

3 Solar panel

4 Differential thermostat with sensors

(T1, T2, T3, T4)

5 Bypass pump

6 Expansion tank

7 Non-return valve

9

T

2

3

1

4

8 Safety valve

9 Air relief valve

10 Fill/drain valve

11 Reduction valve

12 Drain valve

13 Stop valve

14 Test unit

15 Funnel outlet to the drain

4

1

8

6

T

1

12 8 7

Image 7: Connection to solar panels Image 8: Connection to the central heating hot-water system

14 11 13

15

7

5

10

2

T

3

12

9

7

5

141113

12

87

15

T

1

15

518375

USE AND MAINTENANCE

The hot water storage tank is ready for use once it has been connected to water and electricity and other heating sources. The

usual main sources for heating domestic water are central heating or solar power; in this case any regulation of water heating is

performed in the heating system.

The built-in electric heating element is designed for backup heating of water only. The temperature is set by turning the knob in a

clockwise direction to reach the desired temperature level.

- Protection against freezing, temperature around 10 °C.

EN

- Water temperature around 35 °C.

- Water temperature around 55 °C.

- Water temperature around 85 °C.

The thermometer shows the in-situ temperature, whereas by turning the knob on the thermostat the water temperature in the

lower part of the storage tank is set. Thus, these two temperatures may vary.

In case of exposure to sub-zero temperatures, the water should be drained from the storage tank thoroughly before the onset of

freezing conditions. Water from the storage tank is drained through the inlet pipe of the storage tank. For this purpose, a special

fitting (T-fitting) with an outlet valve must be mounted between the safety valve and the inlet pipe. Before discharge make sure the

storage tank is disconnected from the power supply, close the inlet of cold water into the storage tank, open the hot water tap on

the connected mixer tap and wait for the water in the storage tank to cool down. After discharging through the inlet pipe there is

still some water left in the storage tank.

The external parts of the water heater may be cleaned with a soft cloth and mild cleaning fluids. Do not use cleaning fluids

containing alcohol or abrasives.

Regular preventive maintenance inspections ensure faultless performance and long life of your storage tank. Tank Warranty is

subject to regular inspections of the wear of the protective anode. The period between individual regular inspections should not be

longer than specified in the Guarantee statement. Inspection should be carried out by an authorised maintenance service provider

recording the inspection on the Guarantee Certificate of the product. During the inspection, the wear of the corrosion protection

anode will be inspected and any limestone built up in the interior of the storage tank, depending on the quality, quantity and

temperature of used water, will be removed as required. After inspecting the storage tank, the maintenance service provider will

also recommend the date of the next inspection according to the ascertained status.

Please do not try to fix any defects of the storage tank on your own. Call the nearest authorised service provider.

518375

16

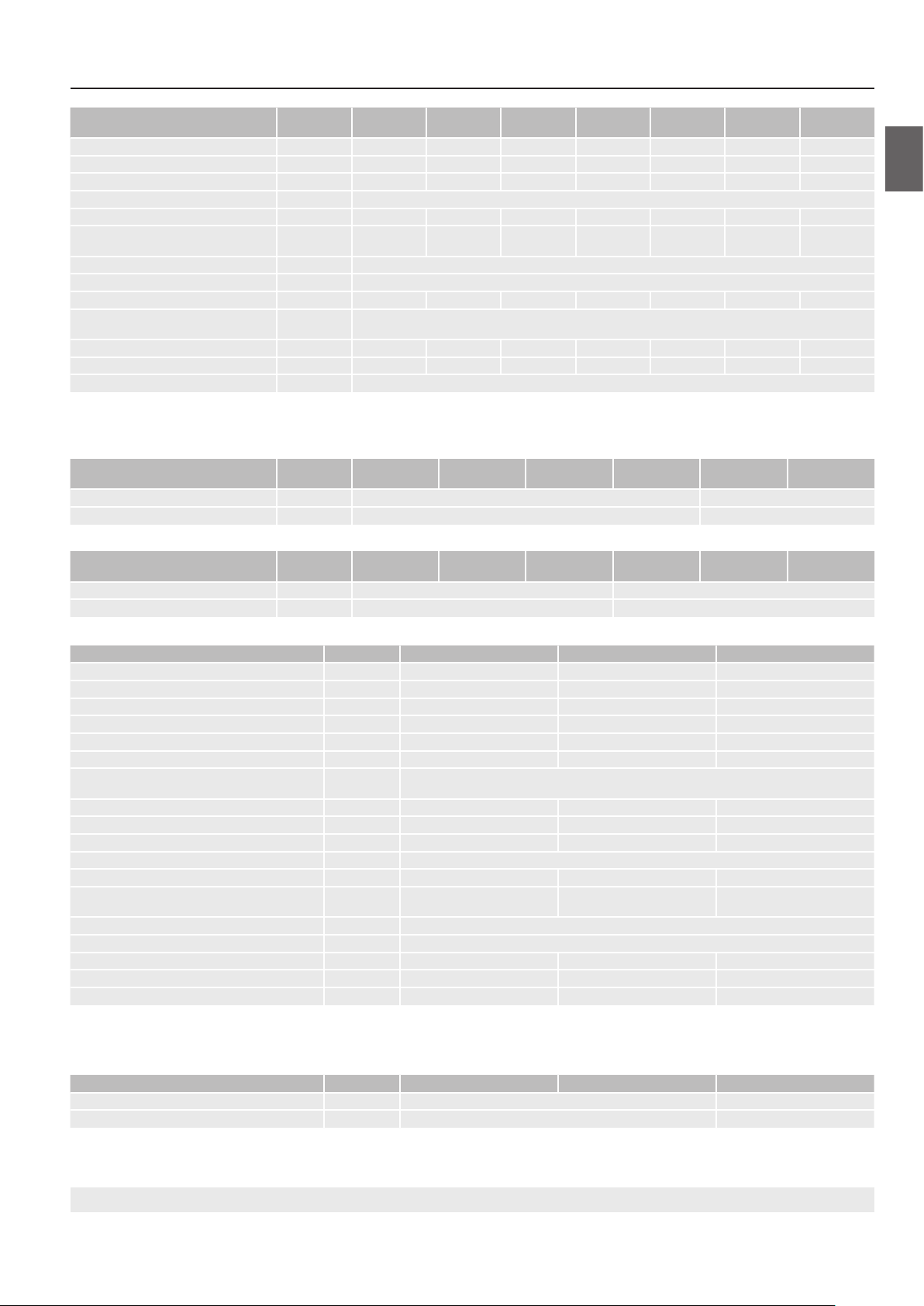

TECHNICAL CHARACTERISTICS OF THE APPLIANCE

Type *

Energy efficiency class

Standing loss S

2)

VLG 200

A1-1G

1)

C B C C B B B

[W] 70,8 58,3 88,8 88,8 68 68 71,9

VLG 200

A3-1G

VLG 300

B1-1G

VLG 300

B2-1G

VLG 300

C1-1G

VLG 300

C1-2G

VLG 400

C1-1G

Storage volume [l] 184 190,3 275,5 262 283,7 283,7 396

Rated pressure [MPa (bar)] 0,6 (6); 0,9 (9); 1,0 (10)

Weight/filled with water [kg] 97 / 281 115 / 305 140 / 416 165 / 427 165/449 170/454 230/626

Anti-corrosion protection of tank

Enamelled/Mg anode

• / • • / • • / • • / • • / • • / • • / •

Protection class I

Degree of protection IP24

Heat exchanger surface [m2] 2,0 2,3 2,5 4,0 3,45 1,05 + 2,4 6,15

Temperature of the heating medium

in the heat exchanger

[°C] < 95

Insulation thickness [mm] 60 110 67 67 75 75 75

Heat loss

2)

[kWh/24h] 1,7 1,4 2,1 2,1 1,6 1,6 1,7

Maximum diameter of sensors [mm] ø8

* If there is no letter G in the type designation, the appliance does not include the electric heater.

1)

Commission Regulation EU 812/2013

2)

Tested pursuant to EN 12897:2006

Model

VLG 200

A1-1G3

VLG 200

A3-1G3

VLG 300

B1-1G3

VLG 300

B2-1G3

VLG 300

B1-1G6

VLG 300

B2-1G6

Connected load [W] 3000 6000

Voltage [V~] 230 400

Model

VLG 300

C1-1G3

VLG 300

C1-2G3

VLG 400

C1-1G3

VLG 300

C1-1G6

VLG 300

C1-2G6

VLG 400

C1-1G6

Connected load [W] 3000 6000

Voltage [V~] 230 400

EN

Type

Use profile

Energy eciency class

1)

Energy eciency of water heating ƞwh

Annual electrical energy consumption

Daily electrical energy consumption

2)

Set thermostat temperature

Potential safety measures

(assembly, installation, maintenance)

Smart value

Storage volume

Mixed water at 40 °C V40 2)

Rated pressure

Weight/filled with water

Anti-corrosion protection of tank

Enamelled/Mg anode

Protection class

Degree of protection

Insulation thickness

Heat loss

3)

Heating time from 10 °C to 65 °C

1)

directive 812/2013; EN 50440

2)

EN 50440

3)

Tested pursuant to SIST EN 60379:2005

Model

Connected load

Voltage

VLG 200 A-G VLG 300 B-G VLG 400 C-G

XL XL XL

C C C

1)

1)

[%] 38,1 38,0 38,1

[kWh] 4399 4412 4400

[kWh] 20,317 20,397 20,328

"eco" "eco" "eco"

Compulsory use of a safety valve with the pressure connection.

0 0 0

[l] 203 319 449

[l] 305 508 712

[MPa (bar)] 0,6 (6); 0,9 (9); 1,0 (10)

[kg] 63/265 97/397 230/626

• / • • / • • / •

I

IP24

[mm] 60 67 75

[kWh/24h] 1,7 2,1 1,7

[h] 4

25

56

6

53

4

VLG 200 A-G3 VLG 300 B-G3 VLG 400 C-G6

[W] 3000 6000

[V~] 230 400

WE RESERVE THE RIGHT TO ANY MODIFICATIONS NOT AFFECTING THE FUNCTIONALITY OF THE APPLIANCE.

The instructions for use are also available on our website http://www.gorenje.com.

17

518375

518375

18

19

518375

VLG 200 - 400 05/2017

518375

Loading...

Loading...