Gorenje Aerogor ECO COMPACT INVERTER 13A, Aerogor ECO COMPACT INVERTER 10A, Aerogor ECO Inverter 13 A, Aerogor ECO Inverter 10 A, Aerogor POWER EVI Inverter 18 A Installation Manual

...Page 1

www.gorenje.com

V 2.0

Aerogor ECO Inverter 10A/13A

Aerogor ECO COMPACT Inverter 10A/13A

Aerogor POWER EVI Inverter 15A/18A

INSTALLATION MANUAL

Page 2

Page 3

TABLE OF CONTENTS

1 BEFORE USE ................................................................................................................ 1

1.1 WARNINGS ............................................................................................................ 1

1.2 DISPOSAL .............................................................................................................. 3

1.3 HEATING SYSTEM REQUIREMENTS (MANDATORY) ......................................... 3

1.4 INCLUDED IN THE PACKAGE ............................................................................... 4

1.5 TECHNICAL TABLE ................................................................................................ 5

1.5.1 AEROGOR ECO COMPACT INVERTER 10A, 13A ......................................... 5

1.5.2 AEROGOR ECO INVERTER 10A, 13A ............................................................ 6

1.5.3 AEROGOR POWER EVI INVERTER 15A, 18A ............................................... 7

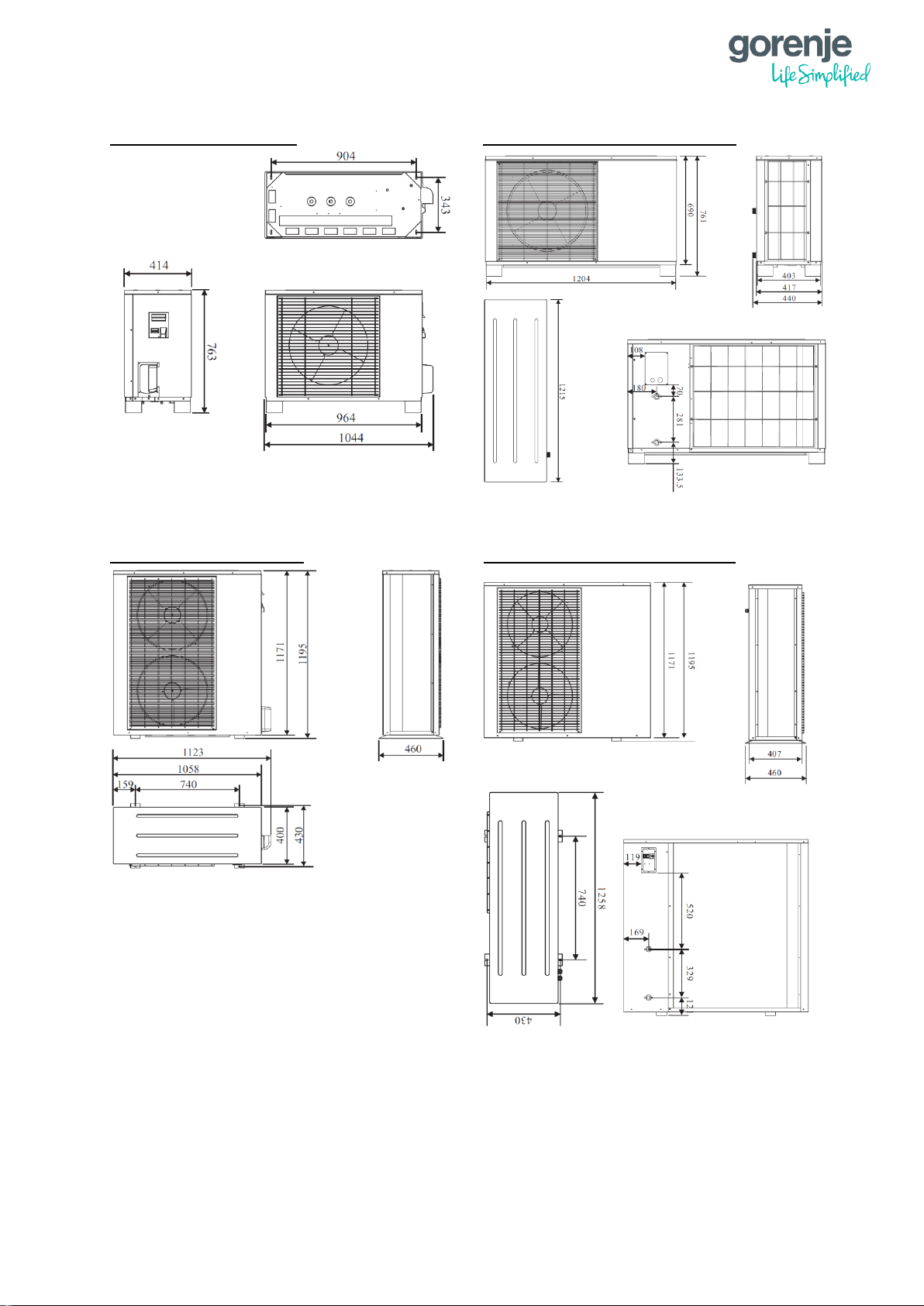

1.6 DIMENSIONS ......................................................................................................... 8

1.6.1 INDOOR UNITS ............................................................................................... 8

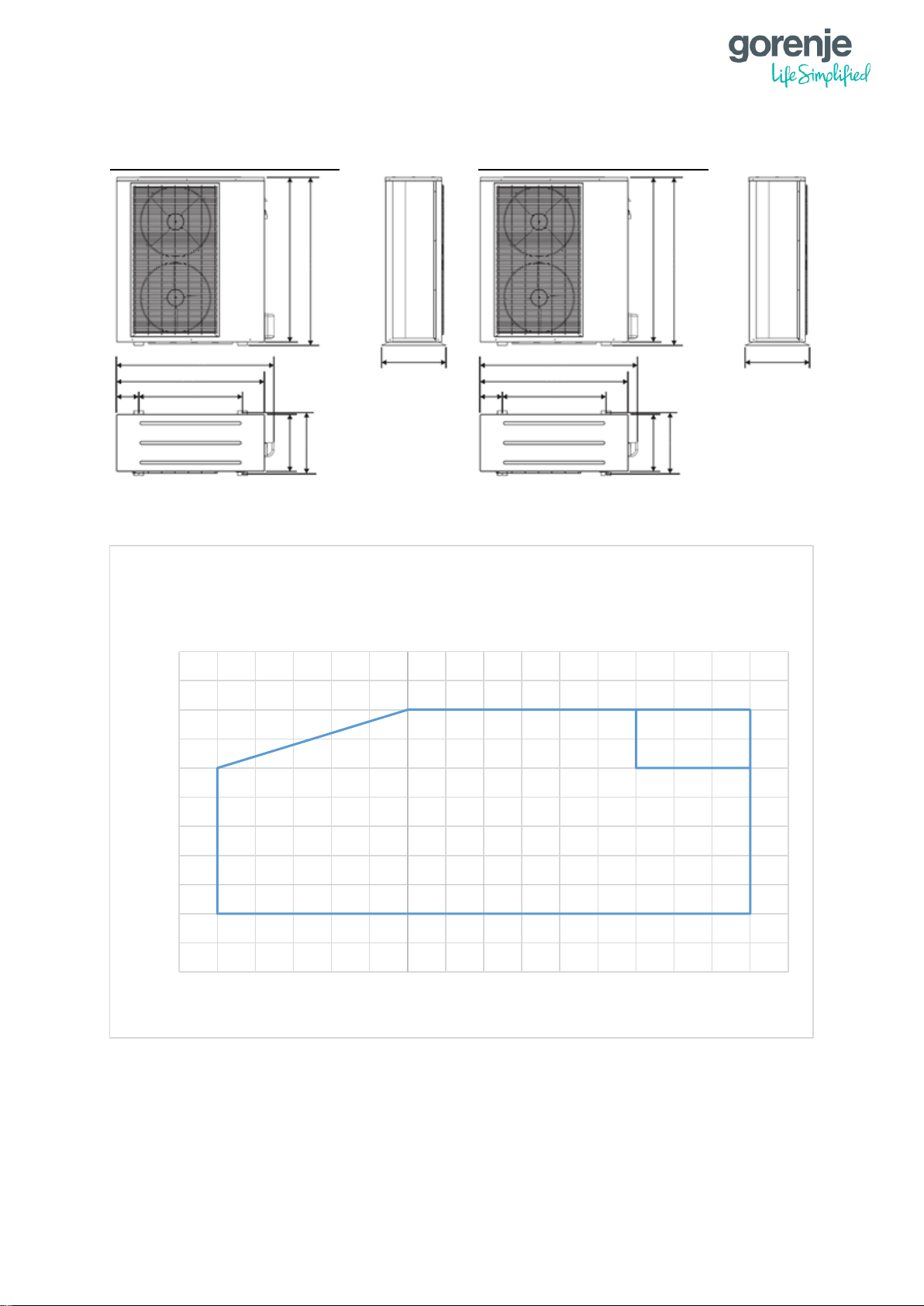

1.6.2 OUTDOOR UNITS ........................................................................................... 9

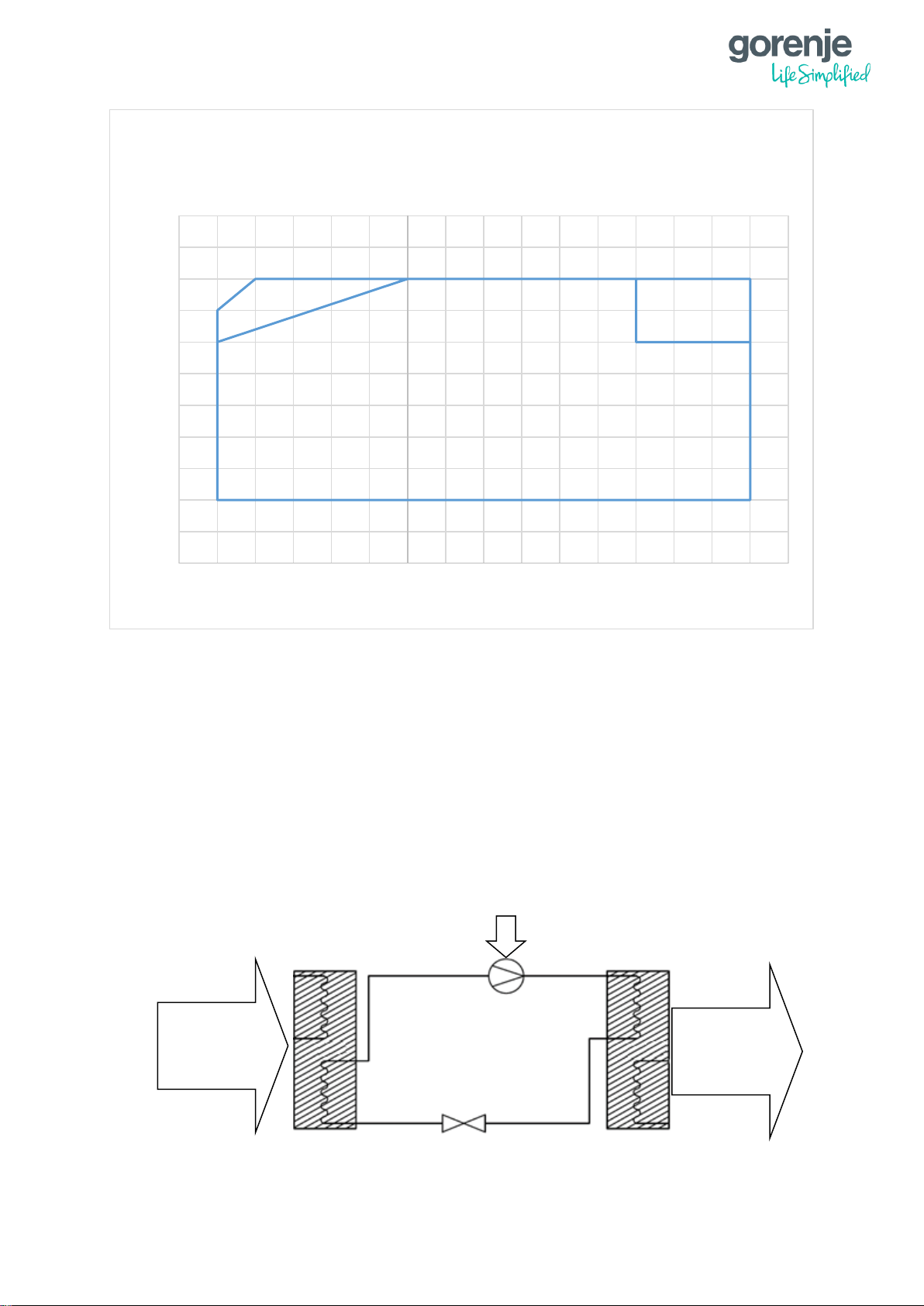

1.7 OPERATING RANGE ............................................................................................10

1.8 WORKING PRINCIPLE ..........................................................................................11

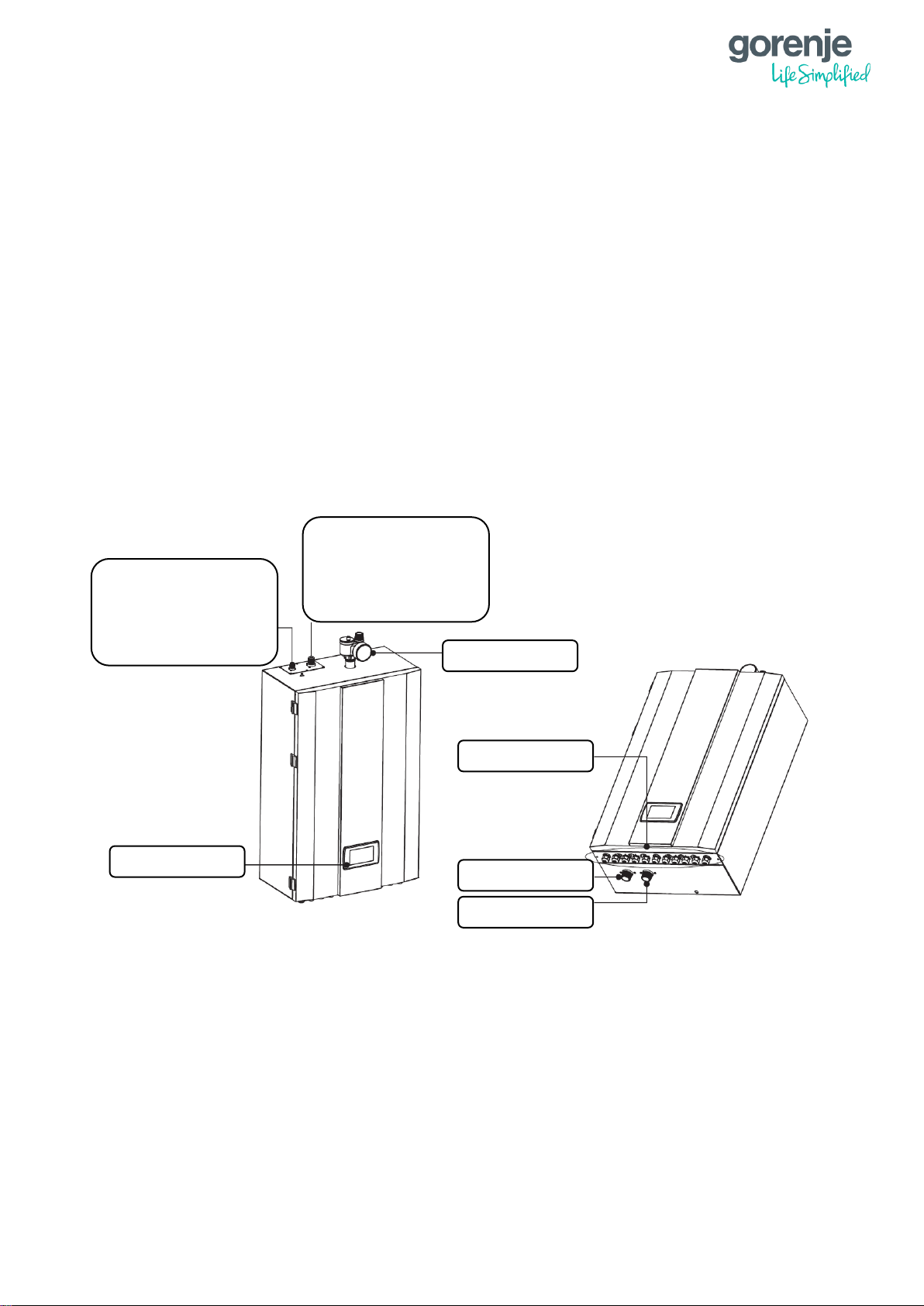

1.9 MAIN COMPONENTS ............................................................................................12

1.9.1 INDOOR UNITS ..............................................................................................12

1.9.2 OUTDOOR UNITS ..........................................................................................14

1.9.3 AEROGOR POWER EVI INVERTER 15A/ 18A ..............................................16

2 INSTALLATION .............................................................................................................17

2.1 INSTALLATION OF THE INDOOR UNIT ...............................................................17

2.2 INSTALLATION OF THE OUTDOOR UNIT............................................................18

2.3 FOUNDATION .......................................................................................................20

2.3.1 INSTALLATION OF C PROFILE AND LEGS ..................................................21

2.4 INSTALATION OF THE REFRIGERANT SYSTEM (SPLIT TYPE) .........................22

2.4.1 Height difference between indoor and outdoor unit .........................................24

2.5 INSTALATION OF HYDRAULIC CONNECTIONS (COMPACT TYPE) ..................26

3 ELECTRICAL WIRING ..................................................................................................27

3.1 AEROGOR ECO INVERTER 10A, 13A AND AEROGOR POWER EVI INVERTER

15A, 18A ...........................................................................................................................27

3.1.1 INDOOR UNIT ................................................................................................27

3.1.2 TEMPERATURE SENSORS ...........................................................................28

3.1.3 CONNECTION BETWEEN INDOOR AND OUTDOOR UNIT ..........................29

3.2 AEROGOR ECO COMPACT INVERTER 10A, 13A ...............................................30

3.2.1 INDOOR UNIT ................................................................................................30

Page 4

3.2.2 TEMPERATURE SENSORS ...........................................................................31

3.2.3 CONNECTION BETWEEN INDOOR AND OUTDOOR UNIT ..........................32

4 CONTROL UNIT ...........................................................................................................33

4.1 DESCRIPTION OF SYMBOLS ON THE CONTROL UNIT .....................................33

4.2 DESCRIPTION OF THE TEMPERATURES ON THE CONTROL UNIT .................36

5 QUICK SETTINGS ........................................................................................................37

5.1 PARALLEL MOVE OF THE HEATING CURVE ......................................................37

5.1.1 SETTING THE PARALLEL MOVE OF THE HEATING CURVE – HEATING

CIRCUIT 1 .....................................................................................................................37

5.1.2 SETTING THE PARALLEL MOVE OF THE HEATING CURVE – HEATING

CURVE 2.......................................................................................................................38

5.1.3 SETTING THE DHW TEMPERATURE ...........................................................38

5.2 SETTING THE FIXED TEMPERATURE OF HEATING CIRCUIT ...........................39

5.2.1 SETTING THE FIXED TEMPERATURE FOR THE FIRST HEATING CIRCUIT

39

5.2.2 SETTING THE FIXED TEMPERATURE FOR THE SECOND HEATING

CIRCUIT .......................................................................................................................39

6 USER INTERFACE .......................................................................................................40

6.1 ARRANGMENT OF MENUS ..................................................................................40

6.2 MENU ACCESS .....................................................................................................40

6.3 SETTINGS .............................................................................................................41

6.3.1 Heating/Cooling Circuit 1 .................................................................................41

6.3.2 Heating/Cooling circuit 2 .................................................................................45

6.4 DHW SETTINGS ....................................................................................................47

6.5 DHW STORAGE ....................................................................................................49

6.5.1 Sanitary Hot Water Storage Function ..............................................................50

6.5.2 Sanitary Hot Water Storage Timer ...................................................................50

6.5.3 Reheating Function .........................................................................................50

6.5.4 Reheating Function Timer ...............................................................................50

6.5.5 Reheating Set Temp. ......................................................................................50

6.5.6 Reheating Restart ∆T Setting ..........................................................................51

6.6 REDUCED SETPOINT ...........................................................................................51

6.6.1 Reduced Setpoint ............................................................................................51

6.6.2 Temp. Drop/Rise .............................................................................................51

6.6.3 Timer for Reduced Setpoint Function ..............................................................51

6.6.4 Quiet Operation ...............................................................................................52

6.6.5 Allowable Temp. Drifting .................................................................................52

6.6.6 Timer for Quiet Operation ................................................................................52

Page 5

6.7 ANTI – LEGIONELLA .............................................................................................52

6.7.1 Anti – Legionella Program ...............................................................................52

6.7.2 Day and Time ..................................................................................................53

6.7.3 Setpoint ...........................................................................................................53

6.7.4 Duration ..........................................................................................................53

6.7.5 Finish Time .....................................................................................................53

6.8 VACATION MODE .................................................................................................53

6.8.1 Vacation Mode ................................................................................................53

6.8.2 Sanitary Hot Water Temp. Drop during Vacation Mode ...................................54

6.8.3 Heating Water Temp. Drop during Vacation Mode ..........................................54

6.8.4 Vacation Start Date .........................................................................................54

6.8.5 Vacation Finish Date .......................................................................................54

6.9 USER MANAGEMENT ...........................................................................................54

6.9.1 Permission Level .............................................................................................54

6.9.2 Heating/Cooling ON/OFF timer .......................................................................54

6.9.3 Language ........................................................................................................55

6.9.4 Set Date and Time ................................................................ ..........................55

6.9.5 Distribution System Setting .............................................................................55

6.9.6 Save Current Settings .....................................................................................55

6.9.7 Load Saved Settings .......................................................................................55

6.9.8 Switch to Factory Settings ...............................................................................55

6.10 MODE SETTINGS..................................................................................................56

6.10.1 Sanitary Hot Water ..........................................................................................56

6.10.2 Heating............................................................................................................56

6.10.3 Cooling ................................................................ ............................................56

6.10.4 Basic Operation Modes ...................................................................................56

6.10.5 Cooling and Heating Switch ............................................................................57

6.10.6 Ambient Temp. To Start Heating .....................................................................57

6.10.7 Ambient Temp. To Start Cooling .....................................................................58

6.11 BACKUP HEATING ................................................................................................58

6.11.1 Backup Heating Sources for Heating ...............................................................59

6.11.2 Priority for Backup Heating Sources (HBH) .....................................................59

6.11.3 Backup Heating Source for Sanitary Hot Water ...............................................60

6.11.4 Priority for Backup Heating Sources (HWTBH) ................................................60

6.11.5 Heating Source Start Accumulating Value (HBH) ............................................60

6.11.6 Water Temperature Rise Reading Interval (hwtbh) ..........................................60

6.11.7 Emergency Operation .....................................................................................60

Page 6

6.12 WATER PUMP SETTINGS ...................................................................................61

6.12.1 Circulation Pump P0 Type ...............................................................................61

6.12.2 Speed Setting of Circulation Pump P0 ............................................................62

6.12.3 Working Mode of Circulation Pump P0 ............................................................62

6.12.4 Pump Off Interval for P0 ..................................................................................62

6.12.5 Pump On Time for P0 ......................................................................................62

6.12.6 Buffer Tank .....................................................................................................62

6.12.7 P1 For Heating Operation ...............................................................................62

6.12.8 P1 For Cooling Operation ................................................................................62

6.12.9 P1 with High Temp. Demand ...........................................................................62

6.12.10 P2 for Heating Operation .............................................................................62

6.12.11 P2 for Cooling Operation .............................................................................63

6.12.12 P2 with High Temp. Demand .......................................................................63

6.13 FLOOR CURING ....................................................................................................63

6.13.1 Floor Curing ....................................................................................................64

6.13.2 Floor Curing Current Stage .............................................................................64

6.13.3 Floor Curing Current Stage Running Duration .................................................64

6.13.4 Floor Curing Current Stage Set Temperature ..................................................64

6.13.5 Floor Curing Current Stage Valid Running Duration ........................................64

6.13.6 Floor Current Total Running Duration ..............................................................64

6.13.7 Highest Water Temp. in Floor Curing Operation ..............................................64

6.14 ELECTRICAL UTILITY LOCK ................................................................................65

6.14.1 Electrical Utility Lock .......................................................................................65

6.14.2 Operation Signal for Electrical Utility Lock .......................................................66

6.14.3 HBH During Electrical Utility Lock....................................................................66

6.14.4 P0 during Electrical Utility Lock .......................................................................66

6.14.5 Heating Eco Operation ....................................................................................66

6.14.6 Ambient Temp. to Start Heating Eco Operation ...............................................66

6.15 OTHER OPTIONS..................................................................................................67

6.15.1 Motorized Diverting Valve switching time ........................................................67

6.15.2 Power on Time for Motorized Diverting Valve ..................................................67

6.15.3 Refrigerant Recycle Function ..........................................................................67

6.15.4 Control Panel Backlight Light ..........................................................................67

6.15.5 Exit System .....................................................................................................68

6.15.6 Anti-freezing protection ...................................................................................68

6.15.7 Mode Switch during Defrosting ........................................................................68

6.15.8 Mode Signal Output.........................................................................................68

Page 7

6.15.9 Mode Signal type ............................................................................................68

6.15.10 Fan Speed Limit ..........................................................................................68

6.15.11 Defrosting Logic Selection ...........................................................................69

6.15.12 Activate Wi-Fi module or not? ......................................................................69

6.15.13 Accept setting from Wi-Fi module? ..............................................................69

6.15.14 Connection to the server ..............................................................................69

6.15.15 Connection to the router ..............................................................................69

6.15.16 MAC ............................................................................................................69

6.15.17 WI-FI module IP address .............................................................................69

6.15.18 SSID ............................................................................................................69

6.15.19 Password .....................................................................................................69

6.15.20 Server address ............................................................................................69

6.15.21 Service port .................................................................................................69

6.16 UNIT REAL-TIME DATA ................................ ........................................................70

7 ERROR CODES............................................................................................................70

7.1 ERROR CODES SHOWN ON THE DISPLAY ........................................................70

7.2 ERROR CODE MENU ...........................................................................................70

7.2.1 ACCESSING THE ERROR CODE MENU .......................................................70

7.2.2 INFORMATIONS IN THE ERROR CODE MENU ............................................71

7.2.3 INFO PAGE ....................................................................................................71

7.3 ERROR CODE LIST ..............................................................................................73

8 CLEANING THE MAGNETIC/DIRT FILTER CALEFFI ..................................................79

9 WATER PRESSURE IN THE SYSTEM .........................................................................80

10 WIRING .....................................................................................................................81

10.1 INDOOR UNIT - ALL INVERTERS .........................................................................81

10.2 INDOOR UNIT TERMINALS – ECO10A,13A, POWER EVI 15A, 18A ....................83

10.3 OUTDOOR PCB ECO INVERTER .........................................................................84

10.4 DRIVE FOR EEV ...................................................................................................86

10.5 OUTDOOR UNIT – POWER EVI INVERTER 15A, 18A .........................................87

10.6 OUTDOOR UNIT DRIVE – AEROGOR POWER EVI 15A, 18A .............................89

Page 8

1

1 BEFORE USE

Thank you for purchasing our product. We ask that you carefully read the manual and to take

into account all of the instructions regarding device operation in order to prevent possible

damage to the device or personnel. Technical data can be changed without notice because

of product upgrades. Please look at the rating label on the device for latest technical

specifications.

1.1 WARNINGS

Warnings in this manual address most important topics for proper and safe operation of the

heat pump, for this reason follow them directly. For further questions contact your installer or

technical support from Gorenje d.d. Contact details are on the last page of this document.

Before first use, read this manual.

This unit can be used by children aged from 8 years and above and persons with

reduced physical, sensory or mental capabilities or lack of experience and knowledge

if they have been given supervision or instruction concerning use of the unit in a safe

way and understand the hazards involved. Children should not play with the unit.

Cleaning and user maintenance shall not be made by children without supervision.

Installation, dismantlement and maintenance must be carried out by qualified

personnel. Any change to structure of the unit is prohibited since they can lead to

personal injury or damage to the unit.

Water or any other kind of fluid should not come in contact with the unit, it may cause

electric shock or destruction of the unit.

If the power cord gets loose or damaged, it must be repaired by qualified personnel.

Page 9

2

To avoid electrical shock, make sure to disconnect the power supply 1 minute or more

before servicing the electrical parts. Even after 1 minute, measure the voltage at the

terminals of main circuit capacitors or electrical parts before touching. Make sure

those voltages are lower than the safe value.

Do not touch the grill of the ventilator while the device is operating.

Improper installation or attachment of equipment or accessories could result in

electric shock, short-circuit, leaks, fire or other damage to the equipment. Be sure

only to use accessories made by Gorenje which are specifically designed for use with

the equipment and have them installed by a professional.

Power supply to the device must be grounded.

For sanitary hot water, please always add a mixture valve before water tap and set it

to proper temperature.

Do not touch the fins of the coil with bare fingers, it might cause injury.

It is mandatory to use a suitable fuse for the heat pump and make sure the power

supply to the unit corresponds to the specifications. Otherwise the unit might be

damaged.

Please discard the batteries as sorted municipal waste at the accessible collection

point.

Instalation of a residual current device (RCD) having a rated residual operating

current of 300 mA.

Page 10

3

1.2 DISPOSAL

This marking indicates that this product should not be disposed with

other household wastes throughout the EU. To prevent possible harm to

the environment or human health from uncontrolled waste disposal,

recycle it responsibly to promote sustainable reuse of material

resources. To return your used device, please use the return and

collection systems or contact the retailer where the product was

purchased. They can take this product for environmental safe recycling.

1.3 HEATING SYSTEM REQUIREMENTS (MANDATORY)

• Installed magnetic filter and dirt separator filter.

• If city water is used for filling of the heating system, the water quality must

comply with local regulations.

• Heating system pressure must be between 1 - 1.8 bar.

• Safety valve (3 bar) must be installed in the heating system.

• Expansion vessels must be installed according to heating system.

• Heat pump must be installed into closed loop heating system.

• Installation maintenance must be carried out by qualified personnel.

• If the heat pump is being installed into an existing hydraulic system, the

system must be cleaned according to standard procedures.

Page 11

4

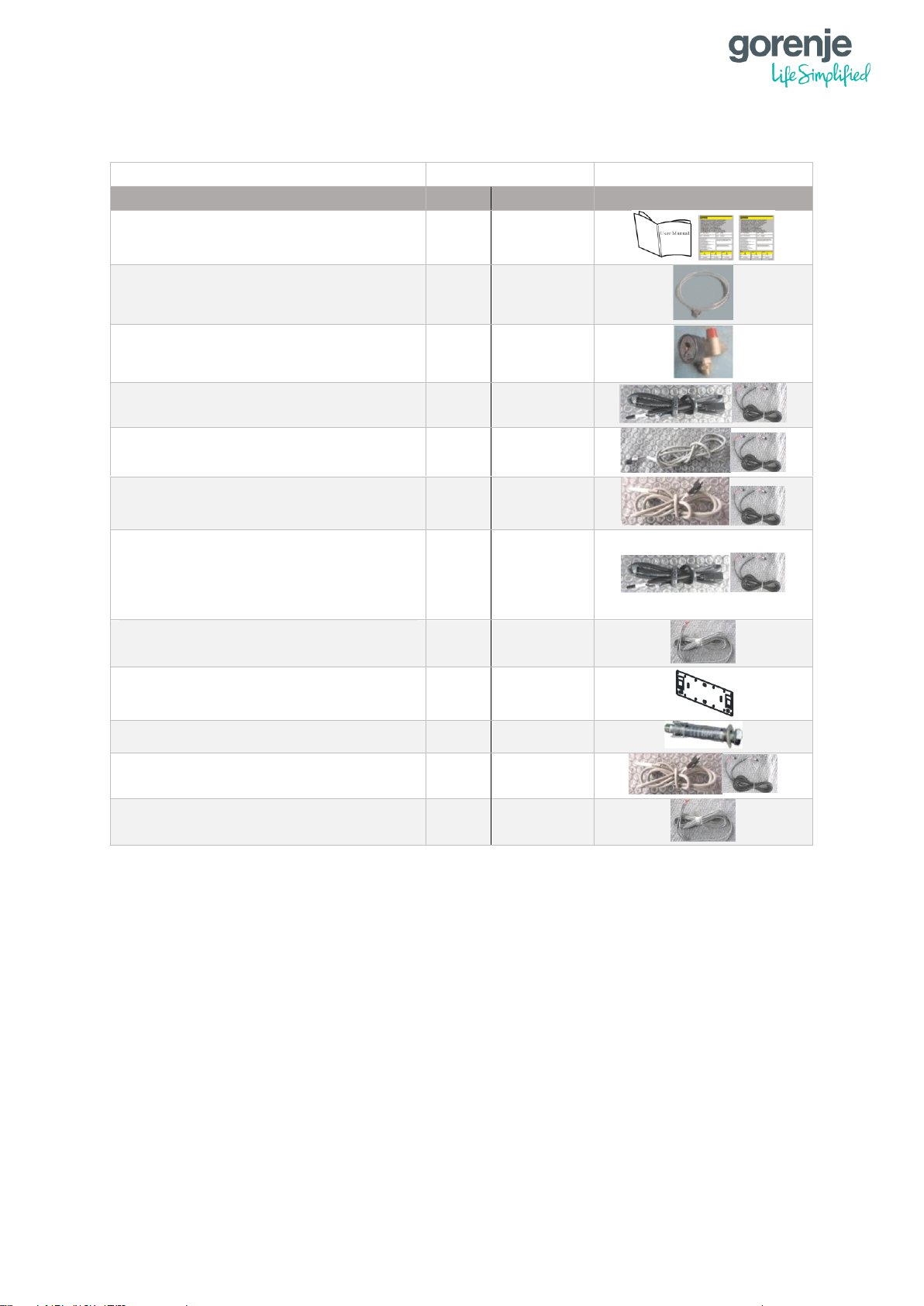

1.4 INCLUDED IN THE PACKAGE

NAME

QUANTITY

SYMBOLIC IMAGE

SPLIT

COMPACT

Installation Manual, Warranty cards

1

1

Drain pipe

1

1

Safety kit

1

1

TR – Room temp. sensor +

extension cable (10m)

1

1

TC – Heat/Cool temp. sensor +

extension cable (10m)

1

1

TW – DHW temp sensor + extension

cable (10m)

1

1

TV1 – mixing circuit 1 temp. sensor

+ extension cable (10m)

TV2 – mixing circuit 1 temp. sensor

+ extension cable (10m)

1

1

Communicaton cable

(20m)(shielded)

1

1

Bracket for indoor unit

1

1

Expansion bolts

2

1

Connection cable for Tui, Tuo, Tup

(20m)(shielded)

/

3 x 1

Connection cable for the Flow

Switch (20m) (shielded)

/

1

Page 12

5

1.5 TECHNICAL TABLE

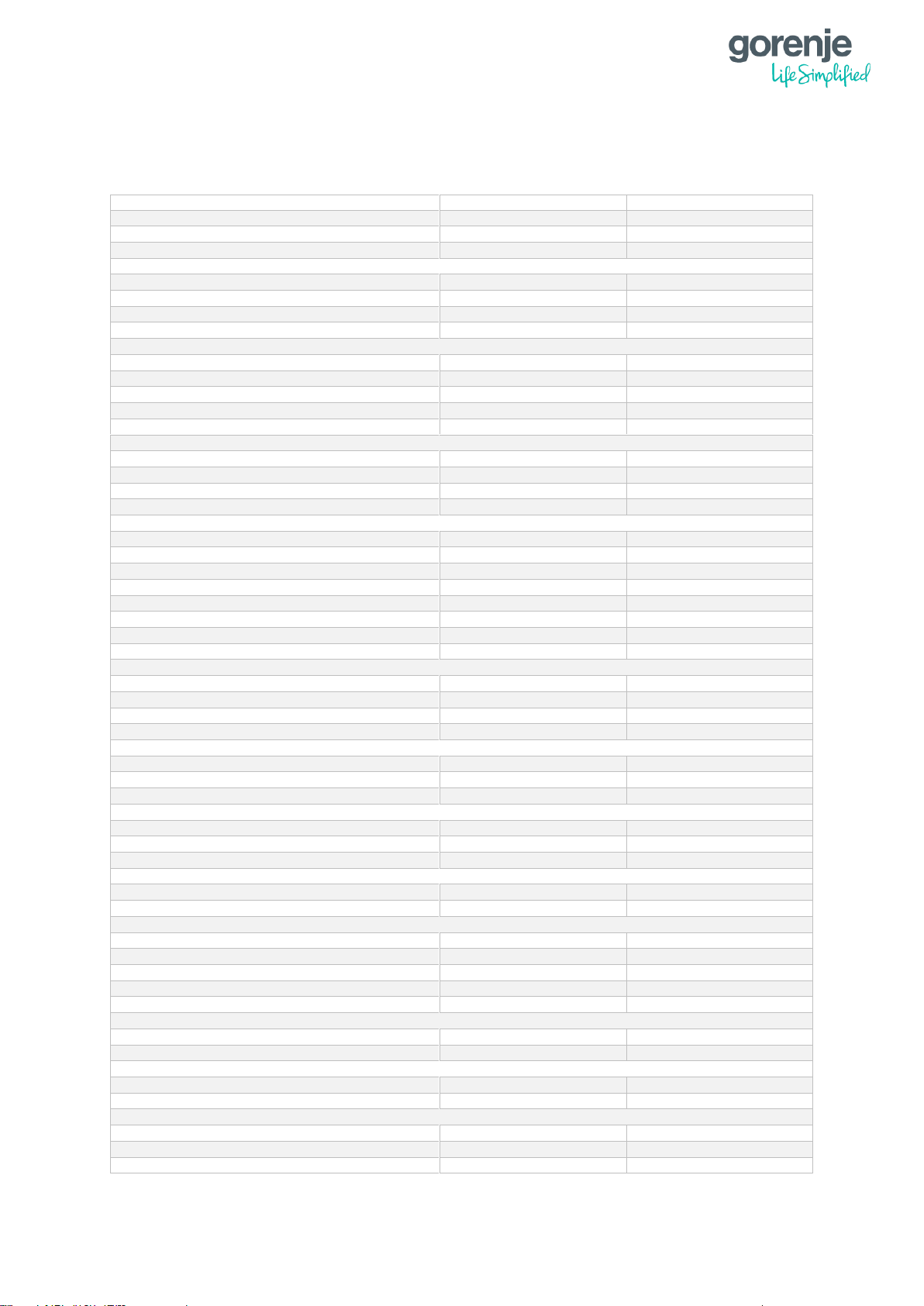

1.5.1 AEROGOR ECO COMPACT INVERTER 10A, 13A

MODEL

ECO COMPACT INVERTER 10A

ECO COMPACT INVERTER 13A

ErP Energy efficiency class

A++

A++

SCOP 35°C (floor heating) EN 14825

3,83

4,08

P

design

for SCOP EN 14825

6,3 kW

7,46 kW

HEATING MODE (A7/W35)

Heating capacity*

4,57 – 10,50 kW

4,1 -12,2 kW

COP - Coefficient of Performance*

3,80 – 4,71

4,0 - 4,57

Max. temperature of heating water

55 °C

55 °C

Operating range of heat pump - Heating (Ambient temp.)

-25 do +45 °C

-25 do +45 °C

COOLING MODE (A35/W7)

Cooling capacity**

2,60 – 8,00 kW

2,34 – 7,91 kW

Rated input power**

1,10 – 3,50

0,97 – 2,98 kW

EER - Energy Efficiency Ratio**

2,30 – 3,22 kW

2,40 – 3,03

Min. temperature of cooling water

7 °C

7 °C

Operating range of heat pump - Cooling (Ambient temp.)

0 to +65 °C

0 to +65 °C

POWER SUPPLY - SPECIFICATION

Voltage

220-240 V/50 Hz/1 Ph

220-240 V/50 Hz/1 Ph

Rated input power*

0,91 – 3,05 kW

0,96 - 3,02 kW

Fuse for heat pump

1 X 1p/20A/C

1 x 1p/20A/C

Fuse for electrical flow heater

3 X 1p/10A/C

3 x 1p/10A/C

REFRIGERANT SPECIFICATION

Type of refrigerant

R410A

R410A

Refrigerant - mass

1,9 kg

3 kg

GWP (global warming potential)

2088 GWP

2088 GWP

Quantity of hydrofluorocarbons in tonnes of CO2 equivalent

4,051 t CO2 Equiv.

6,264 t CO2 Equiv.

Type of compressor

DC inverter (twin rotary)

DC inverter (twin rotary)

Hermetically sealed equipment (indoor/outdoor unit)

Yes

Yes

Type fo connection between outdoor-indoor unit

Refrigerant connection

Water connection

Dimensions of refrigerant pipes connectors

3/8” - 1/2”

/

FAN

Fan type

1 x Axial

2 x Axial

Air flow

3100 m3/h

4100 m3/h

Rated power

60 W

2 x 60 W

„ESP“ – External Static Pressure of the Fan (data per piece)

45 W

50 W

WATER SIDE HEAT EXCHANGER

Type

Plate heat exchanger

Plate heat exchanger

Pressure drop

30 kPa

40 kPa

Dimensions of water piping connection

G1"

G1"

ALLOWABLE FLOW - SECONDARY (WATER) SIDE

Min. water flow

1,15 m3/h

1,32 m3/h

Nominal water flow

1,44 m3/h

2,2 m3/h

Max. water flow

2,16 m3/h

2,63 m3/h

SOUND POWER AND PRESSURE LEVEL

Sound power level LwA - Indoor unit

45 dB(A)

46 dB(A)

Sound power level LwA - Outdoor unit

58 dB(A)

59 dB(A)

SOUND PRESSURE LEVEL ON DISTANCE

Indoor unit - 1 m

37 dB(A)

38 dB(A)

Outdoor unit - 1 m

50 dB(A)

51 dB(A)

Outdoor unit - 5 m

36 dB(A)

37 dB(A)

Outdoor unit - 10 m

30 dB(A)

31 dB(A)

Outdoor unit - 15 m

26 dB(A)

27 dB(A)

NET DIMENSIONS

Indoor unit (WxHxD)

505 x 946 x 288 mm

562 x 686 x 260 mm

Outdoor unit (WxHxD)

1044 × 763 × 414 mm

1258 x 1195 x 407 mm

NET WEIGHT

Indoor unit

50 kg

25 kg

Oudoor unit

75 kg

140 kg

SERIAL INTEGRATED COMPONENTS

Electrical flow heater

6 kW (3ph / 2 stages)

6 kW (3ph / 2 stages)

Circulation water pump - A energy class

Grundfos UPM GEO 25-85 180

Grundfos UPM GEO 25-85 180

3-way diverting valve for DHW tank

Optional external

Optional external

Page 13

6

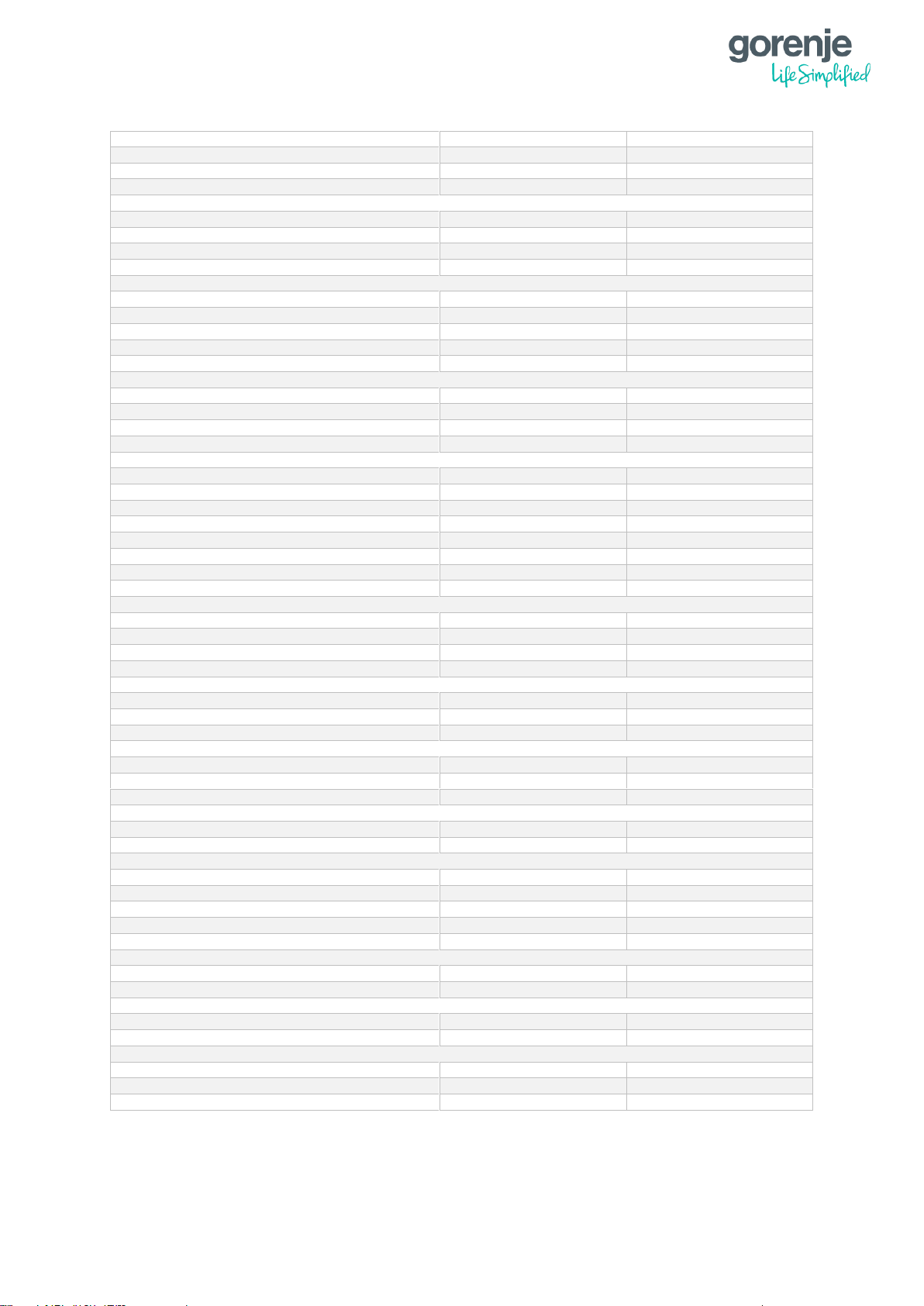

1.5.2 AEROGOR ECO INVERTER 10A, 13A

MODEL

ECO INVERTER 10A

ECO INVERTER 13A

ErP Energy efficiency class

A++

A++

SCOP 35°C (floor heating) EN 14825

3,83

4,08

P

design

for SCOP EN 14825

6,3 kW

7,46 kW

HEATING MODE (A7/W35)

Heating capacity*

4,57 – 10,50 kW

4,1 -12,2 kW

COP - Coefficient of Performance*

3,80 – 4,71

4,0 - 4,57

Max. temperature of heating water

55 °C

55 °C

Operating range of heat pump - Heating (Ambient temp.)

-25 do +45 °C

-25 do +45 °C

COOLING MODE (A35/W7)

Cooling capacity**

2,60 – 8,00 kW

2,34 – 7,91 kW

Rated input power**

1,10 – 3,50 kW

0,97 – 2,98 kW

EER - Energy Efficiency Ratio**

2,30 – 3,22

2,40 – 3,03

Min. temperature of cooling water

7 °C

7 °C

Operating range of heat pump - Cooling (Ambient temp.)

0 to +65 °C

0 to +65 °C

POWER SUPPLY - SPECIFICATION

Voltage

220-240 V/50 Hz/1 Ph

220-240 V/50 Hz/1 Ph

Rated input power*

0,91 – 3,05 kW

0,96 - 3,02 kW

Fuse for heat pump

1 X 1p/20A/C

1 X 1p/20A/C

Fuse for electrical flow heater

3 X 1p/10A/C

3 X 1p/10A/C

REFRIGERANT SPECIFICATION

Type of refrigerant

R410A

R410A

Refrigerant - mass

1,9 kg

3 kg

GWP (global warming potential)

2088 GWP

2088 GWP

Quantity of hydrofluorocarbons in tonnes of CO2 equivalent

4,051 t CO2 Equiv.

6,264 t CO2 Equiv.

Type of compressor

DC inverter (twin rotary)

DC inverter (twin rotary)

Hermetically sealed equipment (indoor/outdoor unit)

Yes

Yes

Type fo connection between outdoor-indoor unit

Refrigerant connection

Refrigerant connection

Dimensions of refrigerant pipes connectors

3/8” - 1/2”

3/8” - 5/8”

FAN

Fan type

1 x Axial

2 x Axial

Air flow

3100 m3/h

4100 m3/h

Rated power

60 W

2 x 60 W

„ESP“ – External Static Pressure of the Fan (data per piece)

45 W

50 W

WATER SIDE HEAT EXCHANGER

Type

Plate heat exchanger

Plate heat exchanger

Pressure drop

30 kPa

40 kPa

Dimensions of water piping connection

G1"

G1"

ALLOWABLE FLOW - SECONDARY (WATER) SIDE

Min. water flow

1,15 m3/h

1,32 m3/h

Nominal water flow

1,44 m3/h

2,2 m3/h

Max. water flow

2,16 m3/h

2,63 m3/h

SOUND POWER AND PRESSURE LEVEL

Sound power level LwA - Indoor unit

45 dB(A)

46 dB(A)

Sound power level LwA - Outdoor unit

58 dB(A)

59 dB(A)

SOUND PRESSURE LEVEL ON DISTANCE

Indoor unit - 1 m

37 dB(A)

38 dB(A)

Outdoor unit - 1 m

50 dB(A)

51 dB(A)

Outdoor unit - 5 m

36 dB(A)

37 dB(A)

Outdoor unit - 10 m

30 dB(A)

31 dB(A)

Outdoor unit - 15 m

26 dB(A)

27 dB(A)

NET DIMENSIONS

Indoor unit (WxHxD)

505 x 946 x 288 mm

505 x 946 x 288 mm

Outdoor unit (WxHxD)

1044 × 763 × 414 mm

1123 x 1195 x 400 mm

NET WEIGHT

Indoor unit

50 kg

58 kg

Oudoor unit

75 kg

113 kg

SERIAL INTEGRATED COMPONENTS

Electrical flow heater

6 kW (3ph / 2 stages)

6 kW (3ph / 2 stages)

Circulation water pump - A energy class

Grundfos UPM GEO 25-85 180

Grundfos UPM GEO 25-85 180

3-way diverting valve for DHW tank

Optional external

Optional external

Page 14

7

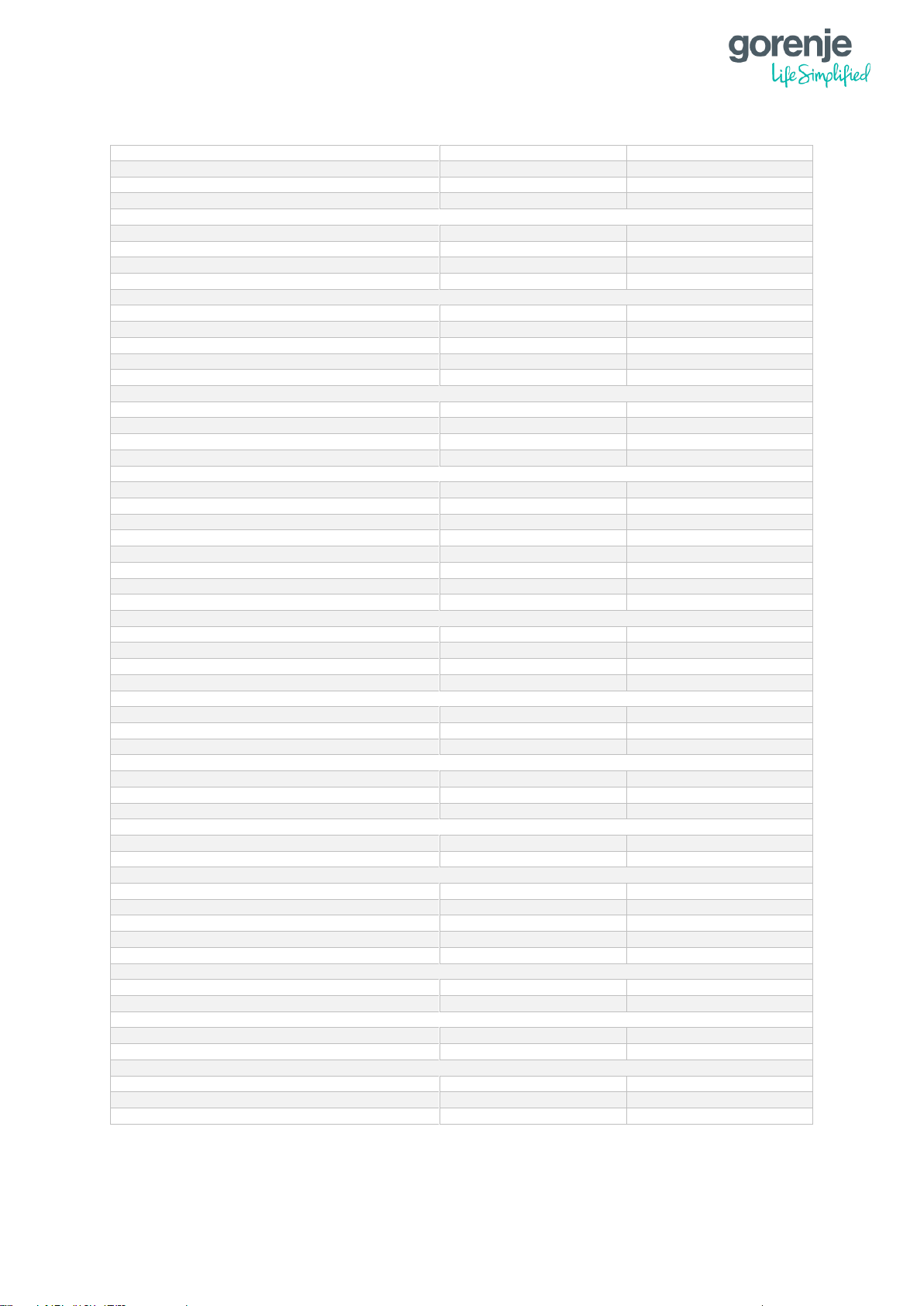

1.5.3 AEROGOR POWER EVI INVERTER 15A, 18A

MODEL

POWER EVI INVERTER 15A

POWER EVI INVERTER 18A

ErP Energy efficiency class

A+

A+

SCOP 35°C (floor heating) EN 14825

3,46

3,42

P

design

for SCOP EN 14825

10,97 kW

13,48 kW

HEATING MODE (A7/W35)

Heating capacity*

6,60 - 14,60 kW

8,2 - 18,0 kW

COP - Coefficient of Performance*

3,80 - 4,46

3,91 - 4,43

Max. temperature of heating water

55 °C

55 °C

Operating range of heat pump - Heating (Ambient temp.)

-25 do +45 °C

-25 do +45 °C

COOLING MODE (A35/W7)

Cooling capacity**

5,56 - 10,00 kW

6,4 - 15,1 kW

Rated input power**

1,57 - 3,82 kW

2,19 – 6,42 kW

EER - Energy Efficiency Ratio**

1,85 - 3,52

2,35 - 2,92

Min. temperature of cooling water

7 °C

7 °C

Operating range of heat pump - Cooling (Ambient temp.)

0 to +65 °C

0 to +65 °C

POWER SUPPLY - SPECIFICATION

Voltage

380-415 V/50 Hz/3 Ph

380-415 V/50 Hz/3 Ph

Rated input power*

1,53 - 4,92 kW

1,53 - 4,92 kW

Fuse for heat pump

1 x 3p/16A/C

1 x 3p/16A/C

Fuse for electrical flow heater

3 x 1p/10A/C

3 x 1p/10A/C

REFRIGERANT SPECIFICATION

Type of refrigerant

R410A

R410A

Refrigerant - mass

6,2 kg

6,6 kg

GWP (global warming potential)

2088 GWP

2088 GWP

Quantity of hydrofluorocarbons in tones of CO2 equivalent

12,946 t CO2 Equiv.

13,780 t CO2 Equiv.

Type of compressor

Scroll EVI DC Inverter

Scroll EVI DC Inverter

Hermetically sealed equipment (indoor/outdoor unit)

Yes

Yes

Type fo connection between outdoor-indoor unit

Refrigerant connection

Refrigerant connection

Dimensions of refrigerant pipes connectors

3/8" - 3/4"

3/8" - 3/4"

FAN

Fan type

2 x Axial

2 x Axial

Air flow

4200 m3/h

4500 m3/h

Rated power

2 x 80

2 x 80

„ESP“ – External Static Pressure of the Fan (data per piece)

50

50

WATER SIDE HEAT EXCHANGER

Type

Plate heat exchanger

Plate heat exchanger

Pressure drop

35

35

Dimensions of water piping connection

G1"

G1"

ALLOWABLE FLOW - SECONDARY (WATER) SIDE

Min. water flow

1,4 m3/h

1,86 m3/h

Nominal water flow

2,56 m3/h

3,09 m3/h

Max. water flow

2,7 m3/h

3,7 m3/h

SOUND POWER AND PRESSURE LEVEL

Sound power level LwA - Indoor unit

47 dB(A)

52 dB(A)

Sound power level LwA - Outdoor unit

68 dB(A)

72 dB(A)

SOUND PRESSURE LEVEL ON DISTANCE

Indoor unit - 1 m

39 dB(A)

44 dB(A)

Outdoor unit - 1 m

60 dB(A)

65 dB(A)

Outdoor unit - 5 m

46 dB(A)

51 dB(A)

Outdoor unit - 10 m

40 dB(A)

45 dB(A)

Outdoor unit - 15 m

36 dB(A)

41 dB(A)

NET DIMENSIONS

Indoor unit (WxHxD)

505 x 946 x 303 mm

505 x 946 x 288 mm

Outdoor unit (WxHxD)

1172 x 1194 x 410 mm

1440 x 1271 x 460 mm

NET WEIGHT

Indoor unit

32 kg

55 kg

Oudoor unit

151 kg

180 kg

SERIAL INTEGRATED COMPONENTS

Electrical flow heater

6 kW (3ph / 2 stages)

6 kW (3ph / 2 stages)

Circulation water pump - A energy class

Grundfos UPM GEO 25-85 180

Grundfos UPMXL GEO25-125 130

3-way diverting valve for DHW tank

Optional external

Optional external

(*) Measured according to standard EN 14511. Heating condition: water inlet/outlet temperature 30°C/35°C, ambient

temperature DB/WB 7°C/6°C.

(**) Measured according to standard EN 14511. Cooling condition: water inlet/outlet temperature 12°C/7°C and ambient

temperature 35°C.

Page 15

8

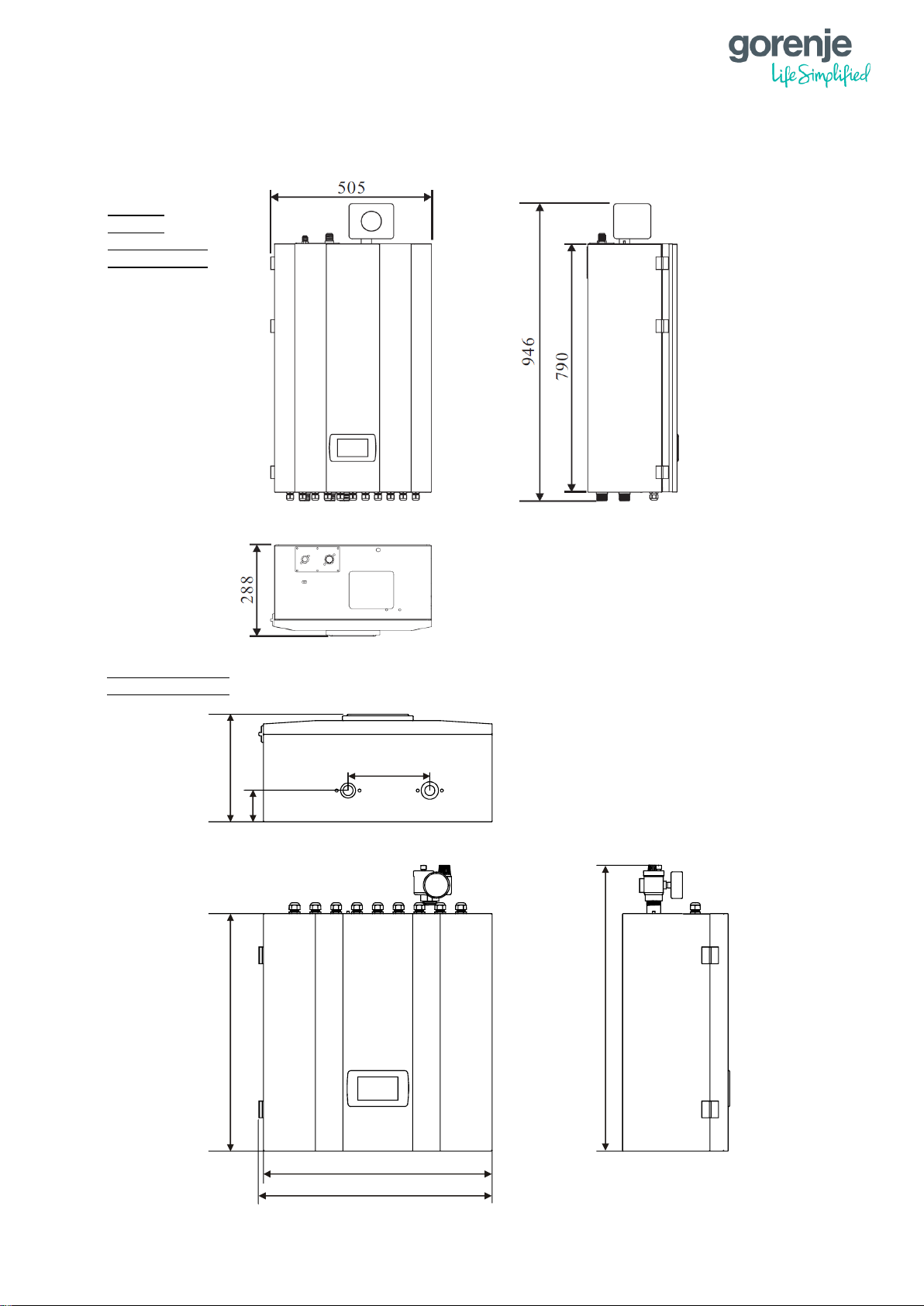

1.6 DIMENSIONS

1.6.1 INDOOR UNITS

ECO 10 A

ECO 13 A

POWER EVI 15 A

POWER EVI 18 A

ECO COMPACT 10 A

ECO COMPACT 13 A

Unit:mm

260

196.5

570

550

686

561.5

75

Page 16

9

1.6.2 OUTDOOR UNITS

AEROGOR ECO INVERTER 10A AEROGOR ECO COMPACT INVERTER 10A

AEROGOR ECO INVERTER 13A, AEROGOR ECO COMPACT INVERTER 13A

Page 17

10

AEROGOR POWER EVI INVERTER 15A AEROGOR POWER EVI INVERTER 18A

1.7 OPERATING RANGE

10

15

20

25

30

35

40

45

50

55

60

65

-30 -25 -20 -15 -10 -5 0 5 10 15 20 25 30 35 40 45 50

Outlet water temperature [

°C]

Outside Ambient temperature [°C]

Operating range - heating mode:

Aerogor ECO Inverter 10-13 A

Aerogor COMPACT ECO Inverter 10-13 A

ECO

1443

1373

860

222

460

402

460

1272

1294

460

1241

1171

715

182

1171

1193

402

460

Page 18

11

1.8 WORKING PRINCIPLE

A heat pump operates similarly as a refrigerator. In a refrigerator, liquids evaporate due to

received thermal energy from the surrounding air and this energy is emitted at a desired spot

during condensation (Carnot’s cycle). A heat pump works in the opposite direction: it accepts

thermal energy from the surrounding air and emits it in heated premises, using the natural

heat collector of the environment. Ground and surface water, earth’s warmth, solar energy

and ambient air can be used as energy sources. The system is composed of four units:

evaporator, compressor, condenser and damper. Heat energy is transferred via the coolant.

In the evaporator, the coolant receives heat energy and evaporates. In the compressor, the

vapour is compressed, which makes it heat up intensively. This hot vapour transmits thermal

energy from the condenser to the heating water and liquefies. In the damper, the coolant

expands (pressure reduces to the starting pressure, from there it proceeds to the evaporator

and the cycle repeats).

10

15

20

25

30

35

40

45

50

55

60

65

-30 -25 -20 -15 -10 -5 0 5 10 15 20 25 30 35 40 45 50

Maximum outlet water temperture [

°C]

Outside ambient temperature [°C]

Operating range - heating mode:

Aerogor POWER EVI Inverter 15 A

Aerogor POWER EVI Inverter 18 A

Heat from

ambient

Produced

heat for

heating

Electric

energy

ECO

EVI

Compressor

Expansion

valve

Evaporator

Evaporator

Condenser

Condenser

Page 19

12

Inverter heat pumps use variable-speed compressors. Traditional heat pumps use fixed

power/rotation speed compressors. In inverter compressors, the compressor speed

constantly adapts to the heat losses of the room and the energy value of the source (air,

brine or water, depending on the system). In traditional heat pumps, the power of the

compressor is always the same. Compressor starts with full power and when it achieves the

desired values/temperatures, it shuts off and waits until it restarts. Inverter heat pumps work

for a longer period, but with lower power (adjusting to the premises), which means lower

consumption of electric energy.

1.9 MAIN COMPONENTS

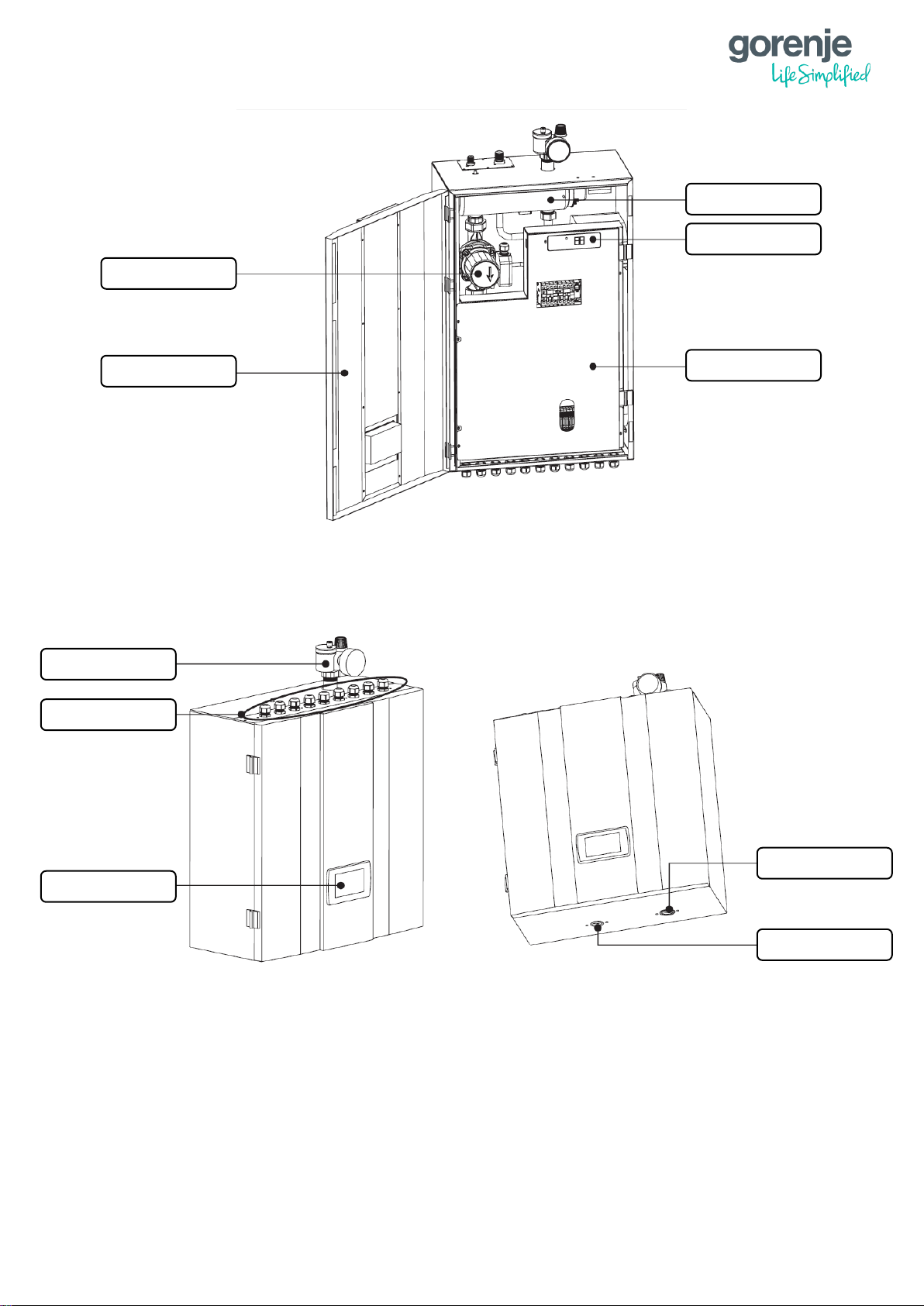

1.9.1 INDOOR UNITS

1.9.1.1 AEROGOR ECO INVERTER 10A/13A AND AEROGOR POWER EVI INVERTER

15A/18A

Refrigerant Connector

ECO 10A: 3/8"

ECO 13A: 3/8"

POWER EVI 15A: 3/8"

POWER EVI 18A: 3/8"

Refrigerant Connector

ECO 10A: 1/2"

ECO 13A: 5/8"

POWER EVI 15A: 3/4"

POWER EVI 18A: 3/4"

Operation panel

Cable gland

Water outlet G1"

Water inlet G1"

Safety valve kit

Page 20

13

1.9.1.2 AEROGOR ECO COMPACT INVERTER 10A/13A

Operation panel

Cable gland

Safety valve kit

Water inlet G1"

Water outlet G1"

Water pump

Door

Electric heater

Digital thermostat

Electric box cover

Page 21

14

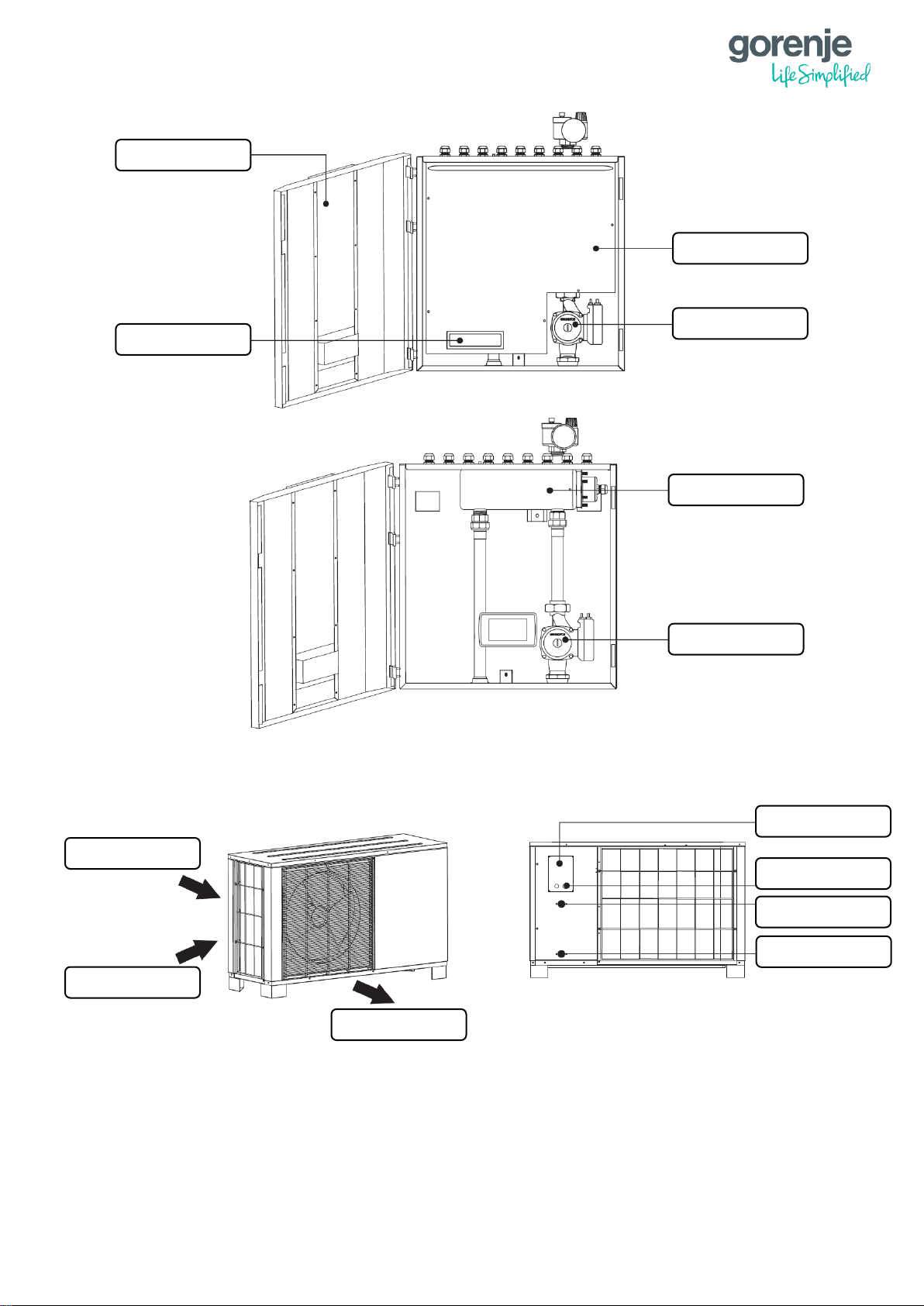

1.9.2 OUTDOOR UNITS

1.9.2.1 AEROGOR ECO COMPACT INVERTER 10A

Electric heater

Water pump

Water pump

Electric box cover

Digital thermostat

Door

Cover

Cable fixture

Air inlet

Air inlet

Air outlet

Water outlet G1"

Water inlet G1"

Page 22

15

1.9.2.2 AEROGOR ECO COMPACT INVERTER 13A

1.9.2.3 AEROGOR ECO INVERTER 10A

Air inlet

Air outlet

Cover

Cable fixture

Water outlet G1"

Water inlet G1"

Air inlet

Air outlet

Handle

Refrigerant connector

3/8" and 1/2"

Valve cover

Page 23

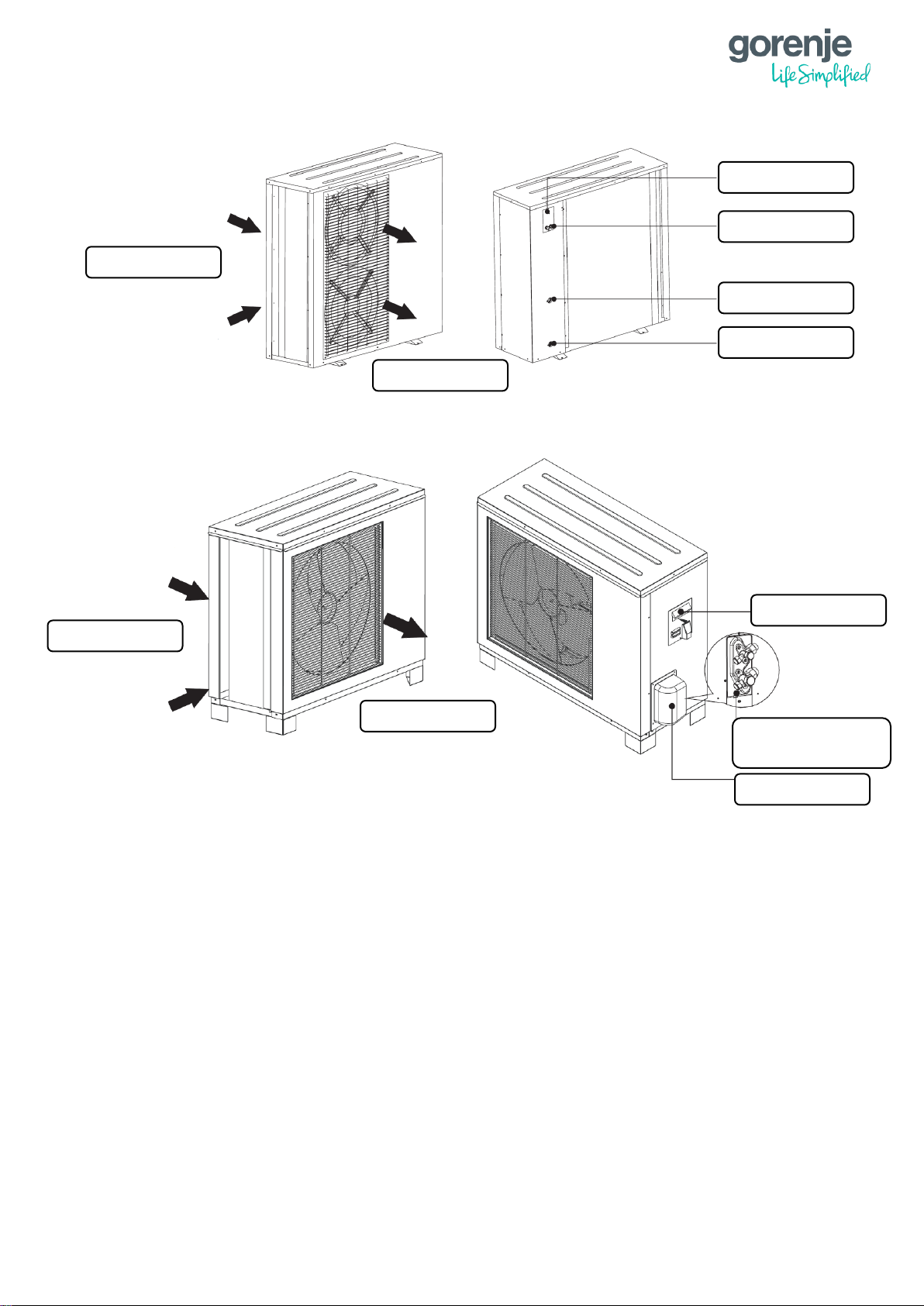

16

1.9.2.4 AEROGOR ECO INVERTER 13A

1.9.3 AEROGOR POWER EVI INVERTER 15A/ 18A

Handle

Refrigerant connector

3/8" and 5/8"

Valve cover

Air inlet

Air outlet

Refrigerant connector

3/4"

3/8"

Cable gland

Air outlet grill

Page 24

17

2 INSTALLATION

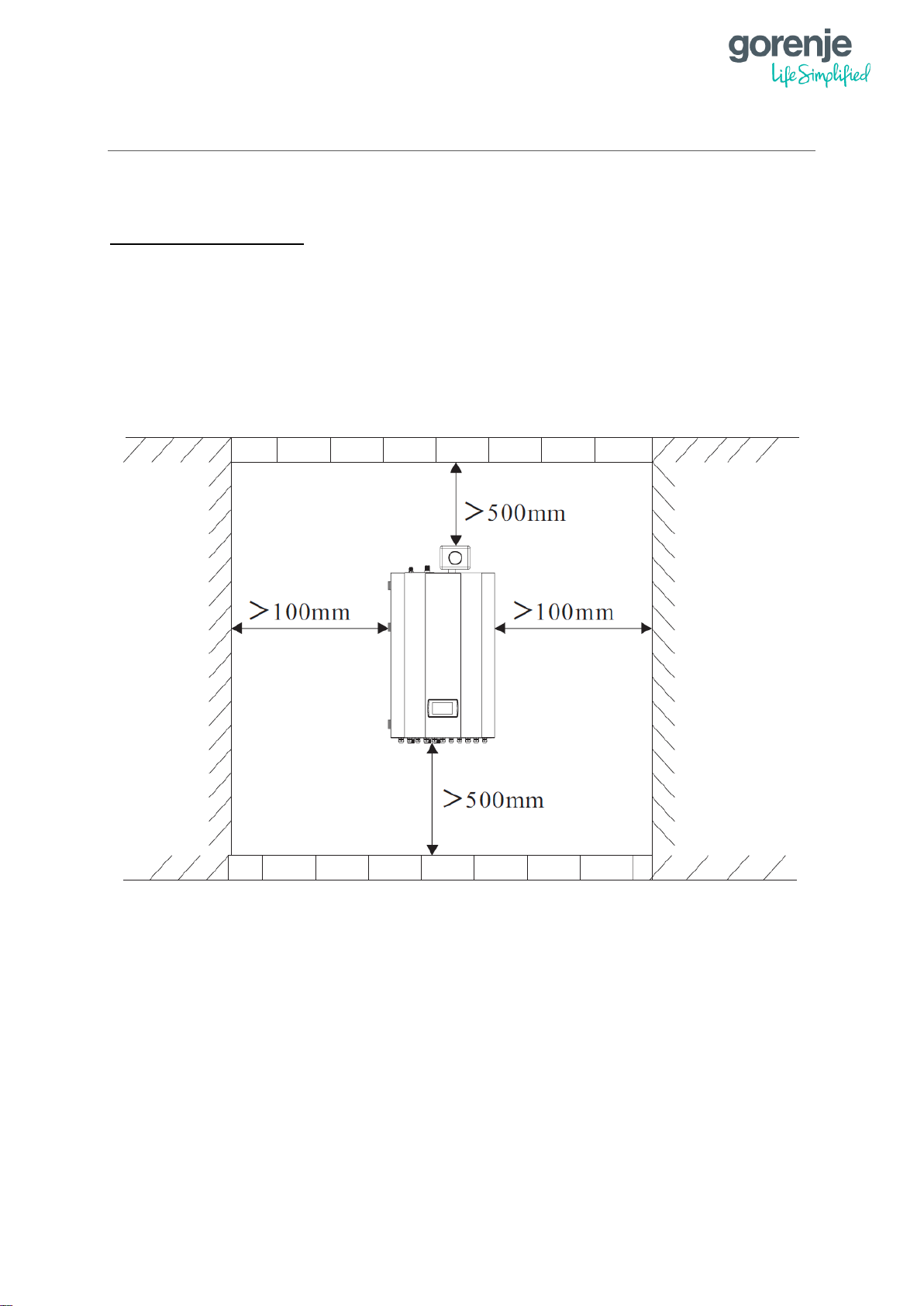

2.1 INSTALLATION OF THE INDOOR UNIT

INSTALLATION NOTES:

1. The indoor unit should be installed indoors and mounted on the wall with water

connections facing downwards.

2. The indoor unit shall be placed in a dry and well-ventilated environment.

3. It is forbidden to install the indoor unit in an environment where there exist volatile,

corrosive or flammable liquids or gases.

4. There should be enough space left around the indoor unit for further maintenance.

Please choose a suitable position to install the indoor unit as follows:

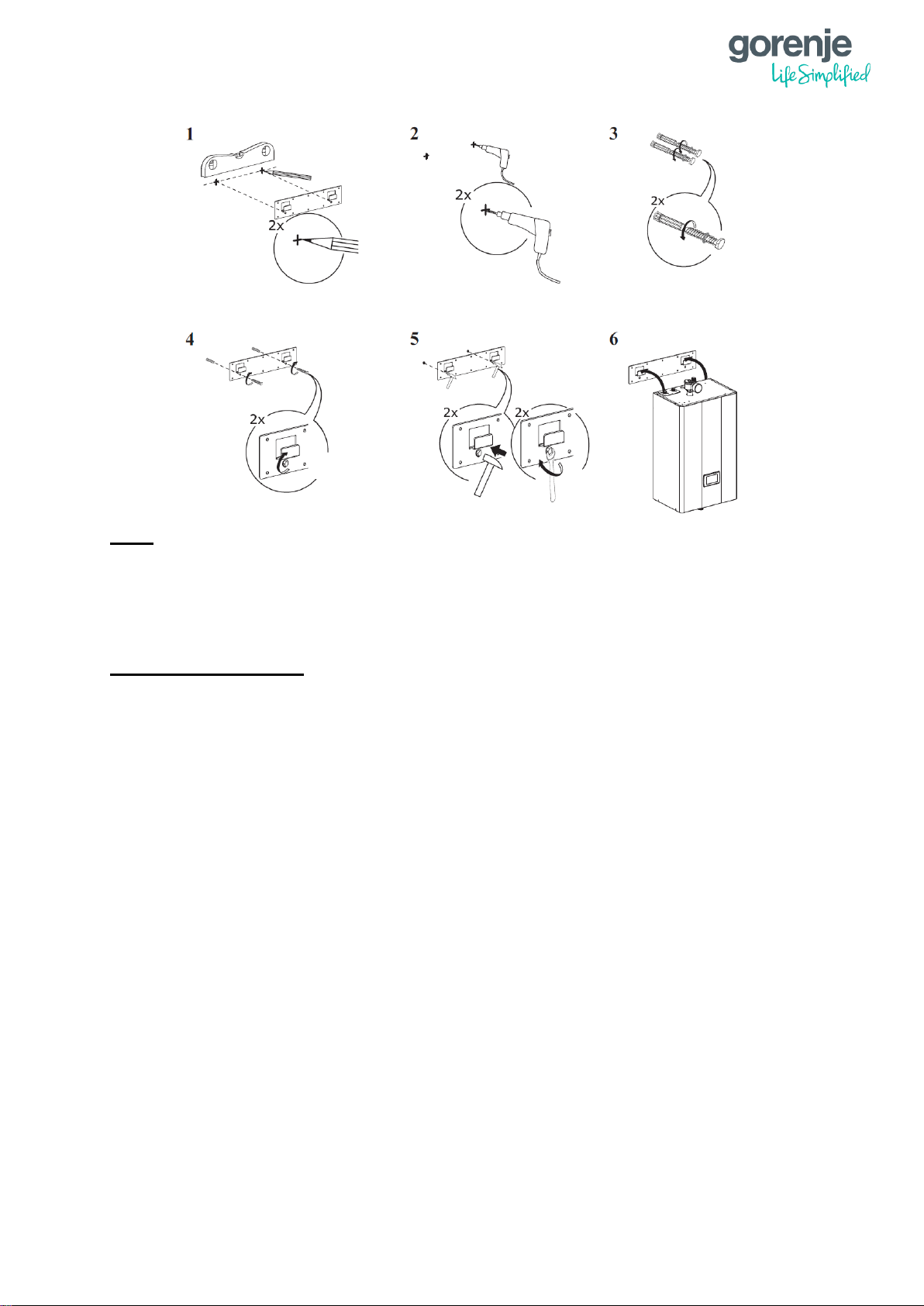

Indoor unit should be mounted on the wall as followed:

1. Take out the expansion bolts and mounting board from the box and put the mounting

board on the wall horizontally.

2. Mark the location of the holes for the bolts on the wall.

3. Drill the holes with proper diameter for the expansion bolts.

4. Unscrew the nuts from the expansion bolts.

5. Fix the mounting board on the expansion bolts a little bit, but don’t be too tight.

6. Use a hammer to pound the expansion bolts into the drilled holes.

7. Fasten the nuts by turning the wrench to fix the mounting board on the wall.

8. Hang the indoor unit onto the mounting board and make sure it’s placed well before

you let go your hands.

9. At this point, the installation is finished.

Page 25

18

Note:

You must choose very firm wall for installation, otherwise the bolts may get loose and

therefore damaging the unit.

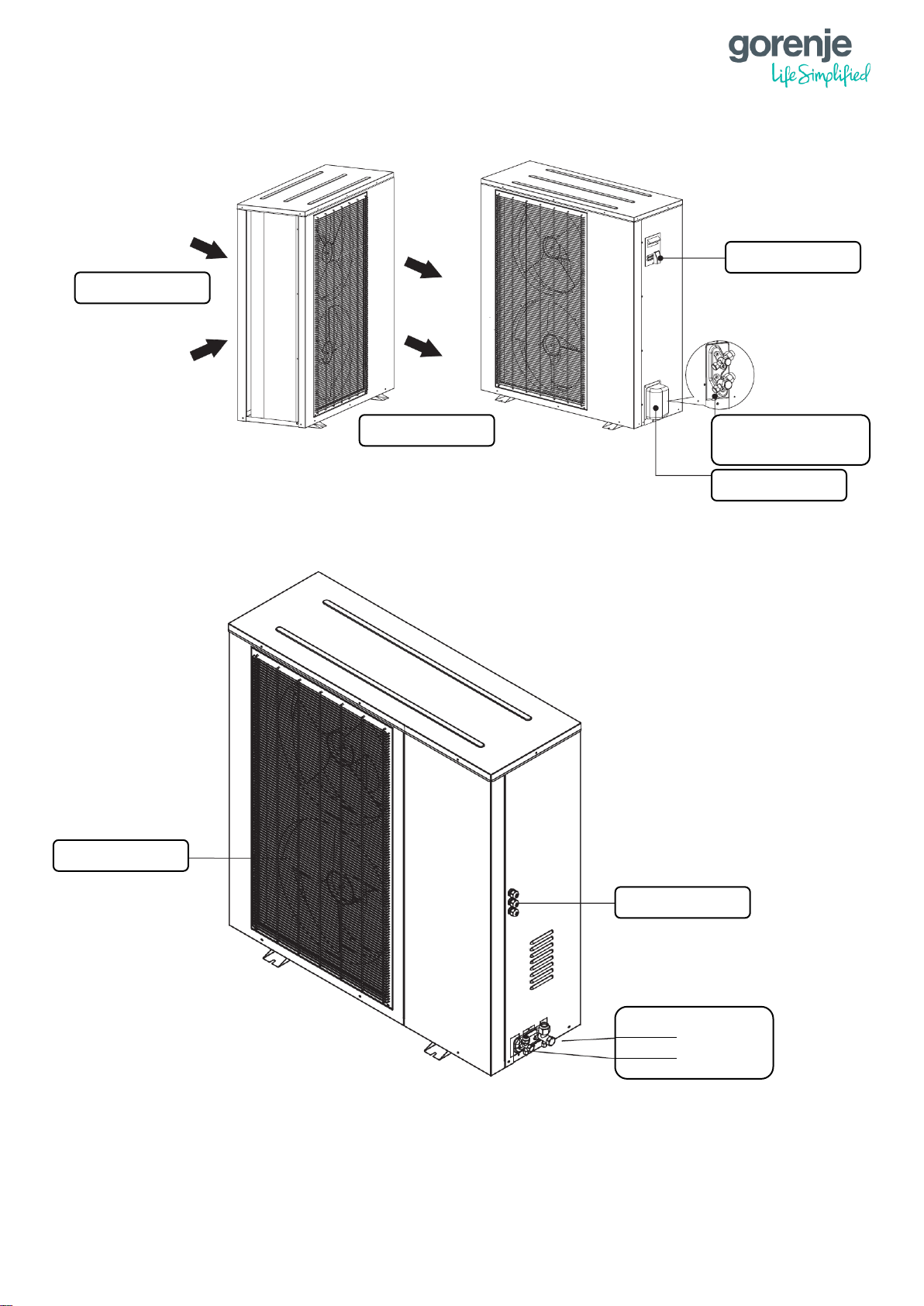

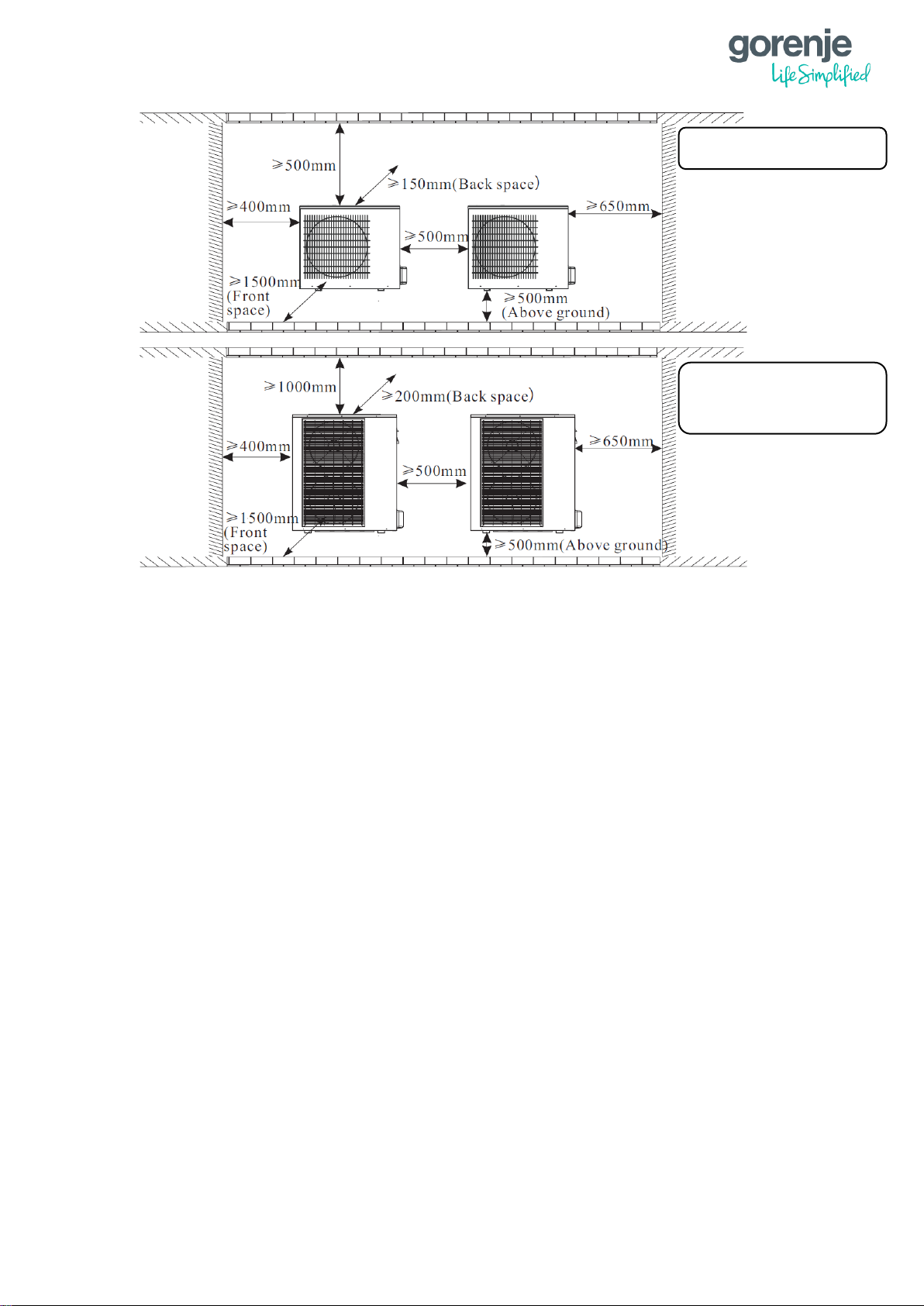

2.2 INSTALLATION OF THE OUTDOOR UNIT

INSTALLATION NOTES:

1. The outdoor unit can be located in an open space, corridor, balcony, roof or hanged

on the wall.

2. The outdoor unit shall be placed in dry and well-ventilated environment; If the outdoor

unit is installed in a humid environment, electronic components may get corroded or

short circuited.

3. Outdoor unit mustn’t be installed in an environment where there exist volatile,

corrosive or flammable liquids or gasses.

4. Please don’t install outdoor unit close to bedroom or living room because it produces

some noise when it’s operating.

5. It is recommended to install an awning above the outdoor unit, to protect the snow

from clogging in the air inlet and outlet to ensure normal operation.

6. Please ensure there is drainage system around the location to drain the condensate

water under defrost mode.

7. When installing the unit, tilt it by 1 cm/m to enable rain water drainage.

8. Install outdoor unit far away from the exhaust port of the kitchen to avoid oil smoke

entering into outdoor unit heat exchanger.

9. Please don’t install the indoor and outdoor unit in damp locations. The units should be

free from corrosive and moisture surrounding otherwise the lifetime of the unit might

be shortened.

10. Please ensure enough space around the outdoor unit for better ventilation and

maintenance.

Please refer to the illustration below.

Page 26

19

User can either use the dedicated mounting bracket from the supplier or prepare a suitable

bracket for the unit installation. Make sure the installation meets the following requirements:

1. The unit must be installed on flat concrete blocks or a dedicated mounting bracket.

The bracket should be able to support at least 5 times of the unit weight.

2. All nuts must be tightened after the bracket is fixed otherwise it may cause damage to

the equipment.

3. Double check and make sure the installation of the unit is firm enough.

4. The bracket can be made from stainless steel, galvanized steel, aluminium and other

materials as required by the user.

5. Besides the mounting bracket, the user can also install the outdoor unit on two

concrete blocks or a raised concrete platform. Please make sure that the unit is

securely fastened after installation.

6. Please see the dimensions of outdoor unit when choosing a suitable wall bracket.

Hole for piping should lean a little bit to outside (≥ 8 degrees) to keep the rain or condensate

water from flowing back indoors.

AEROGOR ECO INVERTER 10A

AEROGOR COMPACT INVERTER 10A

AEROGOR ECO INVERTER 13A

AEROGOR COMPACT INVERTER 13A

AEROGOR POWER EVI INVERTER 15A

AEROGOR POWER EVI INVERTER 18A

Page 27

20

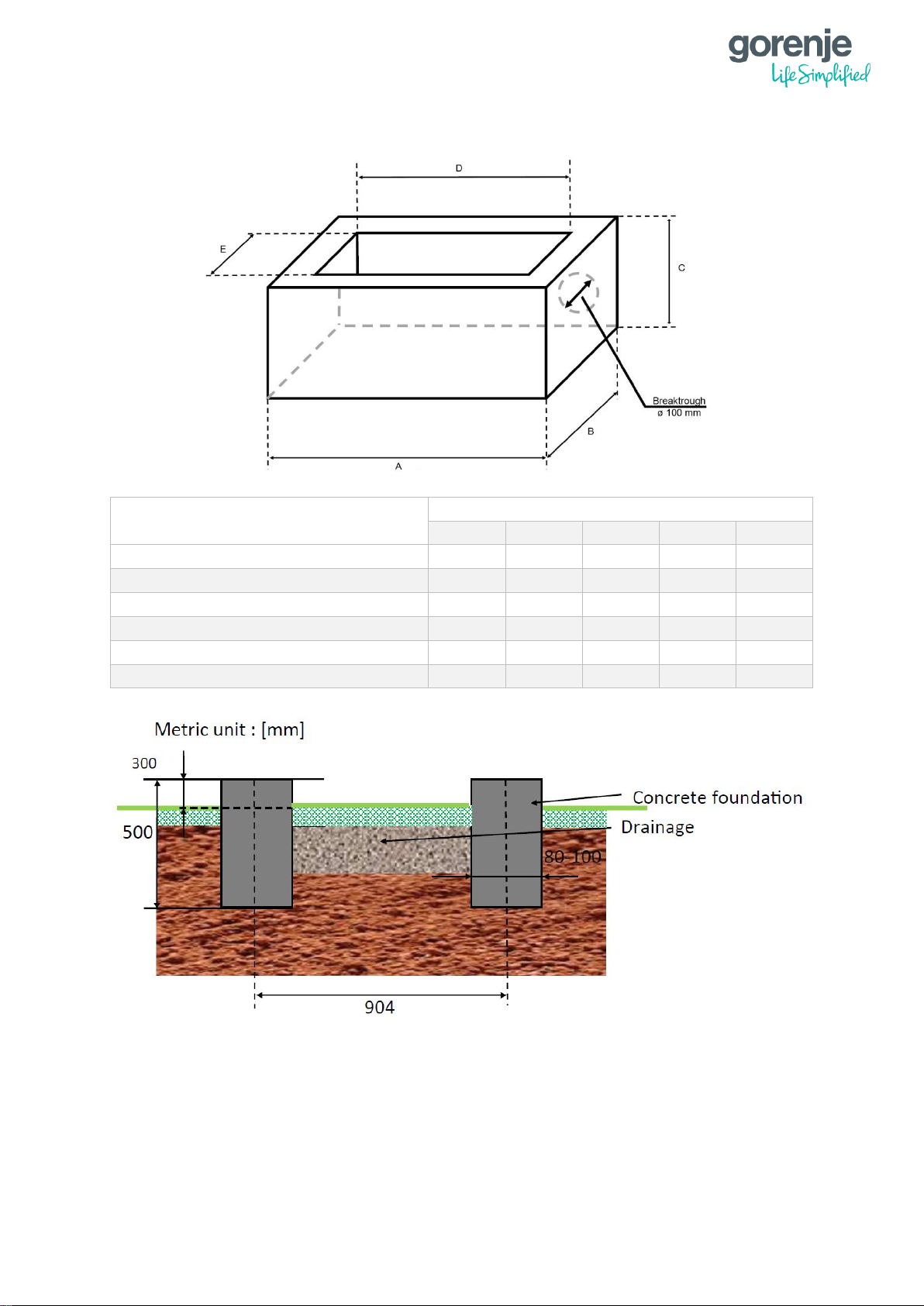

2.3 FOUNDATION

MODEL

SIZE (mm)

A B C D E

ECO COMPACT INVERTER 10A

1390

740

500

1230

580

ECO COMPACT INVERTER 13A

1460

720

500

1300

560

ECO INVERTER 10A

1230

600

500

1070

440

ECO INVERTER 13A

1320

600

500

1160

440

POWER EVI INVERTER 15A

1430

600

500

1270

440

POWER EVI INVERTER 18A

1700

600

500

1540

440

Page 28

21

MODEL

SIZE (mm)

X

Y

ECO COMPACT INVERTER 10A

1140

340

ECO COMPACT INVERTER 13A

740

430

ECO INVERTER 10A

904

343

ECO INVERTER 13A

740

430

POWER EVI INVERTER 15A

720

430

POWER EVI INVERTER 18A

720

430

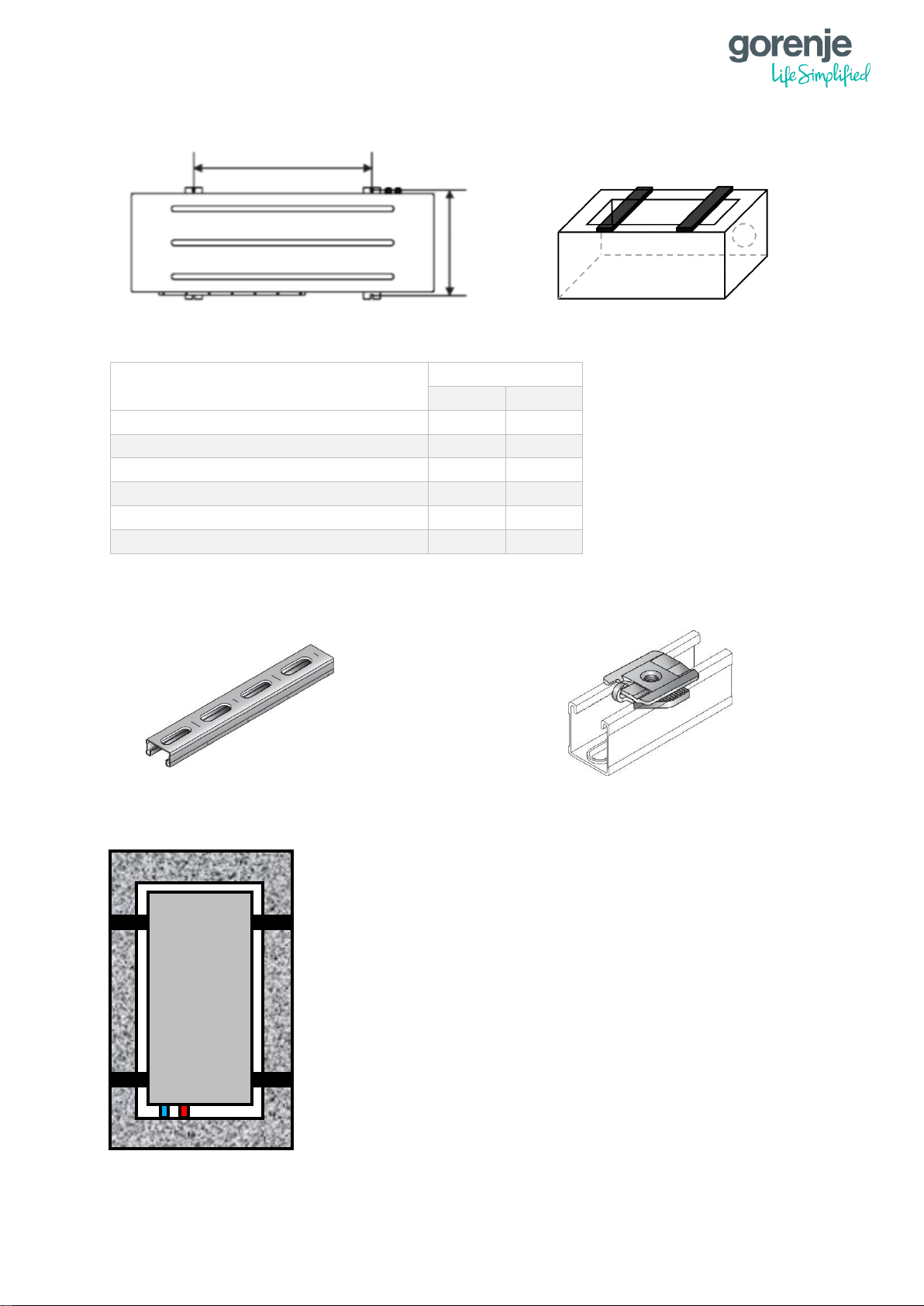

2.3.1 INSTALLATION OF C PROFILE AND LEGS

X

MM-C-16 Double installation profile

MM-S Connector for hose clamp

Y

H

Plan view of the heat pump

fixed on the foundation

Page 29

22

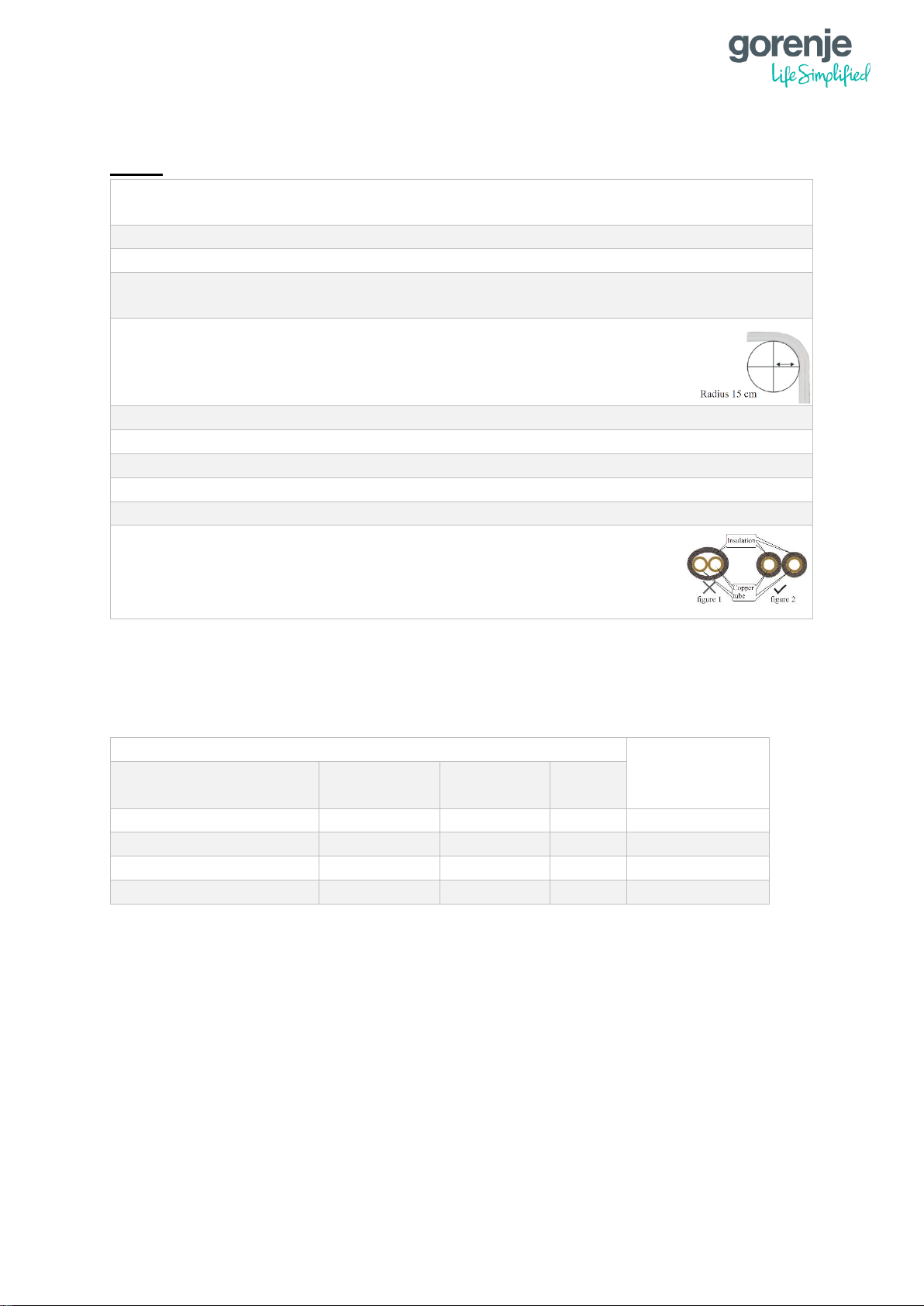

2.4 INSTALATION OF THE REFRIGERANT SYSTEM (SPLIT TYPE)

NOTE:

Only certified personnel are allowed to connect and operate with the refrigerant

system.

It is forbidden to start the unit without Evacuating the refrigerant system.

Pipes used for installation must comply with the specifications of the heat pump

Before starting the unit, always check if the refrigerant connections are sealed and

there is no leakage in the system.

The radius at pipe bends must not be less than 15 cm and the pipes

have to be without flaws.

Do not let any dirt in the refrigerant system

Always use tools without flaws.

Always Evacuate the refrigerant to 500 microns or below.

Evacuating the refrigerant system at sub-zero temperatures is forbidden.

Evacuating the refrigerant system at sub-zero temperatures is forbidden.

When insulating refrigerant pipes, insulate each pipe separately.

The split type heat pumps are factory loaded for a specific length. If the length is longer

than factory load, please check that it does not exceed the maximum length shown in the

table below:

For each meter that is longer than the factory load, you must add 40 g of refrigerant.

REFRIGIRANT PIPING LENGTH

CONNECTIONS

HEAT

PUMP

FACTORY

LOAD

MAXIMUM

LENGTH

ADD

ECO Inverter 10A

5 meters

12 meters

40 g/m

1/4" and 1/2"

ECO Inverter 13A

10 meters

15 meters

40 g/m

3/8" and 1/2"

Power EVI Inverter 15A

15 meters

18 meters

40 g/m

3/8" and 5/8"

Power EVI Inverter 18A

15 meters

18 meters

40 g/m

3/8" and 3/4"

Page 30

23

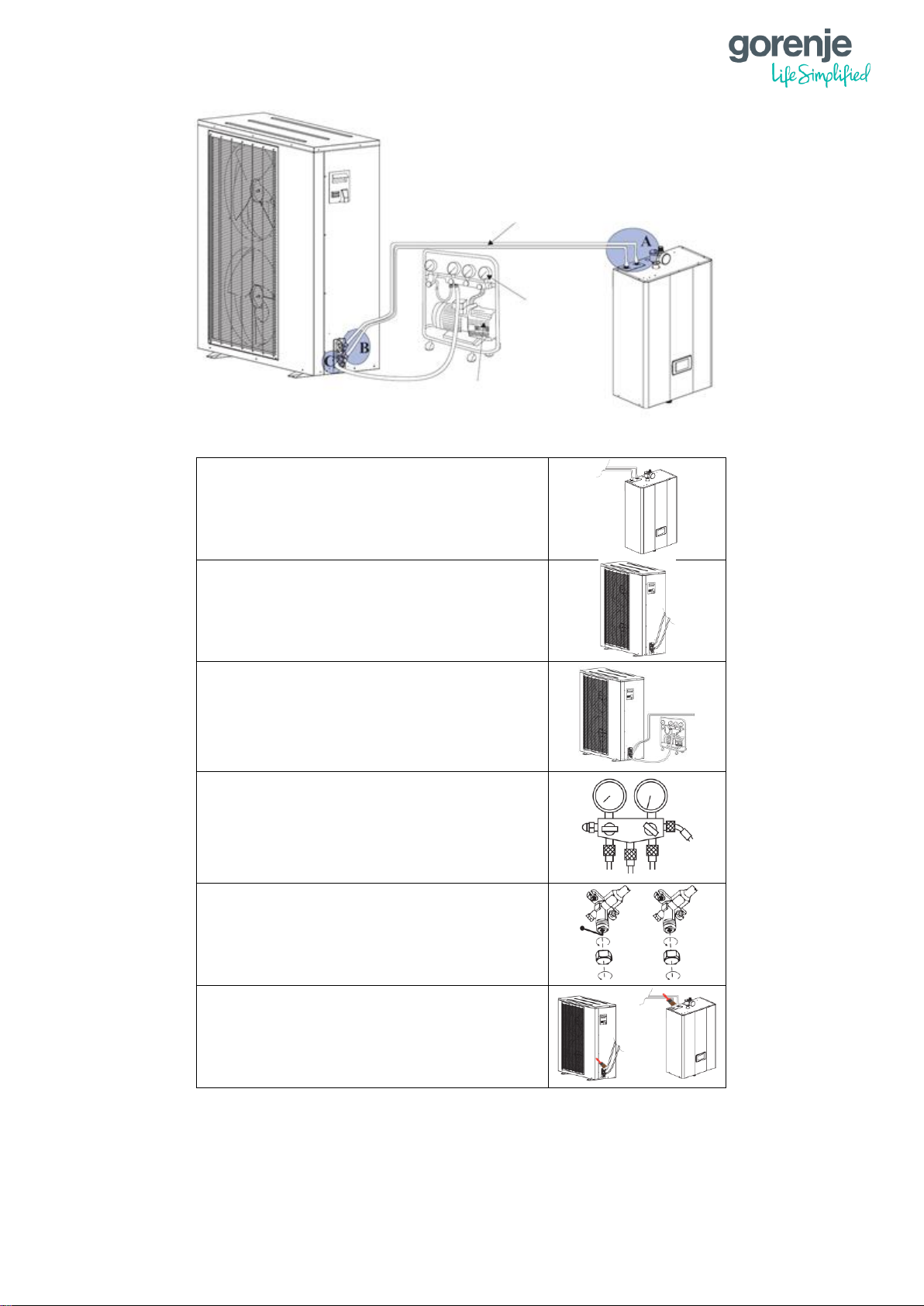

A – Connect the refrigerant piping to the

indoor unit.

B - Connect the other end of the refrigerant

pipes to the outdoor unit.

C – Prepare a vacuum pump and a

pressure gauge. Connect one tube of the

pressure gauge to the vacuum pump and

the other one to the high-pressure

refrigerant connector on the outdoor unit.

Open the pressure gauge and start the

vacuum pump to vacuum the unit to 500

microns or below. After that close, the

pressure gauge and stop vacuuming.

Take off the copper nuts off the connectors

and open the valves with hexagon spanner

as much as possible.

Check if there is any leakage with leakage

detector or soap water. If not, remove the

tubes of the gauges and put back the

copper nuts into the valves.

Vacuum pump

Pressure

gauge

Refrigerant pipe

connection

Page 31

24

2.4.1 HEIGHT DIFFERENCE BETWEEN INDOOR AND OUTDOOR UNIT

EXAMPLE FOR AEROGOR ECO INVERTER 10A

A) Outdoor unit is above Indoor unit

Maximum height difference is X m.

Total pipe length distance can be maximum Y m. In case of 7 m (X) height distance

between indoor and outdoor unit, horizontal pipe distance can be maximum 5 m (Z).

In that case is obligatory to integrate 1 siphon.

B) Outdoor unit is below Indoor unit

Maximum height difference is X m.

Total pipe length distance can be maximum Y m. In case of 5 m height distance

between indoor and outdoor unit, horizontal pipe distance can be maximum 7 m (Z).

Page 32

25

• OUTDOOR UNIT IS ABOVE INDOOR UNIT

Model name

Maximum pipe

length (Y)

Outdoor unit is

above Indoor unit

max. height difference

X [m]

Maximum

horizontal pipe

distance/number

of siphons

(Z)

Aerogor ECO

Inverter 10 A

12 meters

7 m

5 meters / 1

siphon

Aerogor ECO

Inverter 13 A

15 meters

7 m

8 meters / 1

siphon

Aerogor POWER

EVI Inverter 15 A

18 meters

7 m

11 meters / 1

siphon

Aerogor POWER

EVI Inverter 18 A

18 meters

7 m

11 meters / 1

siphon

• OUTDOOR UNIT IS BELOW INDOOR UNIT

Model name

Maximum pipe

length (Y)

Outdoor unit is below

Indoor unit

max. height

difference X [m]

Maximum

horizontal pipe

distance/number

of siphons

(Z)

Aerogor ECO

Inverter 10 A

12 meters

5 m

7 meters / 0

siphon

Aerogor ECO

Inverter 13 A

15 meters

5 m

10 meters / 0

siphon

Aerogor POWER

EVI Inverter 15 A

18 meters

5 m

13 meters / 0

siphon

Aerogor POWER

EVI Inverter 18 A

18 meters

5 m

13 meters / 0

siphon

Page 33

26

2.5 INSTALATION OF HYDRAULIC CONNECTIONS (COMPACT

TYPE)

• The pipes used for connection between indoor and outdoor unit must comply with heat

pump requirements and local regulations.

• If city water is used for filling of the heating system, the water quality must comply with

local regulations.

• Pressure in the heating system must be between 1 – 1.8 bar.

• If the heat pump is being installed into an existing hydraulic system, the system must be

cleaned according to standard procedures.

Maximum pipe length for compact type heat pumps is described in the table below:

*For the correct installation please look at the hydraulic schemes for a specific type of heat

pump from your supplier.

HEAT

PUMP

NO BUFFER

WITH BUFFER

CONNECTIONS

ECO COMPACT Inverter 10A

10 meters

20 meters

G1"

ECO COMPACT Inverter 13A

10 meters

20 meters

G1"

Page 34

27

3 ELECTRICAL WIRING

3.1 AEROGOR ECO INVERTER 10A, 13A AND AEROGOR POWER

EVI INVERTER 15A, 18A

3.1.1 INDOOR UNIT

A

HEAT PUMP POWER SUPPLY (FUSE – 20 A 1P C)

A*

HEAT PUMP POWER SUPPLY (FUSE – 16 A 3P C) (POWER EVI INVERTER 15A,

18A)

B

INTERNAL ELECTRICAL HEATERS POWER SUPPLY (FUSE – 3x10 A 1P C)

C

POWER SUPPLY FOR ADDITIONAL ELECTRICAL HEATER FOR DHW TANK –

DEPENDING ON THE TYPE

D

INDOOR TO OUTDOOR POWER CONNECTION (230 V) – 3x2,5 𝑚𝑚2

D*

INDOOR TO OUTDOOR POWER CONNECTION (400 V) – 5x2,5 𝑚𝑚2 (POWER

EVI INVERTER 15 A, 18 A)

E

CONSTANT 230 V RESERVE – MAX. LOAD 100 W

F

CIRCULATING PUMP – HEATING CIRCUIT 1

G

CIRCULATING PUMP – HEATING CIRCUIT 2

H

CIRCULATING PUMP FOR DHW (230 V on P3 during DHW operation)

I

ADDITIONAL ELECTRICAL HEATER FOR DHW TANK

J

DIVERTING VALVE – DHW MODE WITH POWER

K

MODE SWITCHING SIGNAL (see page 65)

Page 35

28

L

INDOOR TO OUTDOOR COMMUNICATION

Cable included in the package – 3x0,75 𝒎𝒎𝟐 Shielded

M

MIXING VALVE 1 (24 V DC Power supply, 0 – 10 V DC Signal)

N

MIXING VALVE 2 (24 V DC Power supply, 0 – 10 V DC Signal)

O

ELECTRICAL UTILITY LOCK (see page 63)

P

EXTERNAL SWITCH INPUT FOR COOLING MODE (0/1) (see page 55)

R

EXTERNAL SWITCH INPUT FOR HEATING MODE (0/1) (see page 55)

Q

EXTERNAL SWITCH INPUT FOR HIGH TEMPERATURE DEMAND (0/1) (see page

60,61)

3.1.2 TEMPERATURE SENSORS

Temperature sensors have quick connectors with marks.

Temperature

sensor

Cable connected

to the PCB

Extension

cable

Page 36

29

3.1.3 CONNECTION BETWEEN INDOOR AND OUTDOOR UNIT

Communication cables shield must be connected on one side, either indoor or outdoor unit.

Page 37

30

3.2 AEROGOR ECO COMPACT INVERTER 10A, 13A

3.2.1 INDOOR UNIT

A

HEAT PUMP POWER SUPPLY (FUSE – 20 A 1P C)

B

INTERNAL ELECTRICAL HEATERS POWER SUPPLY (FUSE – 3x10 A 1P C)

C

POWER SUPPLY FOR ADDITIONAL ELECTRICAL HEATER FOR DHW TANK –

DEPENDING ON THE TYPE

D

INDOOR TO OUTDOOR POWER CONNECTION (230 V) – 3x2,5 𝑚𝑚2

E

CONSTANT 230 V RESERVE – MAX. LOAD 100W

F

CIRCULATING PUMP – HEATING CIRCUIT 1

G

CIRCULATING PUMP – HEATING CIRCUIT 2

H

CIRCULATING PUMP FOR DHW (230 V on P3 during DHW operation)

I

ADDITIONAL ELECTRICAL HEATER FOR DHW TANK

J

DIVERTING VALVE – DHW MODE WITH POWER

K

MODE SWITCHING SIGNAL (see page 65)

L

INDOOR TO OUTDOOR COMMUNICATION

Cable included in the package – 3x0,75 𝒎𝒎𝟐 Shielded

M

MIXING VALVE 1 (24 V DC Power supply, 0 – 10 V DC Signal)

N

MIXING VALVE 2 (24 V DC Power supply, 0 – 10 V DC Signal)

O

ELECTRICAL UTILITY LOCK

P

EXTERNAL SWITCH INPUT FOR COOLING MODE (0/1) (see page 55)

R

EXTERNAL SWITCH INPUT FOR HEATING MODE (0/1) (see page 55)

Q

EXTERNAL SWITCH INPUT FOR HIGH TEMPERATURE DEMAND (0/1) (see page

60,61)

Page 38

31

S

Tuo – Temperature Sensor – Condenser Outlet

T

Tui – Temperature Sensor – Condenser Inlet

U

Tup – Temperature Sensor – Liquid Refrigerant

V

TV2 – Temperature Sensor – Mixing Circuit 2

W

TV1 – Temperature Sensor – Mixing Circuit 1

X

TR – Temperature Sensor – Room temperature

Y

TC – Temperature Sensor – Heating/Cooling (Buffer or direct circuit)

Z

TW – Temperature Sensor – DHW Tank

FS

FS – FLOW SWITCH

3.2.2 TEMPERATURE SENSORS

The temperature sensors do not have quick connectors on both side, instead there are

terminals for connecting the temperature sensors. An Extension cable is included that still

has a quick connector on one side for the Sensor connection and on the other side are

cables for connecting to the Indoor terminal block.

Temperatur

e sensor

Cable connected

to the PCB

Page 39

32

3.2.3 CONNECTION BETWEEN INDOOR AND OUTDOOR UNIT

Cable connection Indoor – Outdoor Unit

• Power Supply (L, N, PE)

• Communication (A, B)

• Temperature sensors (Tui, Tuo, Tup)

• Flow switch (FS, COM)

Note:

All Cables are included (20 meter), except the Power Supply cable. Terminal block of the

Outdoor Unit is on the back side.

Page 40

33

4 CONTROL UNIT

4.1 DESCRIPTION OF SYMBOLS ON THE CONTROL UNIT

a) Operation mode

This symbol shows the operation mode of the heat pump. Two modes are possible:

automatic or manual operation mode. With a short push on this symbol you can

select the operation mode. The recommended setting is automatic mode.

Automatic operation mode

The heat pump automatically switches between heating or cooling the house and

heating of domestic water!

Manual operation mode

In the manual Operation mode, the heat pump only prepares what you have selected

and ignores timers and the ambient temperature!

Only heating of premises (without domestic water, cooling, timers…)

Only cooling of premises (without domestic water, heating, timers…)

Only domestic water (without heating, cooling, timers…)

QuickHeat DHW (Fast heating of the DHW to the set value with the help of additional

heating sources. During QuickHeat, heating of premises is switched off. When the set

value of DHW water is achieved, the unit continues in normal operation).

e) Display of current

operation mode

f) Additional features,

operation modes

g) Warning or Error

h) Power ON/OFF

i) Settings

a) Operation mode

b) Heating or cooling

c) Communication

d) Heating of

domestic water

Page 41

34

If the “Pause” symbol is displayed, the heat pump is manually switched off!

b) Heating or cooling indicator

The symbol indicates that heating or cooling by ambient temperature or thermostat is

activated, or is activated due to manual operation mode!

Heating or cooling is activated or deactivated based on the ambient temperature!

Factory setting of enabled heating or cooling based on the ambient temperature:

Heating – 18 °C

Cooling – 25 °C

These values can be set as you wish.

Example:

Heating activation temperature is set to 18 °C. This means that when the average

ambient temperature exceeds 18 °C, the heat pump will stop heating. The sun

symbol will disappear from the display.

When the average ambient temperature drops below 18 °C, the sun symbol

reappears on the display and the heat pump will reinitiate heating of the premises,

unless an additional thermostat is used. In that case, the heat pump will require the

deactivation of the thermostat.

c) Activating the heating of domestic water

This symbol is visible on the display only when the heat pump is used for heating

domestic water.

The symbol is always visible on the display, unless the domestic hot water timer is

used.

If the domestic water timer is used, a different symbol appears in the domestic water

heating regime.

d) Communication

This symbol displays the communication status of the heat pump.

A light blue symbol indicates normal communication.

A grey symbol indicates loss of communication.

In this case, an error symbol is displayed as well. Please notify an authorized service

person immediately!

e) Display of the current Operation mode

The heat pump displays the current Operation mode.

Heating

Cooling

Heating of domestic water

QuickHeat

Page 42

35

f) Additional features, modes of operation

This symbol appears when the reduced setpoint for heating is on (see chapter

Reduced Setpoint for Heating).

This symbol appears when the “Floor Curing” feature is on.

This symbol appears when the heat pump is in the “Anti-Legionella” mode.

This symbol appears when “Electrical Utility Lock” is on.

This symbol appears when the heat pump is in the “Defrosting” mode.

This symbol appears when the timer for the preparation of domestic water is on

This symbol appears when the timer for heating / cooling is active.

g) Warning or Error

An exclamation mark appears on the screen, cautioning about an error.

• Minor error; considered as a warning. Heat pump operates normally, but an

authorized service person should be informed immediately!

• Major error; to ensure safety of the system and the heat pump, the pump is shut

off. If the “Emergency Operation” feature is on, the heat pump will continue

working, but only with backup heating sources!

Please inform an authorized service person immediately!

h) Power on/off

Heat pump power on/off.

Heat pump on means that the system is active for heating, cooling and preparation

of hot domestic water! The symbol is blue!

Heat pump off means that the system is switched off except for the Anti-freezing

protection which is on! The symbol is grey!

Anti-freezing protection protects the system from freezing. The heat pump

automatically checks the water temperature. If it drops below a certain value,

potentially causing system damage due to system water freezing, it turns on to

increase the water temperature to a safe temperature level.

i) Settings

This button can be used to access menus.

Page 43

36

4.2 DESCRIPTION OF THE TEMPERATURES ON THE CONTROL

UNIT

j) Current and desired temperature of domestic water

Two temperatures are displayed:

Above – Current temperature

Below – Desired temperature

k) Current and desired temperature of heating/cooling

Two temperatures are displayed:

Above – Current temperature

Below – Desired temperature (calculated from the heating curve or desired

temperature).

l) Ambient temperature

The current ambient temperature is displayed.

m) Room temperature

The current room temperature is displayed.

The temperature sensor does not control the operation of the heat pump! It can be

used for the “Room temp. Effect on the Heating Curve” feature, which automatically

reduces or increases the heating curve by a few percent.

n) Temperature of domestic water

The current temperature of domestic water is displayed.

j) Current and

desired

temperature

of domestic

water

k) Current and

desired

temperature

of heating /

cooling

l) Ambient

temperature

m) Room

temperature

n) Temperature

of domestic

water

Page 44

37

5 QUICK SETTINGS

5.1 PARALLEL MOVE OF THE HEATING CURVE

What is a parallel move of the heating curve?

At start-up, the heating curve is adjusted according to the heating system (Floor heating

system, Radiators, Fan coils) and desired room temperature.

The setting can be changed from the Main screen, but only the complete move of the heating

curve and not each reference point separately. The heating curve can be raised or lowered

for 3 °C (-3 to +3).

By raising the heating curve for 2-3 °C would mean an increase of the room temperature for

approx. 1 °C.

The graph below shows a parallel move of the heating curve – lowering of the heating curve

for 2°C

5.1.1 SETTING THE PARALLEL MOVE OF THE HEATING CURVE – HEATING CIRCUIT

1

Parallel move of the

heating curve for -

2°C (Parallel move

set to - 2)

Heating Curve –

normal setting

(Parallel move set to

0)

Ambient temperature (°C)

Flow temperature of the hating system (°C)

By pressing on the Room

temperature display, an

additional window appears.

With buttons ˝+˝ or ˝– ˝ the

heating curve can be changed

for the desired value. Confirm

the setting with button ˝OK˝.

Page 45

38

5.1.2 SETTING THE PARALLEL MOVE OF THE HEATING CURVE – HEATING CURVE

2

PARALLEL MOVE OF THE HEATING CURVE 2 IS AVAILABLE ONLY WHEN USING TWO

HEATING CIRCUITS!

First the window for parallel move of the first heating circuit appears. To access the setting of

the parallel move for the second heating circuit press . Second page appears with the

setting for the second heating circuit.

With buttons ˝+˝ or ˝– ˝ the heating curve can be changed for the desired value. Confirm the

setting with button ˝OK˝.

5.1.3 SETTING THE DHW TEMPERATURE

By pressing on the DHW temperature, an additional window appears.

With buttons ˝+˝ or ˝– ˝ the DHW set temperature can be changed for the desired value.

Confirm the setting with button ˝OK˝.

Domestic hot water settings depend on the user’s habits.

The recommended setting for domestic hot water is between 47 °C and 50 °C.

Traditional systems (boilers) use smaller domestic water storage tanks, so the temperature

must be significantly higher than in a heat pump system, which causes higher costs of

domestic hot water preparation!

In principle, a heat pump system is planned to store 50 litres of water per person. This

means that a family of four needs a minimum of 200 litres of hot water per day.

Note:

Mixing of cold and warm water in a mixing tap differs according to the systems of how

domestic water is heated.

If the traditional domestic water heating system is used, less hot water is mixed with cold

than in a heat pump system.

By pressing on the room temperature

display, an additional window

appears.

OK

Cancel

System 1 Heating Curve Parallel Move 2: 0°C

OK

Cancel

Desired temperature: 47°C

Page 46

39

In a heat pump system, a larger quantity of hot water is mixed with cold water, as the volume

is larger and the temperature is lower (contributing to lower costs) than in the traditional

system, where the water volume is 2-3 times smaller.

5.2 SETTING THE FIXED TEMPERATURE OF HEATING CIRCUIT

This quick setting is available only when one or both heating circuits are used without heating

curves.

5.2.1 SETTING THE FIXED TEMPERATURE FOR THE FIRST HEATING CIRCUIT

By pressing on the temperature below the line, beside the sun symbol, an additional window

will appear.

With buttons ˝+˝ or ˝– ˝ the fixed temperature for the first heating circuit can be changed for

the desired value. Confirm the setting with button ˝OK˝.

5.2.2 SETTING THE FIXED TEMPERATURE FOR THE SECOND HEATING CIRCUIT

By pressing on the temperature below the line, beside the sun symbol, an additional window

will appear. Press the arrow in the down right corner to access the setting for the second

heating circuit.

With buttons ˝+˝ or ˝– ˝ the fixed temperature for the second heating circuit can be changed

for the desired value. Confirm the setting with button ˝OK˝.

Page 47

40

6 USER INTERFACE

6.1 ARRANGMENT OF MENUS

The control unit has two levels of menus. The first page of the menus is intended for the end

user, and the second page is for the authorized service person or for install settings with

some excluded exceptions.

6.2 MENU ACCESS

By pressing you can access the menus with settings for the end user, as well as the

service settings (see image below)!

Service settings are protected by a service code. The end user is not allowed access to

these settings. The user can view the settings but is not allowed to change them!

User menu Service menu

Page 48

41

6.3 SETTINGS

Heating

The heat pump enables two heating circuits, meaning that it can control two different

temperature modes. Heating/cooling circuit 1 and Heating/cooling circuit 2

When only one heating circuit is in use, the heating settings are defined in the menu

“Heating/cooling circuit 1“!

6.3.1 Heating/Cooling Circuit 1

Page 49

42

6.3.1.1 Heating/Cooling Stops Based on Water ∆T

Temperature setting that allows overheating of the heating system for the set value.

The recommended setting is 2 °C! This enables efficient operation of the Inverter technology

and brings the highest savings.

Please note, that we allow the Heat Pump to overheat the system, to maintain a low working

speed and to avoid a frequent stopping and starting of the compressor.

6.3.1.2 Heating/Cooling Restarts Based on ∆T

The compressor restarts based on the set values of heating/cooling circuits.

The recommended value is 2 °C. This enables efficient operation of the Inverter technology

and brings the highest savings.

6.3.1.3 ∆T Compressor Speed Reduction

This setting tells the system when will the compressor start lowering its working speed. The

recommended value is 2 °C. This enables efficient operation of the Inverter technology and

brings the highest savings.

For example:

If the set/calculated temperature is 30°C and the ˝∆T COMPRESSOR SPEED REDUCTION˝

is set to 2°C, the compressor will work at its max working speed (check chapter ˝Max

Compressor Working Speed˝) till it reaches 28°C. At a 28,1°C and above the compressor

speed will start to decrease towards the lowest working speed of the compressor.

6.3.1.4 Set temp. For cooling

Setting the desired cooling water temperature of the first cooling circuit is set (the second

circuit is set in the menu “Heating/Cooling Circuit 2”).

6.3.1.5 Heating Curve

The heating curve mode is based on the condition that the lower the ambient temperature is,

the higher the water temperature for the heating of facility is. This heating curve mode can

help the heat pump to achieve a higher COP (efficiency rate) and increase the feeling of

comfort in the house.

As the level of home insulation and people’s feeling of cold can differ, the factory set curve

may not be appropriate for everybody. The heating curve may be set according to customers

needs.

The basic setting of the heating curve is made upon the first start-up of the heat pump. The

start-up must be performed by an authorized service person!

The basic setting is always adjusted according to the system that is installed (underfloor

heating, radiators, convectors (Fan Coil)). To determine the basic heating curve, we also

need to take into account the insulation of the facility!

The heat pump enables two heating circuits with different heating curves.

Page 50

43

6.3.1.6 SETTING THE HEATING CURVE FOR THE FIRST HEATING CIRCUIT

Heating curve is set on page 3 of the “Heating/Cooling Circuit 1” menu!

PAGE 3

Tsh – Space heating temp.; T(Ta) – Ambient temp.

Ta1

Ta2 Ta3 Ta4

Ta5

Tsh1

Tsh2

Tsh3

Tsh4

Tsh5

NOTE:

It is recommended to reset only the space heating water temperatures (figure above on

the right). Resetting ambient temperatures for the heating curve affects both heating

circuits.

EXAMPLE

Example:

The customer wants the room temperature to be 21 °C, but the heat pump heats the rooms to 22 °C. In

this case the heating curve must be lowered. On page 3, all temperatures need to be lowered by 2-3 °C,

which means that the room temperature will be lower by 1 °C. If the room temperature is lower than the

desired temperature, the temperature values must be increased.

Page 51

44

6.3.1.7 Room temp. effect on Heating Curve

When the temperature sensor ˝TR˝ is mounted in the living area, this function can make

small corrections of the heating curve, depending on the set “Ideal Room Temp. in Heating”.

Note:

This feature does not mean temperature control by room temperature, but only a correction

of the heating curve!

If this feature is on and the temperature in the room (where the TR room temperature sensor

is located) still exceeds the set ideal value, the heating curve settings should be reset!

6.3.1.8 Ideal Room temp. in Heating

Relates to parameter (6.3.1.6).

The setting is active only when the feature “Room Temp. Effect on Heating Curve” is

enabled.

6.3.1.9 Ideal Room temp. in Cooling

Relates to parameter (6.3.1.6).

The setting is active only when the feature “Room Temp. Effect on Heating Curve” is on

6.3.1.10 Set Temperature for heating – without heating curve

Set temperature for the heating water system – without heating curve.

When the heating curve is disabled, the heat pump operates with fixed system heating water

temperature.

Weather-related control of the heating circuit is disabled, which can lead to higher heating

costs!

NOTE:

The parameters in grey are protected by a service code!

6.3.1.11 Low Temperature Limit

This is for setting the lowest possible temperature that the end customer can set, without

accessing the service level. This setting applies for the heating mode and cooling mode.

6.3.1.12 High Temperature Limit

This is for setting the highest possible temperature that the end customer can set, without

accessing the service level. This setting applies for the heating mode only.

Default setting is 40°C, meaning if a system with higher desired temperatures is used

(radiators, Fan-coils…) the Limitation must be increased.

6.3.1.13 Mixing Valve

Enabling or Disabling the Mixing Valve for the first Heating/Cooling Circuit (Heating/Cooling

Circuit 1).

A check in a box means that the Heating/Cooling Circuit 1 uses a Mixing Valve for the

Circuit.

Please note that if the Mixing Valve is Enabled a temperature sensor (TV1) must be added

after the Mixing Valve.

Page 52

45

6.3.2 Heating/Cooling circuit 2

6.3.2.1 Heating/cooling Circuit 2

A check in a box means that the heating/cooling circuit 2 is on.

6.3.2.2 Set temp. for Cooling

Setting the desired space cooling water temperature in Cooling Circuit 2.

The desired temperature of Cooling Circuit 2 is set.

6.3.2.3 Set Temp. For Heating – without heating curve

Set temperature of space heating water– without heating curve.

When the heating curve is off, the heat pump operates with fixed space heating water

temperature.

Weather-related control of the heating circuit is off, which can lead to higher heating costs!

6.3.2.4 Mixing Valve

Enabling or Disabling the Mixing Valve for the second Heating/Cooling Circuit

(Heating/Cooling Circuit 2).

A check in a box means that the Heating/Cooling Circuit 2 uses a Mixing Valve for the

Circuit.

If the Mixing Valve is Enabled, a temperature sensor (TV2) must be added after the Mixing

Valve.

Page 53

46

NOTE:

If the second heating circuit is active and the room thermostat is not used, a wire must be

placed between TH and COM. If a wire is not placed between TH and COM, the heat pump

will heat the buffer tank according to the lower temperature demand.

6.3.2.5 Heating Curve

The heating curve mode is based on the condition that the lower the ambient temperature is,

the higher the water temperature for the heating of facility is. This heating curve mode can

help the heat pump to achieve a higher COP (efficiency rate) and increase the feeling of

comfort in the house.

As the level of home insulation and people’s feeling of cold can differ, the factory set curve