Gorenje Aerogor ECO 10A, Aerogor POWER 15A, Aerogor ECO 10AS, Aerogor ECO 13A, Aerogor POWER 15AS User Manual

...Page 1

www.gorenje.com

www.gorenje.com

Aerogor ALL-IN-ONE Inverter 10 AS

Aerogor ECO Inverter 10A, 10AS & 13A, 13AS

Aerogor POWER Inverter 15A, 15AS & 18A, 18AS

USER MANUAL

Page 2

EN

Page 3

EN

1 BEFORE USE ................................................................................................................ 1

1.1 SAFETY WARNINGS .............................................................................................. 1

2 Principle of operation of the heat pump .......................................................................... 3

2.1 THE BASIC PRINCIPLE OF OPERATION OF A HEAT PUMP ............................... 3

2.2 INVERTER HEAT PUMP ........................................................................................ 3

2.3 OPTIMISATION OF HEATING COSTS ................................................................... 3

2.3.1 Selection of heat pump ..................................................................................... 3

2.3.2 Heating curve ................................................................................................... 3

2.3.3 Domestic water ................................................................................................ 3

2.3.4 In time of absence ............................................................................................ 4

3 HOW TO MAKE SMALL CHANGES TO REDUCE HEATING COSTS ........................... 4

4 EMERGENCY OPERATION .......................................................................................... 6

4.1 LOCATION OF THE EMERGENCY SWITCH ......................................................... 8

5 CONTROL UNIT ...........................................................................................................10

5.1 DESCRIPTION OF SYMBOLS ON THE CONTROL UNIT .....................................10

5.2 DESCRIPTION OF TEMPERATURES ON THE CONTROL UNIT .........................13

6 RISING / LOWERING THE ROOM TEMPERATURE ....................................................14

6.1 Exclusively according to ambient tepperature .........................................................14

6.2 Combination of Ambient temperature and Room temperature ................................14

7 QUICK SETTINGS ........................................................................................................15

7.1.1 SETTING THE PARALLEL MOVE OF THE HEATING CURVE – HEATING

CIRCUIT 1 .....................................................................................................................15

7.1.2 SETTING THE PARALLEL MOVE OF THE HEATING CURVE – HEATING

CURVE 2.......................................................................................................................16

7.2 SETTING THE DHW TEMPERATURE ..................................................................16

7.3 SETTING THE FIXED TEMPERATURE OF HEATING CIRCUIT ...........................17

7.3.1 SETTING THE FIXED TEMPERATURE FOR THE FIRST HEATING CIRCUIT

17

7.3.2 SETTING THE FIXED TEMPERATURE FOR THE SECOND HEATING

CIRCUIT .......................................................................................................................17

8 USER INTERFACE .......................................................................................................18

8.1 ARRANGMENT OF MENUS ..................................................................................18

8.2 MENU ACCESS .....................................................................................................18

9 SETTINGS ....................................................................................................................19

9.1 HEATING/COOLING CIRCUIT 1 ............................................................................19

9.1.1 Heating/Cooling Stops Based on Water ∆T .....................................................20

Page 4

EN

9.1.2 Heating/Cooling Restarts Based on ∆T ...........................................................20

9.1.3 ∆T Compressor Speed Reduction ...................................................................20

9.1.4 Set temp. For cooling ......................................................................................20

9.1.5 Heating Curve .................................................................................................20

9.1.5.1 SETTING THE HEATING CURVE FOR THE FIRST HEATING CIRCUIT ...21

9.1.6 Room temp. effect on Heating Curve ..............................................................22

9.1.7 Ideal Room temp. in Heating ...........................................................................22

9.1.8 Ideal Room temp. in Cooling ...........................................................................22

9.1.9 Set Temperature for heating – without heating curve ......................................22

9.1.10 Low Temperature Limit ....................................................................................22

9.1.11 High Temperature Limit ................................................................ ...................22

9.1.12 Mixing Valve ....................................................................................................22

9.2 HEATING/COOLING CIRCUIT 2 ............................................................................23

9.2.1 Heating/cooling Circuit 2 .................................................................................23

9.2.2 Set temp. for Cooling .......................................................................................23

9.2.3 Set Temp. For Heating – without heating curve ...............................................23

9.2.4 Mixing Valve ....................................................................................................23

9.2.5 Heating Curve .................................................................................................24

9.2.5.1 SETTING THE HEATING CURVE FOR THE SECOND HEATING CIRCUIT

25

9.3 DHW SETTINGS ....................................................................................................25

9.3.1 Setpoint DHW .................................................................................................26

9.3.2 DHW Restart ∆T Setting ..................................................................................26

9.3.3 Shifting Priority ................................................................................................26

9.3.3.1 Enabling or Disabling the Shifting Priority function: ......................................26

9.3.4 Shifting Priority Starting Temperature ..............................................................26

9.3.5 Sanitary Water Min. Working Hours ................................................................26

9.3.6 Heating Max. Working Hours ...........................................................................26

9.3.7 Allowable temp. Drift in Heating ......................................................................27

9.3.8 DHW Backup Heater for Shifting Priority .........................................................27

9.3.9 DHW ECO Operation ......................................................................................27

9.3.10 Ambient Temp. to Start DHW ECO Operation .................................................27

9.4 DHW STORAGE ....................................................................................................27

9.4.1 Sanitary Hot Water Storage Function ..............................................................27

9.4.2 Sanitary Hot Water Storage Timer ...................................................................27

9.4.3 Reheating Function .........................................................................................28

9.4.4 Reheating Function Timer ...............................................................................28

Page 5

EN

9.4.5 Reheating Set Temp. ......................................................................................28

9.4.6 Reheating Restart ∆T Setting ..........................................................................28

9.5 REDUCED SETPOINT ...........................................................................................29

9.5.1 Reduced Setpoint ............................................................................................29

9.5.2 Temp. Drop/Rise ............................................................................................. 29

9.5.3 Timer for Reduced Setpoint Function ..............................................................29

9.5.4 Quiet Operation ............................................................................................... 29

9.5.5 Allowable Temp. Drifting .................................................................................30

9.5.6 Timer for Quiet Operation ................................................................................30

9.6 ANTI – LEGIONELLA .............................................................................................30

9.6.1 Anti – Legionella Program ...............................................................................30

9.6.2 Day and Time ..................................................................................................31

9.6.3 Setpoint ...........................................................................................................31

9.6.4 Duration ..........................................................................................................31

9.6.5 Finish Time .....................................................................................................31

9.7 VACATION MODE .................................................................................................32

9.7.1 Vacation Mode ................................................................................................32

9.7.2 Sanitary Hot Water Temp. Drop during Vacation Mode ...................................32

9.7.3 Heating Water Temp. Drop during Vacation Mode ..........................................32

9.7.4 Vacation Start Date .........................................................................................32

9.7.5 Vacation Finish Date .......................................................................................32

9.8 USER MANAGEMENT ...........................................................................................33

9.8.1 Permission Level .............................................................................................33

9.8.2 Heating/Cooling ON/OFF timer .......................................................................33

9.8.3 Language ........................................................................................................ 33

9.8.4 Set Date and Time ................................................................ ..........................33

9.8.5 Distribution System Setting .............................................................................33

9.8.6 Save Current Settings .....................................................................................33

9.8.7 Load Saved Settings .......................................................................................33

9.8.8 Switch to Factory Settings ...............................................................................34

9.9 MODE SETTINGS..................................................................................................34

9.9.1 Ambient Temp. To Start Heating .....................................................................34

9.9.2 Ambient Temp. To Start Cooling .....................................................................35

9.10 BACKUP HEATING ................................................................................................35

9.11 WATER PUMP SETTINGS ....................................................................................36

9.12 FLOOR CURING ....................................................................................................36

9.13 ELECTRICAL UTILITY LOCK ................................................................................36

Page 6

EN

9.14 OTHER OPTIONS..................................................................................................37

9.15 UNIT REAL-TIME DATA ................................ ........................................................ 37

10 ERROR CODES ........................................................................................................38

10.1 ERROR CODES SHOWN ON THE DISPLAY ........................................................38

10.2 ERROR CODE MENU ...........................................................................................38

10.2.1 ACCESSING THE ERROR CODE MENU .......................................................38

10.2.2 INFORMATIONS IN THE ERROR CODE MENU ............................................38

10.2.3 INFO PAGE ....................................................................................................39

10.3 ERROR CODE LIST ..............................................................................................41

11 Cleaning the magnetic / Dirt filter Caleffi ....................................................................45

12 WATER PRESSURE IN THE SYSTEM .....................................................................46

Page 7

EN

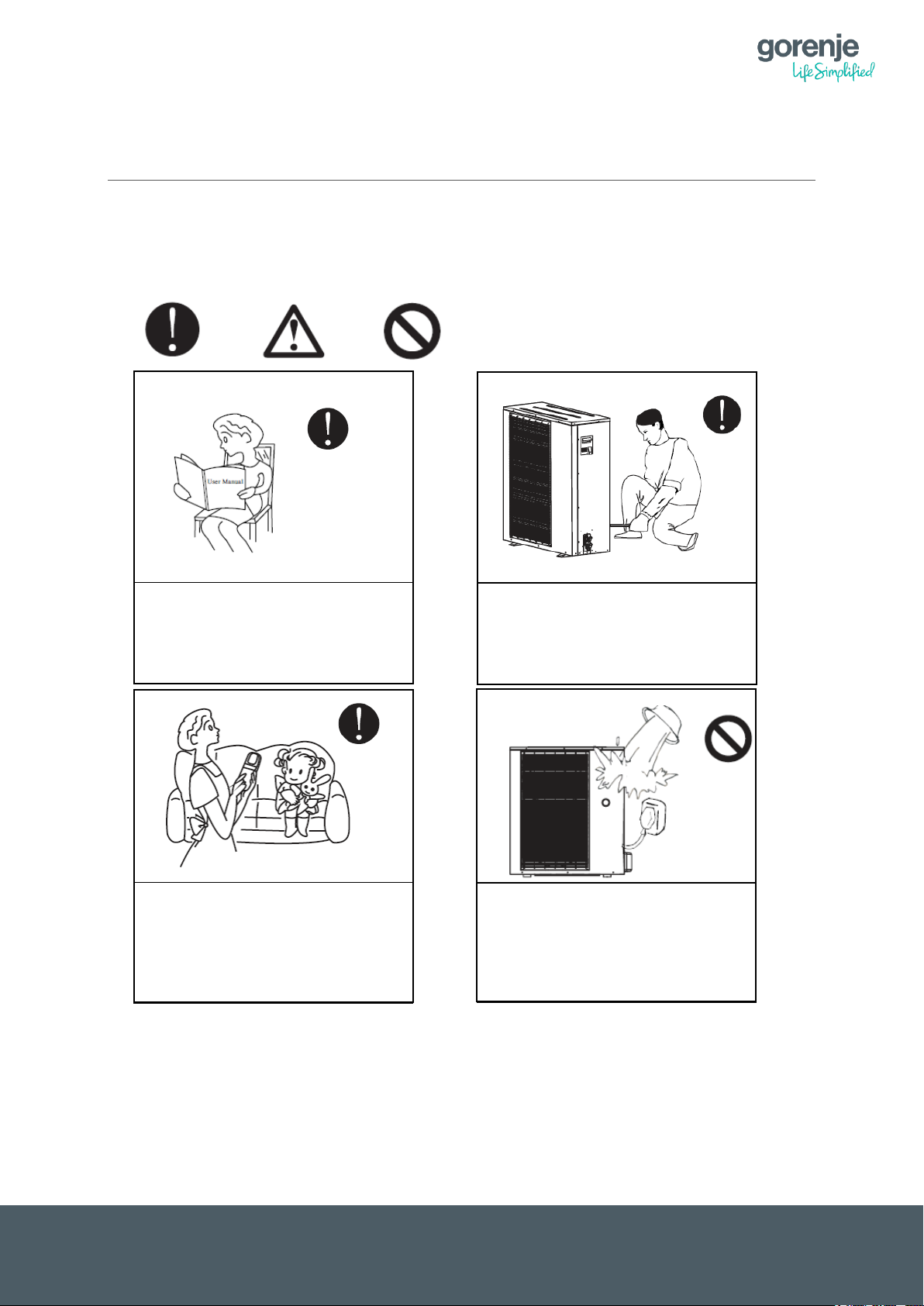

Installation, maintenance and

authorised person from Gorenje!

Pouring of water or any other

damage on the appliance!

Please read this instruction

This appliance is not intended for

person responsible for their safety!

1 BEFORE USE

1.1 SAFETY WARNINGS

Warning Caution Prohibition

manual carefully before using for

the first time!

uninstallation of the heat pump

can only be performed by an

use by people with reduced physical,

sensory or mental capabilities, or

lack of experience or knowledge,

unless they have supervision by a

fluid on or in the appliance is

strictly prohibited! Failure to

comply can lead to injuries and

1

Page 8

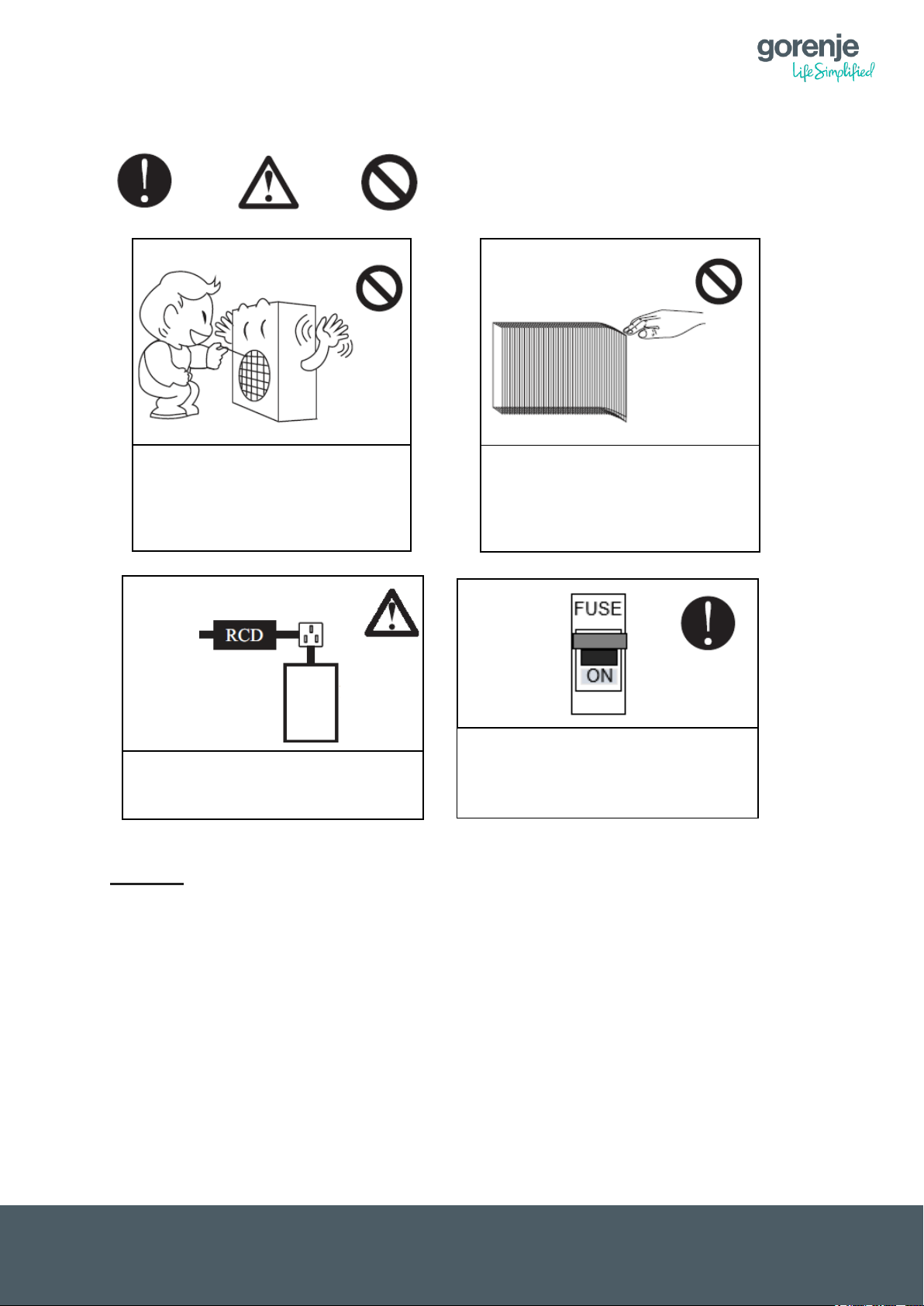

EN

Do not touch the air outlet grid

Do not touch the leaves of the

It is advisable to install a switch on

the nominal current of 300 mA.

Main

Power

Suppl

COMPACT Units (Indoor and Outdoor Unit

automatic anti-freezing protection.

Warning Caution Prohibition

when the fan motor is operating!

vaporiser – their sharp surface

can cause cuts!

IndoorUnit

the differential current (RCD) with

with water system connections) must be

always with power supply to prevent freezing

of the water in the piping. Unit has an

Warning:

The Compact Type heat pumps have a hydraulic connection, which means that the medium

in the pipes (water or a mixture of water and concentrate antifreeze) can freeze if the heat

pump is not under voltage for a longer time. This may cause major damage to the heat pump

and on the system itself. For further information, please contact an authorized Installer or

Gorenje HVAC.

2

Page 9

EN

2 PRINCIPLE OF OPERATION OF THE HEAT PUMP

2.1 THE BASIC PRINCIPLE OF OPERATION OF A HEAT PUMP

A heat pump operates similarly as a refrigerator. In a refrigerator, liquids evaporate due to

received thermal energy from the surrounding air and this energy is emitted at a desired spot

during condensation (Carnot’s cycle). A heat pump works in the opposite direction: it accepts

thermal energy from the surrounding air and emits it in heated premises, using the natural

heat collector of the environment. Ground and surface water, earth’s warmth, solar energy

and ambient air can be used as energy sources. The system is composed of four units:

evaporator, compressor, condenser and damper. Heat energy is transferred via the coolant.

In the evaporator, the coolant receives heat energy and evaporates. In the compressor, the

vapour is compressed, which makes it heat up intensively. This hot vapour transmits thermal

energy from the condenser to the heating water and liquefies. In the damper, the coolant

expands (pressure reduces to the starting pressure, from there it proceeds to the evaporator

and the cycle repeats).

2.2 INVERTER HEAT PUMP

Inverter heat pumps use variable-speed compressors. Traditional heat pumps use fixed

power/rotation speed compressors. In inverter compressors, the compressor speed

constantly adapts to the heat losses of the room and the energy value of the source (air,

brine or water, depending on the system).

In traditional heat pumps, the power of the compressor is always the same. Compressor

starts with full power and when it achieves the desired values/temperatures, it shuts off and

waits until it restarts.

Inverter heat pumps work for a longer period of time, but with lower power (adjusting to the

premises), which means lower consumption of electric energy.

2.3 OPTIMISATION OF HEATING COSTS

2.3.1 Selection of heat pump

The first step towards the optimisation of heating costs is selecting the appropriate heat

pump. An over-dimensioned or under-dimensioned heat pump can cause higher heating

costs and shorten the lifespan of the appliance.

2.3.2 Heating curve

A correctly set heating curve is of key importance for the optimisation of heating costs. If a

room thermostat is used, the heating curve must be adjusted to the building as if it was not

existent. A too highly set heating curve can cause up to 30% higher heating costs!

2.3.3 Domestic water

Incorrect or too highly set desired temperature of domestic water can significantly increase

heating costs! In a traditional system with a 100-litre boiler, where domestic water is heated

by a heating element, the temperature necessary for meeting the needs of an average family

is much higher than in a system where domestic water is heated by means of a heat pump.

The difference lies in the quantity of the water in the water storage tank.

With heat pumps special water storage tanks are used that have a larger volume than

traditional boilers! For a heat pump system, daily consumption of 50 litres is assumed,

multiplied by the number of users of domestic water.

Example:

Family of four – 4 persons x 50 litres = 200 litres

3

Page 10

EN

2.3.4 In time of absence

Complete shutdown of a heat pump can lead to higher heating costs. We recommend using

the vacation mode, which lowers the temperature of heating and domestic water during your

absence, but does not allow the system to get completely cold, which would cause higher

heating costs upon system restart.

The next chapter describes how to make small steps to save a lot of energy.

3 HOW TO MAKE SMALL CHANGES TO

REDUCE HEATING COSTS

Every degree counts!

The use of heating energy depends on the temperature of the room. In a heated

apartment, every degree above 20 means up to 6 % higher energy use, i.e. higher

cost.

All windows and doors must be properly sealed!

Old windows and doors are usually not completely sealed, so draft takes warmth out

of the apartment. If crannies are visible, it’s crucial to take action as soon as possible.

Try to solve the problem by sticking sealing tapes on the contact surfaces or cut

notches for plastic sealing profiles / set the hardware or seal the internal casements in

classic (box) windows with separate casements.

Correct ventilation!

To feel good we need enough oxygen in the air, and we can get fresh air by means of

ventilation. If done correctly, we use up to 20% less energy for heating. Ventilate by

opening the window for a few minutes. Do this three times per day in each room. The

lower the temperature of ambient air, the shorter the ventilation should be.

Do not cover heating elements!

If heating elements are covered, air pockets occur that waste energy. It is

recommended to have curtains that only reach the level of radiators. Covering heating

elements can increase energy use by up to 10 %.

Set the appropriate temperature!

Is your heating regulation set to automatic or do your kids use it? If you want to

select the correct temperatures for your living environment, please consult with

experts who will tell you what temperature is the best for each living space. Already

two degrees – 22 degrees instead of 20 – can cause 12 % higher energy

consumption!

Check the possible causes for high energy consumption related to heating

If you think that you are using excessive amounts of energy, it is advisable to check

among the multiple causes for high heat losses:

– Old radiator valves (where thermostat valves are not built in);

– Poor or damaged heat insulation on internal installations after the measuring

point;

– Poorly maintained internal installations;

– Decrepit or improperly set temperature regulation automatics;

– Poor heat insulation of buildings (esp. older ones);

– Poorly sealed windows (especially without insulated glazing);

4

Page 11

EN

– Incorrect ventilation of premises (when ventilating rooms, make sure the

radiators are closed);

– The charged quantity of used heat for central heating of premises depends

mainly on the average outside temperature, so the consumption increases in

the start of the heating season, usually achieves the highest value in January,

and decreases at the end of the heating season;

– Longer accounting period than usual – may be caused by the inability to read

the status in the regular period, or if the ownership transfer documents arrived

too soon etc.;

– Incorrect operation of the measuring device;

– Status for the period of defect of the measuring device was determined based

on statistics.

Installation of heat cost allocators or calorimeters

If your apartment is in an old apartment building and you are paying for heat energy

consumption per square meter (flat rate), you can install heat cost allocators on

individual radiators in your apartment or, depending on the building, a calorimeter

before heating enters the apartment. In this case you can save heat energy

independently of your neighbour. However, in order to do this, more than one half of

apartment owners must be in favour of this with respect to the Rules on dividing and

billing heating costs in multiple-dwelling buildings. This way an individual apartment

building can save between 20 and 30 % of energy.

5

Page 12

EN

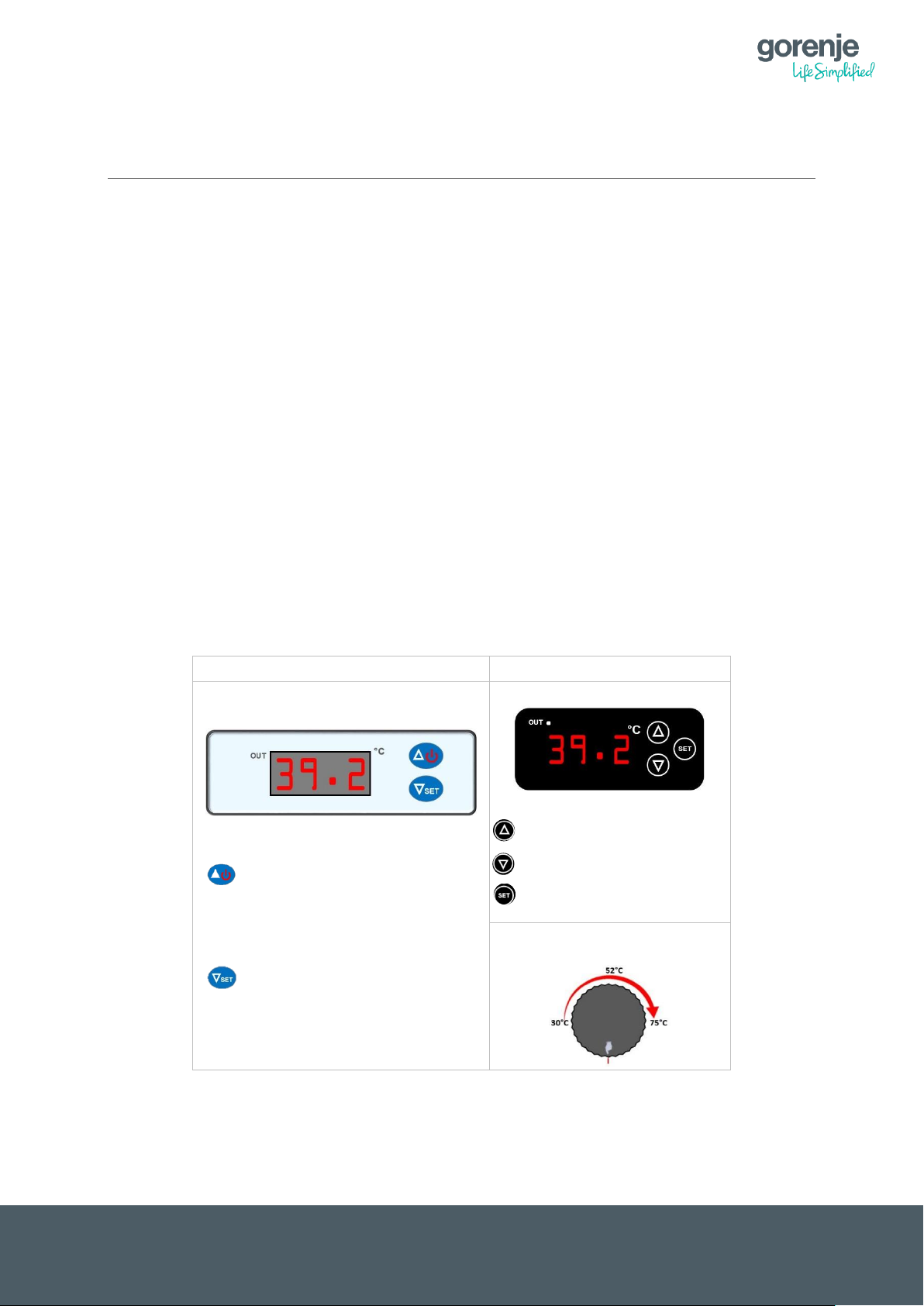

AS (Split) series

All In One AS series

Digital Thermostat

- hold = ON/OFF;

- push = Rising of the desired

temperature

- hold = stting the tempearure

- push = lowering of the desired

tempearture

Digital Thermostat

- rising of the set temp.

- lowering of the set temp.

- setting the desired temp.

Mechanical Thermostat

(DHW)

4 EMERGENCY OPERATION

Emergency operation is the operation of a heat pump with auxiliary heating sources such as

electric heaters, gas furnace, oil furnace or other heating source controlled by the heat pump.

Emergency operation is divided into Automatic and Manual operation.

Automatic Emergency Mode:

If the control detects that it cannot run the heat pumps as sources of heating due to possible

errors, additional heating sources for heating system and heating sanitary water will be

automatically switched on.

Note: the current Heating and DHW set temperature is automatically reduced by 7°C.

Manual emergency mode:

Activating this mode is a responsibility of the end user. This method is used in the event of a

failure of the master controller when it cannot control the system.

The heat pump has a manual switch to activate the manual emergency operation (the signal

light on the switch lights-up when it is activated). At this moment, all settings on the main

controller become invalid, because the control of the desired temperatures is exclusively

controlled by the additional thermostats that are installed on the device.

On the digital thermostat, set the desired heating temperature and the desired DHW

temperature on the mechanical thermostat.

Note: If the Digital Thermostat is manually switched OFF, so that on teh screan are three red

lines - - - , the Automatic emergency operation will be disabled.

6

Page 13

EN

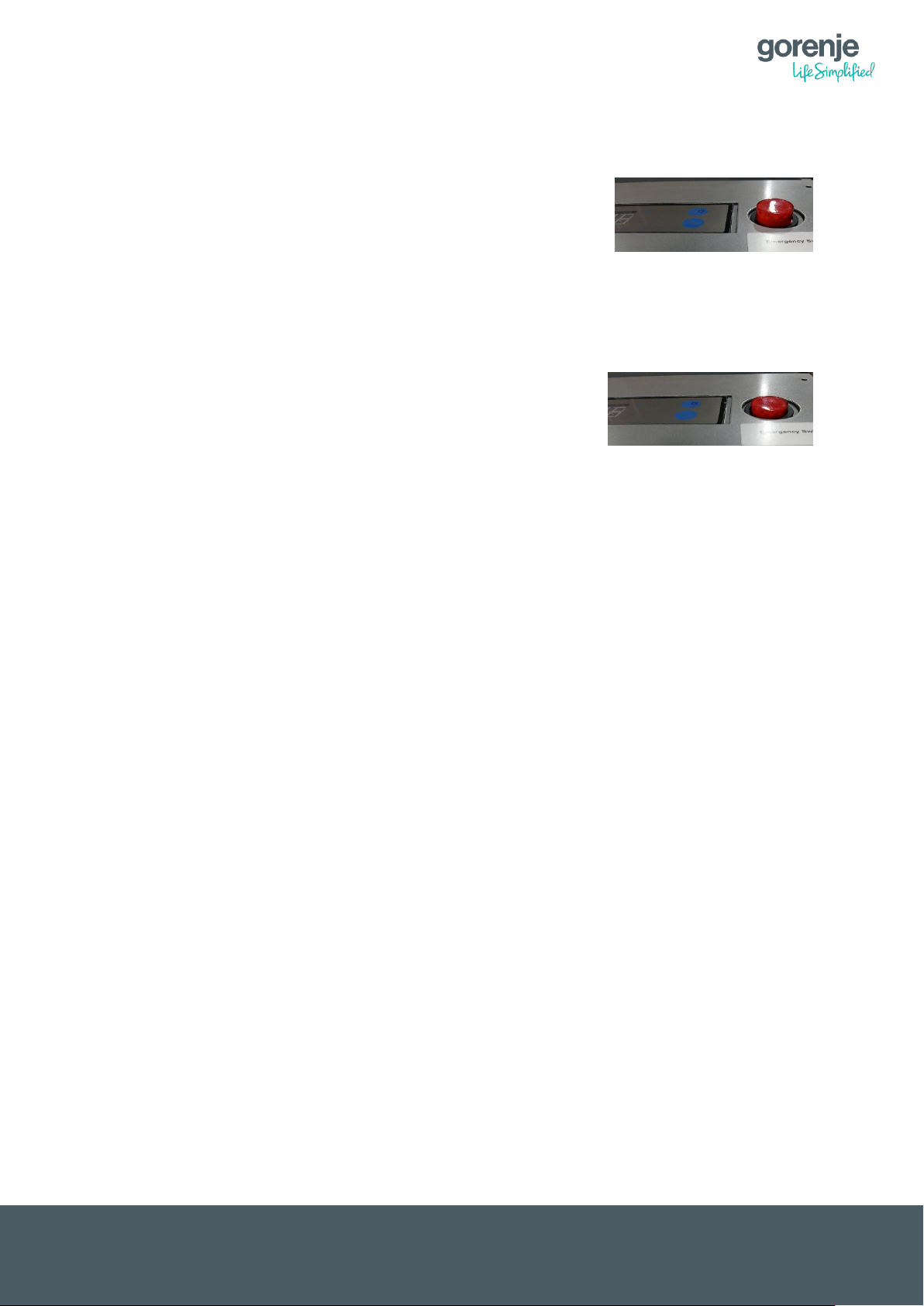

Emergancy switch in OFF position – Heat pump works according to teh settings on the

main controller (tuch-screen controll panel)

Emergancy switch in ON position – Setting of teh main controller (tuch-screen controll

panel) will be disabled. All Circulating pumps (P0, P1, P2 an P3) start to work (always ON).

Temperature controll is only with Digital thermostat (controlling the set temperature of

electrical heaters). Diverting valve has to be set manualy to switch from Heating system to

DHW heating.

7

Page 14

EN

gorenje

gorenje

1 2 1

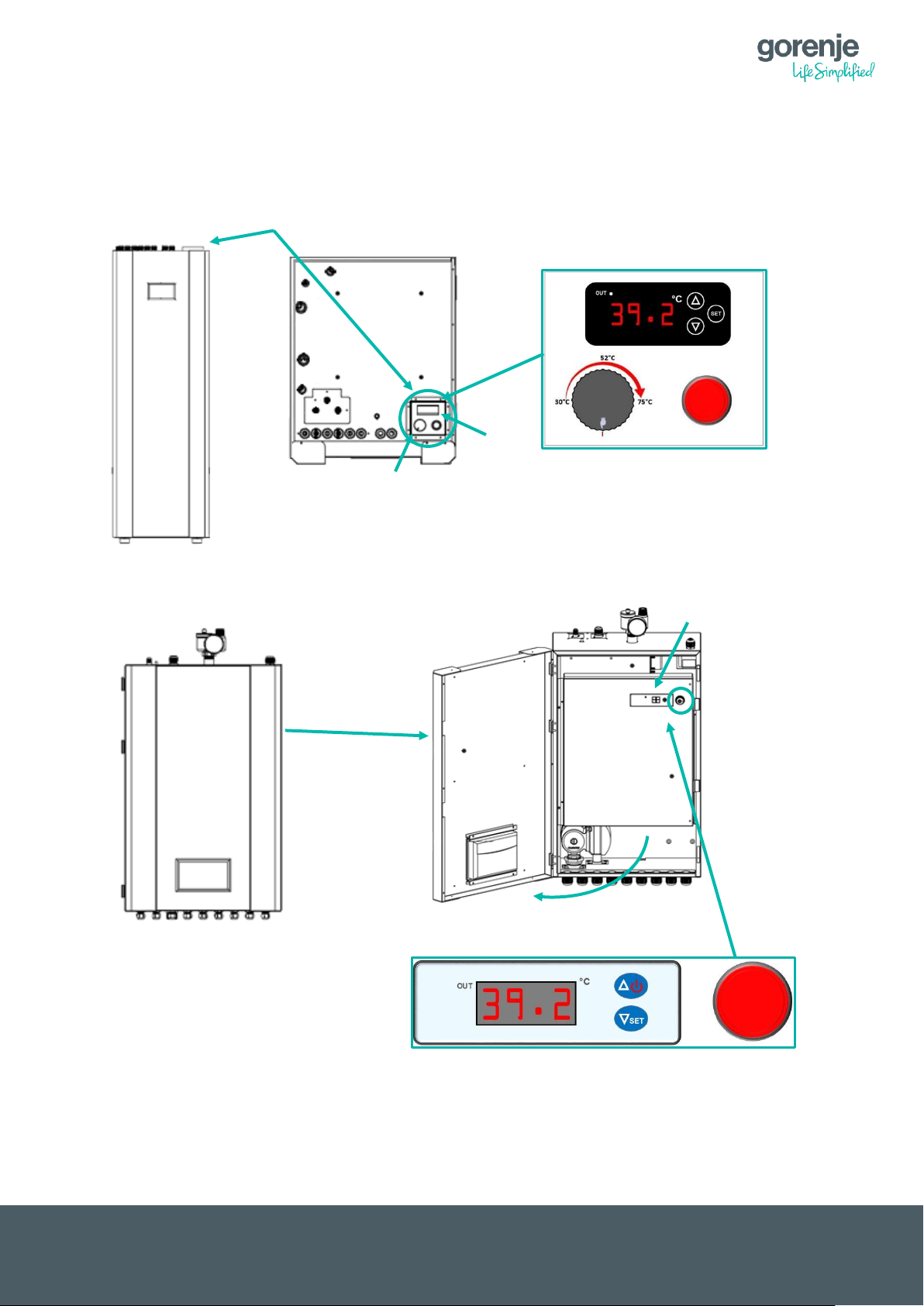

4.1 LOCATION OF THE EMERGENCY SWITCH

ALL-IN-ONE Inverter AS

AEROGOR Inverters AS

8

Page 15

EN

1. Digital thermostat controls the max flow temperature in case of Back-Up or Auto–

Emergency operation. In the Back-Up and Auto–Emergency operation, the Main

controller is still controlling the heating temperature.

Auto – Emergency operation

Example:

If the Unit turns ON the Back-Up heaters or Emergency operation and the setting on

the Digital thermostat is set to 30°C, the heaters will work only until 30°C and then

switch OFF regardless of the demand from the main controller. If, however the Digital

thermostat is set to 60°C, the Main controller will switch OFF the heaters according to

its needs.

Manual operation (manual emergency switch ON):

In manual operation all the circulating pumps are switched ON and the Electrical

heaters work according to the setting on the Digital thermostat, regardless of the

setting on the Main controller.

Example:

if the Manual emergency operation is ON and the temperature set on the Digital

thermostat is set to 50, the heating water will be heated to 50°C. The Circulating

pumps will run all the time.

2. Analog thermostat controls the max flow temperature in case of Back-Up or Auto –

Emergency operation for DHW. In Back-Up and Auto–Emergency operation, the Main

controller is still controlling the DHW temperature.

Auto – Emergency operation

Example:

If the Unit turns ON the Back-Up heaters or Emergency operation for DHW and the

setting on the thermostat is set to 40°C, the heaters will work only until 40°C and then

switch OFF regardless of the demand from the main controller. If however the

thermostat is set to 60°C, the Main controller will switch OFF the heaters according to

its needs (DHW set temperature).

9

Page 16

EN

e) Display of current

operation mode

f) Additional features,

operation modes

g) Warning or Error

h) Power ON/OFF

i) Settings

a) Operation mode

b) Heating or cooling

f) Communication

g) Heating of

domestic water

5 CONTROL UNIT

5.1 DESCRIPTION OF SYMBOLS ON THE CONTROL UNIT

a) Operation mode

This symbol shows the operation mode of the heat pump. Two modes are possible:

automatic or manual operation mode. With a short push on this symbol you can

select the operation mode. The recommended setting is automatic mode.

Automatic operation mode

The heat pump automatically switches between heating or cooling the house and

heating of domestic water!

Manual operation mode

In the manual Operation mode, the heat pump only prepares what you have selected

and ignores timers and the ambient temperature!

Only heating of premises (without domestic water, cooling, timers…)

Only cooling of premises (without domestic water, heating, timers…)

Only domestic water (without heating, cooling, timers…)

10

Page 17

EN

QuickHeat DHW (Fast heating of the DHW to the set value with the help of additional

heating sources. During QuickHeat, heating of premises is switched off. When the set

value of DHW water is achieved, the unit continues in normal operation).

If the “Pause” symbol is displayed, the heat pump is manually switched off!

b) Heating or cooling indicator

The symbol indicates that heating or cooling by ambient temperature or thermostat is

activated, or is activated due to manual operation mode!

Heating or cooling is activated or deactivated based on the ambient temperature!

Factory setting of enabled heating or cooling based on the ambient temperature:

Heating – 18 °C

Cooling – 25 °C

These values can be set as you wish.

Example:

Heating activation temperature is set to 18 °C. This means that when the average

ambient temperature exceeds 18 °C, the heat pump will stop heating. The sun

symbol will disappear from the display.

When the average ambient temperature drops below 18 °C, the sun symbol

reappears on the display and the heat pump will reinitiate heating of the premises,

unless an additional thermostat is used. In that case, the heat pump will require the

deactivation of the thermostat.

c) Activating the heating of domestic water

This symbol is visible on the display only when the heat pump is used for heating

domestic water.

The symbol is always visible on the display, unless the domestic hot water timer is

used.

If the domestic water timer is used, a different symbol appears in the domestic water

heating regime.

d) Communication

This symbol displays the communication status of the heat pump.

A light blue symbol indicates normal communication.

A grey symbol indicates loss of communication.

In this case, an error symbol is displayed as well. Please notify an authorized service

person immediately!

e) Display of the current Operation mode

The heat pump displays the current Operation mode.

Heating

Cooling

Heating of domestic water

QuickHeat

11

Page 18

EN

f) Additional features, modes of operation

This symbol appears when the reduced setpoint for heating is on (see chapter

Reduced Setpoint for Heating).

This symbol appears when the “Floor Curing” feature is on.

This symbol appears when the heat pump is in the “Anti-Legionella” mode.

This symbol appears when “Electrical Utility Lock” is on.

This symbol appears when the heat pump is in the “Defrosting” mode.

This symbol appears when the timer for the preparation of domestic water is on

This symbol appears when the timer for heating / cooling is active.

This symbol appears when Heating ECO operation is active.

g) Warning or Error

An exclamation mark appears on the screen, cautioning about an error.

Minor error; considered as a warning. Heat pump operates normally, but an

authorized service person should be informed immediately!

Major error; to ensure safety of the system and the heat pump, the pump is shut

off. If the “Emergency Operation” feature is on, the heat pump will continue

working, but only with backup heating sources!

Please inform an authorized service person immediately!

h) Power on/off

Heat pump power on/off.

Heat pump on means that the system is active for heating, cooling and preparation

of hot domestic water! The symbol is blue!

Heat pump off means that the system is switched off except for the Anti-freezing

protection which is on! The symbol is grey!

Anti-freezing protection protects the system from freezing. The heat pump

automatically checks the water temperature. If it drops below a certain value,

potentially causing system damage due to system water freezing, it turns on to

increase the water temperature to a safe temperature level.

i) Settings

This button can be used to access menus.

12

Page 19

EN

j) Current and

desired

temperature

of domestic

water

k) Current and

desired

temperature

of heating /

cooling

l) Ambient

temperature

m) Room

temperature

n) Temperature

of domestic

water

5.2 DESCRIPTION OF TEMPERATURES ON THE CONTROL UNIT

j) Current and desired temperature of domestic water

Two temperatures are displayed:

Above – Current temperature

Below – Desired temperature

k) Current and desired temperature of heating/cooling

Two temperatures are displayed:

Above – Current temperature

Below – Desired temperature (calculated from the heating curve or desired

temperature).

l) Ambient temperature

The current ambient temperature is displayed.

m) Room temperature

The current room temperature is displayed.

The temperature sensor does not control the operation of the heat pump! It can be

used for the “Room temp. Effect on the Heating Curve” feature, which automatically

reduces or increases the heating curve by a few percent.

n) Temperature of domestic water

The current temperature of domestic water is displayed.

13

Page 20

EN

6 RISING / LOWERING THE ROOM

TEMPERATURE

There are two posibilitis, to contrll the room temperature:

1. Exclusively accordint to Ambient temperature (Outdoor temperature)

2. Combination of Ambient temperature and Room temperature

6.1 EXCLUSIVELY ACCORDING TO AMBIENT TEPPERATURE

By pressing in the middle of the house an additional window appears. First window is for

setting the Paralel move of the Heating curve for the First Heating Circuit. Changing this

setting will change the Room temperature. It can be set from -3 to 3. The number 0 is the

default setting of the Heating curve. By rising the setting to +3, the room temperature will

increase for 1-2°C, depending on the heating system (Radiators, floor heating system, Fan-

Coils). Both heating circuits can be set separately.

- Setting the parallel move for the first heating circuit – see chapter 7.1.1

- Setting the parallel move for the second heating circuit – see chapter 7.1.2

6.2 COMBINATION OF AMBIENT TEMPERATURE AND ROOM TEMPERATURE

If TR room temperature sensor is used, the function ˝Room temp. effect on Heating Curve˝

can be enabled. Heat pump will not start or stop according to the Romm temperature it will

automaticly correct the heating curve, to come close as possible to the Ideal room

temperature setting.

For example: If the room temperature is too high, the Heating curve will automaticly

decrease. If the room temperature is to low, the heating curve will automaticly increase.

If the room temperature is still far from the Ideal Room temperature setting, the heating curve

itselfe must be increased or decreased.

Ideal room temperature setting can be changed in menu ˝Heating/Cooling Citcuit 1˝, page 4

– ˝Ideal Room temp. in Heating˝

Page 4

Note:

This setting influences both heating circuits.

14

Page 21

EN

Parallel move of the

set to - 2)

Heating Curve –

Ambient temperature (°C)

Flow temperature of the hating system (°C)

By pressing on the Room

temperature display, an

additional window appears.

With buttons ˝+˝ or ˝– ˝ the

heating curve can be changed

for the desired value. Confirm

the setting with button ˝OK˝.

7 QUICK SETTINGS

What is a parallel move of the heating curve?

At start-up, the heating curve is adjusted according to the heating system (Floor heating

system, Radiators, Fan coils) and desired room temperature.

The setting can be changed from the Main screen, but only the complete move of the heating

curve and not each reference point separately. The heating curve can be raised or lowered

for 3 °C (-3 to +3).

By raising the heating curve for 2-3 °C would mean an increase of the room temperature for

approx. 1 °C.

The graph below shows a parallel move of the heating curve – lowering of the heating curve

for 2°C

normal setting

(Parallel move set to

heating curve for -

2°C (Parallel move

7.1.1 SETTING THE PARALLEL MOVE OF THE HEATING CURVE – HEATING

CIRCUIT 1

15

Page 22

EN

By pressing on the room temperature

display, an additional window

appears.

OK

Cancel

System 1 Heating Curve Parallel Move 2: 0°C

OK

Cancel

Desired temperature: 47°C

7.1.2 SETTING THE PARALLEL MOVE OF THE HEATING CURVE – HEATING

CURVE 2

PARALLEL MOVE OF THE HEATING CURVE 2 IS AVAILABLE ONLY WHEN USING TWO

HEATING CIRCUITS!

First the window for parallel move of the first heating circuit appears. To access the setting of

the parallel move for the second heating circuit press . Second page appears with the

setting for the second heating circuit.

With buttons ˝+˝ or ˝– ˝ the heating curve can be changed for the desired value. Confirm the

setting with button ˝OK˝.

7.2 SETTING THE DHW TEMPERATURE

By pressing on the DHW temperature, an additional window appears.

With buttons ˝+˝ or ˝– ˝ the DHW set temperature can be changed for the desired value.

Confirm the setting with button ˝OK˝.

Domestic hot water settings depend on the user’s habits.

The recommended setting for domestic hot water is between 47 °C and 50 °C.

Traditional systems (boilers) use smaller domestic water storage tanks, so the temperature

must be significantly higher than in a heat pump system, which causes higher costs of

domestic hot water preparation!

In principle, a heat pump system is planned to store 50 litres of water per person. This

means that a family of four needs a minimum of 200 litres of hot water per day.

Note:

Mixing of cold and warm water in a mixing tap differs according to the systems of how

domestic water is heated.

If the traditional domestic water heating system is used, less hot water is mixed with cold

than in a heat pump system.

16

Page 23

EN

In a heat pump system, a larger quantity of hot water is mixed with cold water, as the volume

is larger and the temperature is lower (contributing to lower costs) than in the traditional

system, where the water volume is 2-3 times smaller.

7.3 SETTING THE FIXED TEMPERATURE OF HEATING CIRCUIT

This quick setting is available only when one or both heating circuits are used without heating

curves.

7.3.1 SETTING THE FIXED TEMPERATURE FOR THE FIRST HEATING CIRCUIT

By pressing on the temperature below the line, beside the sun symbol, an additional window

will appear.

With buttons ˝+˝ or ˝– ˝ the fixed temperature for the first heating circuit can be changed for

the desired value. Confirm the setting with button ˝OK˝.

7.3.2 SETTING THE FIXED TEMPERATURE FOR THE SECOND HEATING

CIRCUIT

By pressing on the temperature below the line, beside the sun symbol, an additional window

will appear. Press the arrow in the down right corner to access the setting for the second

heating circuit.

With buttons ˝+˝ or ˝– ˝ the fixed temperature for the second heating circuit can be changed

for the desired value. Confirm the setting with button ˝OK˝.

17

Page 24

EN

User menu Service menu

8 USER INTERFACE

8.1 ARRANGMENT OF MENUS

The control unit has two levels of menus. The first page of the menus is intended for the end

user, and the second page is for the authorized service person or for install settings with

some excluded exceptions.

8.2 MENU ACCESS

By pressing you can access the menus with settings for the end user, as well as the

service settings (see image below)!

Service settings are protected by a service code. The end user is not allowed access to

these settings. The user can view the settings but is not allowed to change them!

18

Page 25

EN

9 SETTINGS

Heating

The heat pump enables two heating circuits, meaning that it can control two different

temperature modes. Heating/cooling circuit 1 and Heating/cooling circuit 2

When only one heating circuit is in use, the heating settings are defined in the menu

“Heating/cooling circuit 1“!

9.1 HEATING/COOLING CIRCUIT 1

19

Page 26

EN

9.1.1 Heating/Cooling Stops Based on Water ∆T

Temperature setting that allows overheating of the heating system for the set value.

The recommended setting is 2 °C! This enables efficient operation of the Inverter technology

and brings the highest savings.

Please note, that we allow the Heat Pump to overheat the system, to maintain a low working

speed and to avoid a frequent stopping and starting of the compressor.

9.1.2 Heating/Cooling Restarts Based on ∆T

The compressor restarts based on the set values of heating/cooling circuits.

The recommended value is 2 °C. This enables efficient operation of the Inverter technology

and brings the highest savings.

9.1.3 ∆T Compressor Speed Reduction

This setting tells the system when will the compressor start lowering its working speed. The

recommended value is 2 °C. This enables efficient operation of the Inverter technology and

brings the highest savings.

For example:

If the set/calculated temperature is 30°C and the ˝∆T COMPRESSOR SPEED REDUCTION˝

is set to 2°C, the compressor will work at its max working speed (check chapter ˝Max

Compressor Working Speed˝) till it reaches 28°C. At a 28,1°C and above the compressor

speed will start to decrease towards the lowest working speed of the compressor.

9.1.4 Set temp. For cooling

Setting the desired cooling water temperature of the first cooling circuit is set (the second

circuit is set in the menu “Heating/Cooling Circuit 2”).

9.1.5 Heating Curve

The heating curve mode is based on the condition that the lower the ambient temperature is,

the higher the water temperature for the heating of facility is. This heating curve mode can

help the heat pump to achieve a higher COP (efficiency rate) and increase the feeling of

comfort in the house.

As the level of home insulation and people’s feeling of cold can differ, the factory set curve

may not be appropriate for everybody. The heating curve may be set according to customers

needs.

The basic setting of the heating curve is made upon the first start-up of the heat pump. The

start-up must be performed by an authorized service person!

The basic setting is always adjusted according to the system that is installed (underfloor

heating, radiators, convectors (Fan Coil)). To determine the basic heating curve, we also

need to take into account the insulation of the facility!

The heat pump enables two heating circuits with different heating curves.

20

Page 27

EN

Tsh – Space heating temp.; T(Ta) – Ambient temp.

Ta1

Ta2 Ta3 Ta4

Ta5

Tsh1

Tsh2

Tsh3

Tsh4

Tsh5

NOTE:

It is recommended to reset only the space heating water temperatures (figure above on

the right). Resetting ambient temperatures for the heating curve affects both heating

circuits.

EXAMPLE

Example:

The customer wants the room temperature to be 21 °C, but the heat pump heats the rooms to 22 °C. In

this case the heating curve must be lowered. On page 3, all temperatures need to be lowered by 2-3 °C,

which means that the room temperature will be lower by 1 °C. If the room temperature is lower than the

desired temperature, the temperature values must be increased.

9.1.5.1 SETTING THE HEATING CURVE FOR THE FIRST HEATING CIRCUIT

Heating curve is set on page 3 of the “Heating/Cooling Circuit 1” menu!

PAGE 3

21

Page 28

EN

9.1.6 Room temp. effect on Heating Curve

When the temperature sensor ˝TR˝ is mounted in the living area, this function can make

small corrections of the heating curve, depending on the set “Ideal Room Temp. in Heating”.

Note:

This feature does not mean temperature control by room temperature, but only a correction

of the heating curve!

If this feature is on and the temperature in the room (where the TR room temperature sensor

is located) still exceeds the set ideal value, the heating curve settings should be reset!

9.1.7 Ideal Room temp. in Heating

Relates to parameter (6.3.1.6).

The setting is active only when the feature “Room Temp. Effect on Heating Curve” is

enabled.

9.1.8 Ideal Room temp. in Cooling

Relates to parameter (6.3.1.6).

The setting is active only when the feature “Room Temp. Effect on Heating Curve” is on

9.1.9 Set Temperature for heating – without heating curve

Set temperature for the heating water system – without heating curve.

When the heating curve is disabled, the heat pump operates with fixed system heating water

temperature.

Weather-related control of the heating circuit is disabled, which can lead to higher heating

costs!

NOTE:

The parameters in grey are protected by a service code!

9.1.10 Low Temperature Limit

Service setting.

9.1.11 High Temperature Limit

Service setting.

9.1.12 Mixing Valve

Service setting.

22

Page 29

EN

9.2 HEATING/COOLING CIRCUIT 2

9.2.1 Heating/cooling Circuit 2

A check in a box means that the heating/cooling circuit 2 is on.

9.2.2 Set temp. for Cooling

Setting the desired space cooling water temperature in Cooling Circuit 2.

The desired temperature of Cooling Circuit 2 is set.

9.2.3 Set Temp. For Heating – without heating curve

Set temperature of space heating water– without heating curve.

When the heating curve is off, the heat pump operates with fixed space heating water

temperature.

Weather-related control of the heating circuit is off, which can lead to higher heating costs!

9.2.4 Mixing Valve

Service setting.

NOTE:

If the second heating circuit is active and the room thermostat is not used, a wire must be

placed between TH and COM. If a wire is not placed between TH and COM, the heat pump

will heat the buffer tank according to the lower temperature demand.

23

Page 30

EN

Tsh – Space heating temp.; T(Ta) – Ambient temp.

Ta1

Ta2 Ta3

Ta4

Ta5

Tsh1

Tsh2

Tsh3

Tsh4

Tsh5

9.2.5 Heating Curve

The heating curve mode is based on the condition that the lower the ambient temperature is,

the higher the water temperature for the heating of facility is. This heating curve mode can

help the heat pump to achieve a higher COP (efficiency rate) and increase the feeling of

comfort in the house.

As the level of home insulation and people’s feeling of cold can differ, the factory set curve

may not be appropriate for everybody. The heating curve may be set according to customers

needs.

The basic setting of the heating curve is made upon the first start-up of the heat pump. The

start-up must be performed by an authorized service person!

The basic setting is always adjusted according to the system that is installed (underfloor

heating, radiators, convectors (Fan Coil)). To determine the basic heating curve, we also

need to take into account the insulation of the facility!

The heat pump enables two heating circuits with different heating curves.

NOTE:

It is recommended to reset only the space heating water temperatures (figure above on the

right). Resetting ambient temperatures for the heating curve affects both heating circuits.

24

Page 31

EN

EXAMPLE

9.2.5.1 SETTING THE HEATING CURVE FOR THE SECOND HEATING CIRCUIT

Heating curve is set on page 2 of the “Heating/Cooling Circuit 2” menu!

Example:

The customer wants the room temperature to be 21 °C, but the heat pump heats the rooms to 22 °C.

In this case the heating curve must be lowered. On page 3, all temperatures need to be lowered by 2-

3 °C, which means that the room temperature will be lower by 1 °C. If the room temperature is lower

than the desired temperature, the temperature values must be increased.

9.3 DHW SETTINGS

25

Page 32

EN

9.3.1 Setpoint DHW

Setting of the desired temperature for domestic water.

9.3.2 DHW Restart ∆T Setting

Domestic hot water restart setting.

Example:

Desired temperature of domestic water is 47 °C, and the domestic hot water restart ∆T

setting is 5 °C. (47–5=42)

This means that the heat pump will restart the heating of domestic water when the

temperature drops below 42 °C!

Recommended domestic hot water restart ∆T setting is 5 °C!

9.3.3 Shifting Priority

The heat pump has absolute priority for the preparation of domestic hot water. With this

feature, the priority adjusts to the heat losses when the ambient temperature reaches a

certain point.

This feature is used in new buildings that still lack insulation and that will be without

insulation for at least one heating season.

9.3.3.1 Enabling or Disabling the Shifting Priority function:

Disabled (default setting) – the Heat Pump will switch to Heating mode only when the

desired DHW temperature is reached.

Enabled – the Heat Pump will decide based on the temperatures of the heating system if it

should switch to heating although the DHW set temperature is not reached yet.

For example:

Set temperature for DHW is 47°C and the Heat Pump is currently working in DHW mode.

The actual DHW temperature is 44°C, meaning it still has to heat up the DHW for another

3°C, before it can switch to heating mode (heating the House). In that moment, the Unit sees

that the temperature of the Heating water for the heating system is dropping for a certain

value, meaning it is a high risk of undercooling the house. It switches to Heating mode to

provide heat to the house. When the temperature is in safe level, or the max set time for

heating is exceeded, the Heat Pump switches back to DHW mode to heat up the DHW to the

desired value, before it switches back to Heating mode.

9.3.4 Shifting Priority Starting Temperature

Only valid if Shifting Priority enabled!

Setting the Ambient temperature to activate the Shifting Priority Function.

If the Shifting Priority Function is enabled it will not be active before the Ambient temperature

falls below a certain value (Shifting Priority Starting temperature).

9.3.5 Sanitary Water Min. Working Hours

Only valid if Shifting Priority enabled!

This setting is set in Minutes!

The Heat Pump will try to heat up the DHW for a minimum time before it switches to Heating,

even if all other conditions for Shifting Priority are met.

9.3.6 Heating Max. Working Hours

Only valid if Shifting Priority enabled!

This setting is set in Minutes!

26

Page 33

EN

When the Heat Pump switches to Heating mode in Shifting priority mode, it will allow the unit

to stay in Heating mode only for a certain time, before it switches back to heat up the DHW.

9.3.7 Allowable temp. Drift in Heating

Only valid if Shifting Priority enabled!

Setting for the max. Temperature drift in heating system during DHW heating mode. Only

when this value is exceeded, the Unit will switch to heating.

9.3.8 DHW Backup Heater for Shifting Priority

Only valid if Shifting Priority enabled!

Disabled – Backup heater will work only according to the normal back-up stings.

Enabled – Backup Heater will help to faster heat up the DHW.

9.3.9 DHW ECO Operation

Service setting.

9.3.10 Ambient Temp. to Start DHW ECO Operation

Service setting.

9.4 DHW STORAGE

9.4.1 Sanitary Hot Water Storage Function

Feature on/off.

A check in the box means that the feature is on.

This feature enables water preparation at a certain time and day. It is set for each day of the

week individually.

9.4.2 Sanitary Hot Water Storage Timer

Setting domestic water heater timer!

27

Page 34

EN

If the fields are green, domestic water heating is on.

If the fields are grey, it means the heat pump is not heating domestic water.

9.4.3 Reheating Function

Feature on/off.

A check in the box means that the feature is on.

The feature enables the setting of a second temperature mode for domestic water heating.

This means that it enables two different temperatures of domestic water at various times in

an individual day of the week.

Setting of a second temperature of domestic hot water corresponds to the parameter

“Reheating Set Temp.”.

9.4.4 Reheating Function Timer

Setting the second timer for the heating of domestic hot water!

If the fields are green, domestic water heating is on.

If the fields are grey, it means the heat pump is not heating domestic water.

9.4.5 Reheating Set Temp.

Setting the desired temperature for the second mode of heating of domestic water.

This temperature will be the default temperature for domestic water heating in the “double

mode”.

The temperature can be lower or higher than the primary setting of the desired domestic hot

water temp.!

Note:

If timers overlap, the heat pump will take into account the higher level of desired domestic

water temperature!

9.4.6 Reheating Restart ∆T Setting

For the second temperature mode for heating domestic water, this parameter is used to set

the DHW restart. The recommended setting is 5 °C.

Example:

Desired domestic hot water temperature is 45 °C, and the DHW restart setting is 5 °C. (45–

5=40).

Heat pump will start reheating domestic water once it drops below 40 °C.

28

Page 35

EN

9.5 REDUCED SETPOINT

9.5.1 Reduced Setpoint

Feature on/off.

A check in the box means that the feature is on.

The feature lowers water temperature by the set value for both heating circuits in the set

time. The main purpose is to lower room temperature at night.

9.5.2 Temp. Drop/Rise

The space heating water temperature drop/rise is set for both heating circuits.

9.5.3 Timer for Reduced Setpoint Function

Timer for feature activation is set!

If the fields are green, domestic water heating is on.

If the fields are grey, it means the heat pump is not

heating domestic water.

9.5.4 Quiet Operation

Feature on/off.

A check in the box means that the feature is on.

Quiet operation means that the heat pump tries to operate with the lowest possible rpm of

compressor and fans, so that noise is reduced in the night time.

The maximum deviation from the desired space heating water temperature is set.

29

Page 36

EN

9.5.5 Allowable Temp. Drifting

The maximum allowable space heating water temperature drifting is set for both circuits

when the “Quiet operation” feature is on.

9.5.6 Timer for Quiet Operation

Timer for the Quiet Operation Feature!

If the fields are green, the feature is on.

If the fields are grey, it means the feature is off – normal

operation!

Note:

If the timers “Reduced Setpoint” and “Quiet Operation” overlap, the heat pump will operate in

the quiet mode with an additional temperature drop, as set in the “Temp. Drop/Rise”.

9.6 ANTI – LEGIONELLA

9.6.1 Anti – Legionella Program

Feature on/off.

A check in the box means that the feature is on.

For the Anti-legionella feature to operate, an electric heater must be installed in the DHW

tank!

What is legionella?

Legionellae are bacteria that can appear in ground and surface fresh water. They can also

be found in pipelines, heating systems (apartments, hospitals, and hotels), cisterns, boilers,

whirlpools, pools with heated water, cooling water, cooling towers, air humidifiers, diffusers

etc.

The basic condition for legionella to develop is increased water temperature. The largest

populations of bacteria can be found in the temperature zone between 38 and 42 °C, which

is the temperature most often used when taking a shower. With such conditions, a single

legionella can breed to several hundred thousand in merely three days. It has also been

30

Page 37

EN

found in pipelines with low flow rates or where water was stagnant in pipes for a longer

period of time (inactive parts of buildings, basement etc.). Domestic hot water storage tanks

with layered temperature distribution are also possible sources of contamination. Legionella

can also be found in cool water, but its growth is hindered, which makes it almost nonexistent or at least very rare in subterranean waters and cold potable waters. Water from

pipelines is hygienically safe. Legionella colonies start thriving in hot water systems, where

water can be stagnant for weeks in a hot water tank, offering an additional breeding ground

for legionellae and other bacteria.

To prevent legionella, water must be heated. In fact, it must be heated to over 60° C, in order

to destroy bacteria. It takes 3.5 minutes for the bacteria to be destroyed. This means that

water must be heated to a minimum of 60 °C for at least 3.5 minutes.

9.6.2 Day and Time

The day and time for the feature to be switched on is set here.

The recommended setting is Monday at 2:00 AM.

9.6.3 Setpoint

The desired temperature (setpoint) of the Anti-legionella feature is set here.

9.6.4 Duration

Here you can determine how long the heat pump should maintain the desired temperature in

the Anti-legionella programme!

9.6.5 Finish Time

If the heat pump cannot heat the domestic water in the set time, the programme is

terminated and an error message appears on the display.

31

Page 38

EN

9.7 VACATION MODE

9.7.1 Vacation Mode

A check in the box means that the feature is on.

This feature can be used for the time when you are absent and there is no need for heating

or hot water. The date of departure (start date) and date of arrival (finish date) is set and the

desired heating and water temperature drop for the duration of your vacation.

9.7.2 Sanitary Hot Water Temp. Drop during Vacation Mode

Setting domestic hot water temperature drop during the vacation mode.

9.7.3 Heating Water Temp. Drop during Vacation Mode

Setting heating water temperature (heating) drop during the vacation mode

9.7.4 Vacation Start Date

Setting the start date of vacation.

9.7.5 Vacation Finish Date

Setting the finish date of vacation.

32

Page 39

EN

9.8 USER MANAGEMENT

9.8.1 Permission Level

Enter the Service Password to enter the Service / Installer level.

9.8.2 Heating/Cooling ON/OFF timer

Disabled (default setting) – Normal operation

Enabled – The Heat Pump Will Heat and Cool only according to the setting of a Timer. In the

other time, it will be only in Antifreeze protection mode.

Please note, that this has no influence on the DHW mode.

SETTING THE TIMER:

Green fields mean that heating/cooling depending on the

ambient temperature is on.

Gray fields mean that heating/cooling depending on the

ambient temperature is blocked.

9.8.3 Language

Setting the language of the interface.

9.8.4 Set Date and Time

Setting the time and date.

9.8.5 Distribution System Setting

Service setting.

9.8.6 Save Current Settings

Service setting.

9.8.7 Load Saved Settings

Reset all settings to “Install Settings”.

33

Page 40

EN

All settings are reset to the settings stored during the last intervention by an authorized

service person.

9.8.8 Switch to Factory Settings

Service setting.

9.9 MODE SETTINGS

9.9.1 Ambient Temp. To Start Heating

Setting the Ambient temperature to start Heating mode.

Default setting is 18°C.

Example:

The set temperature to start heating is 18 °C.

The heat pump will heat the facility depending on the set values (heating curve or constant

space heating water temperature, depending on the settings), if the ambient temperature

drops below 18 °C.

When the ambient temperature rises above 18 °C, the heat pump will automatically stop

heating the facility.

It will resume heating when the ambient temperature drops below 18 °C.

Note:

To prevent too frequent switches between operation and non-operation, the control unit

monitors the current temperature and temperature within a certain period and decides based

on this whether heating should be activated or blocked.

34

Page 41

EN

9.9.2 Ambient Temp. To Start Cooling

Setting the activation/start of cooling at a certain ambient temperature.

The factory setting is 25 °C.

Example:

The set temperature to start cooling is 25 °C.

The heat pump will cool the facility depending on the set values if the ambient temperature

rises above 25 °C.

When the ambient temperature drops below 25 °C, the heat pump will automatically stop

cooling the facility.

It will resume cooling when the ambient temperature rises above 25 °C.

Note:

To prevent too frequent switches between operation and non-operation, the control unit

monitors the current temperature and temperature within a certain period and decides based

on this whether heating should be activated or blocked.

9.10 BACKUP HEATING

In the “Backup Heating” menu you can set the backup heating sources. By factory default,

these heating sources are two-stage electric heaters that can be replaced with a different

heating source (pellet burning furnace, oil burning furnace etc.). In this case, the heat pump

regulates the switching on/off of the furnace.

Note:

Resetting the settings in the “Backup Heating” menu is only recommended upon consulting

with an authorised service person!

35

Page 42

EN

Service setting

Service setting

Service setting

9.11 WATER PUMP SETTINGS

9.12 FLOOR CURING

9.13 ELECTRICAL UTILITY LOCK

36

Page 43

EN

Service setting

9.14 OTHER OPTIONS

9.15 UNIT REAL-TIME DATA

Unit real-time data pages can be used for diagnostics of operation of the heat pump. On

these pages, you can see everything that is happening in the heat pump in that moment.

You can see different values for which include:

Software Version

Database Version

Tuo, Tui, Tup, TW, TC temperature values

Water Flow Rate

Compressor Speed

EEV operation

Ambient Temperature (Actual, Average Temp. in 1 h, Average Temp. in 24 h)

High pressure

Low pressure

Td, Ts, Tp temperature values

…

37

Page 44

EN

Main display Error Code Menu

By pressing on the Error code number, a more detailed information for this Error code will appear on the top.

Display of

Active Errors

Error History

Display

10 ERROR CODES

If some faults happen and some errors appear, it is not always because of the heat pump

itself. The most errors happen due to the hydraulics system and especially in the first heating

season (water pressure falls, air in the system, dirt in the piping…).

10.1 ERROR CODES SHOWN ON THE DISPLAY

The error codes will be shown on the Main display and in the Error Code Menu.

10.2 ERROR CODE MENU

10.2.1 ACCESSING THE ERROR CODE MENU

10.2.2 INFORMATIONS IN THE ERROR CODE MENU

38

Page 45

EN

TC

Heating / Cooling (direct circuit or Buffer

Tank)

TW

DHW Temperature

TV1

Mixing Circuit 1

TV2

Mixing Circuit 2

TR

Room Temperature

Line

status 1

Communication – Touch Screen controller to

the Indoor PCB 90 – 100 % = normal

communication

Line

status 2

Communication – Touch Screen controller to

the Outdoor PCB 90 – 100 % = normal

communication

Pump

speed

100 = Pump P0 Activated

0 = Pump P0 Deactivated

TC

By selecting an Error code and pressing More info button, unit displays additional info

regarding the status of the heat pump at the time when the error happened.

10.2.3 INFO PAGE

By pressing the and then takes you to the info page. First thing that is displayed is the

hydraulic scheme with temperature readings from all the sensors. This screen is the same for

all Aerogor Inverter heat pumps.

39

Page 46

EN

Ta

Ambient Temperature Sensor

Tui

Condenser Inlet Temperature Sensor

Tuo

Condenser Outlet Temperature Sensor

Tup

Liquid Refrigerant Temperature Sensor

Ts

Suction Temperature (Compressor) Sensor

Td

Discharge Temperature (Compressor)

Sensor – Hot Gas Temperature

Tp

Evaporation Temperature Sensor

Ps

Low pressure – Suction pressure

Pd

High pressure – Discharge pressure

Fan 1,2

Fan speed for Fan 1 and Fan 2

Compressor speed (Hz)

Compressor current (A)

Pe – Pressure EVI

Te – Temperature EVI

EEV

Opening

EVI

Opening

By pressing the right arrow button , the interface shows the heat pump system scheme.

This scheme is different for ECO and POWER EVI inverters.

Aerogor ECO Inverter

Aerogor POWER EVI Inverter

40

Page 47

EN

Category

Description

Symbol

Notification

Is only to inform the customer that some special function has turned on,

which is still normal operation of the heat Pump.

*

Code

Name

What to do…

If nothing

helps…

P01

Main line current

protection

Clean the cleaning element (filter), check water pressure, water set

temperature for DHW or heating system is set to high, hand valve is

partly or totally closed, problem with power supply to the Heat Pump.

Call customer

service.

P02

Compressor phase

current protection

Clean the cleaning element (filter), check water pressure, water set

temperature for DHW or heating system is set to high, hand valve is

partly or totally closed.

Call customer

service.

P03

IPM module protection

/

Call customer

service.

P04

*

Compressor oil return

protection

Normal operation! This is not an ERROR!

No attention

needed

P05

Compressor shut down

due to high/low

pressure switch open

caused by abnormal

high/low pressure

Clean the cleaning element (filter), check water pressure, water set

temperature for DHW or heating system is set to high, hand valve is

partly or totally closed.

Call customer

service.

P06

Compressor speed

down due to abnormal

high pressure detected

by condensing

pressure sensor

Clean the cleaning element (filter), check water pressure, water set

temperature for DHW or heating system is set to high, hand valve is

partly or totally closed.

Call customer

service.

P07

*

Compressor preheating

Normal operation! This is not an ERROR! Preheating of the

compressor at start up or repowering at low ambient temperatures.

No attention

needed

P08

Compressor discharge

temp. too high

protection

Clean the cleaning element (filter), check water pressure, water set

temperature for DHW or heating system is set to high, hand valve is

partly or totally closed.

Call customer

service.

P09

Outdoor evaporator coil

temp. sensor protection

Clear the Outdoor unit from dirt.

Call customer

service.

P10

AC over high/low

voltage protection

Problem with power supply to the Heat Pump.

Call customer

service.

P11

Compressor shut down

due to too high/low

ambient temperature

Normal protection due to, too high or too low outdoor temperature.

When the ambient temperature gets back in the safe zone for the Heat

Pump to work, it will start again automatically.

No attention

needed

P12

*

Compressor speed

limited due to too

high/low ambient

temperature

Compressor speed down

Normal operation

- no error

P14

Compressor speed

limited due to low

condensing pressure

Call customer service.

/

F01

Outdoor ambient temp.

sensor failure

Call customer service.

/

F02

Outdoor evaporator coil

temp. sensor failure

Call customer service.

/

F03

Compressor discharge

temp. sensor failure

Call customer service.

/

F04

Outdoor Suction temp.

sensor failure

Call customer service.

/

F05

Evaporating pressure

sensor failure

Call customer service.

/

F06

Condensing pressure

sensor failure

Call customer service.

/

10.3 ERROR CODE LIST

In this Code list are Notifications, Protections and Errors!

41

Page 48

EN

F07

High/low pressure

switch failure

Call customer service.

/

F09

DC fan failure (one)

Heat Pump will continue to work, but with lower heating capacity.

Call customer

service.

F10

DC fan failure (two)

Heat Pump will continue to work, but with lower heating capacity.

Call customer

service.

F11

System evaporating

pressure too low

Clear the Outdoor unit from dirt.

Call customer

service.

F12

System condensing

pressure too high

Clean the cleaning element (filter), check water pressure, water set

temperature for DHW or heating system is set to high, hand valve is

partly or totally closed.

/

E01

Communication

between operation

panel and indoor PCB

or outdoor PCB failure

Call customer service.

/

E02

Outdoor power PCB

and driver PCB

communication failure

Call customer service.

/

E03

Compressor phase

current failure

(open/short circuit)

Call customer service.

/

E04

Compressor phase

current overload (over

current)

Call customer service.

/

E05

Compressor driver

failure

Call customer service.

/

E06

Module VDC over

high/low voltage failure

Call customer service.

/

E07

AC current failure

Call customer service.

/

E08

EEPROM failure

Call customer service.

/

E10

Communication error

Call customer service.

/

E11

Clock error

Call customer service.

/

E12

Ext. Memmory error

Call customer service.

/

E13

High pressure

protection

Possible causes: Dirty filter, low water pressure, voltage fluctuation,

set temperature to high, closed or half-closed valve on the hydraulic

system.

Call customer

service.

E14

Low pressure

protection

Call customer service.

/

E15

Power plus offline

Call customer service.

/

E16

Power plus generic

AL

Call customer service.

/

E17

EVI sensor error

Call customer service.

/

E18

Low superheat EEV

Call customer service.

/

E19

Lov evap. Temp.

EEV

Possible causes: Dirty heat exchanger on the outside unit

Call customer

service.

E20

High evap. Temp.

EEV

Call customer service.

/

E21

Low suction temp.

EEV

Call customer service.

/

E22

Comp. Start failure

Call customer service.

/

E23

Envelop error

Possible causes: Dirty filter, low water pressure, voltage fluctuation,

set temperature to high, closed or half-closed valve on the hydraulic

system.

Call customer

service.

42

Page 49

EN

E24

Low press.

Differential error

Call customer service.

/

E25

High discharge

temp.

Possible causes: Dirty filter, low water pressure, voltage fluctuation,

set temperature to high, closed or half-closed valve on the hydraulic

system.

Call customer

service.

E26

Amb. temp. probe

fault(B1)

Call customer service.

/

E27

Outdoor unit alarm:

Evap. coil

temp.probe fault

(B2)

Call customer service.

/

E28

Outdoor unit alarm

Suction temp. Probe

fault

Call customer service.

/

E29

Outdoor unit alarm

Comp. discharge

probe

Call customer service.

/

E30

B5 temp. prob faul

Call customer service.

/

E31

Outdoor unit alarm

Suction pressure

sensor

Call customer service.

/

E32

Outdoor unit alarm:

Discharge pressure

sensor fault (B7)

Call customer service.

/

E33

Outdoor unit alarm:

Defrost time too long

Call customer service.

/

E34

Outdoor unit alarm:

Gas Pressure differ.

too high at Comp.

Start

Call customer service.

/

E35

Outdoor unit alarm:

EVI Sunction temp

probe fault (B8)

Call customer service.

/

E36

Outdoor unit alarm:

EVI sunction

pressure probe fault

(B11)

Call customer service.

/

E37

High press. swtich

defect

Call customer service.

/

E38

Low press. swtich

defect

Call customer service.

/

E39

Outdoor unit alarm :

EVI Low superheat

Call customer service.

/

E40

EVI low evap. Temp.

Call customer service.

/

E41

EVI high evap.

Temp.

Call customer service.

/

E42

Outdoor unit alarm:

Amb. Temp. out of

HP working range

Call customer service.

/

E43

Outdoor unit alarm:

Outlet water temp.

Too low

Call customer service.

/

F13

Room temp. sensor

failure

The Heat Pump will continue to work normal. It will display the error of

temperature sensor. Compensation of the Heating curve will also be

OFF.

Call customer

service.

F14

Sanitary hot water

temp. sensor failure

The Heat Pump will continue to work normal, except it will not prepare

sanitary hot water.

Call customer

service.

43

Page 50

EN

F15

Cooling/heating water

temp. sensor failure

The Heat Pump will continue to work, but less efficiently (up to 5%).

Call customer

service.

F16

Unit water outlet temp.

sensor failure

The Heat Pump will continue to work, but less efficiently (up to 5%).

Call customer

service.

F17

Unit water inlet temp.

sensor failure

The Heat Pump will continue to work, but less efficiently (up to 5%).

Call customer

service.

F18

Indoor coil temp.

sensor failure

The Heat Pump will continue to work normal, except for cooling mode.

Call customer

service.

F21