Page 1

Installation Manual

IM 1203-1

Pathnder® Remote Evaporators

Air-Cooled Screw Compressor Chillers

Model AWS, C Vintage

170 to 550 Tons (600 to 1930 kW)

HFC-134a Refrigerant

60 Hz

Group: Chiller

Part Number: IM1203-1

Date: June 2015

Page 2

Table of ConTenTs

Introduction..............................3

Installation and Application Considerations ...4

Chilled Water Piping ......................6

Remote Evaporator Dimensions............14

Isolator Information ......................18

Lifting and Mounting Locations ............26

Physical Data ...........................53

Table of ConTenTs

Table of ConTenTs

Manufactured in an ISO 9001 & ISO 14001 certied facility

©2015 Daikin Applied. Illustrations and data cover the Daikin Applied product at the time of publication and we reserve the right to

make changes in design and construction at any time without notice.

IM 1203-1 • PATHFINDER® MODEL AWS REMOTE CHILLERS 2 www.DaikinApplied.com

Page 3

Job Name

Installation Location

Customer Order Number

Model Number(s)

G.O. Number(s)

Chilled Water

Yes

No

N/A

Initials

Piping Complete

Water strainer installed on evaporator entering chilled water piping per IM

Water System filled, flushed and vented

Pumps installed and operational (rotation checked, strainers cleaned)

Controls operational (3-way valves, face/bypass dampers, bypass valves, etc.)

Water system operated and tested; flow meets unit design requirements

Flow switch installed and wired

Vent installed on evaporator

Glycol at design %

Electrical

Yes

No

N/A

Initials

Building controls operational

Power leads have been checked for proper phasing and voltage

All interlock wiring complete and compliant with Daikin specifications

Power applied at least 24 hours before startup

Oil heaters energized at least 24 hours before startup

Chiller components (EXV Sensors Transducers) installed and wired properly.

*Wiring complies with National Electrical Code and local codes (See Notes)

Remote EXV wired with shielded cable

Miscellaneous

Yes

No

N/A

Initials

Unit control switches all off

Remote Evaporator Piping factory reviewed and approved

All refrigerant components/piping leak tested, evacuated and charged

Thermometers, wells, gauges, control, etc., installed

Minimum system load of 80% capacity available for testing/adjusting controls

Document Attached: Technical Breakdown from Selection Software

Document Attached: Final Order Acknowledgement

Document Attached: Remote evaporator piping approval

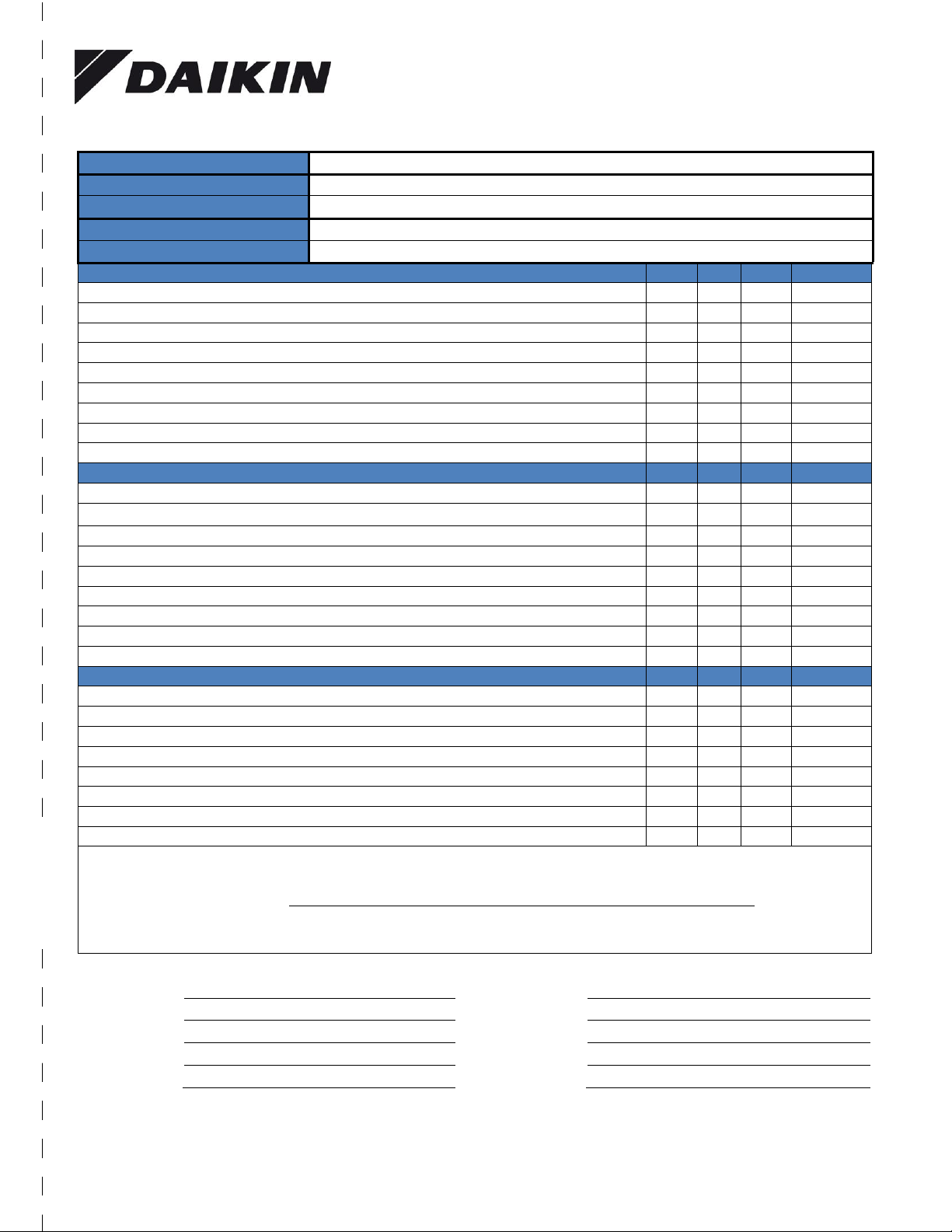

Notes: The most common problems delaying start-up and affecting unit reliability are:

3. Items on this list incorrectly acknowledged may result in delayed start and extra expenses incurred for return trips.

Contractor Representative

Daikin Applied Sales Representative

Signed:

Signed:

Name:

Name:

Company:

Company:

Date:

Date:

Phone/Email:

Phone/Email:

Pre-Start Checklist – Screw Chillers

Must be completed, signed and provided to Daikin Applied at least 2 weeks prior to requested start date.

*Power leads connected to power block or optional disconnect

1. Field installed compressor motor power supply leads too small. Questions: Contact the local Daikin sales representative*. State size, number and

type of conductors and conduits installed:

a. From Power supply to chiller

* Refer to NEC Article 430-22 (a)

Cut Here

2. Remote Evaporator piping incomplete or incorrect. Provide approved piping diagrams.

©2014 Daikin Applied Form SF01017 P/N 331977001 10OCT2014

Page 4

Page 5

InTroduCTIon

This manual contains data specic to AWS-C chiller remote evaporators. Data that is common to both packaged and remote

evaporator models can be found in the current version of the catalog and the unit installation manual available on www.

DaikinApplied.com, and includes:

• Electrical Data

• Pressure Drops

WARNING

Electric shock hazard. Improper handling of this equipment can cause personal injury or equipment damage. This equipment must

be properly grounded. Connections to and service of the MicroTech® control panel must be performed only by personnel that are

knowledgeable in the operation of the equipment being controlled.

• Performance Data (subject to adjustment factor)

• Sound Data

InTroduCTIon

HAZARD IDENTIFICATION INFORMATION

DANGER

Dangers indicate a hazardous situation, which will result in death or serious injury if not avoided.

WARNING

Warnings indicate potentially hazardous situations, which can result in property damage, severe personal injury, or death if not

avoided.

CAUTION

Cautions indicate potentially hazardous situations, which can result in personal injury or equipment damage if not avoided.

www.DaikinApplied.com 3 IM 1203-1 • PATHFINDER® MODEL AWS REMOTE CHILLERS

Page 6

InsTallaTIon and applICaTIon ConsIderaTIons

InsTallaTIon and applICaTIon ConsIderaTIons

Shipment Method

AWS chillers with remote evaporators ship in three pieces.

• Outdoor condensing unit

• Remote evaporator

• Refrigerant specialties kit with the unit has the following

components for eld installation:

— Filter-drier and cores for eld piping

— Sight glass

— Electronic expansion valve

— Solenoid valve

— Evaporator vent and drain shutoff valves - waterside

— Charging Valve (on non-economizer models)

— Suction coupling and ange to attachment evaporator

Performance Derate Data

AWS performance data can be found in the current version of

the catalog, available on www.DaikinApplied.com or the local

sales ofce. There is a derate to the performance of an AWS

with remote evaporator due to eld installed refrigerant line

losses exceeding those found on the packaged arrangement.

For preliminary purposes, use the following as an estimate:

Table 1: Approximate Initial Derate Factors

AWS - C

Actual Line Length

Up To:

75’ 0.96 0.98 0.97

50’ 0.97 0.99 0.98

25’ 0.98 0.99 0.99

Once the pipe design is nalized, the actual adjustment is

determined using the following procedure.

Derate Procedure

1. Sketch the liquid and suction piping, including the actual

pipe lengths and all ttings.

2. Using the recommended pipe sizes from Table 5 and

Table 6, add up the equivalent pressure drop for the

ttings in the suction line. Add this value to the actual

linear feet of tubing to determine the total equivalent

length (TEL) for the piping run.

3. Using Table 5 and Table 6, determine the pressure

drop (in degrees F) based on the TEL. Interpolation

is permitted, extrapolation is not. Consult the Daikin

Technical Response Center for piping installations

outside the published recommendations.

4. Determine the derate factors from Table 2 based on the

suction line pressure drop.

Capacity

Derate

Power

Derate

EER Derate

Table 2: Performance Derate Factors

AWS - C

Suction Line

Pressure Drop (

0.0 1.00 1.00 1.00

1.0 0.98 0.99 0.99

2.0 0.96 0.98 0.97

3.0 0.94 0.98 0.96

4.0 0.92 0.97 0.94

o

F)

Capacity

Derate

Power

Derate

EER

Derate

Remote Evaporator Field Wiring Notes:

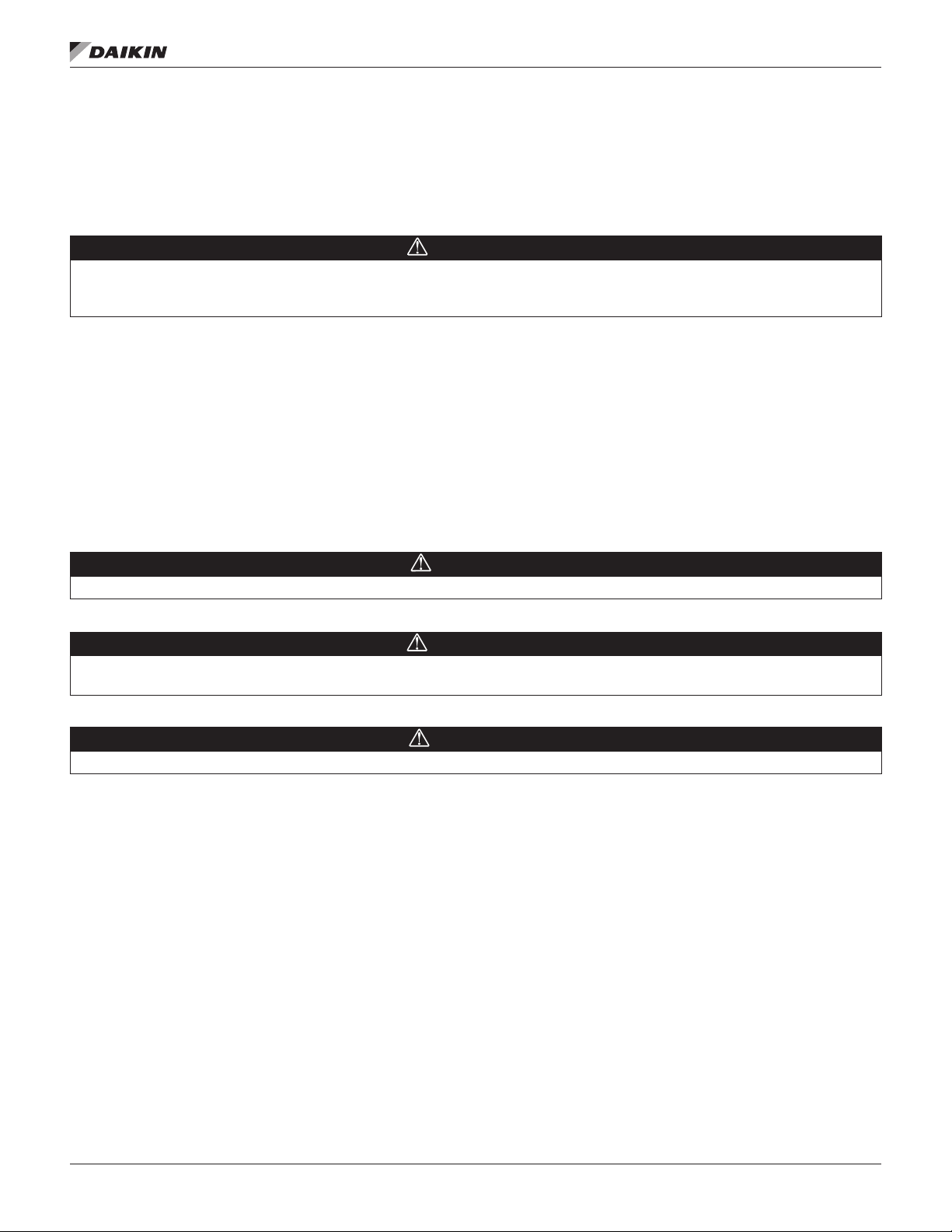

1. The 110V liquid line solenoid valves (LSV) have to

be wired back to the outdoor unit. All the conduit and

wiring is to be eld supplied (14 gauge, red and white

wires, 3/8” conduit with straight and 90 degree ttings).

If additional length is required, use 14 gauge wire up

to a maximum of 100 feet. A din connector is supplied

with refrigerant specialties kits. Field to wire directly into

compressor terminal box terminal block per below:

• Compressor #1: (LSV-1) wire 740-1A (red) wires

into compressor #1 terminal box terminal block at

TB1-2-9. Wire 740-1B (white) wires to TB1-2-10.

• Compressor #2: (LSV-2) wire 740-2A (red) wires

into compressor #2 terminal box terminal block at

TB2-2-9. Wire 740-2B (white) wires to TB2-2-10.

• Compressor #3: (LSV-3) wire 740-3A (red) wires

into compressor #3 terminal box terminal block at

TB3-2-9. Wire 740-3B (white) wires to TB3-2-10.

2. Two evaporator water temperature sensors with 100

feet of cable coiled up and attached to the unit base

for extension to the evaporator and insertion in ttings

located on the side of the inlet and outlet nozzles.

3. One suction line refrigerant temperature sensor per

circuit with 100 feet of cable coiled up and attached to

the unit base for extension to the evaporator.

4. One suction line pressure transducer per circuit with 100

feet of cable coiled up and attached to the unit base for

extension to the evaporator.

5. The electronic expansion valve has a 40-foot long cable

attached and can be used, when the outdoor unit is less

than 40 feet away. Beyond that, a junction box must be

located within 40-feet of the evaporator, and up to 60

additional feet of 14GA wire connected from the cable

to the unit, allowing up to a total distance of 100 feet.

When splicing is required the connections must be

soldered together and individually shrink wrapped to be

made water resistant. The expansion valve wiring cannot

run in conduit with other wiring that is over 24 Volts AC

Shielding must cover the wiring from the unit to the EXV,

including the splice connection.

NOTE: 14 AWG Wire Gauge sizes will use Beldon part

number 83754.

IM 1203-1 • PATHFINDER® MODEL AWS REMOTE CHILLERS 4 www.DaikinApplied.com

Page 7

InsTallaTIon and applICaTIon ConsIderaTIons

ADDRESS=3

T1 T3

T2

T4

E.E.X.V.1

1 2 3 4 5 6

ON

ADDRESS=5

T1 T3

T2

T4

E.E.X.V.2

1 2 3 4 5 6

ON

BRN

WHT

BLU

BLK

RED

GRN

WHT

BLK

RED

GRN

WHT

BLK

BLU

BLK

WHT

BRN

M16

902

900

M26

906

901

POL94E.00/MCQ

D01A

C1

D01B

DI1

R1

T3-M

X3

+5V

X1

T3-M

X2

M1-

M2+

M2-

M1+

+24V

24VGNDB-A+

A+ B-

GND

24V

POL94E.00/MCQ

D01A

C1

D01B

DI1

R1

T3-M

X3

+5V

X1

T3-M

X2

M1-

M2+

M2-

M1+

+24V

24VGNDB-A+

A+ B-

GND

24V

W1

ΘW1Θ

W2

ΘW2Θ

EXV-1

1

2

3

4

GTB5

W1

ΘW1Θ

W2

ΘW2Θ

EXV-2

1

2

3

4

GTB5

A2 A1

M16

(438)

(439)

(440)

NC

NO

903

A2 A1

M26

(538)

(539)

(540)

NC

NO

907

(847) (847) (847) (847)

(848) (848) (848) (848)

(863) (863) (863) (863)

/(756)

/(659)

/(756)

/(659)

Figure 1: Remote EXV Field Wiring

6. A ow switch must be installed in the leaving chilled

water line per manufacturer’s instructions and wired

to terminals 8 and 23 on terminal block M5 in the

chiller control panel. See Unit Field Wiring Diagram in

current version of installation manual available on www.

DaikinApplied.com.

7. Do not reduce the wire lengths of factory wiring.

Remote Evaporator Refrigerant Piping

correct pipe sizing.

5. Keep the refrigerant suction line pressure drop to a

maximum of 2 F. in saturated temperature equivalent.

6. Each suction line’s velocity must be sufcient to carry oil

considering a 25% capacity reduction in each circuit.

7. When facing the unit control box, the left-hand

compressor is circuit # 1, and the right-hand is circuit # 2.

If present, the compressor behind #2, on the right-hand

side, is circuit #3.

8. Liquid lines may be insulated to prevent collection of

condensation, if needed.

The following applies to all size units:

• Maximum linear line length cannot exceed 75 feet

• Maximum total equivalent length (TEL) cannot exceed

180 feet (75 feet for vertical suction lines)

• The evaporator cannot be located more than 20 feet

above or 30 feet below the outdoor unit.

• Suction line connection at unit = 4 1/8-inch OD each

• Underground refrigerant piping is not permitted

• Field piping must include adequate service taps for

checking lter-drier, subcooling, and superheat.

• Insulate complete suction lines. Liquid lines may be

insulated to prevent collection of condensation if required.

• Ensure the braze rod used is appropriate for the

materials being joined

Table 3: Fitting Equivalent Feet of Pipe

IMPORTANT NOTE

Service Form SF99006 (available from the local sales

Line Size

In. OD

Angle

Valve

Globe

Valve

ofce) and an isometric sketch of the Remote Piping Layout

showing pipe size, location of ttings, measured lengths,

and elevations MUST BE SUBMITTED to Daikin Technical

Response Center and reviewed at least two weeks prior

to beginning piping installation. The information can be

forwarded to Daikin Applied by the local sales ofce or sent

directly to E-mail: techresponse@daikinapplied.com

Daikin Applied service will not perform startup without

reviewed Service Form SF99006 and drawing. Installation

must match reviewed drawing.

All eld piping, wiring and procedures must comply with

design guidelines set forth in this manual and be performed

in accordance with ASHRAE, EPA, local codes and industry

standards. Any product failure caused or contributed to

by failure to comply with appropriate design guidelines

will not be covered by manufacturer’s warranty. Daikin

Technical Response Center - Phone : 540-248-9239; E-mail:

techresponse@daikinapplied.com

Careful design of refrigerant piping is necessary for proper

system operation. Design the refrigerant piping to accomplish

the following:

www.DaikinApplied.com 5 IM 1203-1 • PATHFINDER® MODEL AWS REMOTE CHILLERS

1. Assure proper refrigerant feed to the evaporator.

2. Provide practical and economical refrigerant line sizes

without excess pressure drop.

3. Maintain uniform oil return to the compressor under all

load conditions.

4. Refer to the latest version of the ASHRAE Handbook for

recommended piping practice; use included tables for

2 5/8

3 1/8

3 5/8

4 1/8

5 1/8

NOTE: TEL values for the lter-drier and solenoid valve are

already included and should not be added to the

liquid line drop.

Piping Layout

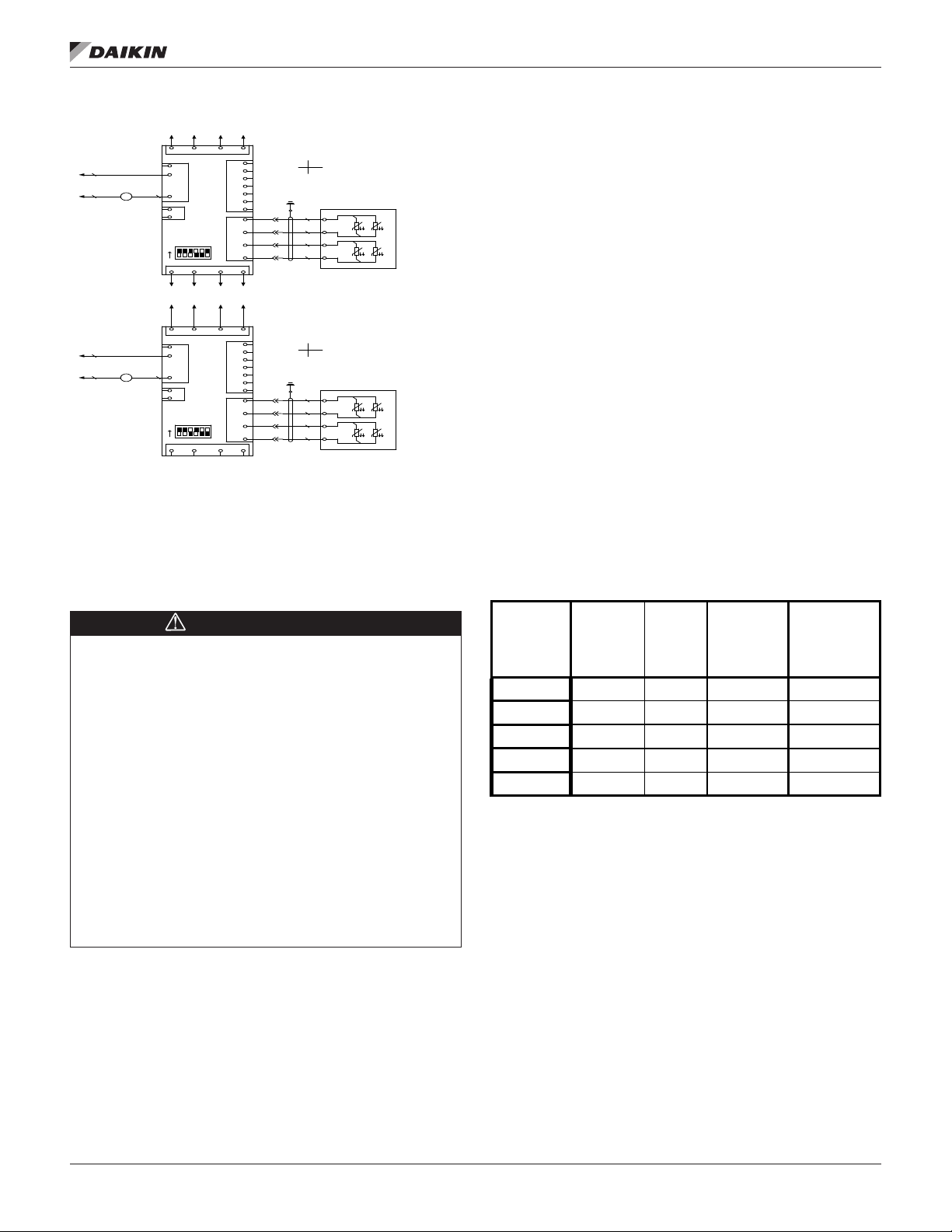

Figure 4 shows the piping layout for one of the two or three

refrigerant circuits for AWS units with a remote evaporator

without the economizer circuit. The outdoor unit, the

evaporator, and a kit of refrigerant components are shipped

as separate pieces for eld mounting, wiring, and piping. The

suction shutoff valve is standard on remote evaporator units.

Note: Field insulation of the suction lines and the liquid line on

circuits with economizers is required. The outdoor unit will have

a refrigerant charge equal to that of a packaged unit pumped

down into the condenser. The additional charge of refrigerant

and oil required by the eld piping is supplied and installed

by the customer. The location and size of the refrigerant

connections are shown on dimensional drawings available from

a Daikin Applied sales representative.

1.00 1.00 1.00 1.00

0.98 0.99 0.99 0.99

0.96 0.98 0.97 0.97

0.94 0.98 0.96 0.96

0.92 0.97 0.94 0.94

90-Degree

Std. Radius

Elbow

90-Degree

Long Radius

Elbow

Page 8

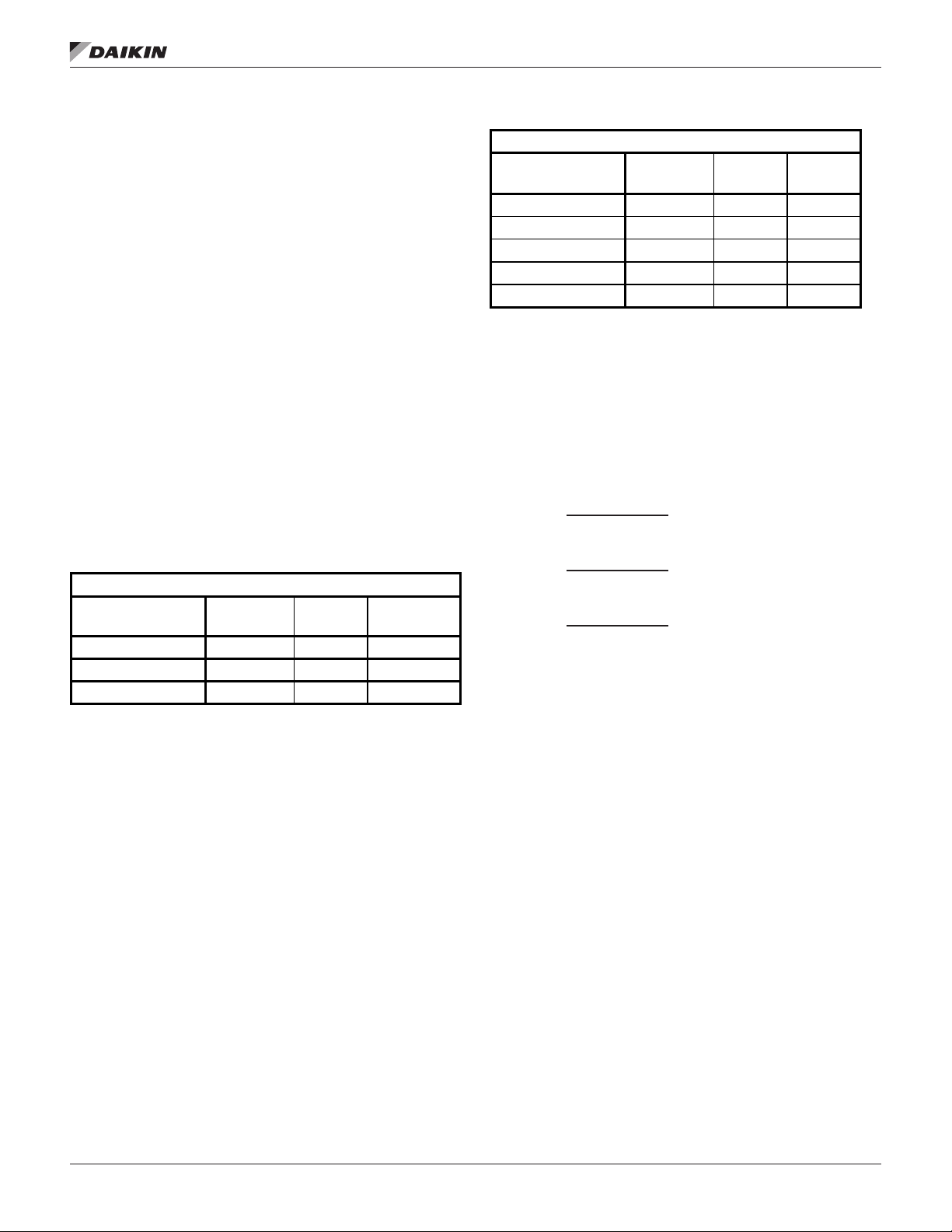

Chilled Water Piping

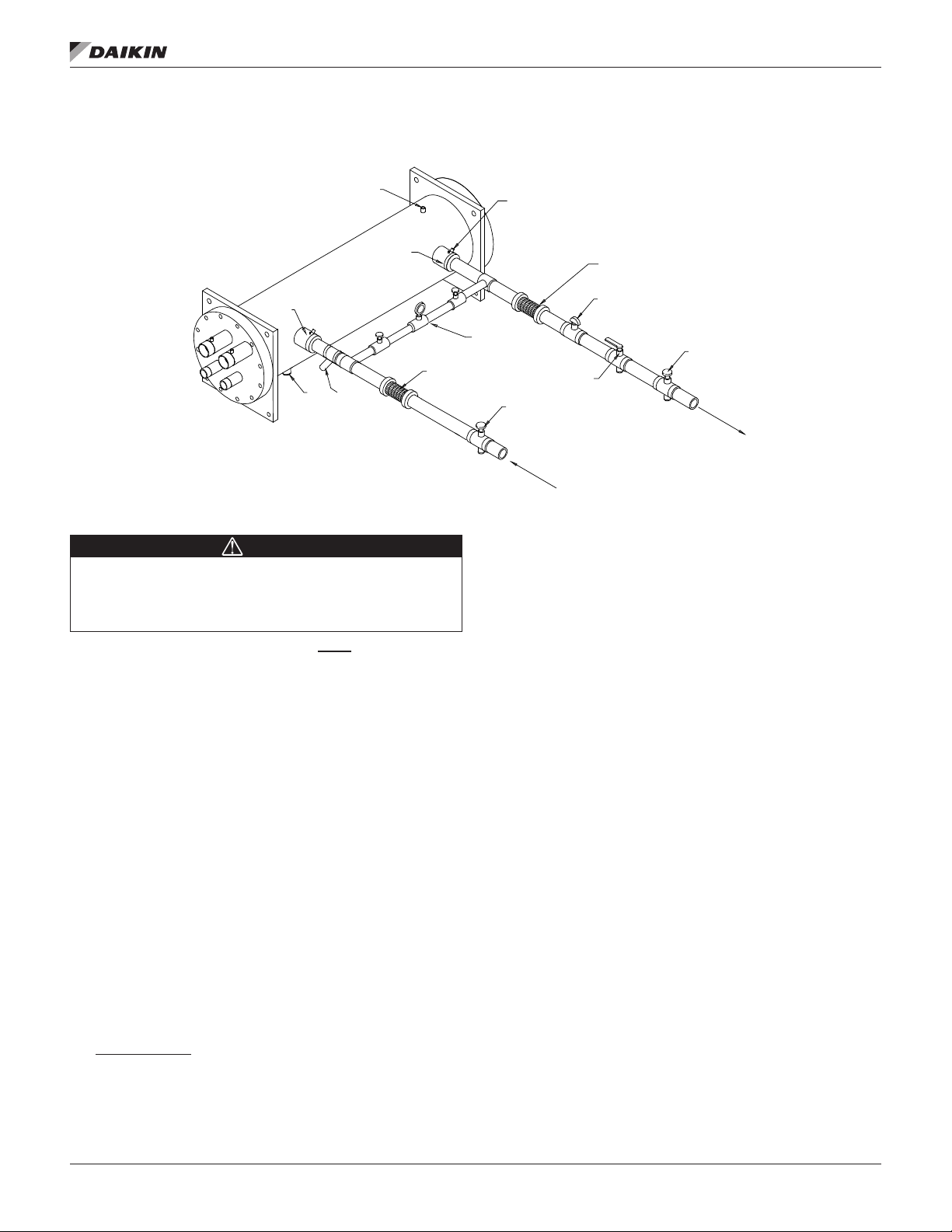

Figure 2: Typical Piping, Shell and Tube Evaporator

InsTallaTIon and applICaTIon ConsIderaTIons

VENT

3/8” PIPE PLUG

OUTLET

INLET

VIBRATION

ELIMINATOR

DRAIN

PROTECT ALL FIELD PIPING

AGAINST FREEZING

WATER

STRAINER

CAUTION

To prevent damage to the evaporator and potential chiller

failure, a supply strainer is required in the inlet water piping

which connects to this evaporator. This strainer must be

installed prior to operation of the chilled liquid pumps.

Field installed water piping to the chiller must include:

• A cleanable strainer installed at the water inlet to the

evaporator to remove debris and impurities before they

reach the evaporator. Install cleanable strainer within

5 feet (1500 mm) of pipe length from the evaporator

inlet connection and downstream of any welded

connections (no welded connections between strainer

and evaporator).

• AWS-C models require a strainer with perforations no

larger than 0.125” (3.2 mm) diameter. See the Inlet

Strainer Guidelines on page 7 for more information.

• A water ow switch must be installed in the horizontal

piping of the supply (evaporator outlet) water line to avoid

evaporator freeze-up under low or no ow conditions. The

ow switch may be ordered as a factory-installed option,

a eld-installed kit, or may be supplied and installed in the

eld. See IOM for more information.

• Purge air from the water system before unit start-up to

provide adequate ow through the evaporator.

• Adequate piping support, independent from the unit,

to eliminate weight and strain on the ttings and

connections.

It is recommended that the eld installed water piping to the

chiller include:

• Thermometers at the inlet and outlet connections of the

evaporator.

• Water pressure gauge connection taps and gauges at

LEAVING FLUID

TEMP. SENSOR

VIBRATION

ELIMINATOR

FLOW

SWITCH

VALVED

PRESSURE

GAUGE

GATE

VALV E

BALANCING

VALV E

FLOW

GATE

VALV E

FLOW

the inlet and outlet connections of the evaporator for

measuring water pressure drop.

• Shutoff valves are necessary to isolate the unit from the

piping during unit servicing.

• Minimum bends and changes in elevation to minimize

pressure drop.

• An expansion tank or regulating valve to maintain

adequate water pressure

• Vibration eliminators in both the supply and return water

lines to reduce transmissions to the building.

• Flush the system water piping thoroughly before making

connections to the unit evaporator.

• Piping insulation, including a vapor barrier, helps prevent

condensation and reduces heat loss.

• Regular water analysis and chemical water treatment

for the evaporator loop is recommended immediately at

equipment start-up.

Chilled Water Pump

The chilled water pumps must be wired to, and controlled by,

the chiller controller. The chiller controller has the capability

to selectively start pump A or B or automatically alternate

pump selection and also has standby operation capability.

The controller will energize the pump whenever at least one

circuit on the chiller is enabled to run, whether there is a call for

cooling or not. This helps ensure proper unit startup sequence.

The pump will also be turned on when the water temperature

goes below the Freeze Setpoint for longer than a specied time

to help prevent evaporator freeze-up.

IM 1203-1 • PATHFINDER® MODEL AWS REMOTE CHILLERS 6 www.DaikinApplied.com

Page 9

InsTallaTIon and applICaTIon ConsIderaTIons

CAUTION

Adding glycol or draining the system is the recommended

method of freeze protection. If the chiller does not have the

ability to control the pumps and the water system is not drained

in temperatures below freezing, catastrophic evaporator

failure may occur.

Failure to allow pump control by the chiller controller may

cause the following problems:

1. If any device other than the chiller attempts to start the

chiller without rst starting the pump, the chiller will lock

out on the No Flow alarm and require manual reset.

2. If the chiller evaporator water temperature drops below

the “Freeze setpoint” the chiller will attempt to start the

water pumps to avoid evaporator freeze. If the chiller

does not have the ability to start the pumps, the chiller

will alarm due to lack of water ow.

3. If the chiller does not have the ability to control the

pumps and the water system is not to be drained in

temperatures below freezing, the chiller may be subject

to catastrophic evaporator failure due to freezing.

Inlet Strainer Guidelines

An inlet water strainer kit must be installed in the chilled water

piping before the evaporator inlet. Two paths are available to

meet this requirement:

1. A eld-installed kit shipped-loose with the unit is available

for all unit sizes and consists of:

• Y-type area strainer with 304 stainless steel perforated

basket, Victaulic pipe connections and strainer cap [a

strainer with perforations no larger than 0.125” (3.2

mm) diameter for AWS-C models].

• Extension pipe with two Schrader ttings that can be

used for a pressure gauge and thermal dispersion ow

switch. The pipe provides sufcient clearance from the

evaporator for strainer basket removal.

• ½-inch blowdown valve

• Two grooved clamps

The strainer is sized per Table 4 and the pressure drop is

shown in the Strainer Pressure Drop graph.

2. A eld-supplied strainer that meets specication and

installation requirements of this manual.

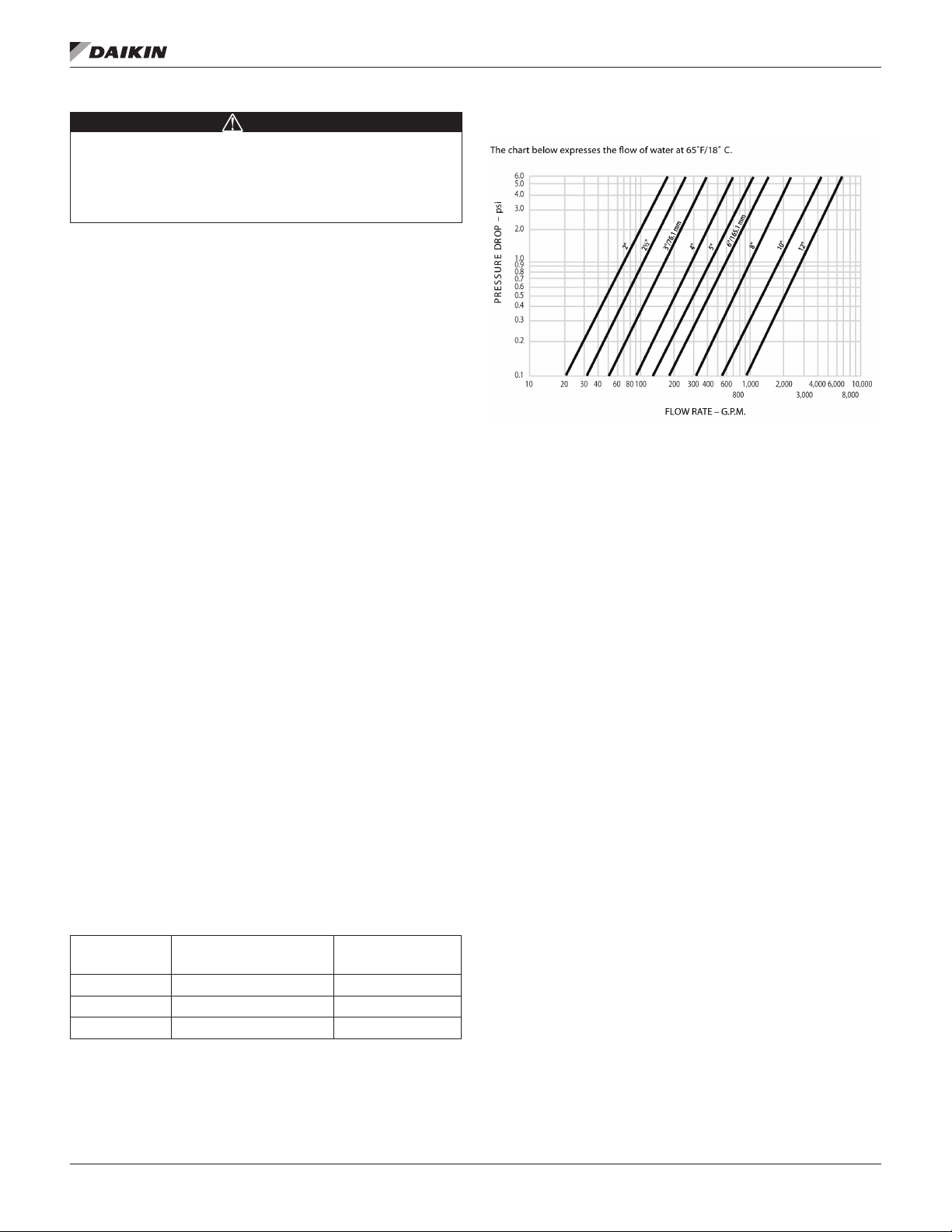

Table 4: Strainer Sizing Data

Strainer Size

(in.)

6 30.5 72

8 36.0 125

10 43.0 205

Strainer Plus Pipe

Length (in.)

Strainer Weight

(lbs)

Figure 3: Strainer Pressure Drop

Evaporator Freeze Protection

Pathnder® chillers are equipped with thermostatically

controlled evaporator heaters that help protect against

freezeup down to -20°F (-28°C). The immersion heater itself

may not be able to properly protect the evaporator from

freezing without circulation of water, and it is important that

the chilled water pumps are wired to, and controlled by,

the chiller’s controller. Additionally, use at least one of the

following procedures IF the mechanical room where the remote

evaporator is installed is subject to ambient temperatures

below 32F:

1. Add a concentration of a glycol anti-freeze with a freeze

point 10°F below the lowest expected temperature. This

will result in decreased capacity and increased pressure

drop. Do not use automotive grade antifreezes as they

contain inhibitors harmful to chilled water systems. Use

only glycols specically designated for use in building

cooling systems.

2. Drain the water from outdoor equipment and piping

and blow the chiller tubes dry from the chiller. Do not

energize the chiller heater when water is drained from

the vessel.

NOTE: The heaters come from the factory connected to

the control power circuit. The control power can be

rewired in the eld to a separate 115V supply (do

not wire directly to the heater). See the eld wiring

diagram on page 60. If this is done, it should power

the entire control circuit. Mark the disconnect switch

clearly to avoid accidental deactivation of the heater

during freezing temperatures. Exposed chilled water

piping also requires protection. If the evaporator is

drained for winter freeze protection, the heaters must

be de-energized to prevent heater burnout.

www.DaikinApplied.com 7 IM 1203-1 • PATHFINDER® MODEL AWS REMOTE CHILLERS

Page 10

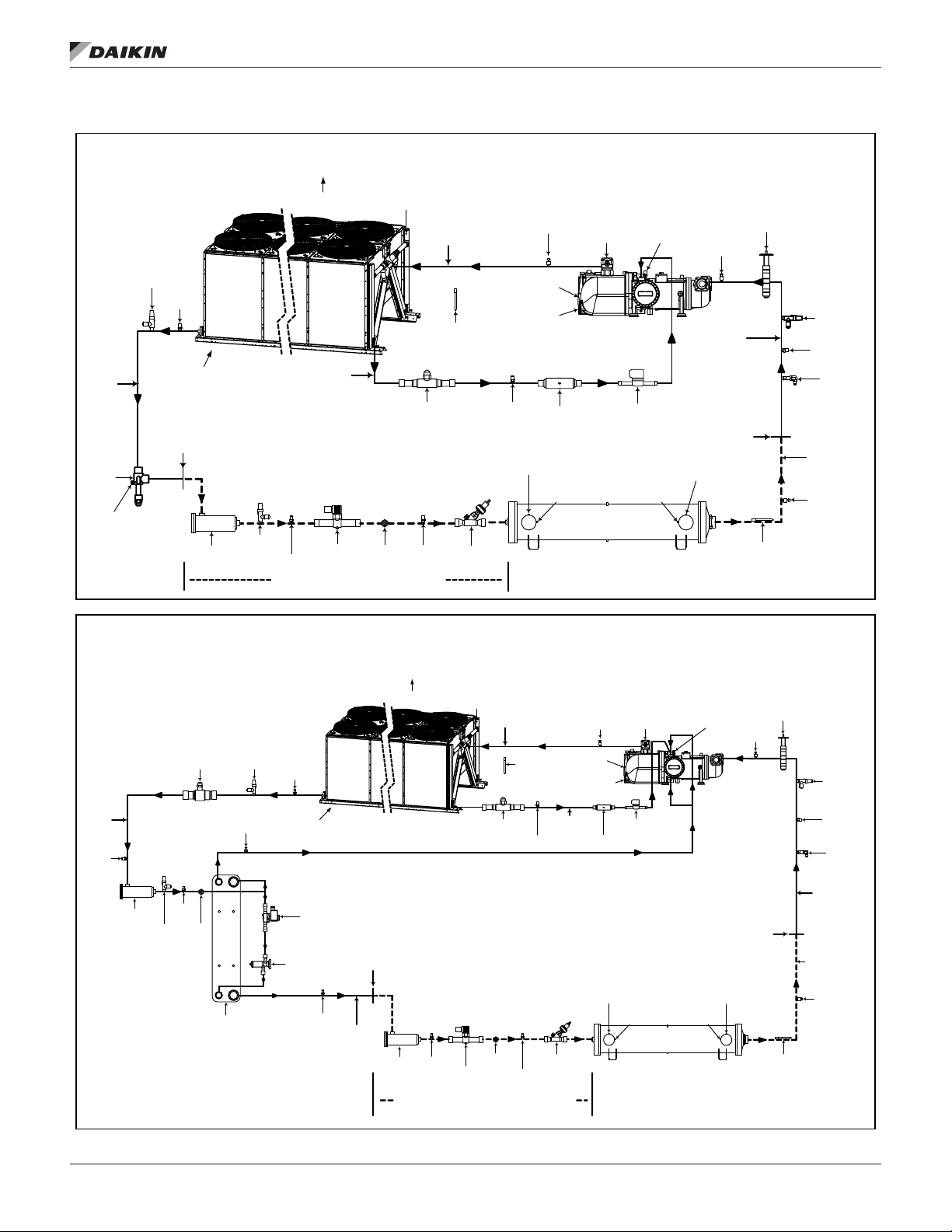

Figure 4: Piping Schematic, Remote Evaporator (One of Two Circuits)

*R3319947010E3*

AWS Remote Evaporator Models (No Economizer)

AWS Remote Evaporator Models ( With Economizer)

*R3319947010E4*

CHAR GING

VALVE

LIQUID

TUBIN G

FILTER

DRYE R

SOLENOID

VALVE

SIGHT

GLASS

EXPAN SION

VALVE

WATER IN

WATER OUT

DX EV APORATOR

SUCTI ON

TUBIN G

(STUB TUBE)

OIL PRES S.

TRANS DUCER

WITH SCHRAD ER

VALVE

DISC HARGE

TUBIN G

AIR

FLOW

AIR

FLOW

CONDE NSER

ASSEMB LY

F3/F4

COMPRE SSOR

RELIEF

VALVE

SUCTI ON

TEMP. SENS OR

SUCTI ON

TRANS DUCER

DISC HARGE

TEMP. SE NSOR

(WOE)

TEMP. SENS OR

(WIE)

TEMP. SE NSOR

OUTSID E AIR

TEMPER ATURE

(WAA)

SCHR ADER

VALVE

SCHR ADER

VALVE

SHUT-OFF

VALVE

BUTTER FLY

VALVE

RELIEF

VALVE

DISC HARGE

TRANS DUCER

SCHR ADER

VALVE

STRAIN ER

BALL

VALVE

SOLENOID

VALVE

LIQUID

INJECTI ON

TUBIN G

SUCTI ON

TRANS DUCER

SCHR ADER

VALVE

CHAR GING

VALVE

FIELD

CONNE CTION

POINT

SCHR ADER

VALVE

FIELD

CONNE CTION

POINT

FIELD PIPING

SHOWN DASHED

LIQUID

SHUTOFF

VALVE

SCHR ADER

VALVE

FIELD INSTALLED LIQUID LINE COMPONENTS

SCHR ADER

VALVE

(HEADER)

CHAR GING

VALVE

NOTE

:

PIPING SHOWN FOR ONE SYSTEM OF UNIT

.

UNIT HAS TWO INDEPENDENT SYSTEMS

.

CHAR GING

VALVE

LIQUID

TUBIN G

FILTER

DRYE R

SOLENOID

VALVE

EXPAN SION

VALVE

WATER IN

WATER OUT

DX EV APORATOR

SUCTI ON

TUBIN G

(STUB TUBE)

OIL PRES S

.

TRANS DUCER

WITH SCHRAD ER

VALVE

DISC HARGE

TUBIN G

AIR

FLOW

AIR

FLOW

COND ENSER

ASSEM BLY

F3/F4

COMPRE SSOR

RELIEF

VALVE

SUCTI ON

TEMP.

SENSOR

SUCTI ON

TRANS DUCER

DISC HARGE

TEMP. SENSOR

(WOE)

TEMP. SENSOR

(WIE)

TEMP

.

SENSOR

OUTSID E AIR

TEMPER ATURE

(WAA)

SCHR ADER

VALVE

SCHR ADER

VALVE

SCHR ADER

VALVE

SHUT-OFF

BALL VALVE

SOLENOID

VALVE

TGE

EXPAN SION

VALVE

ECONOMI ZER

SHUT-OFF

VALVE

ECONOMI ZER FLASH GA S TO COMPRES SOR INTERS TAGE

BUTTER FLY

VALVE

RELIEF

VALVE

DISC HARGE

TRANS DUCER

BALL

VALVE

SCHR ADER

VALVE

LIQUID

INJECT ION

TUBIN G

SOLENOID

VALVE

SCHR ADER

VALVE

SCHR ADER

VALVE

(HEADER)

SCHR ADER

VALVE

CHAR GING

VALVE

FIELD

CONN ECTION

POINT

SCHR ADER

VALVE

SIGHT

GLASS

SCHR ADER

VALVE

FILTER

DRYE R

FIELD

CONN ECTION

POINT

STUB

TUBE

SCHR ADER

VALVE

FIELD INSTALLED LIQUID LINE COMPONENT S

FIELD PIPING

SHOWN DASHED

STRAIN ER

CHAR GING

VALVE

SIGHT

GLASS

SUCTI ON

PRESS

.

TRANS DUCER

NOTE:

PIPING SHOWN FOR ONE SYSTEM OF UNIT.

UNIT HAS TWO INDEPENDENT SYSTEMS

.

InsTallaTIon and applICaTIon ConsIderaTIons

IM 1203-1 • PATHFINDER® MODEL AWS REMOTE CHILLERS 8 www.DaikinApplied.com

Page 11

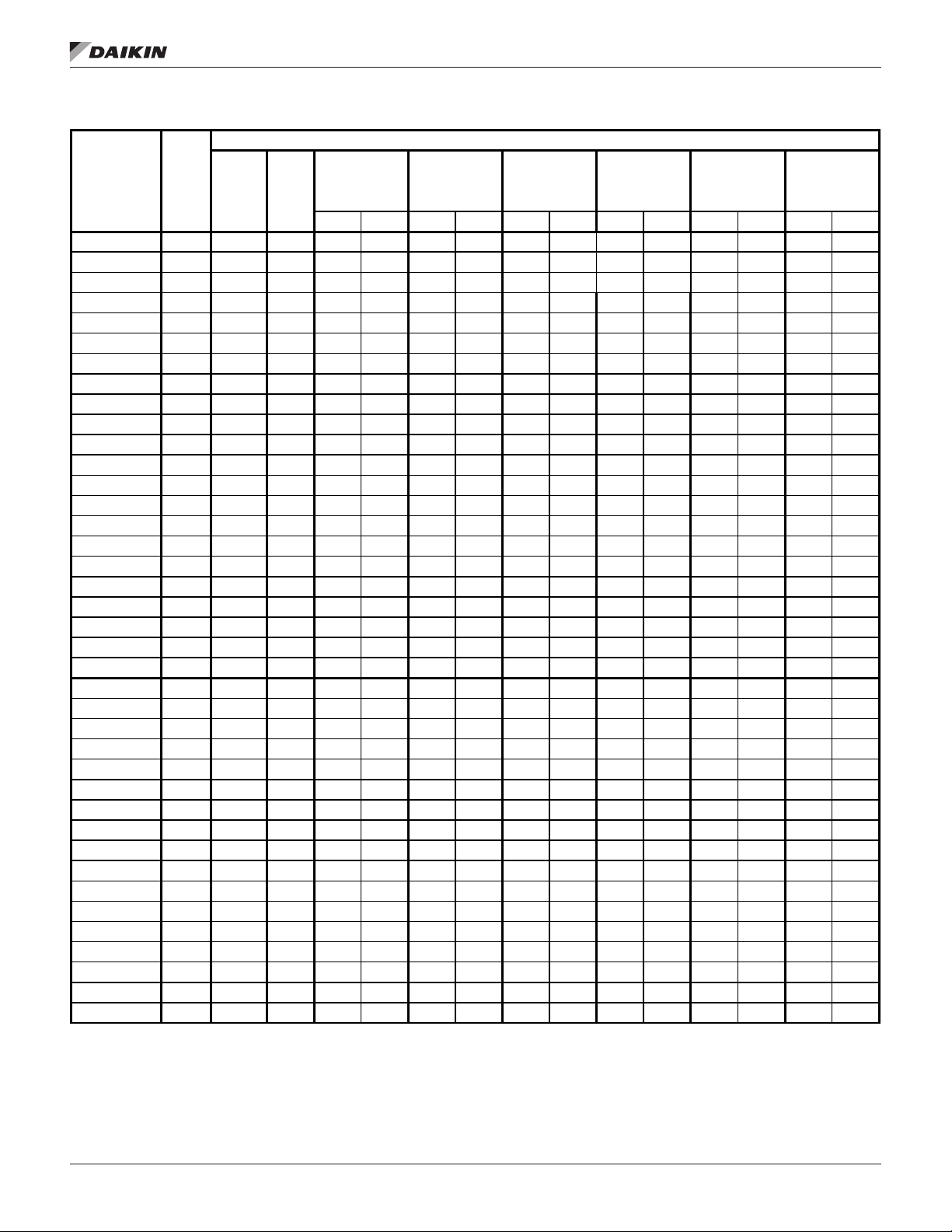

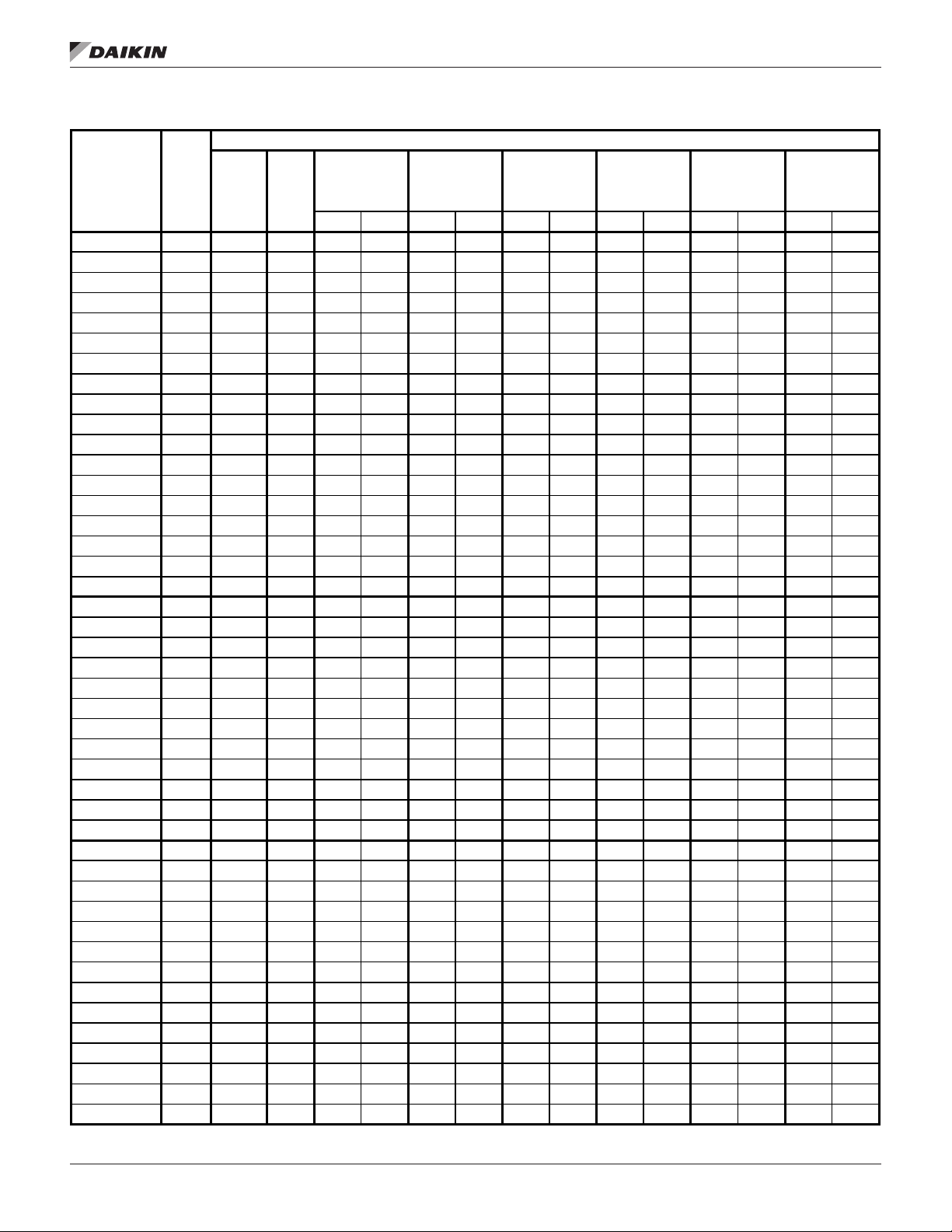

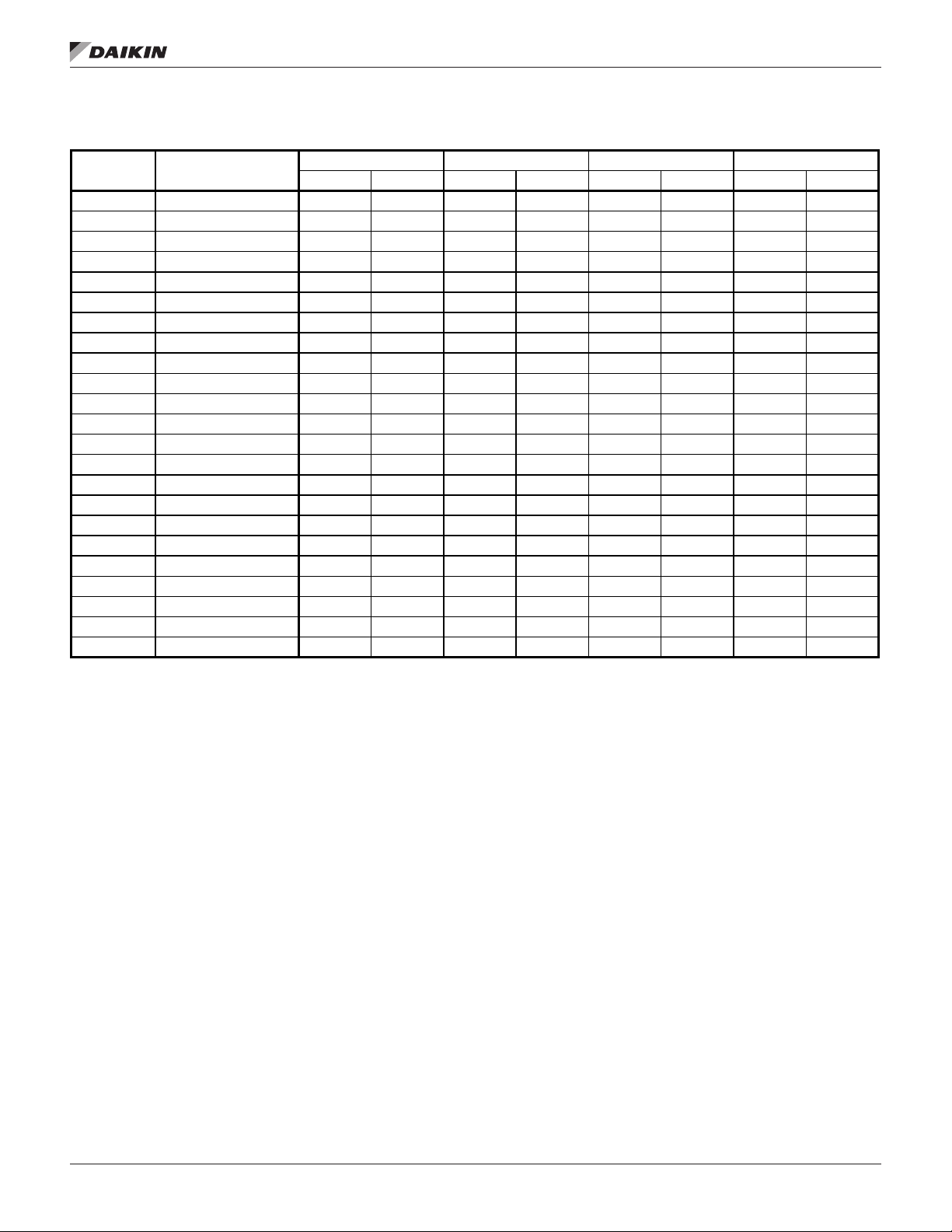

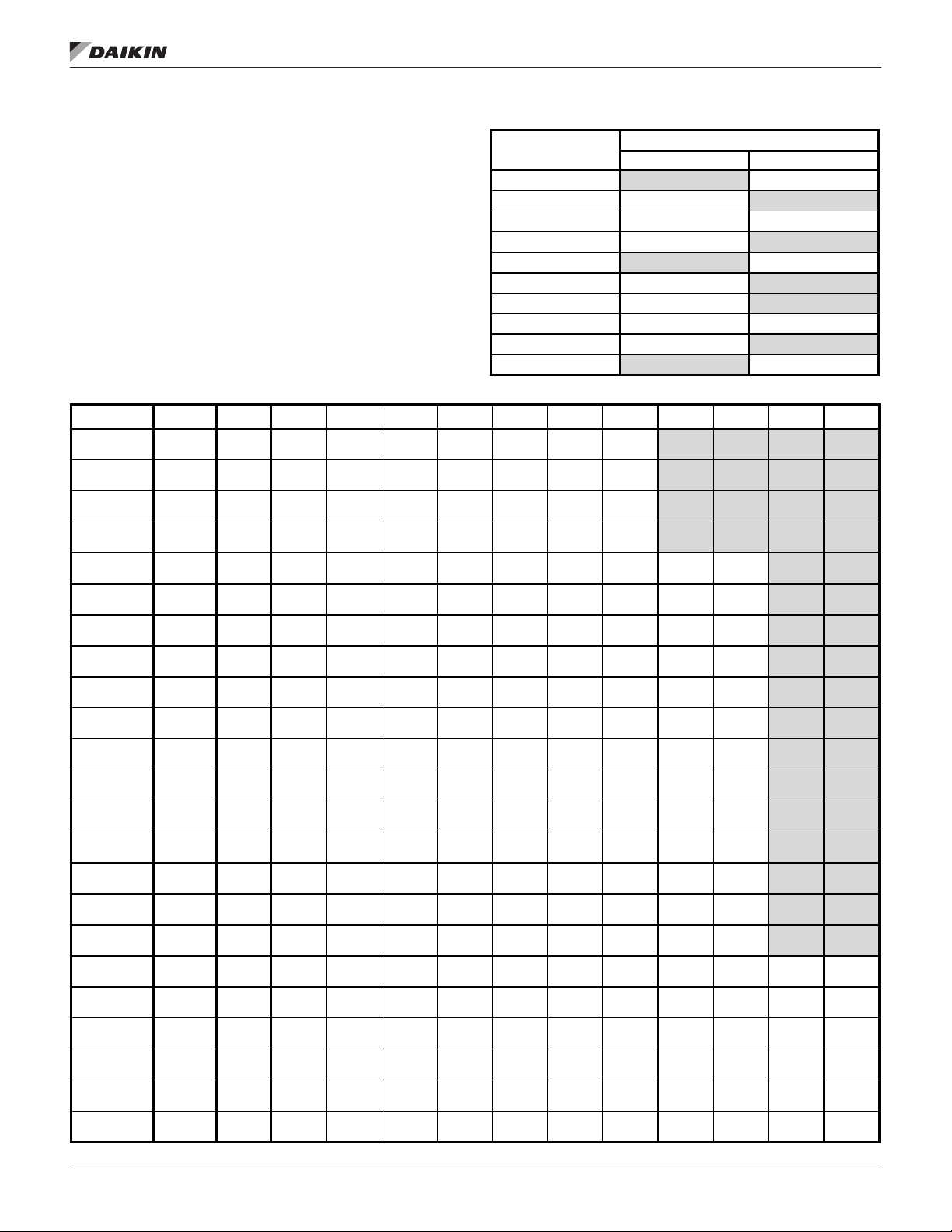

Table 5: Recommended Horizontal or Downow Suction Line Size

Recommended Horizontal or Downow Suction Line Size

InsTallaTIon and applICaTIon ConsIderaTIons

Model Circuit

AWS170CDS 1

AWS170CDS 2

AWS190CDS 1 95 4 1/8 3 5/8 1.23 3 5/8 1.84 4 1/8 1.32 4 1/8 1.66 4 1/8 1.99 4 1/8 2.38

AWS190CDS 2 95 4 1/8 3 5/8 1.23 3 5/8 1.84 4 1/8 1.32 4 1/8 1.66 4 1/8 1.99 4 1/8 2.38

AWS200CDS 1 11 5 4 1/8 3 5/8 1.73 4 1/8 1.40 4 1/8 1.87 4 1/8 2.34 4 1/8 2.80 4 1/8 3.36

AWS200CDS 2 11 5 4 1/8 3 5/8 1.73 4 1/8 1.40 4 1/8 1.87 4 1/8 2.34 4 1/8 2.80 4 1/8 3.36

AWS210CDS 1 95 4 1/8 3 5/8 1.23 3 5/8 1.84 4 1/8 1.32 4 1/8 1.66 4 1/8 1.99 4 1/8 2.38

AWS210CDS 2 11 5 4 1/8 3 5/8 1.73 4 1/8 1.40 4 1/8 1.87 4 1/8 2.34 4 1/8 2.80 4 1/8 3.36

AWS225CDS 1 11 5 4 1/8 3 5/8 1.73 4 1/8 1.40 4 1/8 1.87 4 1/8 2.34 4 1/8 2.80 4 1/8 3.36

AWS225CDS 2 11 5 4 1/8 3 5/8 1.73 4 1/8 1.40 4 1/8 1.87 4 1/8 2.34 4 1/8 2.80 4 1/8 3.36

AWS250CDS 1 11 5 4 1/8 3 5/8 1.73 4 1/8 1.40 4 1/8 1.87 4 1/8 2.34 4 1/8 2.80 4 1/8 3.36

AWS250CDS 2 135 4 1/8 4 1/8 1.25 4 1/8 1.87 4 1/8 2.49 5 1/8 1.10 5 1/8 1.32 5 1/8 1.58

AWS260CDS 1 135 4 1/8 4 1/8 1.25 4 1/8 1.87 4 1/8 2.49 5 1/8 1.10 5 1/8 1.32 5 1/8 1.58

AWS260CDS 2 135 4 1/8 4 1/8 1.25 4 1/8 1.87 4 1/8 2.49 5 1/8 1.10 5 1/8 1.32 5 1/8 1.58

AWS290CDS 1 135 4 1/8 4 1/8 1.25 4 1/8 1.87 4 1/8 2.49 5 1/8 1.10 5 1/8 1.32 5 1/8 1.58

AWS290CDS 2 155 4 1/8 4 1/8 1.60 4 1/8 2.40 5 1/8 1.13 5 1/8 1.41 5 1/8 1.69 5 1/8 2.03

AWS310CDS 1 155 4 1/8 4 1/8 1.60 4 1/8 2.40 5 1/8 1.13 5 1/8 1.41 5 1/8 1.69 5 1/8 2.03

AWS310CDS 2 155 4 1/8 4 1/8 1.60 4 1/8 2.40 5 1/8 1.13 5 1/8 1.41 5 1/8 1.69 5 1/8 2.03

AWS350CDS 1 155 4 1/8 4 1/8 1.60 4 1/8 2.40 5 1/8 1.13 5 1/8 1.41 5 1/8 1.69 5 1/8 2.03

AWS350CDS 2 185 4 1/8 4 1/8 2.20 5 1/8 1.16 5 1/8 1.55 5 1/8 1.94 5 1/8 2.33 5 1/8 2.79

AWS375CDS 1 185 4 1/8 4 1/8 2.20 5 1/8 1.16 5 1/8 1.55 5 1/8 1.94 5 1/8 2.33 5 1/8 2.79

AWS375CDS 2 185 4 1/8 4 1/8 2.20 5 1/8 1.16 5 1/8 1.55 5 1/8 1.94 5 1/8 2.33 5 1/8 2.79

AWS400CTS 1 135 4 1/8 4 1/8 1.25 4 1/8 1.87

AWS400CTS 2 135 4 1/8 4 1/8 1.25 4 1/8 1.87 4 1/8 2.49 5 1/8 1.10 5 1/8 1.32 5 1/8 1.58

AWS400CTS 3 135 4 1/8 4 1/8 1.25 4 1/8 1.87 4 1/8 2.49 5 1/8 1.10 5 1/8 1.32 5 1/8 1.58

AWS425CTS 1 135 4 1/8 4 1/8 1.25 4 1/8 1.87 4 1/8 2.49 5 1/8 1.10 5 1/8 1.32 5 1/8 1.58

AWS425CTS 2 135 4 1/8 4 1/8 1.25 4 1/8 1.87 4 1/8 2.49 5 1/8 1.10 5 1/8 1.32 5 1/8 1.58

AWS425CTS 3 155 4 1/8 4 1/8 1.60 4 1/8 2.40 5 1/8 1.13 5 1/8 1.41 5 1/8 1.69 5 1/8 2.03

AWS450CTS 1 155 4 1/8 4 1/8 1.60 4 1/8 2.40 5 1/8 1.13 5 1/8 1.41 5 1/8 1.69 5 1/8 2.03

AWS450CTS 2 155 4 1/8 4 1/8 1.60 4 1/8 2.40 5 1/8 1.13 5 1/8 1.41 5 1/8 1.69 5 1/8 2.03

AWS450CTS 3 135 4 1/8 4 1/8 1.25 4 1/8 1.87 4 1/8 2.49 5 1/8 1.10 5 1/8 1.32 5 1/8 1.58

AWS470CTS 1 155 4 1/8 4 1/8 1.60 4 1/8 2.40 5 1/8 1.13 5 1/8 1.41 5 1/8 1.69 5 1/8 2.03

AWS470CTS 2 155 4 1/8 4 1/8 1.60 4 1/8 2.40 5 1/8 1.13 5 1/8 1.41 5 1/8 1.69 5 1/8 2.03

AWS470CTS 3 155 4 1/8 4 1/8 1.60 4 1/8 2.40 5 1/8 1.13 5 1/8 1.41 5 1/8 1.69 5 1/8 2.03

AWS500CTS 1 155 4 1/8 4 1/8 1.60 4 1/8 2.40 5 1/8 1.13 5 1/8 1.41 5 1/8 1.69 5 1/8 2.03

AWS500CTS 2 155 4 1/8 4 1/8 1.60 4 1/8 2.40 5 1/8 1.13 5 1/8 1.41 5 1/8 1.69 5 1/8 2.03

AWS500CTS 3 185 4 1/8 4 1/8 2.20 5 1/8 1.16 5 1/8 1.55 5 1/8 1.94 5 1/8 2.33 5 1/8 2.79

AWS525CTS 1 185 4 1/8 4 1/8 2.20 5 1/8 1.16 5 1/8 1.55 5 1/8 1.94 5 1/8 2.33 5 1/8 2.79

AWS525CTS 2 185 4 1/8 4 1/8 2.20 5 1/8 1.16 5 1/8 1.55 5 1/8 1.94 5 1/8 2.33 5 1/8 2.79

Nominal

Tons Per

Circuit

Tubing

Conn.

Size At

Unit

95 4 1/8 3 5/8 1.23 3 5/8 1.84 4 1/8 1.32 4 1/8 1.66 4 1/8 1.99 4 1/8 2.38

95 4 1/8 3 5/8 1.23 3 5/8 1.84 4 1/8 1.32 4 1/8 1.66 4 1/8 1.99 4 1/8 2.38

UP TO 50

EQUIV. FT.

Size PD Size PD Size PD Size PD Size PD Size PD

UP TO 75

EQUIV. FT.

UP TO 100

EQUIV. FT.

4 1/8 2.49 5 1/8 1.10 5 1/8 1.32 5 1/8 1.58

UP TO 125

EQUIV. FT.

UP TO 150

EQUIV. FT.

UP TO 180

EQUIV. FT.

www.DaikinApplied.com 9 IM 1203-1 • PATHFINDER® MODEL AWS REMOTE CHILLERS

Page 12

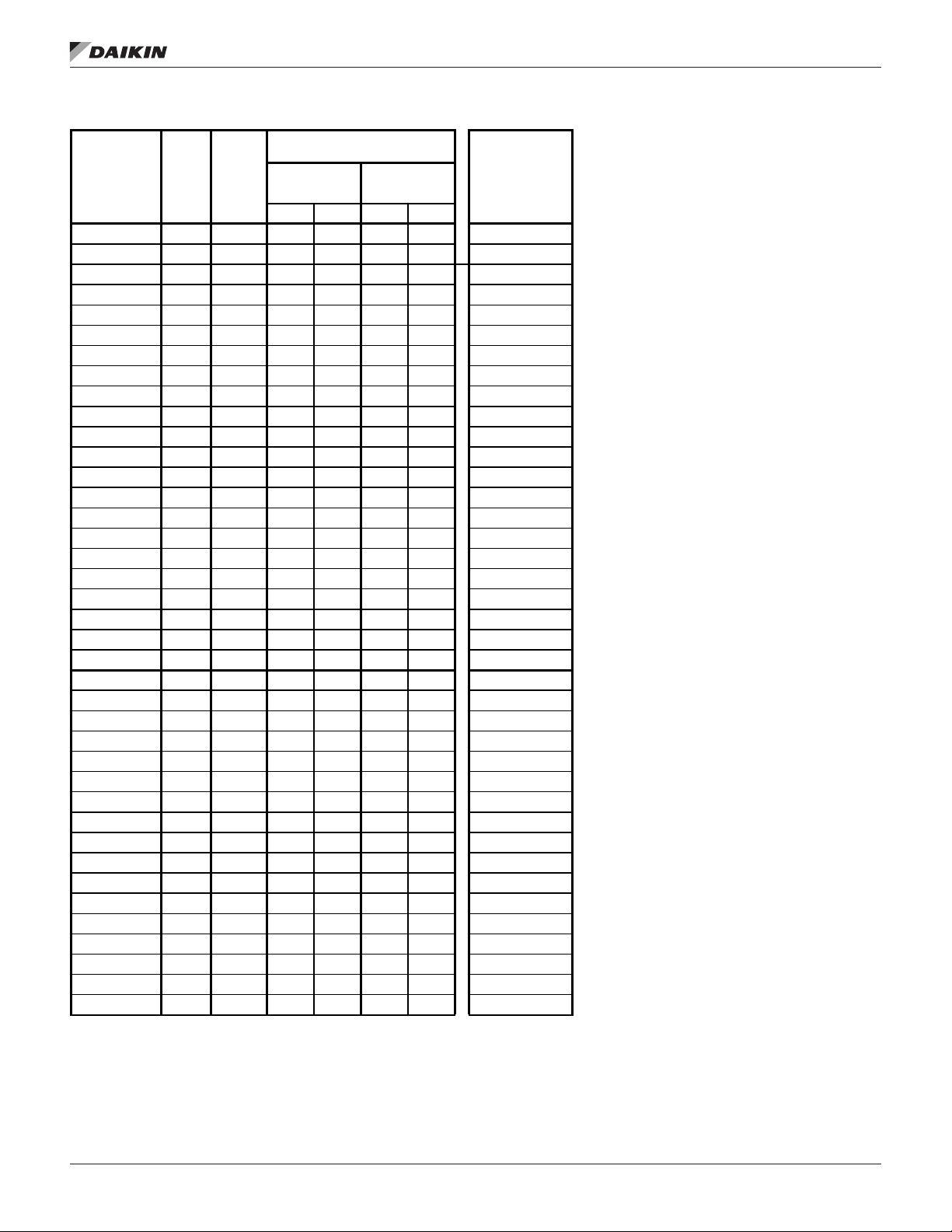

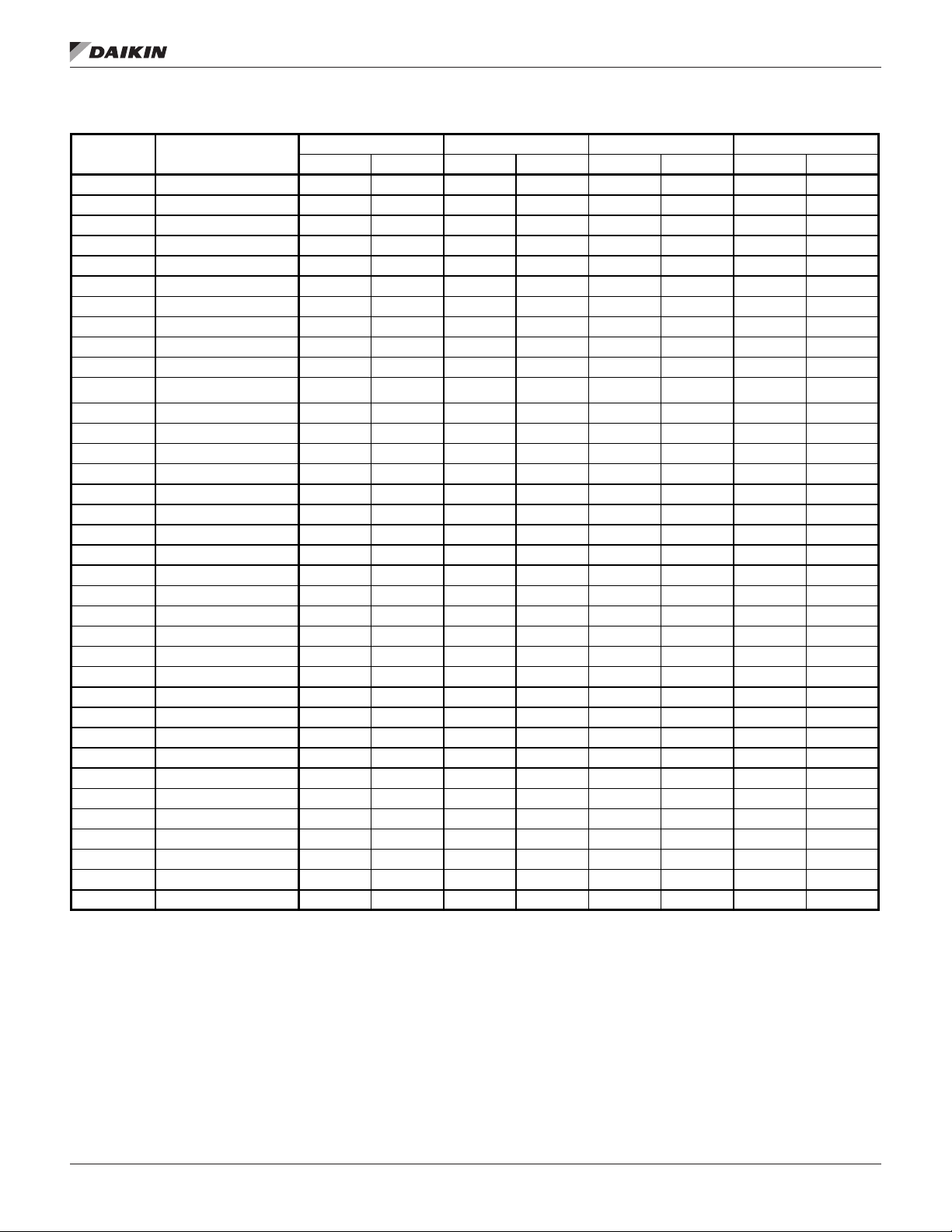

Table 6: Recommended Horizontal or Downow Suction Line Size

Recommended Horizontal or Downow Suction Line Size

InsTallaTIon and applICaTIon ConsIderaTIons

Model Circuit

AWS210CDH 1 105 4 1/8 3 5/8 1.47 3 5/8 2.20 4 1/8 1.59 4 1/8 1.98 4 1/8 2.38 4 1/8 2.86

AWS210CDH 2 105 4 1/8 3 5/8 1.47 3 5/8 2.20 4 1/8 1.59 4 1/8 1.98 4 1/8 2.38 4 1/8 2.86

AWS230CDH 1 105 4 1/8 3 5/8 1.47 3 5/8 2.20 4 1/8 1.59 4 1/8 1.98 4 1/8 2.38 4 1/8 2.86

AWS230CDH 2 125 4 1/8 3 5/8 2.01 4 1/8 1.63 4 1/8 2.17 4 1/8 2.71 4 1/8 3.26 4 1/8 3.91

AWS250CDH 1 125 4 1/8 3 5/8 2.01 4 1/8 1.63 4 1/8 2.17 4 1/8 2.71 4 1/8 3.26 4 1/8 3.91

AWS250CDH 2 125 4 1/8 3 5/8 2.01 4 1/8 1.63 4 1/8 2.17 4 1/8 2.71 4 1/8 3.26 4 1/8 3.91

AWS280CDH 1 125 4 1/8 3 5/8 2.01 4 1/8 1.63 4 1/8 2.17 4 1/8 2.71 4 1/8 3.26 4 1/8 3.91

AWS280CDH 2 150 4 1/8 4 1/8 1.51 4 1/8 2.26 4 1/8 3.01 5 1/8 1.33 5 1/8 1.60 5 1/8 1.92

AWS300CDH 1 150 4 1/8 4 1/8 1.51 4 1/8 2.26 4 1/8 3.01 5 1/8 1.33 5 1/8 1.60 5 1/8 1.92

AWS300CDH 2 150 4 1/8 4 1/8 1.51 4 1/8 2.26 4 1/8 3.01 5 1/8 1.33 5 1/8 1.60 5 1/8 1.92

AWS330CDH 1 150 4 1/8 4 1/8 1.51 4 1/8 2.26 4 1/8 3.01 5 1/8 1.33 5 1/8 1.60 5 1/8 1.92

AWS330CDH 2 175 4 1/8 4 1/8 1.99 4 1/8 2.98 5 1/8 1.40 5 1/8 1.76 5 1/8 2.11 5 1/8 2.53

AWS350CDH 1 175 4 1/8 4 1/8 1.99 4 1/8 2.98 5 1/8 1.40 5 1/8 1.76 5 1/8 2.11 5 1/8 2.53

AWS350CDH 2 175 4 1/8 4 1/8 1.99 4 1/8 2.98 5 1/8 1.40 5 1/8 1.76 5 1/8 2.11 5 1/8 2.53

AWS390CDH 1 175 4 1/8 4 1/8 1.99 4 1/8 2.98 5 1/8 1.40 5 1/8 1.76 5 1/8 2.11 5 1/8 2.53

AWS390CDH 2 205 4 1/8 4 1/8 2.64 5 1/8 1.40 5 1/8 1.87 5 1/8 2.33 5 1/8 2.80 5 1/8 3.36

AWS410CDH 1 205 4 1/8 4 1/8 2.64 5 1/8 1.40 5 1/8 1.87 5 1/8 2.33 5 1/8 2.80 5 1/8 3.36

AWS410CDH 2 205 4 1/8 4 1/8 2.64 5 1/8 1.40 5 1/8 1.87 5 1/8 2.33 5 1/8 2.80 5 1/8 3.36

AWS450CTH 1 150 4 1/8 4 1/8 1.51 4 1/8 2.26 4 1/8 3.01 5 1/8 1.33 5 1/8 1.60 5 1/8 1.92

AWS450CTH 2 150 4 1/8 4 1/8 1.51 4 1/8 2.26 4 1/8 3.01 5 1/8 1.33 5 1/8 1.60 5 1/8 1.92

AWS450CTH 3 150 4 1/8 4 1/8 1.51 4 1/8 2.26 4 1/8 3.01 5 1/8 1.33 5 1/8 1.60 5 1/8 1.92

AWS475CTH 1 150 4 1/8 4 1/8 1.51 4 1/8 2.26 4 1/8 3.01 5 1/8 1.33 5 1/8 1.60 5 1/8 1.92

AWS475CTH 2 150 4 1/8 4 1/8 1.51 4 1/8 2.26

AWS475CTH 3 175 4 1/8 4 1/8 1.99 4 1/8 2.98 5 1/8 1.40 5 1/8 1.76 5 1/8 2.11 5 1/8 2.53

AWS500CTH 1 175 4 1/8 4 1/8 1.99 4 1/8 2.98 5 1/8 1.40 5 1/8 1.76 5 1/8 2.11 5 1/8 2.53

AWS500CTH 2 175 4 1/8 4 1/8 1.99 4 1/8 2.98 5 1/8 1.40 5 1/8 1.76 5 1/8 2.11 5 1/8 2.53

AWS500CTH 3 150 4 1/8 4 1/8 1.51 4 1/8 2.26 4 1/8 3.01 5 1/8 1.33 5 1/8 1.60 5 1/8 1.92

AWS530CTH 1 175 4 1/8 4 1/8 1.99 4 1/8 2.98 5 1/8 1.40 5 1/8 1.76 5 1/8 2.11 5 1/8 2.53

AWS530CTH 2 175 4 1/8 4 1/8 1.99 4 1/8 2.98 5 1/8 1.40 5 1/8 1.76 5 1/8 2.11 5 1/8 2.53

AWS530CTH 3 175 4 1/8 4 1/8 1.99 4 1/8 2.98 5 1/8 1.40 5 1/8 1.76 5 1/8 2.11 5 1/8 2.53

AWS240CDP 1 105 4 1/8 3 5/8 1.47 3 5/8 2.20 4 1/8 1.59 4 1/8 1.98 4 1/8 2.38 4 1/8 2.86

AWS240CDP 2 105 4 1/8 3 5/8 1.47 3 5/8 2.20 4 1/8 1.59 4 1/8 1.98 4 1/8 2.38 4 1/8 2.86

AWS265CDP 1 105 4 1/8 3 5/8 1.47 3 5/8 2.20 4 1/8 1.59 4 1/8 1.98 4 1/8 2.38 4 1/8 2.86

AWS265CDP 2 125 4 1/8 3 5/8 2.01 4 1/8 1.63 4 1/8 2.17 4 1/8 2.71 4 1/8 3.26 4 1/8 3.91

AWS290CDP 1 125 4 1/8 3 5/8 2.01 4 1/8 1.63 4 1/8 2.17 4 1/8 2.71 4 1/8 3.26 4 1/8 3.91

AWS290CDP 2 125 4 1/8 3 5/8 2.01 4 1/8 1.63 4 1/8 2.17 4 1/8 2.71 4 1/8 3.26 4 1/8 3.91

AWS310CDP 1 125 4 1/8 3 5/8 2.01 4 1/8 1.63 4 1/8 2.17 4 1/8 2.71 4 1/8 3.26 4 1/8 3.91

AWS310CDP 2 150 4 1/8 4 1/8 1.51 4 1/8 2.26 4 1/8 3.01 5 1/8 1.33 5 1/8 1.60 5 1/8 1.92

AWS330CDP 1 150 4 1/8 4 1/8 1.51 4 1/8 2.26 4 1/8 3.01 5 1/8 1.33 5 1/8 1.60 5 1/8 1.92

AWS330CDP 2 150 4 1/8 4 1/8 1.51 4 1/8 2.26 4 1/8 3.01 5 1/8 1.33 5 1/8 1.60 5 1/8 1.92

AWS365CDP 1 150 4 1/8 4 1/8 1.51 4 1/8 2.26 4 1/8 3.01 5 1/8 1.33 5 1/8 1.60 5 1/8 1.92

AWS365CDP 2 175 4 1/8 4 1/8 1.99 4 1/8 2.98 5 1/8 1.40 5 1/8 1.76 5 1/8 2.11 5 1/8 2.53

AWS400CDP 1 175 4 1/8 4 1/8 1.99 4 1/8 2.98 5 1/8 1.40 5 1/8 1.76 5 1/8 2.11 5 1/8 2.53

AWS400CDP 2 175 4 1/8 4 1/8 1.99 4 1/8 2.98 5 1/8 1.40 5 1/8 1.76 5 1/8 2.11 5 1/8 2.53

Nominal

Tons Per

Circuit

Tubing

Conn.

Size At

Unit

UP TO 50

EQUIV. FT.

Size PD Size PD Size PD Size PD Size PD Size PD

UP TO 75

EQUIV. FT.

UP TO 100

EQUIV. FT.

4 1/8 3.01 5 1/8 1.33 5 1/8 1.60 5 1/8 1.92

UP TO 125

EQUIV. FT.

UP TO 150

EQUIV. FT.

UP TO 180

EQUIV. FT.

IM 1203-1 • PATHFINDER® MODEL AWS REMOTE CHILLERS 10 www.DaikinApplied.com

Page 13

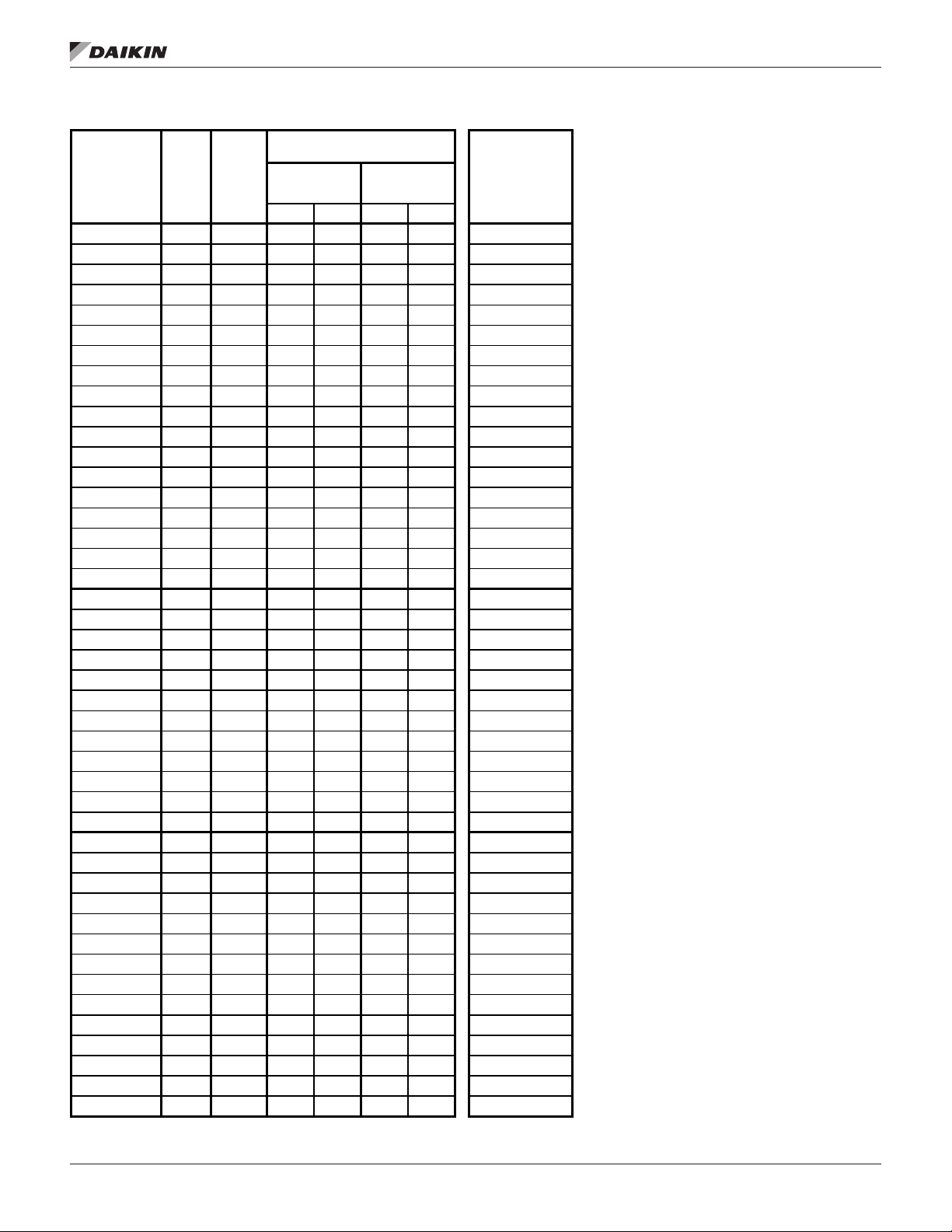

Table 7: Recommended Upow Suction

Recommended Vertical or Upow

Model Circuit

AWS170CDS 1 95 3 5/8 1.23 3 5/8 1.84 3 5/8

AWS170CDS 2 95 3 5/8 1.23 3 5/8 1.84 3 5/8

AWS190CDS 1 95 3 5/8 1.23 3 5/8 1.84 3 5/8

AWS190CDS 2 95 3 5/8 1.23 3 5/8 1.84 3 5/8

AWS200CDS 1 11 5 3 5/8 1.73 3 5/8 2.60 3 5/8

AWS200CDS 2 11 5 3 5/8 1.73 3 5/8 2.60 3 5/8

AWS210CDS 1 95 3 5/8 1.23 3 5/8 1.84 3 5/8

AWS210CDS 2 11 5 3 5/8 1.73 3 5/8 2.60 3 5/8

AWS225CDS 1 11 5 3 5/8 1.73 3 5/8 2.60 3 5/8

AWS225CDS 2 11 5 3 5/8 1.73 3 5/8 2.60 3 5/8

AWS250CDS 1 11 5 3 5/8 1.73 3 5/8 2.60 3 5/8

AWS250CDS 2 135 4 1/8 1.25 4 1/8 1.87 4 1/8

AWS260CDS 1 135 4 1/8 1.25 4 1/8 1.87 4 1/8

AWS260CDS 2 135 4 1/8 1.25 4 1/8 1.87 4 1/8

AWS290CDS 1 135 4 1/8 1.25 4 1/8 1.87 4 1/8

AWS290CDS 2 155 4 1/8 1.60 4 1/8 2.40 4 1/8

AWS310CDS 1 155 4 1/8 1.60 4 1/8 2.40 4 1/8

AWS310CDS 2 155 4 1/8 1.60 4 1/8 2.40 4 1/8

AWS350CDS 1 155 4 1/8 1.60 4 1/8 2.40 4 1/8

AWS350CDS 2 185 4 1/8 2.20 4 1/8 3.30 4 1/8

AWS375CDS 1 185 4 1/8 2.20 4 1/8 3.30 4 1/8

AWS375CDS 2 185 4 1/8 2.20 4 1/8 3.30 4 1/8

AWS400CTS 1 135 4 1/8 1.25 4 1/8 1.87 4 1/8

AWS400CTS 2 135 4 1/8 1.25 4 1/8 1.87 4 1/8

AWS400CTS 3 135 4 1/8 1.25 4 1/8 1.87 4 1/8

AWS425CTS 1 135 4 1/8 1.25 4 1/8 1.87 4 1/8

AWS425CTS 2 135 4 1/8 1.25 4 1/8 1.87 4 1/8

AWS425CTS 3 155 4 1/8 1.60 4 1/8 2.40 4 1/8

AWS450CTS 1 155 4 1/8 1.60 4 1/8 2.40 4 1/8

AWS450CTS 2 155 4 1/8 1.60 4 1/8 2.40 4 1/8

AWS450CTS 3 135 4 1/8 1.25 4 1/8 1.87 4 1/8

AWS470CTS 1 155 4 1/8 1.60 4 1/8 2.40 4 1/8

AWS470CTS 2 155 4 1/8 1.60 4 1/8 2.40 4 1/8

AWS470CTS 3 155 4 1/8 1.60 4 1/8 2.40 4 1/8

AWS500CTS 1 155 4 1/8 1.60 4 1/8 2.40 4 1/8

AWS500CTS 2 155 4 1/8 1.60 4 1/8 2.40 4 1/8

AWS500CTS 3 185 4 1/8 2.20 4 1/8 3.30 4 1/8

AWS525CTS 1 185 4 1/8 2.20 4 1/8 3.30 4 1/8

AWS525CTS 2 185 4 1/8 2.20 4 1/8 3.30 4 1/8

Nominal

Tons Per

Circuit

Suction Line Size

UP TO 50

EQUIV. FT.

Size PD Size PD

UP TO 75

EQUIV. FT.

Max. Suct. Riser

Line Size for

Vertical Upow

to Compressor

InsTallaTIon and applICaTIon ConsIderaTIons

www.DaikinApplied.com 11 IM 1203-1 • PATHFINDER® MODEL AWS REMOTE CHILLERS

Page 14

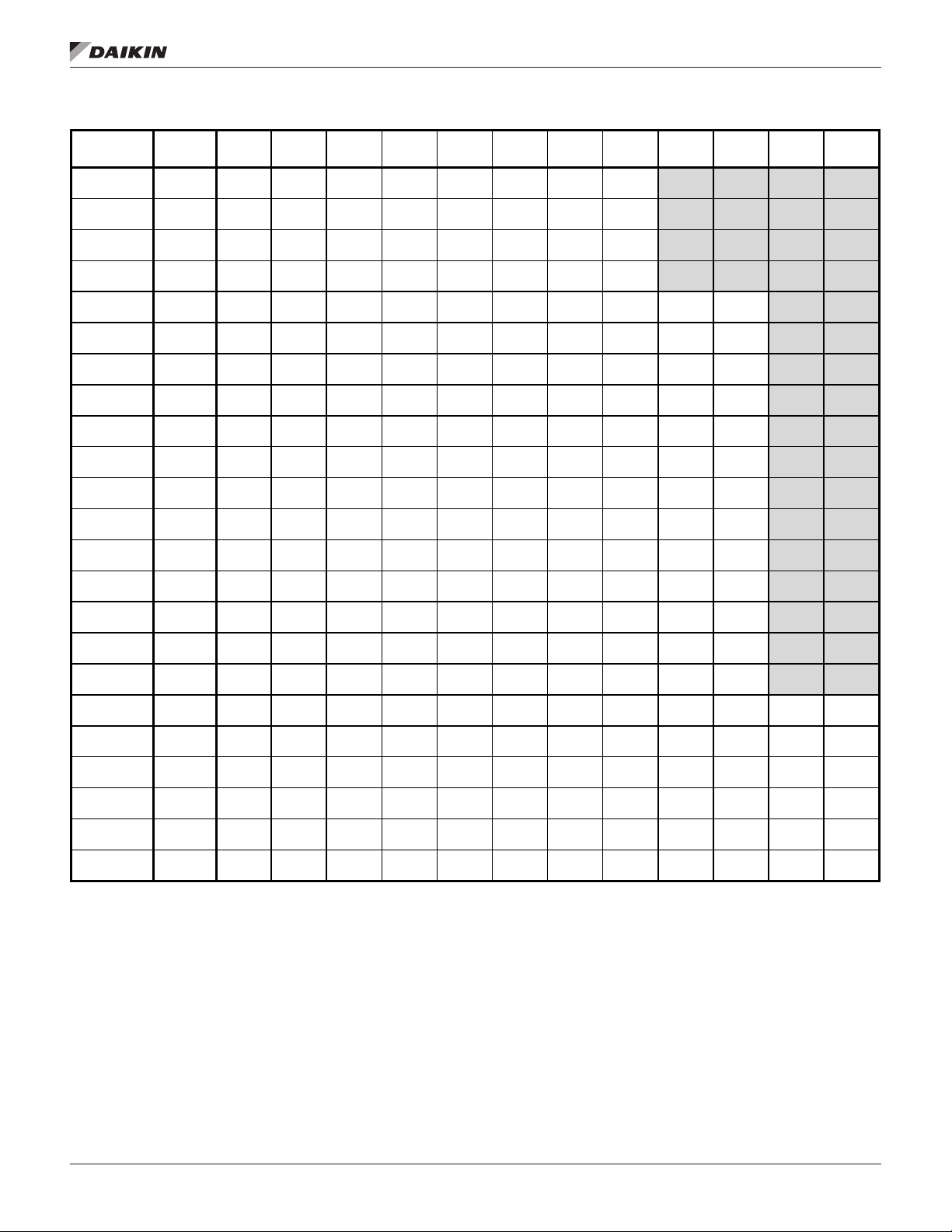

Table 6 continued: Recommended Upow Suction

Recommended Vertical or Upow

Model Circuit

AWS210CDH 1 105 3 5/8 1.47 3 5/8 2.20 3 5/8

AWS210CDH 2 105 3 5/8 1.47 3 5/8 2.20 3 5/8

AWS230CDH 1 105 3 5/8 1.47 3 5/8 2.20 3 5/8

AWS230CDH 2 125 3 5/8 2.01 3 5/8 3.02 3 5/8

AWS250CDH 1 125 3 5/8 2.01 3 5/8 3.02 3 5/8

AWS250CDH 2 125 3 5/8 2.01 3 5/8 3.02 3 5/8

AWS280CDH 1 125 3 5/8 2.01 3 5/8 3.02 3 5/8

AWS280CDH 2 150 4 1/8 1.51 4 1/8 2.26 4 1/8

AWS300CDH 1 150 4 1/8 1.51 4 1/8 2.26 4 1/8

AWS300CDH 2 150 4 1/8 1.51 4 1/8 2.26 4 1/8

AWS330CDH 1 150 4 1/8 1.51 4 1/8 2.26 4 1/8

AWS330CDH 2 175 4 1/8 1.99 4 1/8 2.98 4 1/8

AWS350CDH 1 175 4 1/8 1.99 4 1/8 2.98 4 1/8

AWS350CDH 2 175 4 1/8 1.99 4 1/8 2.98 4 1/8

AWS390CDH 1 175 4 1/8 1.99 4 1/8 2.98 4 1/8

AWS390CDH 2 205 4 1/8 2.64 4 1/8 3.97 4 1/8

AWS410CDH 1 205 4 1/8 2.64 4 1/8 3.97 4 1/8

AWS410CDH 2 205 4 1/8 2.64 4 1/8 3.97 4 1/8

AWS450CTH 1 150 4 1/8 1.51 4 1/8 2.26 4 1/8

AWS450CTH 2 150 4 1/8 1.51 4 1/8 2.26 4 1/8

AWS450CTH 3 150 4 1/8 1.51 4 1/8 2.26 4 1/8

AWS475CTH 1 150 4 1/8 1.51 4 1/8 2.26 4 1/8

AWS475CTH 2 150 4 1/8 1.51 4 1/8 2.26 4 1/8

AWS475CTH 3 175 4 1/8 1.99 4 1/8 2.98 4 1/8

AWS500CTH 1 175 4 1/8 1.99 4 1/8 2.98 4 1/8

AWS500CTH 2 175 4 1/8 1.99 4 1/8 2.98 4 1/8

AWS500CTH 3 150 4 1/8 1.51 4 1/8 2.26 4 1/8

AWS530CTH 1 175 4 1/8 1.99 4 1/8 2.98 4 1/8

AWS530CTH 2 175 4 1/8 1.99 4 1/8 2.98 4 1/8

AWS530CTH 3 175 4 1/8 1.99 4 1/8 2.98 4 1/8

AWS240CDP 1 105 3 5/8 1.47 3 5/8 2.20 3 5/8

AWS240CDP 2 105 3 5/8 1.47 3 5/8 2.20 3 5/8

AWS265CDP 1 105 3 5/8 1.47 3 5/8 2.20 3 5/8

AWS265CDP 2 125 3 5/8 2.01 3 5/8 3.02 3 5/8

AWS290CDP 1 125 3 5/8 2.01 3 5/8 3.02 3 5/8

AWS290CDP 2 125 3 5/8 2.01 3 5/8 3.02 3 5/8

AWS310CDP 1 125 3 5/8 2.01 3 5/8 3.02 3 5/8

AWS310CDP 2 150 4 1/8 1.51 4 1/8 2.26 4 1/8

AWS330CDP 1 150 4 1/8 1.51 4 1/8 2.26 4 1/8

AWS330CDP 2 150 4 1/8 1.51 4 1/8 2.26 4 1/8

AWS365CDP 1 150 4 1/8 1.51 4 1/8 2.26 4 1/8

AWS365CDP 2 175 4 1/8 1.99 4 1/8 2.98 4 1/8

AWS400CDP 1 175 4 1/8 1.99 4 1/8 2.98 4 1/8

AWS400CDP 2 175 4 1/8 1.99 4 1/8 2.98 4 1/8

Nominal

Tons Per

Circuit

Suction Line Size

UP TO 50

EQUIV. FT.

Size PD Size PD

UP TO 75

EQUIV. FT.

Max. Suct. Riser

Line Size for

Vertical Upow

to Compressor

InsTallaTIon and applICaTIon ConsIderaTIons

IM 1203-1 • PATHFINDER® MODEL AWS REMOTE CHILLERS 12 www.DaikinApplied.com

Page 15

InsTallaTIon and applICaTIon ConsIderaTIons

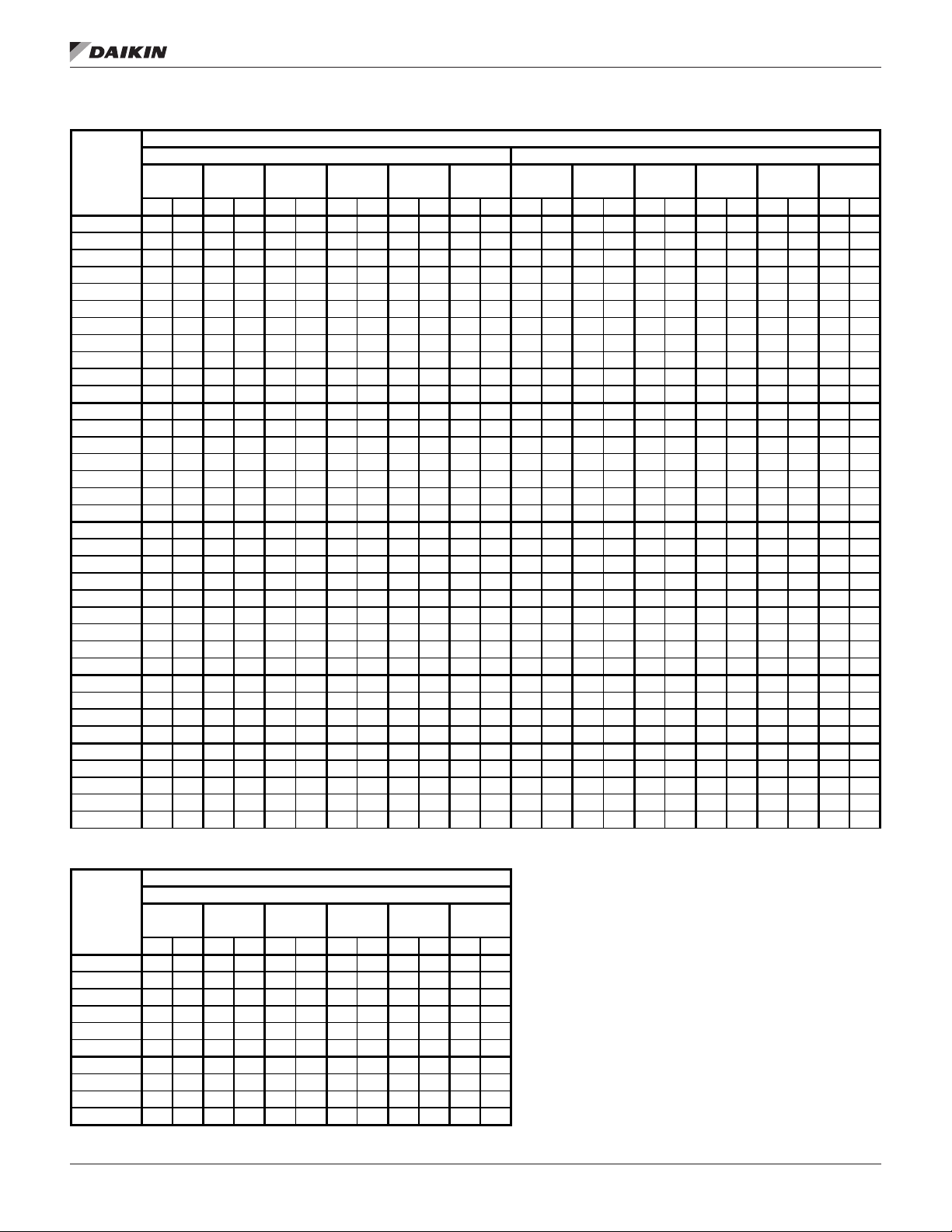

Table 8: Recommended Liquid Line Sizes (Circuits 1 & 2; Circuit 3 below)

Recommended Liquid Line Size

Circuit 1 Circuit 2

Model

AWS170CDS 1 5/8 0.70 1 5/8 1.05 1 5/8 1.41 1 5/8 1.76 1 5/8 2.11 1 5/8 2.53 1 5/8 0.70 1 5/8 1.05 1 5/8 1.41 1 5/8 1.76 1 5/8 2.11 1 5/8 2.53

AWS190CDS 1 5/8 0.70 1 5/8 1.05 1 5/8 1.41 1 5/8 1.76 1 5/8 2.11 1 5/8 2.53 1 5/8 0.70 1 5/8 1.05 1 5/8 1.41 1 5/8 1.76 1 5/8 2.11 1 5/8 2.53

AWS200CDS 1 5/8 0.99 1 5/8 1.49 1 5/8 1.98 1 5/8 2.48 1 5/8 2.98 1 5/8 3.57 1 5/8 0.99 1 5/8 1.49 1 5/8 1.98 1 5/8 2.48 1 5/8 2.98 1 5/8 3.57

AWS210CDS 1 5/8 0.70 1 5/8 1.05 1 5/8 1.41 1 5/8 1.76 1 5/8 2.11 1 5/8 2.53 1 5/8 0.99 1 5/8 1.49 1 5/8 1.98 1 5/8 2.48 1 5/8 2.98 1 5/8 3.57

AWS225CDS 1 5/8 0.99 1 5/8 1.49 1 5/8 1.98 1 5/8 2.48 1 5/8 2.98 1 5/8 3.57 1 5/8 0.99 1 5/8 1.49 1 5/8 1.98 1 5/8 2.48 1 5/8 2.98 1 5/8 3.57

AWS250CDS 1 5/8 0.99 1 5/8 1.49 1 5/8 1.98 1 5/8 2.48 1 5/8 2.98 1 5/8 3.57 1 5/8 1.32 1 5/8 1.99 1 5/8 2.65 1 5/8 3.31 1 5/8 3.97 1 5/8 4.77

AWS260CDS 1 5/8 1.32 1 5/8 1.99 1 5/8 2.65 1 5/8 3.31 1 5/8 3.97 1 5/8 4.77 1 5/8 1.32 1 5/8 1.99 1 5/8 2.65 1 5/8 3.31 1 5/8 3.97 1 5/8 4.77

AWS290CDS 1 5/8 1.32 1 5/8 1.99 1 5/8 2.65 1 5/8 3.31 1 5/8 3.97 1 5/8 4.77 1 5/8 1.70 2 1/8 0.69 2 1/8 0.91 2 1/8 1.14 2 1/8 1.37 2 1/8 1.64

AWS310CDS 1 5/8 1.70 2 1/8 0.69 2 1/8 0.91 2 1/8 1.14 2 1/8 1.37 2 1/8 1.64 1 5/8 1.70 2 1/8 0.69 2 1/8 0.91 2 1/8 1.14 2 1/8 1.37 2 1/8 1.64

AWS350CDS 1 5/8 1.70 2 1/8 0.69 2 1/8 0.91 2 1/8 1.14 2 1/8 1.37 2 1/8 1.64 1 5/8 2.33 2 1/8 0.94 2 1/8 1.26 2 1/8 1.57 2 1/8 1.88 2 1/8 2.26

AWS375CDS 1 5/8 2.33 2 1/8 0.94 2 1/8 1.26 2 1/8 1.57 2 1/8 1.88 2 1/8 2.26 1 5/8 2.33 2 1/8 0.94 2 1/8 1.26 2 1/8 1.57 2 1/8 1.88 2 1/8 2.26

AWS400CTS 1 5/8 1.32 1 5/8 1.99 1 5/8 2.65 1 5/8 3.31 1 5/8 3.97 1 5/8 4.77 1 5/8 1.32 1 5/8 1.99 1 5/8 2.65 1 5/8 3.31 1 5/8 3.97 1 5/8 4.77

AWS425CTS 1 5/8 1.32 1 5/8 1.99 1 5/8 2.65 1 5/8 3.31 1 5/8 3.97 1 5/8 4.77 1 5/8 1.32 1 5/8 1.99 1 5/8 2.65 1 5/8 3.31 1 5/8 3.97 1 5/8 4.77

AWS450CTS 1 5/8 1.70 2 1/8 0.69 2 1/8 0.91 2 1/8 1.14 2 1/8 1.37

AWS470CTS 1 5/8 1.70 2 1/8 0.69 2 1/8 0.91 2 1/8 1.14 2 1/8 1.37 2 1/8 1.64 1 5/8 1.70 2 1/8 0.69 2 1/8 0.91 2 1/8 1.14 2 1/8 1.37 2 1/8 1.64

AWS500CTS 1 5/8 1.70 2 1/8 0.69 2 1/8 0.91 2 1/8 1.14 2 1/8 1.37 2 1/8 1.64 1 5/8 1.70 2 1/8 0.69 2 1/8 0.91 2 1/8 1.14 2 1/8 1.37 2 1/8 1.64

AWS525CTS 1 5/8 2.33 2 1/8 0.94 2 1/8 1.26 2 1/8 1.57 2 1/8 1.88 2 1/8 2.26 1 5/8 2.33 2 1/8 0.94 2 1/8 1.26 2 1/8 1.57 2 1/8 1.88 2 1/8 2.26

AWS550CTS 1 5/8 2.33 2 1/8 0.94 2 1/8 1.26 2 1/8 1.57 2 1/8 1.88 2 1/8 2.26 1 5/8 2.33 2 1/8 0.94 2 1/8 1.26 2 1/8 1.57 2 1/8 1.88 2 1/8 2.26

AWS210CDH 1 5/8 0.84 1 5/8 1.26 1 5/8 1.68 1 5/8 2.11 1 5/8 2.53 1 5/8 3.03 1 5/8 0.84 1 5/8 1.26 1 5/8 1.68 1 5/8 2.11 1 5/8 2.53 1 5/8 3.03

AWS230CDH 1 5/8 0.84 1 5/8 1.26 1 5/8 1.68 1 5/8 2.11 1 5/8 2.53 1 5/8 3.03 1 5/8 1.15 1 5/8 1.73 1 5/8 2.31 1 5/8 2.88 1 5/8 3.46 1 5/8 4.15

AWS250CDH 1 5/8 1.15 1 5/8 1.73 1 5/8 2.31 1 5/8 2.88 1 5/8 3.46 1 5/8 4.15 1 5/8 1.15 1 5/8 1.73 1 5/8 2.31 1 5/8 2.88 1 5/8 3.46 1 5/8 4.15

AWS280CDH 1 5/8 1.15 1 5/8 1.73 1 5/8 2.31 1 5/8 2.88 1 5/8 3.46 1 5/8 4.15 1 5/8 1.60 1 5/8 2.40 1 5/8 3.20 1 5/8 4.00 1 5/8 4.80 1 5/8 5.76

AWS300CDH 1 5/8 1.60 1 5/8 2.40 1 5/8 3.20 1 5/8 4.00 1 5/8 4.80 1 5/8 5.76 1 5/8 1.60 1 5/8 2.40 1 5/8 3.20 1 5/8 4.00 1 5/8 4.80 1 5/8 5.76

AWS330CDH 1 5/8 1.60 1 5/8 2.40 1 5/8 3.20 1 5/8 4.00 1 5/8 4.80 1 5/8 5.76 1 5/8 2.11 2 1/8 0.85 2 1/8 1.14 2 1/8 1.42 2 1/8 1.70 2 1/8 2.05

AWS350CDH 1 5/8 2.11 2 1/8 0.85 2 1/8 1.14 2 1/8 1.42 2 1/8 1.70 2 1/8 2.05 1 5/8 2.11 2 1/8 0.85 2 1/8 1.14 2 1/8 1.42 2 1/8 1.70 2 1/8 2.05

AWS390CDH 1 5/8 2.11 2 1/8 0.85 2 1/8 1.14 2 1/8 1.42 2 1/8 1.70 2 1/8 2.05 1 5/8 2.81 2 1/8 1.13 2 1/8 1.51 2 1/8 1.89 2 1/8 2.27 2 1/8 2.72

AWS410CDH 1 5/8 2.81 2 1/8 1.13 2 1/8 1.51 2 1/8 1.89 2 1/8 2.27 2 1/8 2.72 1 5/8 2.81 2 1/8 1.13 2 1/8 1.51 2 1/8 1.89 2 1/8 2.27 2 1/8 2.72

AWS450CTH 1 5/8 1.60 1 5/8 2.40 1 5/8 3.20 1 5/8 4.00 1 5/8 4.80 1 5/8 5.76 1 5/8 1.60 1 5/8 2.40 1 5/8 3.20 1 5/8 4.00 1 5/8 4.80 1 5/8 5.76

AWS475CTH 1 5/8 1.60 1 5/8 2.40 1 5/8 3.20 1 5/8 4.00 1 5/8 4.80 1 5/8 5.76 1 5/8 1.60 1 5/8 2.40 1 5/8 3.20 1 5/8 4.00 1 5/8 4.80 1 5/8 5.76

AWS500CTH 1 5/8 2.11 2 1/8 0.85 2 1/8 1.14 2 1/8 1.42 2 1/8 1.70

AWS530CTH 1 5/8 2.11 2 1/8 0.85 2 1/8 1.14 2 1/8 1.42 2 1/8 1.70 2 1/8 2.05 1 5/8 2.11 2 1/8 0.85 2 1/8 1.14 2 1/8 1.42 2 1/8 1.70 2 1/8 2.05

AWS240CDP 1 5/8 0.84 1 5/8 1.26 1 5/8 1.68 1 5/8 2.11 1 5/8 2.53 1 5/8 3.03 1 5/8 0.84 1 5/8 1.26 1 5/8 1.68 1 5/8 2.11 1 5/8 2.53 1 5/8 3.03

AWS265CDP 1 5/8 0.84 1 5/8 1.26 1 5/8 1.68 1 5/8 2.11 1 5/8 2.53 1 5/8 3.03 1 5/8 1.15 1 5/8 1.73 1 5/8 2.31 1 5/8 2.88 1 5/8 3.46 1 5/8 4.15

AWS290CDP 1 5/8 1.15 1 5/8 1.73 1 5/8 2.31 1 5/8 2.88 1 5/8 3.46 1 5/8 4.15 1 5/8 1.15 1 5/8 1.73 1 5/8 2.31 1 5/8 2.88 1 5/8 3.46 1 5/8 4.15

AWS310CDP 1 5/8 1.15 1 5/8 1.73 1 5/8 2.31 1 5/8 2.88 1 5/8 3.46 1 5/8 4.15 1 5/8 1.60 1 5/8 2.40 1 5/8 3.20 1 5/8 4.00 1 5/8 4.80 1 5/8 5.76

AWS330CDP 1 5/8 1.60 1 5/8 2.40 1 5/8 3.20 1 5/8 4.00 1 5/8 4.80 1 5/8 5.76 1 5/8 1.60 1 5/8 2.40 1 5/8 3.20 1 5/8 4.00 1 5/8 4.80 1 5/8 5.76

UP TO 50

EQUIV. FT.

Size PD Size PD Size PD Size PD Size PD Size PD Size PD Size PD Size PD Size PD Size PD Size PD

UP TO 75

EQUIV. FT.

UP TO 100

EQUIV. FT.

UP TO 125

EQUIV. FT.

UP TO 150

EQUIV. FT.

UP TO 180

EQUIV. FT.

2 1/8 1.64 1 5/8 1.70 2 1/8 0.69 2 1/8 0.91 2 1/8 1.14 2 1/8 1.37 2 1/8 1.64

2 1/8 2.05 1 5/8 2.11 2 1/8 0.85 2 1/8 1.14 2 1/8 1.42 2 1/8 1.70 2 1/8 2.05

UP TO 50

EQUIV. FT.

UP TO 75

EQUIV. FT.

UP TO 100

EQUIV. FT.

UP TO 125

EQUIV. FT.

UP TO 150

EQUIV. FT.

UP TO 180

EQUIV. FT.

Table 9: Recommended Liquid Line Sizes (Circuit 3; only 3-circuit models shown)

Recommended Liquid Line Size

Circuit 3

Model

AWS400CTS 1 5/8 1.32 1 5/8 1.99 1 5/8 2.65 1 5/8 3.31 1 5/8 3.97 1 5/8 4.77

AWS425CTS 1 5/8 1.70 2 1/8 0.69 2 1/8 0.91 2 1/8 1.14 2 1/8 1.37 2 1/8 1.64

AWS450CTS 1 5/8 1.32 1 5/8 1.99 1 5/8 2.65 1 5/8 3.31 1 5/8 3.97 1 5/8 4.77

AWS470CTS 1 5/8 1.70 2 1/8 0.69 2 1/8 0.91 2 1/8 1.14 2 1/8 1.37 2 1/8 1.64

AWS500CTS 1 5/8 2.33 2 1/8 0.94 2 1/8 1.26 2 1/8 1.57 2 1/8 1.88 2 1/8 2.26

AWS550CTS 1 5/8 2.33 2 1/8 0.94 2 1/8 1.26 2 1/8 1.57 2 1/8 1.88 2 1/8 2.26

AWS450CTH 1 5/8 1.60 1 5/8 2.40 1 5/8 3.20 1 5/8 4.00 1 5/8 4.80 1 5/8 5.76

AWS475CTH 1 5/8 2.11 2 1/8 0.85 2 1/8 1.14 2 1/8 1.42 2 1/8 1.70 2 1/8 2.05

AWS500CTH 1 5/8 1.60 1 5/8 2.40 1 5/8 3.20 1 5/8 4.00 1 5/8 4.80 1 5/8 5.76

AWS530CTH 1 5/8 2.11 2 1/8 0.85 2 1/8 1.14 2 1/8 1.42 2 1/8 1.70 2 1/8 2.05

UP TO 50

EQUIV. FT.

Size PD Size PD Size PD Size PD Size PD Size PD

UP TO 75

EQUIV. FT.

UP TO 100

EQUIV. FT.

UP TO 125

EQUIV. FT.

UP TO 150

EQUIV. FT.

UP TO 180

EQUIV. FT.

www.DaikinApplied.com 13 IM 1203-1 • PATHFINDER® MODEL AWS REMOTE CHILLERS

Page 16

Table 10: Evaporator Data for VFD Models

remoTe evaporaTor dImensIons

remoTe evaporaTor dImensIons

AWS Model Evap Model

170CDS EV40271010/9N2 or N3 1197 543 1761 799 67 255 3 1

190CDS EV40271010/9N2 or N3 1197 543 1761 799 67 255 3 1

200CDS EV40271212/7N2 or N3 1239 562 1770 803 63 240 3 1

210CDH EV40271111/7N2 or N3 1219 553 1773 804 66 250 3 1

230CDH EV40271212/7N2 or N3 1239 562 1770 803 63 240 3 1

250CDH EV40271212/7N2 or N3 1239 562 1770 803 63 240 3 1

280CDH EV50271414/7N2 or N3 1739 789 2631 1193 106 403 4 2

300CDH EV50271414/7N2 or N3 1739 789 2631 1193 106 403 4 2

330CDH EV50271717/5N2 or N3 1819 825 2648 1201 99 374 5 2

350CDH EV50271717/5N2 or N3 1819 825 2648 1201 99 374 5 2

390CDH EV50271717/5N2 or N3 1819 825 2648 1201 99 374 5 2

410CDH EV50271717/5N2 or N3 1819 825 2648 1201 99 374 5 2

450CTH EV6633101010/7N2 or N3 2630 1193 4510 2046 225 850 7 3

475CTH EV6633111111/5N2 or N3 2681 1216 4520 2050 220 831 7 3

500CTH EV6633111111/5N2 or N3 2681 1216 4520 2050 220 831 7 3

530CTH EV6633111111/5N2 or N3 2681 1216 4520 2050 220 831 7 3

240CDP EV50391313/11N2 or N3 2008 9 11 3296 1495 154 582 5 2

265CDP EV50391313/11N2 or N3 2008 9 11 3296 1495 154 582 5 2

290CDP EV66391414/11N2 or N3 2875 1304 5145 2334 271 1027 7 3

310CDP EV66391414/11N2 or N3 2875 1304 5145 2334 271 1027 7 3

330CDP EV66391717/7N2 or N3 2998 1360 5164 2342 259 979 9 4

365CDP EV66391717/7N2 or N3 2998 1360 5164 2342 259 979 9 4

400CDP EV66391717/7N2 or N3 2998 1360 5164 2342 259 979 9 4

Shipping Weight Operating Weight Water Volume Refrigerant Charge

(lb) (kg) (lb) (kg) (gal) (L) (lb) (kg)

IM 1203-1 • PATHFINDER® MODEL AWS REMOTE CHILLERS 14 www.DaikinApplied.com

Page 17

remoTe evaporaTor dImensIons

Table 11: Evaporator Data for Non-VFD Models

AWS Model Evap Model

190CDS EV40271010/9N2 or N3 1197 543 1761 799 67 255 3 1

210CDS EV40271111/7N2 or N3 1219 553 1773 804 66 250 3 1

225CDS EV40271212/7N2 or N3 1239 562 1770 803 63 240 3 1

250CDS EV40271313/5N2 or N3 1259 571 1774 805 61 232 3 2

260CDS EV40271313/5N2 or N3 1259 571 1774 805 61 232 3 2

290CDS EV50271515/5N2 or N3 1649 748 2514 1140 103 390 4 2

310CDS EV50271515/5N2 or N3 1649 748 2514 1140 103 390 4 2

350CDS EV50271717/5N2 or N3 1819 825 2648 1201 99 374 5 2

375CDS EV50271717/5N2 or N3 1819 825 2648 1201 99 374 5 2

400CTS EV6633101010/7N2 or N3 2630 1193 4510 2046 225 850 7 3

425CTS EV6633101010/7N2 or N3 2630 1193 4510 2046 225 850 7 3

450CTS EV6633101010/7N2 or N3 2630 1193 4510 2046 225 850 7 3

470CTS EV6633111111/5N2 or N3 2681 1216 4520 2050 220 831 7 3

500CTS EV6633111111/5N2 or N3 2681 1216 4520 2050 220 831 7 3

525CTS EV6633111111/5N2 or N3 2681 1216 4520 2050 220 831 7 3

550CTS EV6633111111/5N2 or N3 2681 1216 4520 2050 220 831 7 3

210CDH EV40271111/7N2 or N3 1219 553 1773 804 66 250 3 1

230CDH EV40271212/7N2 or N3 1239 562 1770 803 63 240 3 1

250CDH EV40271212/7N2 or N3 1239 562 1770 803 63 240 3 1

280CDH EV50271414/7N2 or N3 1739 789 2631 1193 106 403 4 2

300CDH EV50271414/7N2 or N3 1739 789 2631 1193 106 403 4 2

330CDH EV50271717/5N2 or N3 1819 825 2648 1201 99 374 5 2

350CDH EV50271717/5N2 or N3 1819 825 2648 1201 99 374 5 2

390CDH EV50271717/5N2 or N3 1819 825 2648 1201 99 374 5 2

410CDH EV50271717/5N2 or N3 1819 825 2648 1201 99 374 5 2

450CTH EV6633101010/7N2 or N3 2630 1193 4510 2046 225 850 7 3

475CTH EV6633111111/5N2 or N3 2681 1216 4520 2050 220 831 7 3

500CTH EV6633111111/5N2 or N3 2681 1216 4520 2050 220 831 7 3

530CTH EV6633111111/5N2 or N3 2681 1216 4520 2050 220 831 7 3

240CDP EV50391313/11N2 or N3 2008 9 11 3296 1495 154 582 5 2

265CDP EV50391313/11N2 or N3 2008 9 11 3296 1495 154 582 5 2

290CDP EV66391414/11N2 or N3 2875 1304 5145 2334 271 1027 7 3

310CDP EV66391414/11N2 or N3 2875 1304 5145 2334 271 1027 7 3

330CDP EV66391717/7N2 or N3 2998 1360 5164 2342 259 979 9 4

365CDP EV66391717/7N2 or N3 2998 1360 5164 2342 259 979 9 4

400CDP EV66391717/7N2 or N3 2998 1360 5164 2342 259 979 9 4

Shipping Weight Operating Weight Water Volume Refrigerant Charge

(lb) (kg) (lb) (kg) (gal) (L) (lb) (kg)

www.DaikinApplied.com 15 IM 1203-1 • PATHFINDER® MODEL AWS REMOTE CHILLERS

Page 18

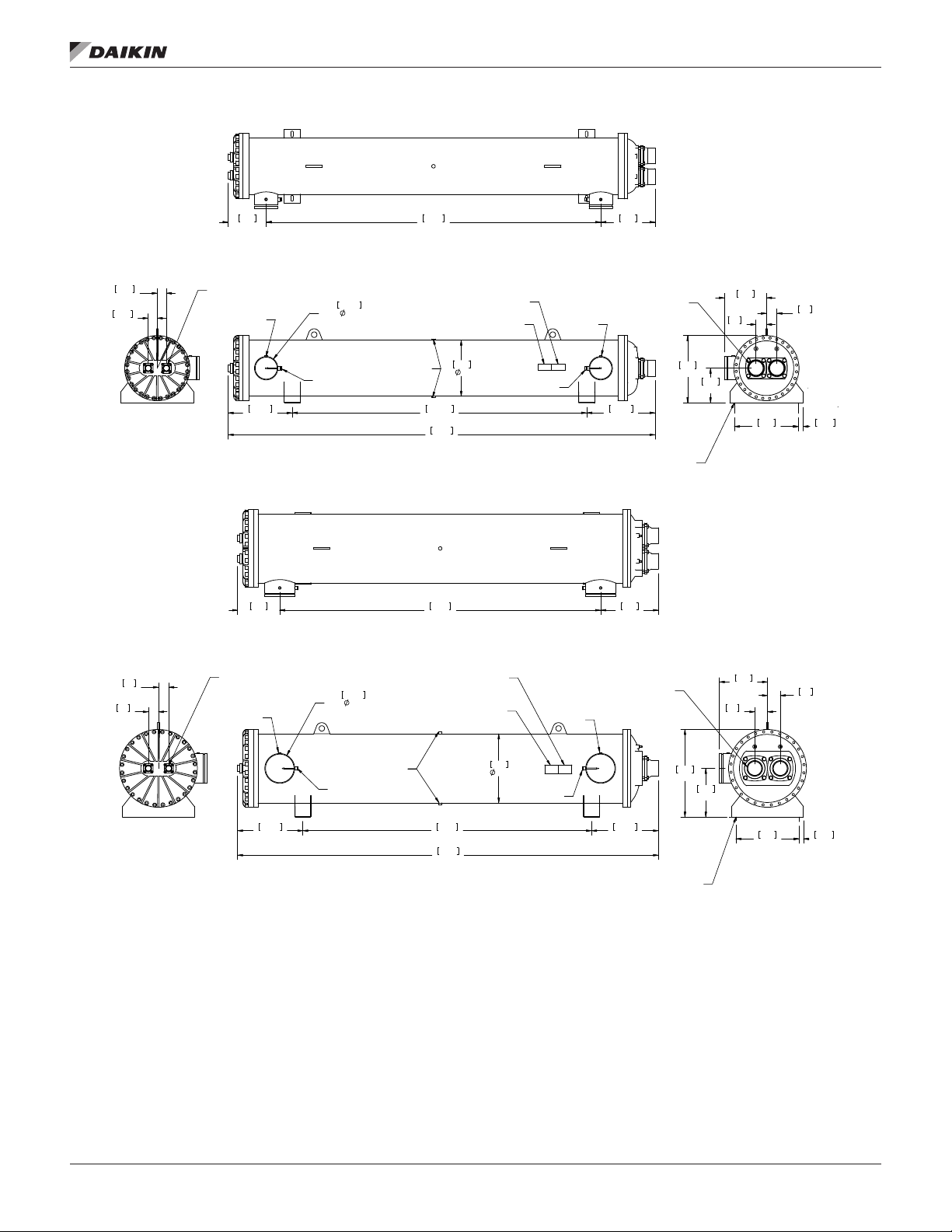

Figure 5: Evaporator Model EV4027

EVAPORATOR: EV4027

remoTe evaporaTor dImensIons

PART NO. 332532100

274

10.8

65.5

65.5

2.6

2.6

1.63IN/41.5MM I.D.

LIQUID CONNECTION

1/4" NPTF

461.6

18.2

OUTLET

Figure 6: Evaporator Model EV5027

310

12.2

168.3

6.63

SCH. 40 PIPE

VICTAULIC GROOVED QTY.2

1/2" NPTF

3000# HALF CPLG.

SENSOR WELL

QTY 2

QTY 2

2412

95.0

2122.9

83.6

3078

121.2

2360

92.9

406

16

EVAPORATOR

NAME PLATE

ASME/CRN

NAME PLATE

1/2" NPTF

QTY 2

SUCTION CONNECTION

1/4" NPTF

INTLET

.71IN/18MM X 1.69IN/43MM

392

15.4

4.13IN/105MM I.D.

493.5

19.4

SLOTS (QTY 4)

425

16.7

DWG NUMBER

334043901

303

11.9

75

3.0

485

19.1

250

9.8

EVAPORATOR: EV5027

PART NO. 332532200

DWG NUMBER

334043901

18.2

REV.

0B

75

3.0

463

REV.

0B

32.5

1.3

2123

83.6

3095

121.9

EVAPORATOR

NAME PLATE

ASME/CRN

NAME PLATE

508

20.0

1/4" NPTF

1/2" NPTF

QTY 2

4.13IN/105MM I.D.

SUCTION CONNECTION

INLET

492.2

19.4

.71IN/18MM X 1.69IN/43MM

SLOTS (QTY 4)

644

25.4

358

14.1

354

13.9

94

3.7

463

18.2

94

3.7

32.5

1.3

75

3.0

75

3.0

1.63IN/41.5MM I.D.

LIQUID CONNECTION

1/4" NPTF

479.8

18.9

219.2

8.63

SCH. 40 PIPE

VICTAULIC GROOVED QTY.2

OUTLET

1/2" NPTF

3000# HALF CPLG.

QTY 2

SENSOR WELL

QTY 2

IM 1203-1 • PATHFINDER® MODEL AWS REMOTE CHILLERS 16 www.DaikinApplied.com

Page 19

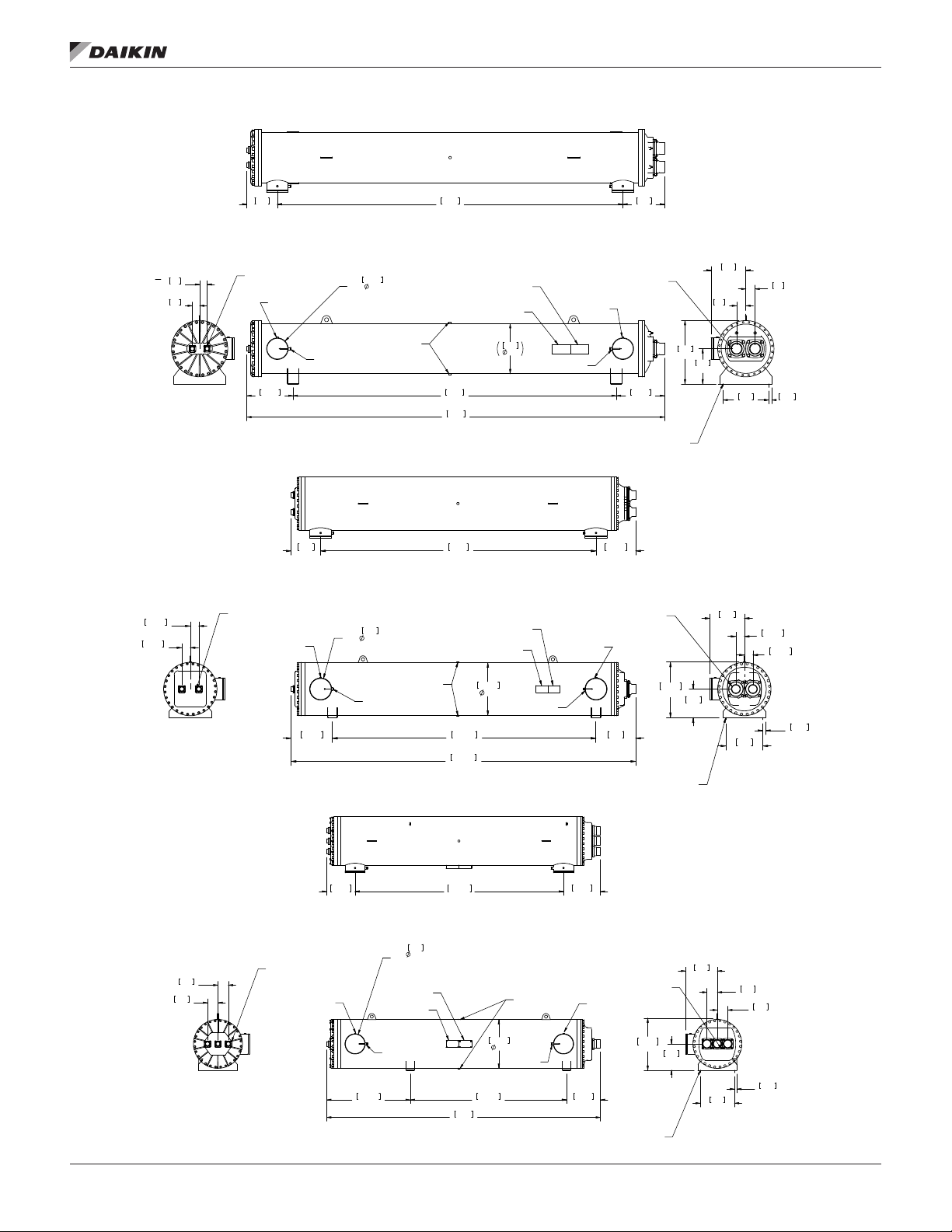

Figure 7: Evaporator Model EV5039

SLOTS (QTY 4)

SLOTS (QTY 4)

310

12.2

75

3.0

75

3.0

1.63IN/41.5MM I.D.

LIQUID CONNECTION

1/4" NPTF

OUTLET

469.8

18.5

Figure 8: Evaporator Model EV6639

367

14.4

VICTAULIC GROOVED QTY.2

SENSOR WELL

QTY 2

219.2

SCH. 40 PIPE8.63

1/2" NPTF

3000# HALF CPLG.

QTY 2

3510

138.2

3283

129.3

167.1

4245

3430

135.0

EVAPORATOR

NAME PLATE

ASME/CRN

NAME PLATE

508

20.0

1/2" NPTF

QTY 2

4.13IN/105MM I.D.

SUCTION CONNECTION

1/4" NPTF

INLET

.71IN/18MM X 1.69IN/43MM

494.5

19.5

remoTe evaporaTor dImensIons

EVAPORATOR: EV5039

PART NO. 332532300

492.2

19.4

DWG NUMBER

334043901

425

16.7

354

13.9

94

3.7

644

25.4

358

14.1

EVAPORATOR: EV6639

PART NO. 332532400

DWG NUMBER

334043901

REV.

0B

94

3.7

32.5

463

1.3

18.2

REV.

0B

2.13IN/54.1MM I.D.

105.8

105.8

4.2

4.2

LIQUID CONNECTION

1/4" NPTF

513.8

Figure 9: Evaporator Model EV6633

2.13IN/54.1MM I.D.

141

5.6

141

5.6

LIQUID CONNECTION

VICTAULIC GROOVED QTY.2

OUTLET

20.2

385.2

15.2

1/4" NPTF

273

10.75

SCH. 40 PIPE

1/2" NPTF

3000# HALF CPLG.

QTY 2

SENSOR WELL

QTY 2

VICTAULIC GROOVED QTY.2

EVAPORATOR

NAME PLATE

ASME/CRN

NAME PLATE

SENSOR WELL

QTY 2

1133.5

44.6

273

SCH. 40 PIPE

10.75

3281.8

129.2

4291.5

169.0

2829.8

111.4

146.3

3715

EVAPORATOR

NAME PLATE

ASME/CRN

NAME PLATE

660.4

26.0

660.4

26.0

2122.9

83.6

1/2" NPTF

QTY 2

1/2" NPTF

3000# HALF CPLG.

QTY 2

INLETOUTLET

1/2" NPTF

QTY 2

4.13IN/105MM I.D.

SUCTION CONNECTION

1/4" NPTF

INLET

19.5

498.7

19.6

4.13IN/105MM I.D.

SUCTION CONNECTION

1/4" NPTF

458.5

18.1

.71IN/18MM X 1.69IN/43MM

SLOTS (QTY 4)

693.5

27.3

496

.71IN/18MM X 1.69IN/43MM

EVAPORATOR: EV6633

PART NO. 332532600

DWG NUMBER

334043901

707.2

27.8

357

14.1

357

14.1

430

16.9

105.8

4.2

105.8

4.2

32.5

463

18.2

REV.

0B

430

16.9

141

5.6

463

18.2

1.3

141

5.6

32.5

1.3

www.DaikinApplied.com 17 IM 1203-1 • PATHFINDER® MODEL AWS REMOTE CHILLERS

Page 20

IsolaTor InformaTIon

IsolaTor InformaTIon

When spring isolators are required, install springs running

under the main unit supports.Then unit should be set initially

on shims or blocks at the listed spring free height. When all

unit installation tasks are complete, the springs are adjusted

upward to loosen the blocks or shims that are then removed.

Install of spring isolators requires exible piping connections

and at least three feet of exible electrical conduit to avoid

straining the piping and transmitting vibration and noise.

A rubber anti-skid pad should be used under isolators if

holddown bolts are not used. Mounting locations for each

model can be found in the Lifting & Mounting Dimensions

beginning on page 26.

Table 12: Isolator Part Numbers

Isolator Color

Brown 331481401

Dark Blue 332620200

Red 332620400 331481402

Black 332620500

Green 331481403

Dark Purple 332620600

Dark Green 332620800

Gray 332620900 331481404

White 332621000

Purple 331481405

Spring Isolator R-I-S Isolator

Isolator P/N

Table 13: Spring Isolators for Aluminum Fin Condensers (VFD)

Unit Model # Kit P/N M1 M2 M3 M4 M5 M6 M7 M8 M9 M10 M11 M12

AWS170CDS

RE VFD

AWS190CDS

RE VFD

AWS200CDS

RE VFD

AWS210CDH

RE VFD

AWS230CDH

RE VFD

AWS250CDH

RE VFD

AWS240CDP

RE VFD

AWS280CDH

RE VFD

AWS300CDH

RE VFD

AWS265CDP

RE VFD

AWS290CDP

RE VFD

AWS310CDP

RE VFD

AWS330CDP

RE VFD

AWS330CDH

RE VFD

AWS350CDH

RE VFD

AWS365CDP

RE VFD

AWS390CDH

RE VFD

AWS400CDP

RE VFD

AWS410CDH

RE VFD

AWS450CTH

RE VFD

AWS475CTH

RE VFD

AWS500CTH

RE VFD

AWS530CTH

RE VFD

332320840 Dk Green Dk Green Dk Green Dk Green Black Black Red Red

332320840 Dk Green Dk Green Dk Green Dk Green Black Black Red Red

332320840 Dk Green Dk Green Dk Green Dk Green Black Black Red Red

332320840 Dk Green Dk Green Dk Green Dk Green Black Black Red Red

332320861 Dk Green Dk Green Dk Green Dk Green Black Black Red Red Dk Blue Dk Blue

332320861 Dk Green Dk Green Dk Green Dk Green Black Black Red Red Dk Blue Dk Blue

332320862 Dk Green Dk Green Dk Green Dk Green Dk Purple Dk Purple Black Black Red Red

332320862 Dk Green Dk Green Dk Green Dk Green Dk Purple Dk Purple Black Black Red Red

332320862 Dk Green Dk Green Dk Green Dk Green Dk Purple Dk Purple Black Black Red Red

332320862 Dk Green Dk Green Dk Green Dk Green Dk Purple Dk Purple Black Black Red Red

332320862 Dk Green Dk Green Dk Green Dk Green Dk Purple Dk Purple Black Black Red Red

332320866 Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Black Black Black Black

332320866 Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Black Black Black Black

332320866 Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Black Black Black Black

332320866 Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Black Black Black Black

332320824 Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green

332320824 Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green

332320863 Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Black Black Black Black

332320863 Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Black Black Black Black

332320863 Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Black Black Black Black

332320826 Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green

332320826 Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green

332320826 Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green

IM 1203-1 • PATHFINDER® MODEL AWS REMOTE CHILLERS 18 www.DaikinApplied.com

Page 21

IsolaTor InformaTIon

Table 14: Spring Isolators for Copper Fin Condensers (VFD)

Unit Model # Kit P/N M1 M2 M3 M4 M5 M6 M7 M8 M9 M10 M11 M12

AWS170CDS

RE VFD

AWS190CDS

RE VFD

AWS200CDS

RE VFD

AWS210CDH

RE VFD

AWS230CDH

RE VFD

AWS250CDH

RE VFD

AWS240CDP

RE VFD

AWS280CDH

RE VFD

AWS300CDH

RE VFD

AWS265CDP

RE VFD

AWS290CDP

RE VFD

AWS310CDP

RE VFD

AWS330CDP

RE VFD

AWS330CDH

RE VFD

AWS350CDH

RE VFD

AWS365CDP

RE VFD

AWS390CDH

RE VFD

AWS400CDP

RE VFD

AWS410CDH

RE VFD

AWS450CTH

RE VFD

AWS475CTH

RE VFD

AWS500CTH

RE VFD

AWS530CTH

RE VFD

332320864 Dk Green Dk Green Dk Green Dk Green Black Black Black Black

332320864 Dk Green Dk Green Dk Green Dk Green Black Black Black Black

332320864 Dk Green Dk Green Dk Green Dk Green Black Black Black Black

332320864 Dk Green Dk Green Dk Green Dk Green Black Black Black Black

332320865 Dk Green Dk Green Dk Green Dk Green Black Black Black Black Red Red

332320865 Dk Green Dk Green Dk Green Dk Green Black Black Black Black Red Red

332320865 Dk Green Dk Green Dk Green Dk Green Black Black Black Black Red Red

332320866 Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Black Black Black Black

332320866 Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Black Black Black Black

332320866 Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Black Black Black Black

332320866 Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Black Black Black Black

332320823 Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Black Black

332320823 Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Black Black

332320823 Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Black Black

332320823 Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Black Black

332320824 Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green

332320824 Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green

332320826 Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green

332320826 Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green

332320826 Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green

332320826 Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green

332320868 Gray Gray Gray Gray Gray Gray Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green

332320868 Gray Gray Gray Gray Gray Gray Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green

www.DaikinApplied.com 19 IM 1203-1 • PATHFINDER® MODEL AWS REMOTE CHILLERS

Page 22

IsolaTor InformaTIon

Table 15: Rubber-in-Shear (RIS) Isolators for Aluminum Fin Condensers (VFD)

Unit Model # Kit P/N M1 M2 M3 M4 M5 M6 M7 M8 M9 M10 M11 M12

AWS170CDS

RE VFD

AWS190CDS

RE VFD

AWS200CDS

RE VFD

AWS210CDH

RE VFD

AWS230CDH

RE VFD

AWS250CDH

RE VFD

AWS240CDP

RE VFD

AWS280CDH

RE VFD

AWS300CDH

RE VFD

AWS265CDP

RE VFD

AWS290CDP

RE VFD

AWS310CDP

RE VFD

AWS330CDP

RE VFD

AWS330CDH

RE VFD

AWS350CDH

RE VFD

AWS365CDP

RE VFD

AWS390CDH

RE VFD

AWS400CDP

RE VFD

AWS410CDH

RE VFD

AWS450CTH

RE VFD

AWS475CTH

RE VFD

AWS500CTH

RE VFD

AWS530CTH

RE VFD

332325851 Green Green Green Green Brown Brown Brown Brown

332325851 Green Green Green Green Brown Brown Brown Brown

332325851 Green Green Green Green Brown Brown Brown Brown

332325851 Green Green Green Green Brown Brown Brown Brown

332325852 Green Green Green Green Brown Brown Brown Brown Brown Brown

332325852 Green Green Green Green Brown Brown Brown Brown Brown Brown

332325858 Green Green Green Green Green Green Brown Brown Brown Brown

332325858 Green Green Green Green Green Green Brown Brown Brown Brown

332325858 Green Green Green Green Green Green Brown Brown Brown Brown

332325858 Green Green Green Green Green Green Brown Brown Brown Brown

332325858 Green Green Green Green Green Green Brown Brown Brown Brown

332325853 Green Green Green Green Green Green Red Red Red Red

332325853 Green Green Green Green Green Green Red Red Red Red

332325853 Green Green Green Green Green Green Red Red Red Red

332325853 Green Green Green Green Green Green Red Red Red Red

332325853 Green Green Green Green Green Green Red Red Red Red

332325853 Green Green Green Green Green Green Red Red Red Red

332325854 Green Green Green Green Green Green Green Green Red Red Red Red

332325854 Green Green Green Green Green Green Green Green Red Red Red Red

332325854 Green Green Green Green Green Green Green Green Red Red Red Red

332325854 Green Green Green Green Green Green Green Green Red Red Red Red

332325854 Green Green Green Green Green Green Green Green Red Red Red Red

332325854 Green Green Green Green Green Green Green Green Red Red Red Red

IM 1203-1 • PATHFINDER® MODEL AWS REMOTE CHILLERS 20 www.DaikinApplied.com

Page 23

IsolaTor InformaTIon

Table 16: Rubber-in-Shear (RIS) Isolators for Copper Fin Condensers (VFD)

Unit Model # Kit P/N M1 M2 M3 M4 M5 M6 M7 M8 M9 M10 M11 M12

AWS170CDS

RE VFD

AWS190CDS

RE VFD

AWS200CDS

RE VFD

AWS210CDH

RE VFD

AWS230CDH

RE VFD

AWS250CDH

RE VFD

AWS240CDP

RE VFD

AWS280CDH

RE VFD

AWS300CDH

RE VFD

AWS265CDP

RE VFD

AWS290CDP

RE VFD

AWS310CDP

RE VFD

AWS330CDP

RE VFD

AWS330CDH

RE VFD

AWS350CDH

RE VFD

AWS365CDP

RE VFD

AWS390CDH

RE VFD

AWS400CDP

RE VFD

AWS410CDH

RE VFD

AWS450CTH

RE VFD

AWS475CTH

RE VFD

AWS500CTH

RE VFD

AWS530CTH

RE VFD

332325855 Green Green Red Red Red Red Brown Brown

332325855 Green Green Red Red Red Red Brown Brown

332325855 Green Green Red Red Red Red Brown Brown

332325855 Green Green Red Red Red Red Brown Brown

332325856 Green Green Green Green Red Red Red Red Brown Brown

332325856 Green Green Green Green Red Red Red Red Brown Brown

332325856 Green Green Green Green Red Red Red Red Brown Brown

332325856 Green Green Green Green Red Red Red Red Brown Brown

332325856 Green Green Green Green Red Red Red Red Brown Brown

332325856 Green Green Green Green Red Red Red Red Brown Brown

332325856 Green Green Green Green Red Red Red Red Brown Brown

332325853 Green Green Green Green Green Green Red Red Red Red

332325853 Green Green Green Green Green Green Red Red Red Red

332325853 Green Green Green Green Green Green Red Red Red Red

332325853 Green Green Green Green Green Green Red Red Red Red

332325853 Green Green Green Green Green Green Red Red Red Red

332325853 Green Green Green Green Green Green Red Red Red Red

332325857 Gray Gray Gray Gray Green Green Green Green Green Green Red Red

332325857 Gray Gray Gray Gray Green Green Green Green Green Green Red Red

332325857 Gray Gray Gray Gray Green Green Green Green Green Green Red Red

332325857 Gray Gray Gray Gray Green Green Green Green Green Green Red Red

332325857 Gray Gray Gray Gray Green Green Green Green Green Green Red Red

332325857 Gray Gray Gray Gray Green Green Green Green Green Green Red Red

www.DaikinApplied.com 21 IM 1203-1 • PATHFINDER® MODEL AWS REMOTE CHILLERS

Page 24

IsolaTor InformaTIon

Table 17: Spring Isolators for Aluminum Fin Condensers (Non-VFD)

Unit Model # Kit P/N M1 M2 M3 M4 M5 M6 M7 M8 M9 M10

AWS190CDS 332320838 Dk Green Dk Green Dk Green Dk Green Red Red

AWS210CDS 332320838 Dk Green Dk Green Dk Green Dk Green Red Red

AWS210CDH 332320828 Dk Green Dk Green Dk Green Dk Green Black Black

AWS225CDS 332320838 Dk Green Dk Green Dk Green Dk Green Red Red

AWS230CDH 332320839 Gray Gray Dk Green Dk Green Black Black

AWS240CDP 332320840 Dk Green Dk Green Dk Green Dk Green Black Black Red Red

AWS250CDS 332320839 Gray Gray Dk Green Dk Green Black Black

AWS250CDH 332320839 Gray Gray Dk Green Dk Green Black Black

AWS260CDS 332320839 Gray Gray Dk Green Dk Green Black Black

AWS265CDP 332320854 Dk Green Dk Green Dk Green Dk Green Dk Purple Dk Purple Red Red

AWS280CDH 332320840 Dk Green Dk Green Dk Green Dk Green Black Black Red Red

AWS290CDS 332320841 Gray Gray Dk Green Dk Green Black Black Dk Blue Dk Blue

AWS290CDP 332320854 Dk Green Dk Green Dk Green Dk Green Dk Purple Dk Purple Red Red

AWS300CDH 332320840 Dk Green Dk Green Dk Green Dk Green Black Black Red Red

AWS310CDS 332320841 Gray Gray Dk Green Dk Green Black Black Dk Blue Dk Blue

AWS310CDP 332320842 Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Black Black

AWS330CDH 332320855 Gray Gray Dk Green Dk Green Dk Green Dk Green Black Black

AWS330CDP 332320842 Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green Black Black

AWS350CDS 332320843 Gray Gray Dk Green Dk Green Dk Green Dk Green Red Red

AWS350CDH 332320855 Gray Gray Dk Green Dk Green Dk Green Dk Green Black Black

AWS365CDP 332320847 Gray Gray Gray Gray Dk Green Dk Green Black Black

AWS375CDS 332320843 Gray Gray Dk Green Dk Green Dk Green Dk Green Red Red

AWS390CDH 332320847 Gray Gray Gray Gray Dk Green Dk Green Black Black

AWS400CTS 332320848 Gray Gray Gray Gray Dk Green Dk Green Dk Green Dk Green

AWS400CDP 332320844 Gray Gray Gray Gray Dk Green Dk Green Black Black Red Red

AWS410CDH 332320844 Gray Gray Gray Gray Dk Green Dk Green Black Black Red Red

AWS425CTS 332320848 Gray Gray Gray Gray Dk Green Dk Green Dk Green Dk Green

AWS450CTS 332320834 Gray Gray Gray Gray Dk Green Dk Green Dk Purple Dk Purple Red Red

AWS450CTH 332320833 Gray Gray Gray Gray Dk Green Dk Green Dk Purple Dk Purple Black Black

AWS470CTS 332320834 Gray Gray Gray Gray Dk Green Dk Green Dk Purple Dk Purple Red Red

AWS475CTH 332320850 Gray Gray Gray Gray Dk Green Dk Green Dk Green Dk Green Black Black

AWS500CTS 332320850 Gray Gray Gray Gray Dk Green Dk Green Dk Green Dk Green Black Black

AWS500CTH 332320850 Gray Gray Gray Gray Dk Green Dk Green Dk Green Dk Green Black Black

AWS525CTS 332320850 Gray Gray Gray Gray Dk Green Dk Green Dk Green Dk Green Black Black

AWS530CTH 332320850 Gray Gray Gray Gray Dk Green Dk Green Dk Green Dk Green Black Black

AWS550CTS 332320850 Gray Gray Gray Gray Dk Green Dk Green Dk Green Dk Green Black Black

IM 1203-1 • PATHFINDER® MODEL AWS REMOTE CHILLERS 22 www.DaikinApplied.com

Page 25

IsolaTor InformaTIon

Table 18: Spring Isolators for Copper Fin Condensers (Non-VFD)

Unit Model # Kit P/N M1 M2 M3 M4 M5 M6 M7 M8 M9 M10

AWS190CDS 332320839 Gray Gray Dk Green Dk Green Black Black

AWS210CDS 332320839 Gray Gray Dk Green Dk Green Black Black

AWS210CDH 332320839 Gray Gray Dk Green Dk Green Black Black

AWS225CDS 332320839 Gray Gray Dk Green Dk Green Black Black

AWS230CDH 332320845 Gray Gray Dk Green Dk Green Dk Purple Dk Purple

AWS240CDP 332320857 Gray Gray Dk Green Dk Green Dk Purple Dk Purple Black Black

AWS250CDS 332320839 Gray Gray Dk Green Dk Green Black Black

AWS250CDH 332320845 Gray Gray Dk Green Dk Green Dk Purple Dk Purple

AWS260CDS 332320839 Gray Gray Dk Green Dk Green Black Black

AWS265CDP 332320855 Gray Gray Dk Green Dk Green Dk Green Dk Green Black Black

AWS280CDH 332320846 Gray Gray Dk Green Dk Green Dk Purple Dk Purple Red Red

AWS290CDS 332320846 Gray Gray Dk Green Dk Green Dk Purple Dk Purple Red Red

AWS290CDP 332320855 Gray Gray Dk Green Dk Green Dk Green Dk Green Black Black

AWS300CDH 332320846 Gray Gray Dk Green Dk Green Dk Purple Dk Purple Red Red

AWS310CDS 332320846 Gray Gray Dk Green Dk Green Dk Purple Dk Purple Red Red

AWS310CDP 332320847 Gray Gray Gray Gray Dk Green Dk Green Black Black

AWS330CDH 332320847 Gray Gray Gray Gray Dk Green Dk Green Black Black

AWS330CDP 332320847 Gray Gray Gray Gray Dk Green Dk Green Black Black

AWS350CDS 332320847 Gray Gray Gray Gray Dk Green Dk Green Black Black

AWS350CDH 332320847 Gray Gray Gray Gray Dk Green Dk Green Black Black

AWS365CDP 332320848 Gray Gray Gray Gray Dk Green Dk Green Dk Green Dk Green

AWS375CDS 332320847 Gray Gray Gray Gray Dk Green Dk Green Black Black

AWS390CDH 332320848 Gray Gray Gray Gray Dk Green Dk Green Dk Green Dk Green

AWS400CTS 332320848 Gray Gray Gray Gray Dk Green Dk Green Dk Green Dk Green

AWS400CDP 332320833 Gray Gray Gray Gray Dk Green Dk Green Dk Purple Dk Purple Black Black

AWS410CDH 332320833 Gray Gray Gray Gray Dk Green Dk Green Dk Purple Dk Purple Black Black

AWS425CTS 332320848 Gray Gray Gray Gray Dk Green Dk Green Dk Green Dk Green

AWS450CTS 332320856 White White Gray Gray Dk Green Dk Green Dk Green Dk Green Black Black

AWS450CTH 332320856 White White Gray Gray Dk Green Dk Green Dk Green Dk Green Black Black

AWS470CTS 332320856 White White Gray Gray Dk Green Dk Green Dk Green Dk Green Black Black

AWS475CTH 332320858 Gray Gray Gray Gray Dk Green Dk Green Dk Green Dk Green Dk Green Dk Green

AWS500CTS 332320859 Gray Gray Gray Gray Dk Green Dk Green Dk Green Dk Green Dk Purple Dk Purple

AWS500CTH 332320860 White White Gray Gray Gray Gray Dk Green Dk Green Dk Green Dk Green

AWS525CTS 332320860 White White Gray Gray Gray Gray Dk Green Dk Green Dk Green Dk Green

AWS530CTH 332320853 White White White White Gray Gray Dk Green Dk Green Dk Green Dk Green