Page 1

AVPTC

AIR HANDLER

INSTALLATION INSTRUCTIONS

© 2011 - 2012 Goodman Manufacturing Company, L.P.

5151 San Felipe, Suite 500, Houston, TX 77056

www.goodmanmfg.com -or- www.amana-hac.com

P/N: IO-346D Date: September 2012

THIS PRODUCT CONTAINS ELECTRONIC COMPONENTS WHICH

REQUIRE A DEFINITE GROUND. PROVISIONS ARE MADE FOR

CONNECTION OF THE GROUND. A DEDICATED GROUND FROM

THE MAIN POWER SUPPLY OR AN EARTH GROUND MUST BE

PROVIDED.

NOTICE

IFA“1F

ENCOUNTEREDONSTARTUP,VERIFYTHATTHEELECTRICHEATER

SWITCHESHAVEBEENSETTOTHEAPPROPRIATEHEATERSIZE

PAGES

AIRFLOWDELIVERY

I

NTRODUCTION

This booklet contains the installation and operating instructions for your air handler. All warnings and precautions within

this booklet must be observed. Improper installation can result in unsatisfactory operation or dangerous conditions and

void the warranty. Read this booklet and any instructions

packaged with accessories prior to installation. Give this booklet to the user and explain its provisions. The user should

retain this booklet for future reference.

NOTE: Upon start up in communicating mode the circuit board

will display a “1 Flash” error code on the diagnostic LED and

an “Ec” HTR TO LARGE error at the communicating display.

This is an indication that the dip switches on the control board

need to be configured in accordance with the Electric Heating Airflow Table on page 13 of this manual. Configuring the

dip switches and resetting power to the unit will clear the

error code.

LASH”ERRORCODEORAN

12

AND

13

FORTHE

DIP

.

“EC”HTRTOOLARGE

ERRORIS

DIP

.SEE

SWITCHSETTINGSANDHEATERKIT

ELECTROSTATIC DISCHARGE (ESD) PRECAUTIONS

NOTE: Discharge body’s static electricity before touching

unit. An electrostatic discharge can adversely affect

electrical components.

Use the following precautions during modular blower installation and servicing to protect the integrated control module

from damage. By putting the modular blower, the control,

and the person at the same electrostatic potential, these steps

will help avoid exposing the integrated control module to electrostatic discharge. This procedure is applicable to both installed and uninstalled (ungrounded) blowers.

1. Disconnect all power to the blower. Do not touch the

integrated control module or any wire connected to the

control prior to discharging your body’s electrostatic

charge to ground.

2. Firmly touch a clean, unpainted, metal surface of the

modular blower near the control. Any tools held in a

person’s hand during grounding will be discharged.

3. Service integrated control module or connecting wiring

following the discharge process in step 2. Use caution

not to recharge your body with static electricity; (i.e., do

not move or shuffle your feet, do not touch ungrounded

objects, etc.). If you come in contact with an ungrounded

object, repeat step 2 before touching control or wires.

4. Discharge your body to ground before removing a new

control from its container. Follow steps 1 through 3 if

installing the control on a blower. Return any old or

new controls to their containers before touching any

ungrounded object.

IMPORTANT NOTE TO THE OWNER REGARDING PRODUCT

WARRANTY

Your warranty certificate is supplied as a separate document

with the unit installed by your contractor. Read the limited

warranty certificate carefully to determine what is and is not

covered and keep the warranty certificate in a safe place. If

you are unable to locate the warranty certificate please contact your installing contractor or contact customer service

(877-254-4729) to obtain a copy.

IMPORTANT: To register your Goodman

www.goodmanmfg.com and click “Warranty Registration”.

Complete registration as prompted.

To register your Amana® brand unit, go to www.amanahac.com and click “Warranty Registration”. Complete registration as prompted.

Product limited warranty certificates for models currently in

production can be viewed at www.goodmanmfg.com or

www.amana-hac.com. If your model is not currently in production or does not appear on the website, please contact

your installing contractor or contact customer service (877254-4729) to obtain a copy of your warranty certificate.

Each product overview page contains a Product Warranty

link; by clicking on it you will be able to view the limited warranty coverage for that specific product. To view warranty

registration information, click on the Product Warranty text

on the left navigation panel on the home page of each website. The Online Product Registration pages are located in

this same section.

®

brand unit, go to

Page 2

C

HECKING PRODUCT RECEIVED

Upon receiving the unit, inspect it for damage from shipment. Claims for damage, either shipping or concealed,

should be filed immediately with the shipping company.

Check the unit model number, specifications, electrical characteristics and accessories to determine if they are correct.

In the event an incorrect unit is shipped, it must be returned

to the supplier and must NOT be installed. The manufacturer assumes no responsibility for installation of incorrectly

shipped units.

R

EPLACEMENT PARTS

ORDERING PARTS

When reporting shortages or damages, or ordering repair

parts, give the complete unit model and serial numbers as

stamped on the unit’s nameplate.

Replacement parts for this appliance are available through

your contractor or local distributor. For the location of your

nearest distributor, consult the white business pages, the

yellow page section of the local telephone book or contact:

CONSUMER AFFAIRS

GOODMAN MANUFACTURING COMPANY, L.P.

7401 SECURITY WAY

HOUSTON, TEXAS 77040

877-254-4729

I

MPORTANT SAFETY INSTRUCTIONS

To avoid property damage, personal injury or death

due to electrical shock, this unit MUST have an

uni nt e r r u pted, un brok e n

electrical ground circuit may consist of an

appropriately sized electrical wire connecting the

ground lug in the unit control box to the building

electrical service panel.

Othe r me th o ds of groundi ng are permi t te d i f pe r fo rm ed

in accordance with the National Electric Code

(NEC)/Amer ican Natio nal Standards Inst itute

(ANSI)/Nati onal Fire Protec tion A ssocia tion (NFPA) 70

and local/state codes. In Canada, electrical grounding

is to be in ac corda n ce with t h e Canadia n El ectri c Code

(CSA) C22.1.

This product is factor y-shipped for use with

208/240/1/60 elec tric al pow er supp ly.

reconfigure th is ai r handler to operate with any other

power supply.

When installing or servicing this equipment, safety

clothing, inc lu ding hand and eye protection, is

strongly reco mmended. If installing in an area that has

special safety requirements (hard hats, etc.), observe

these req uirements.

elec trical ground. The

DO NOT

RECOGNIZE SAFETY SYMBOLS, WORDS, AND LABELS

The following symbols and labels are used throughout this

manual to indicate immediate or potential hazards. It is the

owner’s responsibility to read and comply with all safety information and instructions accompanying these symbols.

Failure to heed safety information increases the risk of property damage, product damage, personal injury or death.

WARNING

HIGHVOLTAGE!

D

ISCONNECT

ULTIPLEPOWERSOURCESMAYBEPRESENT

M

TODOSOMAYCAUSEPROPERTYDAMAGE,PERSONAL

INJURYORDEATH

ONLY

ECHNICIAN

T

ONDITIONING

C

USETHISINFORMATION

WITHOUTSUCHBACKGROUNDMAYRESULTINPRODUCTDAMAGE

PERSONALINJURY,ORDEATH

ALL

POWERBEFORESERVICING

.

.F

AILURE

.

WARNING

INDIVIDUALSMEETINGTHEREQUIREMENTSOFAN

”,ATA

MINIMUM,ASSPECIFIEDBYTHEAIR

,H

EATINGANDREFRIGERATIONINSTITUTE

.A

TTEMPTINGTOINSTALLORREPA IRTHISUNIT

.

“E

(AHRI)

NTRYLEVEL

MAY

,

Do not connect to or use a ny dev ice that i s not designcertified by Goodman for use with this unit. Serious

property damage, personal injury, reduced unit

performance and/or hazardous conditions may result

from the use of such non-ap proved devices.

To prevent the risk of p roperty d amage, personal

injury, or death, do not stor e co mbustible materials or

use gasoline or other f lammable liquids or vapors in

the vicinity of this un it.

2

Page 3

CARBON MONOX IDE POISON ING HAZ ARD

Special Warning for Installation of Furnace or Air Handling Units in

Enclosed Areas such as Garages, Utility Rooms or Parking Areas

Carbon monoxide producing devices (such as an automobile, space

heater, gas water heater, etc.) should not be operated in enclosed areas

such as unventilated garages, utility rooms or parking areas because of

the danger of carbon monoxide (CO) poisoning resulting from the exhaust

emissions. If a furnace or air handler is installed in an enclosed area such

as a garage, utility room or parking area and a carbon monoxide producing

device is operated therein, there must be adequate, direct outside

ventilation.

This ventilation is necessary to avoid the danger of CO poisoning which

can occur if a carbon monoxide producing device continues to operate in

the enclosed area. Carbon monoxide emissions can be (re)circulated

throughout the structure if the furnace or air handler is operating in any

mode.

CO can cause serious illness including permanent brain damage or death.

C

ODES

& R

EGULATIONS

B10259-216

-

This product is designed and manufactured to comply with

national codes. Installation in accordance with such codes

and/or prevailing local codes/regulations is the responsibility of the installer. The manufacturer assumes no responsibility for equipment installed in violation of any codes or regulations.

The United States Environmental Protection Agency

(EPA) has issued various regulations regarding the introduction and disposal of refrigerants. Failure to follow these regulations may harm the environment and

can lead to the imposition of substantial fines. Should

you have any questions please contact the local office of the

EPA.

If replacing an air handler, the system must be manufacturer approved and Air Conditioning, Heating and Refrigera-

tion Institute (AHRI) matched. NOTE: Installation of un-

matched systems is strongly discouraged.

F

EATURES

This air handler is a part of the ComfortNet™ family of products. It may be installed as part of a “non-communicating”

system using a standard 24 VAC thermostat. However, with

the CTK0*AA ComfortNet thermostat kit, this air handler may

be installed as part of a digitally communicating system. The

ComfortNet system provides automatic airflow configuration,

enhanced setup features, and enhanced diagnostics. It also

reduces the number of thermostat wires to a maximum of

four and a minimum of two.

PRE-I

NSTALLATION INSTRUCTIONS

Carefully read all instructions for the installation prior to installing product. Make sure each step or procedure is understood and any special considerations are taken into account before starting installation. Assemble all tools, hardware and supplies needed to complete the installation. Some

items may need to be purchased locally. Make sure everything needed to install the product is on hand before starting.

L

OCATION

NOTE: Air handlers are designed for indoor installation

only.

Give special consideration to minimizing the length of refrigerant tubing when installing air handlers. Refer to Remote

Cooling/Heat Pump Service Manual TP-107 Long Line Set

Application R-410A for guidelines. The unit clearance from

a combustible surface may be 0". However, service clearance is to take precedence. In addition allow a minimum of

24" in front of the unit for service clearance.

If the unit is located in an area with high ambient temperature and/or high humidity, the air handler may be subject to

nuisance sweating of the casing. On these installations, a

wrap of 2” fiberglass insulation with a vapor barrier is recommended.

Do not install the air handler in a location that violates the

instructions provided with the condenser.

Consult all appropriate regulatory codes prior to determining final clearances. When installing this unit in an area that

may become wet, elevate the unit with a sturdy, non-porous

material. In installations that may lead to physical damage

(i.e. a garage) it is advised to install a protective barrier to

prevent such damage.

D

UCTWORK

This air handler is designed for a complete supply and return ductwork system.

Do not operate this pro duct without all the duct work

attached.

To ensure correct system performance, the ductwork is to

be sized to accommodate 375-425 CFM per ton of cooling

with the static pressure not to exceed .5" WC. Inadequate

duct work that restricts airflow can result in improper performance and compressor or heater failure. Ductwork is to be

constructed in a manner that limits restrictions and maintains suitable air velocity. Ductwork is to be sealed to the

unit in a manner that will prevent leakage.

RETURN DUCTWORK

DO NOT TERMINATE THE RETURN DUCTWORK IN AN

AREA THAT CAN INTRODUCE TOXIC, OR OBJECTIONABLE FUMES/ODORS INTO THE DUCTWORK. The return ductwork is to be introduced into the air handler bottom

(upflow configuration).

3

Page 4

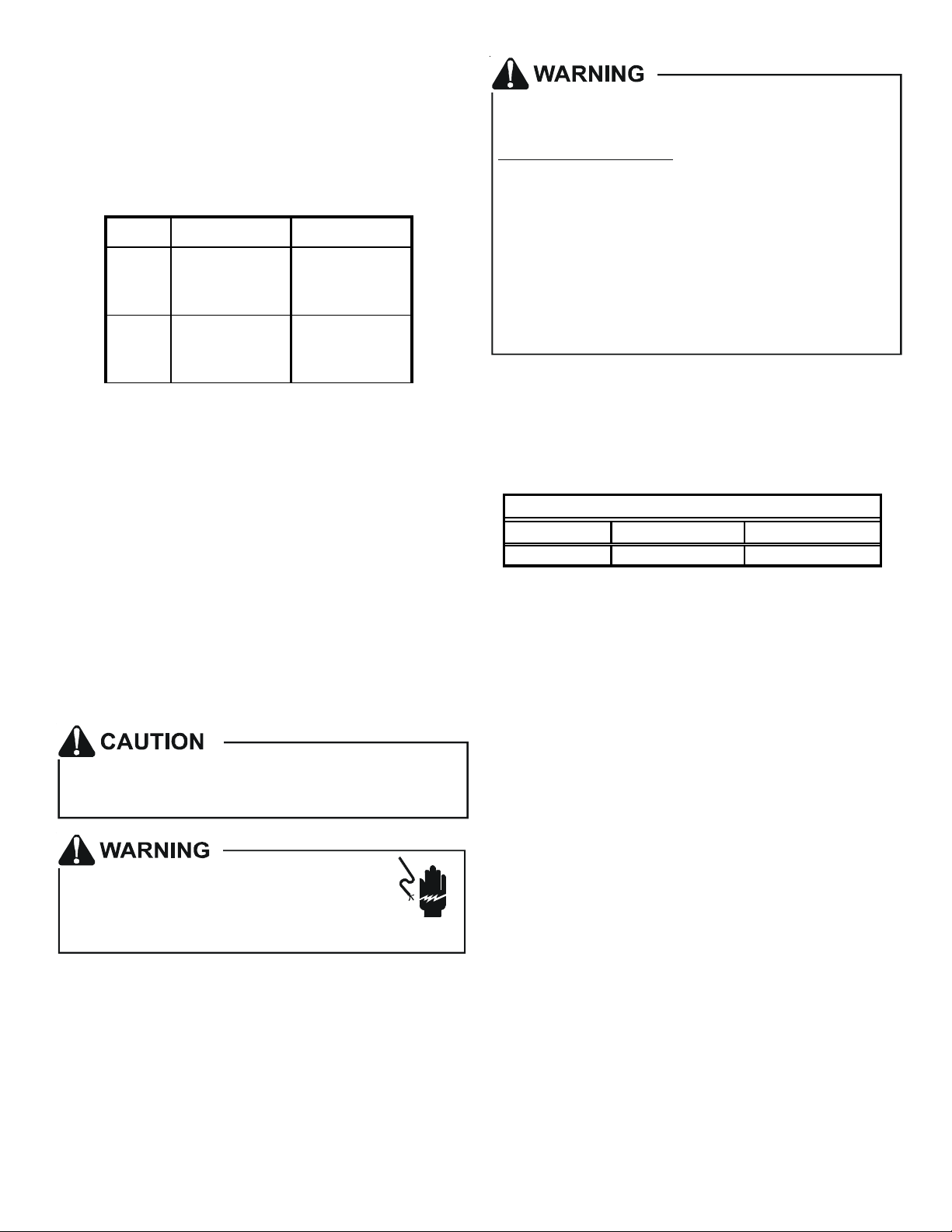

RETURN AIR FILTERS

Each installation must include a return air filter. This filtering

may be performed at the air handler or externally such as a

return air filter grille. Air handlers mounted in the downflow

orientation, including “B” series, require external filtering. A

washable filter is available as an accessory. To ensure optimum performance frequent filter cleaning is advised. Refer

to Air Filter Accessory table for the appropriate filter.

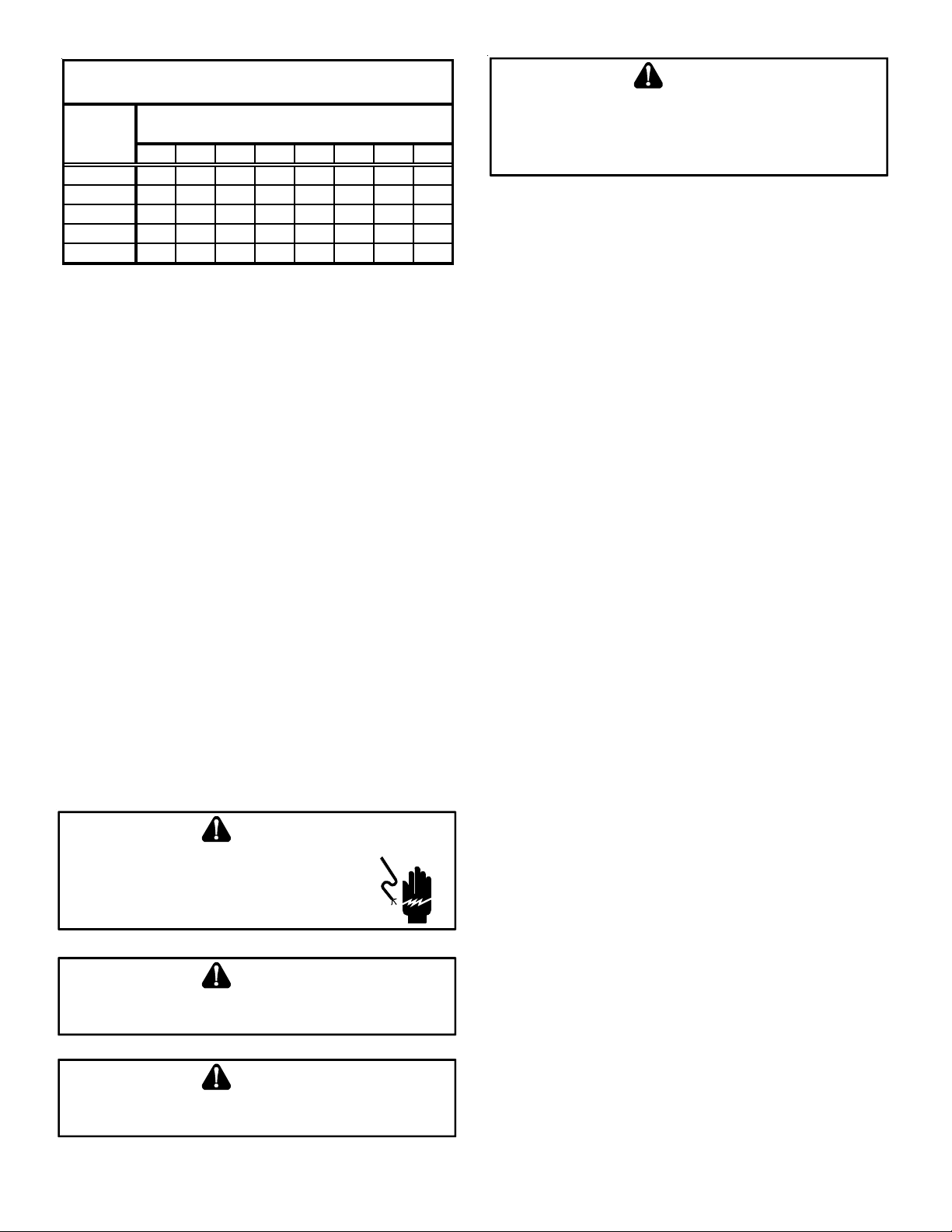

AVPTC Filter Number Qty Required

1830

3137

4260

E

LECTRIC HEAT

Refer to this manual in combination with the instructions provided with the heat kit for the correct installation procedure.

The air handlers listed in this manual do not have factory

installed electric heat. Electric heat is available as an ac-

cessory. If installing this option, the ONLY heat kits that can

be used are the HKR series.

NOTE: The Amana

are NOT approved for use with these air handlers.

FIL 36-42

(19" x 21")

FIL 48-61

(21-1/2" x 23")

Air Filter Accessories

®

brand EHK, ECB, EDB, and EDK kits

1

1

HKR INSTALLATION

Follow instructions listed in Installation and Operating Instructions shipped with the heat kit.

E

LECTRICAL SUPPLY WIRE AND

FIRE HAZARD!

To avoid the risk of property damage, personal injury

or fire, use only copper conductors.

MOP

HIGH VOLTAGE!

T o avoid prope rty dama ge , persona l injury or death

due to el ect rical shock, th is u ni t MU S T have an

uninterrupted, unbroken

electrical ground circuit may consist of an

appro pri at ely sized elec tr ical wi re co nnecting the

ground lug in the unit control box to the building

electrical service panel.

Other methods of grounding are permit ted if perform ed

in accordance with the National Electric Code

(NEC) /Americ an Nation al Standar ds Institut e

(ANSI)/National Fire Protection Association (NFP A) 70

and local/state codes. In Canada, electrical grounding

is to be in ac co rda nce w ith th e C ana dian Elec tric Cod e

(CSA) C22.1.

electrical ground. The

BUILDING ELECTRICAL SERVICE INSPECTION

This unit is designed for single-phase electrical supply. DO

NOT OPERATE ON A THREE-PHASE POWER SUPPLY.

Measure the power supply to the unit. The supply voltage

must be in agreement with the unit nameplate power re-

quirements and within the range specified below.

Power Supply V oltage

Nominal Input Minimum Voltage Maximum Voltage

208/240 187 253

WIRE SIZING

Wire size is important to the operation of your equipment.

Use the following check list when selecting the appropriate

wire size for your unit.

• Wire size must carry the Minimum Circuit Ampac-

ity (MCA).

• Refer to the NEC (USA) or CSA (Canada) for wire

sizing. The unit MCA for the air handler and the optional electric heat kit can be found on the unit Series

and Rating Plate.

• Wire size allows for no more than a 2% voltage

drop from the building breaker/fuse panel to the

unit.

HIGH VOLTAGE!

Disconnect ALL power before servicing.

Multiple power sources may be present.

Failure to do so may cause property damage,

personal in jury or de ath.

Refer to the latest edition of the National Electric Code

or in Canada the Canadian Electric Code when determining the correct wire size. The following table shows

the current carrying capabilities for copper conductors

rated at 75oC with a 2% voltage drop. Use the table

below to determine the voltage drop per foot of various conductors.

4

Page 5

Maximum Allowable Length in Feet

to Limit Voltage Drop to 2%*

Wire Size

(AWG)

14 75 50 37 NR NR NR NR NR

12 118795947NRNRNRNR

10 188 125 95 75 63 54 NR NR

8 301 201 150 120 100 86 75 68

6 471 314 235 188 157 134 118 110

*Based on NEC 1996

Minimum Circuit Ampacity (MCA)

10 15 20 25 30 35 40 45

MAXIMUM OVERCURRENT PROTECTION (MOP)

Every installation must include an NEC (USA) or CEC

(Canada) approved overcurrent protection device. Also,

check with local or state codes for any special regional requirements.

Protection can be in the form of fusing or HACR style circuit

breakers. The Series and Rating Plate can be used as a

guide for selecting the MAXIMUM overcurrent device.

NOTE: Fuses or circuit breakers are to be sized larger than

the equipment MCA but not to exceed the MOP.

E

LECTRICAL CONNECTIONS

Consult the local power company and local codes before

installing this unit. All wiring must be in accordance with the

National Electrical Code as well as all local codes. Knockouts have been provided on side and top of the cabinet for

the installation of the electrical conduit. If the knockouts on

the cabinet sides are used for electrical conduit, an adapter

ring must be used in order to meet UL1995 safety requirements. Use Minimum Circuit Ampacity and type of wire to

determine proper wire size. The unit MUST be properly

grounded. A ground lug is provided in the unit.

Check all factory connections before connecting electrical

power to unit to ensure none were loosened or disconnected

during shipping and handling.

WARNING

HIGHVOLTAGE!

TO

PREVENTPERSONALINJURYORDEATHDUETO

ELECTRICALSHOCK,DISCONNECTTHEELECTRICAL

POWERBEFOREELECTRICALLYCONNECTINGTHEUNIT

WARNING

TO

AVOIDTHERISKOFFIREOREQUIPMENTDAMAGE,USECOPPER

CONDU CTORS

.

CAUTION

TO

AVOIDTHERISKOFPERSONALINJURY,WIRINGTOTHEUNITMUST

BEPROPERLYPOLARIZEDANDGROUNDED

.

.

WARNING

ALL

WIRINGMUSTCOMPLYWITHAPPLICABLELOCALANDNATIONAL

CODES

.T

YPEANDLOCATIONOFFUSEDDISCONNECTSWITCH(ES)MUST

COMPLYWITHALLAPPLICABLECODESANDPROVIDEOVERCURRENT

PROTECTIONASSHOWNONTHENAMEPLATE

.

208/230 VOLT LINE CONNECTIONS

If heater kits will not be installed, remove the proper size

knockout for the electrical conduit connection. Connect electrical conduit to the unit using two washers to make an approved connection.

The power supply wires must be connected to the red and

black power wiring. Two wire nuts are provided in the bag

assembly for this connection. Wrap the wire nuts with electrical tape. (Insulated crimp type connectors, field supplied,

may be substituted for the wire nuts and electrical tape provided proper size connectors are used.) A ground wire MUST

be connected to the ground lug inside the unit.

AIR HANDLER ONLY (NON-HEAT KIT MODELS)

The building supply connects to the stripped black and red

wires contained in the air handler electrical compartment cavity. A ground screw is also contained in this area. Attach the

supply wires to the air handler conductors as shown in the

unit wiring diagram using appropriately sized solderless connectors or other NEC or CEC approved means.

AIR HANDLER WITH NON-CIRCUIT BREAKER HEAT KITS

A terminal block is provided with the HKR kit to attach the

power supply and air handler connections. Follow the HKR

Installation Manual and wiring diagram for complete wiring

details.

AIR HANDLER WITH HEAT KITS CONTAINING A CIRCUIT

BREAKER

HKR models with a “C” suffix contain a circuit breaker(s).

The air handler has a plastic cover on the access panel that

will require either one or both sections to be removed to allow the heat kit circuit breaker(s) to be installed. See the

HKR Installation Instructions for further details. The air handler wires and supply wires are installed directly onto the

HKR circuit breaker(s) as shown in the HKR Installation

Manual and wiring diagram.

OPERATION ON 208 VOLT SUPPLY

The unit transformer is factory connected for 240 V operation. If unit is to operate on 208 V, disconnect the red wire

from terminal 3 of the unit transformer and connect them to

terminal 2 of the unit transformer.

LOW VOLTAGE WIRING

Low voltage wiring connections are made at the top of the

cabinet. See the 24 Volt Thermostat Wiring section of this

manual for typical low voltage wiring connections. A minimum 18 AWG wire must be used for installations up to 100

feet.

5

Page 6

24 VOLT THERMOSTAT WIRING - NON-COMMUNICATING

A

A

THERMOSTAT CONNECTIONS

NOTE: Wire routing must not interfere with the circulator

blower operation or routine maintenance.

The air handler’s integrated control module provides terminals for “Y1” and “Y2” and “W1” and “W2” thermostat connections. This allows the air handler to support the systems

shown in the table below. Refer to the following figures for

typical connections to the integrated control module. Thermostat wiring entrance holes are located in the top of the

blower. Wire routing must not interfere with circulator blower

operation or routine maintenance.

RCG

12RC

RC

Remote Condensing Unit

W/E

W1 W2 Y1 Y2

G

W1 Y

(Single-Stage HP)

Y1

Typical Single-Stage Cool,

O

O

O

Single-Stage Heat

Heat Pump Thermostat

DEHUM

ir Handler

Integrated Control Module

NEU

Dehumidistat

HOT

[Optional]

Typical Single-Stage Heat Pump with Auxiliary/Emergency

Heating

COOLING HEAT PUMP HEATING ELECTRIC HEATING

1-STAGE ------ 1- or 2-STAGE

2-STAGE ------ 1- or 2-STAGE

1-STAGE 1-STAGE -----2-STAGE 2-STAGE -----1-STAGE 1-STAGE 1- or 2-STAGE

2-STAGE 2-STAGE 1- or 2-STAGE

NOTE: A removable plug connector is provided with the

control to make thermostat wire connections. This plug may

be removed, wire connections made to the plug, and

replaced. It is strongly recommended that multiple wires

into a single terminal be twisted together prior to inserting

into the plug connector. Failure to do so may result in

intermittent operation.

Typical Single-Stage Cool,

Single-Stage Heat Thermostat

RCG

12RCG

RC

Remote Condensing Unit

(Single-Stage AC)

W1 Y1

W1 Y1 Y2

W2

Y

Place Jumper Between Y1

and O for Proper

Dehu mid ification Operatio n

and Proper Ramping

Prof ile Operation

Air Handler Integrated

DEHUM

O

NEU

HOT

Control Module

Dehumidistat

[Optional]

______________________________________

RCG

12RC

RC

Remote Condensing Unit

W/E

W2 Y1 Y2

W1 W2 Y1 Y2

G

W1 Y1 Y2

(Two-Stage HP)

Typical Two-Stage Cool,

O

O

O

Two-Stage Heat

Heat Pump Thermostat

DEHUM

Integrated Control Module

NEU

HOT

ir Handler

Dehumidistat

[Optional]

Typical Two Stage Heat Pump heating and Auxiliary/

Emergency Heating

24 VOLT DEHUMIDISTAT WIRING - NON-COMMUNICATING

THERMOSTAT CONNECTIONS

The optional usage of a dehumidistat allows the air handler’s

circulator blower to operate at a slightly lower speed during

a combined thermostat call for cooling and dehumidistat call

for dehumidification. This lower blower speed enhances dehumidification of the conditioned air as it passes through the

AC coil. For proper function, a dehumidistat applied to this

air handler must operate on 24 VAC and utilize a switch which

opens on humidity rise.

To install/connect a dehumidistat:

1. Turn OFF power to air handler.

Typical Single-Stage Cooling with Single-Stage Heating

______________________________________

2. Secure the dehumidistat neutral wire (typically the white

lead) to the screw terminal marked “DEHUM” on the air

handler’s integrated control module.

Typical Two-Stage Cool,

Two-Stage Heat Thermostat

RCG

W1 W2 Y1 Y2

Place Jumper Between Y1

and O for Proper

Dehumidification Operation

and Proper Ramping

Profile Operat ion

3. Secure the dehumidistat hot wire (typically the black

lead) to the screw terminal marked “R” on the air

handler’s integrated control module.

4. Secure the dehumidistat ground wire (typically the green

Air Handler I ntegrate d

12RCG

RC

Remote Condensing Unit

W1 W2 Y1 Y2

Y1 Y2

(Two-Stage AC)

DEHUM

O

NEU

HOT

Control Module

Dehumidistat

[Optional]

Typical Two-Stage Cooling with Two-Stage Heating

lead) to the ground screw on the air handler. NOTE:

Ground wire may not be present on all dehumidistats.

5. Turn ON power to air handler.

6

Page 7

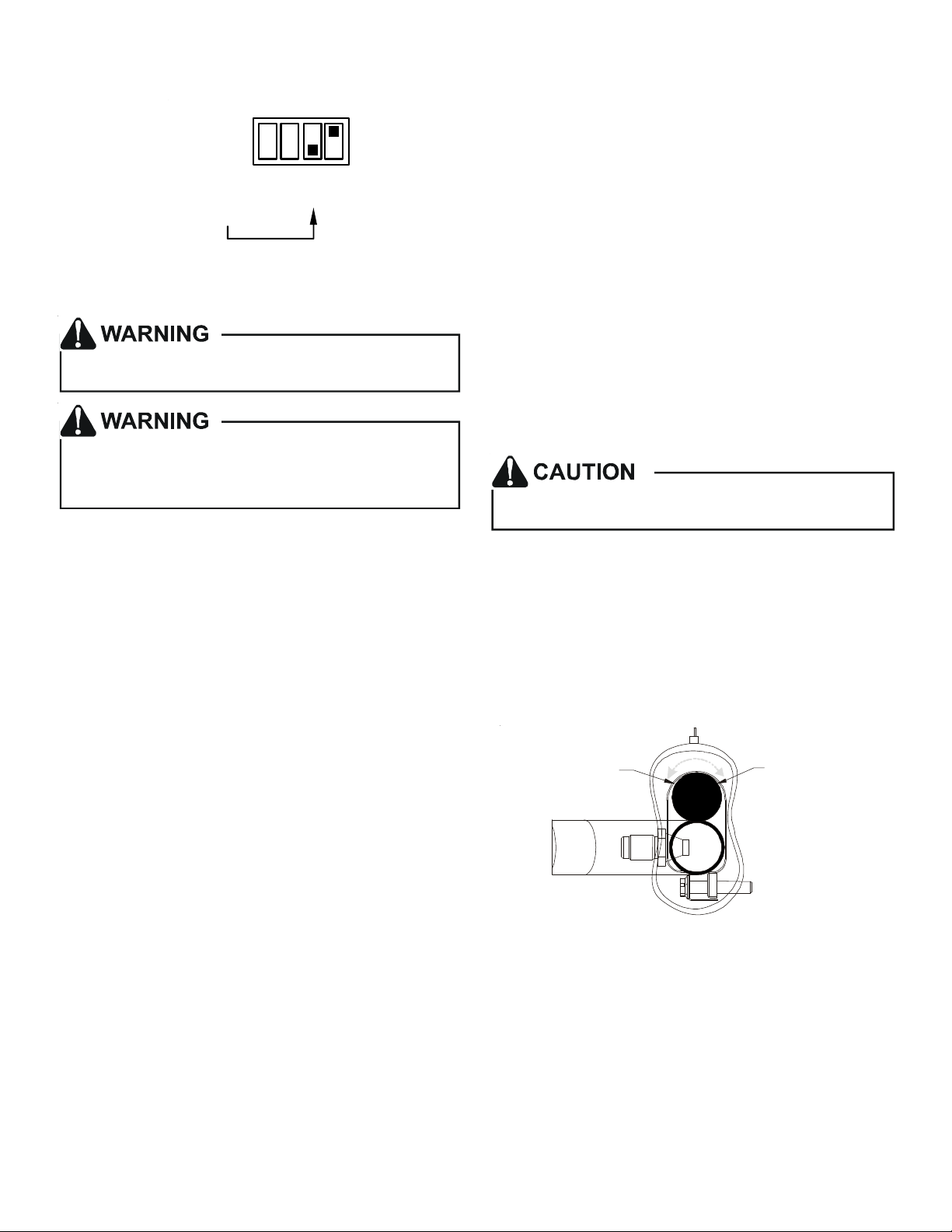

To enable the dehumidification function, move the dehumidification dipswitch from OFF to ON. See following figure.

S7

S8

ONOFF

IMPORTANT NOTE: Sensing bulbs are not permanently

installed at the factory to prevent accidental damage

during brazing. Be sure to follow this checklist step-bystep to ensure the sensing bulb is not damaged during

installation.

Move to the ON

position to enable

dehumidification

Dipswitches - Dehumidification Enable

R

EFRIGERANT LINES

This product is factory-shipped under pressure. Follow

these instructions to prevent injury.

DEHUM

Unused

A qu en c hin g c lo th is st ro ng ly recommended to prev ent

scorching or marring of the eq uipm en t finis h whe n

welding clo s e t o the paint ed surfaces . Us e bra z ing

alloy of 5% minimum silver content.

TUBING PREPARATION

All cut ends are to be round, burr free, and clean.

Failure to follow this practice increases the chances

for refrigerant leaks. The suction line is spun closed

and requires pipe cutters to remove the closed end.

POST BRAZING

Quench all welded joints with water or a wet rag.

1. Loosen the 13/16 nut 1 TURN ONLY. No pressure loss

indicates possible leak.

2. Remove the nut and discard the cap.

3. Follow the instructions on the caution label, and remove

the two mounting screws on the lower access panel.

Then remove the lower access panel.

4. Remove the large front panel and remove the sensing

bulb from suction manifold. TO PREVENT DAMAGE

TO SENSING BULB, ENSURE BULB IS NOT NEAR

FLAME OR IN CONTACT WITH SUCTION LINE OR

MANIFOLD DURING BRAZING.

5. Use a tube cutter to remove the spin closure on the

suction line.

Excessive torque can cause orifices to stick. Use the

proper torque settings when tightening orifices.

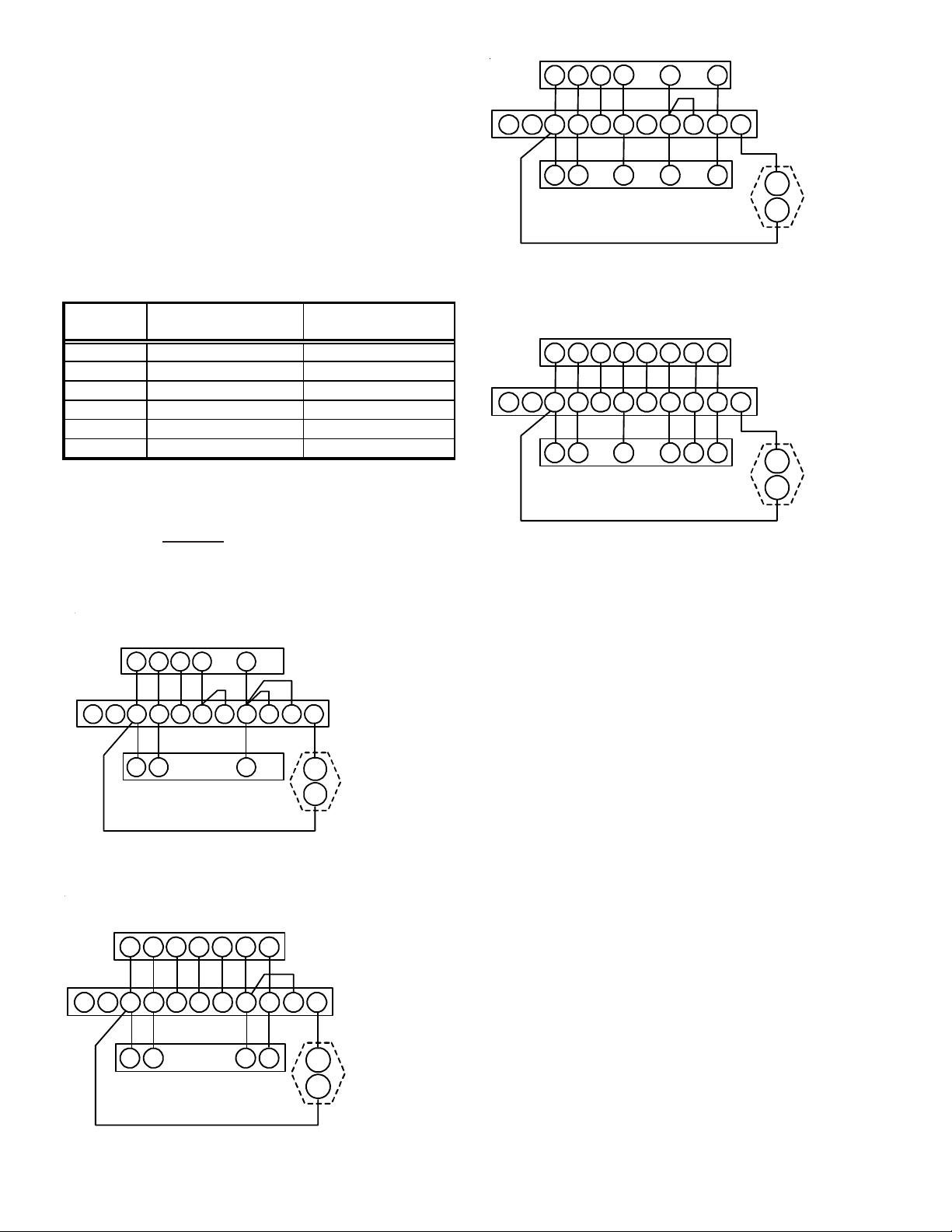

6. Replace sensing bulb to horizontal portion of suction

line just inside cabinet. Place bulb parallel with suction

line between 10 o’clock and 2 o’clock position. Secure

bulb to line with strapping provided in literature envelope. Insulate sensing bulb to line with self-adhesive

insulation provided in the envelope. See the following

figures for correct bulb placement and strapping information.

PIPING SIZE

For the correct tubing size, follow the specification for

the condenser/heat pump.

SPECIAL INSTRUCTIONS

This coil comes equipped with a thermostatic expansion

valve (TXV) for refrigerant management.

IMPORTANT NOTE: Torch heat required to braze tubes of

various sizes is proportional to the size of the tube. Tubes of

smaller size require less heat to bring the tube to brazing

temperature before adding brazing alloy. Applying too much

heat to any tube can melt the tube. Service personnel must

use the appropriate heat level for the size of the tube being

brazed.

NOTE: The use of a heat shield when brazing is

recommended to avoid burning the serial plate or the finish

on the unit. HEAT TRAP OR WET RAGS SHOULD BE

USED TO PROTECT HEAT SENSITIVE COMPONENTS

SUCH AS SERVICE VALVES AND TXV VALVES.

REFRIGERANT BULB

MUST BE POSITIONED

BETWE EN 10 & 2 O’CLOCK

REFRIGERANT BULB

MUST BE POSITIONED

BETWEEN 10 & 2 O’CLOCK

NOTE: The sensing bulb must be permanently located. A

heat shield, heat trap, or wet rag must be used during brazing to prevent damage to the TXV valve.

7

Page 8

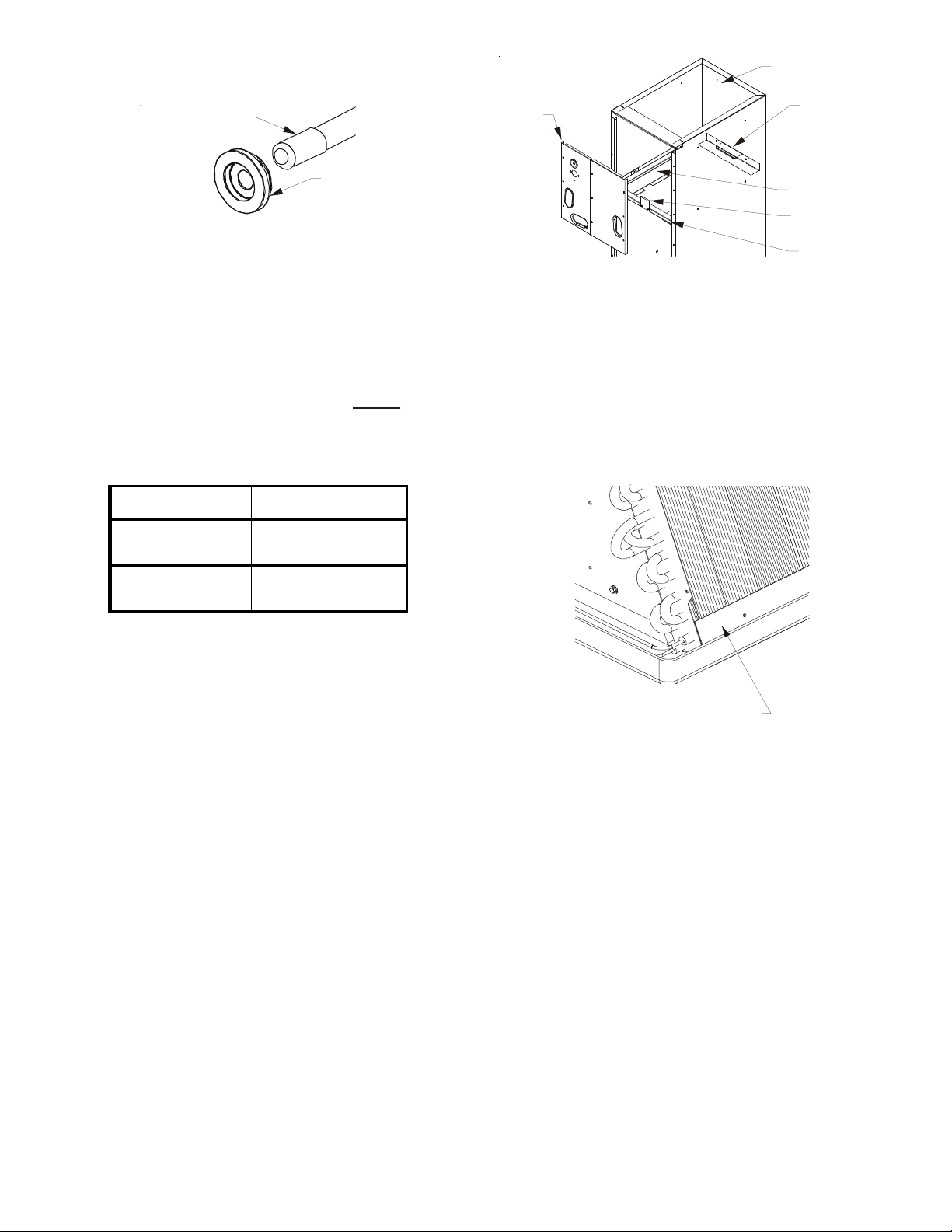

7. Replace access panels, suction line grommet, insulation and all screws.

SUCTION LINE

WITH SPIN CLOSURE

RUBBER

GROMM ET

Suction Line Grommet

A

IRFLOW CONVERSIONS

DOWNFLOW CONVERSION

Conversion to downflow MUST be performed in an area that

allows access to all sides prior to placing the air handler in

its final location. To prevent the evaporator coil pan from

“sweating”, a drain pan insulation (DPI) accessory kit is to

be used when performing this conversion. NOTE: The DPI

kit is not supplied with this product and is to be purchased

separately. See the following Drain Pan Insulation Kit table

for the correct DPI kit.

AVPTC Model Insulation Kit

RETURN AIR SIDE

OF UNIT

ACCESS

PAN EL

NOTE: The filter provision is not applicable

in THIS downf low application.

Downflow Conversion - Conversion Preparation

REAR CHANNEL

BRACKET

ZEE COIL

SUPPORT BRACKET

COIL RETAINING

BRACKET

TIE BRACKET

7. Install the zee coil supports and the wrapper stiffeners.

8. Install the tie bracket.

9. Install the rear channel bracket.

10. To prevent possible condensate “blow off” the insulation retainers are to be laid into the evaporator coil pan

as shown.

1830 DPI36-42/20

3137

4260

Drain Pan Insulation Kits

DPI48-61/-20

Refer to Figures Downflow Conversion - Conversion Prepa-

ration, Downflow Conversion - Insulation Retainers, and

Downflow Conversion - Conversion Completion for the lo-

cation of the components referenced in the following steps.

Figure Downflow Conversion - Conversion Preparation il-

lustrates the new installation location for the removed components.

1. Before inverting the air handler, remove all access panels, the coil rear channel bracket, and the filter closeoff panel.

2. Remove the evaporator coil and the horizontal drain

pan. Discard horizontal drain pan.

3. Install the provided plastic plug into the vacated access panel.

4. Remove the two (2) zee coil support brackets and insulation retaining brackets.

3” FLAT INSULATION

RETAINER (BOTH SIDES)

Downflow Conversion - Insulation Retainers

To complete the conversion, slide the evaporator coil into

the chassis and attach the three (3) access panels.

5. Remove the tie bracket.

6. Install the DPI Insulation Kit onto the bottom of the drain

pan.

8

Page 9

WRAPPER

INSULATION

JACKET

ZEE COIL

SUPPORT

WRAPPER

STIFFENER

DRAIN PAN

INSULATION KIT

Horizontal Left-Hand Conversion

1. Remove two screws beside the liquid line on the lower

access panels. Remove the (3) air handler access panels.

2. Remove the “J” shaped bracket that retains the evaporator coil.

BLOWER

ASSEMBLY

Downflow Conversion - Conversion Completion

NOTE: When converted to downflow position the coil may

protrude above the cabinet on some models.

HORIZONTAL CONVERSION

Dedicated Downflow models are not suitable for horizontal

application and must not be used for this type of installation.

The only field modification required for conversion to “Horizontal Right-Hand” is the removal of the plastic knockouts in

the horizontal panel drain connections. To prevent the horizontal drain pan from sweating in high humidity applications,

it is recommended that a horizontal drain pan insulation

(DPIH) accessory kit be used. NOTE: The DPIH insulation

kit is not supplied with this product and should be purchased

separately. See Horizontal Drain Pan Insulation Kits table

for the correct DPIH kit.

AVPTC Model Insulation Kit

1830 DPIH36-42

3. Slide out the evaporator coil and horizontal drain pan.

4. Remove the gasket from the horizontal pan drain connections.

5. Remove the oval shaped plastic plug from the left side

access panel. Remove the oval shaped rubber gasket

seal from the lower right side access panel.

6. The drain connections for the horizontal pan are sealed

with a thin coating of plastic. Carefully knock out this

plastic seal with a screwdriver and hammer.

Note: The

upper drain will become the secondary drain which

is mandatory in many municipalities .

7. Install the plastic plug removed in step 5 to the right

side lower access panel and the oval shaped rubber

gasket to the lower left access panel.

8. Reinstall the evaporator coil with the horizontal panel

on the left side. Note: Push the assembly completely

to the rear to ensure the engagement of the upflow pan

with the rear channel bracket.

9. Install the “J” bracket (removed in step 2) to support

the upflow pan to the tie channel.

10. Attach all panels and the metering device.

3137

4260

Horizontal Drain Pan Insulation Kits

DPIH 48-61

The following describes converting to “Horizontal Left-Hand”.

Conversion to downflow MUST be performed in an area that

allows access to all sides prior to placing the air handler in

its final location. See Horizontal Left-Hand Conversion fig-

ure below.

AVPTC MOTOR ORIENTATION

If the unit is in the upflow position, there is no need to rotate

the motor. If the unit is in the downflow position, loosen

motor mount and rotate motor as shown in the AVPTC Mo-

tor Orientation figure below. Be sure motor is oriented with

the female connections on the casing down. If the motor is

not oriented with the connections down, water could collect

in the motor and may cause premature failure.

9

Page 10

A

A

FRONT VIEW

FEMALE CONNECTIONS

AVPTC Motor Orientation

C

ONDENSATE REMOVAL

SIDE VIEW

W

RNING

SOFTW

RE VER.

Field experience has shown condensate drain traps with an

TOP

open vertical Tee between the air handler and the condensate drain trap can improve condensate drainage in some

applications, but may cause excessive air discharge out of

the open Tee. Goodman® does not prohibit this type of

drain but we also do not recommend it due to the resulting

air leakage. Regardless of the condensate drain design used,

it is the installer’s responsibility to ensure the condensate

drain system is of sufficient design to ensure proper condensate removal from the coil drain pan.

Drain

Connection

The coil drain pan has a primary and an optional secondary

drain with 3/4" NPT female connections. The connectors re-

Air Handler

2" MIN.

quired can be 3/4" NPT male either PVC or metal pipe and

should be hand tightened to a torque of approximately 37 inlbs. to prevent damage to the drain pan connection. An insertion depth between .355 to .485 inches (3-5 turns) should

POSITIVE LIQUID

SEAL REQUIRED

AT TRAP

3" MIN.

be expected at this torque. Use the female (3/4 fpt) threaded

fitting that protrudes outside of the enclosure for external

connections.

1. Ensure drain pan hole is NOT obstructed.

2. To prevent potential sweating and dripping on to finished space, it may be necessary to insulate the condensate drain line located inside the building. Use

Armaflex® or similar material.

A Secondary Condensate Drain Connection has been provided for areas where the building codes require it. Pitch the

drain line 1/4" per foot to provide free drainage. Insulate drain

lines located inside the building to prevent sweating. Install

a condensate trap to ensure proper drainage. If the secondary drain line is required, run the line separately from the

primary drain and end it where it can be easily seen.

NOTE: Water coming from this line means the coil primary

drain is plugged and needs clearing.

Use of a condensate removal pump is permitted when necessary. This condensate pump should have provisions for

shutting off the control voltage should a blocked drain occur.

A trap must be installed between the unit and the condensate pump.

IMPORTANT NOTE: The evaporator coil is coated with oils

that may dissolve styrofoam and certain types of plastics.

Therefore, a removal pump or float switch must not contain

any of these materials.

Tip: Priming the “P” trap may avoid improper draining at the

initial installation and at the beginning of the cooling season.

When coils are installed above ceilings, or in other locations

where damage from condensate overflow may occur, it is

MANDATORY to install a field fabricated auxiliary drain pan

under the coil cabinet enclosure. Drain lines from the auxiliary pan must be installed and terminated so that the home-

Condensate Drain Trap

owner can see water discharges.

CAUTION

A

If secondary drain is not installed, the secondary

access must be plugged.

CHIEVING

Ensure that the Neoprene gasket with PSA remains intact

on all surfaces that the access panels are secured to. These

The installation must include a “P” style trap that is located

as close as is practical to the evaporator coil. See Conden-

sate Drain Trap figure for details of a typical condensate line

“P” trap.

NOTE: Trapped lines are required by many local codes. In

the absence of any prevailing local codes, please refer to

surfaces are the entire length of the wrapper and areas between the upper tie plate, upper and lower access panels.

Be sure that upper access panel breaker insert gasket is

intact and also flowrator gasket is installed on the lower access panel. An additional drain hole cover is required.

C

IRCULATOR BLOWER

the requirements listed in the Uniform Mechanical Building

Code.

A drain trap in a draw-through application prevents air from

being drawn back through the drain line during fan operation thus preventing condensate from draining, and if connected to a sewer line to prevent sewer gases from being

drawn into the airstream during blower operation.

This air handler is equipped with a multi-speed circulator

blower. This blower provides ease in adjusting blower

speeds. The Specification Sheet applicable to your model

provides an airflow table, showing the relationship between

airflow (CFM) and external static pressure (E.S.P.), for the

proper selection of heating and cooling speeds. The heating blower speed is shipped set at “21 kW”, and the cooling

blower speed is set at “D”. These blower speeds should be

10

2% L

OW LEAKAGE RATE

Page 11

adjusted by the installer to match the installation requirements so as to provide the correct electric heating CFM and

correct cooling CFM.

Use the CFM LED (green), adjacent to the integrated control module electric heat connector to obtain an approximate

airflow quantity. The green CFM LED blinks once for each

100 CFM of airflow.

1. Determine the tonnage of the cooling system installed

with the air handler. If the cooling capacity is in BTU/hr

divide it by 12,000 to convert capacity to TONs.

Example: Cooling Capacity of 30,000 BTU/hr.

Tap A Tap B

OFF OFF OFF OFFON ON ON ON

S1

S2

Cooling Air flow Speed Tap (*indicates factory setting)

Normal* +10%

OFF OFF OFF OFFON ON ON ON

S1

S2

Tap C Tap D*

S1

S2

-10% Normal

S1

S2

30,000/12,000 = 2.5 Tons

2. Determine the proper air flow for the cooling system.

Most cooling systems are designed to work with air flows

between 350 and 450 CFM per ton. Most manufacturers recommend an air flow of about 400 CFM per ton.

Example: 2.5 tons X 400 CFM per ton = 1000 CFM

The cooling system manufacturer’s instructions must be

checked for required air flow. Any electronic air cleaners or

other devices may require a specific airflow; consult installation instructions of those devices for requirements.

3. Knowing the air handler model, locate the high stage

cooling air flow charts in the Specification Sheet applicable to your model. Look up the cooling air flow determined in step 2 and find the required cooling speed

and adjustment setting.

Example: An AVPTC183014 air handler installed with

a 2.5 ton air conditioning system. The air flow needed

is 1000 CFM. Looking at the cooling speed chart for

AVPTC183014, find the air flow closest to 1000 CFM.

A cooling airflow of 1000 CFM can be attained by setting the cooling speed to “C” and the adjustment to “0”

(no adjustment).

S3

S4

Air flow Adjust Taps (*indicates factory setting)

S3

S4

S3

S4

S3

S4

Dipswitches - Cooling Airflow and Airflow Adjust Taps

6. The multi-speed circulator blower also offers several

custom ON/OFF ramping profiles. These profiles may

be used to enhance cooling performance and increase

comfort level. The ramping profiles are selected using

DIP switches 5 and 6. Refer to the following Dipswitches

- Cooling Airflow Ramping Profiles figure for switch po-

sitions and their corresponding taps. Refer to the bullet

points below for a description of each ramping profile.

Verify profile selection by counting the green CFM LED

blinks and timing each step of the ramping profile.

• Profile A provides only an OFF delay of one (1) minute

at 100% of the cooling demand airflow.

OFF

100% CFM 100% CFM

1 min

OFF

4. Locate the blower speed selection DIP switches on the

integrated control module. Select the desired “cooling”

speed tap by positioning switches 1 and 2 appropriately. Select the desired “adjust” tap by positioning

switches 3 and 4 appropriately. Refer to the following

Dipswitches - Cooling Airflow and Airflow Adjust Taps

figure for switch positions and their corresponding taps.

Verify CFM by counting the number of times the green

CFM LED blinks.

5. Continuous fan speed is 30% of the air handler’s maximum airflow capability.

Example: If the air handler’s maximum airflow capabil-

ity is 2000 CFM, the continuous fan speed will be 0.30

x 2000 CFM = 600 CFM.

• Profile B ramps up to full cooling demand airflow by

first stepping up to 50% of the full demand for 30 seconds. The motor then ramps to 100% of the required

airflow. A one (1) minute OFF delay at 100% of the

cooling airflow.

OFF

50% CFM

1/2 min

100% CFM

100% CFM

1 min

• Profile C ramps up to 82% of the full cooling demand

airflow and operates there for approximately 7 1/2 minutes. The motor then steps up to the full demand airflow. Profile C also has a one (1) minute 100% OFF

delay.

OFF

100% CFM

11

OFF

OFF

Page 12

• Profile D ramps up to 50% of the demand for 1/2 minute,

then ramps to 82% of the full cooling demand airflow

and operates there for approximately 7 1/2 minutes.

The motor then steps up to the full demand airflow.

Profile D has a 1/2 minute at 50% airflow OFF delay.

OFF

Tap A Tap B Tap C Tap D*

OFF OFF OFF OFFON ON ON ON

S5

S6

S5

S6

S5

S6

Dipswitches - Cooling Airflow Ramping Profiles

S5

S6

OFF

7. If an electric heater kit has been installed, determine

the heater kilowatt (kW) rating. Find the heater size in

the table below. Set dip switches 9, 10, and 11 for the

installed heater as shown in the Dipswitches - Electric

Heat Airflow figure below. The adjust setting (already

established by the cooling speed selection) also applies to the electric heater kit airflow. Thus, the electric

heater airflow is adjusted by the same amount. Verify

selected CFM by counting the green CFM LED blinks.

ELECTRIC HEAT TEMPERATURE RISE:

The heating mode temperature rise is dependent upon the

system airflow, the supply voltage, and the heat kit size (kW)

selected. Use the supply voltage/temperature rise tables

below to determine the temperature rise (

º

F).

CFM

HEAT KIT NOMINAL kW

3 5 6 8 10152021

60018283541

8001321263142

1000 11 17 21 25 34 50

1200 9 14 18 21 28 42 56 62

1400 8 12 15 18 24 36 48 53

1600 7 10 13 15 21 31 42 46

1800 6 9 12 14 19 28 37 41

2000 5 8 11 12 17 25 34 37

230/1/60 Supply Voltage - Temperature Rise Table °F

CFM

3 5 6 8 10152021

HEAT KIT NOMINAL kW

600 17 27 34 39

800 13 20 25 30 40

1000 10 16 20 24 32 48

1200 8 13 17 20 27 40 53 59

1400 7 11 14 17 23 34 46 51

1600 6 10 13 15 20 30 40 44

1800 6 9 11 13 18 27 36 39

2000 5 8 10 12 16 24 32 35

220/1/60 Supply Voltage - Temperature Rise Table °F

CFM

356810152021

HEAT KIT NOMINAL kW

600 16 25 32 37

800 12 19 24 38 38

1000 10 15 19 22 30 46

1200 8 13 16 19 25 38 51 56

1400 7 11 14 16 22 33 43 48

1600 6 9 12 14 19 28 38 42

1800 5 8 11 12 17 25 34 37

2000 5 8 10 11 15 23 30 34

208/1/60 Supply Voltage - Temperature Rise Table °F

21 kW* 20 kW

OFF OFF OFF OFFON ON ON ON

S9

S10

S11

S9

S10

S11

15 kW 10 kW

S9

S10

S11

S9

S10

S11

8 kW 6 kW 5 kW 3 kW

OFF OFF OFF OFFON ON ON ON

S9

S10

S11

S9

S10

S11

S9

S10

S11

S9

S10

S11

Electric Heating Air Flow (*indicates factory setting)

NOTE: Upon start up in communicating mode the circuit board will display a “1 Flash” error code on the diagnostic LED

and an “Ec” HTR TO LARGE error at the communicating display. This is an indication that the dip switches on the control

board need to be configured in accordance with the Electric Heating Airflow Table on the following page of this manual.

Configuring the dip switches and resetting power to the unit will clear the error code.

12

Page 13

NOTE: For installations not indicated in the preceding

Temperature Rise Tables, the following formula is to be used:

TR = (kW x 3412) x (Voltage Correction) x (1.08 x CFM)

Where: TR = Temperature Rise

kW = Heater Kit Actual kW

3412 = Btu per kW

Voltage Correction =.96 (230 Supply Volts)

=.92 (220 Supply Volts)

=.87 (208 Supply Volts)

1.08 = Constant

CFM = Measured Airflow

NOTE: The Temperature Rise Tables can also be used to

determine the air handler airflow delivery. When using these

tables for this purpose set the room thermostat to maximum

heat and allow the system to reach steady state conditions.

Insert two thermometers, one in the return air and one in the

supply air. The temperature rise is the supply air temperature

minus the room air temperature.

Use HKR specification sheets to determine the HKR available for a given air handler.

Speed Selection Dip Switches

Cool

Selection

Switches

Tap 1 2

AOFFOFF

BONOFF

COFFON

DONON

TO SET AIRFLOW:

1.Select appropriate model from Cooling/Heat P ump Airflow Table.

Based on desired Ai rflow for your application select c orresponding tap

(A,B,C or D). Set dip switches 1 & 2 to the appropriate ON/O FF

positions.

2. Select appropr iate Airflow adjustme nt factor for appli cation

(0%. +10%, -10%) . Set dip switches 3 & 4 to the appropria te ON/OFF

positions.

If installed with Heater Kit:

3.

Using Electric Heat Airflow Table, set di p switches 9, 10 and 11 t o the

appropriate ON/OFF positions ba sed on Heater kit installed.

If installed without Heater Kit:

Ensure dip switches 9, 10 and 11 are set to a valid heater kit selecti on.

Example: The only valid heat er kits for AVPTC183014* applic ations

are 3, 5, 6, 8 and 10 kW.

Failure to do so will result in a Heater Kit er ror code.

TO SET COMFORT MODE:

Select desired Comfort Mode profile (see profil es above). Set switches

5 and 6 to the appropriate ON/OFF position s.

Profiles 5 6

Pre-Run Short-Ru n Off Delay

AOFFOFF

BONOFF

COFFON

DONON

------- ------- 60 sec/100%

------- 30 sec/50% 60 sec/100%

------- 7.5 mins/82% 60 sec/100%

30 sec/50% 7.5 mins/82% 30 sec/50%

TRIM

0%

+ 10%

- 10%

0%

Ad ju st

Selection

Switches

34

OFF OFF

ON OFF

OFF ON

ON ON

Sel ec t io n

Switches

Profile

AVPTC183014*

AVPTC313714*

AVPTC426014*

NOTE: Airfl ow dat a s hown app lies t o no n- com munic at ing m ode ope rat ion onl y. For a fully

commu nic at in g syste m, plea se see the ou tdoor unit 's ins tall at ion instr uctions for c oo lin g and heat

pump airflow data. S ee C o m fortNe t™ System - Ai r flow Cons id er ation sec tion for detail s.

Htr k W 9 10 11

3 ONONON630610600

5 ON O N O FF 7 30 710 680

6 ON O FF O N 8 40 840 790

8 ON O FF O FF 108 0 1060 99 0

10 OFF ON ON 1270 1260 1190

15 OFF O N OFF NR 14 7 0 13 90

20 OFF OFF ON NR NR 1580

21 OFF OFF OFF NR NR 1580

NOTE: Airfl ow dat a s hown app lies t o t he e me rg ency hea t mode ( elec tric heat onl y) in eit her noncommu nicatin g mod e operat ion or full y com mun icat ing m ode oper ation.

Cooling/Heat Pump Airflow Table

Model

Tap

A 420 630

B 560 840

C 700 10 40

A 410 610

B 560 830

C 700 10 40

D 830 12 40

A 810 12 10

B 940 14 10

C10501560

D12101800

Electr ic He at Airflow Tabl e

AVPTC

183014*

Low

Stage

Coo l

AVPTC

313714*

High

Stage

Cool

AVPTC

426014*

NOTE: Airflow blink codes are approximations of actual airflow.

Heat Kit Selection

MODELS HKR-03* HKR-05*/-05C* HKR-06* HKR-08*/-08C* HKR-10*/-10C* HKR-15C# HKR-20C# HKR-21C*

AVPTC183014A* X X X

AVPTC313714A* X X X

AVPTC426014A* X X X X X X

* Revision level that may or may not be designated.

C Circuit breaker option.

# Indicates Model A or Model B. Model A is 208V only and Model B is 240V only.

NOTE:

When 8kW and 10kW heat kits are used with an AVPTC1830 and AVPTC3137, matched with 2- ton outdoor unit, see Note 1 below.

1

Set Heater Kit dip switches 9, 10 and 11 to 6kW setting (9-ON, 10-OFF,11-ON) to obtain 840 CFM.

2

This heater kit can only be used for ‘1000 CFM or higher’ applications.

3

This heater kit can only be used for ‘1200 CFM or higher’ applications.

1

X

1

X

1

X

1

X

--- --- ---

2

X

--- ---

3

X

13

3

X

Page 14

T

ROUBLESHOOTING

ELECTROSTATIC DISCHARGE (ESD) PRECAUTIONS

NOTE: Discharge body’s static electricity before touching

unit. An electrostatic discharge can adversely affect electrical

components.

Use the following precautions during air handler installation

and servicing to protect the integrated control module from

damage. By putting the air handler, the control, and the

person at the same electrostatic potential, these steps will

help avoid exposing the integrated control module to electrostatic discharge. This procedure is applicable to both installed and uninstalled (ungrounded) blowers.

1. Disconnect all power to the blower. Do not touch the

integrated control module or any wire connected to the

control prior to discharging your body’s electrostatic

charge to ground.

FAULT RECALL

The integrated control module is equipped with a momentary push-button switch that can be used to display the last

six faults on the red diagnostic LED. The control must be in

Standby Mode (no thermostat inputs) to use the feature. Depress the push-button for approximately two seconds and

less than five seconds. The LED display will then display

the six most recent faults beginning with the most recent

fault and decrementing to the least recent fault. The faults

may be cleared by depressing the button for greater than

five seconds.

NOTE: Consecutively repeated faults are displayed a

maximum of three times. Example: A clogged return air filter

causes the air handler’s motor to repeatedly enter a limiting

condition. The control will only store this fault the first three

consecutive times the fault occurs.

C

OMFORTNET

™ S

YSTEM

2. Firmly touch a clean, unpainted, metal surface of the

modular blower near the control. Any tools held in a

person’s hand during grounding will be discharged.

3. Service integrated control module or connecting wiring

following the discharge process in step 2. Use caution

not to recharge your body with static electricity; (i.e., do

not move or shuffle your feet, do not touch ungrounded

objects, etc.). If you come in contact with an ungrounded object, repeat step 2 before touching control

or wires.

4. Discharge your body to ground before removing a new

control from its container. Follow steps 1 through 3 if

installing the control on a blower. Return any old or

new controls to their containers before touching any

ungrounded object.

DIAGNOSTIC CHART

WARNING

HIGHVOLTAGE!

TO

AVOIDPERSONALINJURYORDEATHDUETO

ELECTRICALSHOCK,DISCONNECTELECTRICALPOWER

BEFOREPERFORMINGANYSERVICEORMAINTENANCE

Refer to the Troubleshooting Chart at the end of this manual

for assistance in determining the source of unit operational

problems. The red diagnostic LED blinks to assist in troubleshooting the unit. The number of blinks refers to a specific

fault code.

.

OVERVIEW

The ComfortNet system is a system that includes a

ComfortNet compatible air handler and air conditioner or heat

pump with a CTK0*AA thermostat. Any other system configurations are considered invalid ComfortNet systems and

must be connected as a traditional (or non-communicating)

system (see Electrical).

A ComfortNet heating/air conditioning system differs from a

non-communicating/traditional system in the manner in which

the indoor unit, outdoor unit and thermostat interact with one

another. In a traditional system, the thermostat sends commands to the indoor and outdoor units via analog 24 VAC

signals. It is a one-way communication path in that the indoor and outdoor units typically do not return information to

the thermostat.

On the other hand, the indoor unit, outdoor unit, and thermostat comprising a ComfortNet system “communicate” digitally with one another. It is now a two-way communications

path. The thermostat still sends commands to the indoor

and outdoor units. However, the thermostat may also request and receive information from both the indoor and outdoor units. This information may be displayed on the

ComfortNet thermostat. The indoor and outdoor units also

interact with one another. The outdoor unit may send commands to or request information from the indoor unit. This

two-way digital communications between the thermostat and

subsystems (indoor/outdoor unit) and between subsystems

is the key to unlocking the benefits and features of the

ComfortNet system.

Two-way digital communications is accomplished using only

two wires. The thermostat and subsystem controls are powered with 24 VAC Thus, a maximum of 4 wires between the

equipment and thermostat is all that is required to operate

the system.

14

Page 15

AIRFLOW CONSIDERATION

Airflow demands are managed differently in a fully communicating system than they are in a non-communicating wired

system. The system operating mode (as determined by the

thermostat) determines which unit calculates the system

airflow demand. If the indoor unit is responsible for determining the airflow demand, it calculates the demand and

sends it to the ECM motor. If the outdoor unit or thermostat

is responsible for determining the demand, it calculates the

demand and transmits the demand along with a fan request

to the indoor unit. The indoor unit then sends the demand

to the ECM motor. The table below lists the various

ComfortNet systems, the operating mode, and airflow demand source.

System

Air Conditioner +

Air Hand ler

He a t Pu m p + A ir

Ha ndl er

System Operating

Mode

Cooling Air Conditio ner

Heating Air Handler

Cont inu ous Fan The rmos t at

Cooling Heat Pump

He at P ump Heat ing

On ly

HP + Electric Heat

Strips

Elect ric Heat Str ips

On ly

Cont inu ous Fan The rmos t at

Air flow De ma nd S ourc e

Heat Pump

> of Heat Pump or Air

Handler Demand

Air Handler

In continuous fan mode, the CTK0*AA thermostat provides

the airflow demand. The thermostat may be configured for a

low, medium, or high continuous fan speed. The low, medium,

and high fan speeds correspond to 25%, 50% and 75%,

respectively, of the air handlers’ maximum airflow capability.

During continuous fan operation, the thermostat sends a fan

request along with the continuous fan demand to the air

handler. The air handler, in turn, sends the demand to the

ECM motor. The ECM motor delivers the requested

continuous fan airflow.

CTK0*AA WIRING

NOTE: Refer to section Electrical Connections for 208/230

volt line connections to the air handler.

NOTE: A removable plug connector is provided with the

control to make thermostat wire connections. This plug may

be removed, wire connections made to the plug, and

replaced. It is strongly recommended that multiple wires

into a single terminal be twisted together prior to inserting

into the plug connector. Failure to do so may result in

intermittent operation.

Typical 18 AWG thermostat wire may be used to wire the

system components. One hundred (100) feet is the maximum length of wire between indoor unit and outdoor unit, or

between indoor unit and thermostat.

FOUR-WIRE INDOOR AND OUTDOOR WIRING

Typical wiring will consist of four wires between the indoor

unit and outdoor unit and between the indoor unit and thermostat. The required wires are: (a) data lines, 1 and 2; (b)

thermostat “R” (24 VAC hot) and “C” (24 VAC common).

12RC

CTK0*AA

Thermostat

For example, assume the system is a heat pump matched

with an air handler. With a call for low stage cooling, the

heat pump will calculate the system’s low stage cooling

airflow demand. The heat pump will then send a fan

request along with the low stage cooling airflow demand

to the air handler. Once received, the air handler will send

the low stage cooling airflow demand to the ECM motor.

The ECM motor then delivers the low stage cooling

airflow. See the applicable ComfortNet air conditioner or

heat pump installation manual for the airflow delivered

during cooling or heat pump heating.

12RC

ComfortNet™ Compatible

Air Handler

Integrated Control Module

12RC

System Wiring Using Four-Wires

ComfortNet Compatible AC/HP

Integrated Control Module

TWO-WIRE OUTDOOR, FOUR-WIRE INDOOR WIRING

Two wires only may be utilized between the indoor and outdoor units. For this wiring scheme, only the data lines, 1

and 2, are required between the indoor and outdoor units. A

40VA, 208/230 VAC to 24 VAC transformer must be installed

in the outdoor unit to provide 24 VAC power to the outdoor

unit’s electronic control. The transformer is included with

the CTK0*AA kit. See kit instructions for mounting and wiring instructions. Four wires are required between the indoor

unit and thermostat.

15

Page 16

Optional

40VA Transformer

(included in

CTK0*AA kit)

208/230 VAC

24 VAC

12RC

12RC

12RC

CTK0*AA

Thermostat

ComfortNet

Air Handler Integrated

Control Module

ComfortNet

AC/HP Integrated

Control Module

Compatible

Compatible

• Red communications LED – Indicates the status of

the network. The table below indicates the LED status and the corresponding potential problem.

• Green receive LED – Indicates network traffic. The

table below indicates the LED status and the corresponding potential problem.

• Learn button – Used to reset the network. Depress

the button for approximately 2 seconds to reset the

network.

System Wiring using Two-Wires between Air Handler and

AC/HP and Four-Wires between Air Handler and Thermostat

COMFORTNET™ SYSTEM ADVANCED FEATURES

Refer to the communicating thermostat installation manual

for information on accessing advanced features and menus.

DIAGNOSTICS

Accessing the air handler’s diagnostics menu provides ready

access to the last six faults detected by the air handler. Faults

are stored most recent to least recent. Any consecutively

repeated fault is stored a maximum of three times. Example:

A clogged return air filter causes the air handler’s motor to

repeatedly enter a limiting condition. The control will only

store this fault the first three consecutive times the fault oc-

curs. Navigate to the diagnostics menu as described above

in Accessing and Navigating the Advanced Features Menus.

NOTE: It is highly recommended that the fault history be

cleared when performing maintenance or servicing the air

handler.

NETWORK TROUBLESHOOTING

NOTE: Indoor Unit BIAS and TERMINATION Dipswitches

are factory set and should not be changed.

SYSTEM TROUBLESHOOTING

NOTE: Refer to the instructions accompanying the

ComfortNet compatible outdoor AC/HP unit for

troubleshooting information.

Refer to the Troubleshooting Chart at the end of this manual

for a listing of possible air handler error codes, possible

causes and corrective actions.

S

TART-UP PROCEDURE

• Prior to start-up, ensure that all electrical connections

are properly sized and tightened.

• All panels must be in place and secured. For Air Tight

application, neoprene gasket must be positioned at

prescribed locations to achieve 2% leakage.

• Tubing must be leak free.

• Unit should be elevated, trapped and pitched to allow

for drainage.

• Low voltage wiring is connected.

• Auxiliary drain is installed when necessary and pitched

to allow for drainage.

BIAS

BIAS

TERM

ONOFF

S2

S1

S3

Dipswitches - Indoor Unit BIAS and TERMINATION

The ComfortNet system is a fully communicating system,

and thus, constitutes a network. Occasionally the need to

troubleshoot the network may arise. The integrated air handler control has some on-board tools that may be used to

troubleshoot the network. These tools are: red communications LED, green receive (Rx) LED, and learn button. Refer

to the Communications Troubleshooting Chart at the end of

this manual for error codes, possible causes and corrective

actions

• Drain pan and drain tubing has been leak checked.

• Return and supply ducts are sealed.

• Unit is elevated when installed in a garage or where

flammable vapors may be present.

• Unit is protected from vehicular or other physical damage.

• Return air is not obtained from any areas where there

may be objectionable odors, flammable vapors or products of combustion such as carbon monoxide (CO),

which may cause serious personal injury or death.

16

Page 17

R

EGULAR MAINTENANCE

HIGH VOLTA GE!

Disconnect ALL power before servicing or

installing this unit. Multiple power sources may

be present. Failure to do so may cause property

damage, personal injury or death.

The only item to be maintained on a regular basis by the

user is the circulating air filter(s). Filter should be cleaned or

replaced regularly. A certified service technician must perform all other services.

NOTE: THESE INSTRUCTIONS ARE SPECIFICALLY FOR

AVPTC MODELS. DO NOT USE THESE DIAGRAMS FOR

ANY OTHER MODELS. SEE SEPARATE INSTALLATION

AND OPERATING INSTRUCTIONS FOR ATUF, ARUF,

ARPT, ADPF, AND ASPF MODELS.

NOTICE: THIS PRODUCT CONTAINS ELEC-

TRONIC COMPONENTS WHICH REQUIRE A DEFINITE GROUND. PROVISIONS ARE MADE FOR

CONNECTION OF THE GROUND. A DEDICATED

GROUND FROM THE MAIN POWER SUPPLY OR

AN EARTH GROUND MUST BE PROVIDED.

17

Page 18

AIR HANDLER ADVANCED FEATURES MENUS

)

CONFIGURATION

Subm e nu Item Indication (for Displa y Only; not Use r Modifiabl e)

Electric Heat Size (HTR KW ) Displays the size in kW of the selected electric heaters.

Motor HP (1/2, 3/4, or 1 MTR HP) Displays the air handler indoor blower motor horsepower.

Heat ON Delay (HT ON) Displays the electric heat indoor blower ON delay.

Heat OFF Delay (HT OFF) Display s the electric heat indoor blower OFF delay.

DIAGNOSTICS

Sub m enu It em In dicat i on/U s er Modifiabl e Optio ns Com m en ts

Fault 1 (FAULT #1) Most recent fault For display only

Fault 2 (FAULT #2) Next most recent fault For display only

Fault 3 (FAULT #3) Next most recent fault For display only

Fault 4 (FAULT #4) Next most recent fault For display only

Fault 5 (FAULT #5) Next most recent fault For display only

Fault 6 (FAULT #6) Least recent fault For display only

Clear Fault History (CLEAR) NO or YES Selecting “ YES” clears the fault

history

NOTE:

Consecutively repeated faults are shown a maximum of 3 times

IDENTIFIC ATION

Submenu Item Indication (for Display Only; not Use r Modifiable)

Model Number (MOD NUM) Displays the air handler model number

Serial Number (SER NUM) Displays the air handler serial number (Optional)

Software (SOFTWARE) Displays the application software revision

SET-UP

Submenu Item U ser Modifiable Option s Comments

Heat Airflow Trim (HT

TRM

Subm e nu Item Indication (for Displa y Only; not Use r Modifiable )

Mode (MODE) Displays the current air handler operating mode

CFM (CFM) Displays the airflow for the current operating mode

-10% to +10% in 2% increments,

default is 0%

STATUS

Trims the electric heating airflow by the

selected amount.

18

Page 19

COMMUNICATIONS TROUBLESHOOTING CHART

LED LED

Red

Communications

LED

2 Flashes

1 Steady

Green Receive

LED

Flashing

On Solid

Status

Off

1 Flash

Off

Flash

Rapid

Indication Possible Causes Corrective Action(s) Notes & Cautions

x Normal condition x None x None x None

x Communications

Failure

x Out-of-box reset x Control power up

x No power

x Communications

error

x No network found x Broken/ disconnected

x Normal network

traffic

x Data 1/ Data 2

miss-wire

x Communications

Failure

x Learn button

depressed

x No power to air

handler

x Open fuse

x Communications error

data wire(s)

x Air handler is installed

as a noncommunicating/

traditional system

x Control is “talking” on

network as expected

x Data 1 and data 2

wires reversed at air

handler, thermostat,

or ComfortNet™

compatible outdoor

AC/HP

x Short between data 1

and data 2 wires

x Short between data 1

or data 2 wires and R

(24VAC) or C (24VAC

common)

x Depress Learn Button

x Verify that bus BIAS

and TERM

dipswitches are in the

ON position.

x None x None

x Check fuses and

circuit breakers;

replace/reset

x Replace blown fuse

x Check for shorts in

low voltage wiring in

air handler/system

x Reset network by

depressing learn

button

x Check data 1/ data 2

voltages

x Check

communications

wiring (data 1/ data 2

wires)

x Check wire

connections at

terminal block

x Verify air handler

installation type (noncommunicating/

traditional or

communicating)

x Check data 1/ data 2

voltages

x None x None

x Check

communications

wiring (data 1/ data 2

wires)

x Check wire

connections at

terminal block

x Check data 1/ data 2

voltages

x Depress once

quickly for a powerup reset

x Depress and hold

for 2 seconds for

an out-of-box reset

x Turn power OFF

prior to repair

x Turn power OFF

prior to repair

x Verify wires at

terminal blocks are

securely twisted

together prior to

inserting into

terminal block

x Verify data1 and

data voltages as

described above

x Turn power OFF

prior to repair

x Verify wires at

terminal blocks are

securely twisted

together prior to

inserting into

terminal block

x Verify data1 and

data voltages as

described above

19

Page 20

T

ROUBLESHOOTING

Notes & Cautions

C

HART

Corrective Actions

Possible Causes

ComfortNet ™

Thermostat Only

x Normal operation x None x Normal operation

None None

Message Code

model.

x Turn power OFF prior to repair.

x Use memory card for the specific

settings

x Verify electric heat dipswitch

x Verify the installed electric

dipswitches is too large for heater

kits in shared data set

x Heater kit selected via

Ec

LARGE

HTR TOO

turning power ON. Memory card

x Insert memory card BEFORE

heater is valid for the air handler.

Check nameplate or

model.

turning power ON. Memory card

may be removed after data is

loaded.

memory card.

may be removed after data is

loaded.

memory card.

data is loaded.

x Turn power OFF prior to repair.

x Use memory card for the specific

settings

x Verify electric heat dipswitch

x Verify the installed electric

dipswitches is too small for heater

kits in shared data set

x Heater kit selected via

Ec

SMALL

HTR TOO

x Insert memory card BEFORE

heater is valid for the air handler.

x Turn power OFF before removing

x Error code will be cleared once

Specification Sheet applicable to

your model* for allowable heater

kit(s).

for the specific model. Re-

populate data using correct

memory card if required.

x Verify shared data set is correct

x

Check nameplate or

Specification Sheet applicable to

your model* for allowable heater

kit(s).

x Turn power OFF before removing

x Verify shared data set is correct

for the specific model. Re-

populate data using correct

x Error code will be cleared once

memory card if required.

data is loaded.

x Turn power OFF prior to repair.

x Verify electric heat dipswitch

x Heater kit selected via

Ec

NO HTR

model.

x Use memory card for the specific

x Insert memory card BEFORE

settings

heater is valid for the air handler.

x Verify the installed electric

dipswitches is doesn’t match

heater kits in shared data set

MATCH

turning power ON. Memory card

Check nameplate or

may be removed after data is

loaded.

memory card.

data is loaded.

x Turn power OFF before removing

x Error code will be cleared once

Specification Sheet applicable to

your model* for allowable heater

kit(s).

for the specific model. Re-

populate data using correct

x Verify shared data set is correct

x Turn power OFF prior to repair.

x Replace fuse with 3-amp

voltage wiring

memory card if required.

x Short in low voltage wiring x Locate and correct short in low

Not

Displayed

Not

Displayed

automotive type

module fuse with 3A automotive

fuse.

x Turn power OFF prior to repair.

x Replace integrated control

power to air handler and

integrated control module.

x Assure 208/230 volt and 24 volt

x Check integrated control module

24 volt wire improperly

connected or loose

x Manual disconnect switch OFF or

x Blown fuse or circuit breaker

EE

FAULT

INTERNAL

x Replace integrated control

fuse (3A). Replace if necessary.

x Integrated control module has an

module with correct replacement

x Check for possible shorts in

internal fault

part

x Read precautions in “Electrostatic

208/230 volt and 24 volt circuits.

Repair as necessary.

Discharge” section of manual.

module.

x Replace bad integrated control

Fault Description

LED Codes

Diagnostic/Status

Symptoms of Abnormal Operation

(Communicating & Non-communicating

dipswitches is too large

for heater kits specified

x Normal operation

x Heater kit selected via

in shared data set

x Heater kit selected via

dipswitches is too small

for heater kits specified

in shared data set

x Heater kit selected via

dipswitches does not

heater kits specified in

shared data set

x Open Fuse

to air handler or no 24