Goodman AVPTC42D14, AVPTC48D14, AVPTC30C14, AVPTC24B14, AVPTC60D14 Installation Manual

...

AVPTC**14**

®

AIR HANDLERS

INSTALLATION & OPERATING INSTRUCTIONS

1 Important Safety Instructions ....................................................................2

2 Shipping Inspection ..................................................................................2

2.1 Parts ..............................................................................................3

2.2 Handling ........................................................................................3

3 Codes & Regulations................................................................................3

4 Replacement Parts ...................................................................................3

5 Pre-Installation Considerations................................................................3

5.1 Preparation....................................................................................3

5.2 System Matches............................................................................3

5.3 Interconnecting Tubing..................................................................3

5.4 Clearances ....................................................................................3

5.5 Horizontal Applications ..................................................................4

6 Installation Location.................................................................................4

6.1 Upflow Installation .........................................................................4

6.2 Horizontal Left Installation .............................................................4

6.3 Downflow/Horizontal Right Installation ..........................................4

7 Refrigerant Lines ......................................................................................7

7.1 Tubing Size....................................................................................7

7.2 Tubing Preparation........................................................................7

7.3 Tubing Connections for TXV Models.............................................7

8 Condensate Drain Lines ...........................................................................7

9 Ductwork...................................................................................................8

9.1 Return Ductwork ...........................................................................8

10 Return Air Filters .....................................................................................8

11 Electric Heat ...........................................................................................9

12 Electrical and Control Wiring ................................................................10

12.1 Building Electrical Service Inspection .......................................10

12.2 Wire Sizing ................................................................................10

12.3 Maximum Overcurrent Protection (MOP) ..................................10

12.4 Electrical Connections – Supply Voltage...................................10

12.4.1 Air Handler Only (Non-Heat Kit Models) ................................ 11

12.4.2 Air Handler - Non-Circuit Breaker Heat Kits ...........................11

12.4.3 Air Handler With Circuit Breaker Heat Kit...............................11

12.5 Low Voltage Connections..........................................................11

13 Achieving 2% Low Leakage Rate.........................................................11

14 Start-Up Procedure...............................................................................11

15 Regular Maintenance ........................................................................... 11

Circulator Blower..........................................................................................14

Troubleshooting ...........................................................................................18

ComfortNet™ System ..................................................................................19

Start-Up Procedure ......................................................................................21

Regular Maintenance ...................................................................................21

Troubleshooting ...........................................................................................24

Diagnostic Codes .........................................................................................28

Wiring Diagrams ..........................................................................................29

© 2013-2014 Goodman Manufacturing Company, L.P.

5151 San Felipe, Suite 500, Houston, TX 77056

www .goodmanmfg.com - or - www.amana-hac.com

P/N: IO-443D Date: August 2014

RECOGNIZE

THIS SYMBOL AS A

SAFETY PRECAUTION.

ATTENTION

INSTALLING

PERSONNEL

Prior to installation, thoroughly familiarize yourself with this Installation

Manual. Observe all safety warnings.

During installation or repair, caution is

to be observed. It is your responsibility

to install the product safely and to educate the customer on its safe use.

is a registed trademark of Maytag Corporation or its related companies and is used under license to

Goodman Company, L.P., Houston, TX, USA. All rights reserved.

1 Important Safety Instructions

The following symbols and labels are used throughout this manual to indicate immediate or potential safety hazards. It is the

owner’s and installer’s responsibility to read and comply with all safety information and instructions accompanying these

symbols. Failure to heed safety information increases the risk of personal injury, property damage, and/or product damage.

HIGH VOLTAGE!

Disconnect ALL power before servicing.

Multiple power sources may be present.

Failure to do so may cause property damage,

personal injury or death.

Install ati on an d re pa ir of t hi s u nit sho ul d b e p erform ed

by indiv id uals me et in g the re qui re men ts of an

ONLY

“entry level technician” as specified by

the Ai r-Co ndi ti on in g, H eati ng a nd Re fri g era ti on Inst i tu te

(AHRI). Attempting to install or repair this unit without

such ba ck grou nd may re sul t i n p rod uct da mag e,

personal inju ry or death.

This product is factory-shipped for use with

208/240/1/60 electrical power supply.

reconfigure this air handler to operate with any other

power supply.

To avoid property damage, personal injury or death

due to electrical shock, this unit MUST have an

uninterrupted, unbroken

electrical ground circuit may consist of an

appropriately sized electrical wire connecting the

ground lug in the unit control box to the building

electrical service panel.

Other meth ods of gro unding are permitted if pe rfo rmed

in accordance with the National Electric Code

(NEC)/A mer ican National Stan dard s Inst itut e

(ANSI)/ Nati onal Fire P rotec tion Assoc iation (NFP A) 70

and local /s ta te c ode s. I n Canad a, e lect ri ca l gro unding

is to be in accordance with t he Cana di an El ec tr ic C ode

(CSA) C22.1.

, at a mini mum,

DO NOT

electrical ground. The

Do not connect to or use any device that is not designcertified by Goodman for use with this unit. Serious

property damage, personal injury, reduced unit

performance and/or hazardous conditions may result

from the use of such non-approved devices.

T o prev en t th e ri sk of pro perty damage, personal

injury , or dea th, do not store co mb ustible mater ials or

use gasoline or other flammable liquids or vapo rs in

the vicin ity of this uni t.

When installing or servicing this equipment, safety

clothing, including hand and eye protection, is

strongly recommended. If installing in an area that has

special safety requirements (hard hats, etc.), bserve

these requirements.

o

B10259-216

2 Shipping Inspection

Always transport the unit upright; laying the unit on its side or top during transit may cause equipment damage. The installer

should inspect the product upon receipt for shipping damage and subsequent investigation is the responsibility of the carrier.

The installer must verify the model number, specifications, electrical characteristics, and accessories are correct prior to

installation. The distributor or manufacturer will not accept claims from dealers for transportation damage or installation of

incorrectly shipped units.

2

2.1 Parts

Also inspect the unit to verify all required components are present and intact. Report any missing components immediately to Goodman® or to the distributor. Use only factory authorized replacement parts (see Section 5). Make sure to

include the full product model number and serial number when reporting and/or obtaining service parts.

2.2 Handling

Use caution when transporting/carrying the unit. Do not move unit using shipping straps. Do not carry unit with hooks or

sharp objects. The preferred method of carrying the unit after arrival at the job site is to carry via a two-wheel hand truck

from the back or sides or via hand by carrying at the cabinet corners.

3 Codes & Regulations

This product is designed and manufactured to comply with applicable national codes. Installation in accordance with such

codes and/or prevailing local codes/regulations is the responsibility of the installer. The manufacturer assumes no responsibility for equipment installed in violation of any codes or regulations.

The United States Environmental Protection Agency (EPA) has issued various regulations regarding the introduction and disposal of refrigerants. Failure to follow these regulations may harm the environment and can lead to the

imposition of substantial fines. Should you have any questions please contact the local office of the EPA and/or refer to

EPA’s website www.epa.gov.

4 Replacement Parts

When reporting shortages or damages, or ordering repair parts, give the complete product model and serial numbers as

stamped on the product. Replacement parts for this product are available through your contractor or local distributor. For the

location of your nearest distributor consult the white business pages, the yellow page section of the local telephone book or

contact:

CONSUMER AFFAIRS

GOODMAN MANUFACTURING COMPANY, L.P.

7401 SECURITY WAY

HOUSTON, TEXAS 77040

(877) 254-4729

5 Pre-Installation Considerations

5.1 Preparation

Keep this document with the unit. Carefully read all instructions for the installation prior to installing product. Make sure

each step or procedure is understood and any special considerations are taken into account before starting installation.

Assemble all tools, hardware and supplies needed to complete the installation. Some items may need to be purchased

locally. Make sure everything needed to install the product is on hand before starting.

5.2 System Matches

The entire system (combination of indoor and outdoor sections) must be manufacturer approved and Air-Conditioning,

Heating, and Refrigeration Institute (AHRI) listed. NOTE: Installation of unmatched systems is not permitted and will void

the product warranty.

5.3 Interconnecting Tubing

Give special consideration to minimize the length of refrigerant tubing when installing air handlers. Refer to Remote

Cooling/Heat Pump Service Manual RS6200006, and TP-107 Long Line Set Application R-410A for tubing guidelines. If

possible, allow adequate length of tubing such that the coil may be removed (for inspection or cleaning services) from the

cabinet without disconnecting the tubing.

5.4 Clearances

The unit clearance from a combustible surface may be 0". However, service clearance must take precedence. A minimum of 24" in front of the unit for service clearance is required. Additional clearance on one side or top will be required

for electrical wiring connections. Consult all appropriate regulatory codes prior to determining final clearances. When

installing this unit in an area that may become wet (such as crawl spaces), elevate the unit with a sturdy, non-porous

material. In installations that may lead to physical damage (i.e. a garage) it is advised to install a protective barrier to

prevent such damage. Always install units such that a positive slope in condensate line (1/4" per foot) is allowed.

3

5.5 Horizontal Applications

If installed above a finished living space, a secondary drain pan (as required by many building codes), must be installed

under the entire unit and its condensate drain line must be routed to a location such that the user will see the condensate

discharge.

6 Installation Location

NOTE: These air handlers are designed for indoor installation only.

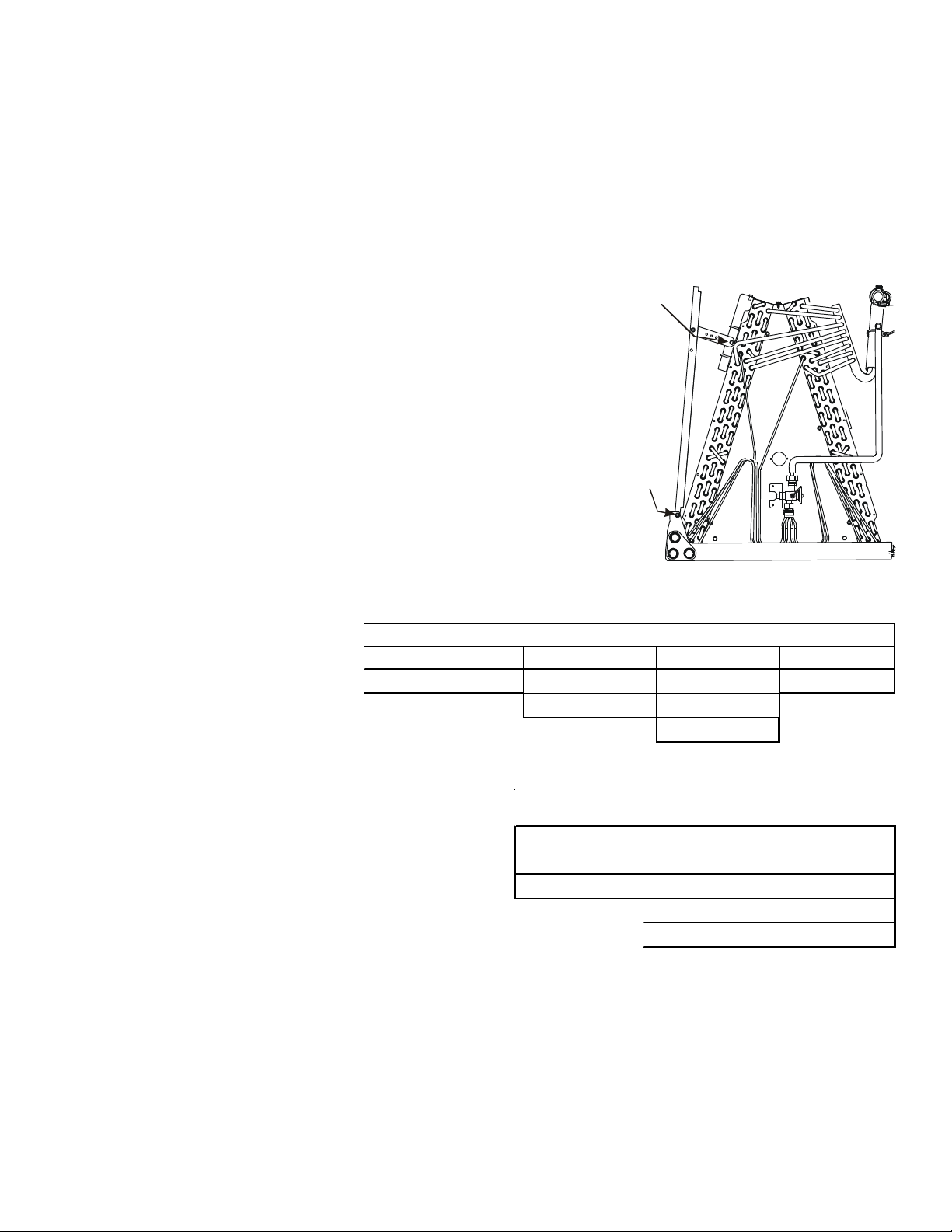

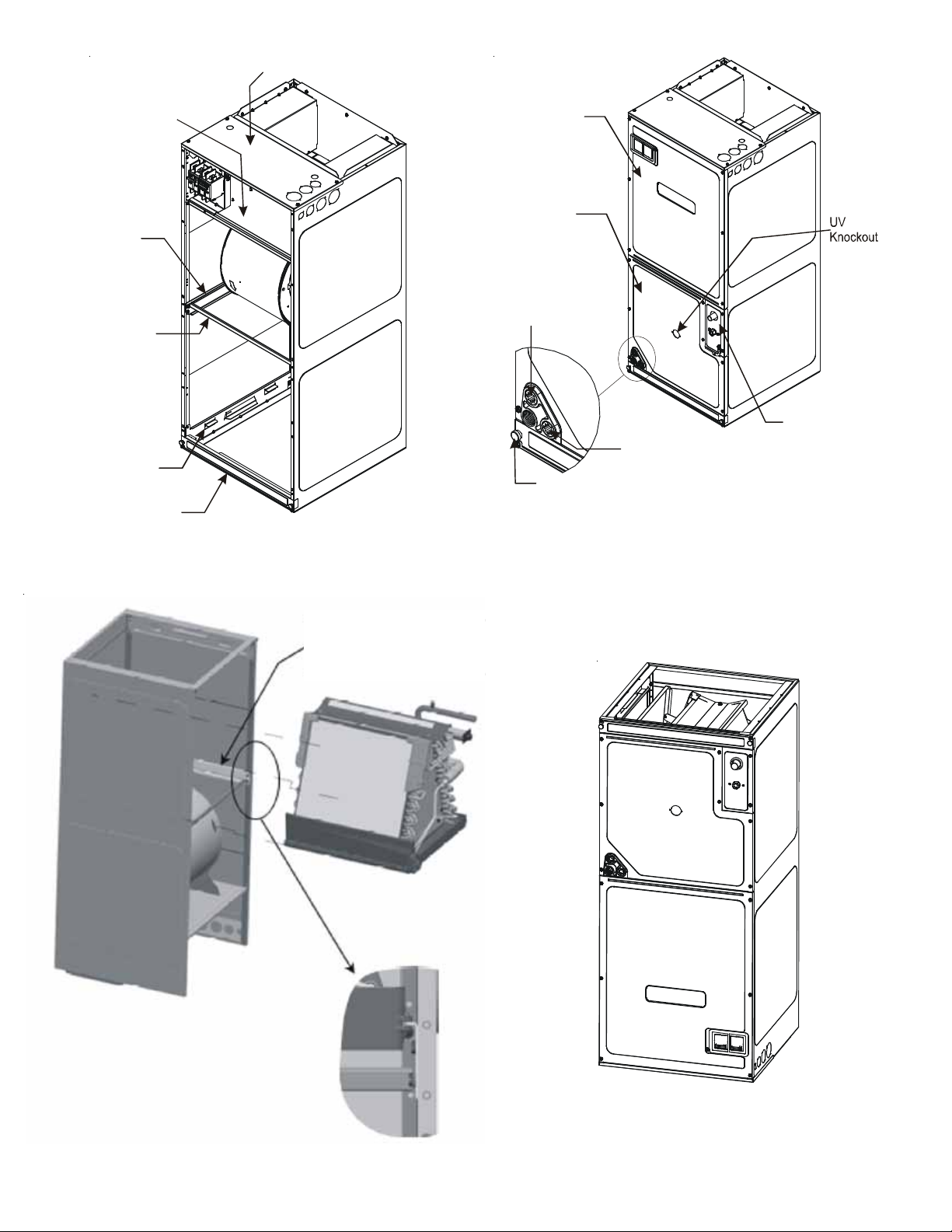

The AVPTC**14** product line may be installed in one of the upflow, downflow, horizontal left or horizontal right orientations as

shown in Figures 2, 3, 4 and 5. The unit may be installed in upflow or horizontal left orientation as shipped (refer to specific

sections for more information).

Minor field modifications are necessary to convert to downflow or horizontal right as indicated in below sections.

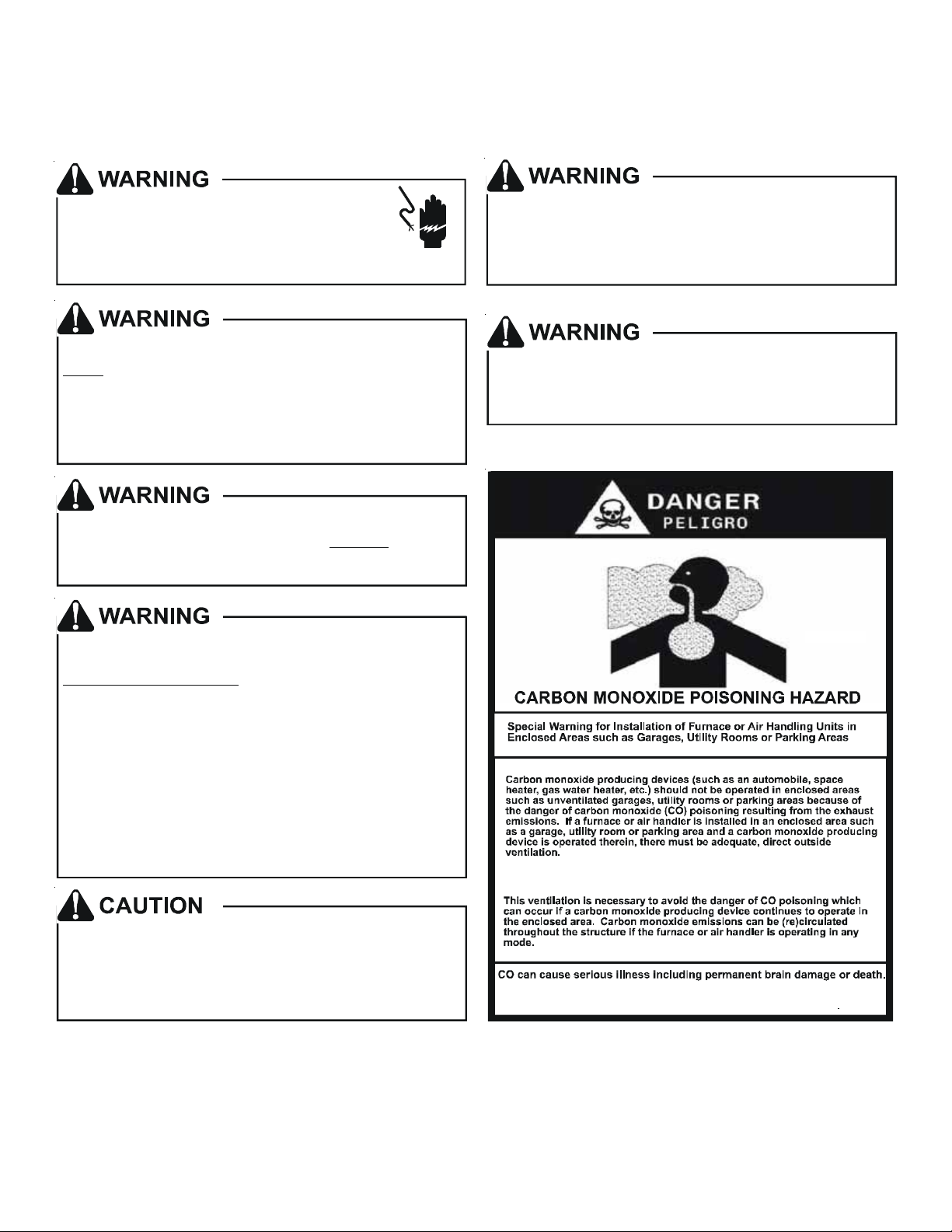

6.1 Upflow Installation

No field modifications are mandatory however to obtain maximum efficiency,

the horizontal drip shield must be removed.

Drip Shield Removal: Refer to Figure 1, remove the two (2) screws that

secure the drip shield support brackets to the condensate collectors (one

screw per side). Remove the two (2) screws that secure the drip shield to the

drain pan. The drip shield and drip shield brackets may now be removed.

The bottom left drain connection is the primary drain for this application and

condensate drain line must be attached to this drain connection. The top

connection of the three drain connections on the drain pan must remain

plugged for this application. The bottom right drain connection is for the secondary drain line (if used).

6.2 Horizontal Left Installation

No field modifications are permissible for this application.

The bottom right drain connection is the

primary drain for this application and

condensate drain line must be attached

to this drain connection. The top connection of the three drain connections

on the drain pan must remain plugged

CMK0001 CMK0002 CMK0003 CMK0007

AVPTC42D14** AVPTC48D14** AVPTC30C14** AVPTC24B14**

MODEL LISTS FOR HORIZONTAL LEFT KITS

AVPTC60D14** AVPTC36C14**

for this application. The bottom left drain

connection is for the secondary drain

line (if used).

Screw

Screw

DRIP SHIELD REMOVAL

Figure 1

AVPTC48C14**

Table 1

Use condensate management kit if equipment is installed in

high humidity condition (for example: 70% or higher).

6.3 Downflow/Horizontal Right Installation

IMPORTANT NOTE: In the downflow application, to prevent

coil pan “sweating”, a downflow kit (DFK) is available through

your local Goodman distributor. The DFK is not supplied with

the air handler and is required by Goodman on all downflow

installations. See Table 2 for the correct DFK and follow the

instructions provided for installation.

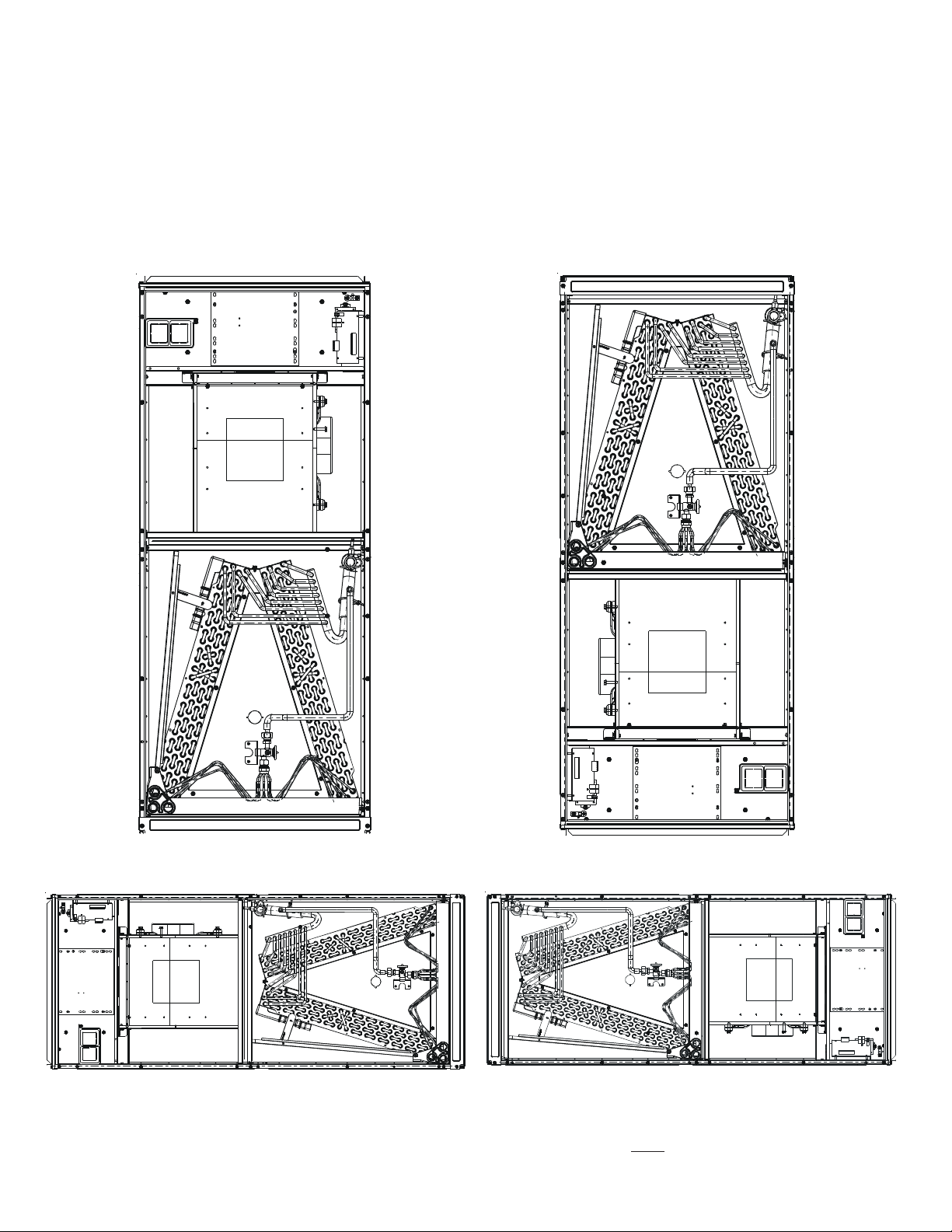

Refer to Figure 6 and 7 for the location of the components

MODEL LIST FOR DOWNFLOW KITS

DFK-B

Downflo w Kit

AVPTC24B14** AVPTC30C14** AVPTC42D14**

DFK-C

Downf l o w Ki t

AVPTC36C14** AVPTC48D14**

AVPTC48C14** AVPTC60D14**

DFK-D

Downflo w Kit

DOWNFLOW KIT

Table 2

referenced in the following steps.

1. Before inverting the air handler, remove blower access panel and coil access panel. The coil access panel and tubing

panel may remain screwed together during this procedure. Remove and retain the seven (7) screws securing the coil

access panel to the cabinet and the six (6) screws securing the blower access panel to the cabinet.

2. Slide the coil assembly out using the drain pan to pull the assembly from the cabinet.

NOTE: DO NOT USE MANIFOLDS OR FLOWRATOR TO PULL THE COIL ASSEMBLY OUT. FAILURE TO DO SO

MAY RESULT IN BRAZE JOINT DAMAGE AND LEAKS.

4

3. Removal of the center support is required on units with 21" wide cabinet. Remove and retain the two (2) screws that

secure the center support to the cabinet. Remove the center support.

4. Using the drain pan to hold the coil assembly, slide the coil assembly back into the cabinet on the downflow brackets as

shown in Figure 8.

5. Re-install the center support (if removed) using the two (2) screws removed in Step 4.

6. Re-install the access panels removed in Step 1 as shown in Figure 9.

7. The bottom left drain connection is the primary drain for this application and condensate drain line must be attached to

this drain connection. The top connection of the three drain connections on the drain pan must remain plugged for this

application. The bottom left drain connection is for the secondary drain line (if used).

UPFLOW

Figure 2

HORIZONTAL LEFT

Figure 4

DOWNFLOW

Figure 3

HORIZONTAL RIGHT

Figure 5

NOTE: If removing only the coil access panel from the unit, the filter access panel must be removed first. Failure to do so

may result in panel damage.

5

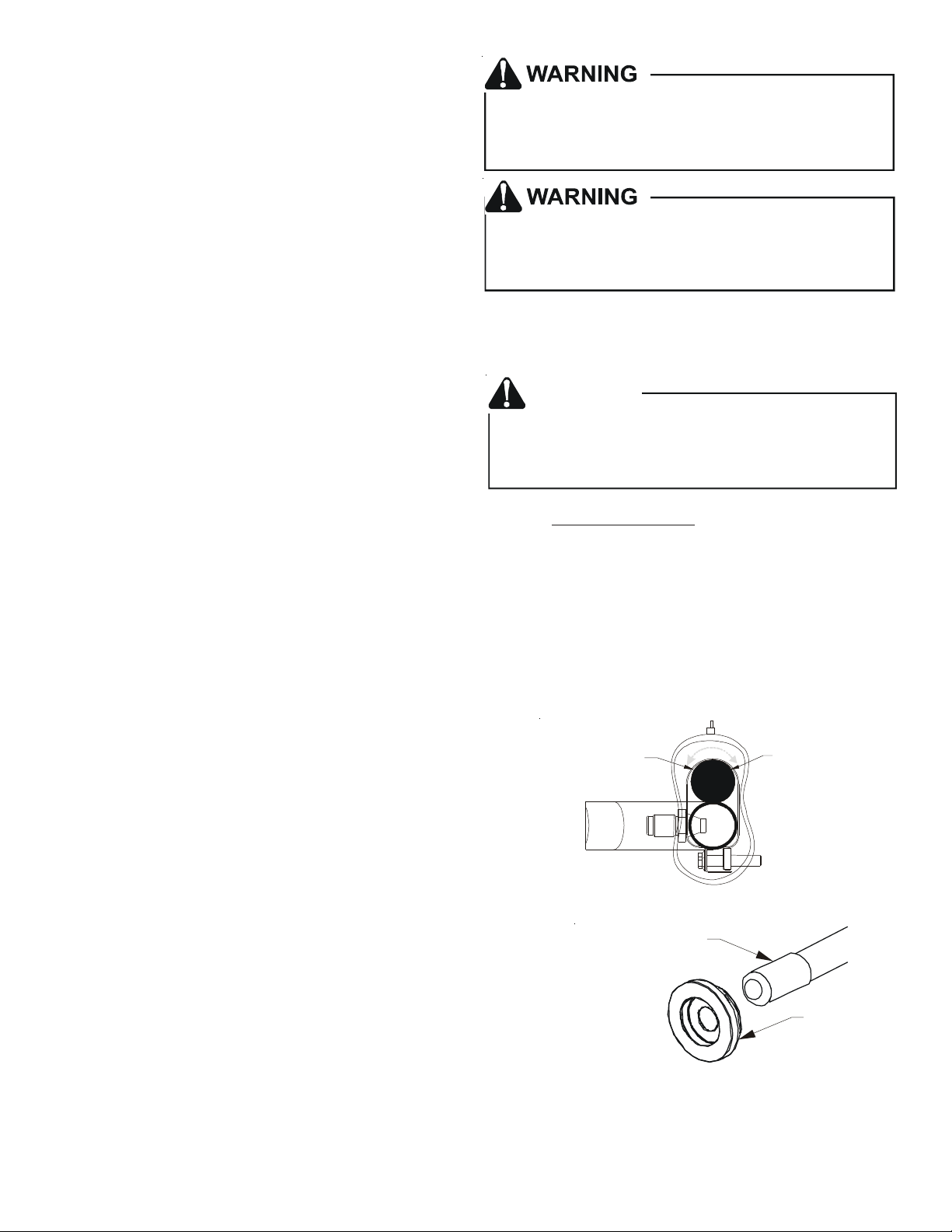

Upper Tie Plate

Control

Deck

Downflow

Bracket

Center

Support

Filter

Bracket

Filter Acces s

Panel

INTERNAL PART TERMINOLOGY

Figure 6

Blower

Access

Panel

Coil

Access

Panel

Secondary

Drain Port

for Horizontal

Application

Thumb

Screw

Secondary Dra in Port

for Upflow/Downflow

Application

EXTERNAL PART TERMINOLOGY

Figure 7

Tubing

Panel

IMPORTANT NOTE:

Ensure coil slides o n the rails

along the groove provided

on the drain pan side walls.

Failure to do so will resu lt

in improper condensate drainage.

COIL INSTALLATION FOR DOWNFLOW

Figure 8

Coil Slides

on the

downflow bracket

ACCESS PANEL

CONFIGURATION FOR

DOWNFLOW OR

HORIZONTAL RIGHT

Figure 9

6

7 Refrigerant Lines

NOTE: Refrigerant tubing must be routed to allow adequate

access for servicing and maintenance of the unit.

Do not install the air handler in a location that violates the

instructions provided with the condenser. If the unit is located

in an unconditioned area with high ambient temperature and/

or high humidity, the air handler may be subject to nuisance

sweating of the casing. On these installations, a wrap of 2"

fiberglass insulation with a vapor barrier is recommended.

7.1 Tubing Size

For the correct tubing size, follow the specification for

the condenser/heat pump.

7.2 Tubing Preparation

All cut ends are to be round, burr free, and clean. Failure to follow this practice increases the chances for refrigerant

leaks. The suction line is spun closed and requires tubing cutters to remove the closed end.

NOTE: To prevent possible damage to the tubing joints,

do not handle coil assembly with manifold or flowrator

tubes. Always use clean gloves when handling coil assemblies.

NOTE: The use of a heat shield is strongly recommended

when brazing to avoid burning the serial plate or the finish of the unit.

sensitive components such as service valves and TXV valves sensing bulb.

This product is factory-shipped with R410A and dry

nitrogen mixture gas under pressure. Use appropriate

service tools and follow these instructions to prevent

injury .

A quenching cloth is strongly recommended to prevent

scorching or marring of the equipment finish when

brazin g close to the painted surfaces. Use brazing

alloy of 5% minimum silver content.

CAUTION

Applying too muc h heat to any tube can melt the tube. T orc h

heat required to braze tubes of various sizes must be

proportiona l to th e size of th e tube. S er vice p er sonn el m u st

use the appropriate he at level for the size of the tube being

brazed.

Heat trap or wet rags must be used to protect heat

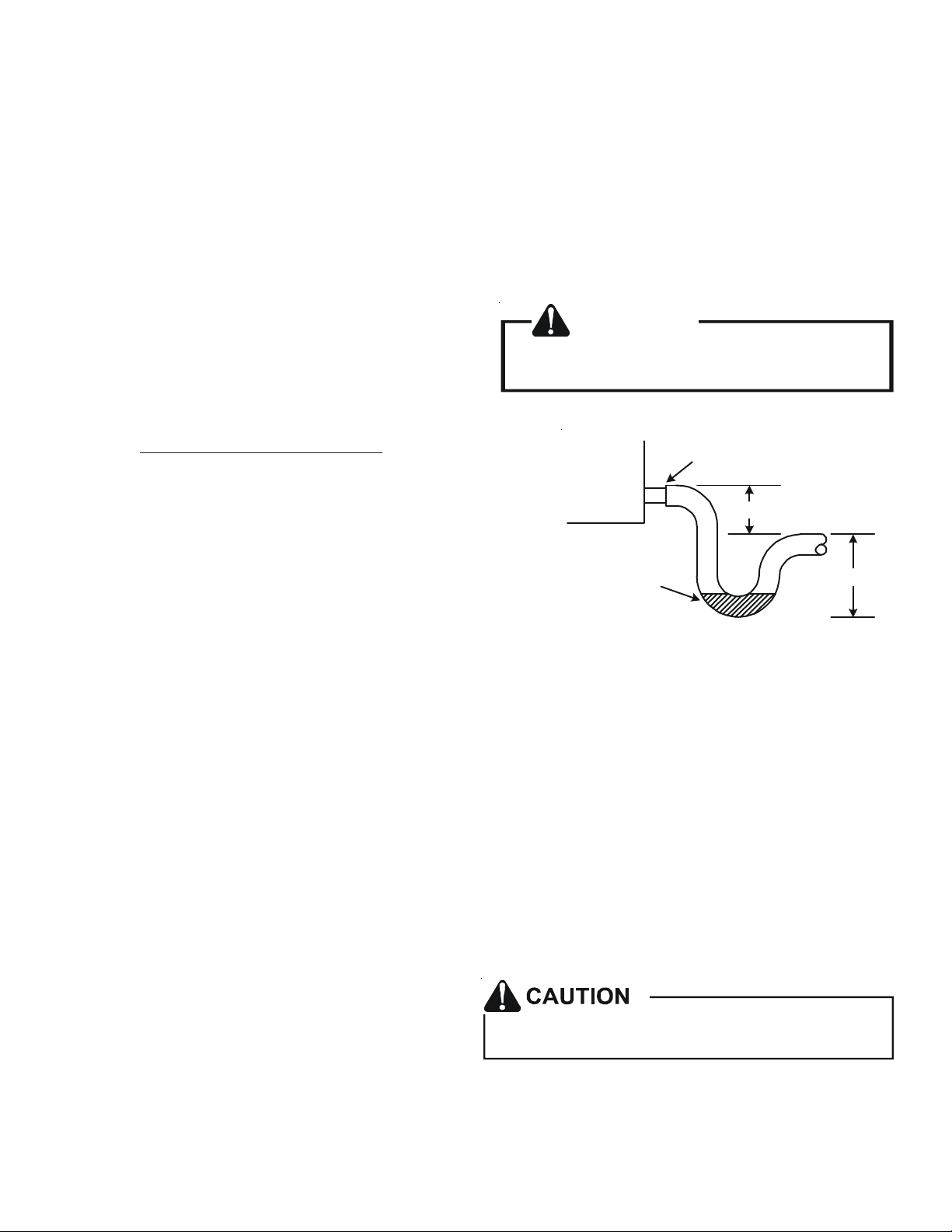

7.3 Tubing Connections for TXV Models

TXV models come with factory installed TXV with the bulb pre-installed on the vapor tube.

1. Remove refrigerant tubing panel or coil (lower) access panel.

2. Remove access valve fitting cap and depress the valve stem in access fitting to release pressure. No pressure indicates possible leak.

3. Replace the refrigerant tubing panel.

4. Remove the spin closure on both the liquid and suction tubes

using a tubing cutter.

REFRIGERANT BULB

MUST BE POSITIONED

BETWEEN 10 & 2 O’CLOCK

REFRIGERANT BULB

MUST BE POSITIONED

BETWEEN 10 & 2 O’CLOCK

5. Insert liquid line set into liquid tube expansion and slide grommet about 18" away from braze joint.

6. Insert suction line set into suction tube expansion and slide insulation and grommet about 18" away from braze joint.

7. Braze joints. Quench all brazed joints with water or a wet rag

upon completion of brazing.

NOTE: The sensing bulb must be permanently located. A heat shield,

heat trap, or wet rag must be used during brazing to prevent damage to

SUCTION LINE

WITH SPIN CLOSURE

Figure 10

the TXV valve.

8. Replace access panels, suction line grommet, insulation and all

screws.

RUBBER

GROMMET

8 Condensate Drain Lines

The coil drain pan has a primary and a secondary drain with 3/4" NPT

female connections. The connectors required are 3/4" NPT male, either

Suction Line Grommet

Figure 11

PVC or metal pipe, and should be hand tightened to a torque of no more than 37 in-lbs. to prevent damage to the drain pan

connection. An insertion depth of approximately 3/8” to 1/2” (3-5 turns) should be expected at this torque.

7

1. Ensure drain pan hole is not obstructed.

2. To prevent potential sweating and dripping on to finished space, it may be necessary to insulate the condensate drain

line located inside the building. Use Armaflex® or similar material.

A secondary condensate drain connection has been provided for areas where the building codes require it. Pitch all drain

lines a minimum of 1/4" per foot to provide free drainage. Provide required support to the drain line to prevent bowing. If the

secondary drain line is required, run the line separately from the primary drain and end it where condensate discharge can

be easily seen.

NOTE: Water coming from secondary line means the coil primary drain is plugged and needs immediate attention.

Insulate drain lines located inside the building or above a finished living space to prevent sweating. Install a condensate trap

to ensure proper drainage.

NOTE: When units are installed above ceilings, or in other locations where damage from condensate overflow may occur,

it is MANDATORY to install a field fabricated auxiliary drain pan

under the coil cabinet enclosure.

The installation must include a “P” style trap that is located as

close as is practical to the evaporator coil. See Figure 12 for

If secondary drain is not installed, the secondary

access must be plugged.

CAUTION

details of a typical condensate line “P” trap.

NOTE: Trapped lines are required by many local codes. In the

absence of any prevailing local codes, please refer to the requirements

listed in the Uniform Mechanical Building Code.

Drain

Connection

A drain trap in a draw-through application prevents air from being drawn

back through the drain line during fan operation thus preventing condensate from draining, and if connected to a sewer line to prevent sewer

Air Handler

2" MIN.

gases from being drawn into the airstream during blower operation.

Field experience has shown condensate drain traps with an open verti-

cal Tee between the air handler and the condensate drain trap can improve condensate drainage in some applications, but may cause exces-

POSITIVE LIQUID

SEAL REQUIRED

AT TRAP

3" MIN.

sive air discharge out of the open Tee. Goodman® does not prohibit this

type of drain but we also do not recommend it due to the resulting air

leakage. Regardless of the condensate drain design used, it is the

Figure 12

installer’s responsibility to ensure the condensate drain system is of sufficient design to ensure proper condensate removal from the coil drain pan.

Use of a condensate removal pump is permitted when necessary. This condensate pump should have provisions for shutting off the control voltage should a blocked drain occur. A trap must be installed between the unit and the condensate pump.

IMPORTANT NOTE: The evaporator coil is fabricated with oils that may dissolve styrofoam and certain types of plastics.

Therefore, a removal pump or float switch must not contain any of these materials.

Tip: Priming the “P” trap may avoid improper draining at the initial installation and at the beginning of the cooling season.

9 Ductwork

This air handler is designed for a complete supply and return ductwork system.

To ensure correct system performance, the ductwork is to be sized to accommodate 350-450 CFM per ton of cooling with

the static pressure not to exceed 0.5" in w.c. Refer to ACCA Manual D, Manual S and Manual RS for information on duct

sizing and application. Flame retardant ductwork is to be used and sealed to the unit in a manner that will prevent leakage.

NOTE: A downflow application with electric heat must have an L-shaped sheet metal supply duct without any outlets or

registers located directly below the heater.

9.1 Return Ductwork

DO NOT LOCATE THE RETURN DUCTWORK IN AN

AREA THAT CAN INTRODUCE TOXIC, OR OBJECTIONABLE FUMES/ODORS INTO THE DUCTWORK.

The return ductwork is to be connected to the air han-

Do not operate this product without all the ductwork

attached.

dler bottom (upflow configuration).

10 Return Air Filters

Each installation must include a return air filter. This filtering may be performed at the air handler using the factory filter rails

or externally such as a return air filter grille. When using the factory filter rails, a nominal 16x20x1”, 20x20x1” or 24x20x1”

(actual dimension must be less than 23-½”x20”) filter can be installed on a B, C and D cabinet respectively (the cabinet size

is the seventh letter of the model number).

8

11 Electric Heat

Refer to the installation manual provided with the electric heat kit for the correct installation procedure. All electric heat must

be field installed. If installing this option, the ONLY heat kits that are permitted to be used are the HKS series. Refer to the

air handler unit’s Serial and Rating plate or the HKS specification sheets to determine the heat kits compatible with a given

air handler. No other accessory heat kit besides the HKS series may be installed in these air handlers.

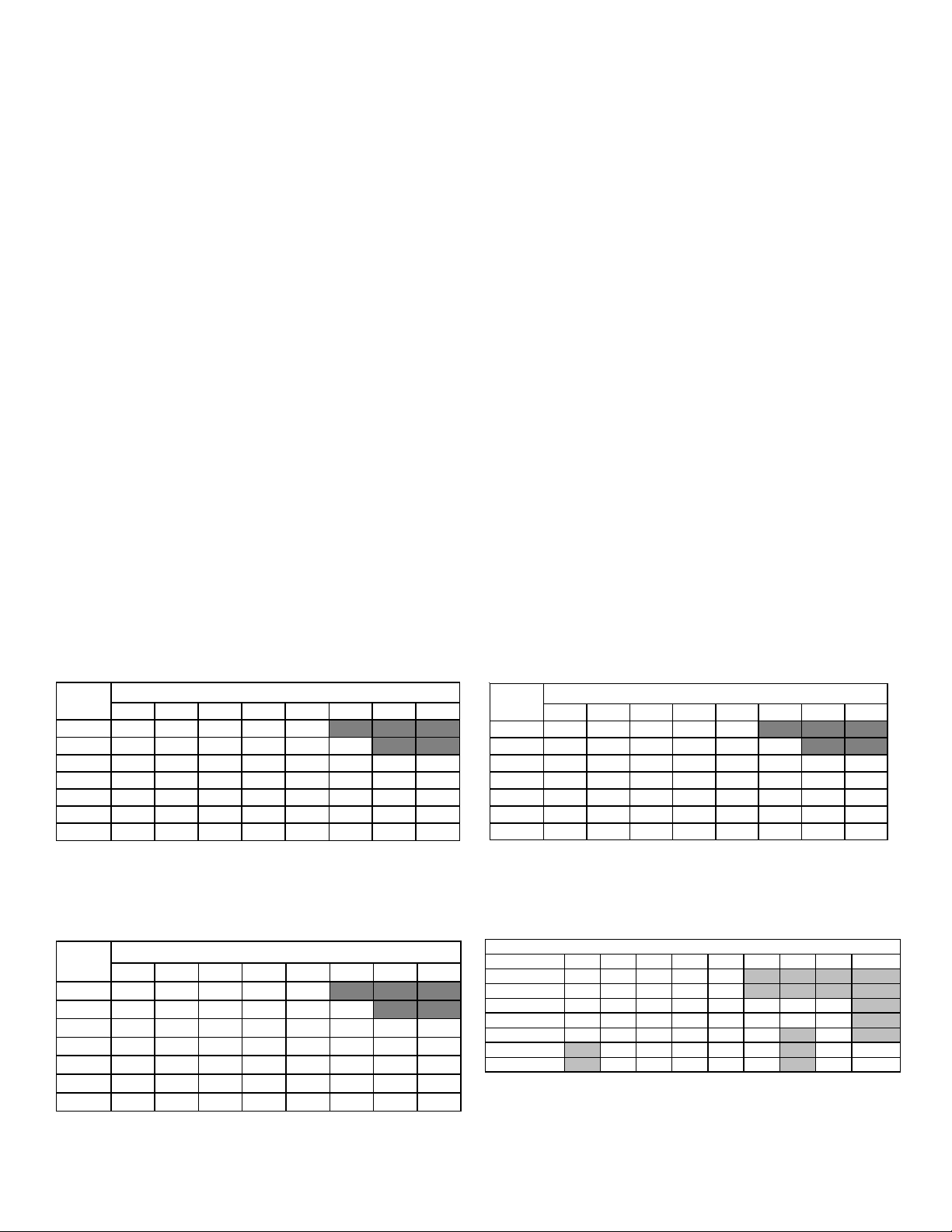

The heating mode temperature rise is dependent upon the system airflow, the supply voltage, and the heat kit size (kW)

selected. Use data provided in Tables 3, 4 and 5 to determine the temperature rise (°F).

NOTE: For installations not indicated above the following formula is to be used:

TR = (kW x 3412) x (Voltage Correction) / (1.08 x CFM)

Where: TR = Temperature Rise

kW = Heater Kit Actual kW

3412 = Btu per kW

VC* = .96 (230 Supply Volts)

= .92 (220 Supply Volts)

= .87 (208 Supply Volts)

1.08 = Constant

CFM = Measured Airflow

VC* (Voltage Correction)

NOTE: The Temperature Rise Tables can also be used to estimate the air handler airflow delivery. When using these tables

for this purpose set the room thermostat to maximum heat and allow the system to reach steady state conditions. Insert two

thermometers, one in the return air and one in the supply air. The temperature rise is the supply air temperature minus the

return air temperature. Using the temperature rise calculated, CFM can be estimated from the TR formula above. See

Technical Manual and/or Service Manual for more information.

CFM

8001219233137

1000 9 1519253044

1200 8 12152125374962

1400 7 11131821324253

1600 6 9 12 15 19 28 37 46

1800 5 8 10 14 16 25 33 41

2000 5 7 9 12 15 22 30 37

3 5 6 8 10 15 19/20 25

HEAT KIT NOMINAL kW

230/1/60 SUPPLY VOLTAGE - TEMP. RISE °F

Table 3

CF M

3 5 6 8 10 15 19/20 25

8001017212833

10008 1317222740

12007 11141922334556

14006 10121619293848

1600 5 8 10 14 17 25 33 42

18005 7 9 1215223037

20004 7 8 1113202733

HEAT KIT NOMINAL kW

208/1/60 SUPPLY VOLTAGE - TEMP. RISE °F

Table 5

CFM

8001118223035

1000 9 14 18 24 28 42

1200 7 12 15 20 24 35 47 5 9

1400 6 10 13 17 20 30 40 5 1

1600 6 9 11 15 18 27 35 44

1800 5 8 10 13 16 24 31 39

2000 4 7 9 12 14 21 28 35

3 5 6 8 10 15 19/20 25

HEAT KIT NOMINAL kW

220/1/60 SUPPLY VOLTAGE - TEMP. RISE °F

Table 4

Heater Kit (Kw)

AVPTC24B14

AVPTC30B14

AVPTC36C14

AVPTC48C14

AVPTC42D14

AVPTC48D14

AVPTC60D14

Please refer to page 16 for specific heater kit application guidelines.

3 5 6 8 1 0 15 19 20 21 or 25

550 650 700 800 850 NR NR NR NR

600 700 750 875 950 NR NR NR NR

NR 850 900 1000 1200 1440 1500 1500 NR

NR 850 900 1000 1200 1440 1500 1500 NR

†

850** 1250 1300 1500 1550 1720 NR 1800 NR

††

NR 1250 1300 1500 1550 1720 NR 1815 1850

†††

NR 1250 1300 1500 1550 1780 NR 1850 1850

MINIMUM CFM REQUIRED FOR HEATER KITS

Table 6

9

12 Electrical and Control Wiring

IMPORTANT: All routing of electrical wiring must be made through provided electrical knockouts. Do not cut, puncture or

alter the cabinet for electrical wiring.

12.1 Building Electrical Service Inspection

This unit is designed for single-phase electrical

supply only. DO NOT OPERATE ON A THREEPHASE POWER SUPPLY. Measure the power

supply to the unit. The supply voltage must be

measured and be in agreement with the unit

nameplate power requirements and within the

range shown.

12.2 Wire Sizing

Wire size is important to the operation of your equipment. Use the following check list when selecting the

appropriate wire size for your unit.

• Wire used must carry the Minimum Circuit Ampac-

ity (MCA) listed on the unit’s Series and Rating

Plate.

Nominal Input Minimum Voltage Maximum Voltage

208-240 197 253

ELECTRICAL VOLTAGE

Table 7

FIRE HAZARD!

To avoid the risk of property damage, personal injury

or fire, use only copper conductors.

• Refer to the NEC (USA) or CSA (Canada) for wire sizing. The unit MCA for the air handler and the optional

electric heat kit can be found on the unit Series and

Rating Plate.

• Wire must be sized to allow no more than a 2%

voltage drop from the building breaker/fuse panel

to the unit.

• Wires with different insulation temperature rating have

varying ampacities - be sure to check the temperature

rating used.

Refer to the latest edition of the National Electric Code

or in Canada the Canadian Electric Code when determining the correct wire size.

12.3 Maximum Overcurrent Protection (MOP)

Every installation must include an NEC (USA) or CEC

(Canada) approved overcurrent protection device.

Also, check with local or state codes for any special

regional requirements.

Protection can be in the form of fusing or HACR style

circuit breakers. The Series and Rating Plate provides

the maximum overcurrent device permissible.

NOTE: Fuses or circuit breakers are to be sized larger than the

equipment MCA but not to exceed the MOP.

HIGH VOLTAGE!

Disconnect ALL power before servicing.

Multiple power sources may be present.

Failure to do so may cause property damage,

personal injury or death.

HIGH VOLTAGE!

T o avoid prope rty dama ge , persona l injury or death

due to el ect rical shock, this unit MUST have an

uninterrupted, unbroken

electrical ground circuit may consist of an

appro pri at ely sized electrical wire connecting the

ground lug in the unit control box to the building

electrica l s ervice panel.

Other methods of grounding are p ermitted if pe rformed

in ac co rda n ce w ith th e N a tio na l E le ctr ic C ode

(NEC) /Americ an Nation al Standar ds Institu te

(ANSI)/National Fire Protection Assoc iation (NFPA ) 70

and local/state codes. In Canada, electrical gro unding

is to be in ac co rda nce w ith t he Cana dian E lectric C ode

(CSA) C22.1.

electrical ground. The

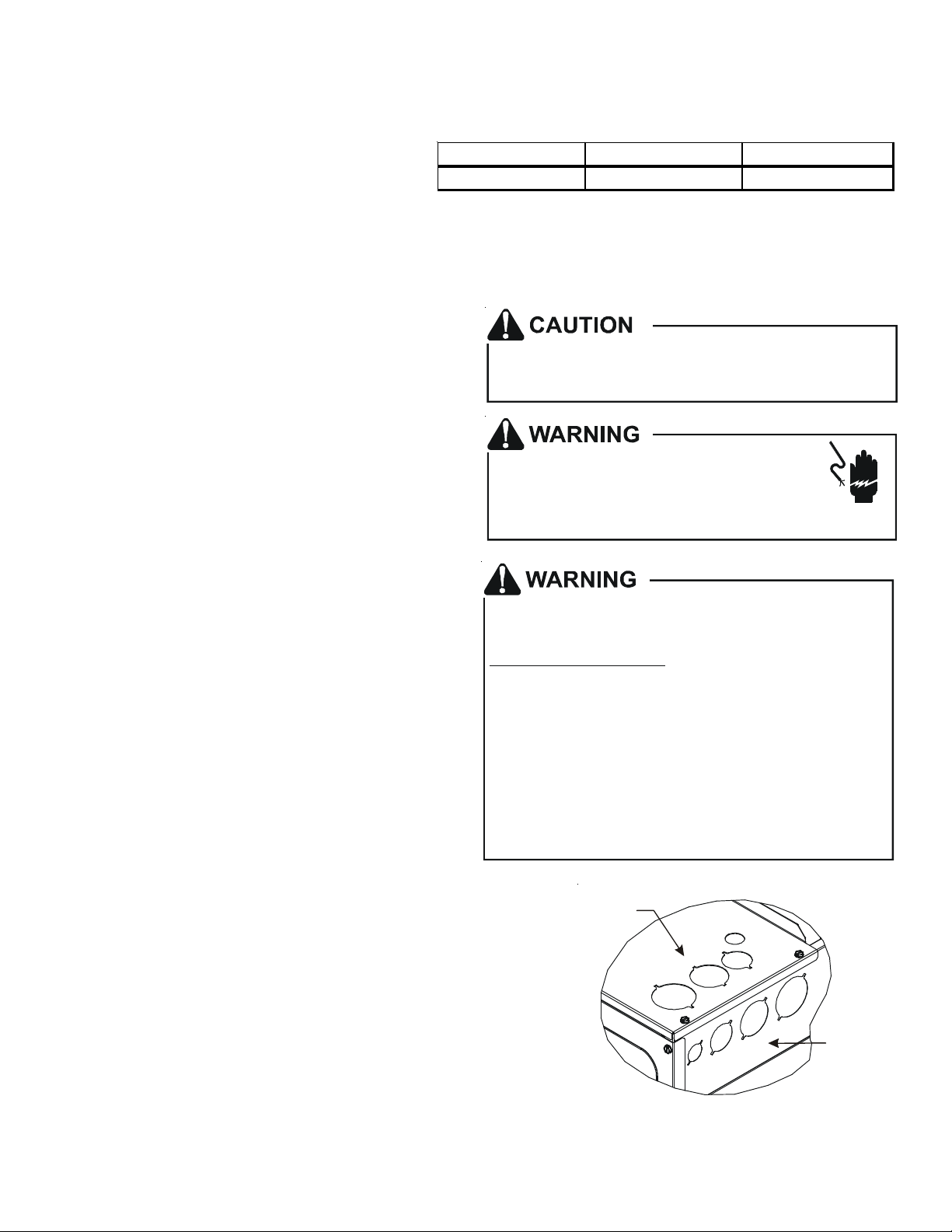

Top of

Cabinet

12.4 Electrical Connections – Supply Voltage

IMPORTANT NOTE: USE COPPER CONDUCTORS ONLY.

Knockouts are provided on the air handler top panel and sides of

the cabinet to allow for the entry of the supply voltage conductors,

as shown in Figure 13. If the knockouts on the cabinet sides are

used for electrical conduit, an adapter ring must be used in order

to meet UL1995 safety requirements. An NEC or CEC approved

strain relief is to be used at this entry point. Some codes/municipalities require the supply wire to be enclosed in conduit. Consult

your local codes.

Side of

Cabinet

KNOCK-OUT FOR ELECTRICAL

CONNECTIONS

Figure 13

10

Loading...

Loading...