Goldstar WG1205R, WG1005R, WG8005R, BG8000ER Service Manual

R OOM AIR CONDITIONER

SERVICE MANUAL

CAUTION

• BEFORE SERVICING THE UNIT, READ THE SAFETY PRECAUTIONS

IN THIS MANUAL.

• ONLY FOR AUTHORIZED SERVICE PERSONNEL.

MODEL: BG8000ER, WG8005R,

WG1005R, WG1205R

website http://www.lgservice.com

2 Room Air Conditioner

Air Conditioner Service Manual

TABLE OF CONTENTS

Safety Precautions..........................................................................................................................................3

Dimensions .....................................................................................................................................................6

Outside Dimensions...................................................................................................................................6

Product Specifications ..................................................................................................................................7

Installation.......................................................................................................................................................8

Select the Best Location ............................................................................................................................8

Installation Check.......................................................................................................................................8

How to Secure the Drain Pipe....................................................................................................................8

How to Install..............................................................................................................................................9

Operation ......................................................................................................................................................13

Location and Function of Controls ...........................................................................................................13

Remote Control Operations ....................................................................................................................14

Disassembly ..................................................................................................................................................15

Mechanical Parts......................................................................................................................................15

Air Handling Parts ...................................................................................................................................16

Electrical Parts .........................................................................................................................................17

Refrigerating Cycle...................................................................................................................................19

Schematic Diagram.......................................................................................................................................22

Wiring Diagram.........................................................................................................................................22

Electronic Control Device.........................................................................................................................24

Components Location(For Main P.W.B ASM)...........................................................................................25

Troubleshooting Guide.................................................................................................................................26

Piping System ........................................................................................................................................26

Troubleshooting Guide .............................................................................................................................27

Exploded View ..............................................................................................................................................35

Replacement Parts List ................................................................................................................................36

Safety Precautions

CAUTION

Safety Precautions

To prevent injury to the user or other people and property damage, the following instructions

must be followed.

Incorrect operation due to ignoring instructions will cause harm or damage. The seriousness

is classified by the following indications.

WARNING

Meanings of symbols used in this manual are as shown below.

This symbol indicates the possibility of death or serious injury.

This symbol indicates the possibility of injury or damage to property only.

Be sure not to do.

Be sure to follow the instruction.

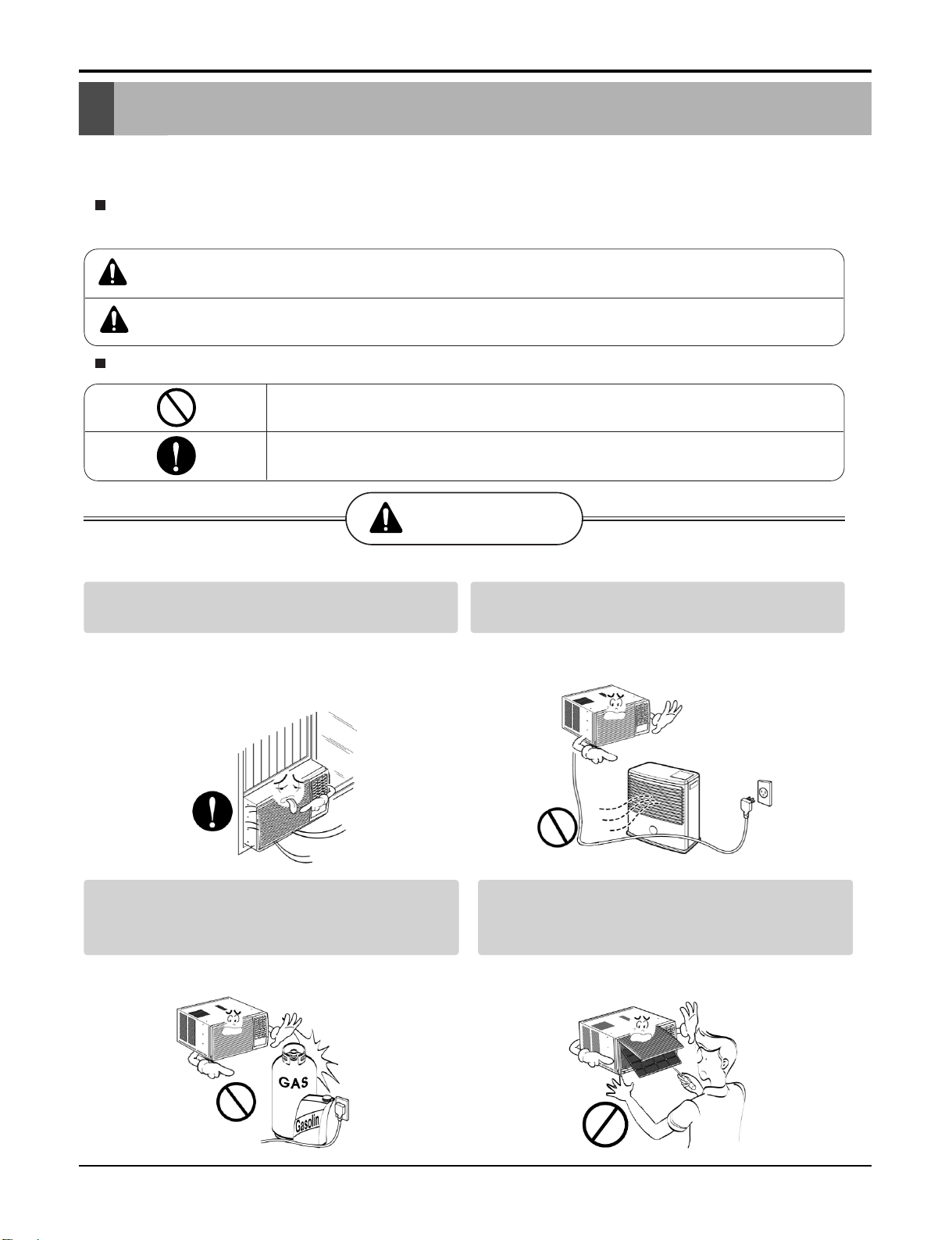

WARNING

Always install the expansion panel(s).

• Improper assembly or installation may cause

incorrect operation, including injury, fire, and

electric shock hazards.

Do not place the power cord near a heater.

• It may cause fire and electric shock.

Do not use the power cord near flammable

gas or combustibles such as gasoline,

benzene, thinner, etc.

• It may cause explosion or fire.

Do not disassemble or modify products.

• It may cause failure and electric shock.

Service Manual 3

Safety Precautions

Plug in the power plug

properly.

• Otherwise, it will cause

electric shock or fire.

Do not modify power corDo not modify poDo not modify po dwer cor

Do not modify po

length.

Do not operate or stop the

unit by inserting or pulling

out the power plug.

• It will cause electric shock or

fire.

Use the air conditioner on a

single outlet circuit.(see page 7.)

Do not share the outlet with

other appliances.

Do not damage or use an

unspecified power cord.

• It will cause electric shock or

fire.

Always plug into a

grounded outlet.

• •• It will cause electr ic shoc• k or

fire.

Ventilate before operating air

conditionerwhen gas goes

out.

It may cause explosion, fire,

and burn.

•

It will cause electric shock or

fire.

Do not use the socket if it is

loose or damaged.

•• It may cause fire and electric

shock.

• No •• grounding • may cause

electric shock.

Do not operate with wet

hands or in damp

environment.

• It will cause electric shock.

4 Room Air Conditioner

Service Manual 5

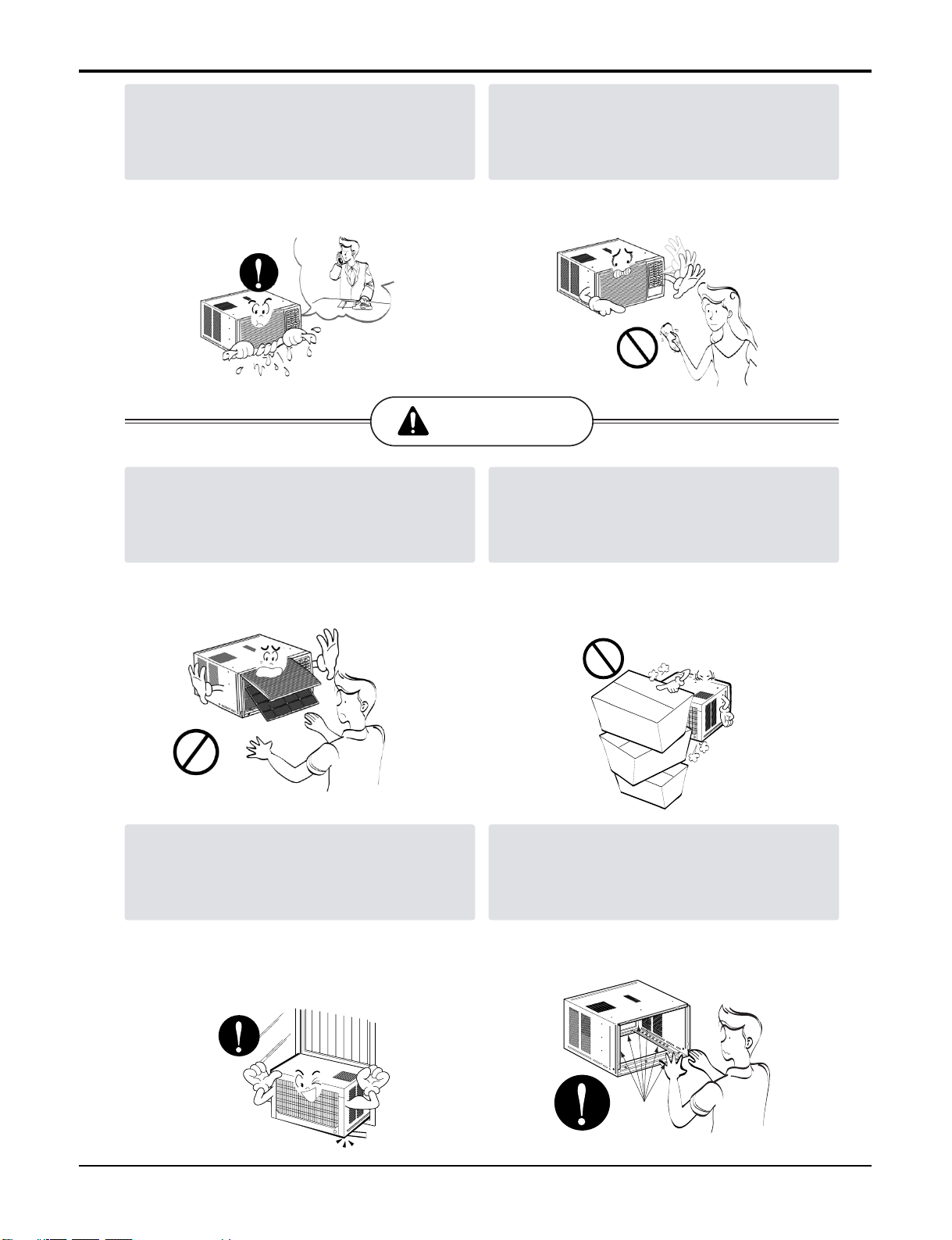

Safety Precautions

If water enters the product, turn off the the

power switch of the main body of appliance.

Contact service center after taking the powerplug out from the socket.

• It will cause electric shock or failure of

machine.

CAUTION

Never touch the metal parts of the unit

when removing the filter.

Do not clean the air conditioner with water.

• Water may enter the unit and degrade the

insulation. It may cause an electric shock.

Do not block the inlet or outlet.

They are sharp and may cause injury.

••

Ensure that the outer caseis not damaged

by age orwear.

Leaving it damaged couldresult in the air

conditioner falling out of the window, creating

a safety hazard.

It may cause failure of appliance or

•

performance deteriorate.

Be cautious not to touch the sharp edges

•

when installing.

It may cause injury.

•

Sharp

edges

6 Room Air Conditioner

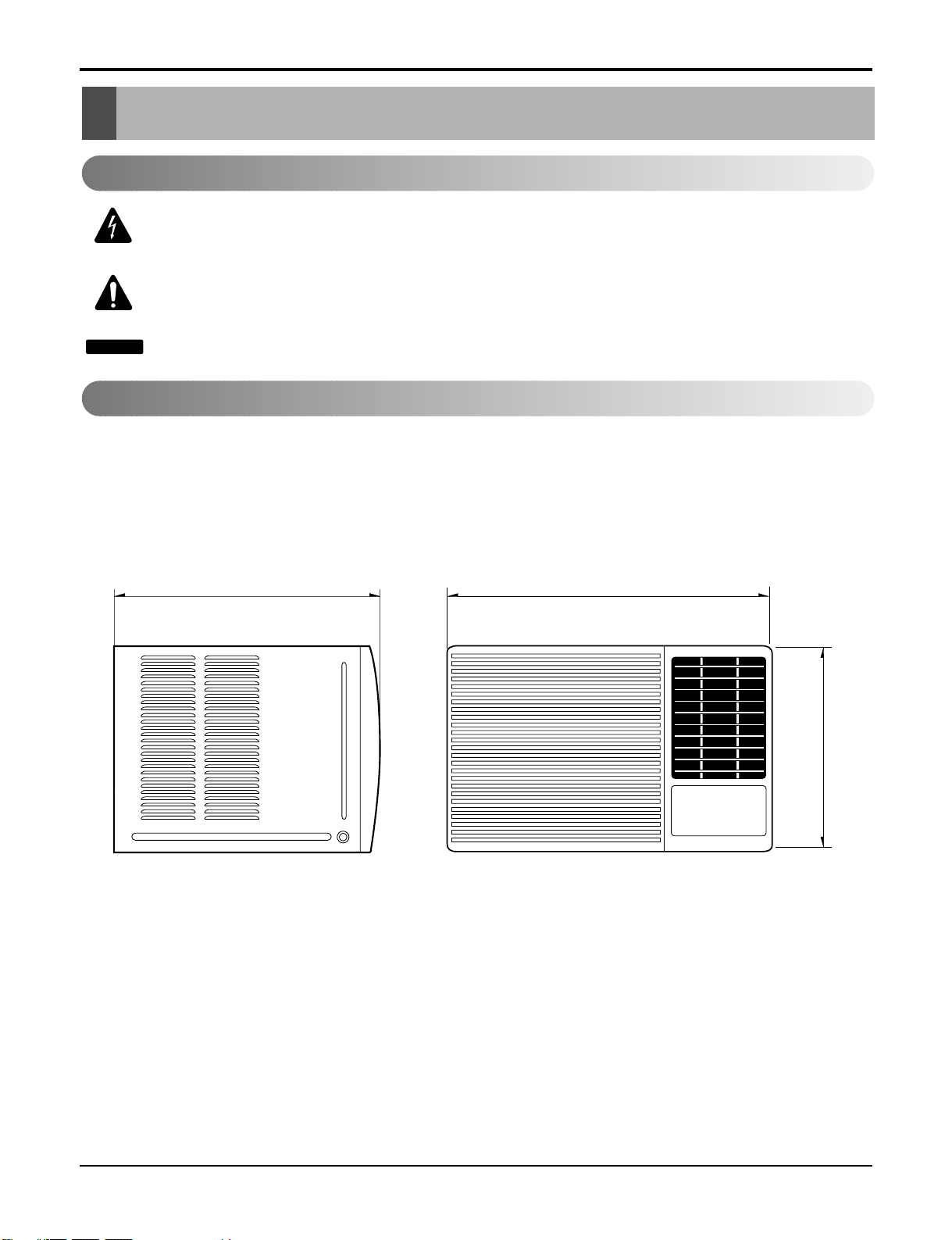

Dimensions

Dimensions

Outside Dimensions

This symbol alerts you to the risk of electric shock.

This symbol alerts you to hazards that could cause harm to the

air conditioner.

This symbol indicates special notes.

NOTICE

Symbols Used in this Manual

470(18 1/2")525(20 11/16")

/8")

7

353(13

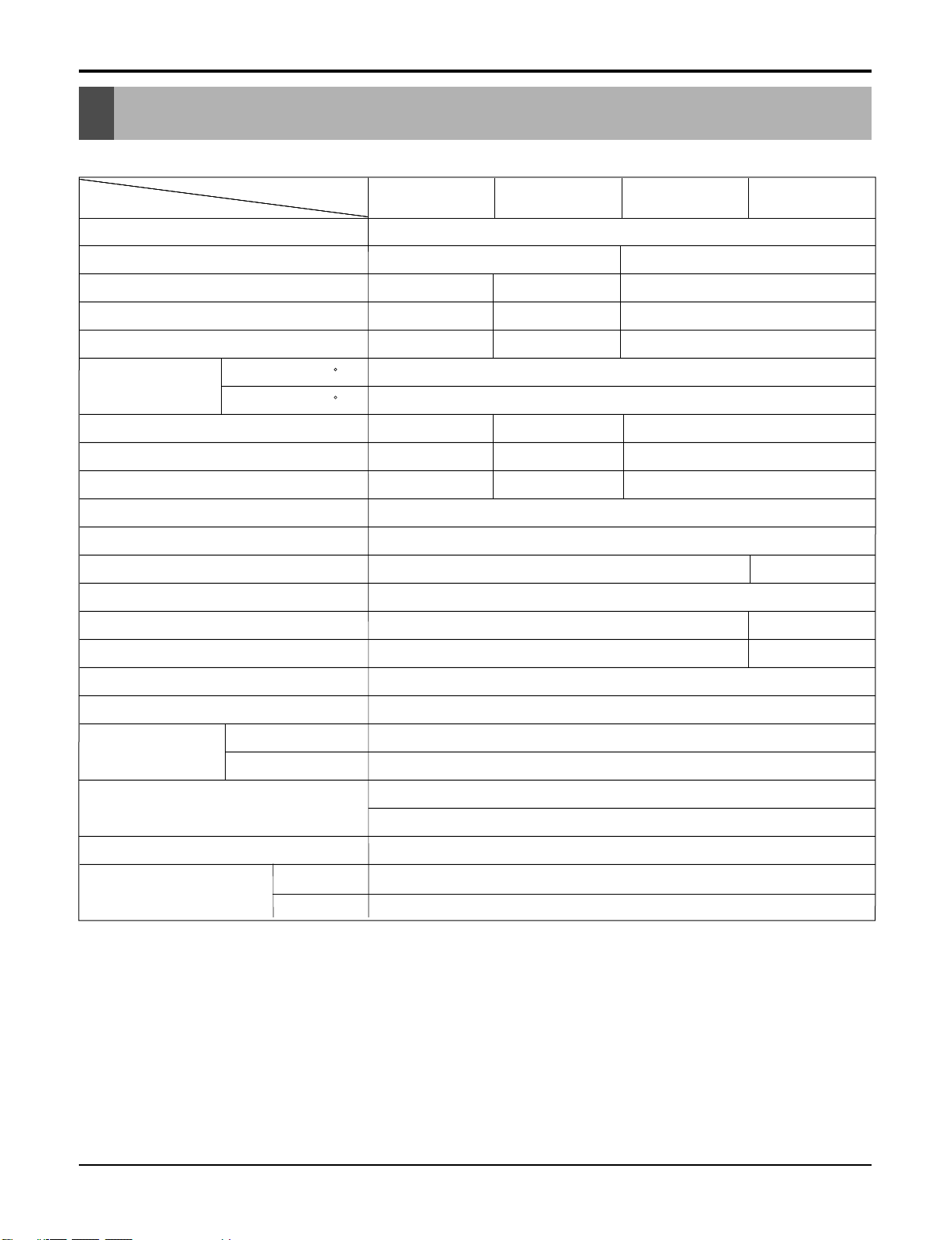

Product Specifications

Product Specifications

Product Specifications

Product Specifications

Specfications

MODELS

ITEMS

POWER SUPPLY

COOLING CAPACITY (Btu/h)

INPUT (W)

RUNNING CURRENT (A)

.

.

E.E.R (BTU/W.h)

OPERATING

CONDITION

REFRIGERANT (R-22) CHARGE

EVAPORATOR

CONDENSER

FAN, INDOOR

FAN, OUTDOOR

FAN SPEEDS, FAN/COOLING

FAN MOTOR

OPERATION CONTROL

INDOOR ( C)

OUTDOOR ( C)

.

C)

BG8000ER WG8005R WG1005R WG1205R

1Ø, 115, 60Hz

8,000 10,000 12,000

740 1020 1220

6.8 9.2 11.0

7.6

10.8 9.8

9.8

385g(13.6oz) 260g(9.2oz) 440g(15.5oz) 380g(13.4oz)

Ø9.52, 2ROW 12STACKS

Ø7.0, 2ROW 16STACKS

.0

.0

.0

PROPELLER TYPE FAN WITH SLINGER RING

820

26.7(DB)* 19.4(WB)**

35(DB)* 23.9(WB)**

Ø7.0, 2ROW 14STACKS

Ø5.0, 2ROW 16STACKS

Ø

TURBO FAN

REMOTE CONTROLLER

Ø

7, 3R 14STACKS .7, 2R 14STACKS

Ø7, 2R 16STACKS 5, 2R 18STACKS

3/3

6 POLES

Ø

Ø

ROOM TEMP. CONTROL

AIR DIRECTION CONTROL

CONSTRUCTION

PROTECTOR

POWER CORD

DRAIN SYSTEM

OUTSIDE DIMENSION

(W x H x D)

H x

* DB:Dry Bulb

**

WB:Wet Bulb

COMPRESSOR

FAN MOTOR

(inch)

(mm)

THERMISTOR

HORIZONTAL LOUVER (UP & DOWN), VERTICAL LOUVER (RIGHT&LEFT)

SLIDE IN-OUT CHASSIS

OVERLOAD PROTECTOR

INTERNAL THERMAL PROTECTOR

3 WIRE WITH GROUNDING

ATTACHMENT PLUG (CORD-CONNECTED TYPE)

DRAIN PIPE OR SPLASHED BY FAN SLINGER

18 1/2 x 13 7/8 x 20 11/16 235/8x1431/32x225/16

469 x 353 x 526 380 x 600 x 555

Service Manual 7

Ser 7

Ser 7

7

8 Room Air Conditioner

Installation

Installation

Select the Best Location

Installation Check

How to Secure the Drain Pipe

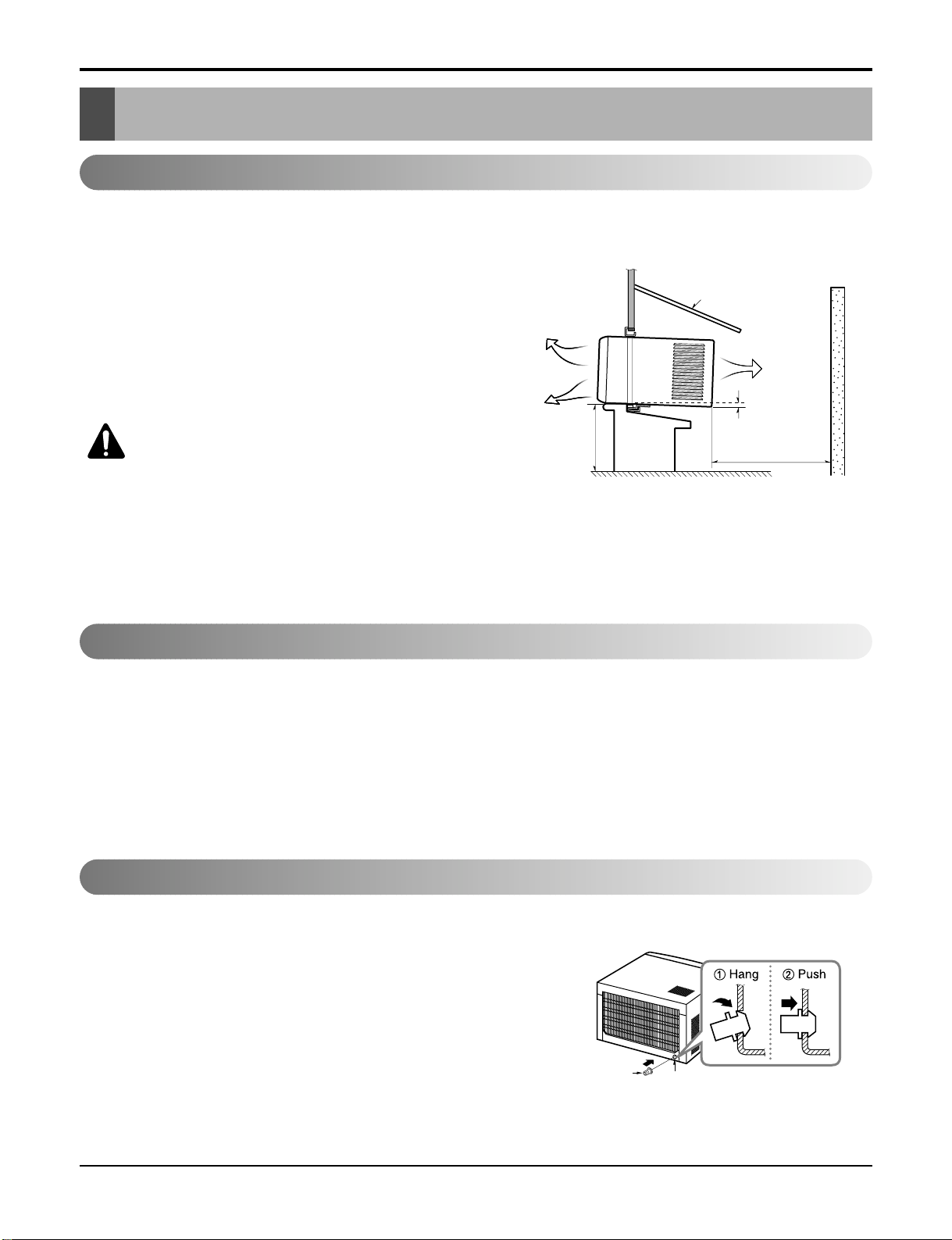

1. To prevent vibration and noise, make sure the unit is installed

securely and firmly.

2. Install the unit where the sun does not shine directly on the

unit.

3. The outside of the cabinet must extend outward for at least

11" and there should be no obstacles, such as a fence or

wall, within 20" from the back of the cabinet because it will

prevent heat radiation of the condenser.

Restriction of outside air will greatly reduce the cooling efficiency of the air conditioner.

CAUTION: All side louvers of the cabinet must

remain exposed on the outdside of the structure.

4. Install the unit slanted slightly so the back is slightly lower

than the front (about 1/

4"). This will force condensed water

to the outside.

5. Install the unit with the bottom about 30"~60" above the

floor level.

The setting conditions must be checked prior to initial starting.

The following items are especially important checking points when the installation is finished.

1. Grounding wire (Green or Green and Yellow) is provided in the power cord. The green wire must be grounded.

2. Connect to a single-outlet 15A circuit.

(or 20A circuit for Electric Heater Model)

3. To avoid vibration or noise, make sure the air conditioner is installed securely.

4 Avoid placing furniture or draperies in front of the air inlet and outlet.

In humid weather, excess water may cause the Base Pan to

overflow. To drain the water, remove the Drain Cap and secure

the Drain Pipe to the rear hole of the Base Pan. (Figure. 2)

ABOUT / "

Over 20"

HEAT

RADIATION

FENCE

AWNING

OUTSIDE

INSIDE

COOLED AIR

30"-60"

1

4

Drain Pipe

Drain Cap

Figure 1

Figure 2

Service Manual 9

Installation

How to Install

Window Requirements

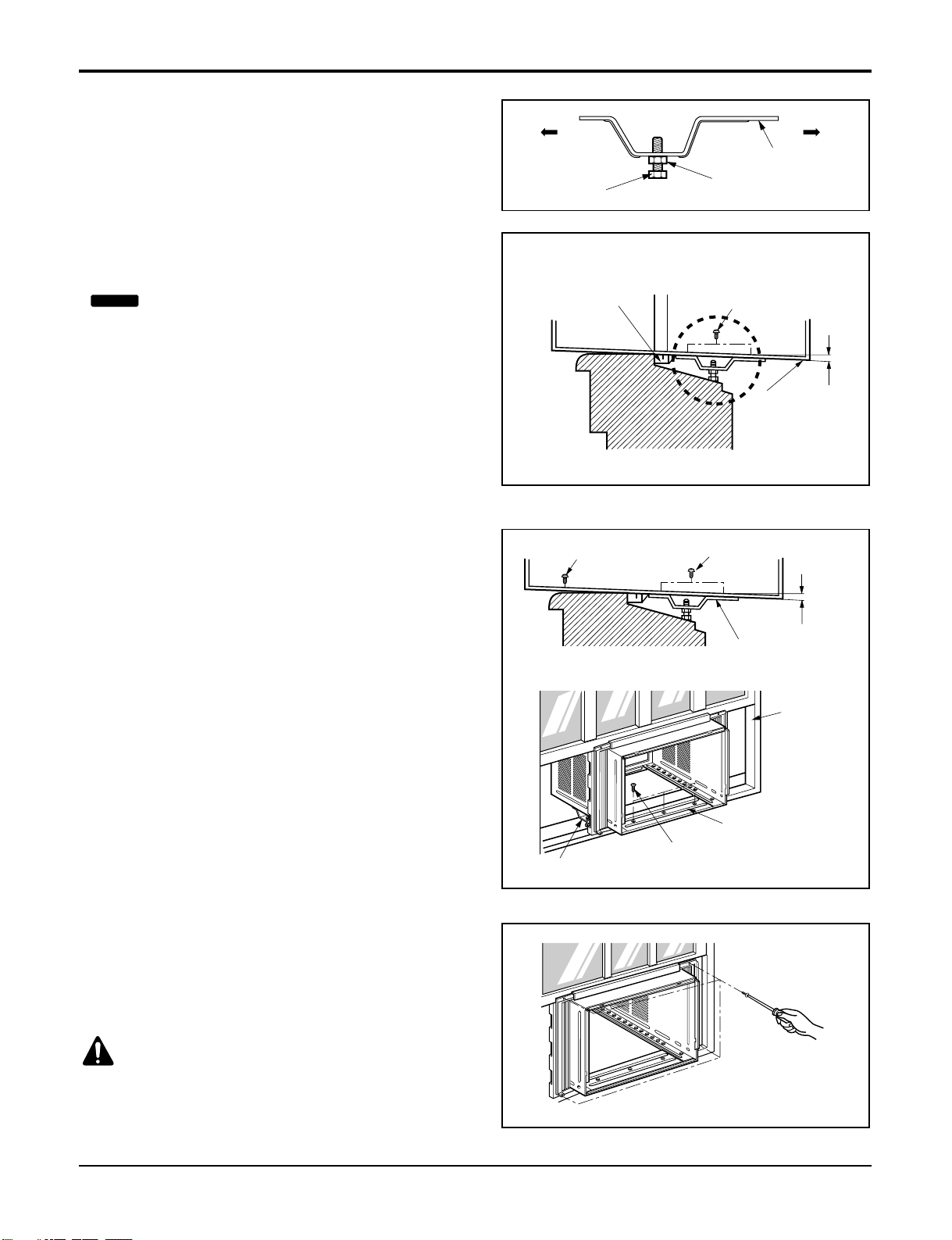

All supporting parts should be secured to

firm wood, masonry, or metal.

1. This unit is designed for installation in standard double

hung windows with actual opening widths of 22" to 36".

The upper and lower sash must open sufficiently to allow

a clear vertical opening of 15" from the bottom of the

sash to the window stool.

2. If storm window presents interference, fasten a 2" wide

wood strip to the inner window sill across the full width of

the sill. The wood strip should be thick enough to raise

the height of the window sill so that the unit can be

installed without interference by the storm window

frame. See Figure. 4. Top of wood strip should be

approximately 3/4" higher than the storm window frame

(STORM WINDOW FRAME) or wood strip (OUTDOORS) to help condensation to drain properly to the

outside.

3.

Install a second wood strip (approximately 6" long by 11/2"

wide and same thickness as first strip) in the center of the

outer sill flush against the back off the inner sill. This will

raise the L bracket as shown Figure. 4.

4. If the distance between STORM WINDOW FRAME and

WOOD STRIP MOUNTED ON TOP OF INNER SILL is

more than 1", two of wood strip are not necessary.

Installation

NOTICE

OUTDOORSINDOORS

INNER

SILL

OUTER

SILL

INNER

SILL

WOOD STRIP MOUNTED

ON TOP OF INNER SILL

WOOD STRIP

FOR

L

BRACKET

3/4"

CLEARANCE

1" MAX.

STORM

WINDOW

FRAME

OUTDOORSINDOORS

OUTER

SILL

Figure 3

Figure 4

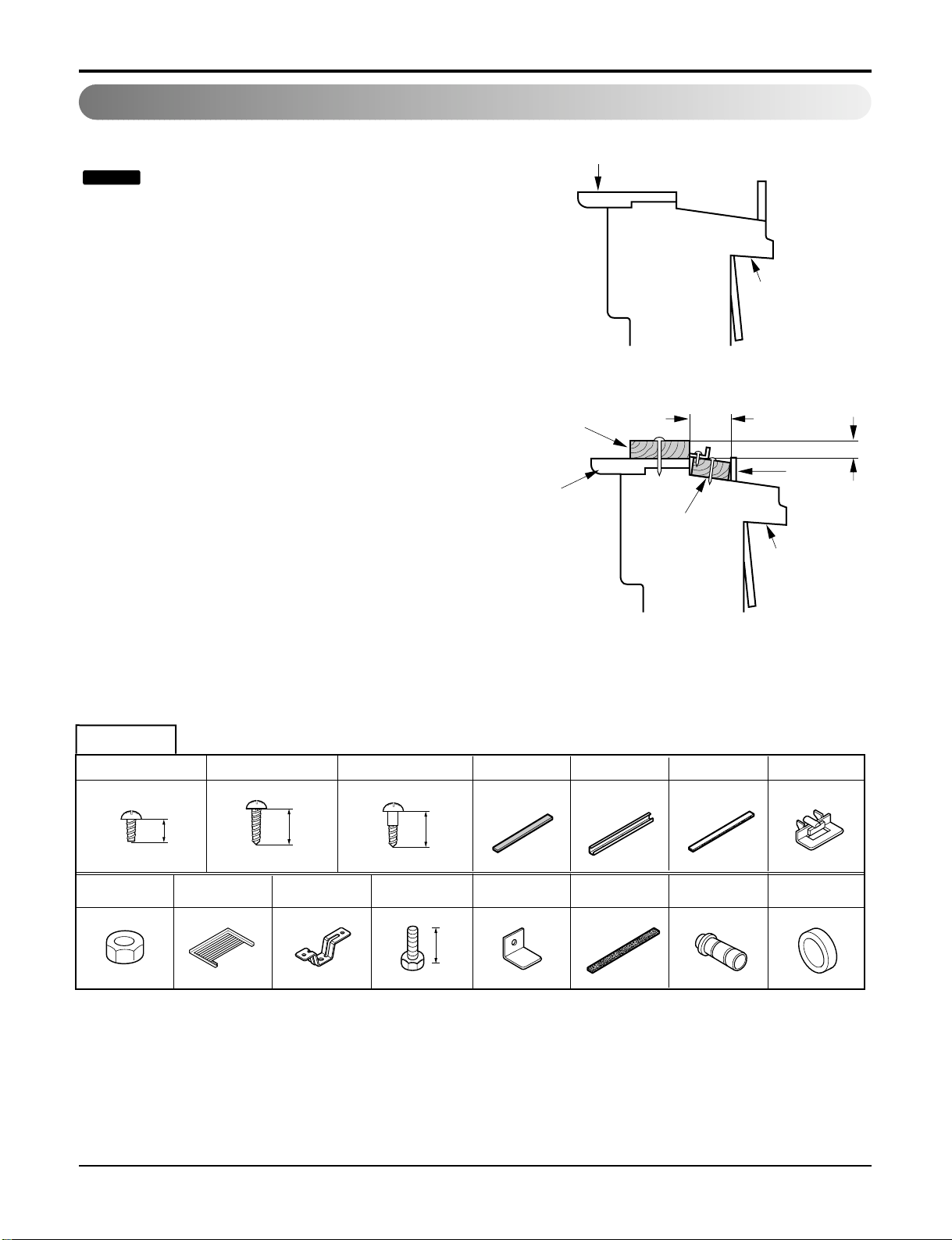

HARDWARE

Type A:16EA

(SCREW)

10mm

Type D:2EA

(NUT)

Type E:2EA

(FRAME CURTAIN)

Type B:3EA

(SCREW)

16mm

Type F:2EA

(SILL SUPPORT)

Type C:5EA

(SCREW)

Type G:2EA

(BOLT)

16mm

10

Type H:1EA

(FOAM-STRIP)

Type L:1EA

(WINDOW LOCKING BRACKET)

Type I:1EA

(UPPER GUIDE)

Type M:1EA

(FOAM-PE)

Type J:1EA

(FOAM-PE)

Type N:1EA

(DRAIN JOINT PIPE)

Type K:2EA

(FRAME-GUIDE)

(DRAIN WASHER)

Type O:1EA

10 Room Air Conditioner

Installation

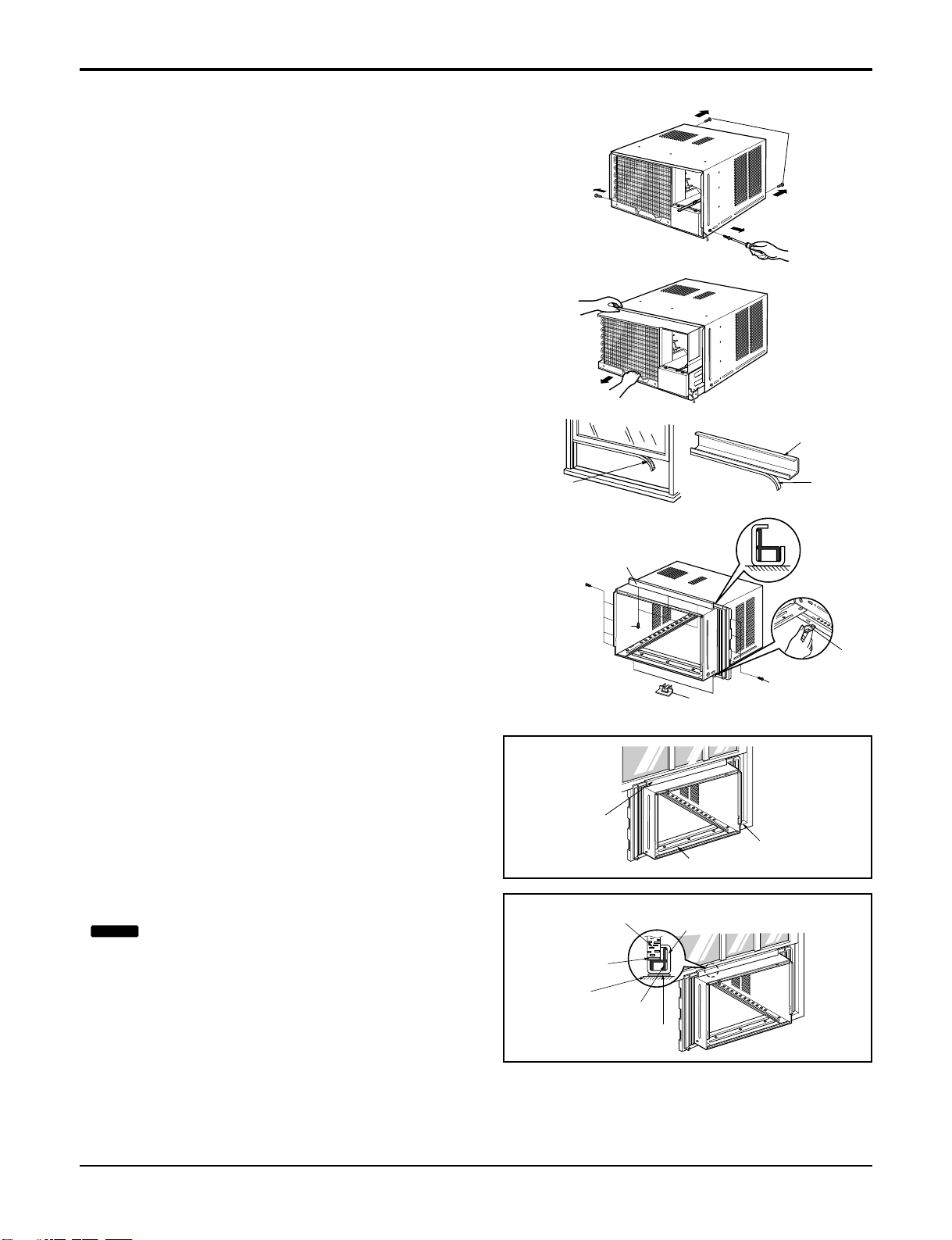

PREPARATION OF CHASSIS

1. Remove the screws which fasten the cabinet at both

sides and at the back.

2. Slide the unit from the cabinet by gripping the base

pan handle and pulling forward while bracing the

cabinet.

3. Cut the window sash seal to the proper length.

Peel off the backing and attach the Foam-Pe

to the

underside of the window sash.

4. Remove the backing from the top Upper Guide FoamPe and attach it to the bottom of the Upper Guide.

5. Attach the Upper Guide onto the top of the cabinet with

3 type A screws.

6. Insert the Frame Guides into the bottom of the cabinet.

7. Insert the Frame Curtain

into the Upper Guide

and Frame Guides .

8. Fasten the curtains to the unit with 4 Type A screws.

CABINET INSTALLATION

1.Open the window. Mark a line on center of the

window stool(or desired air conditioner location).

Carefully place the cabinet on the window stool and

align the center mark on the bottom front with the

center line marked in the window stool.

2. Pull the bottom window sash down behind the Upper

Guide until it meets.

Upper Guide

Upper Guide

Screw

Frame-Guide

(Type A)

Upper Guide

Window Sash

Window stool

Front Angle

Upper guide

Frame Curtain

Foam-pe

Foam-pe

Cabinet

Foam-Pe

Shipping

Screws

Figure 5

Figure 6

Foam-Pe

Frame-Guide

Screw

Screw

(Type A)

(Type A)

NOTICE

Do not pull the window sash down so tightly

that the movement of Frame Curtain is restricted.

Service Manual 11

Installation

INDOOR OUTDOOR

Sill Support

Nut

Bolt

INDOOR OUTDOOR

Frame Guide

About 1/2"

Screw(Type A)

Cabinet

About 1/2"

Screw(Type B) Screw(Type A)

Sill support

Sash track

Front Angle

Type C

Screw(Type B)

Sill support

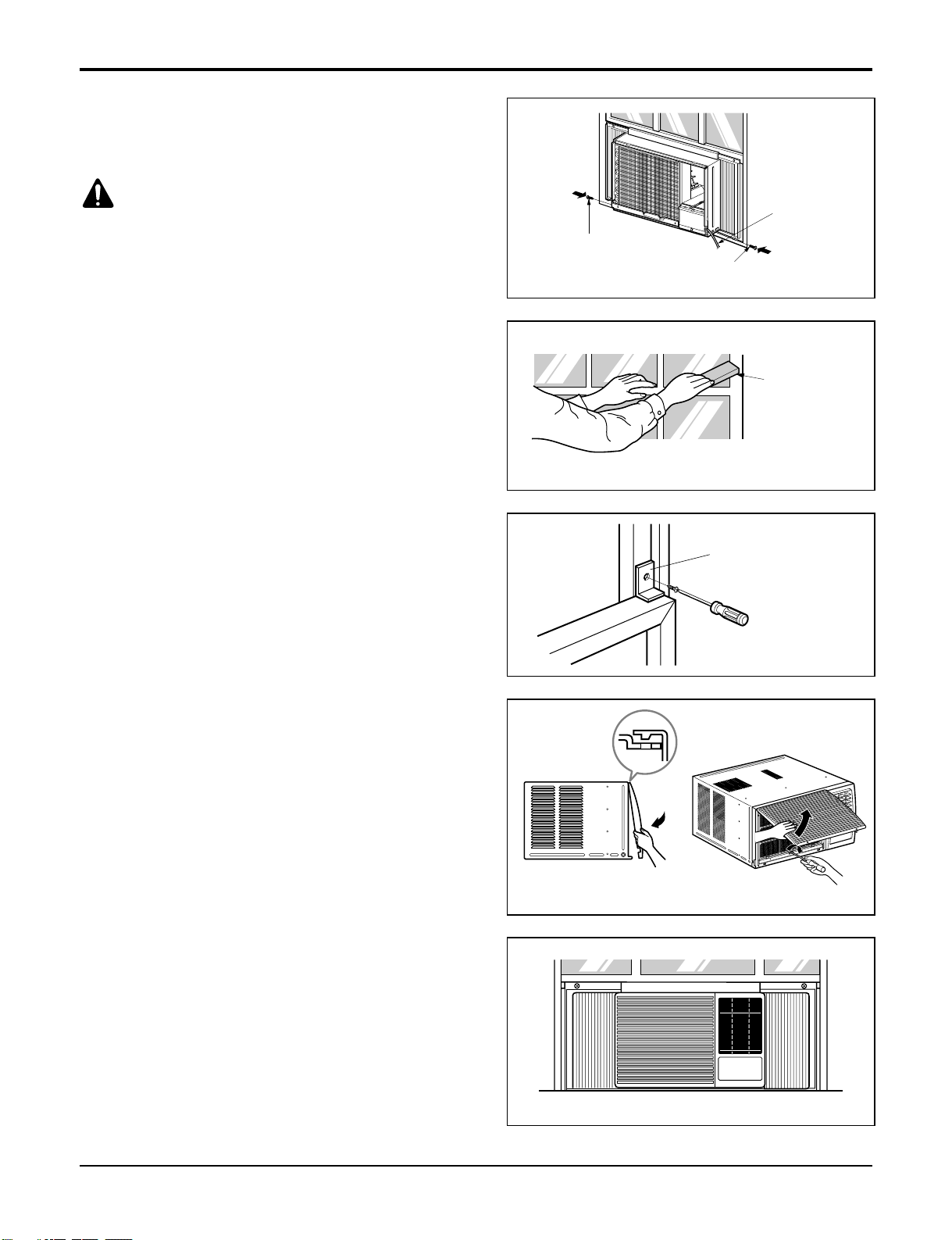

3. Loosely assemble the Sill Support using the parts in

Figure 7.

4. Select the position that will place the Sill Support

near the outer most point on sill (See Figure 8)

5. Attach the Sill Support to the cabinet track hole in

relation to the selected position using 2 Type A

screws in each support(See Figure 8).

6. The cabinet should be installed with a very slight

tilt(about1/2") downward toward the outside (See

Figure 9).

Adjust the bolt and the nut of Sill Support for

balancing the cabinet.

7. Attach the cabinet to the window stool by driving the

screws (Type B: Length sixteen millimeters and

below.) through the front angle into window stool.

8. Pull each Frame Curtain fully to each window sash

track, and repeat step 2.

9. Attach each Frame Curtain the window sash using

screws (Type C).(See Figure 10)

Figure 7

Figure 8

Figure 9

Figure 10

NOTICE

Be careful when you install the cabinet (Frame

Guides are broken so easily).

CAUTION: DO NOT DRILL A HOLE IN THE

BOTTOM PAN.

The unit is designed to operate with approximately

1/2" of water in bottom pan.

Screw(Type A)

Screw(Type A)

Power cord

Foam-Strip

Window Locking Bracket

10. Slide the unit into the cabinet.(See Figure 11)

11. Cut the Foam-Strip to the proper length and insert

between the upper window sash and the lower

window sash.

(See Figure 12)

12. Attach the Window Locking Bracket with a Type C

screw. (See Figure 13)

13. Attach the front grille to the cabinet by inserting the

tabs on the grille into the tabs on the front of the

cabinet. Push the grille in until it snaps into place.

(See Figure 14)

14. Lift the inlet grille and secure it with a Type A screw

through the front grille.

(See Figure 15)

15. Window installation of room air conditioner is now

completed. See ELECTRICAL DATA for attaching

power cord to electrical outlet.

Figure 11

Figure 12

Figure 13

Figure 16

Figure 15

Figure 14

12 Room Air Conditioner

Installation

CAUTION: For security purpose, reinstall screws

(Type A) at cabinet's sides.

Loading...

Loading...