Page 1

- 8 -

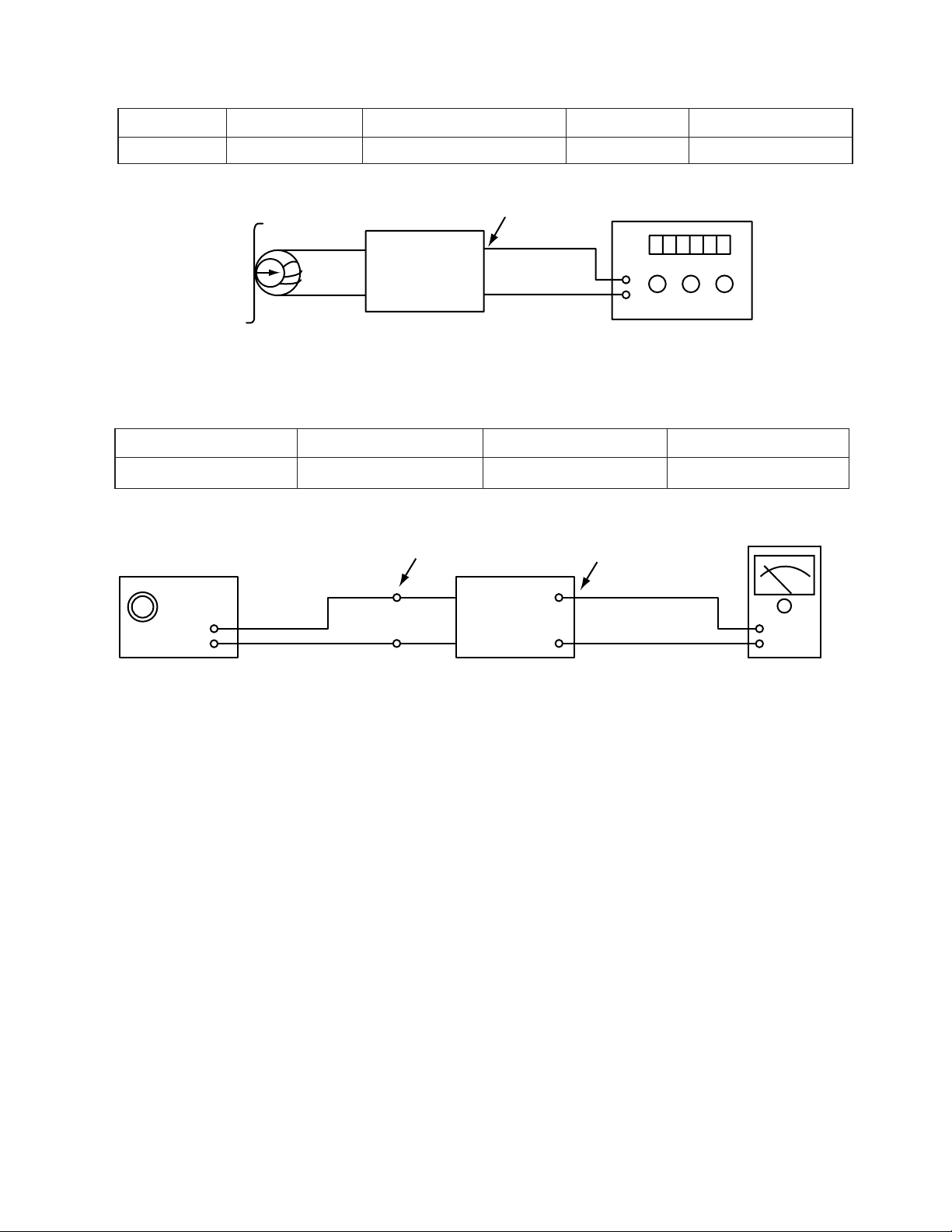

CH1 CH2

Speaker Out

Playback Mode

Head

Test Tape

MTT-114

L ch

R ch

GND

Dual-trace

synchroscope

Electronic

Voltmeter

L out

R out

Unit

This set has been aligned at the factory and normally will not require further adjustment. As a result, it is not

recommended that any attempt is made to modificate any circuit. If any parts are replaced or if anyone tampers

with the adjustment, realignment may be necessary.

IMPORTANT

1. Check Power-source voltage.

2. Set the function switch to band being aligned.

3. Turn volume control to minimum unless otherwise noted.

4. Connect low side of signal source and output indicator to chassis ground unless otherwise specified.

5. Keep the signal input as low as possible to avoid AGC and AC action.

ADJUSTMENTS

Deck Mode Test Tape Test Point Adjustment Adjust for

A Deck Playback MTT-114 Speaker Out DECK Screw Maximum

B Deck Playback MTT-114 Speaker Out Azimuth Screw Maximum

2. MOTOR SPEED ADJUSTMENT

Figure 1. Azimuth Adjustment Connection Diagram

Figure 2. Motor Speed Adjustment Connection Diagram

Head

Playback Mode

Unit

Speaker Out

GND

L out

R out

Record/Playback

head

Test Tape

MTT-111

Frequency Counter

Deck Mode Test Tape Test Point Adjustment Adjust for Remark

Normal Speed MTT-111 Speaker Out VR201 3kHz ± 1%

Hi-Speed MTT-111 Speaker Out more than 5.4kHz High-Speed Dubbing Mode

TAPE DECK ADJUSTMENT

1. AZIMUTH ADJUSTMENT

Page 2

- 9 -

3. RECORD BIAS ADJUSTMENT

Head

Unit

PN202

GND

Record/Playback

head

Test Tape

MTT-5511

Record/Playback

and Pause Mode

Frequency Counter

Deck Mode Test Tape Test Point Adjustment Adjust for

Rec/Pause MTT-5511 ERASE HEAD Wire(PN202) L203 90kHz±5kHz

Figure 3. Record Bias Adjustment Connection Diagram

Figure 4. Tuner(S curve) Adjustment Connection Diagram

4. TUNER ADJUSTMENT

Unit

Signal Generator

GND

Electronic

OSCILLOSCOPE

FM Antenna

Terminal

Speake

Item Test Point Adjustment Adjust for

DC Voltage Checker Pin TP1, TP2 L106 0V±50mV

Page 3

- 10 -

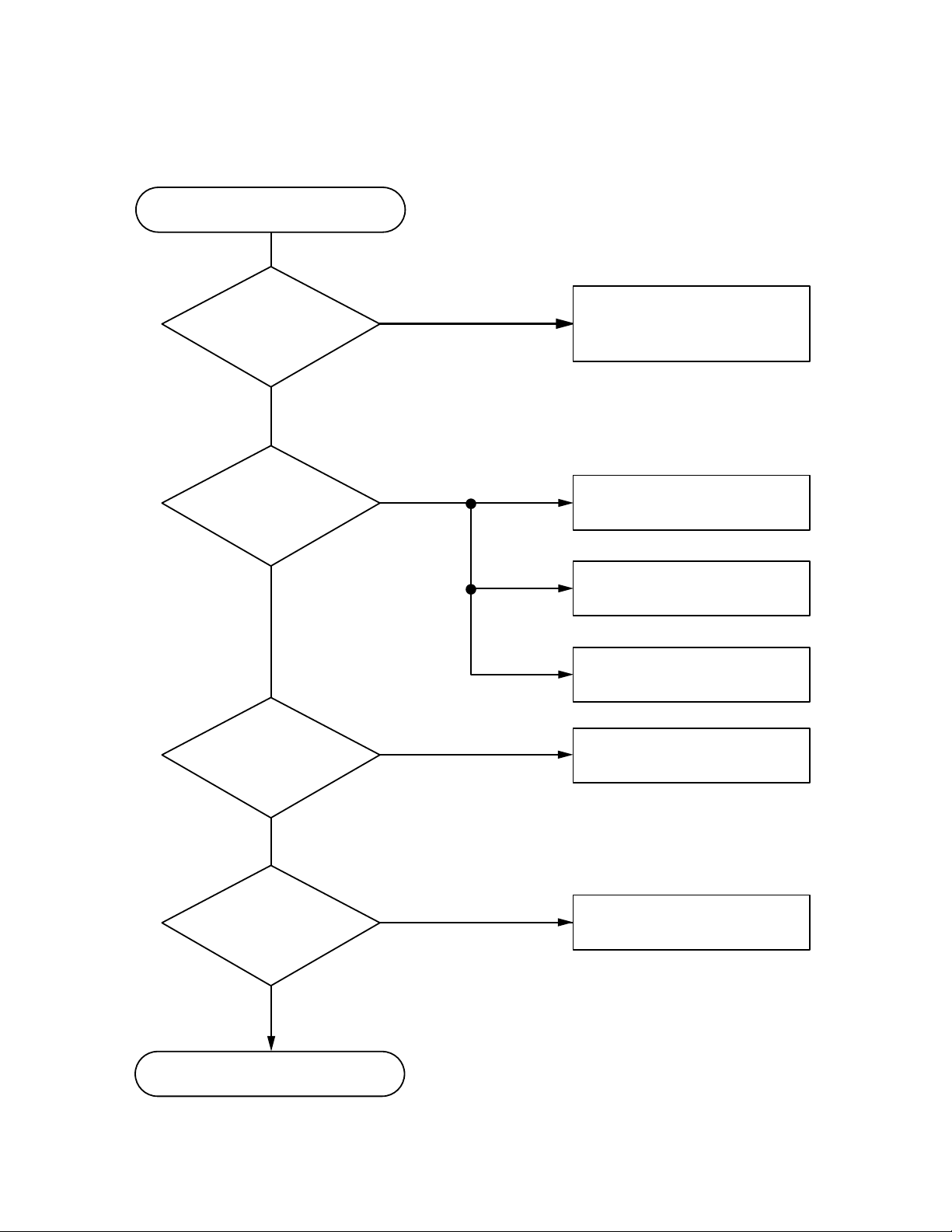

TROUBLESHOOTING

Turn power on.

Is power on?

Does initial read work?

Does it play?

Does it output audio?

Check power supply circuit.

(Check PN 701)

Check laser circuit.

Check focus circuit.

Check disc.

Check tracking servo circuit.

Check audio circuit.

OK

YES

YES

YES

YES

NO

NO

NO

NO

Page 4

- 11 -

Fails to initial read

1.3V

A

B

YES

YES

YES

YES

YES

YES

YES

YES

NO

NO

NO NO NONO

NO

NO

NO

NO

Does laser light?

Disc motor turns.

Does RF

waveform

appear?

TP 801(RF)

Does tracking

servo work?

Lower envelope

of TP801(RF)

waveform is flat.

Does signal

appear at

TP801(TEO)?

Does signal appear at IC 803

Pin and Pin ?

Does GFS (IC802 pin )

show as below?

Is rotation normal?

Is there no dropout of RF

signal?

Does TE2 signal

appear at pin

of IC801?

Defective IC

801, pick up

and/or open

wire.

Detective pattern.

Defective IC 801

and/or IC 803

Defective pick-up

and/or connector.

Defective IC 801.

Scratch in disc

initial read area.

Defective pick-up

adjustment focus offset.

53

26

27

Page 5

- 12 -

A

NO

NO

NO

NO

NO

NO

Laser does not light.

Is “3.5V” applied to pin of IC 801?

Is power supplied to laser Q801?

(Q 801 collector: about 1.8V)

Does laser current flow?

1.0V across R801

Is data transferred from

MICOM IC ?

Does voltage appear at IC

803 pin ⑪, ⑫?

Defective MICOM.

Defective MICOM.

Defective connector.

Defective IC 801, 803

Defective slide motor and/or

connector.

Defective LMT SW and/or

connector.

Defective Q 801 and/or laser.

Defective laser and/or

connector.

Did pickup return to

innermost circular?

Does it stop at inner pick

circular after shift?

Is defect output from LM

SW applied to pin ② of

PN803?

R801≫1.0V

R801≪1.0V

YES

YES

YES

YES

OPEN

CLOSE

YES

YES

YES

YES

YES

YES

70

Page 6

- 13 -

B

C

Does lens move up/down?

Does IC 801 out focus

search signal?

IC 801 pin (FEO)

Is focus search signal

applied to pin , of

CN801?

Laser lights.

Confirm

initial

read with

disc

Defective IC801

Defective IC803

Defective IC 801.

Open activator and/or

connector.

Open connector and/or

defective IC 801.

Incorrect turntable height.

Degraded laser diode.

Does TP 801 RF signal appear even in

low level?

Is laser output adjustment correct?

Does FOK(focus ok) signal appear?

YES

YES

YES

YES

YES

YES

TP801

(RF)

IC801 pin

(FOK)

NO

NO

NO

NO

NO

NO

48

13

16

40

Page 7

- 14 -

FER

ISTAT(SENSE)

C

Start mode

Does FE1 signal appear? IC 801 pin

Does FZC signal (focus zero cross signal)

appear at pin of IC 801, ISTAT (SENSE)

terminal?

Does SMON signal appear

at pin of IC 802?

Does SMPO signal appear

at pin of IC 802?

Is drive voltage applied to disk motor?

Defective IC 801.

Open pick diode

Defective IC 801.

Defective Pattern between IC 801 and

IC 802.

Defective IC 801, 803 and/or

peripheral circuit.

Defective disk motor and/or insulation.

(Focus servo turns

ON by FZC signal

of FOK mod.)

NO

NO

NO

NO

YES

YES

YES

YES

YES

73

75

31

59

Page 8

- 15 -

(CH1)

(CH2)

WAVEFORMS OF MAJOR CHECK POINT

1. HF signal (RF signal ) waveform

(Test Point TP801) during normal play

2. EFM signal (pin IC 801)waveform

during Normal Play

3. Focus coil drive waveform(Pin NO

① , ② of IC 803)

·When focus search failed or there is no disc on the tray

·Focus coil drive waveform(pin NO ①, ② of IC803) and

FOK (pin NO of IC 801) when focus search is

accomplished

4. Tracking coil drive waveform (pin NO , of IC 803)

and TEO during track traverse

(1) When time division is 20nS/div

(2) When time division 0.5nS/div.

(During forward track traverse)

(3) When time division is 0.5nS/div.

(During backward Track Traverse)

5. Feed motor drive waveform(pin NO

⑪, ⑫ of IC 803)

During normal play

CH1 : FOCUS COIL DRIVE

SIGNAL 2V/Div.

CH2 : FOAK

CH1 : TEO(TP801)

1V/Div.

CH2 : TRACKING COIL DRIVE

SIGNAL 2V/Div.

j

j

j

CH1 : TEO(TP801)

1V/Div.

CH2 : TRACKING COIL DRIVE

SIGNAL 2V/Div.

j

CH1 : TEO(TP801)

1V/Div.

CH2 : TRACK COIL DRIVE

SIGNAL 2V/Div.

j

40

26

33

27

0.5V/Div.

500nS/Div.

j

2V/Div.

500nS/Div.

j

0.5V/Div.

500nS/Div.

OV

OV

OV

(CH1)

(CH2)

(CH1)

(CH2)

(CH2)

OV

OV

OV

OV

OV

OV

OV

OV

OV

Page 9

- 16 -

MEMO

Loading...

Loading...