Page 1

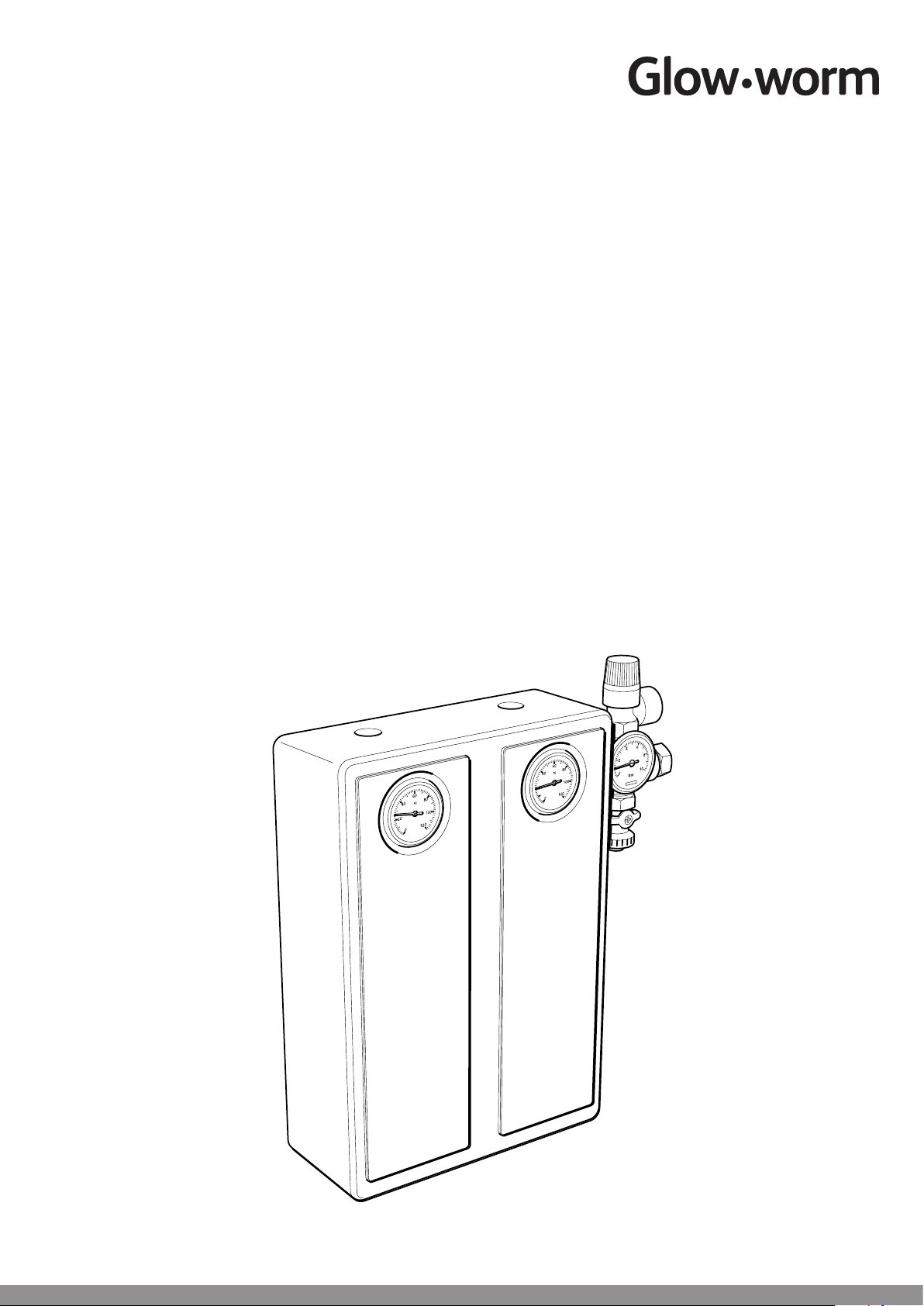

Clearly Solar

Installation and Servicing

System Hydraulics

including

Solar Pump Station

and Accessories

www.glow-worm.co.uk

1

Page 2

Guarantee Registration

Thank you for installing a new Glow-worm solar system.

Glow-worm products are manufactured to the very highest standard so we are pleased to offer our

customers a Comprehensive Guarantee.

This product is guaranteed for 24 months from the date of installation or 30 months from the date

of manufacture, whichever is the shorter, for parts and labour.

The second year of the guarantee, from the beginning of the 13th month onwards after installation

or manufacture, is conditional upon the product having been serviced by a competent person

(i.e. clear skies registered engineer), in accordance with the manufacturer’s recommendations.

We strongly recommend regular servicing of your product, but where the condition is not met, any

chargeable spare parts or components issued within the applicable guarantee period still benet

from a 12 month warranty from the date of issue by the manufacturer.

The “Benchmark” Installation, Commissioning and Service Record must be completed on

installation and kept up to date.

We recommend you complete and return as soon as possible your guarantee registration card.

If your guarantee registration card is missing you can obtain a copy or record your registration by

telephoning the Glow-worm Customer Service number 01773 596510.

Customer Service:

01773 596510

Technical Helpline:

01773 828300

General and Sales enquiries:

Tel. 01773 824639

Fax: 01773 820569

To register your Glow-worm product call:

0800 0732142

Benchmark places responsibilities on both manufacturers and installers. The purpose is to ensure that customers are provided

with the correct equipment for their needs, that it is installed, commissioned and serviced in accordance with the manufacturer’s

instructions by competent persons and that it meets the requirements of the appropriate Building Regulations. The Benchmark

Checklist can be used to demonstrate compliance with Building Regulations and should be provided to the customer for future

reference.

Installers are required to carry out installation, commissioning and servicing work in accordance with the Benchmark Code of

Practice which is available from the Heating and Hotwater Industry Council who manage and promote the Scheme.

Visit www.centralheating.co.uk for more information.

2

Page 3

These instructions consist of, Installation, Servicing, Fault Finding. The instructions

are an integral part of the product and must be handed to the user on completion of the

installation.

CONTENTS DESCRIPTION SECTION PAGE

Warnings 4

Important Information 4

INTRODUCTION

Statutory Requirements 5

Notes on the Documentation 6

Safety Instructions 6

System Specications 1 7

Product Specications 2 8

Component Specications 3 9

INSTALLATION

Installation 4 11

Commissioning 5 16

Commissioning Checklist 6 18

Commissioning Data 6 19

MAINTENANCE

Inspection and Maintenance 7 21

Fault Finding 8 22

Solar Fluid Safety Data 9 25

3

Page 4

WARNINGS

SAFETY

The system must be installed by a competent person, who is responsible for adhering to

the existing standards and regulations.

ALTERATIONS

Under no circumstances should you ever attempt to make alterations to these

components or any other part of the system

SEALED COMPONENTS

Under no circumstances must the user interfere with or adjust sealed parts.

Important Information

Installation and Use Regulations

In your own interests and that of safety, it is the LAW that this

product is installed by a competent person in accordance

with the current issue of these regulations.

Local authority planning permission may be required for the

installation. The local authority should be notied.

Control of Substances Hazardous to Health

Under Section 6 of The Health and Safety at Work Act

1974, we are required to provide information on substances

hazardous to health.

The adhesives and sealants used in this product are cured

and give no known hazard in this state.

Solar uid safety data, see section 9.

Manual Handling

With regards to the “Manual Handling Operations, 1992

Regulations”, the appliance exceeds the recommended

weight for a one man lift, refer to section 9 for more

information.

Electrical Supply

The product MUST be earthed.

All system components shall be of an approved type and all

wiring to current I.E.E. wiring regulations.

External wiring must be correctly earthed, polarised and in

accordance with the relevant standards.

In GB, this is BS 7671.

In IE, this is the current edition of ETCI rules.

The product MUST be connected to a permanent 230V ac,

50Hz supply.

CE Mark

The CE mark on this product indicates that it complies with

the basic requirements of the applicable directives as stated

on the data badge.

“Benchmark scheme”

Glow-worm support the Benchmark initiative. It is very

important that the service record is completed by the

installation engineer and handed over to the user.

Testing and Certification

This product is tested and certicated for safety and

performance. It is, therefore, important that no alteration is

made to the product, without permission, in writing, by Glowworm.

Any alteration not approved by Glow-worm, could invalidate

the certication, warranty and may also infringe the current

issue of the statutory requirements.

4

Page 5

Statutory Requirements

IMPORTANT

Where no British Standards exists, materials and equipment

should be t for their purpose and of suitable quality and

workmanship.

The installation of this product must be carried out by a

competent person in accordance the rules in force in the

countries of destination.

Manufacturer’s instructions must not be taken as overriding

statutory requirements.

Statutory Requirements

In GB, the installation of the product must be carried out by a

competent person as described in the following regulations:

The manufacturer’s instructions supplied.

The appropriate Buildings Regulations either The Building

Regulations, The Building Regulations (Scotland),The

Building Regulations (Northern Ireland).

The Water Fittings Regulations or Water byelaws in Scotland.

The Health and Safety at Work Act, Control of Substances

Hazardous to Health (COSHH).

The Current I.E.E. Wiring Regulations.

Where no specic instructions are given, reference should be

made to the relevant British Standard Code of Practice.

In IE, the installation must be carried out by a competent

person and installed in accordance with the current edition

of I.S.813 “Domestic Gas Installations”, the current Building

Regulations and reference should be made to the current

ETCI rules for Electrical Installation.

GB: the following Codes of Practice apply:

BS4814, BS6798, BS5440 Part 1 and 2, BS5546 Part 1,

BS5449, BS6891, BS6700, BS7074 Part 1 and 2, BS7593,

BS7671.

IE: I.S.813, BS5546, BS 5449, BS 7074, BS 7593.

Solar system in general

EN ISO 9488 Thermal solar system and components,

terminology (ISO/DIS 9488; 1995)

EN 12975-1 Thermal solar systems and components;

Collectors, Part 1: General requirements

EN 12975-2 Thermal solar systems and components;

Collectors; Part 2: Test methods

ENV 1991-2-3 Eurocode 1 – Basis of design and actions on

structures, Part 2–3: Actions on structures - Snow loads

EN 12976-1 Thermal solar systems and components; Factory

made systems - Part 1: General requirements

EN 12976-2 Thermal solar systems and components; Factory

made systems - Part 2: Testing methods

ENV 12977-1 Thermal solar systems and components;

Custom built systems, Part 1: General requirements

ENV 12977-2 Thermal solar systems and components;

Factory made systems, Part 2: Testing methods

ISO 9459-1: 1993 Solar heating – Domestic water heating

systems – Part 1: Performance rating procedure using indoor

test methods

ISO/TR 10217 Solar energy – Water heating systems – Guide

to material selection with regard to internal corrosion

Collectors and collector assembly

ENV 1991-2-4 Eurocode 1 – Basis of design and actions on

structures - Part 2–4: Actions on structures - Wind actions

Solar cylinder and cylinder installation

Pressure equipment directive 97/23/EC Directive of the

European Parliament and Council from 29th May, 1997 for

the approximation of the laws on pressure equipment of the

Member States

EN 12977-3 Thermal solar systems and components; Custom

built systems, Part 3: Performance characterisation of stores

for solar heating systems

EN 12897 Water supply - specication for indirectly heated

unvented (closed) storage water heaters

EN 806-1 Specications for installations inside buildings

conveying water for human consumption - Part 1: General

EN 1717 Protection against pollution of potable water

installations and general requirements of devices to prevent

pollution by backow

EN 60335-2-21 Safety of household and similar electrical

appliances; Part 2: Particular requirements for storage water

heaters (hot water cylinders and hot water boilers) (IEC 335-

2-21: 1989 and supplements 1; 1990 and 2; 1990, modied).

Lightning protection

ENV 61024-1 Protection of structures against lightning – Part

1: General principles (IEC 1024-1: 1990; modied) BS 6651

Code of practice for protection of structures against lightning.

Regulations in Great Britain

Building Regulation, dating from 1991 (England and Wales)

Requirement G3, L1 and Regulation 7

BS 7671 Requirements for electrical installations (IEE Wiring

Regulations, 16th edition)

BS 6759-1 Directive for the usage of the safety assembly for

hot water cylinders.

5

Page 6

Notes on the Documentation

Notes on the documentation

Your solar system is a quality product from Glow-worm.

This manual covers the solar system, excluding the

cylinder and provides you with information on installation,

commissioning, maintenance and fault nding. It is

supplemented by the installation instructions of the individual

components.

Observe the manuals for each individual system component

in conjunction with this manual.

Look after this manual and pass it on to the user for safe

keeping.

Glow-worm accepts no liability for any damage caused by

failure to observe this manual.

Safety Instructions

Safety instructions

The entire solar system must always be installed and

operated in accordance with recognised technical standards.

IMPORTANT: Risk of falling! Make sure you adhere to the

valid work protection regulations, in particular when working

on the roof. Make absolutely sure you wear anti-fall devices

whenever there is a risk of falling. (We recommend Glowworm fall protection systems, item no. 0020054985.) Observe

the accident prevention regulations of the trade associations.

IMPORTANT: Risk of being burned or scalded by hot

components! Install and replace collectors or collector parts

on very cloudy days. Perform installation work on sunny days

only in the morning or evening or with the collector covered.

IMPORTANT: Risk of being burned or scalded by hot solar

uid or components! Fill and ush the solar

system when the collectors are cold. Cover the

collectors while doing so.

IMPORTANT: Risk of being burned or scalded by escaping

hot steam! Steam can escape from the expansion relief valve

of the solar pump unit if the system is shut down. To avoid

injuries, you must connect the expansion relief valve to a

collecting container with a hose line.

Other applicable documents

Collector installation instructions.

System hydraulic installation instructions.

System electrical installation instructions including Fluropro.

System user instructions including Fluropro.

Installation and user instructions for the boiler.

Installation instructions for all sub components and

accessories used.

Warranty card.

Please observe the safety instructions in this manual when

installing this solar system.

IMPORTANT: A thermostatic mixing valve must be tted to

the outlet of the cylinder and can be adjusted to the desired

domestic hot water temperature by an installation or service

engineer. Otherwise there is a risk of scalding as the cylinder

outlet temperature at the taps could be up to 85°C.

IMPORTANT: Risk of being burned or scalded by escaping

hot steam! Steam can escape from unblocked automatic

bleeders if the system is shut down. Therefore block all

automatic bleeders after bleeding.

We recommend using the automatic air separator system

supplied as part of Glow-worm optional pipework kit. It works

fully automatically and does not need to be subsequently

blocked. It must be installed in an area however, in which no

steam can enter, preferably in the return pipe nearby the solar

cylinder.

6

Page 7

1 System Specications

1.1 Intended use

The solar system is used for the solar-supported supply of

DHW.

Any other use is considered to be improper. The manufacturer

/ supplier is not liable for any resulting damage. The user

alone bears the risk.

Intended use includes the observance of the system

description and all other applicable documents, as well as

adherence to the maintenance and inspection conditions.

IMPORTANT: We accept no liability for any damage or injuries

caused by failure to observe this manual.

At the end of this manual is a commissioning protocol, which

should be lled in by the installer and/or commissioning

engineer and handed over to the user.

1.2 Design and function of the solar system

The solar system consists of four main components:

The collectors, which absorb the solar radiation and utilise it.

The solar control, which monitors, displays and controls all

functions of the system.

The solar pump unit, which transports the solar heat.

The solar cylinder.

The solar collector transforms solar energy into heat and

transfers the heat energy to a frost-protected solar uid.

The solar pump of the solar pump unit ensures the heat is

transported from the collector to the twin coil solar cylinder via

a pipe system. The solar pump unit is controlled by the solar

control.

The solar control switches the solar pump on or off as soon

as the difference in temperature between the collector and

solar cylinder falls below or exceeds the preset value. If the

solar energy is insufcient, the control system switches on the

boiler so that the upper third of the cylinder is reheated to the

set value for the domestic hot water temperature. In addition

the solar cylinder can be reheated by the immersion heater

installed by the manufacturer.

The solar expansion vessel compensates pressure

uctuations in the solar circuit.

On days on which the solar radiation is insufcient to heat the

DHW in the cylinder, the stored water must be reheated by a

heating system. This can be done with boilers or electrically

with an immersion heater.

The optional protection vessel protects the expansion

vessel from increased temperatures in the solar circuit. We

recommend installing a protection vessel.

Local authority planning permission may be required for

the installation. The local authority should be notied

about the intended installation.

The solar system is a closed system and must be bled

carefully. We recommend the automatic air separator

system for this purpose (item no. 0020054969). It works fully

automatically and does not need to be subsequently blocked.

The automatic air separator system must be installed in an

area in which no steam can enter, preferably in the return pipe

between the solar pump unit and the solar cylinder.

7

Page 8

2 Product Specications

Solar Pump Unit

Flow

Return

14162

Clearly Solar

Collector

Protection

Vessel

Solar Expansion Vessel

Automatic Air

Separator System

Boiler

Flow Return

DHW

2 Port Valve

M

Flurocyl

Immersion

Heater

Drinking Water

Expansion Vessel

M

2 Port Valve

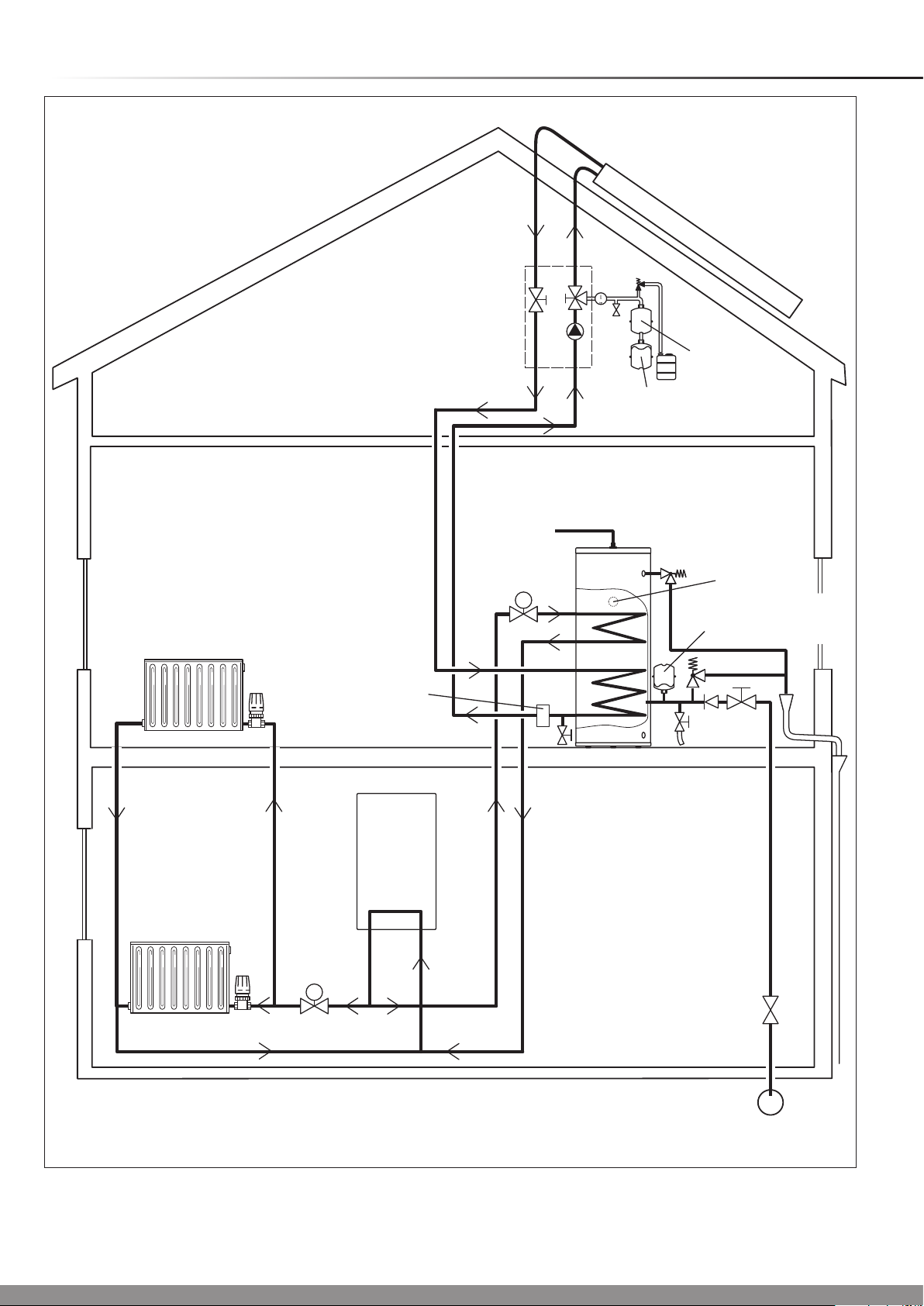

2.1 Diagramatic view of the system installation

Refer to diagram 2.1

Diagram 2.1

8

Page 9

3 Component Specications

358

120

Ø 22

Ø 22

Ø 22

Ø 22

Ø 22

Ø 22

250

1

5

6

2

3

4

CONTAINER

SOLAR

EXPANSION

VESSEL

7

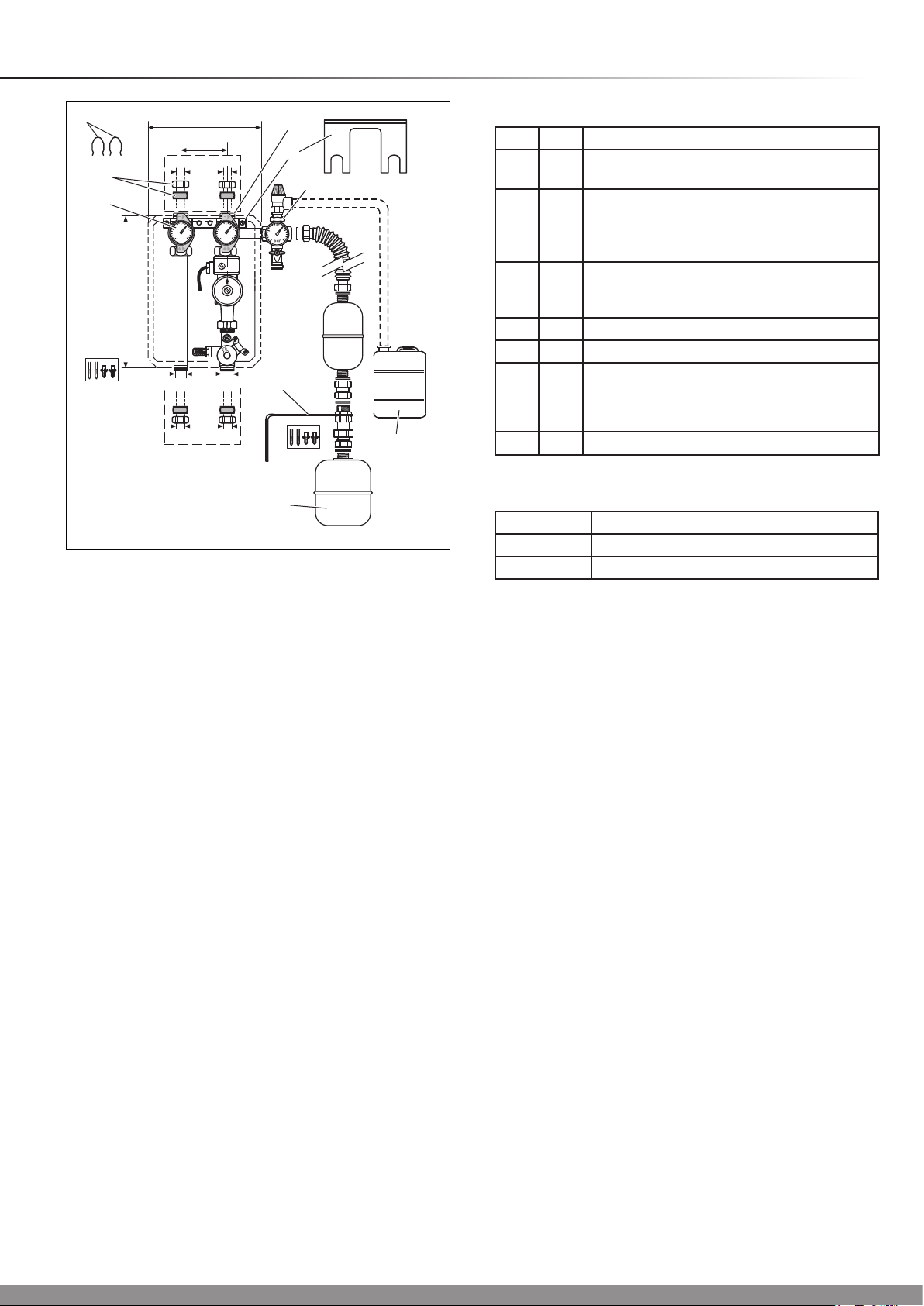

Solar Pump Station part no. 0020054961

14829

Item Qty. Description

1 1 Flow tube with isolating valve with integrated

gravity brake and temperature display

2 1 Return tube with isolating valve with

integrated gravity brake and temperature

display, ow rate meter with ll/vent valve,

circulating pump

3 1 Safety valve with pressure gauge, ll valve

and corrugated tube DN16 including wall

bracket for solar expansion vessel

4 1 Wall bracket for expansion vessel with tting

5 1 Wall bracket for solar pump station

6 4

7 2 C-clips

22mm Compression nuts

22mm Brass olives

4

22-18mm Reducers (discard)

4

Solar Expansion Vessel

Diagram 3.1

18 litre Supplied with 1 collector pack

25 litre Supplied with 2 collector packs

35 litre Supplied with 3 collector packs

3.1 Solar pump station

Refer to diagram 3.1 for contents and description.

The solar pump unit is equipped with a three-speed solar

pump for the optimum adaptation of the required circulating

volume and the pump capacity in the solar circuit.

Select the pump capacity, depending on the solar system (e.g.

collector surface, pipe diameter, length of the solar circuit), so

that the actual ow rate is slightly higher than the nominal ow

rate. The ow rate meter is used for ne adjustment of the

ow rate.

The solar pump unit is delivered with a water control pack,

consisting of an expansion relief valve and a pressure gauge.

The ow rate meter installed in the return pipe is an essential

component of the solar system. To achieve optimum heat

transfer, you must achieve a certain ow rate, refer to section

5.2.

Upper deviations are not as serious as lower deviations.

Make the rough adjustments with the solar pump rst. You can

make the ne adjustments with the adjustment valve of the

ow rate meter. You can view the set value on the display of

the ow rate meter.

The ow rate meter has a ll/vent valve for lling and draining

the solar circuit.

NOTE: Do not under any circumstances set the ow rate

below the calculated ow rate. The collector efciency will be

considerably reduced.

If you would like to use the solar exible pipework (DN16

0020054964) from the pump station to the cylinder, please

order an additional two ttings packs, part No. 0020054965,

these contain the relevant ttings for this application.

9

Page 10

3 Component Specications

3.2 Solar expansion vessel

The solar expansion vessel, is used to equalise the pressure

while the pressure relief valve blows off the solar uid into

the collecting container via the pressure release pipe if the

operating pressure of 6 bar is exceeded.

The size of the solar expansion vessel is based on the

expansion volume of the solar system.

The expansion vessel not only accommodates the expansion

volume of the solar uid, but also the entire volume of the

collectors in the event of a shutdown. The total volume of

the solar system is the total of the individual values of the

collector, heat exchanger volume and the volume of the

pipeline.

The admission pressure of the solar expansion vessel can be

set between 0.5 and 4.0 bar.

Component Volume (l)

Flurocyl 200 l heat exchanger solar circuit 3.04

Flurocyl 250 l heat exchanger solar circuit 3.04

Flurocyl 300 l heat exchanger solar circuit 4.14

Flurocyl 200 l heat exchanger reheating circuit 3.7

Flurocyl 250 l heat exchanger reheating circuit 3.7

Flurocyl 300 l heat exchanger reheating circuit 3.7

Solar pump unit 0.9

Vertical solar thermal at plate collector 1.85

Horizontal solar thermal at plate collector 2.16

Protection vessel 5.0

Table 3.2 Volume of individual circuits

3.3 Thermal cut out of the solar pump

The solar pump must be protected by its own thermal cut out

(TCO) which must be mounted on the solar cylinder (preassembled at the factory on the Glow-worm Flurocyl cylinder).

The power supply to the pump MUST be interrupted at

cylinder temperatures higher than 90°C.

3.4 Solar fluid

This information applies to Glow-worm solar uid (20 l

canister: item no. 0020054968).

Glow-worm solar uid is a ready-mixed antifreeze and

anticorrosive, consisting of approximately 45% propylene

glycol with anti-corrosion inhibitors and 55% water. It is

resistant to high temperatures.

Furthermore the solar uid has a high thermal capacity.

The inhibitors provide reliable corrosion prevention when

using different types of metal (mixed installations).

NOTE: Do not use any other anti-freeze or inhibitors with the

collector. Only Glow-worm solar uid is approved.

IMPORTANT: Risk of damage! Glow-worm solar uid is ready

mixed. You may not under any circumstances mix it with water

or other uids. Otherwise it will become ineffective as an

antifreeze or anticorrosive, resulting in damage to collectors or

other parts of the system.

Glow-worm solar uid is innitely durable in hermetically

sealed containers.

Skin contact is normally not dangerous. Eye contact only

causes minor irritations, you should nevertheless immediately

wash your eyes.

Observe the safety data sheet, see section 9.

3.5 Protection of the solar circuit against frost

and corrosion

To protect the solar system reliably against frost in winter, the

entire solar circuit must be lled 100% with solar uid.

NOTE: You can achieve frost resistance of about -28°C by

lling the solar system with Glow-worm solar uid. No damage

is caused by frost even at outside temperatures below -28°C,

since the expansive effect of the water is reduced. Check the

antifreeze effect after lling the system and then once a year.

To check the solar uid; refer to the operating manual of the

solar uid tester (item no. 0020054984).

10

Page 11

4 Installation

Make sure that you have all the components required, see

diagram 4.1, 4.2 and tables 4.1 and 4.2, below.

4.1 Recommended installation sequence

Assuming that the cylinder and collectors are tted with

the exception of the solar system hydraulics and wiring, it

is recommended that the solar pump station is now tted

followed by the solar circuit pipework.

The cylinder and collectors must be installed in accordance

with the separate installation instructions.

Proceed with the installation as described in the following

sections and shown in the diagrams 4.3 and 4.4 .

Item Description

1 Solar collector panel

2 On-roof, In-roof or Flat roof kit

3 Solar pump unit

4 Fluropro solar control

5 Roof bracket set, concrete tiles

6 Solar uid (20 litre)

7 Automatic air separator

8 Expansion vessel

9 Protection vessel

Table 4.1 Typical solar items

14172

1

2

4

3

5

9

6

Item Description

1 Single insulated tube DN16 15m x 2

2 Fittings pack for DN16 tube

Table 4.2 Optional pipework kit

8

Solar set items

1

Optional pipework kit items

7

Diagram 4.1

14351

2

Diagram 4.2

11

Page 12

4 Installation

14213

SOLAR COLLECTOR

THERMOSTAT

MIXER

BOILER

MOTORISED

2 PORT VALVE

SOLAR COLLECTOR

CIRCUIT PUMP

MOTORISED

2 PORT VALVE

AUTO AIR

SEPARATOR

HOT

WATER

CONNECTION

FLOW

RETURN

FLOW

RETURN

LEGIONNELLA

LOOP (optional)

PUMP

TEMPERATURE

AND PRESSURE

RELIEF VALVE

(95 °C, 7 BAR)

EXPANSION

VESSEL

TUNDISH

EXPANSION

RELIEF

VALVE

(6.0 BAR)

PRESSURE

LIMITING VALVE

(3.5 BAR)

WITH LINE

STRAINER

COLD

WATER

SUPPLY

12

FLUROCYL

DRAIN VALVE

Diagram 4.3

Page 13

4 Installation

Collector arrays setup for East / West orientation

14212

N

SOLAR

COLLECTOR

SOLAR

COLLECTOR

CIRCUIT PUMP

HOT

WATER

CONNECTION

SOLAR

COLLECTOR

LEGIONNELLA

LOOP (optional)

W

S

THERMOSTAT

MIXER

PUMP

TEMPERATURE

AND PRESSURE

RELIEF VALVE

(95 °C, 7 BAR)

E

BOILER

MOTORISED

2 PORT VALVE

MOTORISED

2 PORT VALVE

AUTO AIR

SEPARATOR

FLOW

RETURN

FLOW

RETURN

13

EXPANSION

VESSEL

EXPANSION

RELIEF

VALVE

(6.0 BAR)

TUNDISH

FLUROCYL

DRAIN VALVE

COLD

WATER

SUPPLY

PRESSURE

LIMITING VALVE

(3.5 BAR)

WITH LINE

STRAINER

Diagram 4.4

Page 14

4 Installation

4.2 Fitting the solar pump station

(wall-mounted installation)

Fit the wall bracket and the pump station ow and return

assemblies.

Secure the assemblies in the wall bracket using the two C-

clips. Put them onto the ow and return assemblies below the

wall bracket.

4.3 Pressure relief valve and expansion vessel

Fit the pressure relief valve assembly to the connection nozzle

in the pump station return tube assembly.

IMPORTANT: Loss of solar uid! Install a discharge pipe from

the pressure relief valve outlet to a container to ensure that

any hot solar uid escaping from the system is contained.

The solar uid container is intended as a collecting container

when the system is lled and the container is empty. Connect

a discharge pipe from the relief valve outlet to the intended

location for the container.

Mount the expansion vessel wall bracket using screws and

plugs. Screw the ange and the expansion vessel to the wall

bracket.

The expansion vessel must be mounted vertically and the ow

from the system must enter the vessel from the top. To avoid

accidental spillage or access by children to the uid, best

practice is to take the discharge pipe right to the bottom of

(but not touching) the container.

The empty solar uid container is recommended, as reusing it helps to reduce landll, the contents of the container

are visible (you must be able to see if the safety valve has

discharged) and offers a practical solution. However, if

preferred, an alternative vessel may be used, provided it is

of adequate size, the contents are visible and it is not fully

sealed.

4.4 Notes on the solar circuit pipework

When installing solar circuit pipework between the collector

array and the cylinder, carefully consider the location of

the pump station and the requirement for an automatic air

separator. The Glow-worm solar system is a closed hydraulic

system in which heat can only be transferred to the cylinder

by means of special heat transfer uid in the solar system.

Observe the following points to ensure perfect operation with

maximum energy utilisation:

Bleed the system completely during commissioning and

servicing since air in the system has a considerable effect on

the efciency.

The pipe diameters should not be too large, otherwise the

the ow in the solar system will slow down, reducing the

efciency.

Lay all system components in such a way to ensure an even

ow at the required nominal ow rate.

Provide sufcient thermal insulation of the pipes to prevent

excessive heat loss. The insulation must withstand

temperatures up to 150°C. Select weather and UV resistant

insulation which is “bird peck proof“ especially for pipes laid

outside.

When using compression ttings, you must consult the

manufacturer of these ttings to check their suitability for solar

systems.

Use compression ttings only if temperatures of up to 200°C

are allowed by the manufacturer.

IMPORTANT: Use hard solder only, soft solder is NOT

suitable.

Do not use any plastic pipes.

Flexible stainless steel pipes supplied by Glow-worm or

copper pipes should be used for the solar circuit.

Optional Glow-worm exible pipes for the connection of the

collectors to the solar pump unit.

0020054994: 2 in 1 exible pipe DN 16 x 15 m

0020054964: single exible pipe DN 16 x 15 m

Two single exible pipes DN 16 x 15 m are available as part

of the Glow-worm optional pipework kit. Instructions for the

connection of these exible pipes can be found in separate

installation instructions.

Due to the occasionally high temperatures of the solar uid,

plastic pipes must not be used for the solar circuit. Copper

pipes must be joined using hard soldering or compression

ttings. Soft soldering is NOT suitable.

Teon tape can be used on pipework below the Solar Pump

Station.

IMPORTANT: Earth the solar circuit!

The solar pipework must be earthed in accordance with the

requirements of BS 7671 IEE Wiring Regulations. Wiring

protection should be provided if there is high risk of lightning

strikes. The electronics in the solar system, heating system or

in the house could otherwise be destroyed if they were to be

hit by lightning. Connect the collectors to an existing lightning

protection on the house.

IMPORTANT: Risk of damage to the collectors due to

excessive pressure. The installation of a motorised 2 port

valve in the pipes of the solar system is not allowed, since the

safety devices in the solar circuit could be overridden by it.

The right selection of the pipe diameters plays a signicant

role in terms of maximum efciency of the solar system.

To keep the pressure loss in the solar circuit to a minimum,

the ow velocity in the copper pipe should not be higher than

1.5 m/s.

A nominal ow rate of 0.66 l/min per net m

required by the collectors to achieve optimum heat transfer.

Another decisive criteria for the optimum operation of your

solar system is the speed of the solar pump. The pump must

be able to deliver more than the nominal ow rate at the

specied operating pressure. The selection of the required

pump speed depends on the installed system. Reference

value for the pump selection can be found in section 5.2.

Connections to solar pump station

IMPORTANT: An air separator is required - refer to diagram

4.5.

Using the compression ttings supplied with the pump station,

connect the pump station ‘ow’ assembly to the collector ow

pipe and the pump station ‘return’ assembly to the collector

return pipe. IMPORTANT: ensure the collector pipes are

connected correctly - the pump station ‘return’ assembly

includes the pump.

Use the ttings included to connect to 22mm copper pipes.

Again using the compression ttings supplied with the pump

station, connect the pump station ‘ow’ assembly to the

cylinder ‘solar circuit ow’ connection then the pump station

‘return’ assembly to the cylinder ‘solar circuit return’.

2

collector surface is

14

Page 15

4 Installation

IMPORTANT: Ensure the cylinder pipes are connected

correctly - the pump station return assembly includes the

pump.

4.5 Automatic air separator

Air in the system impairs the efciency of the solar system

considerably. Install an automatic air separator in the return of

the solar circuit, between the cylinder and solar pump station.

High temperature vapour is unlikely in this area. However,

check with the manufacturer that the device is suitable for

domestic solar system applications.

A suitable and effective air separator is supplied in all

solar packs or separately (item no. 0020054969). This is

recommended.

The air separator system works fully automatically and does

not need to be isolated.

The system must be bled whenever it is lled or subjected to

maintenance. Bleeding is performed constantly by means of

the automatic air separator system as long as the solar pump

is in operation.

Fit the protection vessel as shown in diagram 4.6.

The protection vessel must be mounted vertically. The ow

from the safety group must enter the vessel at the upper

connection.

14183

14236

Diagram 4.5

Flexpipe

Protection Vessel

3/4” Adapter Fitting

Wall Bracket

Solar Expansion

Vessel

Diagram 4.6

15

Page 16

5 Commissioning

0,5

1

2

3

0,5

1

2

3

4

5

6

4

5

6

L/min

L/min

You must adhere to the following procedure for the

commissioning of the total system:

Use only Glow-worm solar uid (item no. 0020054968) for

pressure tests and for ushing and lling the solar circuit.

5.1 Flushing and filling the solar circuit

Glow-worm recommends using the Glow-worm lling pump,

part no. 0020054986, to ush and ll the solar circuit. Observe

the separate user manual when using the Glow-worm lling

pump.

Expansion vessel admission pressure

During the commissioning, the gas side admission pressure

p

of the expansion vessel must be adjusted to the equipment

v

height whilst disconnected. The static pressure p

corresponds, to a certain extent, to the static height h between

the collector array and the expansion vessel.

10m static height correspond to approx. 1 bar.

p

= p

= h x 0.1 but not less than 1.5 bar.

v

stat

NOTE: A deviation from the optimum admission or lling

pressure always results in a reduction of the expansion

vessel's effective volume. This can cause operational

malfunctions.

Flushing is performed from the solar pump station to the

cylinder via the collector.

A self-priming pump with a pressure of 2 to 3 bar is required

to ll the solar circuit.

Collector circuit lling pressure

The lling pressure Pa should be approx. 0.5 bar over the

static pressure Pstat.

Pa = h x 0.1 + 0.5 bar but not less than 2 bar.

stat

EXAMPLE: The installed (net) collector surface area for

Clearly Solar collectors is 2.35 m2. Multiplied with the value

for the specic ow rate of 0.66 l/m2 • min, it results in a

calculated ow rate, which should be indicated by the ow

rate meter, see diagram 5.1.

Select the next pump speed if the calculated ow rate is not

achieved on the ow rate meter. Switch to a lower speed if it

is exceeded. If the ow rate cannot be achieved even at the

highest pump speed, check whether it is possible to use fewer

collectors in series reverting to a combination of series and

parallel connections (eg 2 collectors in series in parallel with

an additional 2 collectors in series).

Use an Allen key to nely adjust the ow rate at the

adjustment valve, see diagram 5.1.

The adjusted ow rate can be viewed on the display, see

diagram 5.1.

Table 5.1 provides reference values for possible pump speeds

depending on the collector connection and pipe length and

cross-section.

The ow rate can be used to calculate and display the

gain. To make an accurate calculation, the ow rate must

be entered into the Fluropro solar control. You can nd

further information in the separate system wiring instructions

including the Fluropro solar control.

The pump speed is used to achieve a particular ow rate

in the collector array. The nal ow rate should not be

signicantly above or below the calculated value. Up to 10%

lower solar gain or unnecessarily high power consumption of

the pump could occur.

5.2 Setting the flow rate / pump speed

The 3-speed circulating pump can be ne-tuned to adjust the

ow rate to the collector's performance.

NOTE: We recommend a value of 0.66 l/min per m2 collector

surface area.

This is how to do it:

Use Table 5.1 to calculate the ow rate to be set by

multiplying the installed collector surface area with the value

of 0.66 l/m2 • min.

Set the pump speed to roughly set the ow rate as follows:-

1,1 l/min

Let the pump run rst at the lowest speed (minimum power

consumption).

Check whether the calculated value is achieved on the ow

rate meter.

Clearly Solar, solar collector panel Flow rate

Flow Rate

Display

Minimum cross-section of the copper pipe in the

solar circuit at a total pipe length of:

Number in series l/min 20m 50m

1 1 1.55 15 15

2 2 3.1 15 15

3 3 4.65 15 15

Pump speed: Minimum (speed 1) Maximum (speed 3)

Table 5.1 Layout of pipe cross-section and pump speed depending on the collector connection

Adjustment

Valve

Diagram 5.1

14168

16

Page 17

5 Commissioning

5.3 Commissioning checklist

Fill in the commissioning checklist, refer to section 6.

5.4 Benchmark

GB: It is a requirement that the “Benchmark” Installation,

Commissioning and Service Record is completed and left with

the user. This is supplied with the Glow-worm ‘Flurocyl’ range

of cylinders.

IE: it is necessary to complete a “Declaration of Conformity” to

indicate compliance to I.S.813. An example of this is given in

the current edition of I.S.813.

5.5 Hand over to the householder

l Hand over all manuals to the householder.

l Advise the householder to keep the manuals near to the

system.

l Draw special attention to the safety instructions which the

householder must follow.

l Review the user instructions with the householder and

answer any questions.

l Show the householder how to operate the solar control, CH

control and any separate DHW control.

l Inform the householder that the cylinder temperature is

factory set at 65°C and that the DHW temperature can be

adjusted using the TMV by the installer.

l Inform the householder that the immersion heater is

intended as a standby device and should not be used

simultaneously with the boiler to heat the cylinder.

l Inform the householder that they are not permitted to

change the settings made on the solar system.

l Inform the householder that to ensure the continued

efficient and safe operation of the solar system it is

recommended that it is checked and serviced at regular

intervals. The frequency of servicing will depend upon the

installation conditions and usage, but in general, once a year

should be enough.

lInform the householder that the boiler and solar cylinder

should be serviced by a qualied engineer annually.

Leave these instructions and the “Benchmark” Installation,

Commissioning and Service record document with the user.

17

Page 18

6 Commissioning Checklist

1. Assembly O.K. Remarks

Roof bracket xed according to instructions?

Solar pipework connected to potential equalisation?

Roof covering rexed according to instructions after laying the roof bracket?

Roof membrane not damaged?

Pressure release pipe installed at the expansion relief valve of the solar

circuit?

Catch vessel (empty canister) placed under pressure release pipe?

Pressure release pipe installed at expansion relief valve on hot water side

and connected to waste water?

Thermostat mixer installed, temperature set and checked?

2. Commissioning O.K. Remarks

System lled with prescribed solar uid?

Solar circuit ushed with solar uid?

Line strainer cleaned after ushing the system?

System bled several times?

Solar circuit subjected to hydraulic pressure test, including leak inspection

of screw connections and soldering points?

Stufng boxes at stop valve and ll/vent valve checked for leaks (retighten

union nuts if necessary)?

Temperature and pressure relief valve checked?

Stop valve for reheating source installed (normally motorised 2 port valve)?

Flow rate set according to system manual?

Pump, cylinder heat exchanger and collector bled (gravity brake blocked for

bleeding)?

Gravity brake released?

Fill/vent valve caps screwed tight?

Cylinder bled?

Heating circuit bled?

Does the system installation meet the requirements of the building

regulations?

Has the system been installed and started up in accordance with the

installation manuals of the manufacturer?

3. Control systems O.K. Remarks

Do the temperature sensors display plausible values?

Solar pump running and circulating (ow rate measuring meter)?

Solar circuit and cylinder become warm?

The temperature difference between the ow and return is a max. of 10 to

14 °C at full sunshine?

Correct hydraulic plan set

4. Instruction O.K. Remarks

The system user has been instructed as follows:

– Basic functions and operation of the solar control?

– Functions and operation of the reheating system?

– Frost protection of the system?

– Maintenance intervals?

– Manuals/documents (possibly with special circuit plan) handed over to the

user?

Table 6.1 Commissioning checklist

18

Page 19

6 Commissioning Data

Information Unit Value/Detail

Benchmark no.

Registration no.

Basic acceptances

Number of persons

Additional hot water equipment Washing machine,

dishwasher etc.

Circulation Available/Not available

Circulation runtime h/d

(please tick as appropriate)

Daily hot water consumption in l/d

At a cylinder temperature of °C

Estimated solar coverage of the total hot water consumption %

Collector array performance data

Installed effective collector surface area m

Maximum power at full solar radiation kW (500–600 W/m2

2

collector)

Solar cylinder

Appliance type Vented/Unvented

Appliance designation

Capacity l

Serial number

Boiler

Appliance type

Appliance designation

Serial number

Boiler system type Open/Closed

Installation location of pressure limiting valve

System values

Hot water temperature at the nearest tap °C

Achievable maximum cylinder temperature °C

Maximum hot water temperature °C

Maximum hot water volume at maximum temperature l/min.

Boiler ow temperature °C

Operating pressure setting at pressure limiting valve bar

Charge pressure in DHW expansion vessel (check before

lling)

Charge pressure in solar expansion vessel (check before

lling)

Cold water system pressure at pressure limiting valve (cold) bar

Set ow rate l/min

Temperature difference between ow and return at full solar

radiation

Volume of solar expansion vessel l

Operating pressure at solar pump unit pressure gauge in

cold condition

bar

bar

Kelvin

bar

Table 6.2 Commissioning data

19

Page 20

6 Commissioning Data

Information Unit Value/Detail

Frost protection set to Density of solar uid >

1.05 g/cm3

Controller settings

Installed controller(s)/timer(s)

Manufacturer

Reheating with boiler starts at (TSP1 min. see installation

manual of solar control)?

Switch-on temperature difference: Kelvin

Switch-off temperature difference: Kelvin

Other settings

°C

Important activated functions

Name of the installer (in block letters)

Corgi ID No.

Date

Signature

Signature of the user to conrm the receipt of all manuals of

the system

Table 6.2 Commissioning data (continued)

20

Page 21

7 Inspection and Maintenance

The operational reliability of the solar system may be

impaired, resulting in damge to property or personal injury, if

the inspections and maintenance work are not carried out.

The main maintenance work on the solar system and the

corresponding maintenance intervals are specied in table

7.1.

Maintenance Maintenance interval

Solar circuit

Check the frost protection of the solar uid (use the Glow-worm 0020054984 solar uid tester) Annually

Check the system pressure Annually

Check the pH value of the solar uid (with litmus paper, pH > 7.5) Annually

Check the solar pump function Annually

Bleed the system Annually

Check the circulating volume in the solar circuit Annually

Check the hot water thermostat mixer function Annually

Rell with solar uid if necessary Annually

Check the quantity of blow-off liquid Annually

Release the return ow preventer Annually

Check the charge pressure of the expansion vessel Annually

Collector

Visual inspection of the collector, collector fastenings and connections Annually

Check whether the brackets and collector components are clean and tted properly Annually

Check the pipe insulation for damage Annually

Solar control

Check the pump function (on/off, automatic) Annually

Check the sensor temperature display Annually

Reheating

Check the circulation pump Annually

Check the timer/time programme settings Annually

Reheating: does it deliver the desired deactivation temperature? Annually

Solar cylinder

Bleed the heat exchanger if necessary Annually

Check the connections for leaks Annually

Check the temperature and pressure relief valve Annually

Checking the expansion relief valve Annually

Table 7.1 Maintenance checklist

21

Page 22

8 Fault Finding

The following tables provide information on possible

malfunctions during the operation of the solar system as well

as their cause and remedy.

All work on the Glow-worm solar system (installation,

maintenance, repairs etc.) may be performed only by

approved specialists.

IMPORTANT: Risk of serious injury or death! Never try to

correct faults in the solar system yourself. Bear in mind

that you risk death or serious injury if the work is performed

incorrectly. Consult an approved qualied servicing company

in the event of malfunctions.

NOTE: Only use original spare parts from Glow-worm. for the

replacement of parts. We recommend making a maintenance

agreement.

Malfunction Cause Remedy

Solar pump

Pump is not running although the

collector is warmer than the cylinder

(neither motor noises can be heard nor

vibrations felt).

Pump is running, but no solar uid

is coming from the collector (pump

gets hot). Forward and return ow

temperatures are the same or the storage

tank temperature not increasing at all or

only slowly.

Pump goes on too late and stops running

early.

Pump starts up and goes off shortly

afterwards. This is repeated several times

until the system runs its course. The

same occurs in the evening.

The pump is making noises. 1. Air in the pump Bleed the pump.

Solar system

Clocking of the system. Incorrect position of the collector sensor. Position the collector sensor in the ow.

1. No current available. Check the power cables and fuses.

2.Temperature difference set too high or

controller is not switching.

3. Maximum temperature reached.

4. Pump shaft jammed by deposits in the

bearings.

5. Pump dirty. Dismantle the pump and clean it. Close

6. Pump defective. Replace the pump.

7. Flow rate set incorrectly Check the setting and adjust it if

Air is in the pipework. Check the system pressure. Operate the

1. The temperature difference between

the collector and cylinder has been set

too high.

2. Collector connection pieces not

insulated (tube collector).

The temperature difference of the

controller is too low or the pump speed is

set too high. The solar radiation is not yet

sufcient to heat up the entire pipework.

2. Insufcient system pressure. Increase the system pressure.

Check the controller.

Check the temperature sensor.

Reduce the temperature difference.

Switch temporarily to max. speed or

unblock the rotor, insert a screwdriver in

the notch and turn it by hand.

the ow rate meter and pump ball valve.

necessary.

pump intermittently at maximum power.

Open the bleeder at the pump and at the

cylinder and bleed. Bleed the back ow

prohibition. If there is no improvement,

check whether there is a “u pocket”

anywhere in the piping (e. g. at beam

projections or at the bend of water pipes).

Change the pipework or install additional

air vents. If the system has already been

started up and is relled again, check

the automatic air vent: Unscrew the

protective cap and check the oater for

mobility with a blunt needle. If the oater

is jammed, replace the air vent.

Reduce the temperature difference.

Insulate the collector connection pieces.

Check whether the entire pipework is

fully insulated. Increase the temperature

difference of the controller.

Insulate the collector sensor.

Table 8.1 Fault Finding

22

Page 23

8 Fault Finding

Malfunction Cause Remedy

The pressure gauge indicates a drop in

pressure.

The water pressure and amount of

discharged water decreases at hot water

taps.

The system is making noises. Normal in

the rst few days after lling the system.

If it occurs later, there are two possible

causes:

The solar gain is unusually low. The pipe insulation is too thin or incorrect.

Solar control

Display example “NTCA Err“ or similar

(reference system wiring instructions

including Fluropro solar controller)

Solar cylinder

The cylinder cools down at night. The

ow and return temperatures vary after

switching off the pump. The collector

temperature is higher than the air

temperature at night.

Reheating is not working. The boiler

runs for a short time, goes off and then

back on again. This is repeated until the

cylinder is at its target temperature.

A drop in pressure is normal shortly

after lling the system, since air still

escapes from the system. If a pressure

drop occurs again later on, the cause

may be an air bubble, which has been

subsequently released.Furthermore there

are uctuations to the pressure in normal

operation mode between 0.2 to 0.3 bar,

depending on the system temperature. If

the pressure drops continuously, there is

a leak in the solar circuit, in particular in

the collector array.

Pressure in the main cold water supply

too low.

Line strainer in the pressure limiting valve

dirty.

Pressure limiting valve defective. Replace the pressure limiting valve.

Blockage in the system. Unblock the blockage and replace any

1. The system pressure is too low. The

pump is drawing air via the bleeder.

2. Pump power set too high. Switch to a lower speed.

The system may have been designed

incorrectly.

Defective sensor (short circuit or

interruption).

1. The gravity brake is blocked. 1. Check the position of the blue handle.

2. One-pipe circulation in the event of

short pipe networks with low pressure

loss.

1. Air in the reheating heat exchanger. Bleed the reheating heat exchanger.

2. Heat exchanger surface area too small. Compare the specications of the boiler

First check all screw connections, stufng

boxes at gate valves and threaded

connections, then the soldering points.

Check the collector array and replace a

tube or the collector if necessary.

Inform the user and notify the water

supply company.

Clean the line strainer in the pressure

limiting valve and replace it if necessary.

blocked parts.

Check the system for water leaks at the

expansion relief valve and temperature /

pressure limiting valve.

Increase the system pressure.

Check the insulation. Check the layout

of the system (collector size, shading,

pipe lengths) and modify the system if

necessary.

1. Check the cable connection.

2. Measure the resistance values of

the disconnected sensor at known

temperatures, and compare these with

the manufacturer's specications.

3. Inspect the piping for damage.

2. Check the gravity brake for tightness

(jammed cuttings, particles of dirt in the

sealing face).

3. Do not connect the solar heat

exchanger directly, rather pull the supply

pipes downwards and then upwards to

the collector (syphon supports the gravity

brake) or install a 2-port valve, which

is switched on at the same time as the

pump.

Install a gravity brake (as close as

possible to the cylinder).

manufacturer with those of the cylinder

manufacturer. The problem may be able

to be solved by a higher setting of the

ow temperature at the boiler.

Table 8.1 Fault Finding (continued)

23

Page 24

8 Fault Finding

Malfunction Cause Remedy

Only cold or lukewarm water comes out

of the taps.

Water ows out of the expansion relief

valve (only when heating up).

Water comes out of the temperature and

pressure relief valve (only when heating

up).

1. Cold and hot water connections on the

cylinder have been mixed up.

2. Hot water thermostat mixer set too low. Increase the setting.

3. Solar heating insufcient; boiler does

not reheat.

External control device faulty.

Air in the reheating heat exchanger

Cylinder temperature sensor defective.

Dirt on the valve seat of the expansion

relief valve.

Pressure limiting valve defective. Switch off the boiler and immersion

Expansion vessel defective. Check the pressure in the expansion

Expansion relief valve defective. If the pressure is normal, replace the

Dirt on the valve seat of the temperature

and pressure relief valve.

Temperature control of the boiler

defective.

Cylinder temperature sensor defective. Check the cylinder temperature sensor

Two port valve defective. Check whether the two port valve is

Temperature and pressure relief valve

defective.

Immersion heater defective. Check the temperature sensor of the

Turn off the cold water supply, then

let water ow out via the hot water

connection. Only a few litres of water

ow out if the connection is laid correctly.

The inlet of the hot water draw-off pipe

then rests in the air space; no further

emptying is possible. If the entire solar

cylinder runs empty via the hot water

connection, the connections have been

laid incorrectly. Change the connections!

Check whether the boiler is working.

Check whether the external control

device is working.

Check whether the two port valve is in the

hot water position.

Replace the two port valve.

Bleed the reheating heat exchanger.

Check the thermal cut out and reset it.

Replace the cylinder thermostat.

Check the expansion relief valve and

reset it manually.

heater and check whether the pressure

behind the pressure limiting valve is lower

than 3.0 bar if water ows out only when

heating up. If so, replace the pressure

limiting valve.

vessel. If the pressure is insufcient,

re-establish the pressure and check

whether the equalisation tank maintains

the pressure.

expansion relief valve.

Check the seat of the temperature

and pressure relief valve and reset it

manually.

Check the temperature control of the

boiler if water only comes out when

reheating with the boiler. Check whether

the two port valve switches to the heating

position after reaching the cylinder

temperature.

and the corresponding thermal cut outs

and replace the temperature sensor and

reset the thermal cut outs if necessary.

working and replace it if necessary.

Replace the temperature and pressure

relief valve if water only comes out when

heating up with the immersion heater.

immersion heater and the corresponding

thermal cut out and replace the

immersion heater if necessary.

Table 8.1 Fault Finding (continued)

24

Page 25

9 Solar Fluid Safety Data

10.1 Safety data sheet

1 Substance/Formulation and company name

Information on the product:

Trade name of the Glow-worm solar uid (item no.

0020054968)

2 Composition/Information on components

Chemical properties

Watery solution of 1.2 propylene glycol with corrosion

inhibitors

3 Possible risks

No particular risks known

4 First-aid measures

General notes:

Remove dirty clothes.

After inhaling:

Discomfort after inhaling fumes/aerosol: fresh air, help from a

doctor.

After skin contact:

Wash off with water and soap.

After eye contact:

Wash thoroughly under running water with wide open eyes for

at least 15 minutes.

After swallowing:

Rinse your mouth and then drink plenty of water.

Notes for the doctor:

Treatment of symptoms (decontamination, vital function), no

specic antidote known.

5 Fireghting measures

Appropriate extinguishing agents:

Spray, solid extinguishing agent, alcohol-fast foam, carbon

dioxide (CO

Particular hazards:

Fumes which are detrimental to health. Formation of smoke/

mist. The specied substances/substance groups may be

released in the event of a re.

Special protective equipment for re ghting:

Wear a breathing apparatus which is independent of the

circulating air in the event of a re.

Further details:

The hazard depends on the combustible substances and

the re conditions. Polluted re water must be disposed of

according to local ofcial regulations.

)

2

6 Measures to be taken if substances are released

accidentally

Individual-related measures:

No particular measures required.

Environmental measures:

The product may not be discharged into waters without pretreatment (biological sewage plant).

Cleaning/Collection methods:

Pump out the product in the event of large quantities. Absorb

small quantities with appropriate uid bonding material.

Then dispose of them according to regulations. Rinse away

splashes with plenty of water. Inform the local water authority

in the event of large quantities which could ow into the

drainage or waters.

7 Handling and storage

Handling:

Good ventilation of the workplace, no other particular

measures required.

Fire and explosion protection:

No exceptional measures required. Cool any endangered

containers with water.

Storage:

Close containers tightly and store them at dry places. Do not

use any galvanised containers for storage.

8 Limitation of exposure and personal protective

equipment

Personal protective gear:

Hand protection: chemical-resistant protective gloves (EN

374). Suitable materials even in the event of prolonged, direct

contact (recommended: protection index 6, corresponding

to > 480 minutes permeation time according to EN 374):

our elastomer (FKM) – 0.7 mm layer thickness. Suitable

materials for brief contact or splashes (recommended: at least

protection index 2, corresponding to > 30 minutes permeation

time according to EN 374): nitrile rubber (NBR) – 0.4 mm

layer thickness. Due to the large variety of types, observe the

instruction manuals of the manufacturer.

Eye protection:

Safety glasses with lateral protection (framed glasses) (EN

166)

General safety and hygiene measures:

Observe the usual protective measures for dealing with

chemicals.

9 Physical and chemical properties

Form: uid

Colour: violet

Odour: product-specic

Solidication temperature: approx. -28 °C (DIN 51583)

Boiling temperature: > 100 °C (ASTM D 1120)

Flash point: none

Lower explosion limit: 2.6 % by vol. (details for

Upper explosion limit: 12.6 % by vol. 1.2 propylene glycol)

Ignition temperature: omitted

vapour pressure (20 °C): 20 mbar

Density (20 °C): approx. 1.030 g/cm3 (DIN 51757)

Water solubility: entirely soluble

Solubility (qualitative) solvent: polar solvents: soluble

pH value (20 °C): 9.0 – 10.5 (ASTM D 1287)

Viscosity, kinematic (20 °C): approx. 5.0 mm2/s (DIN 51562)

25

Page 26

9 Solar Fluid Safety Data

10 Stability and reactivity

Substances to be avoided: Strong oxidants

Dangerous reactions:

No dangerous reactions if the storage and handling

regulations/notes are observed

Dangerous decomposition products:

No dangerous decomposition products if the storage and

handling regulations/notes are observed.

11 Toxicological information

Acute toxicity:

LD50/oral/rat: > 2000 mg/kg

Primary skin irritation/rabbit: not irritating.

(OECD guideline 404)

Primary irritation to the mucous membrane/rabbit: not

irritating.

(OECD guideline 405)

Additional notes:

The product has not been checked. The statements have

been taken from the individual components.

12 Ecological information

Ecological toxicity:

Fish toxicity: LC50 leuciscus idus (96 h): > 100 mg/l

Aquatic invertebrates: EC50 (48 h): > 100 mg/l

Water plants: EC50 (72 h): > 100 mg/l

Micro-organisms/effect on activated sludge:

DEV-L2 > 1000 mg/l. No disturbances to the biodegrading

activity of the activated sludge are expected in adapted

biological sewage plants if discharged appropriately in low

concentrations.

Assessment of aquamatic toxicity:

The product has not been checked. The statements have

been taken from the properties of the individual components.

Persistence and biodegradability/information on elimination:

OECD 301 A test method (new version)

Analysis method: DOC acceptance

Degree of elimination > 70 % (28 d)

Assessment: easily biodegradable.

13 Note on disposal

Disposal:

Glow-worm solar uid (item no. 0020054968) must be

disposed of at an appropriate waste site or waste incineration

plant, for example, while observing local regulations.

Contact the local municipal sanitation ofce or the mobile

environmental service for quantities under 100 l.

Uncleaned packings:

Uncontaminated packings can be reused. Dispose of

packings which are unable to be cleaned together with the

substance.

14 Transport information:

VbF: not subject to the ordinance on combustible uids.

Mailing permitted. GGVE/RID: -, UN no.: -, GGVS/ADR: -,

IATA DGR: -, IMDG code: -, TA air: -. No dangerous goods

according to transport regulations.

15 Regulations

Labelling in accordance with EC directives/national

regulations: No labelling obligation

Other regulations: water hazard class (Germany, Appendix 4

of the VwVwS (administrative regulation on water-pollutant

substances) from 17.05.1999): (1), slightly water-pollutant

16 Other information

The safety data sheet is intended to provide essential

physical, safety-related, toxicological and ecological data

and give recommendations for safe handling or safe storage,

handling and safe transport of chemical substances and

formulations.

No liability is assumed for damage in connection with the

usage of this information or the usage, application, adaptation

or processing of the products described here.

This does not apply as long as we, our statutory agents

or assistants are liable in the event of intention or gross

negligence.

No liability is assumed for indirect damage.

This information has been compiled to the best of our

knowledge and conscience according to our current state of

knowledge.

No guarantee can be made for product properties.

26

Page 27

27

Page 28

0020055003

Glow-worm, Nottingham Road, Belper, Derbyshire. DE56 1JT

Because of our constant endeavour for improvement, details may vary slightly from those shown in these instructions.

28

0020055003-04 02.09

Loading...

Loading...