Page 1

Clearly Solar

Installation and Servicing

System Wiring

including

Fluropro

Solar Control

www.glow-worm.co.uk

1

Page 2

Customer Service:

01773 596510

Technical Helpline:

01773 828300.

General and Sales enquiries:

Tel. 01773 824639

Fax: 01773 820569

To register your Glow-worm appliance

call:

0800 0732142

Benchmark places responsibilities on both manufacturers and installers. The purpose is to ensure that customers are provided

with the correct equipment for their needs, that it is installed, commissioned and serviced in accordance with the manufacturer’s

instructions by competent persons and that it meets the requirements of the appropriate Building Regulations. The Benchmark

Checklist can be used to demonstrate compliance with Building Regulations and should be provided to the customer for future

reference.

Installers are required to carry out installation, commissioning and servicing work in accordance with the Benchmark Code of

Practice which is available from the Heating and Hotwater Industry Council who manage and promote the Scheme.

Visit www.centralheating.co.uk for more information.

2

Page 3

These instructions consist of, Installation, Commissioning, Service and Fault Finding.

The instructions are an integral part of the appliance and must be handed to the user on

completion of the installation.

CONTENTS DESCRIPTION SECTION PAGE

Regulations 4

Electrical Supply 4

Testing and Certication 4

CE Mark 4

GENERAL

INFORMATION

Safety Instructions 4

Intended Use 5

Documents 5

Servicing 5

Cleaning 5

Recycling 5

INSTALLATION

MAINTENANCE

Specication 1 5

Functions 2 6

Installation 3 7

Electrical Installation 4 9

Commissioning 5 19

Service / Diagnostics 6 24

Sensor Characteristics 7 26

Control - Fault Finding 8 27

3

Page 4

WARNINGS

SAFETY

The uropro must be installed by a competent person, who is responsible for adhering to

the existing standards and regulations.

ALTERATIONS

Under no circumstances should you ever attempt to make alterations to these

components or any other part of the system

SEALED COMPONENTS

Under no circumstances must the user interfere with or adjust sealed parts.

IMPORTANT

Danger of death by electric shock! All live parts of the system may be installed, serviced and repaired

only by a qualied servicing company!

Risk of overvoltage! Earth the solar circuit as potential equalisation and protection against

overvoltage! Attach earthing pipe clips to the solar circuit pipes and connect the clips to a potential

rail with a 16mm2 copper cable.

Regulations

When installing and commissioning the system, the current

version of regulations below shall be observed.

The electrical installation must be installed by a competent

person and in accordance with the relevant standards

Electrical Supply

The product MUST be earthed.

All system components shall be of an approved type and all

wiring to current I.E.E. wiring regulations.

External wiring must be correctly earthed, polarised and in

accordance with the relevant standards.

In GB, this is BS 7671.

In IE, this is the current edition of ETCI rules.

The product MUST be connected to a permanent 230V ac,

50Hz supply.

Connection of the whole electrical system of the product,

including any heating controls, to the electrical supply MUST

be through one common isolator and must be fused 3 Amp

maximum.

Isolation should be by a double pole switched fused spur box,

with a minimum gap of 3mm for both poles. The fused spur

box should be readily accessible and preferably adjacent to

the product. It should be identied as to its use.

Alternatively connection can be made through an unswitched

shuttered socket and 3A fused 3-pin plug both to the current

issue of BS 1363, provided they are not used in a room

containing a bath or shower.

Wiring to the product must be PVC 85°C insulated cable, not

less than 0.75mm2 (24/0.20mm).

CE Mark

The CE mark on the Fluropro solar control indicates that

it complies with the basic requirements of the applicable

directives as stated on the data badge.

“Benchmark scheme”

Glow-worm support the Benchmark initiative. It is very

important that the service record is completed by the

installation engineer and handed over to the user.

Safety Instructions

The entire solar system must always be installed and

operated in accordance with recognised technical standards.

IMPORTANT: Danger of death by electric shock! All live parts

of the system may be installed, serviced and repaired only by

a qualied servicing company!

IMPORTANT: Risk of overvoltage! Earth the solar circuit as

potential equalisation and protection against overvoltage!

Attach earthing pipe clips to the solar circuit pipes and

connect the clips to a potential rail with a 16mm2 copper cable.

Testing and Certication

This product is tested and certicated for safety and

performance. It is, therefore, important that no alteration is

made to the product, without permission, in writing, by Glowworm.

Any alteration not approved by Glow-worm, could invalidate

the certication, warranty and may also infringe the current

issue of the statutory requirements.

4

Page 5

General Information

Intended use

The Fluropro solar control is a temperature differential

controller for solar DHW provision with a cylinder reheat

programmer for a supplementary boiler.

The control is suitable for controlling solar systems with a

collector array and a storage cylinder.

The Fluropro solar control can be used for controlling a

second collector array

If a second collector array is connected, an additional

collector sensor (available as an accessory) must be installed.

It is possible to determine the solar gain by using an

additional gain sensor (supplied with Glow-worm Clearly Solar

sets).

The Fluropro solar control is a state-of-the-art control which

has been constructed in accordance with recognised safety

regulations. Nevertheless, improper use can cause serious

or fatal injury to the user or others, and the appliance or other

property can be damaged.

The manufacturer or supplier is not liable for any damage

resulting from improper use.

The control is not suitable for outdoor use and must be

installed in a dry room.

Documents

Please retain these instructions as well as any documents

enclosed, for future reference.

We accept no liability in case of damage due to the noncompliance of these instructions.

Servicing

To obtain service, please call your installer or Glow-worm’s

own service organisation using the telephone number on the

inside front cover of this booklet.

Cleaning

You can clean the housing of the Fluropro solar control with a

damp cloth and a little soap.

NOTE: Do not use scouring or cleaning agents which could

damage the display.

Recycling

The Fluropro solar control comprises many recyclable parts.

The packaging and control shall not be disposed of with

domestic waste but according to the current regulations.

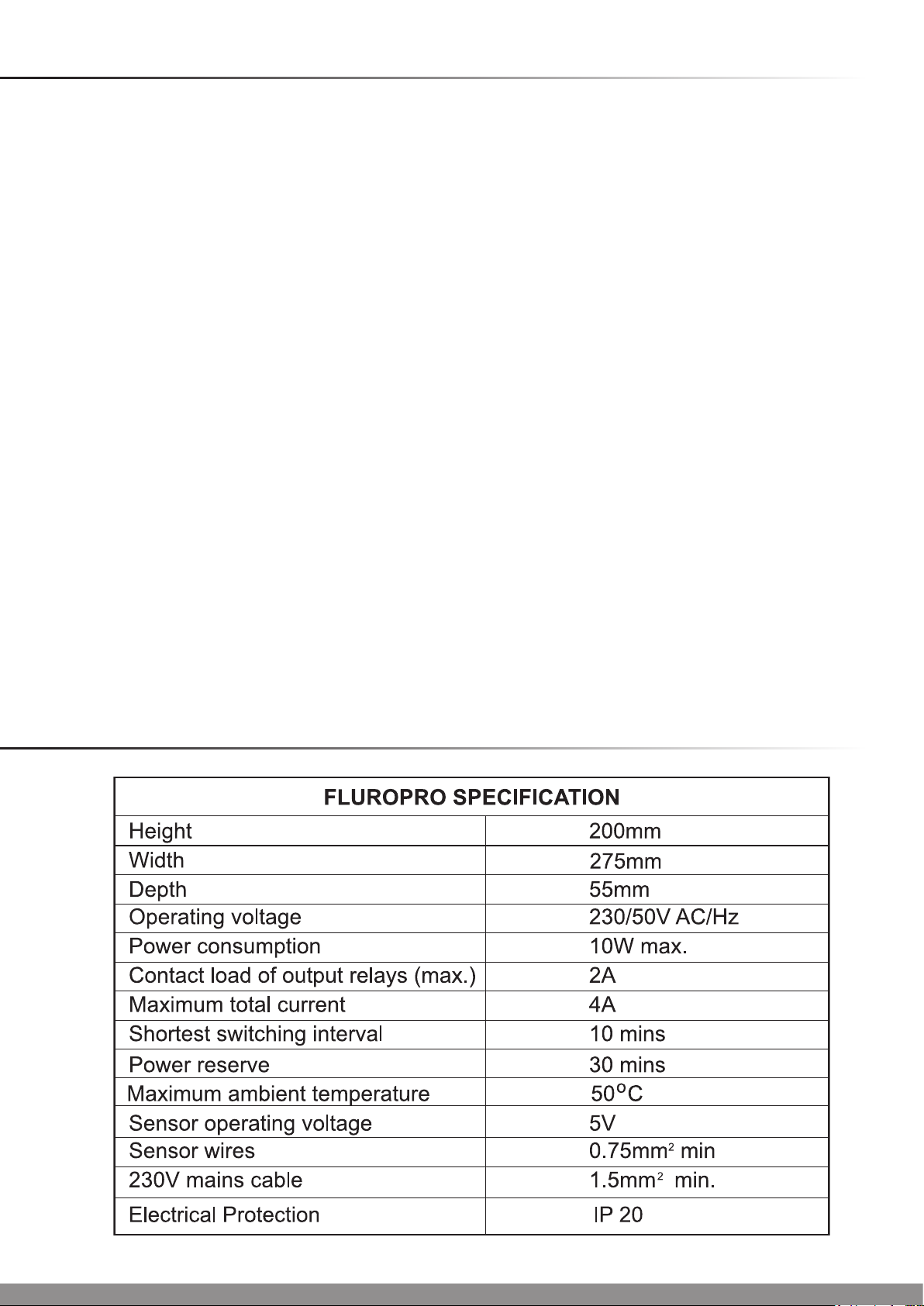

1 Specication

14276

5

Page 6

2 Functions

2.1 Solar gain

The Fluropro solar control works on the principal of differential

temperature control. The control always switches on the

collector pump when the difference in temperature (collector

temperature - cylinder temperature) is greater than the

programmed activation difference.

The controller switches off the collector pump when the

difference in temperature (collector temperature - cylinder

temperature) is less than the programmed deactivation

difference.

The installation engineer activates and congures the solar

gain function within the Fluropro installer menu.

The solar gain is determined from:

– The difference of temperature between the collector ow

and return.

– The ow rate setting of the ow rate adjuster.

– The operating time of the collector pump.

During installation the engineer sets the actual ow rate and

enters the setting into the solar control. The solar gain is

calculated and displayed by the solar control. The total gain

can be called up and reset in the installer menu.

2.2 Solar gain modulation

The rate of solar gain can be modulated to ensure the solar

heat at the bottom of the cylinder has sufcient time to

dissipate to the top of the cylinder. This maintains demand for

solar energy and prevents excessive on and off periods that

are inefcient.

The modulation is achieved by means of more frequent on

and off operations of the solar pump during solar demand.

The pump is switched on and off and the rate depends upon

the difference between the collector temperature and lower

cylinder sensor. When the activation difference is reached, the

function is started (if activated) with an activation duration of

50 % - i.e., the pump is switched on for 30 seconds and then

switched off for 30 seconds. If the difference in temperature

increases, the activation duration is prolonged (e.g., 45

sec. on, 15 sec. off). When the difference in temperature

decreases, the activation duration is reduced (e.g., 20 sec.

on, 40 sec. off). The period length is always a minute.

2.3 Cylinder reheat

The cylinder reheat function allows the cylinder to heat up

to the required temperature during a set time window, even

if the solar gain is insufcient. In this case the water can be

reheated using an external boiler or the immersion heater.

You can set up times for reheating the solar cylinder, refer to

Settings section in Instructions for Use.

2.5 Legionella protection

The Legionella protection function is designed to kill germs in

the cylinder and pipes.

When the function is activated, the cylinder, the hot water

pipes, and the circulation pump (if installed), are brought to

a temperature of 70°C on the programmed day(s) and at the

programmed time

In doing so, the cylinder temperature is raised to 70°C and the

corresponding circulation pump is switched on (if installed).

First, an attempt will be made using solar gain alone to reach

the target temperature over a 90 min. period. If this is not

successful, the Legionella protection is carried out using an

external boiler or an immersion heater, whichever has been

set up for this thermal protection. The Legionella protection

function will stop once a temperature of at least 70°C has

been maintained for a period of 30 minutes.

The installation engineer activates the Legionella protection

function within the Fluropro installer menu and species

whether the thermal disinfection should take place at 3:30

p.m. or at 4:00 a.m., i.e. offset gain versus cheaper electricity.

2.6 Anti-seize protection for pumps

If no pumping has occurred for 23 hours, all installed pumps

are switched on for approx. 3 seconds to prevent pumps from

seizing.

2.7 Secondary recirculation

The Fluropro solar control includes a programmer channel for

a DHW secondary return. A secondary return should not be

used with Glow-worm twin coil unvented solar cylinders.

2.8 Calendar

The controller is equipped with a calendar so that it can

automatically adjust the clock by 1hr between GMT and BST.

To activate, simply enter the current date within the Fluropro

installer menu

NOTE: In the event of a power failure, the controller only has

a power reserve of 30 minutes. After 30 minutes, the internal

clock stops and the calender will not automatically resume

function once power has been restored. In this case the time

and date will need to be reset.

2.4 Reheat delay

To prevent unnecessary cylinder reheating by a boiler or an

immersion heater, the Fluropro solar control includes a reheat

delay function. This function delays the cylinder reheat by up

to 30 mins if solar gain is available.

If the solar pump is off and the desired cylinder temperature

is not reached after the delay period, the cylinder will be

reheated using an external boiler or the immersion heater.

The reheat delay function is activated by an engineer within

the Fluropro installer menu.

6

Page 7

3 Installation

11Fluropro

21Collector sensor

32Cylinder sensor

UPPER

SENSOR

3.1 Contents of sets

Using Table1, verify the contents of the Fluropro solar control

set.

Item Quantity Components

Table 1

The gain sensor is a separate item and is also supplied as

part of the Glow-worm Clearly Sets.

3.2 Installing cylinder sensors

The cylinder sensors are designed so that they can be used

as immersion sensors or surface sensors.

Install the two sensors in the solar cylinder, see diagram 3.1,

and connect to the wiring as shown in wiring diagram.

When used as a surface sensor, the sensor is secured to

the ow pipe or the return pipe as appropriate using the

supplied tension band, see diagram 3.2. In order to guarantee

good heat transfer, the sensor is at on one side. We also

recommend that the pipe with the sensor is insulated, in order

to enable the best possible measuring of temperature.

Refer to cylinder instructions for the location of sensors and

specic tting instructions.

14361

TEMPERATURE

SENSOR

TEMPERATURE

SENSOR

GAIN

LOWER

TEMPERATURE

Diagram 3.1

3.3 Accessories

If a second collector array is connected, it is necessary

to install a second collector sensor from the Glow-worm

accessory range.

3.4 Installing the Fluropro housing

The Fluropro solar control is designed to be mounted on

a wall. The wiring terminals within this control includes the

connectors. These connectors must be used for all wiring to

this control.

The cover consists of two parts, which can be removed

separately:

• As shown in diagram 3.3, pull the lower front cover off of the

controller housing.

• Mark the position of both holes and drill, see diagram 3.4.

• Select wall plugs to suit, and screw the controller housing on

tightly.

14261

Diagram 3.2

14260

Diagram 3.3

7

Page 8

3 Installation

230230

Diagram 3.4

14260

14263

Diagram 3.5

• Lift up the control panel, see diagram 3.5.

• Wire the controller according to the selected hydraulic plan

(see Section 4 Electrical installation).

• Secure all cables with the accompanying cable clamps.

• Push the control panel back into place.

• Re-attach the lower front cover.

8

Page 9

4 Electrical Installation

Electrical Supply

The product MUST be earthed.

All system components shall be of an approved type and all

wiring to current I.E.E. wiring regulations.

External wiring must be correctly earthed, polarised and in

accordance with the relevant standards.

In GB, this is BS 7671.

In IE, this is the current edition of ETCI rules.

The product MUST be connected to a permanent 230V ac,

50Hz supply.

Connection of the whole electrical system of the product,

including any heating controls, to the electrical supply MUST

be through one common isolator and must be fused 3 Amp

maximum.

Isolation should be by a double pole switched fused spur box,

with a minimum gap of 3mm for both poles. The fused spur

box should be readily accessible and preferably adjacent to

the product. It should be identified as to its use.

Alternatively connection can be made through an unswitched

shuttered socket and 3A fused 3-pin plug both to the current

issue of BS 1363, provided they are not used in a room

containing a bath or shower.

Wiring to the product must be PVC 85°C insulated cable, not

less than 0.75mm2 (24/0.20mm).

IMPORTANT: Risk of fatal electric shock from touching live

connections.

Before working on the system wiring, including the Fluropro,

isolate the power supply.

The circuit board can be damaged if short circuited through

the connection leads. For safety purposes, a max. of 30 mm

of insulation may be removed from the ends of 230 V leads

which will be connected to Fluropro wiring connectors. If more

insulation is removed, there is a risk of short circuiting the

circuit board.

When exchanging the solar controller in an existing

system, sensor-curve characteristics should be taken

into consideration and the sensors should be replaced if

necessary!

The immersion heater must be installed with an additional

relay or contactor with a circuit-breaking capacity of at least

16 A. Never operate an immersion heater in connection with

the Fluropro without an additional external relay or contactor.

9

Page 10

4 Electrical Installation

SOLAR COLLECTOR

BOILER

SOLAR COLLECTOR

CIRCUIT PUMP

AUTO AIR

SEPARATOR

MOTORISED

2 PORT VALVE

MOTORISED

2 PORT VALVE

FLOW

FLOW

HOT

WATER

CONNECTION

TUNDISH

THERMOSTAT

MIXER

FLUROCYL

DRAIN VALVE

RETURN

RETURN

EXPANSION

RELIEF

VALVE

(6.0 BAR)

PRESSURE

LIMITING VALVE

(3.5 BAR)

WITH LINE

STRAINER

COLD

WATER

SUPPL

Y

PUMP

EXPANSION

VESSEL

TEMPERATURE

AND PRESSURE

RELIEF VALVE

(95 °C, 7 BAR)

LEGIONNELLA

LOOP (optional)

4.1 Hydraulic plan

IMPORTANT: Reference cylinder instructions for wiring to

cylinder thermostats and thermal cut-outs.

(NOTE: The Glow-worm Flurocyl cylinder is fitted with a solar

thermal cut-out - other manufacturers cylinders may not be

fitted with this device).

IMPORTANT: To simplify the system wiring, two hydraulic

plans are stored in the Fluropro solar control.

Hydraulic Plan 1 includes one collector array and

Hydraulic Plan 2 includes two collector arrays,

(separate circuits and pump stations). The relevant plan must

be selected within the Fluropro installer menu.

14213

10

Hydraulic Plan 1

Page 11

4 Electrical Installation

Collector arrays setup for East / West orientation

14212

N

SOLAR

COLLECTOR

SOLAR

COLLECTOR

CIRCUIT PUMP

HOT

WATER

CONNECTION

SOLAR

COLLECTOR

LEGIONNELLA

LOOP (optional)

W

S

THERMOSTAT

MIXER

PUMP

TEMPERATURE

AND PRESSURE

RELIEF VALVE

(95 °C, 7 BAR)

E

BOILER

MOTORISED

2 PORT VALVE

MOTORISED

2 PORT VALVE

AUTO AIR

SEPARATOR

FLOW

RETURN

FLOW

RETURN

EXPANSION

VESSEL

EXPANSION

RELIEF

VALVE

(6.0 BAR)

PRESSURE

LIMITING VALVE

(3.5 BAR)

WITH LINE

STRAINER

TUNDISH

FLUROCYL

DRAIN VALVE

Hydraulic Plan 2

COLD

WATER

SUPPLY

11

Page 12

4 Electrical Installation

Boiler

Flexicom hx / sx,

Ultracom hxi / sxi,

old hxi / sxi

3rd party ov / sys

Ultracom hxi / sxi

with

options board

Wiring

11 way terminal

block

11 way terminal

block

Solar Circuit

Control

Fluropro

Fluropro

DHW

programming

Fluropro

3rd party

programmer

Internal

programmer

Fluropro

CH

programming

3rd party

programmer

3rd party

programmer

Internal

programmer

Internal

programmer

Climapro or

Climapro RF

Diagram

4.1

4.2

4.3

4.4

4.5

Installer interface options for Glow-worm boilers

4.6

12

Page 13

4 Electrical Installation

FLUROCYL

E N

L

3rd PARTY

EXTERNAL

PROGRAMMER

FOR CH

COMMON 230V

MAINS TERMINAL

BLOCK

ROOM

THERMOSTAT

L

or

E

N

NOC

L

TERMINAL BLOCK

230V~50Hz

MAINS SUPPLY

L

N

E

Double

pole

isolator

RETURN PIPE

AT 16A

FUSED

AT 3A

COLLECTOR

PUMP

SOLAR

COLLECTOR

DAO

LN

E N L E N 2 1 L

or g g

b b

g/y g/y br br

br

bl

g/y

N L

E

H

3 4 5 6 7 8 9

LINK E N L

10

ADDITIONAL

TERMINAL

BLOCK

DHW

VALVE

CH

VALVE

FLUROPRO

CONTROLLER

230v~ PCSA

NTCA

TAC1

TAC2

GAIN R

L

BROWN br

BLUE b

BLACK bl

ORANGE or

WHITE w

PURPLE p

GREEN gn

GREY g

GREEN

/YELLOW g/y

KEY

REFER TO BOILER WIRING

INTERFACE, PAGE 17.

bl

230V~50Hz

MAINS SUPPLY

L

N

E

Double

pole

isolator

AT 3A

14793

Diagram 4.1

13

Page 14

4 Electrical Installation

FLUROCYL

3rd PARTY

EXTERNAL

PROGRAMMER

FOR CH

ROOM

THERMOSTAT

L

or

E

E

N

NOC

L

TERMINAL BLOCK

RETURN PIPE

FUSED

AT 3A

COLLECTOR

PUMP

SOLAR COLLECTOR

DAO

LN

E N L E N 2 1 L

or g g

b b

g/y g/y br br

br

N NL

L

E

H

NOHW

3 4 5 6 7 8 9

LINK E N L

10

ADDITIONAL

TERMINAL

BLOCK

DHW

VALVE

CH

VALVE

FLUROPRO

CONTROLLER

230v~ PCSA

NTCA

TAC1

TAC2

GAIN

R

L

BROWN br

BLUE b

BLACK bl

ORANGE or

WHITE w

PURPLE p

GREEN gn

GREY g

GREEN

/YELLOW g/y

KEY

bl

g/y

bl

COMMON 230V

MAINS TERMINAL

BLOCK

230V~50Hz

MAINS SUPPLY

L

N

E

Double

pole

isolator

AT 16A

REFER TO BOILER WIRING

INTERFACE, PAGE 17.

230V~50Hz

MAINS SUPPLY

L

N

E

Double

pole

isolator

AT 3A

14794

Diagram 4.2

14

Page 15

4 Electrical Installation

FLUROPRO

CONTROLLER

14795

SOLAR COLLECTOR

FUSED

AT 3A

DHW

VALVE

orgg

NTCA

or

230v~ PCSA

ENL E N 21L

CH

VALVE

bb

g/yg/y br br

TAC2

TAC1

TERMINAL BLOCK

GAINR

COLLECTOR

PUMP

L

LINKE N L

ADDITIONAL

TERMINAL

BLOCK

bl

g/y

bl

KEY

BROWN br

BLUE b

BLACK bl

ORANGE or

WHITE w

PURPLE p

GREEN gn

GREY g

GREEN

/YELLOW g/y

E

Wiring for

boiler installer

interface

cartridge for

Ultracom hxi

ONLY

Wiring for

boiler installer

interface

cartridge for

Ultracom sxi

ONLY

BOILER

OPTIONS

N L 3 4 5 6 7 8 9

SYSTEM

PUMP

230V

4 ON TERMINAL

BLOCK

230V

4 ON TERMINAL

BLOCK

LN

ROOM

THERMOSTAT

EBUS

OV

24V

EBUS

OV

OTC1

OTC2

N

L

N

L

R

F

N

L

R

F

10

br

L DAO

FLUROCYL

RETURN PIPE

COMMON 230V

MAINS TERMINAL

BLOCK

HW ON

HEATING

X12

HW OFF

X40a

OPTIONS BOARD

X40b

Double

pole

isolator

AT 3A

230V~50Hz

MAINS SUPPLY

15

LNE

Double

pole

isolator

AT 16A

230V~50Hz

MAINS SUPPLY

LNE

Diagram 4.3

Page 16

4 Electrical Installation

FLUROPRO

CONTROLLER

14796

SOLAR COLLECTOR

FUSED

AT 3A

DHW

VALVE

orgg

NTCA

or

230v~ PCSA

ENL E N 21L

CH

VALVE

bb

g/yg/y br br

E

N L 3 4 5 6 7 8 9 10

TAC2

TAC1

TERMINAL BLOCK

GAINR

COLLECTOR

PUMP

LINKE N LL

BROWN br

BLUE b

BLACK bl

ORANGE or

WHITE w

PURPLE p

GREEN gn

GREY g

GREEN

/YELLOW g/y

ADDITIONAL

TERMINAL

BLOCK

bl

g/y

bl

KEY

Wiring for

boiler installer

interface

cartridge for

Ultracom hxi

ONLY

Wiring for

boiler installer

interface

cartridge for

Ultracom sxi

ONLY

BOILER

OPTIONS

X12

X40a

PUMP

EBUS

OV

24V

EBUS

OV

OTC1

OTC2

N

L

N

L

4 ON TERMINAL

R

BLOCK

F

N

L

R

F

X40b

SYSTEM

PUMP

230V

230V

4 ON TERMINAL

BLOCK

LN

L DAO

ROOM

THERMOSTAT

Double

pole

isolator

AT 3A

br

br

L

E

N

RETURN PIPE

COMMON 230V

MAINS TERMINAL

BLOCK

Double

pole

isolator

AT 16A

FLUROCYL

L

N

E

HW ON

HEATING

HW OFF

OPTIONS BOARD

230V~50Hz

MAINS SUPPLY

16

230V~50Hz

MAINS SUPPLY

Diagram 4.4

Page 17

4 Electrical Installation

FLUROPRO

CONTROLLER

14797

SOLAR COLLECTOR

FUSED

AT 3A

DHW

VALVE

orgg

NTCA

or

230v~ PCSA

ENL E N 21L

CH

VALVE

bb

g/yg/y br br

TAC2

TAC1

TERMINAL BLOCK

GAINR

COLLECTOR

PUMP

LINKE N LL

ADDITIONAL

TERMINAL

BLOCK

bl

g/y

bl

KEY

BROWN br

BLUE b

BLACK bl

ORANGE or

WHITE w

PURPLE p

GREEN gn

GREY g

GREEN

/YELLOW g/y

E

Wiring for

boiler installer

interface

cartridge for

Ultracom hxi

ONLY

Wiring for

boiler installer

interface

cartridge for

Ultracom sxi

ONLY

BOILER

OPTIONS

X12

N L 3 4 5 6 7 8 9 10

CLIMAPRO

or

CLIMAPRO

RF

SYSTEM

PUMP

TO CLIMASTAT

OR CLIMAPRO

IF FITTED

230V

4 ON TERMINAL

BLOCK

TO CLIMASTAT

OR CLIMAPRO

IF FITTED

230V

4 ON TERMINAL

BLOCK

X40b

Double

pole

isolator

AT 3A

EBUS

EBUS

OTC1

OTC2

X40a

OV

24V

OV

N

L

N

L

R

F

N

L

R

F

br

br

COMMON 230V

MAINS TERMINAL

BLOCK

L

E

N

RETURN PIPE

Double

pole

isolator

AT 16A

FLUROCYL

L

E

N

HW ON

HEATING

HW OFF

OPTIONS BOARD

230V~50Hz

MAINS SUPPLY

17

230V~50Hz

MAINS SUPPLY

Diagram 4.5

Page 18

Main supply

3 Amp fused

LN

bl blE

TCO

Collector

Pump

Flurocyl

Cylinder

4 Electrical Installation

LEG/BYPPCSB/PCPCSA230 V~

E LNE LNLN

Pump East

L N

4 763

Relay

14839

V3VR

E LNE 12LN

EL N

Collector

EL N

Collector

Pump West

Diagram 4.6

4.2 Additional wiring for East/West

installations.

To maintain compliance with G3 regulations when using

an East/West arrangement with independant pump station

control, it is necessary to install an additional external relay.

(Drayton RBI shown, see diagram 4.6, but any suitable double

pole relay or 2 separate relays could be used).

Wiring for boiler installer

interface cartridge for

Glow-worm XI hxi ONLY

24V

EBUS

OV

OTC1

OTC2

N

230V

L

R

F

4 ON TERMINAL

BLOCK

N

L

N

L

4 ON TERMINAL

R

BLOCK

F

SYSTEM

PUMP

230V

4.3 Using Third party heating appliances

in conjunction with the Glow-worm solar

system solution.

It is possible to use a non Glow-worm boiler with the Glowworm solar system solution which is controlled by the

Fluropro.

In order to achieve this, consult your boiler installation manual

to determine the switched live connection to the boiler. The

switched live input is the 230v input voltage to the boiler which

makes a heating demand.

The heating demand to your non Glow-worm boiler will be

provided from the Fluropro or a third party programmer at

terminal 4 of the wiring centre.

14277

4 ON TERMINAL

BLOCK

BOILER CONNECTIONS

230V CONTROLS INTERFACE

230V SWITCHED LIVE

FROST THERMOSTAT

230V SWITCHED LIVE

r

HEATING CONTROLS

DO NOT CONNECT

w

r

gr

Wiring for boiler installer

interface cartridge for

New Flexicom sx

Ultracom sxi ONLY

Wiring for boiler installer

interface cartridge for

New Flexicom hx

Ultracom hxi ONLY

BOILER OPTIONS

EBUS

OV

N

L

SYSTEM

PUMP

N

F

4 ON TERMINAL

R

L

BLOCK

If there are no system controls available

the red link will allow the boiler to run

continuously. REMOVE the red link if

fitting system controls

230V

INSTALLER INTERFACE OPTIONS FOR

GLOW-WORM BOILERS

Diagram 4.7

18

Page 19

5 Commissioning

1

Display

User Control Panel

14722

Button

Button

Display overview Display symbols

13

12

11

10

8

2

3

5

4

6

9

7

Timer programs:

Cylinder reheat

Not used

Operating modes:

Cylinder reheat function in timed mode

Cylinder reheat function in constant mode

Button

Button

Diagram 5.1

Key

1 Programming menu

2 Service/diagnostic menu

3 Cylinder reheat

4 Not used

5 Info menu

6 Solar gain (blinks if solar gain is available)

7 Units

8 Cursor

9 Multifunction display

10 Days of the week

11 Target/actual value

12 Operating modes

13 Special functions

No cylinder reheat

Solar pump(s) not activated

No cylinder reheat

Special functions:

Party

Advanced cylinder reheat

Holiday function

Diagram 5.2

19

Page 20

Changing the hydraulic plan

1, 2, 3

1

Setting the flow rate

0 – 165 litres/min

0

Resetting the solar gain.

-

-

Resetting the operating hours.

-

-

Setting the max. temperature for cylinder 1

20 to 90 °C

75 °C

5 Commissioning

Installer menu

Access the installer menu by pressing the button for 3

seconds.

Press the

button for 3 seconds again to return to the

operating menu.

These parameters should only be adjusted by the installation

engineer.

5.1 Setting the system parameters

Certain system parameters have to be set in order to optimise

the system for the respective conditions. These parameters are

all together in the installer menu and should only be set by the

installation engineer.

Access the installer menu.

Display

Press + or - to adjust

Press PROG to accept

1. 1 collector array.

2. 2 collector arrays (East/West system).

3. Not used.

IMPORTANT:

l The hydraulic plan, ow rate and current date must be

entered.

l It is also recommended that the solar gain modulation and

cylinder reheat delay are activated.

l Ask the householder how long they normally program the

DHW to be on for before they actually require it. If one hour or

more, activate the cylinder reheat delay.

l It may not be necessary to change any other settings from

the factory defaults

Exit the installer menu.

The following table gives an overview of all system parameters

and their factory settings and range.

Setting range Factory setting

When setting the the required flow rate,

please observe the measurement units,

required for display of Solar gain.

The solar gain is reset to 0 by turning the dial

to 1.

The operating hours are reset to 0 by turning

the dial to 1.

Setting the activation difference for cylinder 1.

(The activation difference should always be 2

K greater than the deactivation difference)

2 – 15 K 7 K

Setting the deactivation difference for cylinder

1.

(The deactivation difference should always be

2 K less than the activation difference)

1 – 10 K 3 K

20

Page 21

Not used.

20 - 90 °C

60 °C

Not used

.

5 – 12 K

7 K

Not used.

1 – 10 K

3 K

PRIO

1, 2

1

AGEL:

-5oC – 10oC; OFF

OFF

PROT

OFF, 110oC – 150oC

130oC

CST:

1, 2

1

LEG

OFF, 1, 2, 3, 4, 5, 6, 7, 1-7

OFF

LEGT:

00:00 - 23:50

04:00

5 Commissioning

Display Turn the dial to adjust Setting range Factory setting

Cylinder with highest priority

Frost protection function

Solar circuit safeguard

Collector type

1 = Flat collector

2 = Tubular collector

Anti-Legionella function

Start time for the anti-Legionella function

Table 1 System parameters (continued)

21

Page 22

Cylinder reheat delay function

0=deactivated; 1=activated

0

Solar gain modulation function

0=off; 1=on

0

Setting the current day

1 - 31

0

Setting the current month

1 - 12

0

Setting the current year

2000 - 2159

2000

5 Commissioning

Display Turn the dial to adjust Setting range Factory setting

Table 1 System parameters (continued)

22

Page 23

5 Commissioning

Adjust the solar water heating target temperature setting

Important: Set the solar water heating target temperature to

the maximum adjustment

Press and hold the button to increase the solar water

heating target temperature, or press and hold the button

to decrease the solar water heating target temperature.

Once or is pressed a cursor appears beside the

current target temperature. The temperature begins to ash

as it is being adjusted. Once the desired target temperature

is selected wait 5 seconds. The display returns to running

screen.

5.2 Resetting parameters to default

You can reset the system parameters and the timer programs

to the default settings by pressing the button for

ten seconds. Then the display ashes twice and all of the

parameters are reset to the factory defaults.

5.4 Hand over to the householder

l Hand over all manuals to the householder.

l Advise the householder to keep the manuals near to the

system.

l Draw special attention to the safety instructions which the

householder must follow.

l Review the user instructions with the householder and

answer any questions.

l Show the householder how to operate the solar control, CH

control and any separate DHW control.

l Inform the householder that the cylinder temperature is

factory set at 65°C and that the DHW temperature can be

adjusted using the TMV by the installer.

l Inform the householder that the immersion heater is

intended as a standby device and should not be used

simultaneously with the boiler to heat the cylinder.

l Inform the householder that they are not permitted to

change the settings made on the solar system.

l Inform the householder that to ensure the continued

efcient and safe operation of the solar system it is

recommended that it is checked and serviced at regular

intervals. The frequency of servicing will depend upon the

installation conditions and usage, but in general, once a year

should be enough.

l Inform the householder that the boiler and solar cylinder

should be serviced by a qualied engineer annually.

5.3 Benchmark

GB: It is a requirement that the “Benchmark” Installation,

Commissioning and Service Record is completed and left with

the user.

IE: it is necessary to complete a “Declaration of Conformity” to

indicate compliance to I.S.813. An example of this is given in

the current edition of I.S.813.

Leave these instructions and the “Benchmark” Installation,

Commissioning and Service record document with the user.

23

Page 24

6 Service / Diagnostics

Collector pump test (array 1)

Collector pump 1 on, all other actuators off

Collector pump test (array 2 if applicable)

Collector pump 2 on, all other actuators off

Cylinder reheat 230V demand test

Cylinder reheat 230V demand on, all other actua-

Cylinder reheat demand - volt free contacts test

Cylinder demand - volt free contacts - closed cir-

Upper cylinder sensor value

6 Service menu

Access the service menu by simultaneously pressing the

button and button for approx. 3 seconds. All

relays and sensors can be controlled and checked in this

menu (refer to the system wiring manual included with

Fluropro).

Display Relay check/sensor values Test procedure

The display returns to the main operating menu if you press

the

and sensors should be checked only by the installation and

service engineer.

button and button for 3 seconds. The relays

Switching valve test Switching valve on, all other actuators off

Legionella protection pump test Legionella protection pump on, all other actuators

off

tors off

cuit, all other actuators off

Table 1 Actuators and sensors

24

Page 25

Collector sensor value (array 1)

Collector sensor value (array 2 if applicable)

Gain sensor value

6 Service / Diagnostics

Display Relay check/sensor values Test procedure

Low cylinder sensor value

Not used

Table 1 Actuators and sensors (continued)

You can check the visual display by pressing

Diagram 6.1 Check visual display

With another press, the current version of the controller’s

software is displayed.

Diagram 6.2 Controller software version

You can exit the service/diagnostic level by pressing the

and buttons simultaneously.

again.

Emergency mode

When the Fluropro detects an error, its basic display always

shows the error. If either the solar yield or reheating function

is possible, the controller carries out this function despite the

error.

25

Page 26

Sensor values

Resistance value

0 °C

9191 Ohm

20 °C

3384 Ohm

25 °C

2692 Ohm

30 °C

2158 Ohm

50 °C

954 Ohm

60 °C

658 Ohm

70 °C

463 Ohm

120 °C

105 Ohm

Sensor values

Resistance value

-20 °C

97070 Ohm

0 °C

32650 Ohm

5 °C

25390 Ohm

10 °C

19900 Ohm

20 °C

12490 Ohm

25 °C

10000 Ohm

30 °C

8057 Ohm

40 °C

5327 Ohm

50 °C

3603 Ohm

60 °C

2488 Ohm

90 °C

918 Ohm

100 °C

680 Ohm

130 °C

301 Ohm

7 Sensor Characteristics

Cylinder sensors, type NTC 2.7 K

5 °C 7064 Ohm

10 °C 5214 Ohm

40 °C 1416 Ohm

80 °C 333 Ohm

Collector sensor, type NTC 10 K

-10 °C 55330 Ohm

-5 °C 42320 Ohm

15 °C 15710 Ohm

35 °C 6532 Ohm

70 °C 1752 Ohm

80 °C 1258 Ohm

110 °C 511 Ohm

120 °C 389 Ohm

26

Page 27

8 Control - Fault Finding

Error messages

The Fluropro solar controller shows error messages in

the main operating menu if there is a problem with the

temperature sensor.

The sensor conguration will always be displayed when the

controller is switched on for the rst time, or if the power

has been switched off and on again. Depending on the set

hydraulic plan, the controller recognises whether there is a

problem, or if the sensor is not necessary for operation.

The following diagrams assume that the day is Monday

and that the timer is active for reheat but is not currently

reheating.

Error collector sensor (array 1)

This error occurs if the there is a problem with the collector

sensor, or if it is not connected.

Error collector sensor (array 2)

This error occurs if a sensor is connected for hydraulic plan

1. Alternatively for hydraulic plan 2 or 3, if there is a problem

with the connected sensor or it is not connected.

Error Upper cylinder sensor

This error occurs if there is a problem with the heating circuit

sensor connected.

Error Lower cylinder sensor

This error occurs if there is a problem with the solar circuit

sensor, or if it is not connected.

27

Page 28

0020055002

Glow-worm, Nottingham Road, Belper, Derbyshire. DE56 1JT

Because of our constant endeavour for improvement, details may vary slightly from those shown in these instructions.

28

0020055002-04 03.09

Loading...

Loading...