Page 1

Clearly Solar

Solar Thermal Flat Plate Collector

Installation Instructions

Flat Surface Mounting

SRH 2.3 and SRV 2.3

www.glow-worm.co.uk

1

Page 2

Guarantee Registration

These Clearly Solar Flat Plate collectors come with a comprehensive manufacturer’s guarantee.

Details of the guarantee, and the terms and conditions that apply can be found on the Guarantee

registration card. We recommend you complete and return this as soon as possible.

Customer Service:

01773 596510

Technical Helpline:

01773 828300

General and Sales enquiries:

Tel. 01773 824639

Fax: 01773 820569

To register your Glow-worm appliance call:

0800 0732142

Benchmark places responsibilities on both manufacturers and installers. The purpose is to ensure that customers are provided

with the correct equipment for their needs, that it is installed, commissioned and serviced in accordance with the manufacturer’s

instructions by competent persons and that it meets the requirements of the appropriate Building Regulations. The Benchmark

Checklist can be used to demonstrate compliance with Building Regulations and should be provided to the customer for future

reference.

Installers are required to carry out installation, commissioning and servicing work in accordance with the Benchmark Code of

Practice which is available from the Heating and Hotwater Industry Council who manage and promote the Scheme.

Visit www.centralheating.co.uk for more information.

2

Page 3

These instructions must be handed to the user on completion of the installation.

CONTENTS DESCRIPTION SECTION PAGE

GENERAL

INFORMATION

TECHNICAL

SPECIFICATION

FLAT SURFACE

MOUNTING

Warnings 4

Important Information 4

Statutory Requirements 5

Technical Specication 1 6

Vertical Collector Technical Data 2 7

Vertical Collector and Hydraulic

Connection Arrangement 3 8

Hydraulic Connection Kits

- Vertical Collector 4 9

Flat Surface Installation

- Vertical Collector 5 10

Horizontal Collector Technical Data 6 17

Horizontal Collector and Hydraulic

Connection Arrangement 7 18

Hydraulic Connection Kits

- Horizontal Collector 8 19

Flat Surface Installation

- Horizontal Collector 9 20

3

Page 4

WARNINGS

Metal Parts

This solar panel contains metal parts (components) and care should be taken when handling,

with particular regard to edges.

Risk of death from falls and falling objects

Observe the national regulations for working at heights.

Danger of burning and scalding

In case of solar irradiation inside the units, solar panels can reach 200°C.

Remove the sun protection lm installed at the factory only after the solar energy system has been started up.

Sealed Components

Under no circumstances must the user interfere with or adjust sealed parts.

Important Information

General

These instructions must be handed to the user on completion

of the installation.

This installation instruction applies exclusively to the mounting

of the solar collector.

The solar collector is one component in a solar system and

it is recommended that you read all other component(s)

literature prior to installation.

We accept no liability for any damage caused by failure to

observe these instructions.

Control of Substances Hazardous to Health

Under Section 6 of The Health and Safety at Work Act

1974, we are required to provide information on substances

hazardous to health.

The adhesives and sealants used in this appliance are cured

and give no known hazard in this state.

Solar uid

For solar uid safety data, please refer to Clearly Solar

System Hydraulics literature.

Manual Handling

With regards to the “Manual Handling Operations, 1992

Regulations”, this product exceeds the recommended weight

for a one man lift.

Recommend 2 person lift. Ensure safe lifting techniques are

used – keep back straight – bend using legs. Keep load as

close to body as possible. Ensure co-ordinated movements

during lift. Clear the route before attempting the lift. If

removing from truck straddle the load and tilt forwards to

facilitate secure grip. Do not twist – reposition feet instead.

Take care to avoid trip hazards, slippery or wet surfaces and

when climbing steps or ladders. Always use assistance if

required.

Installation of the solar collector will require a risk

assessment.

Testing and Certication

This solar collector is tested and certicated for safety and

performance. It is, therefore, important that no alteration is

made, without permission, in writing, by Glow-worm.

Any alteration not approved by Glow-worm, could invalidate

the certication, warranty and may also infringe the current

issue of the statutory requirements.

CE Mark

The CE mark on the solar collector indicates that it complies

with the basic requirements of the applicable directives as

stated on the data label.

Damage from lightning

If the installation height is more than 20m, electro-conductive

components must be connected to a lightning protection

device.

Frost Protection

Under no circumstances should water be in the solar collector

if there is a danger of frost.

After pressurisation and ushing, the solar collector(s) may

contain water residue.

Water remaining in the solar circuit will dilute the uid.

Immediately ll the solar system with solar uid. Check the

uid concentration with a frost protection tester.

4

Page 5

Statutory Requirements

IMPORTANT

Where no British Standards exists, materials and equipment

should be t for their purpose and of suitable quality and

workmanship.

The installation of this solar collector panel must be carried

out by a competent person in accordance the rules in force

in the countries of destination.

Manufacturer’s instructions must not be taken as overriding

statutory requirements.

Statutory Requirements

In GB, the installation of the solar collector panel must comply

with the requirements of the current issue of the following

regulations:

The manufacturer’s instructions supplied.

The appropriate Buildings Regulations either The Building

Regulations, The Building Regulations (Scotland),The

Building Regulations (Northern Ireland).

Working at Heights Regulations 2005.

Connecting thermal solar appliances.

Lightning protection requirements.

Equipotential bonding of electrical installations.

The Health and Safety at Work Act

Control of Substances Hazardous to Health (COSHH).

The Current I.E.E. Wiring Regulations.

The Water Supply (water ttings) Regulations 1999 or the

Water Byelaws 2000 (Scotland).

Where no specic instructions are given, reference should be

made to the relevant British Standard Code of Practice.

Regulations for the prevention of accidents

At all times follow the national regulations on working at

heights.

Make sure there is suitable safety equipment such as

scaffolding or protective walls to prevent falling from roofs.

Fall protection systems such as the Glow-worm fall protection

system (item no. 0020054985) also has a fall arresting device

if the roof scaffold and protective roof wall are inappropriate

for the specic task.

Only use tools and equipment such as lifting gear or ladders

in accordance with the lifting regulations.

Cordon off areas below the working area sufciently to protect

people from falling objects.

Mark the working area, for example with warning signs as

described by the national regulations.

5

Page 6

1 Technical Specication

Design Description

The Clearly Solar, solar at plate collector, collects the

available solar radiation and transfers the heat through the

solar uid to be utilised by the system.

It has been designed to compliment the complete range of

Glow-worm solar system components.

The kits are suitable for at roof or at surface installation.

The solar thermal at plate collector includes a saltwater-

resistant aluminium frame as well as a copper surface

absorber with a high selective coating.

The at plate collector has a CFC-free, standstill temperature-

resistant mineral wool insulation for long-life and excellent

heat insulation.

Hydraulic connections are tool free with double ‘O’ ring

sealing. The sensor sleeve is integrated into the hydraulic ow

connection.

Hydraulic connections are push-t with double ‘O’ ring

sealing. The sensor sleeve is integrated into the hydraulic ow

connection.

IMPORTANT: The completed works shall comply with all

necessary BS EN Standards and Codes of practice as well

as Building control or planning requirements, these should be

conrmed where necessary by notication to building control

or the appropriate competence based notication body.

The following kits are available and dependant upon the

number of collectors, the quantities required are listed in the

following table and illustrated in the appropriate sections:-

Number of collectors: 1 2 3 4 5 6 7 8 9 10 11 12

Gravel tray Part number 0020059905

Easy fit hydraulic connection set - Section 4.

Part number 0020060207

Easy fit hydraulic extension set - Section 4.

Part number 0020059909

Vertical

Vertical frame Part number 0020060312

Diagram 5.1.

collector position

Vertical rail, aluminium

Part number 0020060308 - Diagram 5.1.

Gravel tray art.-no. 0020059904

Easy fit hydraulic connection set - Section 4.

Part number 0020060207

Easy fit hydraulic extension set - Section 4.

Part number 0020059909

Horizontal frame Part number 0020060311

Horizontal

Diagram 9.1.

collector position

Horizontal rail, aluminium

Part number 0020060307 - Diagram 9.1.

2 3 4 5 6 7 8 9 10 11 12 13

- 1 2 3 4 5 6 7 8 9 10 11

2 3 4 5 6 7 8 9 10 11 12 13

2 4 6 8 10 12 14 16 18 20 22 24

2 3 4 5 6 7 8 9 10 11

- 1 2 3 4 5 6 7 8 9

2 3 4 5 6 7 8 9 10 11

1 2 3 4 5 6 7 8 9 10

1

1

Flat surface installation components

6

Page 7

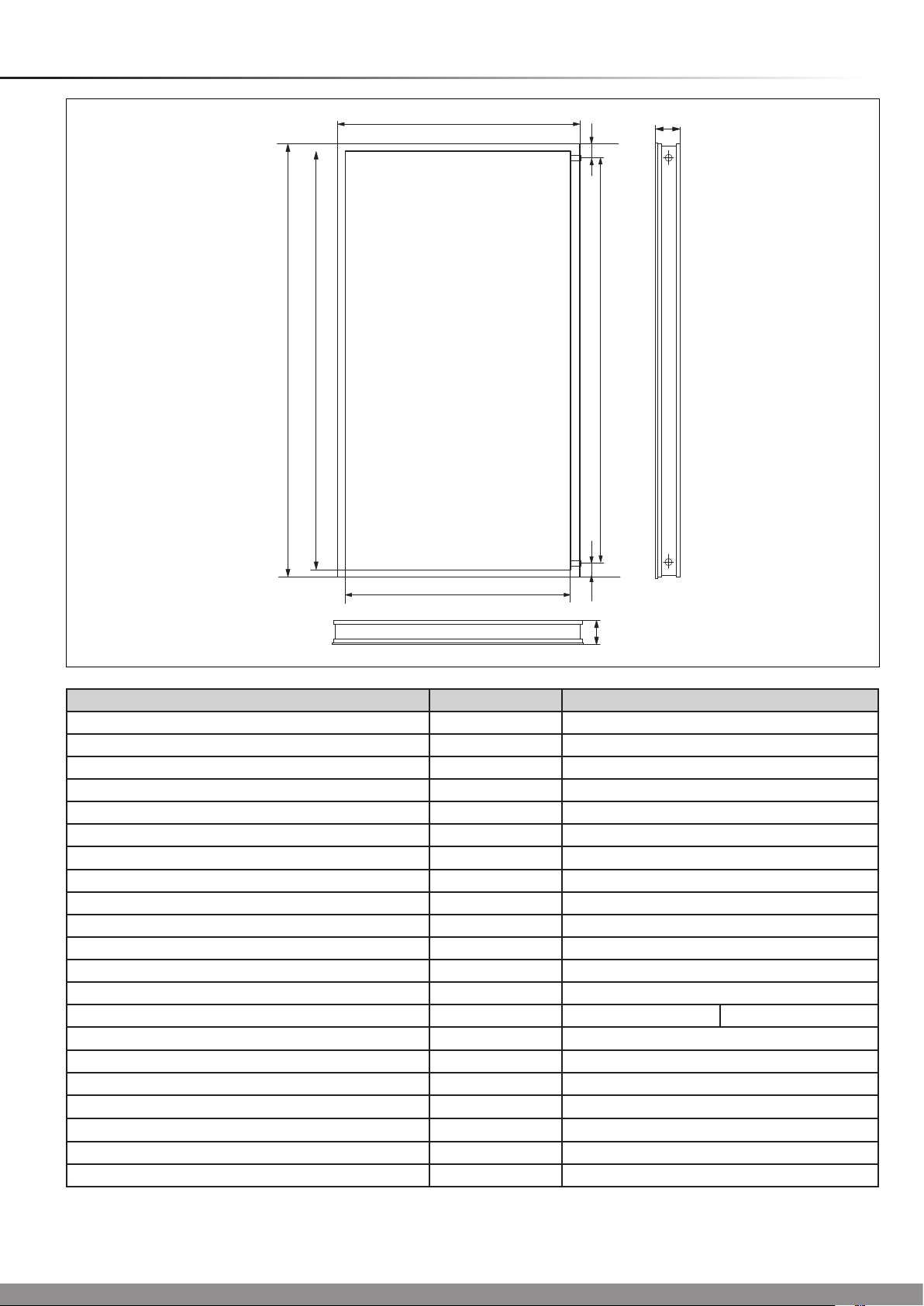

2 Vertical Collector Technical Data

2033

1978

1233

79

80

14922

1875

1178

79

80

Diagram 2.1Vertical Collector

Appliance designation Unit. Clearly Solar

Absorber type Serpentine

Gross area m

Aperture surface area m

Absorber surface area m

2

2

2

Absorber Aluminium (vacuum coated) 0.5 x 1178 x 1978

Dimensions (L x W x H) mm 2033 x 1233 x 80

Weight (Dry) kg 38

Fluid content l 1.85

Copper pipe connection, at-face Ø mm G 3/4" (DN16)

Insulation thickness mm 40

Max. operating pressure bar 10

Glass type Solar safety glass (prismatic structure)

Glass covering mm 3.2 (thickness) x 1233 x 2033

Coating High selective (blue) α = 95% ε = 5%

Transmission %

2

Back wall insulation mm, W/m

K, kg/m340 λ = 0.035 ρ = 55

Stagnation temperature °C 210

Efciency η

0

% 80

Heat capacity Ws/m•K 5014

Heat loss factor k

Heat loss factor k

1

2

W/m2•K 3.7

W/m2•K

2

2.51

2.35

2.33

t = 91

0,012

7

Page 8

3 Vertical Collector and Hydraulic Connection Arrangement

Collector Panel

The recommended collector panel arrangements are shown

below.

Vertical

THE HYDRAULIC FLOW CAN BE TOP AND BOTTOM OR DIAGONAL

1-5 Collectors

1 4 5...

TOP & BOTTOM DIAGONAL

6 and up to 12 max Collectors

THE HYDRAULIC FLOW MUST BE DIAGONAL

Hydraulic Connections

It is recommended that the hydraulic connections should be

made as shown below.

15025

1 4 5...

14915

1

2

...

DIAGONAL

11

12

Diagram 3.1

8

Page 9

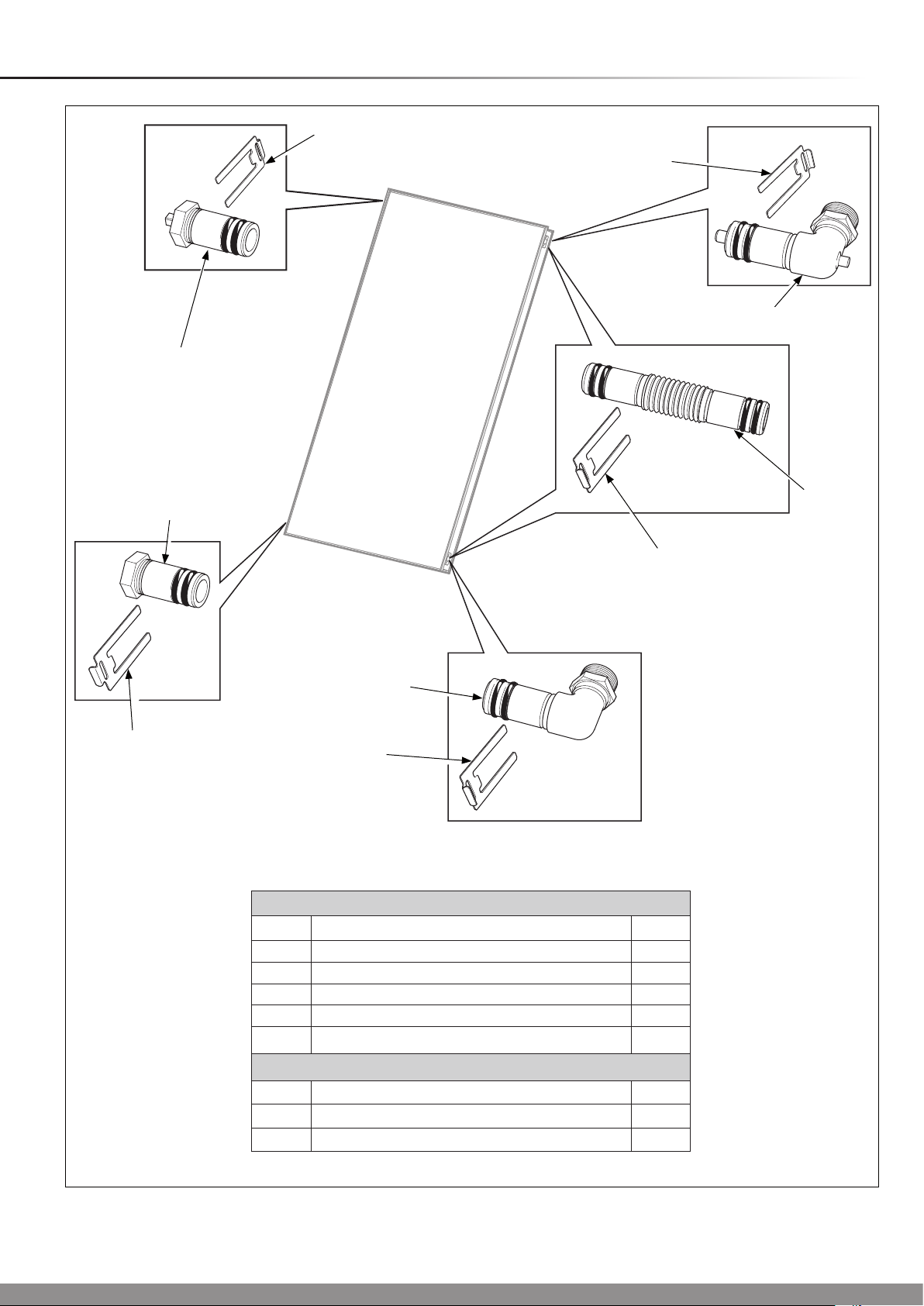

15303

4 Hydraulic Connection Kits - Vertical Collector

5

5

1

4

6

3

7

2

5

Easy fit hydraulic connection set - Part No. 0020060207

Part Description Qty.

1 Upper supply (with probe) 1

2 Return (inlet) 1

3 Lower plug 1

4 Upper plug (with ventilation) 1

5 Securing clip 4

5

Easy fit hydraulic extension set - Part No. 0020059909

Part Description Qty.

6 Pipe coupling 2

7 Securing clip 4

9

Diagram 4.1

Page 10

5 Flat Surface Installation - Vertical Collector

1

14998

2

4

3

Flat Surface Mounting Kit

Flat surface mounting kit

Part Description Qty.

1 Mounting rail 2

2 Frame with clamping assembly 1

3 Safety clamp 2

4 Gravel tray (optional) 2-3

Diagram 5.1

10

Page 11

5 Flat Surface Installation - Vertical Collector

5.1 Flat surface installation

IMPORTANT

● Do not remove the protection lm until the system is to be

commissioned.

● With due regard to the complete weight of the solar

collector system, (refer to technical data) ensure the

surface is at and has a sufcient load carrying capacity.

● Ensure that a roof surface is adequately protected and

watertight.

The at surface frames allow the collectors to be installed at

an angle of 30°, 45° or 60°.

The mounting rails can be adjusted to compensate for oor

irregularities.

Angle 0-10 m 10-18 m 18-25 m

30° 159 Kgs 178 Kgs 197 Kgs

45° 225 Kgs 252 Kgs 279 Kgs

60° 276 Kgs 309 Kgs 342 Kgs

Table 5.1

5.2 Ballast and frame weight

Dene the necessary load required to secure the frame and

collector, refer to Table 5.1.

For the required space and the distances among collectors,

refer to Table 5.2.

Height above ground

B

(30° 45° 60°)

Number of

collectors

1* 1136

2 2300

3 3563

4 4826

5 6089

6 7352

7 8615

E

A

C

F

D

(30° 45° 60°)

C

8 9878

9 11141

10 12404

30° 45° 60°

A

B F B F B F

1283

4400

1740

6100

2080

7200

C D A

- -

2357

1150

-

1263

* Possible only with 4 offset gravel trays.

Table 5.2

11

Page 12

5 Flat Surface Installation - Vertical Collector

5.3 Collector Installation

NOTE: Roof installation

With due regard to the complete weight of the ballast, frame,

collector and system, proceed as follows:

14999

With the oor section secured (screwed or gravel trays) to the

at surface, x the lower telescopic section with retaining pin

and safety clip, see diagram 5.2.

NOTE: If gravel trays are used, slide the gravel tray onto the

oor section before xing the lower telescopic section, see

diagram 5.3.

Apply the safety clamps from the top oor sections (2x frame)

to x the gravel tray.

Collectors should have 3 gravel trays per frame.

Extend the telescopic sections until the hole of the desired

position is aligned, then secure with retaining pin and safety

clip, see diagram 5.4.

You can choose 30º, 45º or 60º, the standard is 45º.

SAFETY

CLIP

RETAINING

PIN

FLOOR

SECTION

Diagram 5.2

14933

SAFETY

CLAMPS

RETAINING

PIN

GRAVEL

TRAY

Diagram 5.3

SAFETY

CLIP

14934

12

Diagram 5.4

Page 13

5 Flat Surface Installation - Vertical Collector

Fix the lower mounting rail with the frame clamping assembly,

see diagram 5.5.

If multiple collectors are mounted, the mounting rails meet in

the centre of the clamping assemblies, see diagram 5.6.

On the rst and last frame, the mounting rails can be

projected by 20mm.

Insert the mounting rail connector into the mounting rails, see

diagram 5.6

Position another frame (see diagrams 5.1 to 5.3).

Join the mounting rails and x them to the frame clamping

assemblies as shown in diagram 5.7.

Compensate any difference in height by moving the clamping

assembly.

LOWER

MOUNTING RAIL

CLAMPING

ASSEMBLY

15000

Diagram 5.5

MOUNTING RAIL

CONNECTOR

MOUNTING

RAIL

15004

Diagram 5.6

15003

13

MOUNTING RAIL

(First and last frame only)

Diagram 5.7

Page 14

5 Flat Surface Installation - Vertical Collector

Place the collector with the lower edge in the section of the

mounting rail, see diagram 5.8.

Make sure that the upper part of the clamping assembly is

above the collector edge.

Slide the upper mounting rail until it is ush with the collector.

Make sure that the upper part of the clamping assembly is

above the collector edge, see diagram 5.9.

Tighten the lower clamping assemblies with the socket/

combination wrench (SW13).

CLAMPING

ASSEMBLY

15404

COLLECTOR

LOWER EDGE

LOWER

MOUNTING

RAIL

Diagram 5.8

CLAMPING

ASSEMBLY

UPPER

MOUNTING

RAIL

15001

COLLECTOR

EDGE

Diagram 5.9

14

Page 15

5 Flat Surface Installation - Vertical Collector

Remove the plugs from the openings of the collector and

insert the pipe couplings up to their stops, see diagram 5.10.

Slide the retaining clips into place to secure the pipe

couplings.

NOTE: The collector design is symmetrical and does not have

a top or bottom.

Place the next collector on the lower mounting rail and slide

towards the rst collector.

Secure the pipe couplings to the second collector with the

securing clips.

Tighten the clamping assemblies of the rst collector with the

socket/ combination wrench (SW13).

With regards to the hydraulic system you have chosen, insert

and secure the hydraulic connections, see diagram 5.9.

Insert the collector sensor into the appropriate elbow (ow,

top), see diagram 5.11. The collector sensor is packed with

the Fluropro controller, part no. 0020054960.

Mount the plug with the bleed valve (vent) in the opposite top

position.

PIPE

COUPLING

SECURING

CLIP

Diagram 5.10

15005

Connect the collector to the system circuit.

UPPER PLUG

WITH VENT

LOWER PLUG

SECURING

CLIP

FLOW

ELBOW (with sensor)

15006

SECURING

CLIP

RETURN

ELBOW (inlet)

SECURING

CLIP

TOP AND BOTTOM OR DIAGONAL FLOW

1-5 Collectors

15

SECURING

CLIP

Diagram 5.11

Page 16

5 Flat Surface Installation - Vertical Collector

Ensure that all of the following steps have been performed:-

- All the connections have been xed with securing clips.

- All hydraulic connections laid properly.

- The collector sensor has been connected.

- The collector is connected to a lightning protection device.

- A pressure test.

- All insulation is intact.

NOTE: After initial commissioning and according to the

season, high outside temperature oscillations can cause

condensation in the collector, this is normal.

FLOW

ELBOW

(with sensor)

LOWER PLUG

SECURING

CLIP

15008

UPPER PLUG

WITH VENT

SECURING

CLIP

SECURING

CLIP

RETURN

ELBOW (inlet)

SECURING

CLIP

DIAGONAL FLOW

6 and up to 12 Collectors

16

Diagram 5.10

Page 17

6 Horizontal Collector Technical Data

80

1233

79

1075

79

2033

1978

14921

1178

Horizontal Collector

Diagram 6.1

Appliance designation Unit. Clearly Solar

Absorber type Serpentine

Gross area m

Aperture surface area m

Absorber surface area m

2

2

2

2.51

2.35

2.33

Absorber Aluminium (vacuum coated) 0.5 x 1178 x 1978

Dimensions (L x W x H) mm 1233 x 2033 x 80

Weight (Dry) kg 38

Fluid content l 2.16

Copper pipe connection, at-face Ø mm G 3/4" (DN16)

Insulation thickness mm 40

Max. operating pressure bar 10

Glass type Solar safety glass (prismatic structure)

Glass covering mm 3.2 (thickness) x 2033 x 1233

Coating High selective (blue)

Solar safety glass transmission t (dew)

Absorber emission ε (epsilon)

%

t = 91

% 5 ± 2

α = 95% ε = 5%

Back wall insulation mm, W/mk, kg/m 95 ± 2

Stagnation temperature °C 210

Efciency η

0

% 80

Heat capacity Ws/ (m•K) 5014

2

Efciency coefcient k1 W/(m

Efciency coefcient k2 W/(m

•K) 3.7

2

•K2) 0,012

17

Page 18

7 Horizontal Collector and Hydraulic Connection Arrangement

Collector Panel

The recommended collector panel arrangements are shown

below.

Horizontal

1-5 Collectors

THE HYDRAULIC FLOW CAN BE DIAGONAL OR TOP AND BOTTOM

1

...

6 and up to 10 max Collectors

THE HYDRAULIC FLOW MUST BE DIAGONAL

1

...

Hydraulic Connections

It is recommended that the hydraulic connections should be

made as shown below.

15045

4 5

9 10

Diagram 7.1

18

Page 19

8 Hydraulic Connection Kits - Horizontal Collector

4

5

5

15305

1

6

3

5

7

2

5

Easy fit hydraulic connection set - Part No. 0020060207

Part Description Qty.

1 Upper supply (with probe) 1

2 Return (inlet) 1

3 Lower plug 1

4 Upper plug (with ventilation) 1

5 Securing clip 4

Easy fit hydraulic extension set - Part No. 0020059909

6 Pipe coupling 2

7 Securing clip 4

19

Diagram 8.1

Page 20

9 Flat Surface Installation - Horizontal Collector

1

15136

2

3

4

Flat Surface Mounting Kit

On-roof mounting kit

Part Description Qty.

1 Mounting rail 2

2 Frame with clamping element 1

3 Gravel tray (optional) 2-3

4 Safety clamps 2

Diagram 9.1

20

Page 21

9 Flat Surface Installation - Horizontal Collector

9.1 Flat surface installation

IMPORTANT

● Do not remove the protection lm until the system is to be

commissioned.

● With due regard to the complete weight of the solar

collector system, (refer to technical data) ensure the

surface is at and has a sufcient load carrying capacity.

● Ensure that a roof surface is adequately protected and

watertight.

The at surface frames allow the collectors to be installed at

an angle of 30°, 45° or 60°.

The mounting rails can be adjusted to compensate for oor

irregularities.

Angle 0-10 m 10-18 m 18-25 m

30° 159 178 197

45° 225 252 279

60° 276 309 342

9.2 Ballast and frame weight

Dene the necessary load required to secure the frame and

collector, refer to Table 9.1.

For the required space and the distances among collectors,

refer to Table 9.2.

Height above ground

Table 9.1

B

(30° 45° 60°)

Number of

collectors

1* 1650

2 3900

3 5963

4 8026

5 10089

6 12152

E

A

D

(30° 45° 60°)

7 14215

8 16278

9 18341

10 20404

30° 45° 60°

A

B F B F B F

883

3100

1173

4100

1387

4800

C D E

- -

1812

1950

-

2063

C

* Possible only with 4 offset gravel trays.

F

Table 9.2

C

21

Page 22

9 Flat Surface Installation - Horizontal Collector

9.3 Collector Installation

NOTE: Roof installation

With due regard must to the complete weight of the ballast,

frame, collector and system, proceed as follows:

With the oor section secured (screwed or gravel trays) to the

at surface, x the lower telescopic section with retaining pin

and safety clip, see diagram 9.1.

NOTE: If gravel trays are used, slide the gravel tray onto the

oor section before xing the lower telescopic section, see

diagram 9.2.

Apply the safety clamps from the top oor sections (2x frame)

to x the gravel tray.

Collectors should have 3 gravel trays per frame.

Extend the telescopic sections until the hole of the desired

position is aligned, then secure with retaining pin and safety

clip, see diagram 9.3.

You can choose 30º, 45º or 60º, the standard is 45º.

14999

SAFETY

CLIP

RETAINING

PIN

Diagram 9.1

RETAINING

PIN

SAFETY

CLAMPS

GRAVEL

TRAY

Diagram 9.2

SAFETY

CLIP

14933

14934

22

Diagram 9.3

Page 23

9 Flat Surface Installation - Horizontal Collector

Fix the lower mounting rail with the frame clamping assembly,

see diagram 9.4.

If multiple collectors are mounted, the mounting rails meet in

the centre of the clamping assemblies, see diagram 5.5.

On the rst and last frame, the mounting rails can be

projected by 20mm.

Insert the mounting rail connector into the mounting rails, see

diagram 9.5

Position another frame (see diagrams 9.1 to 9.3).

Join the mounting rails and x them to the frame clamping

assemblies as shown in diagram 9.6.

Compensate any difference in height by moving the clamping

assembly.

CLAMPING

ASSEMBLY

15156

LOWER

MOUNTING

RAIL

Diagram 9.4

MOUNTING RAIL

CONNECTOR

MOUNTING

RAIL

15004

Diagram 9.5

15003

23

MOUNTING RAIL

(First and last frame only)

Diagram 9.6

Page 24

9 Flat Surface Installation - Horizontal Collector

Place the collector with the lower edge in the section of the

mounting rail, see diagram 9.7.

Make sure that the upper part of the clamping assembly is

above the collector edge.

Slide the upper mounting rail until it is ush with the collector.

Make sure that the upper part of the clamping assembly is

above the collector edge, see diagram 9.8.

Tighten the lower clamping assemblies with the socket/

combination wrench (SW13).

CLAMPING

ASSEMBLY

15404

COLLECTOR

LOWER EDGE

LOWER

MOUNTING

RAIL

Diagram 9.7

CLAMPING

ASSEMBLY

15001

COLLECTOR

EDGE

Diagram 9.8

24

Page 25

9 Flat Surface Installation - Horizontal Collector

Remove the plugs from the openings of the collector and

insert the pipe couplings up to their stops, see diagram 9.9.

Slide the retaining clips into place to secure the pipe

couplings.

NOTE: The collector design is symmetrical and does not have

a top or bottom.

Place the next collector on the lower mounting rail and slide

towards the rst collector.

Secure the pipe couplings to the second collector with the

securing clips.

Tighten the clamping assemblies of the rst collector with the

socket/ combination wrench (SW13), see diagrams 9.10 and

9.11.

With regards to the hydraulic system you have chosen, insert

and secure the hydraulic connections, see diagram 9.10.

Insert the collector sensor into the appropriate elbow (ow,

top), see diagram 9.10. The collector sensor is packed with

the Fluropro controller, part no. 0020054960.

Mount the plug with the bleed valve (vent) in the opposite top

position.

PIPE

COUPLING

SECURING

CLIP

Diagram 9.9

15157

SECURING

CLIP

UPPER PLUG

WITH VENT

FLOW

ELBOW

(with sensor)

SECURING

CLIP

15158

SECURING

CLIP

RETURN

ELBOW

LOWER PLUG

TOP AND BOTTOM OR DIAGONAL FLOW

(inlet)

1-5 Collectors

25

SECURING

CLIP

Diagram 9.10

Page 26

9 Flat Surface Installation - Horizontal Collector

Connect the collector to the system circuit.

Ensure that all of the following steps have been performed:-

- All the connections have been xed with securing clips.

- All hydraulic connections laid properly.

- The collector sensor has been connected.

- The collector is connected to a lightning protection device.

- A pressure test.

- All insulation is intact.

NOTE: After initial commissioning and according to the

season, high outside temperature oscillations can cause

condensation in the collector, this is normal.

SECURING

CLIP

15159

SECURING

CLIP

UPPER PLUG

WITH VENT

FLOW

ELBOW

(with sensor)

LOWER PLUG

RETURN

ELBOW (inlet)

SECURING

CLIP

SECURING

CLIP

DIAGONAL FLOW

6 and up to 12 Collectors

26

Diagram 9.11

Page 27

27

Page 28

0020077782-02 03.09

Because of our constant endeavour for improvement, details

may vary slightly from those shown in these instructions.

Glow-worm, Nottingham Road, Belper, Derbyshire. DE56 1JT

28

Loading...

Loading...