Page 1

Installation

and Servicing

Hydraulic module HB

Page 2

Page 3

TABLE OF CONTENTS

INTRODUCTION

1 Instructions guidance .........................................................................................................................2

1.1 Product documentation...........................................................................................2

1.2 Associated documents ..........................................................................................2

1.3 Explanation of symbols...........................................................................................2

1.4 Guarantee registration ............................................................................................2

2 Appliance description .........................................................................................................................2

2.1 Safety devices ........................................................................................................ 2

2.2 Data label ...............................................................................................................2

2.3 Hydraulic schematic ...............................................................................................3

3 Safety instructions and regulations ....................................................................................................3

3.1 Safety instructions .................................................................................................. 3

3.2 Regulations.............................................................................................................4

4 Recycling ...........................................................................................................................................4

4.1 Appliance ................................................................................................................4

4.2 Packaging ...............................................................................................................4

INSTA L L ATION

5 Appliance location ..............................................................................................................................5

6 Appliance installation ........................................................................................................................5

6.1 Scope of delivery ....................................................................................................5

6.2 Recommendations before installing .......................................................................5

6.3 Dimensions .............................................................................................................6

6.4 Mounting .................................................................................................................6

7 Hydraulic connection ..........................................................................................................................8

8 Electrical connections ........................................................................................................................9

9 Commissioning ..................................................................................................................................9

10 Specic adjustment ...........................................................................................................................9

11 Assembly of the casing ....................................................................................................................10

12 User information ...............................................................................................................................10

MAINTENANCE

13 Trouble-shooting .............................................................................................................................. 11

14 Servicing ........................................................................................................................................ 11

15 Replacement of Parts ......................................................................................................................11

16 Technical Data .................................................................................................................................11

- 1 -

Page 4

INTRODUCTION

INTRODUCTION

1 Instructions guidance

1.1 Product documentation

The instructions are an integral part of the appliance and must

be handed to the user on completion of the installation in order

to comply with the current regulation.

• Carefully read the manual, to understand all the information

to enable safe installation, use and servicing. No liability can

be accepted in the event of damage for not complying with

the guidance in this instruction manual.

1.2 Associated documents

- 1 Instructions for use

- Instructions for other system components

1.3 Explanation of symbols

We recommend you complete and return as soon as possible

your guarantee registration card. If your guarantee registration

card is missing you can obtain a copy or record your registration

by telephoning the Glow-worm Customer Service number

01773 828100.

2 Appliance description

2.1 Safety devices

This appliance is equipped with a safety valve.

- The safety valve opens when the pressure in the heat pump

circuit exceeds 3 bars.

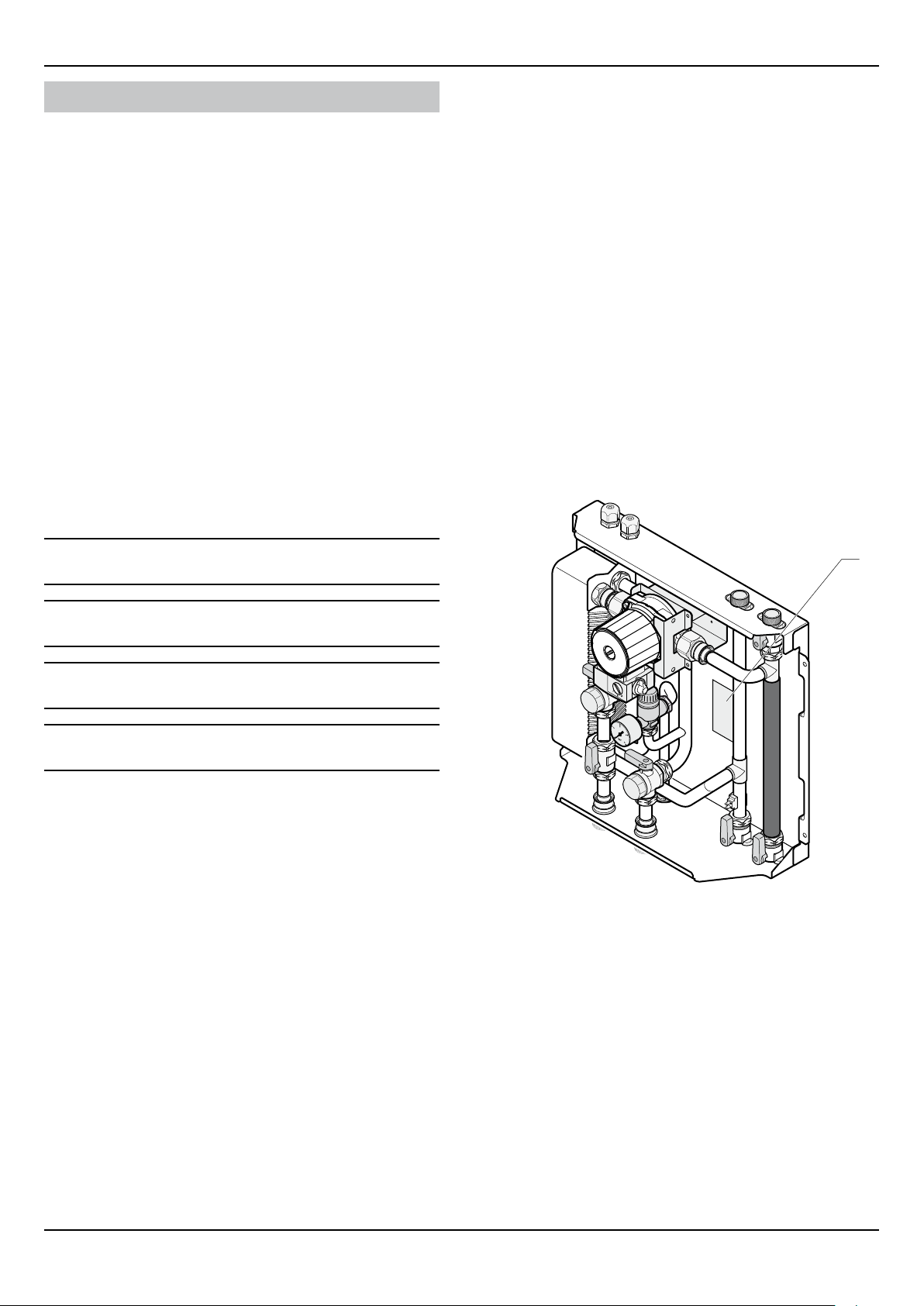

2.2 Data label

The data label certies the country where the appliance is

intended to be installed.

Data label location:

a

e

b

i

DANGER: Risk of injuries.

DANGER: Risk of electric shock.

ATTENTION: Risk of damage to the appliance or

to its surroundings.

IMPORTANT: Important information.

1.4 Guarantee registration

Thank you for installing a new Glow-worm appliance in your home.

Glow-worm appliances are manufactured to the very

highest standard so we are pleased to offer our customers a

Comprehensive Guarantee.

This product is guaranteed for 24 months from the date

of installation or 30 months from the date of manufacture,

whichever is the shorter, for parts and labour.

The second year of guarantee, from the beginning of the

13th month onwards after installation or manufacture, is

conditional upon the appliance having been serviced by a

competent person approved at the time by the Health and

Safety Executive, in accordance with the manufacturer’s

recommendations. We strongly recommend regular servicing

of your gas appliance, but where the condition is not met,

any chargeable spare parts or components issued within

the applicable guarantee period still benet from a 12 month

warranty from the date of issue by the manufacturer.

1

Key

1 Data label

The data label contains the following data:

- The name of the manufacturer

- The commercial name of the appliance and its serial number

- The maximum pressure in the heating circuit

- The maximum pressure in the heat pump circuit

- The type and voltage of electricity supply

- 2 -

0020096881_02 - 08/10 - Glow-worm

Page 5

INTRODUCTION

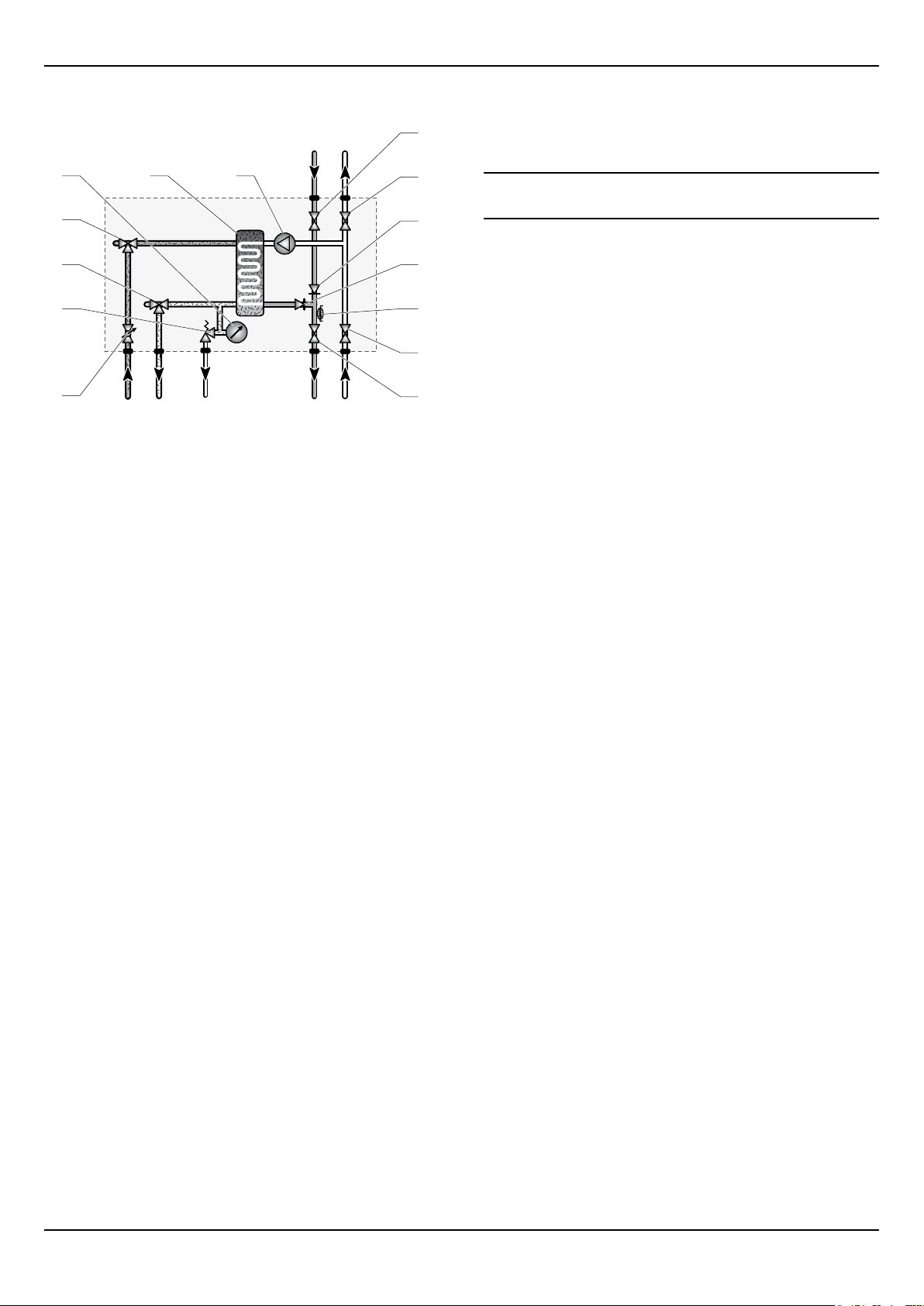

2.3 Hydraulic schematic

5

4

3

2

1

Key

1 Flow control valve

2 Safety valve

3 3-wayvalvewithshut-offvalveforlling

4 3-wayvalvewithshut-offvalveforlling

5 Manometer

6 Plate to plate heat exchanger

7 Pump

8 Boilerowcircuitisolatingvalve

9 Boiler return circuit isolating valve

10 Boilerowcircuitnon-returnvalve

11 Heat exchanger output non-return valve

12 Heatingowthermistor

13 Heating return circuit isolating valve

14 Heatingowcircuitisolatingvalve

6

7

E

A B

D CG F

10

11

12

13

14

3 Safety instructions and regulations

8

9

3.1 Safety instructions

Incorrect installation can cause electric shock or

e

• Never disable security devices and do not try to adjust them.

• Be sure to consider the following handling techniques and

- Grip the appliance at its base

- Use safety clothing where appropriate, e.g. gloves, safety

• Ensure safe lifting techniques are used:

- Keep back straight.

- Avoid twisting at the waist.

- Avoid upper body/top heavy bending.

- Always grip using the palm of the hand.

- Use designated hand holds.

- Keep load as close to body as possible.

- Always use assistance if required.

• Under no circumstances must the user interfere with or

appliance damage.

precautions:

footwear.

adjust sealed parts.

A Boilerowcircuit

B Boiler return circuit

C Heating return circuit

D Heatingowcircuit

E Safety valve discharge

F Heat pump return circuit

G Heatpumpowcircuit

• When assembling the connections, correctly position the

seals to avoid any leakage of water.

• This appliance contains metal parts (components) and care

should be taken when handling and cleaning, with particular

regard to edges.

The basic safety instructions must be followed before

attempting to maintain or replace spare parts:

• Stop the appliance.

• Electrically isolate the appliance from the power supply.

• Hydraulically isolate the appliance using the isolation valves

if provided.

• Should you need to replace hydraulic components, drain the

appliance.

• Protect all the electrical components from water while

working on the appliance.

• Use only original spare parts.

• Use only new O-rings and gaskets.

• After having completed work on water carrying components,

check for their tightness.

0020096881_02 - 08/10 - Glow-worm

• When work on the appliance is completed, perform an

operational test and check for safety.

- 3 -

Page 6

INTRODUCTION

3.2 Regulations

IMPORTANT

Where no British Standards exists, materials and equipment

should be t for their purpose and of suitable quality and

workmanship.

The installation of this appliance must be carried out by a

competent person approved at the time by the Health and

Safety Executive and in accordance with the rules in force in the

countries of destination.

Manufacturer’s instructions must not be taken as overriding

statutory requirements.

Statutory Requirements

In GB, the installation of the appliance must comply with the

requirements of the current issue of BS6798 and be carried out

by a competent person approved at the time by the Health and

Safety Executive and as described in the following regulations:

- The manufacturer’s instructions supplied.

- The Gas Safety (Installation and Use) Regulations.

- The appropriate Buildings Regulations either The Building

Regulations, The Building Regulations (Scotland), The Building

Regulations (Northern Ireland).

- The Water Supply (water ttings) Regulations 1999 and water

byelaws 2000, Scotland.

- The Health and Safety at Work Act, Control of Substances

Hazardous to Health (COSHH).

- The Current I.E.E. Wiring Regulations.

Domestic Hot Water

All domestic hot water circuits, connections, ttings must be

in accordance with the relevant standards and water supply

regulations.

GB: Guidance G17 to G24 and recommendation R17 to R24 of

the Water Regulations Guide.

IE: The current edition of I.S.813 “Domestic Gas Installations”.

Heating System

In GB, it is necessary to comply with the Water Supply (Water

Fittings) Regulations 1999 (for Scotland, the Water Byelaws

2000, Scotland). To comply with the Water regulations your

attention is drawn to: The Water Regulations guide published

by the Water Regulations Advisory Service (WRAS) gives full

details of the requirements.

In IE, the requirements given in the current edition of I.S.813

“Domestic Gas Installations” and the current Building

Regulations must be followed.

4 Recycling

The recycling of the packaging must be carried

i

out by the qualied professional who installed the

appliance.

Where no specic instructions are given, reference should be

made to the relevant British Standard Code of Practice.

In IE, the installation must be carried out by a competent person

approved at the time by the Health and Safety Executive and

installed in accordance with the current edition of I.S.813

“Domestic Gas Installations”, the current Building Regulations

and reference should be made to the current ETCI rules for

Electrical Installation.

GB: the following Codes of Practice apply: BS4814, BS6798,

BS5440 Part 1 and 2, BS5546 Part 1, BS5449, BS6891,

BS6700, BS7074 Part 1 and 2, BS7593, BS7671.

IE: I.S.813, BS5546, BS 5449, BS 7074, BS 7593.

NOTE: For further information, see the current issue of the

Building Regulations, approved document L1 ( in the UK) and

the following current issues of:

1) Central heating system specication (CheSS) and

2) Controls for domestic central heating system and hot water.

BRECSU.

Gas Supply

The gas installation must be in accordance with the relevant

standards.

In GB, this is BS6891.

In IE, this is the current edition of I.S.813 “Domestic Gas

Installations”.

4.1 Appliance

Most of the appliance is made of recyclable materials.

This symbol indicates that this appliance must not

be disposed of with household waste, that it should

be selectively collected for energy recovery, reuse

or recycling.

• Take the appliance to an appropriate collection point.

By complying with this directive, you will contribute

i

to the preservation of natural resources and the

protection of human health.

4.2 Packaging

We recommend that you recycle the packaging of the appliance

in a responsible fashion.

• Sort the waste in order to separate those elements which

can be recycled (cardboard, plastics ...) and those which

cannot be recycled.

• Dispose of the waste in accordance with existing regulations.

The supply from the governed meter must be of adequate size

to provide a steady inlet working pressure of 20mbar (8in wg) at

the boiler. On completion, test the gas installation for tightness

using the pressure drop method and suitable leak detection

uid, purge in accordance with the above standard.

- 4 -

0020096881_02 - 08/10 - Glow-worm

Page 7

INSTALLATION

INSTALLATION

5 Appliance location

• Before choosing a site for the appliance, carefully read the

safety warnings and installation manual.

• Ensure that wall to which the appliance will be mounted on is

structurally safe in order to support the weight of the appliance.

• Ensure there is sufcient space available for the appliance,

taking care that minimum clearances are adhered to ensure

that the connections to the water can be accessed and

inspected.

• The appliance must be installed in a room protected from

freezing. Take all necessary precautions.

• Explain these requirements to the appliance user.

6 Appliance installation

6.1 Scope of delivery

3.1

2

3

3.2

3.3

3.3 Module instructions for use (x1)

3.4 Guarantee conditions (x1)

3.5 Guarantee card (x1)

4 Frame

5 Accessories bag (x1)

5.1 Flat seal ¾" (x6)

5.2 Frame screws (x4)

5.3 Flat seal 1 " (x4)

• Check the contents of the packages.

(x2)

6.2 Recommendations before installing

6.2.1 Heating circuit design

The heat transmitters may be low temperature (under-oor

heating, low-temp radiator ...) and high temperature (cast iron

radiator ...).

The installation pipework should be calculated using a ow /

pressure curve. The distribution will be determined by the ow

corresponding to the power actually required, regardless of

the maximum power that can be provided by the installation’s

generators.

The pipework should be designed and installed in such a way

so as to make all provisions necessary to avoid air pockets and

facilitate the permanent degassing of the installation. Venting

valves must be placed at each high point of the tubes, as well as

on all radiators.

3.4

3.5

4

5.3

5.2

1

Key

1 Hydraulic module cover (x1)

2 Hydraulic module (x1)

5.1

5

The total volume of water for the heating circuit depends,

among other factors, on the cold static load of the boiler’s

expansion tank. It is recommended that a drainage valve be

installed at the lowest point of the installation.

If using thermostatic valves, do not equip all radiators with

them, placing these valves at high demand sites and never at

the sites in which the room thermostats are installed.

- In both new and existing installations, the radiator circuit

must be ushed prior to installing the new appliance in

accordance with BS:7593.

- If a system component is not put in place immediately,

protect the different connections so that the plaster and paint

does not spoil water tightness for later connecting.

6.2.2 Heat pump circuit design

The pipework should be designed and installed in such a way

so as to make all provisions necessary to avoid air pockets and

facilitate the venting of air from the installation. Bleed valves are

to be installed at each of the pipes' highest points.

• In order to avoid the transmission of vibration to surrounding

structures, use hoses for water connections.

Insulate the pipes with a UV- and high-

b

temperature-resistant insulation.

3 Documents bag (x1)

3.1 System installation manual (x1)

3.2 Module installation manual (x1)

0020096881_02 - 08/10 - Glow-worm

- 5 -

Page 8

INSTALLATION

6.3 Dimensions

6.3.1 Hydraulic module

81

431

65

41

36

i

6.3.2 Frame

Appliance weight : 12,5 kg

34

284

137

85

470

122

157

414

72

6.4 Mounting

Depending on the installation, you may install the

i

• Make sure that the equipment used for implementing the

• Determine the assembly location. See the "Appliance

• The applications should be anchored in accordance with

frame supplied with the appliance.

installation is compatible with that of the appliance.

location" chapter.

the characteristics of the supporting wall and must take into

account the weight of the appliance.

414

- 6 -

476

200

0020096881_02 - 08/10 - Glow-worm

Page 9

INSTALLATION

6.5.1 Attaching the appliance to a wall without a

frame

385

375

Key

1 Hydraulic module

2 Frame

3 Screw

• Attach the frame (2) to the hydraulic module using the

provided screws (3).

385

1

• Attach the appliance to the wall in accordance with the

diagram shown above.

6.5.2 Attaching the appliance to a wall with a frame

2

3

Key

1 Cutting tool

2 Metallic component

Depending on the installation, you can cut the metal

i

• Attach the appliance to the wall in accordance with the

component (2) in order to pass the connections

along the side of the appliance.

diagram shown above.

2

1

0020096881_02 - 08/10 - Glow-worm

33

2

- 7 -

Page 10

INSTALLATION

A

C

7 Hydraulic connection

A label located inside the cover enables the

i

identication of the module’s hydraulic connections.

D Heatingowcircuitؾ"

E Safety valve discharge

F HeatpumpreturncircuitØ1"

G HeatpumpowcircuitØ1"

• Take care to clean the pipes before assembly removing any

debris or burrs. Grease and oils may need to be removed

they are not possible to remove by cleansing and ushing.

1

Foreign bodies in the system may enter the appliance and

interrupt its operation.

• Do not use any solvent products, due to the risk of damaging

the circuit.

Do not perform any 'hot work' directly under

a

• Only use original seals supplied with the appliance.

• Check that there are no leaks.

the appliance, this may cause damage to the

appliance base. Heat may also damage the

isolation valves.

Always pre-assemble pipes before tting them to

the appliance.

Key

1 Hydraulic connection label

B

G

F

Key

A Boilerowcircuitؾ"

B Boilerreturncircuitؾ"

C Heatingreturncircuitؾ"

- 8 -

E

D

0020096881_02 - 08/10 - Glow-worm

Page 11

INSTALLATION

REL1

8 Electrical connections

Incorrect installation can cause electric shock or

e

The external wiring must be earthed, with correct polarity and in

accordance with current standards.

The manufacturer declines any responsibility for damages to

persons or others caused by the incorrect installation of the

appliance earthing. This includes failure to comply with current

standards.

1

2

appliance damage. The electrical connection of

the appliance must be made only by a qualied

engineer.

NTC1

A

A

B

9 Commissioning

• Refer to the system’s installation manual in order to activate

the installation.

Pump ow / pressure curve

21

60

50

40

30

20

10

3

0

Key

1 Speed 2

4

2 Speed 3 (Factory setting)

A Available pressure (kPa)

B Flow in the circuit (l / h)

300 600 900 1200

B

1

Key

1 Pump cable

2 Pump cable gland

3 Heatingowthermistorcable

4 Heatingowthermistorcablegland

Component Voltage (cable section)

Pump 230 V (3 x 0.75 mm ²)

Thermistor 3.3 V (2 x 0.34 mm ²)

i

Speed 1 is not applicable to this system.

10 Specicadjustment

3

• Refer to the system’s installation manual to adjust the

installation.

• Pass the pump cable (1) through the gland (2).

• Connect the cable (1) to the REL1 terminal in the Systempro.

• Tighten the gland (2).

• Pass the thermistor cable (3) through the gland (4).

• Connect the cable (3) to the NTC1 terminal in the Systempro.

• Tighten the gland (4).

0020096881_02 - 08/10 - Glow-worm

- 9 -

Page 12

INSTALLATION

11 Assembly of the casing

1 2

Key

1 Hydraulic module cover

2 Hydraulic module

• Once the installations settings have been completed, t the

cover (1) to the hydraulic module (2).

12 User information

At the end of the installation, the installer must:

- explain the operation of the appliance and its safety devices

to the user, if necessary provide a demonstration and answer

any questions;

- hand over to the user all the required documentation,

- ll in the documents where necessary;

- advise the user of the precautions necessary to prevent

damage to the system, appliance and the building;

- remind the user to service the appliance annually.

- 10 -

0020096881_02 - 08/10 - Glow-worm

Page 13

MAINTENANCE

MAINTENANCE

13 Trouble-shooting

The following checks should be performed before proceeding

onto specic diagnostics:

- Make sure that the electricity supply has not been interrupted

and that the appliance is connected correctly.

• Ensure that the isolating valves are open.

• Check that all external controls are connected correctly.

14 Servicing

• See the "Safety instructions" chapter for a list of operations

to be performed prior to the maintenance of the application.

• Once the maintenance operations have been completed,

refer to the system’s installation manual to restart the

installation.

Annual Maintenance

16 Technical Data

Description Unit Value

Maximum heating circuit pressure

Maximum heat pump circuit pressure

Pump supply voltage V/Hz 230 / 50

Thermistor supply voltage V 3.3

Dimensions

Height mm 476

Length mm 470

Depth mm 200

Lift weight kg 12,5

bar 3

Pa 3 x 10

bar 3

Pa 3 x 10

5

5

• Check the proper functioning of safety devices.

• Check the pressure of the circuits.

• Check the airtightness of the connections.

• Ensure that the appliance’s components are neither worn nor

broken.

15 Replacement of Parts

In order to guarantee the safe and prolonged life of the product,

manufacturers genuine spare parts must be used.

Use only the manufacturer’s authorised, original,

i

• Ensure that spare parts are correctly mounted in the right

new spare parts.

position and direction. After tting any spare part or servicing,

the appliance must be tested for its safe operation.

0020096881_02 - 08/10 - Glow-worm

- 11 -

Page 14

Page 15

Page 16

Glow-worm

Subject to engineering changes

0020096881_02 - 08/10

Nottingham Road,

Belper, Derbyshire.

DE56 1JT

www.glow-worm.co.uk

Because of our constant endeavour for

improvement, details may vary slightly

from those shown in these instructions.

Loading...

Loading...