Page 1

Glow•worm

Clearly Heat Recovery

Atmosorb

Installation and Servicing

Instructions

HRD 275

Part. No. 0010008891

HRD 350

Part. No. 0010008892

Mechanical Ventilation

system with heat recovery

www.glow-worm.co.uk

Page 2

Guarantee

Glow-Worm guarantees that the high-quality product that you have purchased is free from any manufacturing defects. This guarantee

is in addition to and does not replace nor limit your statutory rights. Your local Trading Standards ofce may advise you.

The guarantee is valid only for Glow-Worm Atmosorb Heat Recovery Products that are (1) purchased in Great Britain and Northern

Ireland and installed and put into operation by a qualied and competent installer and (2) the Atmosorb is properly serviced annually in

accordance with the manufacturer’s specications and the work is undertaken by suitably qualied and competent servicing personnel.

Proof of servicing may be requested for these purposes. In particular, the following conditions apply:

Glow-Worm provide you with a manufacturer’s guarantee of up to 2 years on this product for parts and labour only subject

to the conditions below.

The guarantee periods shall commence from the date of installation or for 2 years after manufacture whichever is the sooner.

If any material or manufacturing defects occur within the guarantee periods described above, they shall be corrected free of charge by

Glow-Worm Customer Service. Whether the Atmosorb is repaired or replaced shall be decided at the sole discretion of Glow-Worm

Customer Service. In the event of a replacement we shall be entitled to make a similar product available if the Atmosorb is no longer

produced at the time of reporting the defect.

Under no circumstances shall any replacement parts provided lead to an extension of the guarantee period.

Prior to any visit by Customer Services to your premises on the agreed date your co-operation is essential to provide the appropriate

facilities necessary for the unhindered performance of the engineer’s visit. In particular you must make provision for the appliance to

be easily accessible; any costs incurred in doing so shall be borne by you.

The guarantee is valid only for defects in materials or defects in manufacturing. In particular it is not valid for any defects that are

caused due to:

- installation by incompetent and untrained personnel;

- a defective system design, system conguration or type of installation;

- defective wiring/installation work or due to defective handling during such work;

- non-compliance with the installation and operating instructions;

- non-compliance with Glow-Worm’s servicing instructions for Atmosorb;

- unsuitable servicing and unsuitable tests;

- any issues caused by associated ductwork connected to the appliance;

If any work on the Atmosorb is not performed by either our Group Service or by a competent specialised company, the guarantee shall

lapse. This shall also apply, if the Atmosorb is connected to any parts that have not been approved by Glow-Worm.

Claims that go beyond the free-of-charge correction of defects, e.g. claims for indemnication, are not covered by the guarantee.

IMPORTANT: The purchase receipt or the installer’s invoice is valid as proof of your guarantee right in relation to Glow-Worm’s

Customer Service. For this reason please keep these documents in a safe place!

Please report any guarantee incidences to our customer service on the following telephone number: Glow-Worm Service support line:

01773 596510. Alternatively please write to the Issuer of this Guarantee at:

Glow-Worm Service

Lynx House

Nottingham Road,

Belper,

Derbyshire

DE56 1JN

Customer Service:

01773 596510

Technical Helpline:

General and Sales enquiries:

Tel. 01773 824639

Fax: 01773 820569

01773 828300

2

Page 3

These instructions consist of, Installation, Servicing, Fault Finding.

The instructions are an integral part of the unit and must, to comply with the current

Regulations, be handed to the user on completion of the installation.

CONTENTS DESCRIPTION SECTION PAGE

INTRODUCTION

INSTALLATION

MAINTENANCE

Statutory Requirements 4

Important Information 5

Technical Specication 1 6

Siting the Unit 2 10

Ducting, Controls and Condensate 3 11

Installation 4 12

Commissioning 5 18

Servicing 6 22

Fault Finding 7 24

Reports 26

3

Page 4

Statutory Requirements

IMPORTANT

Where no British Standards exists, materials and equipment

should be fit for their purpose and of suitable quality and

workmanship.The installation of this unit must be carried

out by a competent person approved at the time by the

Health and Safety Executive and in accordance with the

rules in force in the countries of destination. Manufacturer’s

instructions must not be taken as overriding statutory

requirements.

Regulations

In your own interests and that of safety, it is the Law that

ALL gas appliances are installed by a competent person

approved at the time by the Health and Safety Executive in

accordance with the current issue of these regulations.

If the system is to be operated with boilers or other gas

appliances which are dependent on the ambient air, the

ventilation must be balanced in accordance to the needs of

these appliances.

The following current laws, rules, regulation standards and

guidelines must be complied with for the installation:

• Safety instructions and regulations for low-voltage

installations EN 1010

• EST Good Practice guide 268 – Efficient ventilation of

buildings – A guide to specifiers

• Rules and regulations for air circulation in flats and

habitable areas and residential buildings EN 1087

• Rules and regulations for ventilation systems

DIN 1946

• Any pertaining rules and regulations of the local or national

building authorities

• The present instructions for installation

Related documents

The installation of the heat recovery ventilation unit and any

associated ductwork and outlets must be in accordance with

the relevant requirements of the Health and Safety Document

No. 635 (The Electricity at Work Regulations 1989), BS7671

(IEE Wiring Regulations). It should also be in accordance

with the relevant requirements of the Local Authority, Building

Regulations, The Building Regulations (Scotland), The

Building Regulations (Northern Ireland) and the relevant

recommendations of the following:

BS 5588 – Fire precautions in design construction and use in

buildings.

BSEN 13141 - Ventilation for buildings. Performance testing

of components/products for residential ventilation.

BS EN 1506 - Ventilation for buildings. Sheet metal air ducts

and ttings with circular cross-section.

BS EN 13142 - Ventilation for buildings. Components/

products for residential ventilation. Required and optional

performance characteristics.

BS EN 12236 - Ventilation for buildings. Ductwork hangers

and supports. Requirements for strength.

CE label

The CE label shows that this unit complies with the following

directives:

• Low-voltage Directive 73/23/EEC, modied with Directive

93/68/EEC

• EMC-Directive 89/336/EEC, modied by the Directive

91/263/EEC, 92/31/EEC and 93/68/EEC

Testing and Certification

This unit is tested and certicated for safety and performance.

It is, therefore, important that no alteration is made to the unit,

without permission, in writing, by Glow-worm.

Any alteration not approved by Glow-worm, could invalidate

the certication, unit warranty and may also infringe the

current issue of the statutory requirements.

Control of Substances Hazardous to

Health

Under Section 6 of The Health and Safety at Work Act

1974, we are required to provide information on substances

hazardous to health.

The adhesives and sealants used in this unit are cured and

give no known hazard in this state.

Manual Handling

With regards to the “Manual Handling Operations, 1992

Regulations”, the appliance exceeds the recommended weight

for a one man lift.

The handling of the unit will involve lifting, pushing and pulling,

the use of a sack truck may be required.

The following handling techniques and precautions should be

considered:

- Grip the unit at its base

- Be physically capable

- Use safety clothing where appropriate, e.g. gloves,

safety footwear.

Ensure safe lifting techniques are used:

- Keep back straight.

- Avoid twisting at the waist.

- Avoid upper body/top heavy bending.

- Always grip using the palm of the hand.

- Use designated hand holds.

- Keep load as close to body as possible.

- Always use assistance if required.

Electrical Supply

The unit MUST be earthed. All system components shall be

of an approved type and all wiring to current I.E.E. wiring

regulations. External wiring must be correctly earthed,

polarised and in accordance with the relevant standards.

In GB, this is BS 7671.

In IE, this is the current edition of ETCI rules.

The unit MUST be connected to a permanent 230V ac, 50Hz

supply. Connection of the whole electrical system of the

unit, including any controls, to the electrical supply MUST

be through one common isolator and must be fused 3 Amp

maximum. Isolation should be by a double pole switched

fused spur box, with a minimum gap of 3mm for both poles.

The fused spur box should be readily accessible and

preferably adjacent to the appliance. It should be identied as

to its use. Alternatively connection can be made through an

unswitched shuttered socket and 3A fused 3-pin plug both to

the current issue of BS 1363, provided they are not used in

a room containing a bath or shower.

Wiring to the boiler must be PVC 85OC insulated cable, not

less than 0.75mm2 (24/0.20mm).

4

Page 5

Important Information

Notes on the documentation

The following notes serve as a guide for the entire

documentation. Further documents apply in combination with

this installation instructions. We accept no liability for any

damage caused by non-observance of these instructions.

Documentation Storage

Give this installation manual and all accompanying

documents to the operator who will store them so that they

are available when required.

Manual Validity

This installation manual is exclusively for the appliances:

Atmosorb HRD 275 part number 0010008891

Atmosorb HRD 350 part number 0010008892

For the part number of your unit, refer to the data plate

positioned on the underside of the bottom panel.

Intended Use

The Atmosorb is a wall-mounted ventilation system with heat

recovery.

The unit is connected to an air ducting system, which is

equipped with silencers, pre-lters, fresh-air and exhaust-air

grilles and louvres.

Fresh air grilles supply fresh air to the living areas and stale

moist air is extracted from the kitchen, bathroom and WC.

An optional bypass is available for summer operation, it can

directly provide living rooms with cool external air whenever

it is necessary. The external air ow bypasses the heat

exchanger.

With the digital remote control the user is able to automatically

switch and adapt the units power to suit their own

requirements.

The unit ensures:

• A constant air exchange in the building.

• The hygienic minimum air exchange in accordance with UK

building regulations Part F.

• Energy savings thanks to high efciency heat recovery.

• A high hygiene standard due to the prevention of humidity

and mould damages of the building.

Safety Instructions

The Atmosorb ventilation units are built and designed

according to accepted safety rules and regulations.

Nevertheless, there is still a risk of injury or death to the user

or others or of damage to the unit and other property in the

event of improper use or use for which it is not intended.

The unit must be installed by a competant person, who is

responsible for the observance of the current regulations,

rules and guidelines.

The remote control including the operating mode selector

and the timer must only be used for controlling the unit as

described in these instructions; it is not designed for any other

purpose.

Due to high level of dust, operation during any construction

phase is not allowed.

Any other or additional use is considered to be improper.

The unit is not suitable for ventilating swimming pools.

The manufacturer/supplier shall not be responsible for any

damages resulting from such improper use.

The user alone bears the risk.

Intended use includes the observance of the operating and

installation manual and all other applicable documents,

as well as adherence to the maintenance and inspection

conditions Installation of the device can be only carried out by

a competent person approved at the time by the Health and

Safety Executive and will be responsible for the changes in

the air ow adjustment.

This unit should only be used in conjunction with a propriety

ductwork system installed in accordance with HVCA guide

DW144 (steel ductwork) & DW154 (plastic ductwork).

The unit is equipped with a frost protecting sensor.

This sensor measures the temperature of the discharge

air. The fresh air fan is switched off if the discharge air

temperature falls below 3°C.

Once switched off, the fresh air fan is only switched on again

when the discharge air temperature has risen above 8 °C.

If the protection circuit is activated against the low pressure

(STOV, see section 5.1.1), the frost protection sensor switches

both ventilators off.

The outside air ow may be much cooler than the temperature

of the discharge air measured by the frost protection sensor

before the anti-freeze monitoring device is activated. Its

operation is possible up to -7 °C outside temperature.

Manufacturer’s Warranty and Liability

Glow-worm warrants that this product is free from defects of

manufacture.

It is covered by a manufacturer’s warranty of 24 months. The

aforesaid manufacturer’s warranty shall be applied in addition

to any legal warranty cover and shall not replace or restrict

your legal claims under the Sale of Goods Act. This warranty

shall become effective from the day of installation, or 2 years

after the manufacture of this system whichever is soonest.

This warranty shall be applicable only for such appliances

which have been installed in UK by a competent installer.

If on the rare occasion that material or fabrication defects

arise during the warranty period, the Glow-worm Customer

Service will repair these defects free of charge. It shall be at

the sole discretion of the manufacturer’s Customer Service

if he is to repair a defective unit or to replace it. Work under

warranty shall never cause an extension of the warranty

period.

This warranty shall only cover material or manufacturing

defects. The warranty shall not be applicable to such faults or

defects caused due to improper installation, commissioning,

handling and use, insufcient maintenance or intervention by

unauthorised persons. The warranty shall become void if such

work is executed to the appliance by other persons than those

belonging to our customer service or an authorised installer.

The aforesaid shall apply as well if parts or components are

incorporated in the unit or if the unit is connected to parts or

components which have not been approved and certied by

Glow-worm. Furthermore, the aforesaid warranty shall not be

applicable to such claims exceeding the elimination of defects

and faults free of charge, e.g. claims for damages.

Please call our service number 01773 596510 to report any

defects under warranty.

Service and Maintenance

To ensure regular servicing, it is strongly recommended

that arrangements are made for a Maintenance Agreement.

Please contact Glow-worm Aftersales Service (01773 596510)

for further details.

Spare Parts

Remember, when replacing a part on this appliance, use

only spare parts that you can be assured conform to the

safety and performance specication that we require. Do not

use reconditioned or copy parts that have not been clearly

authorised by Glow-worm.

If a part is required contact Glow-worm’s own service

organisation using the telephone number on the inside front

cover of this booklet.

5

Page 6

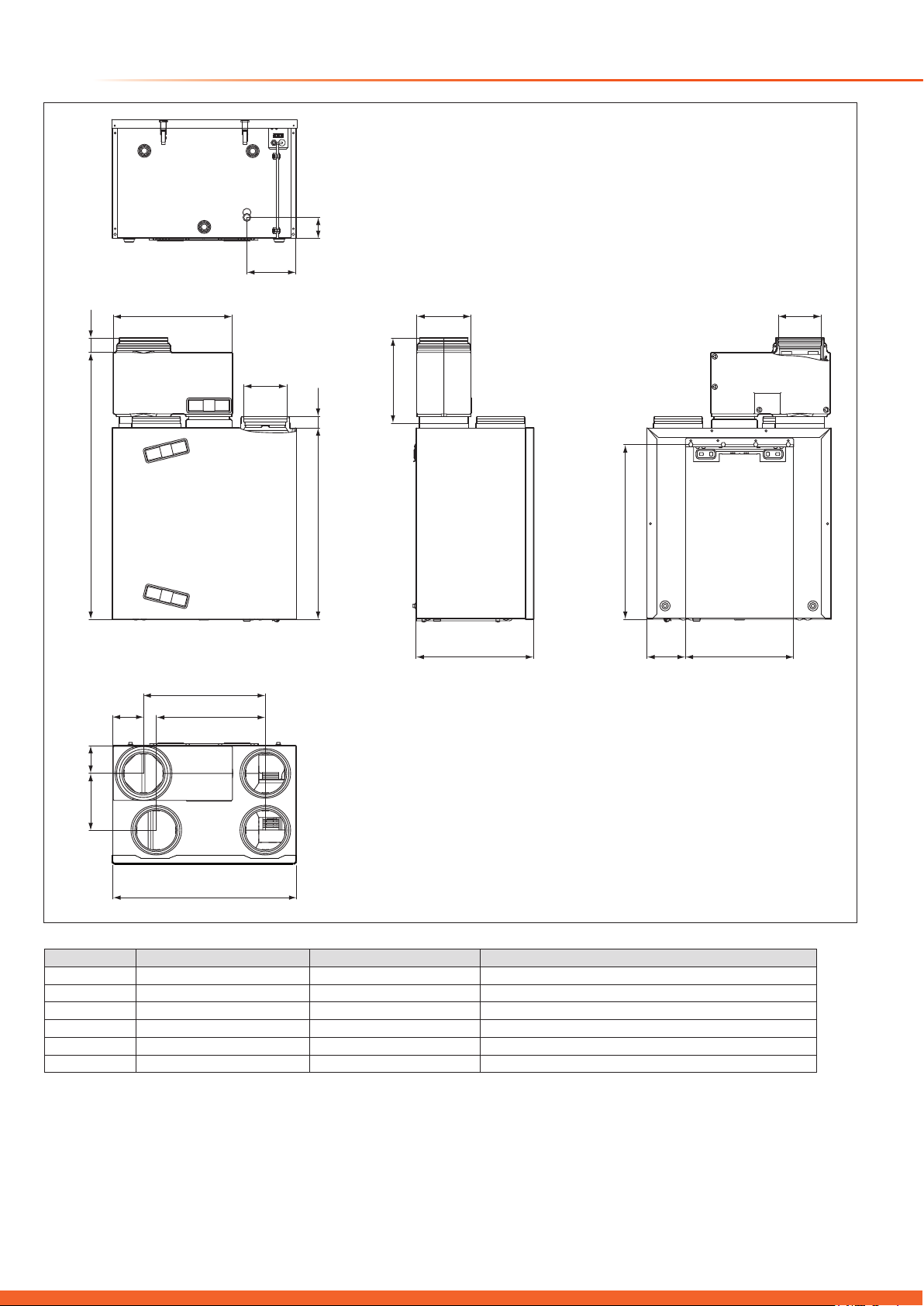

1 Technical Specication

A

77

127

B

471

521

D

ø 150/ø 160/ø 178/ø 198

ø 150/ø 160/ø 178/ø 198

Pipe diameter to be selected for the bypass connection

A14

18 2

18 2

14882

53EF

986

115

4 4 1

Y-Y

450

4 0 3

ØC (4 x)

709

315

200

D

6 4 5

B

14 2 400

680

Atmosorb HRD 275 Atmosorb HRD 350 Remarks

C ø 150/ø 160/ø 178 ø 180/ø 198 Pipe diameter to be selected for all 4 air connections

A 102 122

F 210 240

6

Overall Dimensions

Page 7

1 Technical Specication

P

210 W

Maximum electrical power consumption

T

Max

60 °C

Maximum operating temperature

1.1 Data Label - Atmosorb

The identification plate is positioned below the unit.

The indications given on the identification plate have the

following meaning:

Units Value Description

230 V ~50 Hz Mains voltage

max

V

dP

275 m3/h Maximum air volume flow

max

170 Pa allowable pressure loss of the device

max

at V

Max

For further information please read section “Technical Data”

Serial-no. 1234567890xxxxxx

HRD 275

230V~ 50 HZ

P

V

dP

T

Max

Max

Max.

210 W

275 m³ / h

170 Pa

Max

60 °C

1.2 Data Label - Bypass

You can find the identification plate on the top of the device.

The indications given on the identification plate have the

following meaning:

Units Value Description

12 V DC Voltage supply

P

3 W Maximum electrical power consumption

max

Serial-no. 1234567890xxxxxx

Bypass HRD 275 - HRD 350

12 V DC

P

3 W

Max

IPX2

Bar – Code

IPX2

nur zu verwenden mit Atmosorb HRD 275 / 350

only to use with Atmosorb HRD 275 / 350

alleen te gebruiken met Atmosorb HRD 275 / 350

utiliser seulement avec le Atmosorb HRD 275 / 350

Kan kun bruges sammen med Atmosorb HRD 275/350

Bar – Code

7

Page 8

1 Technical Specication

Feed pressure at max. volume flow

Pa

170

265

Frost protection mode active

°C-7-7

Dimensions height x length x depth

mm

709 x 680 x 471

709 x 680 x 521

Weight (gross)

kg4751

Heat exchanger material

Aluminium

Aluminium

Acoustic power

db(A)4852

Power consumption at 30 % of max. air volume flow

W

21 (83 m3/h, 15Pa)

30 (105 m3/h, 24Pa)

Minimum power consumption

W2130

Maximum power consumption

W

210

350

Protection class

IP X2

IP X2

* Standard Assessment Procedure (SAP)

Operating voltage Umax

V

24

Current consumption

mA

< 17

Level of protection

IP

20

Dimensions

Depth

mm

40

Voltage supply

V DC

12

Maximum ambient tempera-

°C

40

Minimum ambient tempera-

°C

5

Protection class for controller

IP X2

Air connections

mm

Diameter 150, diameter

Description Units Atmosorb HRD 275 Atmosorb HRD 350

Air specifications

Maximum air volume flow m

3

/h 275 350

Filter class EU/G 3 3

Filter surface area m

Thermal specifications

Thermal efficiency as per SAP* % 90,5 < 90

Maximum ambient temperature °C 40 40

Minimum ambient temperature °C 5 5

Mechanical specifications

Air connections mm ø 150, ø 160 and ø 180 ø 180 and ø 200

Electric specifications

Voltage supply V/Hz 230/50 230/50

Power consumption at 60 % of max. air volume flow W 55 (165 m3/h, 61Pa) 85 (165 m3/h, 61Pa)

Power consumption at max. air volume flow W 175 (275 m

Maximum current consumption A 0,77 1,29

2

0,25 0,25

3

/h, 170Pa) 295 (350 m3/h, 265Pa)

Remote Control Bypass

Description Units

Permitted ambient temperature

Minimum cross-section of the

connection lines

Protection class for

controller

Height mm 97

Width mm 146

°C 40

2

mm

0,75

III

ture

ture

Current consumption mA 200

Dimensions height x length x

depth

Description Units

mm

315 x 441 x 200

160, diameter 180,

diameter 200

8

Page 9

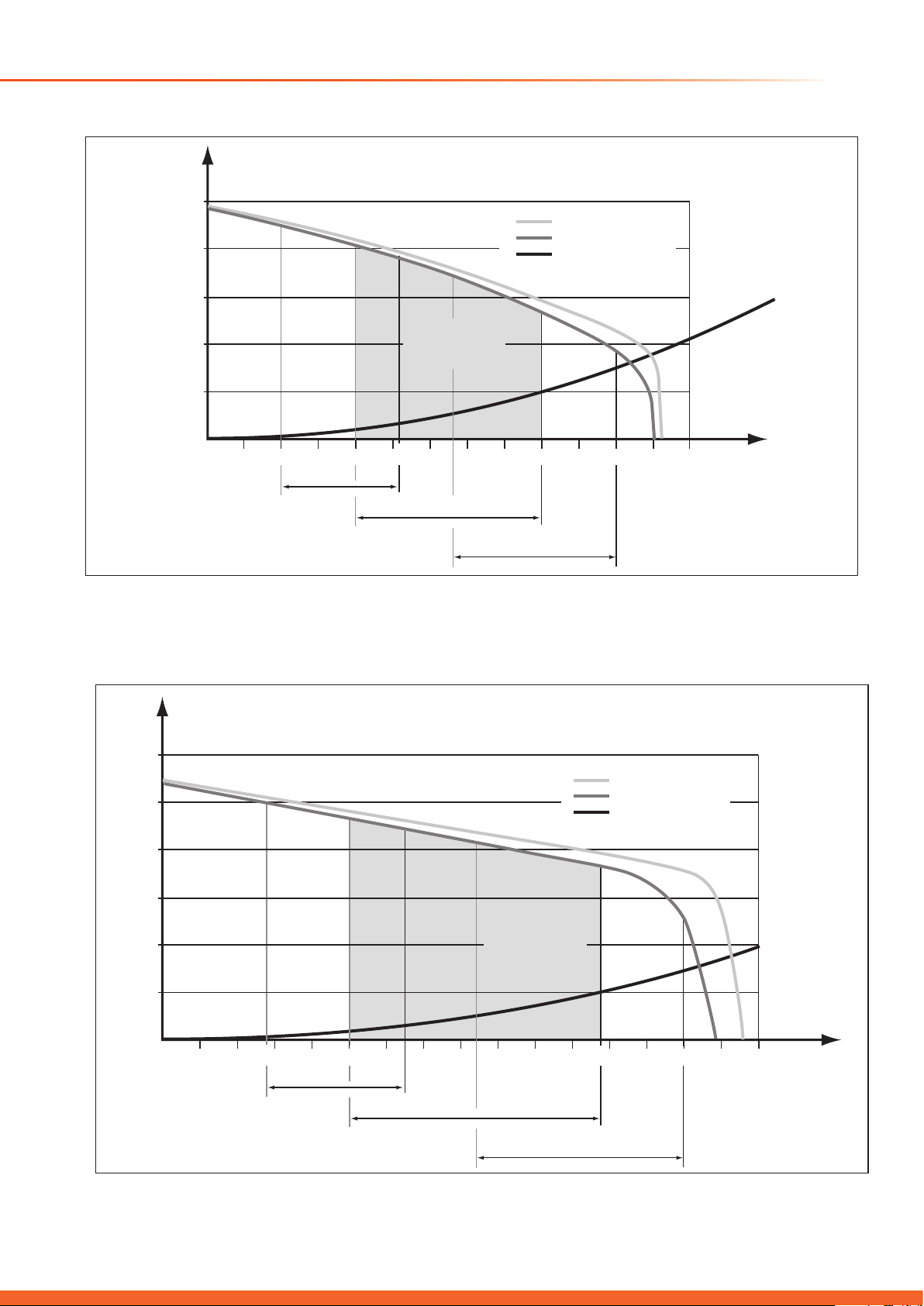

1 Technical Specication - Fan Curves

Performance Diagrams

[Pa]

500

400

300

200

100

Exhaust air

Fresh air

System

characteristic

Recommended

design range

Air 2

Atmosorb HRD 275

[Pa]

600

500

400

0

0 25 50 75 100 125 150 175 200 225 250 275 300 325

Air 1

Air 2

High

Exhaust air

Fresh air

System

characteristic

[m

3

/h]

300

200

100

0

0 25 50 75 100 125 150 175 200 225 250 275 300 325 350 375 400

Atmosorb HRD 350

Air 1

Air 2

Recommended

design range

Air 2

High

[m

3

/h]

9

Page 10

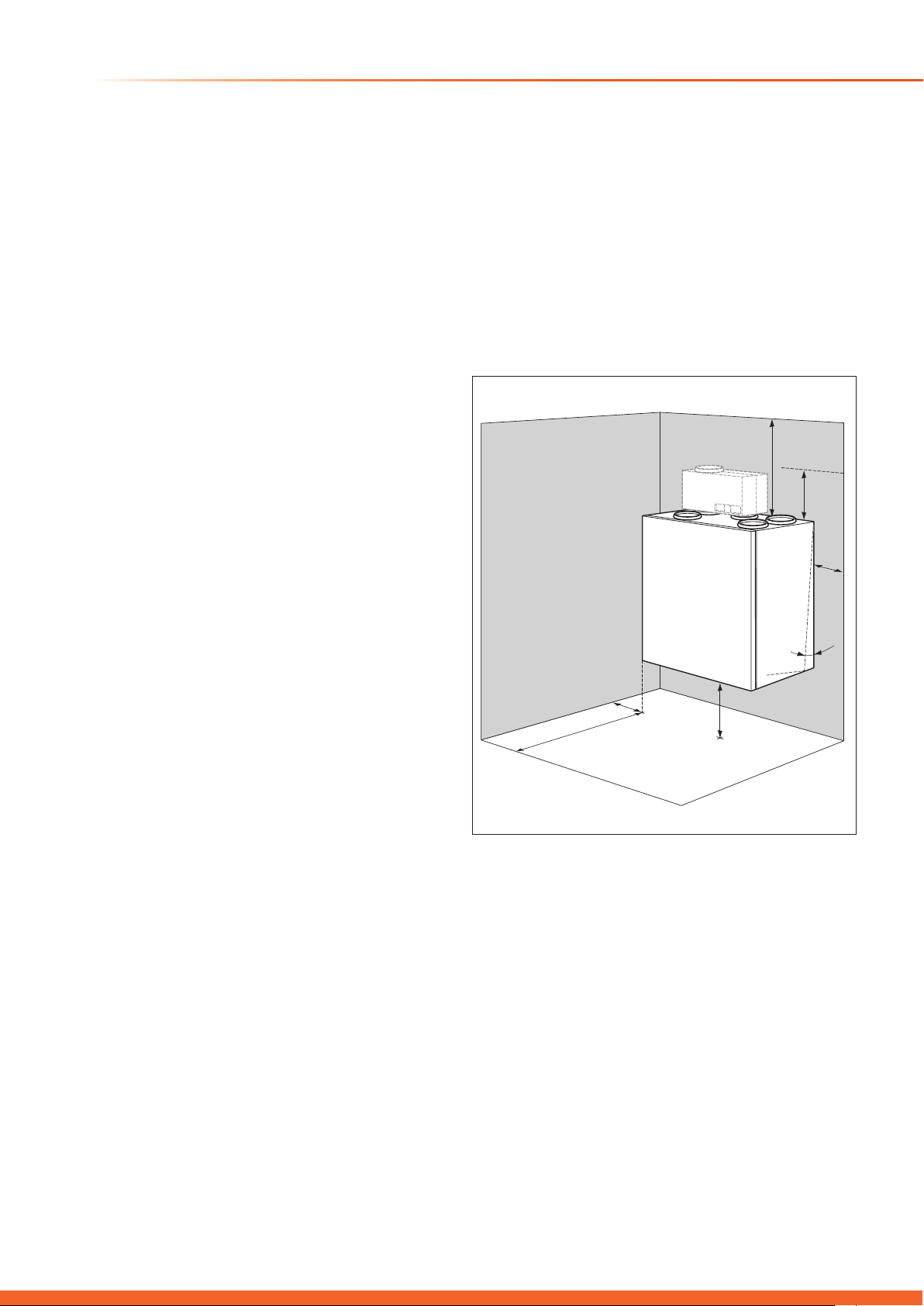

2 Siting the Unit

1000

100 300

100

300

0-1˚

600

2.1 Site Requirements

The site for the unit must be dry and frost-free. The system

installation must be planned in detail, with particular attention

to the positioning of the fresh air and exhaust air ducts and to

include sufficient sound insulation.

NOTE: The temperature of the unit can be considerably lower

than the temperature of the room, it is being installed in. To

avoid undesirable accumulation of condensate, the circulation

of fresh and exhaust air must be provided in the room.

The unit is wall-mounted and should preferably be close to a

drain outlet for the condensation drain.

• The unit must be installed with due consideration of the

requirement for adequate and practical air ducting and

services (fresh air and exhaust air, electrical power). Ensure

enough space is provided on top of the unit and at its sides to

be able to mount the required air ducts, additional silencers

and bypass unit, see diagram 2.1.

• The installation site must be selected so that the ductwork

distances to and from the unit are as short as possible.

• The wall to which the unit is to be mounted must be of a

sufficient load-carrying capacity for the weight.

• It is possible that the supplied fixing are not suitable for the

installation wall, then it is the responsibility of the installer to

provide the fixings.

• The condensate drain must be connected with the supplied

condensate drain trap and to the water outlet with an odour

trap (siphon).

• If the unit is mounted on an internal wall, do not select

a location directly above bedrooms due to possible sound

transfer. Always choose a location above a non-occupied

room such as a hall or bathroom.

• With wood-joist ceilings or similar you can provide additional

sound insulation by adding insulation between the joists.

• Always ensure that the condensate drain is free running.

• To avoid annoyance by excessive noise select a sound-

absorbing hose for final connections from the unit to the air

outlets.

• Install a silencer. This will help to neutralise possible noise

transmission between the unit and the air ducting and reduce

annoyance by noise.

• Keep the air supply inlet at a sufficient distance from

discharge air, exhaust air and drain ventilation. Comply with

the legal building rules and regulations.

• When installing the fresh air input and discharge air ducts

you will have to ensure sufficient separation to avoid that the

discharged air being re-circulated into the fresh air input.

To avoid re-circulation, the minimum recommended distance

between supply and extract is 2 metres.

2.3 Remote Control

• The remote control must be mounted such that there is

enough space around it to complete the electric wiring as well

as easy operation of the control.

• The remote control must be installed inside the living space

and be easily accessible. For further details see section

“Installation - Controls”.

2.4 Atmosorb

• Electrical connection above mains voltage socket with

230 V 50 Hz mains voltage.

The connection must comply with the current rules and

regulations.

14880

Diagram 2.1

2.2 Installation Minimum Clearances

• Please refer to diagram 2.1.

• For the installation, at least 100mm of free space on the

side of the device must be provided.

• For installation, filter replacement and maintenance works,

1 m working space in front of the ventilation unit is needed.

Over and beneath the device at least 30 cm are required.

10

Page 11

3 Ducting, Controls and Condensate

3.1 Ducting connections

Refer to diagram 3.3.

• Atmosorb HRD 275: 4 x air duct connections ø 150 mm, or

alternative ø 160 mm and ø 180 mm

• Atmosorb HRD 350: 4 x air duct connections ø 180 mm, or

alternative ø 200 mm

3.2 Bypass(Optional)

Refer to diagram 3.2.

• Atmosorb HRD 275 and HRD 350: 4 x air duct connections

ø 150 mm, or alternative ø 160 mm and ø 180 mm.

BYPASS CONNECTION

EXTERNAL AIR INLET

AIR EXHAUST

3.3 Remote Control

• Control cable from the remote control to the unit is a 2-core

cable, with cross-section 0,75 mm2. Maximum cable length

300m.

The connection must comply with the current rules and

regulations.

3.4 Condensate Drain Trap

The condensate drain trap must be connected to the threaded

tube under the unit. Additionally, an odour trap is required in

the waste water system. For hygienic reasons, between the

drain traps an air gap of at least 20 mm must be provided.

• Condensed water drain G 3/4 connection for the condensate

drain trap.

• The attached condensed water drain trap is designed to

compensate pressure between the device and the installation

room, for that reason it must always be filled with clear water.

EXTERNAL AIR OUTLET

14879

FRESH AIR OUTLET

(TO ROOM)

EXHAUST AIR FILTER

HEAT EXCHANGER

EXTERNAL AIR FILTER

AIR INLET FROM

OUTSIDE

FILTER

14881

14878

FAN

CIRCUIT BOARD

FAN EXHAUST

CONDENSATE DRAIN

OUTLET

3 STAGE SWITCH

CONNECTION

1 Outside air

2 Exhaust air (from living room)

1

3 Fresh air (to living room)

4 Outgoing air (to outside)

Diagram 3.1

VENTILATION FLAP

Diagram 3.2

2

4

3

Diagram 3.3

11

Page 12

4 Installation

4.1 Contents of Pack

• Digital remote control

• Mounting set consisting of:

• Fixing brackets 405 x 60 mm

• Condensate drain trap

Accessories (optional)

• Bypass Atmosorb

• Filtersets H.E. F6

Ensure that the wall offers the appropriate load carrying

capacity and that appropriate fixing are used to secure the

unit. It is possible that the attached mounting set with the

fixing screws and wall plug is not suitable for every wall.

The ventilation unit weighs about 35 kg. When hooking the

unit onto the fixing bracket, never lift the unit alone.

NOTE: This unit is solely intended for vertical wall mounting.

When mounting the system it is absolutely necessary to

ensure the horizontal positioning of the ventilation unit and an

angle of > 0° and < 1° in vertical position to ensure that the

condensation water can easily flow out of the unit.

• Atmosorb unit

4.2 Installation of the Unit

With due regards to the minimum clearances, condensate

drain position and ducting, mark and drill the position for the

wall bracket securing screws, see diagram 4.1.

Secure the wall bracket with suitable wall fixings.

Mount the unit, by hooking over the wall bracket, see diagram

4.1.

WALL MOUNTING

BRACKET

945 min

300 min

clearance

0-1˚

Diagram 4.1

14883

15530

4.3 Connection of the Condensate Drain

Fit the connecting piece for the condensate drain trap to the

connection outlet on the bottom of the unit.

Connect the attached condensate drain trap with the

connection piece, see diagram 4.2.

IMPORTANT: For the condensate discharge of the unit a

second drain trap is required, see diagram 4.3.

For hygienic reasons, the condensate drain trap must not be

directly connected to the waste water system.

An air gap of at least 20 mm must be provided. A wrongly

installed condensate outlet can lead to condensate

accumulation and to an uncontrollable escape of condensate.

Use of the customer service and possible subsequent

damages are not covered by the Glow-worm warranty.

CONNECTING

PIECE AND

WASHER

CONDENSATE

DRAIN OUTLET

CONDENSATE

DRAIN TRAP

Diagram 4.2

12

Page 13

4 Installation

4.4 Air Duct Connections

Before executing the final connection check the air ducts are

still clean. If necessary, clean the air ducts.

Only then connect the air ducts to the unit.

Connect the air ducts to the connections on top of the unit.

NOTE: Air ducts must be tightly connected to the unit - use

suitable accessories or sealing material. Insulation of the

fresh air and outgoing air ducts must be diffusion resistant.

4.5 Opening and Closing the Unit

The unit is equipped with a fixed front panel. For mounting

and maintenance work on the unit it is necessary to remove

the front panel.

IMPORTANT: Switch off the mains supply to the unit before

starting to work.

Remove the filters from the Atmosorb first, to enable removal

of the front panel.

Pull both filters out of the unit, see diagram 4.4

Remove the screw from the LH toggle-type fastener below the

unit.

Then open both toggle-type fasteners.

Pull the lower part of the front panel towards you.

Now lift the front panel above the top fixing points.

To close the unit, carry out the steps in reverse order.

IMPORTANT: Always ensure the screw is replaced into the

left hand toggle after re-assembly to avoid unauthorised

access to the unit.

14885

a

a

airVENT

> 2 cm

airVENT airVENT

Diagram 4.3

b

c

e

d

Diagram 4.4

13

Page 14

4 Installation - Bypass (Optional)

4.6 Mounting and Electrical Connection

of the Bypass (optional)

IMPORTANT: Switch off the mains supply to the unit before

starting to work.

Improper electric installation may cause accidents. Therefore

it is absolutely mandatory to have a competent person

approved at the time by the Health and Safety Executive to

complete the electrical installation.

NOTE: The bypass electrical connection must be completed

before mounting.

Open the unit as previously described.

Remove the plug from the middle air connection by pushing it

upwards from the inside, see diagram 4.5.

Inside the bypass air connection in the unit, there is a 10-pole

connector to which the bypass plug is connected.

You will find a plug in the bag in the casing wall. Pull the plug

out of the bag of the casing wall.

Release the cable with the 10-pin connector from the casing

wall and connect the bypass plug with the connector.

To install the temperature sensor, proceed as follows, refer to

diagram 4.5.

Remove the plug from the sensor hole in the outside air duct.

Push the temperature sensor through the hole into the

exhaust air duct.

NOTE: To ensure the correct bypass function the temperature

sensor must project at least 25 mm into the exhaust air flow.

14886

TEMPERATURE

SENSOR

25mm

ELECTRICAL

PLUG

Diagram 4.5

After completing the electrical connection of the bypass, you

can mount the bypass unit.

Push the bypass into or over the both outside air connections

of the unit.

Make sure that the filter unit is aligned towards you.

Check that the bypass is completely inserted.

Plug in the mains plug into the plug socket.

14886

Diagram 4.6

14

Page 15

4 Installation - Controls

4.7 Installation of the Remote Control

Site the remote control on an inside wall at a height of about

1.5 m, were the controller is able to detect the circulating

ambient air clearly and unimpeded from furniture, curtains or

other external influences. The position should be selected so

that neither air drafts from the door or the window nor heat

sources such as radiators, TV or solar irradiation may directly

influence the controller.

A connection with the ventilation unit is established via a

2-core connection cable.

Pull the remote control from the wall base.

Refer to diagram 4.7.

With due regard to the position of the cable entry, mark the

wall base securing points on the wall. Using a 6mm diameter

drill and fixings supplied, secure the wall base to the wall

having first pulled the cable through the cable entry.

Connect the cable to the corresponding terminals (eBUS “+”

and “-”) on the terminal connecting strip.

Place the control on to the wall base such that the pins at the

back of the upper part locate into the seats.

Press the casing to the wall base till it locates, taking care not

to bend the controller connection pins. Make sure that you do

not bend the contacts.

15544

TERMINAL

STRIP

WALL BASE

CONTROL

CASING

SECURING

POINT

4.8 Electrical Connection of the Remote

Control

IMPORTANT: Switch off the mains supply to the unit before

starting to work.

To prevent accidents, electric installation can only be carried

out by a competent person approved at the time by the

Health and Safety Executive.

The remote control is connected to the ventilation unit via

a two-core cable. Communication is via a 2-pole eBUS.

The eBUS connector is sized to accommodate wiring of 2 x

0.75 mm2 (recommended). It is possible to interchange the

connections without affecting communication. This connection

is at the bottom of the unit.

Connect the control cable as shown in diagram 4.8, to the

eBUS-clamps + and -.

SECURING

POINT

eBUS

CONNECTION

15543

Diagram 4.7

15545

VIEW ON UNDERSIDE OF UNIT

Diagram 4.8

15

Page 16

4 Installation - Controls

1 ("0")

Control system with remote

0↓ open

3 ("H")

HIGH position

0↓ connected to H↑

4.9 Establishment of Electrical Connection

of the 3-stage Switch (optional)

In addition to the standard control unit, you can also use

a universal 3-stage switch, routed into X12 of the PCB, to

control the ventilation unit. This must be potential-free (no

voltage), see diagram 4.9.

Connect as shown in diagram 4.10 to the clamps „0↓”, “D↑”

and “H↑”.

The following switch positions are possible:

Position Function Electrical contact

control

2 ("D") Day position (fans stage 2) 0↓ connected to D↑

(fans stage 3)

Mains connection

BUS connection

Switch 2

Switch 1

0 - 10 V Control

signal (analog)

Alarm input

Alarm output

X 15

X 16

230 V~

F4

2AT

Bus

Switch 2

Switch 1

Analog

Error In Err. Out

PC

connection

X 1X 9

white whitewhite

N L

N L N L

Freh air fan

Exhaust air fan

X 2

Control signal

X 3

X 4

X 5

0 - 10 V

Hz

Gnd

Control signal

0 - 10 V

Hz

Gnd

Temperature sensor EAO

ϑ

(Frost protection sensor)

Bypass Motor

M

ϑ

Temperature sensor EAI

ϑ

Temperature sensor SAO

ϑ

Temperature sensor SAI

- + 1 2 1 2D OH

red blue white

X 10

D OH

X 11

white white white

X 12

-

X 13

+

10

white

X 14

X 17

9

5

4

8

3

7

2

6

1

X 6

X 7

16

X 8

Diagram 4.9

Page 17

Installation - Controls

4.10 Alarm Input (optional)

The alarm input (connection „X 14“ on the board) is bridged

when the unit is delivered. If the connection is undone with an

external potential-free switching contact (break contact), both

fans will be switched off. On the display of the remote control

you will see the message “LOCK“.

IMPORTANT: Disconnect from the mains electricity supply

before starting to work on the unit.

Remove the unit front panel as described previously.

Now place the 2-core cable (minimum 0.35 mm2) in the

respective cable routing to the PCB.

Connect the lines to the connection “X 14” (alarm input) in

accordance with diagram 4.9 “Wiring scheme”.

When the contact is opened, the word “LOCK”

NOTE:

appears on the display of the remote control.

The fans on the domestic ventilation unit are then switched

off.

4.11 Alarm Output (optional)

The alarm output (connection „X 16“ on the board) is made of

a potential-free switching contact with a resistive load (Ohm)

of maximum 2 A.

4.12 Removal of cable insulation

Remove the cable insulation as shown in diagram 4.11.

Lead the cable through the strain relief, see diagram 4.8 and

screw them together.

An alarm will be triggered:

• If the time set for the filter replacement has expired. The

duration is set under the installer level option on the remote

control.

• If one of the error messages described in fault finding

section, is indicated in the remote control display.

Disconnect from the mains electricity supply.

Remove the unit front panel as described previously.

Now place the 2-core cable (minimum 0.35 mm2) in the

respective cable routing to the PCB.

Connect the lines to the connection “X 16” (alarm output) in

accordance with diagram 4.9 “Wiring scheme”.

15531

0 D

0

H

Switch

D

BUS

-

H

+

0

D

H

40 mm

Ø 4,5 - 10 mm

Diagram 4.10

Diagram 4.11

17

Page 18

5 Commissioning

5.1 Function checks

Once all connections are correctly installed in accordance

with the wiring scheme, check the functions of the remote

control, the ventilation unit and the bypass. When doing so,

note that the unit must not be started until all ventilation ducts

are connected to the unit and the unit and all ductwork are

completely sealed.

In the user sections of the “Instructions for Use” manual you

will find in detail all the settings for the individual operating

modes and the special functions. For testing functions

proceed as follows:

• Select the “night” operating mode and check that the fans in

the domestic ventilation unit are operating at low output.

• Select the “day” operating mode and check that the fans in

the domestic ventilation unit are operating at medium output

(AIR2).

• Activate the special function”advance”. Check that the

fans in the domestic ventilation unit are operating at medium

output (AIR2).

• If the output stages are not correctly switched, you must

check the wiring on the terminals of the remote control and

the domestic ventilation unit.

5.2 Start-Up

The start-up and the operation of the unit as well as

instruction to the user must be done by a competent person

approved at the time by the Health and Safety Executive.

Please note that the device can only be started up if all

ventilation pipes of the device are connected and the entire

device is closed.

As part of the start-up it is necessary to adjust the ventilation

unit.

The ventilation units are delivered with basic setting for both

fans. As each fresh air and exhaust air installation is different

and thus offers different external resistance in the air ducting

you will have to separately adjust the fresh air and the

exhaust air fan to suit.

You can adjust the domestic ventilation unit using the remote

control. Below are the necessary steps.

5.3 Adjustment of the Digital Remote

Control

To optimally match the system parameters to the required

conditions it is necessary to set these parameters with the

remote control, see diagram 5.1. The system parameters are

located in an upper operation level and should only be set by

a competent person approved at the time by the Health and

Safety Executive.

5.4 Expert Technician Level

Hold down the “mode” button for about 10 seconds to go to

the installer level. The symbol appears on the display.

Then, by pressing the dial, it is possible to select the

functions. The functions shown in table 5.1 can be scrolled

through one after the other.

To change the parameters just press “prog”.

If you want to return to the basic display, shortly press the

“mode” button.

The adjustable air volume flows apply jointly to fresh air and

exhaust air.

15541

18

Diagram 5.1

Page 19

5 Commissioning

Min m3/h

50

70

Max m3/h

AIR2

AIR2

Atmosorb HRD

275

350

press

Atmosorb HRD

275

350

Default setting m3/h

275

350

Max m3/h

325

400

Must value of the volume flow after the activati-

press

AIR5

Min. volume flow with activated

bypass

Atmosorb HRD

275

350

Min m3/h

AIR1

AIR1

Max m3/h

HIGH

HIGH

press

Atmosorb HRD

275

350

Factory setting

OFF

OFF

ON = If one fan fails, the other fan is also de-

press

FILT

Days till the next filter replacement

Default setting/days

180

180

Max. days

180

180

press

POL1

No function

Please refer to diagram 5.1 for control panel buttons and layout:

Action

press

mode

button

for 10

secs

press

prog

button

Display

AIR1

AIR2

Meaning

Set volume flow night

1st stage

Atmosorb HRD 275 350

Default setting m

Set volume flow for the

non-programmed periods.

Set volume flow day

2nd stage

Default setting m3/h 165 210

Min m

Max m

Set volume flow for the programmed periods.

Table 5.1 Installer level

3

/h 80 105

3

/h AIR1 AIR1

3

/h HIGH HIGH

Action

prog

button

press

prog

button

prog

button

prog

button

Display Meaning

HIGH Set volume flow, 3rd stage

Min m3/h AIR2 AIR2

on of the special function "Advance Mode" with

the key F.

AIR4 Set volume flow holiday

Atmosorb HRD 275 350

3

Default setting m

3

Min m

/h 50 70

3

/h AIR2 AIR2

Max m

Set volume flow after activation of the special

function "holidays" with the F button, additionally in "OFF" mode.

Default setting m3/h 110 140

Minimum volume flow when the connected bypass switches to summer mode (without heat

recovery).

STOV Protective switching against

negative pressure

/h 60 75

activated.

This protective switching prevents negative

pressure as a result of only disconnecting the

supply fan. If the protective switching against

the low pressure is activated, both fans are

switched off by the frost protection function.

prog

button

prog

POL2

Atmosorb HRD 275 350

Min. days 30 30

Adjusted in 30 day steps to which the indication "FILT" is shown on the remote control display. (Alarm output is closed)

button

Table 5.1 Installer level (continued)

19

Page 20

5 Commissioning

press

C-AIR

Set volume flow correction

Default setting in %

0

0

Adjustment of the set volume flow for fresh air

Factory setting in °C

0

0

Min in °C

-3

-3

Correction of the room temperature indicated on

Factory setting

0

0

press

MON

Desired value of the current month*

Factory setting

01

01

press

YEAR

Desired value of the current year*

Atmosorb HRD

275

350

Max/year

2159

2159

* Setting will be required if the automatic switching from

summer to winter time is to be activated.

5.5 Service/Diagnostics Level

The service/diagnostics level should help the installer during

the service.

Keep the mode and prog buttons simultaneously pressed for

about 3 seconds to reach the service/diagnostics level. The

display will show the symbols .

By pressing and holding the “mode” button you will return to

the basic display.

You can display the following functions / information:

Action Display Meaning

prog

button

press

prog

button

press

prog

button

prog

C-RT Room temperature correction

DAY Desired value of the current day*

Atmosorb HRD 275 350

Min in % -50 -50

Max in % +50 +50

in order to produce a slightly negative pressure

in the building. At low temperatures it prevents

ice formation due to condensation water on the

doors and windows.

Atmosorb HRD 275 350

Max in °C +3 +3

the display of the remote control.

Atmosorb HRD 275 350

Min 0 0

Max 31 31

Atmosorb HRD 275 350

button

Min/month 01 01

Max/month 12 12

prog

button

Factory setting 2005 2005

Min/year 2000 2000

Table 5.1 Installer level (continued)

Please refer to diagram 5.1 for control panel buttons and

layout:

20

Page 21

5 Commissioning

press +

press +

press +

press

AIR/

Current air volume flow indication in

press

APPL/

Display of the unit type

press

Display

Display test: All symbols of the display

press

VER1/

Display of the software version of the

press

press mode

Action Display Meaning

press mode

and prog

BYP

ON

Bypass switches to summer mode

button for 3

seconds

press +

button

press +

button

button

button

button

prog button

prog button

prog button

prog button

+ button

ALAR ONAlarm output is activated

SAO/*

xx oC

EAO/

xx oC

EAI*

xx oC

SAI/*

xx oC

xx m3/h

1 / 2

x.xx

VER2/

x.xx

(contact closed).

Display of fresh air temperature (Supply Air Out)

Display of the discharge air temperature at the frost protection sensor (Exhaust Air Out)

Display of the exhaust air temperature

(Exhaust Air In)

Display of the outside air temperature

(Supply Air In)

the ventilation unit. By turning the dial

it is possible to change the air quantity

during the test mode.

1 = Atmosorb HRD 275

2 = Atmosorb HRD 350

Turn the dial to select the unit type.

are indicated, however, not all symbols

of recoVAIR have a meaning.

remote control

Display of the software version of the

recoVAIR PCB

Return to basic display

and prog

button

5.8 Domestic Ventilation Unit Adjustment

Adjustment procedure

First of all ensure that the overall air flow calculated for the

installation is reached by the system. Then adjust the air

flow rates for the individual living spaces. Finally adjust the

individual air flow distribution within each living space.

Total Air Flow Adjustment

First adjust the desired air quantity calculated when the

system was designed with the remote control for all operating

modes (installer level). Proceed step by step as described in

table 5.1, page 19. In the table you will find the information for

the desired values.

NOTE: The planned air flow must be in the in the day mode

(2nd stage) because this is the standard operation mode.

Adjusting the air quantities at the system

1. Adjust all the exhaust and fresh air valves in the living

rooms to the middle opening of about 50 %. Then proceed in

accordance with the instructions given in the manufacturer

operating manual.

The air speed must not exceed 1.5 m/s at a distance of 50 cm

from the valve.

2. Make sure that all valves in the existing air duct manifolds

are completely opened.

3. Switch the domestic ventilation device into the operation

mode “day mode” using the remote control.

4. Measure the partial air flow at the strings with control

dampers if there are some available. Correct these settings if

required by adjusting the control dampers.

5. Open, if necessary, air inlet and air outlet valves if the

desired total air flow has not been reached.

6. Raise the ventilator revolution speed using the values in

table 5.1 if the total air flow is too low.

7. Go to the installer level in the remote control by pressing

the “mode” button for 10 seconds.

8. Press the “prog” buttons until “C-AIR” appears on the

display.

9. Correct the inlet air flow by pressing the - or + buttons until

the inlet and the outlet air volume are equal (see table 5.1).

5.9 Operator Delivery

Completely fill in the attached measurement report

(page 27) and hand it over to the operator.

Functions of the service/diagnostics level

* These values can only be called with a bypass unit installed.

Please refer to diagram 5.1 for layout of control panel buttons:

5.6 Testing of the bypass and other

functions

Go to the service/diagnostics level as described in

section 5.5. Now test successively all functions in accordance

with the above table. If the bypass is not connected or if a

sensor is defective, the display will show the “-” symbol.

5.7 Reset to the Factory Setting

• Press the “prog” button for 15 seconds to reset the controller

to the default setting.

As soon as the display lights up twice, the controller is

completely re-set to its default settings. This means that you

will have to perform all individual settings again.

21

Page 22

6 Servicing

NOTE: Replace the filters at least once a year or

after maximum 2000 operating hours. If the filters are heavily

soiled, they should be replaced at shorter intervals.

A competent person approved at the time by the Health and

Safety Executive in the area of the air pollution control, should

carry out regular inspections. The first inpection should be

performed 3 months after commissioning.

To avoid damaging the unit, the following maintenance work

must be carried out by a competent person approved at the

time by the Health and Safety Executive.

The functional operation of the ventilation unit requires it to be

serviced once per year, this includes the following:

• Check the general condition of the unit

• Remove any dirt and soiling at the unit.

• Clean or replace soiled filters.

• Clean the condensate outlet and check if the duct is free

• Clean soiled fan.

• Check the function of the unit, the remote control and the

bypass.

14885

a

a

6.1 Removing and Cleaning the Filter of the

Ventilation Unit

Open the unit and remove the filters then the front panel as

shown in diagram 6.1.

If the filters are not heavily soiled, you may clean them with a

normal vacuum cleaner.

If this is not enough, the filters must be replaced.

Cleaning the filters with water or other liquids is expressly

prohibited.

Description

Filter Atmosorb G3 0020064722

Filter Atmosorb Bypass G3 0020064723

High efficiency filter Atmosorb F6 0020064720

High efficiency filter Atmosorb Bypass F6 0020064721

Filter

class

Ordering number

b

c

e

d

Diagram 6.1

22

Page 23

6 Servicing

6.2 Cleaning the Heat Exchanger

IMPORTANT: When removing and replacing the heat

exchanger take care not to damage it.

Take care not to damage the heat exchanger fins. Any

damage will lead to premature wear in the system.

Refer to section 4.5 and open the unit and remove the filters

then the front panel.

Hold the heat exchanger with both hands at the edges

and without damaging the fins, carefully pull out the heat

exchanger, see diagram 6.2.

Clean the heat exchanger with a washing liquid with neutral

pH and lukewarm water, then rinse it again with clear

lukewarm water.

NOTE: detergents, especially acidic detergents (such as

vinegar cleaner), damage the unit.

The heat exchanger must be dry before replacement.

With the removed heat exchanger check as well if the

condensate water drain is clean, if necessary clean as

described below.

Slide the heat exchanger back into the unit. Take care that

the heat exchanger correctly fits into the guide rails at the

top and bottom of the housing and that it is not installed off

centre.

IMPORTANT: The heat exchanger must be flush with the

front side of the EPP body. A protruding heat exchanger can

cause leakages and condensate escape.

6.3 Cleaning the Condensate Drain

With the heat exchanger removed.

Unscrew the condensate drain trap from the bottom of the

unit, see diagram 4.2.

Check if the drain is free, see diagram 6.3.

Clean it if is blocked.

If required, clean any dirt in the drain pan.

Clean the condensate drain trap and fill it with clean water.

14889

Diagram 6.2

BYPASS

FILTER

14890

6.4 Cleaning or Replacing the Bypass

Filter

Bypass, if fitted.

See diagram 6.3 for the location of the bypass filter.

If the filter is not heavily soiled, you may clean it with a

normal vacuum cleaner.

If this is not enough, the filter must be replaced.

Cleaning the filter with water or other liquids is expressly

prohibited.

6.5 Test Operation and Restart

After servicing check the correct functioning of the unit:

• Check that the unit casing is correctly fitted.

• Insert the mains plug into the plug socket and start the

unit.

• Check the correct function of the unit.

• Check the correct function of the remote control.

Diagram 6.3

23

Page 24

7 Fault Finding

on the PCB.

Replace or clean ventilators, check the reason of soiling.

None or insufficient

Filters are extremely soiled.

Fan defective.

Clean the filter.

Replace the fan if necessary.

No or insufficient

Filters are extremely soiled.

Fan defective.

Clean the filter.

Replace the fan if necessary.

Bypass summer mode

Bypass function not activated or set days for

In the programming level of the remote control, set or activate

are detected at the remote control. See section 6

Fresh air too cold

Exhaust air and fresh air flows not balanced.

Adjust the unit in accordance with section 5.8.

if necessary, replace the bypass.

No fresh air or

Frost protection activated.

discharge air temperature above 3 °C.

Check the resistance of the frost protection sensor based on

other rooms

different parts of the roof.

Planned air flow not

System is not air-tight.

Seal all pipe connections properly if necessary.

Noise in the unit after

Wrong mounting of the fans.

Check the correct positioning of the fans.

7.1 Fault Finding

The faults listed below may only be rectified by a competent

person approved at the time by the Health and Safety

Executive.

The following checks should be performed before proceeding

onto specific diagnostics:

• Check the external electrical supply to the boiler is on and

a supply of 230V is present at the ‘L’ and ‘N’ terminals on

the installer interface, refer to section 11.4 for access and

diagram 14.4.

• Check the electrical installation and unit, carry out tests for

earth continuity, polarity, short circuit and resistance to earth,

using a suitable multimeter.

• Check that all external controls are on.

• Check the functional flow diagram, 14.5.

Fault Cause Remedy

The unit does not

operate

Temporary interruption of the mains voltage supply

or no supply at all. Power supply circuit breaker

tripped. Electricity disconnector was activated.

Fuse F4 in the unit is defective.

After a mains failure the unit automatically restarts once the

mains voltage is re-established. Re-set circuit breaker in mains

distribution board. Check that all cables are properly

connected and undamaged. If necessary, replace the fuse F4

Unit operation is very

loud even at the

minimum fan speed

fresh air supply

exhaust air flow

(i.e. in the bathroom

the mirror stays

fogged up)

does not work

Noise in the

condensation water

drain trap

Water dripping from

the unit

No silencers in the fresh air and exhaust air ducts.

Wrong silencers, or silencers are too short. Filters

are extremely soiled.

Ventilators are defective or heavily soiled.

Fresh air valves/grilles closed too much.

Exhaust air or fresh air ducts obstructed.

Fresh air input louvre too small.

Incorrect wiring.

Exhaust air valves closed too much.

Exhaust air or fresh air ducts obstructed.

Fresh air input louvre too small.

Incorrect wiring.

summer mode expired.

Incorrect positioning of the temperature sensor.

Flap position and/or motor for bypass defective.

Defective bypass motor wiring.

Drain trap incorrectly connected. Connect the drain in accordance with section 4.3.

Exhaust air and fresh air ducts are not vapoursealed.

Wrong flap position and bypass motor defective.

Mount additional silencers in accordance with the system

design.

Reduce the air quantity to the minimum fan stage. Clean or

replace filters.

Open the fresh air valves/grilles. Adjust the system again.

Clean the exhaust air and fresh air ducts.

Fit a larger louvre.

Check the wiring.

Open the exhaust air valves. Adjust the system again.

Clean the exhaust air and fresh air ducts.

Fit a larger louvre.

Check the wiring.

the bypass function.

Correctly position the temperature sensor.

Check the flap position and the motor and, if required, replace

them.

Check that the plug to the flap motor is correctly positioned.

Check in the Service/Diagnostics menu whether the sensors

Insulate exhaust air and fresh air ducts, make ducts air-tight or

use specially insulated pipes.

Check the flap and motor,

Clean the flap and bracket,

exhaust air (only one

fan running)

Odours from the

kitchen/WC enter into

Sound transmitted

between the rooms

reached at the start-up

replacing the fan.

24

With outside temperatures below -7 °C, correct

operation.

The frost protection sensor will not work at a

Outlets for fresh air and exhaust air are too close

to each other.

No crosstalk absorbers mounted. Additionally install crosstalk absorbers.

table, “Resistance Values of the Temperature Sensor“.

If necessary, replace the frost protection sensor.

Extend the distance between the outlets for fresh air and

exhaust air. We recommend to position these junctions in

Adjust the unit in accordance with section 5.8.

Page 25

7 Fault Finding

COM Err

Fans turn with 20% PWM

Communication error between the PCB in the

channel.

Pull the mains plug and insert it again.

error, contact Glow-worm Customer Service.

Wiring interrupted.

EAO Err

Temperature sensor discharge

Temperature sensor defective (interrupted or

Wiring interrupted.

Contact Glow-worm Customer Service.

SAO Err*

Temperature sensor fresh air

Temperature sensor defective (interrupted or

Wiring interrupted.

Contact Glow-worm Customer Service.

-20

95862

0

32510

25

10000

40

5330

Error Messages in the Remote Control

* Error message only with installed bypass

Indication

on the

display

LOCK Both fans inoperative Alarm input "X 14" opened. Check whether a separate switch is

SAI Err* Temperature sensor outside air Temperature sensor defective (interrupted or

EAI Err* Temperature sensor exhaust

SFAN Err Contact Glow-worm Customer Service.

EFAN Err Contact Glow-worm Customer Service.

FILT Check all filters for soiling. Time for programmed filter timer expired. Set the filter timer (in the installer level) to

Check/

component

air

air

Cause Remedy

unit and the remote control.

230 V eBUS line laid parallel in pipe or cable

short-circuited).

Wiring interrupted.

Temperature sensor defective (interrupted or

short-circuited).

short-circuited).

short-circuited).

If this does not help to eliminate the error,

contact Glow-worm Customer Service.

connected to "X 14". Check why the switch is

open.If this does not help to eliminate the

Contact Glow-worm Customer Service.

Contact Glow-worm Customer Service.

RESET.

Resistance Values of the Temperature

Sensor

Temperature in oC Resistance in Ω

-10 54892

10 19862

20 12486

30 8060

25

Page 26

Template: Start-up Measuring Report

Fresh air flow

Room Grille/louvre size 1. measurement 2nd measurement 3rd measurement

Total

Exhaust air flow

Room Grille/louvre size 1. measurement 2nd measurement 3rd measurement

26

Total

Page 27

Template: Filter Replacement Report

Date Operating hours next change Name

27

Page 28

Template: Hygiene Check Report

Date Operating hours opt. Impression filter

Visual check of the unit

(swept clean)

Name

28

Page 29

Notes on Installation

29

Page 30

Notes on Installation

30

Page 31

31

Page 32

Because of our constant endeavour for improvement, details may vary slightly from those shown in these instructions.

0020063535-01 08.09

Glow-worm, Nottingham Road, Belper, Derbyshire. DE56 1JT

www.high-efciency.info

Loading...

Loading...