Page 1

The energy you need

Installation manual

Envirosorb3 8

Envirosorb

11

3

Page 2

TABLE OF CONTENTS

1 Safety ....................................................... 3

1.1 Symbols used ......................................................... 3

1.2 Qualifi cations .........................................................3

1.3 General safety advices ............................................. 3

1.4 R410A Refrigerant ...................................................3

1.5 Intended use ........................................................... 4

1.6 Rules and regulations ............................................. 4

1.7 CE label .................................................................. 4

2 Notes on the documentation ..................... 5

2.1 Observe other applicable documents ........................ 5

2.2 Storing documents .................................................. 5

2.3 Validity of the instructions ....................................... 5

3 Appliance description ............................... 5

3.1 Safety devices .........................................................5

3.2 Concept of operation ...............................................5

3.3 Structure of the appliance ........................................ 7

3.4 Type designation and serial number .........................8

3.5 Data plate description .............................................8

4 Mounting and installation ......................... 8

7 Trouble-shooting .................................... 20

7.1 Fault diagnosis ......................................................20

7.2 Error codes ........................................................... 20

8 Decommissioning ...................................20

9 Recycling ................................................ 20

9.1 Packaging .............................................................20

9.2 Appliance ............................................................. 20

9.3 Refrigerant fl uid .................................................... 20

10 Technical data .........................................21

11 Appendix ................................................ 23

11.1 Table of Diagnosis codes........................................ 23

11.2 Fault codes ........................................................... 24

4.1 Preparing mounting and installation ......................... 8

4.2 Mounting the appliance ......................................... 10

4.3 Hydraulic installation ............................................ 11

4.4 Electrical Installation ............................................. 12

5 Start-up .................................................. 17

5.1 Filling the hydraulic circuit ..................................... 17

5.2 Activating the heat pump ....................................... 17

5.3 Checking the operation of the device ...................... 17

5.4 Adjustment of HP circuit fl ow ..................................17

5.5 Installation of side panel .......................................18

5.6 User information ................................................... 18

6 Maintenance ........................................... 19

6.1 Observe maintenance intervals .............................. 19

6.2 Preparing maintenance .......................................... 19

6.3 Pre-maintenance instructions ................................ 19

6.4 Annual Maintenance .............................................. 19

6.5 Draining ............................................................... 19

6.6 Checking the appliance status codes ...................... 19

6.7 Checking the electrical installation ......................... 20

6.8 Start-up after maintenance .................................... 20

EN

2

0020154078_00 - 02/13 - Glow-worm

Page 3

SAFETY

1 Safety

1.1 Symbols used

The warning notes are classifi ed in accordance with the

severity of the possible danger using the following warning

signs and signal words.

Warning symbol Explanation

Danger!

Immediate danger to life or risk of severe

a

e

a

b

1.2 Qualifi cations

Any work carried out must be by suitably qualifi ed personnel.

∙ Incorrect installation can cause damage to the unit, to the

site or injury to others.

personal injury.

Danger!

Risk of death from electric shock.

Warning!

Risk of minor personal injury.

Caution!

Risk of material or environmental damage.

1.3.3 Danger due to improper use

Nonprofessional work on the product can cause damage to

the installation and as a consequence even personal injury.

∙ Only work on the product if you are a competent person.

1.3.4 Risk of material damage by additives in the

heating water

Frost and corrosion protection agents can cause changes

to seals, noise during heating mode and may lead to other

consequential damage.

∙ Do not use any unsuitable frost or corrosion protection

agents.

1.3.5 Risk of material damage caused by

unsuitable tools

The use of unsuitable tools or improper use thereof may cause

damage, such as gas or water leaks.

∙ When tightening or loosening threaded connections,

always use suitable opened spanners, but do not use pipe

wrenches, extensions, etc.

1.3.6 Risk of structural damages by escaping water

Incorrect installation can cause leakages.

∙ Make sure there are no stresses in the hydraulic lines.

1.3 General safety advices

∙ Before to read this chapter, also read the general safety

advices of the operating instructions.

1.3.1 Danger to life by electric shock

Touching live connections can cause serious personal injury.

∙ Before carrying out any work on the product, switch off the

power supply.

∙ Secure the power supply against being switched on again.

1.3.2 Danger to life due to missing or not properly

working safety devices

Missing safety devices can cause life-threatening scalding

and other injuries, for example by burst pipes.

The information contained in this document do not show all

schemes required for a professional installation of safety

devices.

∙ Install the necessary safety devices in the system.

∙ Inform the user about the function and location of safety

devices.

∙ Observe the relevant national and international laws,

standards and guidelines.

∙ Correctly position the seals.

1.4 R410A Refrigerant

Danger!

Risk of injury due to incorrect work on the refrig-

a

R410A fl uorinated greenhouse gases are contained within

a fully sealed system (Kyoto Protocol PES 1975). Under

normal use and conditions, the refrigerant is not dangerous.

Degassing refrigerant fl uid into the atmosphere is prohibited,

except when necessary to ensure personal safety.

The refrigerant fl uid contains gases that, when released into

the atmosphere, may aff ect the environment, contributing

to the greenhouse eff ect and an increase in temperature.

The risk of leakage cannot be excluded for devices intended

to operate for many years and subject to the eff ects of the

environment.

erant circuit!

The appliance contains refrigerant fluid and must

be handled with caution. Any work on the refrigerant circuit must be performed by trained and

approved personnel.

• Only work on the refrigerant circuit if you are a

trained and approved specialist equipped with

appropriate protective equipment.

• Perform draining and filling operations in a

properly ventilated area.

• Avoid any contact with the skin or eyes.

0020154078_00 - 02/13 - Glow-worm

∙ Use only R410A refrigerant.

∙ The tools used for charging, for measuring pressure, for

creating a vacuum and for the recovery of the fl uid must be

compatible with and employed solely for R410A.

3

Page 4

SAFETY

∙ Welding is to be carried out with nitrogen and the circuit’s

air-tightness is to be tested under pressure, with nitrogen.

∙ Refi lling must be done at the liquid phase.

∙ In case of leakage, do not add fl uid: drain the remaining

fl uid from the circuit and eliminate, in accordance with the

applicable regulations.

∙ Create a vacuum in the circuit with a maximum pressure of

10 mbar (10 x 102 Pa) (static pressure).

∙ Bleed the circuit before any welding work.

∙ Comply with the values given in chapter 10 when charging

with refrigerant.

1.5 Intended use

The product is a state-of-the-art product which has been

constructed in accordance with recognised safety regulations.

Nevertheless, there is still a risk of injury or death to the user

or others or of damage to the product and other property in

the event of improper use or use for which it is not intended.

The heat pump is a air -water system which heats all types of

buildings by using the energy contained in the outside air.

The system enhances the recuperated energy so that it can

be utilized by traditional heating (heating fl oor and/or low-

temperature radiators).

The heat pump cannot be used without its control box

Systempro.

Intended use includes the following:

- observing the included operating, installation and

maintenance instructions for this product and any other

parts and components of the system

- installing and fi tting the product in accordance with the

product and system approval

- complying with all of the inspection and maintenance

conditions listed in the instructions.

Any other use than the use described in the instructions at

hand or any use extending the described use is not intended.

Any direct commercial or industrial use is also deemed to be

improper.

Any unintended use is prohibited.

1.6 Rules and regulations

On installing and commissioning the appliance you must

adhere to the technical rules, standards and provisions in

eff ect at the time.

1.7 CE label

The CE mark indicates that the products described in these

instructions are in compliance with the following directives:

- Directive 2006/95/EC of the Council with amendments

"Directive Concerning Electrical Equipment for Use Within

Specifi c Voltage Limits" (Low voltage directive)

- Directive 2004/108/EC of the Council with amendments

"Directive Concerning Electromagnetic Compatibility"

- Directive 97/23/EEC of the Council with amendments

"Directive Concerning pressure equipment"

- Directive 2007/1494/EC of the Council with amendments,

dated December 17, 2007, determining, in accordance with

Directive 2006/842/EC of the Council with amendments,

the label type and the additional requirements as regards

the labelling of products and equipment containing certain

fl uorinated greenhouse eff ect gas.

- Directive 2006/842/EC of the Council with amendments

of May 17, 2006 on certain fl uorinated greenhouse gasses

(OJEU of June 14, 2006)

1.8 Approvals

This product has been fully tested in accordance with:

- BS EN 14511:2011

1.8.1 Local regulations

Benchmark places responsibilities on both

manufacturers and installers. The purpose is to

ensure that customers are provided with the correct

equipment for their needs, that it is installed,

commissioned and serviced in accordance with the

manufacturer’s instructions by a competent person

approved at the time by the Health and Safety

Executive and that it meets the requirements of the

appropriate Building Regulations.

The Benchmark Checklist can be used to demonstrate

compliance with Building Regulations and should be

provided to the customer for future reference.

Installers are required to carry out installation,

commissioning and servicing work in accordance with

the Benchmark Code of Practice which is available

from the Heating and Hotwater Industry Council who

manage and promote the Scheme.

∙ Visit www .centralheating.co.uk for more information.

4

0020154078_00 - 02/13 - Glow-worm

Page 5

1.9 Regulations

1.9.1 Statutory requirements

IMPORTANT

Where no British Standards exists, materials and equipment

should be fi t for their purpose and of suitable quality and

workmanship.

The installation of this appliance must be carried out by a

competent person in accordance the rules in force in the

countries of destination.

Manufacturer’s instructions must not be taken as overriding

statutory requirements.

Standards

On installing and commissioning the appliance you must

adhere to the technical rules, standards and provisions in

eff ect at the time.

Reminder of existing regulatory acts

- EC regulation No. 20372000 from the 29th of June 2000

This European regulation repeals regulation No. 3093/94

and presents the elimination schedules of CFC and HCFC.

It also deals with the collection of refrigerants, system

leaks, particularly systems containing more than 3 kg of

CFC or HCFC, as well as the minimum level of qualifi cation

required by the technicians.

SAFETY

- EC regulation No. 0842/2006 from the 17th of May 2006

regarding the containment, use, collection and disposal

of the fl uorinated greenhouse gases, the labelling and

elimination of the products and equipment containing

these gases, the restriction of use and banning of certain

products from the market, as well as the training and

certifi cation of personnel and companies operating in

the activities targeted by this regulation: refrigeration,

air-conditioning, heat pumps and fi re protection systems

containing greenhouse gases.

1.9.2 Other regulations

Control of Substances Hazardous to Health

Under Section 6 of The Health and Safety at Work Act 1974,

we are required to provide information on substances

hazardous to health. The adhesives and sealants used in this

appliance are cured and give no known hazard in this state.

The refrigerant used in this appliance is R410a the use of

which is strictly controlled by F Gas regulation EN842/2006.

0020154078_00 - 02/13 - Glow-worm

5

Page 6

NOTES ON THE DOCUMENTATION

2 Notes on the documentation

∙ These instructions consist of, Installation, Servicing, Fault

Finding and Replacement of Parts. The instructions are an

integral part of the appliance and must be handed to the

user on completion of the installation.

2.1 Observe other applicable documents

- An anti-freezing protection device runs the heat pump

hydraulic pump when the hydraulic circuit temperature is

lower than 3°C. However, it is necessary to add anti-freeze

to the heat pump hydraulic circuit. Without the addition

of outside energy or in the case of a power cut, the circuit

water can drop below the freezing point.

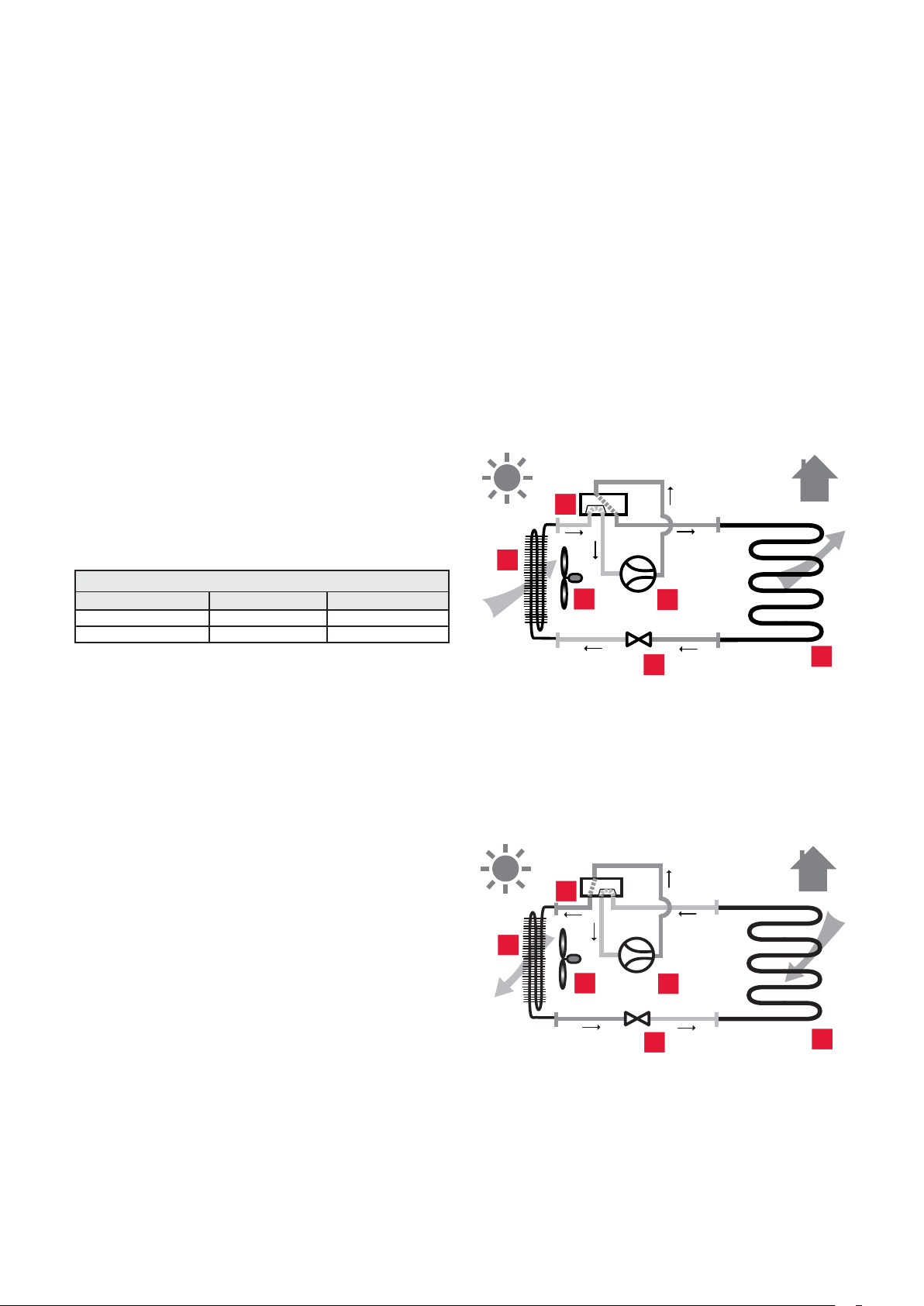

3.2 Concept of operation

A heat pump (HP) is a thermodynamic machine which

transfers heat from one location to another. To do so, it

employs the characteristics of a refrigerant fl uid.

∙ Observe absolutely all operating and installation

instructions enclosed with the product, for the various

parts and components of the system.

2.2 Storing documents

∙ Pass these instructions and all other applicable documents

to the system user.

The system user should retain these instructions so that they

are available when required.

2.3 Validity of the instructions

These instructions apply exclusively to:

Type overview

Product Type designation Article number

Envirosorb3 8 0010011967

Envirosorb3 11 0010011968

For all system schematics and information please refer to the

heatpump system manual.

3 Appliance description

3.1 Safety devices

The system is composed of the following circuits:

- The refrigerant circuit which transfers heat to the

water circuit following the evaporation, compression,

condensation and expansion of the fl uid.

- The heating circuit.

3.2.1 Heating mode

2

1

3

Key

1 Fin exchanger

2 Four way valve

3 Ventilating fan

4 Compressor

5 Expansion valve

6 Plate to plate heat exchanger

4

5

6

- The appliance is designed to operate with an outside

temperature between -20°C and 35°C in heating mode and

between -20°C and 46°C for tank heating.

- A high pressure switch limits the operation of the

appliance when the refrigerant fl uid pressure exceeds

41.5 bar (gauge pressure) (41.5 x 105 Pa) (relative pressure).

- When the appliance is shut down, the compressor

crankcase heater is activated below 7°C at the compressor

outlet to prevent any damage when restarting.

- If the compressor outlet temperature is below 1°C, the

appliance will not allow the compressor to start.

- A temperature sensor at the compressor outlet limits

the operation of the heat pump when the temperature

measured by this sensor is higher than the maximum

limit. This value varies depending on the evaporation and

condensation temperatures.

- The appliance is equipped with a measuring device that

checks the water fl ow rate at start-up.

3.2.2 Defrosting mode

2

1

3

Key

1 Fin exchanger

2 Four way valve

3 Ventilating fan

4 Compressor

4

5

6

6

0020154078_00 - 02/13 - Glow-worm

Page 7

5 Expansion valve

6 Plate to plate heat exchanger

3.2.3 Operating limits in heating mode

APPLIANCE DESCRIPTION

A

70

60

50

40

30

20

10

0

Key

A Water temperature

B Air temperature

[-15;53]

[-20;43]

[-20;15]

-20 -10 0 10 20 30 40 50

Heating operating limits

Domestic hot water operating limits

[2;63]

[28;63]

[35;63]

[35;58]

[35;26]

[46;58]

[46;26]

[35;15][28;15]

B

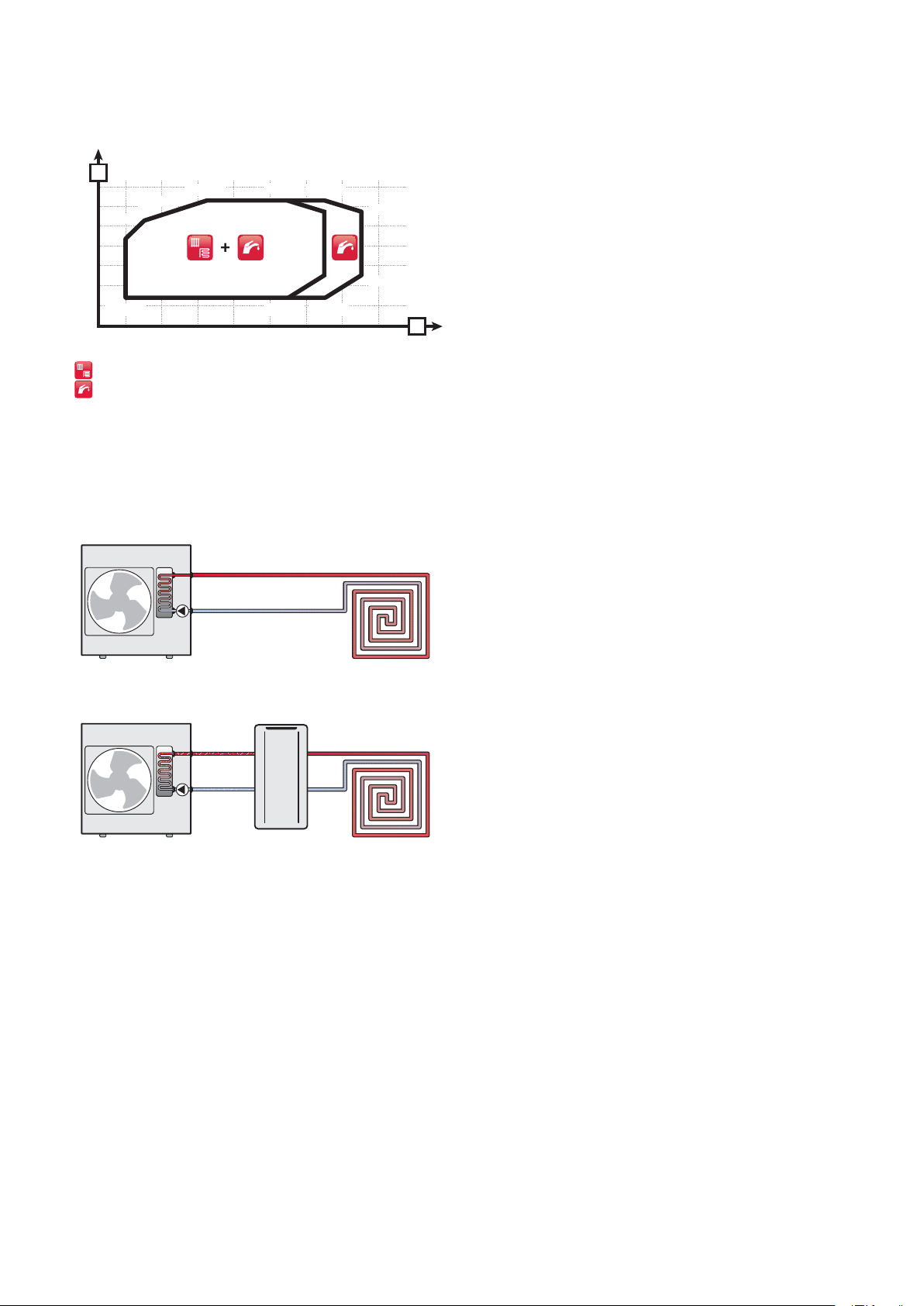

3.2.4 Permitted hydraulic confi gurations

3.2.4.1 Direct connection to the installation heating

circuit

3.2.4.2 Indirect connection with a hydraulic module

For detailed configurations please refer to the

system manual.

i

0020154078_00 - 02/13 - Glow-worm

7

Page 8

APPLIANCE DESCRIPTION

3.3 Structure of the appliance

3.3.4.1 Hydraulic and refrigerant schematic

3

2

1

4

10

B

5

11

A

17

19

21

Key

1 Ventilating fan

2 Outside air temperature sensor

3 Finned heat exchanger

4 Finned heat exchanger temperature sensor

5 4-way valve

6 Heat pump return circuit temperature sensor

7 Expansion vessel

8 Modulating high performance pump including a water fl ow rate

sensor

9 Water bleed

10 Heat pump fl ow temperature sensor

11 Draining valve for the heat pump circuit

12 Plate to plate heat exchanger

13 Temperature sensor after plate to plate heat exchanger

14 High-pressure circuit maintenance valve

15 Refrigerant pressure switch

14

18

22

24 25

16 Refrigerant circuit high pressure sensor

17 Compressor discharge temperature sensor

18 Rotary compressor

19 Filter

20 Anti-slugging bottle

21 Electronic expansion valve

22 Compressor suction temperature sensor

23 Low-pressure circuit maintenance valve

24 Flow rate limiter in cooling mode

25 Filter

26 Gas buff er

A Heat pump return

B Heat pump fl ow

15

16

20

13

23

26

12

6

7

9

8

8

0020154078_00 - 02/13 - Glow-worm

Page 9

MOUNTING AND INSTALLATION

3.4 Type designation and serial number

Data plate location:

1

1

Key

1 Data plate

The type designation and the serial number are shown on the

data plate.

3.5 Data plate description

The data plate contains the following data:

Abreviation/

symbol

Serial-no Commercial name and serial number

IP The electrical protection class

V/Hz

I max The maximum current

R410A

PS

R The max. working pressure of the cooling circuit

PS

H min

PSH max

COP (Ax/Wxx)

(

Ax/Wxx)

EER (Axx/Wx)

(

Axx/Wx)

Description

The pump + compressor + regulatory devices supply

voltage

The type of refrigerant fl uid, the amount necessary

for fi lling

Minimum and maximum hydraulic pressure

The coeffi cient of performance (COP) for an air

temperature of xx°C and heating fl ow temperature

of xx°C

The heating power for an air temperature of xx°C

and heating fl ow temperature of xx°C

The Energy Effi ciency Ratio (EER) for an air

temperature of xx°C and cooling fl ow temperature

of xx°C

The refrigerating power f

xx°C and cooling fl ow temperature of xx°C

See chapter "CE label"

or an air temperature of

4 Mounting and installation

4.1 Preparing mounting and installation

4.1.1 Delivery, transport and installation on site

4.1.1.1 Transport

Warning!

Risk of injuries due to big carrying loads.

a

b

Too big carrying loads can cause injuries, e.g. on

the backbone.

• Observe all relevant laws and other prescrip-

tions when carrying heavy products.

• Refer to chapter 10 for the weight of the appli-

ance.

• Plan two people at minimum to move

the appliance.

Caution!

Risk of equipment damage due to appliance

transport.

If the appliance is tilted more than 45° during

transport, the refrigerant circuit can be damaged

which may result in complete failure of the installation.

• Do not tilt the appliance more than 45° during

transport.

1

0020154078_00 - 02/13 - Glow-worm

1

Key

1 Transport strap

9

Page 10

MOUNTING AND INSTALLATION

∙ Use the transport strap (1) to move the appliance.

Installation pipework must be designed and installed to

ensure venting of air from the system is possible.

∙ Only lift the appliance from the rear and the side

containing the hydraulic connectors.

∙ Attach the appliance to the two-wheeled trolley with a

strap.

∙ Protect surfaces in contact with the trolley to avoid

scratching or damaging the appliance.

∙ Use a suffi ciently solid ramp to lower the appliance from

the pallet.

4.1.1.2 Unwrapping

B

1

A

13mm

2

4.1.1.3 Checking the equipment delivered

∙ Check the contents of the packages.

The appliance is delivered with a bag of documents and a box

of accessories which contains the following items:

- 1 condensate drain assembly (adaptor + elbow + clip)

- 1 bag of seals

- 4 anti-vibration blocks

- 1 bleeding tube

4.1.2 Observing distances and mounting

clearances

All the drawings dimensions are shown in mm.

i

4.1.2.1 Product dimensions

415

D

3

4

E

Key

1 Bag of documents

2 Accessory box

3 Heat Pump

4 Transport strap

∙ Remove the screws from the transport pallet at the front

and rear of the unit (E).

C

1103

942

162,6

778

162,6

∙ Remove the bag of documents (B) and the accessory box

(A).

∙ Detach the transport strap (C).

∙ Carefully remove the packaging and protections without

damaging the parts of the appliance (D).

10

0020154078_00 - 02/13 - Glow-worm

Page 11

MOUNTING AND INSTALLATION

4.1.2.2 Accessibility

A

E

D

Distance In heating mode only

A > 250 mm

B > 1000 mm

C > 120 mm

D > 600 mm

E > 300 mm

∙ Avoid areas exposed to strong winds directed against the

appliance’s air outlet.

∙ Do not install the fan facing nearby windows. If necessary,

install a noise barrier.

B

C

A

∙ Set the appliance on one of the following supports:

- concrete slabs,

- crane beam,

- concrete blocks.

∙ Do not expose the heat pump to corrosive or dusty

atmospheres (near to dirt roads, for example).

∙ Do not place near to stale air extraction fans.

∙ Provide passages for electrical cables (very low and low

voltage).

4.1.3.1 Properties of the mounting surface

∙ Before choosing the position of the device, carefully read

the warnings relating to safety and the instructions in the

installation and user manuals.

∙ Place the appliance on a beam or concrete blocks or on the

wall supports sold separately.

∙ Ensure that the appliance is protected from water and from

snow.

∙ Comply with the distances above to obtain the correct air

fl ow and facilitate maintenance operations.

∙ Make sure that the available space is suffi cient for the

installation of the water system piping.

∙ If the heat pump is installed in an area subject to heavy

snow fall, ensure that snow does not build up around

the appliance to maintain the distances given above.

Otherwise, install a backup heat generator in the

building’s heating system.

4.1.3 Appliance location

∙ Observe current regulations.

∙ Install the appliance outside.

∙ Do not install the appliance:

- near a heat source,

- near fl ammable materials,

- near the ventilation points of adjacent buildings

- beneath deciduous trees.

∙ Take into account the following when installing the heat

pump:

- prevailing winds,

4.1.3.2 Condensate drain

Danger!

Risk of injury due to freezing of condensates.

a

The condensates fl ow from the central drain located in the

bottom of the heat pump.

Condensates freezing in a passageway can cause

slips.

• Ensure that the drain system presents no risk

of condensates freezing on a passageway.

>100mm

∙ Provide a condensate drain either into a bed of pebbles or

connected to a drain with installation of a siphon.

- the noise generated by the fan and the compressor

- the visual impact on the surrounding neighbourhood.

0020154078_00 - 02/13 - Glow-worm

11

Page 12

MOUNTING AND INSTALLATION

4.2 Mounting the appliance

4.2.1 Opening the appliance

4.2.2 Positioning the appliance

The heat pump must be installed with the anti-

vibration pads supplied. The anti-vibration pads

i

are used to raise the unit, limit the transmission

of vibrations and to facilitate the discharge of

condensates.

4.3 Hydraulic installation

Caution!

Risk of damage caused by contaminated lines!

b

b

B

C

A

4.3.1 Hydraulic connection

A

i

i

∙ Do not weld pipes mounted up : this operation may

damage the seals.

Foreign bodies such as welding remnants, sealing

residue or dirt in the supply lines can cause damage to the product.

• Flush the supply lines thoroughly before instal-

lation.

Caution!

Risk of damage due to corrosion.

If plastic pipes that pass oxygen are used in the

heating installation, this may corrode or sludge

up the appliance’s heating circuit or the appliance

itself.

• If you use plastic pipes that pass oxygen in the

heating installation, add a corrosion inhibitor

to the circuit water.

Insulate the pipes (between the heat pump and

the installation including those underground)

with an UV- and high-temperature-resistant insulation.

In order to avoid the transmission of vibrations to

surrounding structures, flexible hoses of at least

750mm in length should be used for the hydraulic

connections from the heatpump.

∙ Install the appliance level so that the condensates drain

correctly.

∙ If the heat pump is not located at the highest point of the

hydraulic circuit, install additional bleed valves in suitable

places.

∙ Install the following components on the heat pump return

circuit.

Installation with

hydraulic module

- a drain tap

- an air separator (if

necessary)

- an anti-sludge fi lter

- an expansion tank, if the

length of the hydraulic circuit

is greater than the max.

permitted length (see table

below)

- a 3 bar (3 x 10

valve if the hydraulic module

does not have one

Max. length of the hydraulic circuit DN 28

In the case of the installation of a module

without an expansion tank

5

Pa) safety

Installation without

hydraulic module

- a drain tap

- an air separator (if

necessary)

- an anti-sludge fi lter

- an expansion tank suitable

for the complete hydraulic

installation

- a 3 bar (3 x 105 Pa) safety

valve

- a pressure gauge

(recommended)

30 m

12

0020154078_00 - 02/13 - Glow-worm

Page 13

MOUNTING AND INSTALLATION

D

C

5

4

5

3

2

1

Key

1 Return circuit ¼ turn shut-off valve in the direction of the heat

pump (not included) (*)

2 Heat pump fl ow circuit ¼ turn shut-off valve in the direction of

the building (not included) (*)

3 Flow heat pump circuit hose in the direction of the building (not

supplied)

4 O ring

5 Cap

6 Flow heat pump connection (Ø 1¼") to the building

7 Return connection (Ø 1¼") to the heat pump

8 Return circuit hose in the direction of the heat pump (not

supplied)

9 Insulation (not supplied)

(*) Available as an accessory

8

0.75m min.

4

6

7

9

4.3.3 Condensate discharge

Observe these instructions, the legal directives

and the local regulations to evacuate conden-

i

sates.

102,5

1

3

Ø25

550

2

A

B

4

∙ Remove the protection caps (4) located on the connections.

∙ Install the fi lter on the heat pump return pipe. Install it

between 2 shut-off valves in order to be able to remove if

from the circuit and clean it periodically.

∙ Connect a fl exible pipe + the O ring and a shutoff valve to

the heat pump outlet and return connectors.

∙ Check that there are no leaks. Repair if necessary.

4.3.2 Swimming pool option

Caution!

Risk of damage in the case of a direct connection

b

∙ In the case of an installation with a swimming pool option,

take into account the water volume up to the swimming

pool kit for proper sizing of the installation (e.g.:

expansion tanks...).

to the swimming pool.

If the heat pump is connected directly to the

swimming pool, the appliance may be damaged

by corrosion.

• Do not connect the heat pump hydraulic circuit

directly to a swimming pool

• Use a swimming pool kit with an external heat

exchanger.

Key

1 Condensate drain pipe

2 Adapter

3 Clip

4 Elbow

∙ Assemble the elbow and the adapter (A) and then secure it

with the clip (B).

∙ Install the condensate evacuation pipe onto the elbow.

∙ Insert the heat pump electric heater into the pipe to

prevent condensates freezing in the pipe.

∙ Insert the adapter into the hole in the base of the heat

pump (C), then turn the adapter a ¼ turn to lock it into

position (D).

∙ Connect the pipe to the condensate evacuation circuit

either in a bed of pebbles or connected to a drain using a

siphon.

∙ Make sure that the condensate does not stagnate in the

drain hose.

∙ Make sure that the drain hose is not connected tightly to

the waste water piping.

0020154078_00 - 02/13 - Glow-worm

13

Page 14

MOUNTING AND INSTALLATION

4.4 Electrical Installation

Danger!

Risk of electric shock due to an improper electri-

e

Key

1 Electrical wires

2 Insulation

When you connect the electrical wires to a connector on the

electronic board:

∙ Keep a distance of a maximum of 20 mm between

connector and the start of the insulation.

∙ Fix the electrical cables with the clamps installed inside

the heat pump.

4.4.1 Connecting the power input (mains

The external wiring must be earthed, with correct polarity and

in accordance with current standards.

∙ Always check that the Live and Neutral are connected

correctly.

The cables connecting the switchboard and the heat pump

must be:

- Suitable for a fi xed installation.

- weather resistant.

- equipped with wires adapted to appliance’s power rating.

∙ Connect the heat pump to an electrical panel via an

independent protection system (diff erential breaker with at

least 3 mm between each contact).

Additional protection may be required during installation to

ensure surge category II.

The power supply cut-off devices must allow complete

disconnection of the power under the conditions required for

over-voltage category III.

cal connection!

Improper electrical connection can cause electric

shock or might negatively affect the operational

safety of the product and might cause material

damage.

• The electrical connection of the product must

be carried out only by a suitably qualified person.

1

20 mm max.

connection)

2

4.4.1.1 230V heat pump

Caution!

Risk of damage from too great voltage.

b

b

Key

1 Heat pump power supply connection

2 Installation power supply and electric protection

Electricity supply 1/N/PE 230V 50Hz 1/N/PE 230V 50Hz

Circuit breaker 16 A - Type C or D 20 A - Type C or D

Recommended cable size

230V

∙ Connect a cable to the appliance’s power terminal.

∙ Pass the cables through the heat pump cable gland (see

section 4.4.3).

∙ Suitable breaker size and type must be used to fi t

installation site requirements.

∙ Cable size must be suitable for installation site

requirements

At mains voltages higher than 253 V, electronic

components may be destroyed.

• Make sure that the rated voltage of the mains

is 230 V.

Caution!

Risk of malfunction due to the electrical supply.

If the imbalance between the phases of the electrical supply is too large, a malfunction may occur.

• Install the appliance on a electrical supply with

a maximum imbalance of 2% between phases.

X7

FLOOR H

X4

EBUS

X9

21

1

X2

Envirosorb3 8 Envirosorb3 11

3G x 2.5 mm² 3G x 2.5 mm²

4.4.2 24V cable connection

3

2

14

X7

2

FLOOR H

X4

EBUS

1

Key

1 eBUS connection to the heat pump (comply with the polarity ±)

2 Connect the fl oor heating protection device to the heat pump

3 e-BUS connection terminal on the control box

X9

0020154078_00 - 02/13 - Glow-worm

Page 15

Envirosorb3 8 Envirosorb3 11

Recommended cable size

eBus

Recommended cable size

eBUS + FLOOR H

2 x 0.75 mm² 2 x 0.75 mm²

4 x 0.75 mm² 4 x 0.75 mm²

∙ Pass the cables through the heat pump cable gland (see

section 4.4.3).

∙ Connect the e-BUS cable to the system control box

complying with the polarity ±.

∙ If a manual reset floor heating protection device (55°C)

is installed on the heating circuit outlet, remove the link

from the terminal (2) and then connect the floor heating

protection device to this terminal.

4.4.3 Cable routing

Caution!

Risk of appliance malfunction

b

If the very low voltage and low voltage cables are

in the same duct, the very low voltage signal will

be disturbed by the low voltage.

• Run the very low voltage and low voltage

cables in different ducts.

MOUNTING AND INSTALLATION

eBus

230V

ØA

12

C

34

56

7

8910

D

11

12

13

14

15

A

16

ØA

B

Key

eBUS e-BUS cable and fl oor heating protection device cable

gland

230V 230V supply cable gland

∙ Measure the diameter of the cable (A).

∙ Use a drill of the same diameter as the cable and drill

through the cable gland seal (B).

∙ Pass the cable through the cable gland provided for this

purpose (C)

∙ Set the cable gland with 2 fl at spanners (D) to get it tight.

0020154078_00 - 02/13 - Glow-worm

15

Page 16

MOUNTING AND INSTALLATION

4.4.4 Circuit diagram (230V heat pump)

10 9 8 7 6

54321

X23

X30 X60

18 16 15 14 13 12 11 10

9

17

87654321

X21

20 17 16 15 14 13 12 11

10

19

9

18

87654321

X22

HMU

11

43

21

13

X24

X26

X14

12

24V=

S20

24V=

S21

BUS

16

X60DA

14

14567

15

X700

X15

17

FMU

18

X13

19

X16

NL NL NL1X3

X11

NL

X1

230V~

F1

20

X23

10 9 8 7 6

54321

9

10

X21

18 16 15 14 13 12 11 10

9

17

87654321

8

X22

20 17 16 15 14 13 12 11

10

19

9

18

87654321

7

6

2

1

5

4

3

Key

1 Fin exchanger temperature

2 Temperature sensor after plate to plate heat exchanger

3 Refrigerant circuit high pressure sensor

4 Compressor suction temperature sensor

5 Compressor discharge temperature sensor

6 Refrigerant pressure switch

7 Heat pump fl ow temperature sensor

8 Heat pump return temperature sensor

9 Air outside temperature sensor

10 Electronic expansion valve

11 Main PCB

12 Product coding resistor

22

X60

X3

RL1

X6

X1

X8

X5

21

X7

FLOOR H

X4

EBUS

X9

X2

23

UVW

INVERTER

21

43

24

25

13 Diagnostic tool connector

14 Fan

15 Fan management card

16 Compressor crankcase heater

17 Condensate drain electric heater

18 Steady red LED (appliance on)

19 Modulating high performance pump including a water fl ow rate

sensor

20 4 way valve

21 Installer interface

22 Overheating safety

23 Rotary compressor

24 Inverter box

25 Fin exchanger

21

16

0020154078_00 - 02/13 - Glow-worm

Page 17

START-UP

5 Start-up

∙ Refer to the operating instructions before starting the

product.

∙ Check that the diff erential breaker is installed.

∙ Check that the hydraulic and electrical connections are

correct.

∙ Check that the fi lter on the heat pump return is installed.

∙ Check the airtightness of the connections.

∙ Open all the hydraulic circuits’ valves.

5.1 Filling the hydraulic circuit

We recommend that you use propylene enriched

with corrosive inhibitors.

i

∙ Do not dispose of glycol into drains and the environment.

∙ Mix a maximum of 50% of propylene or ethylene glycol

with water. The mixture must provide anti-freezing

protection for the heat pump hydraulic circuit.

∙ Use an antifreeze test kit to ensure accurate dosing.

∙ In order to bleed the hydraulic circuit of the heat pump

during the fi lling, use a fi lling pump.

∙ Put the heat pump circuit under pressure between 1.5 and 2

bars.

The hydraulic circuit pressure may decrease dur-

ing the first month following the commissioning

i

of the installation. It may also vary in accordance

with the outdoor temperature.

5.2 Activating the heat pump

∙ Ensure that the setting of the maximum temperature of

heating fl ow is compatible with the installation.

∙ Refer to the system installation manual in order to fully

activate the installation.

∙ Switch ON the circuit breaker which is located on the

electrical panel and connected to the heat pump.

5.3 Checking the operation of the device

∙ Ensure that the external regulators (thermostat, external

sensor, ...) send a request to the heat pump. In the case of

a multi-zone confi guration, perform the test zone by zone

and ensure that the appropriate zone gets warmer.

14mm

A

1

2

3

4

Key

1 Air trap

2 Flat wrench (*)

3 Hose

4 Deposit (*)

(*) Not included

∙ Connect one end of the hose to the tap (A).

∙ Insert the other end of the hose (3) into the container

during the venting of the circuit.

∙ Ensure that all the heating circuit’s thermostatic valves are

open.

∙ Balance the heat emitters, if necessary.

5.4 Adjustment of HP circuit fl ow

B

5.4.1 Bleeding the hydraulic circuit

If the swimming pool option is installed on the

circuit put the kit's 3 way valve on AUTO position.

i

∙ Connect one end of the hose to the tap.

∙ Insert the other end of the hose into the container in order

to recover any residual glycol during the venting of the

circuit.

∙ Close the shutoff valves at the rear of the heat pump.

∙ Pressurise the hydraulic circuit.

∙ Using a fl at spanner, open the bleed valve.

∙ Open the lower shutoff valve at the rear of the heat pump.

∙ When liquid comes out of the pipe, close the bleed valve

∙ Check that the hydraulic circuit pressure is between 1.5

and 2 bar. Otherwise, top up the hydraulic circuit.

∙ Completely open the two shutoff valves at the rear of the

heat pump.

∙ Remove the hose and the container.

∙ Using a fl at wrench, open the tap a ¼ turn (B) in order to

remove the air present in the glycol circuit, then close it

quickly (in order to avoid emptying the circuit).

0020154078_00 - 02/13 - Glow-worm

17

Page 18

MAINTENANCE

5.4.2 Adjusting the hydraulic circuit fl ow rate

The heat pump is designed to operate above a minimum fl ow

rate. If the heat pump functions at a minimum fl ow rate, this

will result in a loss of power and performance. The heating

comfort will still be guaranteed but the energy savings will be

reduced.

Envirosorb3 8 Envirosorb3 11

Minimum fl ow 380 l/h 540 l/h

Recommended fl ow 1400 l/h 1900 l/h

It is possible to read the fl ow rate directly on the controller.

Depending on the type of fl uid used in the hydraulic circuit,

the fl ow rate displayed on the control box may be over-

estimated.

Example: If you use a 30% propylene glycol mixture and the

fl uid temperature is 5°C, you must subtract 400l/h from the

value displayed on the control box.

∙ Refer to the table below for the various values of over-

estimation of the fl ow rate depending on the fl uid type and

temperature.

Flow rate over-estimation (l/h)

Water 000

Fluid type

Propylene glycol 30% 400 240 120

Propylene glycol 50% 650 500 400

Incorrect venting of the installation may lead to

flow variations.

Fluid temperature

5°C 15°C 25°C

i

∙ If you cannot reach the minimum fl ow rate, install an

auxiliary pump.

∙ Refer to the system documentation for the information

necessary for installing the auxiliary pump.

5.5 Installation of side panel

B

A

C

C

5.6 User information

After completing the installation:

∙ Explain to the user the system operation.

∙ Draw special attention to the safety instructions that the

user must follow.

∙ Inform the user of the necessity to ensure that the system

is regularly maintained (maintenance contract).

∙ Explain to the user how to check the water level/fi lling

pressure of the system.

∙ Answer any questions the user may have.

∙ If you cannot achieve the recommended fl ow rate, adjust

the circuit pressure on the control box and, if necessary,

use the fl ow rate adjusting tap on the hydraulic module.

5.4.2.1 Available pressure in hydraulic circuit of the

heat pump

A

80

70

60

50

40

30

20

10

0

5000 1000 1500 2000

Key

1 Envirosorb3 8 (with the water circuit at 20 ° C)

2 Envirosorb3 11 (with the water circuit at 20 ° C

A Available pressure (kPa)

B circuit fl ow rate (l/h)

2

1

B

6 Maintenance

Danger!

Risk of injury due to unintended intervention on

a

the refrigerant circuit!

The device contains refrigerant fluid and must be

handled with care. Any work carried out on the

refrigerant circuit must be conducted by qualified

engineers.

• Only work on the refrigerant and cooling circuit

if you are a trained and approved specialist

equipped with appropriate protective equipment.

• Perform draining and filling operations in a

properly ventilated area.

• Avoid any contact with the skin or eyes.

18

0020154078_00 - 02/13 - Glow-worm

Page 19

MAINTENANCE

6.1 Observe maintenance intervals

∙ Maintain the product only if you are a competent person.

∙ Carry out annual maintenance.

6.2 Preparing maintenance

6.2.1 Providing spare parts for maintenance and

repair work

∙ In case you need spare parts during maintenance or repair,

exclusively use genuine Glow Worm spare parts.

The genuine component parts of the product have been

certifi ed together with the product in the course of the

CE conformity check. If you do NOT use certifi ed genuine

Glow Worm spare parts during maintenance or repair, the

CE conformity of the product will expire. That is why we

imperatively recommend to install genuine Glow Worm spare

parts.

6.3 Pre-maintenance instructions

Comply with the basic safety rules before performing

maintenance or installing spare parts.

∙ Shut down the system.

6.5 Cleaning

6.5.1 External cleaning

∙ If the appliance needs cleaning, refer to the user manual.

6.5.2 Cleaning the components

∙ Check the absence of ice on the compressor.

∙ Remove any dust from electronic boxes.

∙ Clean the air / refrigerant battery and make sure that air

circulates between the fi ns and around the unit.

∙ Check that condensates can properly drain from the heat

pump by removing the adapter located under the heat

pump (turn it a ¼ turn to unlock).

∙ Clean the evaporator on both sides using a brush with soft

bristles. Remove the fan blades and the rear grill before

cleaning.

Warning!

Risk of minor injury.

a

Handling the fan blades and grill can cause cuts.

• Wear protective gloves to perform this

operation.

∙ Switch off the system electrical supply.

∙ Isolate the hydraulic circuit from the appliance using the

shut-off valves where necessary.

∙ Drain the appliance if you need to replace hydraulic circuit

components.

∙ Protect all electric components from water if you have to

work on the appliance.

6.4 Annual Maintenance

∙ Check the proper functioning of safety devices.

∙ Check the pressure of the water system.

∙ Check tightness of refrigerant circuit.

∙ Check that there are no traces of rust or oil around the

refrigerant circuit’s components.

∙ Ensure that the appliance’s components are neither worn

nor broken.

∙ Check that the wires are fi rmly attached to the electrical

terminals.

∙ Check the appliance’s grounding.

6.6 Draining

∙ Cut off the appliance’s electricity supply.

1

2

14mm

Key

1 Hydraulic circuit venting valve

2 Draining hose

∙ Close the shut-off valves located behind the heat pump.

∙ Engage a hose (2) to the venting valve (1) or place a

container under the venting valve (1) to drain the hydraulic

circuit.

∙ Check the fl ow temperature of the heat pump and the

setting points.

∙ Check that the fan rotates freely.

∙ Check the pressure of the expansion vessel.

0020154078_00 - 02/13 - Glow-worm

∙ Open the bleed valve (1) with a fl at spanner.

Note: if necessary, the heating installation can be drained via

this bleed valve by opening the shutoff valves located at the

rear of the heat pump.

19

Page 20

TROUBLE-SHOOTING

6.7 Checking the appliance status codes

The status codes can be checked at any time to know what

operating phase the appliance is in. These codes can be read

on the system control box screen.

The status codes are described in a table in the appendix (see

section 11.1).

6.8 Checking the electrical installation

∙ Check the electrical installation observing all relevant

regulations

6.8.1 Checking the cables

If the power cable of this product is damaged, then to prevent

danger, only the manufacturer, the after-sales service or

similarly qualifi ed persons shall replace the power cable.

∙ When replacing the power cable see chapter 4.4.

6.9 Start-up after maintenance

∙ Once the maintenance operations have been completed,

start-up the product (see chapter 5).

7.3 Resetting the overheating safety

In the case of overheating, the heat pump shuts down. Once

the temperature has returned to normal, you must reset the

overheating thermostat to restart the heat pump.

1

2

C

∙ After having completed work, check for the tightness of

hydraulic components.

∙ When work on the product is completed, perform an

operational test and check system safety.

7 Trouble-shooting

7.1 Fault diagnosis

The following checks should be performed before proceeding

onto specifi c diagnostics:

∙ Make sure that the electricity supply has not been

interrupted and that the appliance is connected correctly.

∙ Ensure that the isolating valves are open.

∙ Check that all external controls are connected correctly.

7.2 Error codes

The error codes are described in a table in the appendix (see

section 11.2).

∙ Remove the side panels (1 and 2).

(Refer to section 5.5)

Danger!

Danger of death by electrocution

e

Resetting the heat pump can present a risk of

electrocution.

• Do not open the electrical box during the

resetting procedure.

C

In the case of a fault, the fault code number is displayed on

the control unit.

∙ Carry out any necessary repairs.

∙ Switch ON/OFF the appliance using heat pump circuit

breaker.

20

0020154078_00 - 02/13 - Glow-worm

Page 21

DECOMMISSIONING

9 Recycling

9.1 Packaging

∙ Sort the waste to separate those which can be recycled

(cartons, plastics...) from those that cannot (strapping ...).

∙ Recycle the product packaging according to all relevant

regulations.

9.2 Appliance

∙ Do not dispose of your product or any of its accessories in

the household waste.

∙ Make sure the old unit and any accessories are disposed of

properly.

∙ Observe all relevant regulations.

Resetting the heat pump is only possible if the

temperature has dropped below 110°C.

i

∙ Push the screwdriver into the overheating safety(1) until a

“Click” is heard.

8 Decommissioning

∙ Switch off the product.

∙ Isolate the product from the power mains.

∙ Drain the appliance (see chapter 6.5).

∙ Recycle or dispose the product and its components (see

chapter 9).

0020154078_00 - 02/13 - Glow-worm

21

Page 22

TECHNICAL DATA

9.3 Refrigerant fl uid

Attention!

Risk of pollution!

b

The recycling of the refrigerant fl uid must be performed by the

qualifi ed professional who installed the device.

The personnel approved for this recuperation must have an

appropriate certifi cation according to the regulations in force.

This appliance contains R410-A refrigerant fluid

which must never be released to the atmosphere.

R410-A is a fluoride greenhouse gas covered by

the Kyoto protocol.

• Before discarding the appliance, correctly

recover the refrigerant fl uid into an appropriate

container to be recycled in compliance with the

regulations in force.

10 Technical data

This technical data is valid for a new appliance

with its own heat exchangers.

i

Description Unit Envirosorb3 8 Envirosorb3 11-1ph

Min. operating air temperature (heating and tank heating) °C -20 -20

Max. operating air temperature (heating) °C 35 35

Max. operating air temperature (domestic hot water) °C 46 46

Specifi cations, with radiators

(start : 45°C, return : 40°C, dry temperature (wet) 7 (6)°C)

Heating output kW 7,20 10,20

COP* A7(6) W45-40 3,5 3,35

(start : 55°C, return: 47°C, dry temperature (wet) : 7 (6)°C)

Heating output kW 6,60 9,40

COP* A7(6) W55-47 2,70 2.60

Specifi cations, with underfl oor heating

(start : 35°C, return : 30°C, dry temperature (wet) : 7 (6)°C)

Heating output kW 7,60 10,60

COP* A7(6) W35-30 4,50 4,30

(start : 35°C, return : 30°C, dry temperature (wet) 2 (1)°C)

Heating output kW 5,60 8,40

COP* A2(1) W35-30 3,40 3,10

Refrigerant circuit

Type of refrigerant R-410A

Quantity of refrigerant kg 1.950 3.530

Type of compressor Rotary

Type of oil specifi c Polyvinylether (PVE) oil.

Type of regulator Electronic

Maximum relative operating pressure (PS)

Heat pump circuit

Min. fi lling pressure.

bar 41.5 41.5

Pa 41.5 x 10

bar 1 1

Pa 1 x 10

5

5

41.5 x 10

1 x 10

5

5

22

0020154078_00 - 02/13 - Glow-worm

Page 23

TECHNICAL DATA

Description Unit Envirosorb3 8 Envirosorb3 11-1ph

Max. fi lling pressure.

Minimum water fl ow rate l/h 380 540

Maximum water fl ow rate l/h 1400 1900

Expansion vesel capacity l 2 2

Capacity of the hydraulic circuit internal to the heat pump l 4 4

Minimum capacity of the complete hydraulic circuit l 21 35

Plate heat exchanger material AISI 304

Electrical

Supply voltage/frequency V/Hz 1/N/PE 230V 50Hz

Electronic card fuses FMU and HMU T4A / 250V

Inverter controller fuse HRC 20A 550V HRC 32A 550V

Maximum absorbed current (I max) A 16A 20A

Starting current A < 16A < 20A

Index of electrical protection IP25 IP25

Electrical classifi cation II

Surge category II II

Pollution rating 22

Fan electrical consumption W 45 80

Pump electrical consumption W 70 70

Nominal input current at A7W35 A 8,27 12,3

bar 3 3

Pa 3 x 10

5

3 x 10

5

Description Unit Envirosorb3 8 Envirosorb3 11-1ph

Dimensions

Height mm 939 939

Width mm 1103 1103

Depth mm 415 415

Heat pump Ø Water circuit connections " 1 ¼ 1 ¼

Nett total weight kg 105 129

Sound power level : overall exterior noise

(according to EN 12102 and EN ISO 9614-1) under nominal A7W45 conditions.

Fan rotation speed

* Coeffi cient Of Performance (according to EN 14511)

** Energy Effi ciency Ratio (according to EN 14511)

dBA 60 65

tr/

min

-1

550 675

Fluorinated greenhouse gases as identified in the

Kyoto protocol, are contained within a fully

i

sealed system.

0020154078_00 - 02/13 - Glow-worm

23

Page 24

APPENDIX

11 Appendix

11.1 Table of Diagnosis codes

Réf.

Description

état

0 Heat pump waiting

1 Pump pre-run before heating

2 Pump pre-run correct in heating mode

3 Water temperature / heating setting compatibility test

4 Heating phase start activation

5 Pre-run of pump at maximum speed in heating

6 Pre-run of fan in heating

7 Setting the 4-way valve to the heating position

8 Setting electronic expansion valve to the heating position

9 Compressor start request in heating mode

10 Heat pump in heating mode

11 Heat pump in domestic hot water heating mode

12 Water temperature exceeded in heating mode

Water temperature exceeded in domestic hot water heating

13

mode

14 Pump post-run after heating

15 Pump pre-run before de-icing

16 Heat pump in de-icing mode

17 Pump post-run after de-icing

18 Pump remote controlled (top-up)

19 Compressor oil temperature too low for start-up

30 Pump pre-run before cooling

31 Pump pre-run correct in cooling

32 Water temperature / cooling setting compatibility test

33 Cooling phase start activation

34 Pre-run of pump at maximum speed

35 Fan pre-run

36 Setting 4-way valve to cooling position

37 Setting electronic expansion valve to the cooling position

38 Compressor start request in cooling mode

39 Heat pump in cooling mode

40 Water temperature exceeded in cooling mode

41 Post-run of the pump after cooling

50 Pressure balance fault

51 Pressure switch fault

52 Pressure envelop fault detected

53 Start envelop not ok error detected

54 Loss of “cheap tariff ” supply block

55 Refrigerant circuit pressure out of range: HP/LP ratio too low

Réf.

Description

état

Refrigerant circuit pressure out of range: condensation too

56

low

Refrigerant circuit pressure out of range: evaporation too

57

high

Refrigerant circuit pressure out of range: condensation too

58

high

59 Refrigerant circuit pressure too low

60 Compressor outlet over-heat

61 Compressor inlet temperature sensor fault

62 Compressor outlet temperature sensor fault

63 Plate exchanger temperature sensor fault

64 Fin exchanger temperature sensor fault

65 Outside air temperature sensor fault

66 Flow water temperature sensor fault

67 Return water temperature sensor fault

68 Refrigerant circuit high pressure sensor fault

69 Low voltage fault – inverter box bus

70 Inverter box disconnected fault

71 Inverter box over-heat fault

72 Inverter box current-voltage fault

73 Under power fault – inverter box bus

74 Overvoltage power fault – inverter box bus

75 Inverter box internal fault

76 Inverter box radiator sensor fault

77 Inverter box overload fault

78 “FMU” fan circuit board fault

79 e-BUS communications fault

80 Water fl ow rate fault

81 Communications fault with the inverter box

82 Compressor overcurrent fault

83 Water fl ow temperature too high

84 Electronic expansion valve fault

85 Fan speed too low

86 Detection of potential icing in the plate exchanger

87 Water ΔT too high fault

88 Coding resistor fault

89 Heated floor overheating safety device fault

90 4-way valve fault

Appliance fault, refer to section 7.2 to see the corresponding

99

error code.

11.2 Fault codes

∙ Read the heat pump status code number from the control

box screen (see control box installation manual).

∙ Refer to the table in section 11.1 of this manual to see the

heat pump state.

Fault

Description Possible cause

codes

There is an obstacle in the heat

37 Fan speed too low.

Product coding resistor

42

error.

pump’s air fl ow.

The fan motor is defective or

disconnected.

The product coding resistance is

missing or defective.

The resistance value is outside

the authorised limits.

24

Fault

Description Possible cause

codes

The floor heating over

86

heat contact is open.

Spare part

103

identifi cation error.

The heated fl oor temperature is

too high.

The fl ow rate of the installation

hydraulic circuit is too low.

The heated fl oor circuits are

closed.

The circuit board or inverter driver

used as a replacement part does

not correspond to the product.

0020154078_00 - 02/13 - Glow-worm

Page 25

APPENDIX

Fault

Description Possible cause

codes

The compressor inlet

514

temperature sensor or

connection is out.

The compressor outlet

517

temperature sensor or

connection is out.

The heating return

519

temperature sensor or

connection is out.

The fl ow heating

520

temperature sensor or

connection is out.

Coil sensor interrupt or

526

short circuit.

The fl ow on heat pump

water circuit is too low

532

or too high (see section

5.4.2).

The compressor

discharge temperature

536

is too high (depends

on the compressor

operating zone).

Position of 4-way valve

755

error.

The discharge pressure

on compressor is too

high.

537

Blocking fault after 3rd

trigger attempt

The discharge pressure

on compressor is too

high.

537

Blocking fault after 3rd

trigger attempt

The pressure of the

539

low pressure circuit is

too low.

Cooling circuit pressure

546

sensor fault.

The sensor is defective or is not

correctly connected to the main

PCB.

Water pump defective.

There is a lack of water.

Anti-silt fi lter missing or clogged

in the brine water circuit’s

backfl ow.

The circuit was not properly bled.

The pressure drop is too high in

the hydraulic circuit.

The compressor safety thermostat

is tripped.

The pressure switch or its

electrical connection is defective.

The refrigerant fl uid level is low

The sensor is defective or is not

correctly connected to the main

PCB.

Pre-expansion in the liquid line

(load loss)

The electronic expansion valve is

defective.

The plate exchanger is clogged.

There is a mechanical or electrical

problem. Force the 4-way valve

from the control box. While

forcing, check that the coil voltage

is correct.

There is an excess or a lack of

refrigerant.

Vacuum insuffi cient

Presence of incondensables in the

circuit

The pressure switch or its

electrical connection is defective.

Pre-expansion in the liquid line

(load loss)

Poor water fl ow rate.

The water fl ow sensor is defective.

Insuffi cient heat exchange at the

plate to plate exchanger.

Lack of refrigerant.

Lack of airfl ow.

There is no defrosting.

The condensate tray resistance

heater is faulty.

The 4-way valve is defective.

The electronic expansion

valve’s motor is defective or the

connection is defective.

The sensor is defective or not

correctly connected to the main

circuit board.

Fault

Description Possible cause

codes

An excess or a lack of refrigerant.

Presence of incondensables.

The electronic expansion valve is

defective.

554 Operation outside the

compressor's limit.

The expansion valve

582

motor or connection

is out.

The subcooling

temperature sensor

585

in heating mode or

connection is out.

eBus communication

685

with heat pump is out.

Compressor

750

disconnected.

Compressor

751

overcurrent.

752 Inverter driver error.

Communications error

753

with the inverter box.

Fan coil board internal

754

error (FMU).

The air inlet

774

temperature sensor or

connection is out.

Pre-expansion in the liquid line

(load loss)

Insuffi cient heat exchange at the

plate to plate exchanger or tube

exchanger.

The 4-way valve is defective.

The wiring harness is damaged or

disconnected.

The sensor is defective or is not

correctly plugged in to the main

PCB.

The appliance is not connected to

the control box.

The cable polarity is reversed.

The wiring harness is damaged or

disconnected.

Compressor fault.

The heat pump supply voltage is

too low.

The fi nned heat exchanger is

dirty.

The plate heat exchanger is dirty.

The inverter box is damaged.

The inverter box radiator is

blocked.

The supply voltage is incorrect.

The connection between the main

circuit board and the inverter box

is damaged or disconnected.

The inverter box is not powered

up.

The fan is defective.

The connection between the main

circuit board and the fan card is

damaged or disconnected.

The fan card is defective.

The fan card power supply is

defective.

The sensor is defective or not

correctly connected to the main

circuit board.

For further technical information please

call 0844 736 1143

0020154078_00 - 02/13 - Glow-worm

25

Page 26

Page 27

Page 28

GLOW-WORM

0020154078_00 - 02/13 Subject to engineering changes

Nottingham Road,

Belper, Derbyshire.

DE56 1JT

www.glow-worm.co.uk

Because of our constant endeavour for

improvement, details may vary slightly

from those shown in these instructions.

The energy you need

Loading...

Loading...