Page 1

System Installation

STANDALONE

Page 2

Page 3

TABLE OF CONTENTS

INTRODUCTION

1 Instructions guidance ................................................................................................................... 2

1.1 Product documentation .......................................................................................2

1.2 Associated documents ........................................................................................2

1.3 Explanation of symbols .......................................................................................2

1.4 Guarantee registration ........................................................................................2

2 System description ...................................................................................................................... 2

2.1 Concept of operation ...........................................................................................2

2.2 Summary of installation diagrams ........................................................................3

2.3 Diagram 4: Heat pump eBus, one heating zone .....................................................4

2.4 Diagram 7: Heat pump controlled by On/Off contact, one heating zone ...................6

2.5 Example installation with multi-zone heating option .............................................8

2.6 Example of system installation with the domestic hot water cylinder option ..........10

INSTALLATION

3 Confi guring the installation ........................................................................................................ 12

4 "Thermostat / sensor" menu ....................................................................................................... 12

4.1 Thermostat(s) ...................................................................................................12

4.2 Outdoor sensor .................................................................................................13

5 Self check .................................................................................................................................. 13

6 Settings..................................................................................................................................... 14

6.1 Heating ............................................................................................................14

6.2 Domestic hot water ...........................................................................................15

6.3 Cooling ............................................................................................................15

6.4 HP Management ...............................................................................................15

6.5 Resetting parameters ........................................................................................16

7 Commissioning .......................................................................................................................... 16

7.1 Filling and venting the heating circuit .................................................................16

7.2 Venting the HP circuit ........................................................................................18

7.3 Adjustment of HP circuit fl ow .............................................................................18

8 Status reports ............................................................................................................................ 18

9 Re-check and restart ................................................................................................................... 19

10 User information ........................................................................................................................ 19

MAINTENANCE

11 Trouble-shooting ........................................................................................................................ 20

11.1 Fault diagnosis .................................................................................................20

11.2 System fault codes ............................................................................................20

12 Servicing ................................................................................................................................... 21

13 Control unit maintenance menu ................................................................................................... 21

13.1 Test menu .........................................................................................................21

13.2 Aftersales information .......................................................................................22

- 1 -

EN

Page 4

INTRODUCTION

INTRODUCTION

1 Instructions guidance

1.1 Product documentation

The instructions are an integral part of the system appliances and

must be handed to the user on completion of the installation in

order to comply with the current regulation.

• Carefully read the manual, to understand all the information

to enable safe installation, use and servicing. No liability can

be accepted in the event of damage for not complying with the

guidance in this instruction manual.

These instructions consist of, Installation, Servicing, Fault

Finding. The instructions are an integral part of the appliance and

must be handed to the user on completion of the installation.

1.2 Associated documents

- Heat pump use and installation instructions

- Hydraulic module installation instructions

- Systempro Control unit use and installation instructions

- Climapro2 RF programmable Room thermostat use and

installation instructions

- Wireless outdoor sensor installation instructions

- Accessories installation instructions (motorized 2 port valve...)

1.3 Explanation of symbols

a

e

DANGER: Risk of injuries.

DANGER: Risk of electric shock.

2 System description

2.1 Concept of operation

The Standalone system consists of the following components:

-A Glow-worm Envirosorb 5 heat pump,

- A "Standalone" hydraulic module,

- The Systempro control unit

- A Climapro2 RF wireless programmable room thermostat,

- A wireless photovoltaic outdoor sensor

The following options may be added to the system:

- 2 port valves for zoning,

- A domestic hot water cylinder.

2.1.1 Operating principle in heating

The system is designed to provide a heating need of 6kW max at

the reference temperature.

The heat generator consists of a heat pump and a hydraulic

module equipped with an electric heater. The heat emitters can

also be low temperature (heated fl oor, gentle heat radiators...) or

medium temperature (steel panels...). In order to always obtain

the best comfort/economy trade-off , the module heat pump and/

or electric heater supply the heating installation with hot water

at the temperature necessary to obtain the desired ambient

temperature.

When the power of the heat pump is no longer adequate to

ensure heating, the self-controlled electric heater in the hydraulic

module can operate simultaneously in steps of 2 kW up to a

power of 6 kW (in the case of a heat pump ≤ 5 kW the top-up

power is limited to 4 kW when the heat pump is operating). This

guarantees optimal use of the heat pump while guaranteeing

that the total electrical power consumption will never exceed

6kW. When the heat pump is not operating, the electric heater

can reach a power level of 6kW independent of the outside

temperature conditions.

ATTENTION: Risk of damage to the appliance or to its

b

i

surroundings.

IMPORTANT: Important information.

1.4 Guarantee registration

We recommend you complete and return as soon as possible your

guarantee registration card (delivered with the hydraulic module).

If your guarantee registration card is missing you can obtain a

copy or record your registration by telephoning the Glow-worm

Customer Service number 01773 596510.

EN

- 2 -

The changeover point between the heat pump and the electric

heater is managed automatically, depending on the outside and

ambient temperatures. Thus, the system always optimises the

use of the heat pump with respect to the electric top-up heater.

Avoid programmes with high temperature variations

i

in the case of power sizing without a signifi cant

margin (based on a calculation with a stabilised

temperature).

0020096321_01 - 02/11 - Glow-worm

Page 5

INTRODUCTION

2.1.2 Operating principle of the domestic hot water

system

The domestic hot water heating circuit consists of a heat pump,

a 3-way valve and a FLUROCYL hot water tank equipped with an

electric heater.

In order to always obtain the best comfort/economy trade-off ,

the heat pump and/or the FLUROCYL tank electric heater provide

the energy needed to maintain the stored water at the required

temperature.

The lower part of the tank is heated 3 times a day by the heat

pump. In order to provide maximum economy, the electric heater

heats the top part of the tank just to provide the comfort desired

by the user.

The lower the hot water temperature setting, the more the

heat pump will provide energy and, therefore, more economic

operation.

2.2 Summary of installation diagrams

Hybrid Back-up

Heat Pump Diagram

Envirosorb 5 eBus 4

Envirosorb2 7

Envirosorb2 12

Envirosorb2 15

controlled by on/off contact 7

0020096321_01 - 02/11 - Glow-worm

EN

- 3 -

Page 6

INTRODUCTION

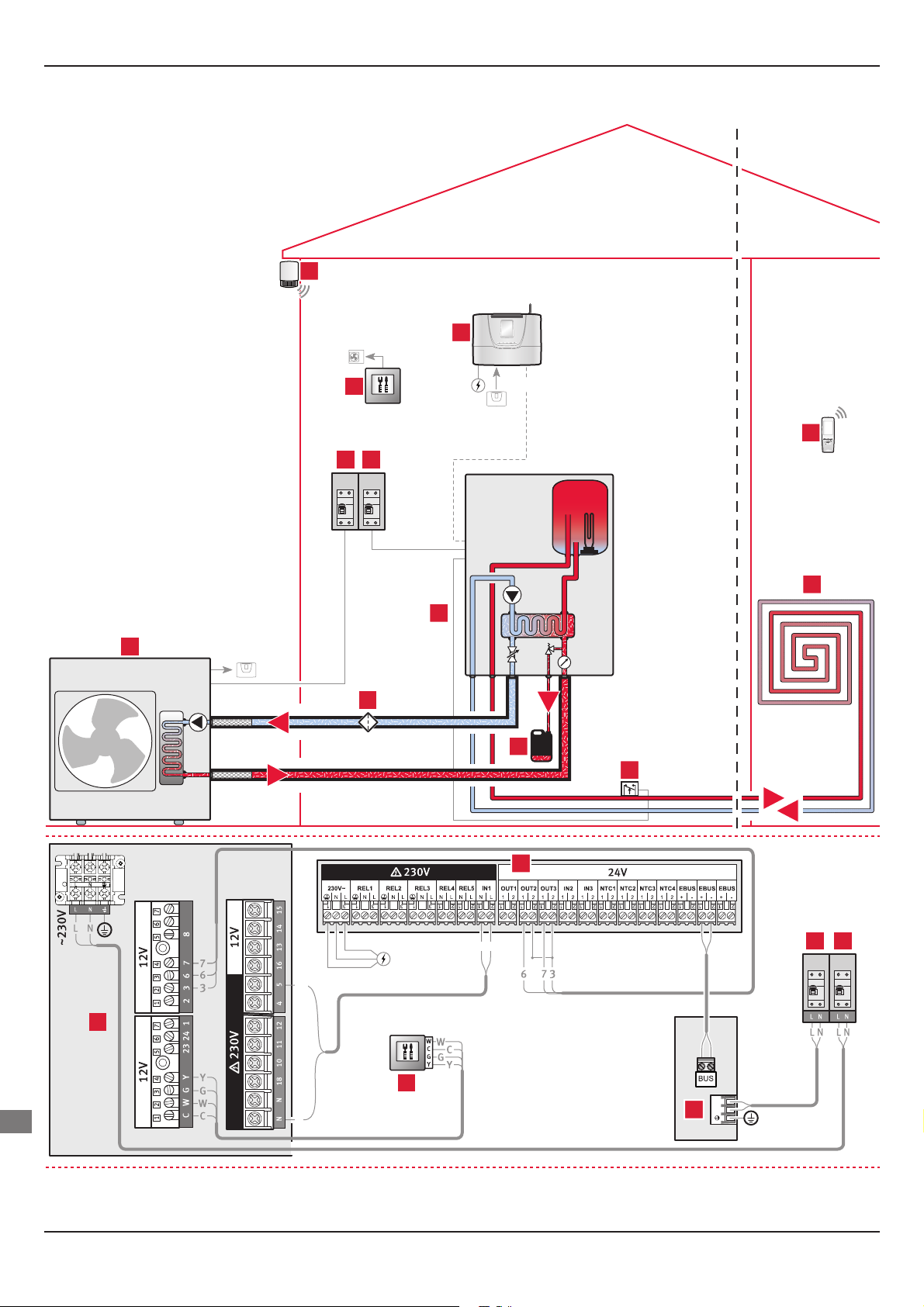

2.3 Diagram 4: Heat pump eBus, one heating zone

5

EBUS

4

6

7 8

230V230V

3

2

9

C

1

B

11

A

5

D

10

E

230V

8

EN

- 4 -

9

2

NL

0020096321_01 - 02/11 - Glow-worm

Page 7

Key

1 Overheating safety (UFH shown, but can be underfl oor or radiators)

2 Hydraulic module

3 Heating circuit

4 Climapro2 RF programmable wireless room thermostat

5 Systempro control unit

6 Wireless outdoor sensor

7 Hydraulic module electrical supply + protection (This must have it's

own single isolation)

8 Heat pump electrical supply + protection (This must have it's own

single isolation)

9 EBus heat pump

10 Heat pump circuit fi lter (not supplied)

11 Glycol PRV discharge

A Heating circuit return

B Heating circuit fl ow

C Heat pump circuit safety valve discharge

D Heat pump circuit fl ow

E Heat pump circuit return

Application conditions

- The Systempro control unit manages the operation of the

boiler, the heat pump and the module.

- The Systempro control unit manages up to 3 heating zones.

INSTALLATION

- Each wireless room thermostat can control a heating zone.

- The installation can be performed with a low-temperature

heated fl oor (heating outlet temperature < 50°C) or low

temperature radiators (heating outlet temperature < 70°C).

- The overheating safety device must be connected to the

hydraulic module pump power supply.

Use 0.75 mm² section cables for the electrical

e

Description of main settings Setting

Diagram no. 4

Did you install a multizone kit ? No

Heating curves 0.1 - 1.5

Max. heating fl ow temperature 30°C < T < 70°C

connections to the control unit.

Control unit settings

0020096321_01 - 02/11 - Glow-worm

EN

- 5 -

Page 8

INSTALLATION

2.4 Diagram 7: Heat pump controlled by On/Off contact, one heating zone

7

8

6

EBUS

9

4 5

230V 230V

10

3

1

2

C

E

12

D

11

B

A

EN

- 6 -

8

L5

N

L5

4 5

230V230V

1

6

NL

N

3

0020096321_01 - 02/11 - Glow-worm

Page 9

Key

1 Heat pump controlled by On/Off contact

2 Heat pump circuit fi lter (not supplied)

3 Hydraulic module

4 Electrical power and protection of the heat pump

5 Electrical power and protection of the module

6 Heat pump control unit

7 Wireless outdoor sensor

8 Systempro control unit

9 Climapro2 RF programmable wireless room thermostat

10 Heating circuit

11 Overheating safety (UFH shown, but can be underfl oor or radiators)

12 Glycol PRV discharge

A Heating circuit return

B Heating circuit fl ow

C Heat pump circuit safety valve discharge

D Heat pump circuit fl ow

E Heat pump circuit return

Application conditions

- The Systempro control unit manages the operation of the

boiler, the heat pump and the module.

- The Systempro control unit manages up to 3 heating zones.

MAINTENANCE

- The heat pump command unit is used as a setting or

diagnostic tool.

- Each wireless room thermostat can control a heating zone.

- The installation can be performed with a low-temperature

heated fl oor (heating outlet temperature < 50°C) or low

temperature radiators (heating outlet temperature < 70°C).

- The overheating safety device must be connected to the

hydraulic module pump power supply.

Use 0.75 mm² section cables for the electrical

e

connections to the control unit.

Control unit settings

Description of main settings Setting

Diagram no. 7

Did you install a multizone kit ? No

Heating curves

Max. heating fl ow temperature 30°C < T < 70°C

Heat pump external shutdown temperature -20°C < T < 20°C

0.1 - 1.5

Heat pump control unit settings

• Refer to the heat pump installation manual to access the

“After-sales” parameters listed below.

Menu Function name Setting

112 Heating curves (*) 7 - 12

114 ECO heating mode (*) 1 - 20°C

(*) Refer to the correspondence table in the “Settings > Heating”

section.

0020096321_01 - 02/11 - Glow-worm

EN

- 7 -

Page 10

INTRODUCTION

2.5 Example installation with multi-zone heating option

2 zone low temperature or high

temperature heating

6

5

4

3 zone low temperature or high

temperature heating

9

8

7

6

5

4

3

3

2

2

1

1

B

A

1010

B

A

EN

- 8 -

LNLN

1

4

7

LNLNLN

1

4

0020096321_01 - 02/11 - Glow-worm

Page 11

Key

1 2 port valve "heating zone 1"

2 Heating circuit zone 1

3 Climapro2 RF programmable wireless room thermostat "zone 1"

4 2 port valve "heating zone 2"

5 Heating circuit zone 2

6 Climapro2 RF programmable wireless room thermostat "zone 2"

7 2 port valve "heating zone 3"

8 Climapro2 RF programmable wireless room thermostat "zone 3"

9 Heating circuit zone 3

10 Systempro control unit

A Heating circuit return

B Heating circuit fl ow

Application conditions

- The Systempro control unit manages up to 3 heating zones.

- Each wireless room thermostat can control a heating zone.

- Zones must be same temperatures.

- The installation can be performed with a low-temperature

underfl oor heating (heating outlet temperature < 50°C) or low

temperature radiators (heating outlet temperature < 70°C).

INTRODUCTION

Use 0.75 mm² section cables for the electrical

e

Description of main settings Setting

Did you install a multizone kit ? Yes

Max. heating fl ow temperature for the low

temperature zone

Max. heating fl ow temperature for the high

temperature zone

- When the 2 port valve is connected to REL3:

• Connect the neutral wire (blue) of the valve to the “N” of the

• Connect the live wire (brown) of the valve to the “L” of the REL3

• Connect the earth wire (yellow/green) of the valve to the earth

• Electrically insulate the red and grey wires of the valve as they

connections to the control unit.

Control unit settings

T < 30°C

T < 70°C

2 port valve electrical connections

REL3 connector.

connector.

of the REL3 connector.

are not used.

- When the 2 port valve is connected to REL4 or 5:

• Connect the neutral wire (blue) of the valve to the “N” and

the live wire (brown) of the valve to the “L” of the REL4 or 5

connector.

• Connect the earth wire (yellow/green) of the valve to the earth

of the REL3 connector.

• Electrically insulate the red and grey wires of the valve as they

are not used.

0020096321_01 - 02/11 - Glow-worm

EN

- 9 -

Page 12

INTRODUCTION

2.6 Example of system installation with the

domestic hot water cylinder option

2

3

1

4

G

230V

16A

3.1

3.2

3.3

F

C

D

A

B

9

E

2

H

5

6

I

8

7

230V

16A

4

EN

- 10 -

3.3 3.1

8

3.2

5

0020096321_01 - 02/11 - Glow-worm

Page 13

Key

1 Hydraulic module

2 Systempro control unit

3 Domestic hot water cylinder

3.1 Top domestic hot water NTC

3.2 Electric heater

3.3 Bottom domestic hot water NTC

4 Electric heater electrical supply + protection (This must have it's

own single isolation)

5 Power relay for the electric heater (not supplied)

6 Heat pump

7 Heat pump circuit fi lter (not supplied)

8 3 port valve

9 Glycol PRV discharge

A Heating circuit return

B Heating circuit fl ow

C Heat pump circuit safety valve discharge

D Heat pump circuit fl ow to module circuit

E Heat pump circuit return

F Cold water supply

G Domestic hot water fl ow

H Heat pump circuit return

I Heat pump circuit fl ow to cylinder circuit

Application conditions

INTRODUCTION

- The Systempro control unit manages the Domestic Hot Water

cylinder.

- The maximum working pressure of the domestic hot water

circuit is 10 bar. If the cold water supply pressure exceeds this,

then a pressure-reducing valve must be fi tted in the supply to

the boiler.

- In areas where the water is ‘hard’ (i.e. more than 200 mg/L

of calcium carbonate), it is recommended that the hot water

setting is reduced and that a scale reducer is fi tted, refer to the

manufacturer’s instructions or consult the local water company

for additional advice.

Use 0.75 mm² section cables for the electrical

e

connections to the control unit.

Control unit settings with eBus heat pump

Description of main settings Setting

Diagram no. 4

Option choice: Domestic Hot Water cylinder On

The type of tank

NTC sensor (1 top NTC)

or

NTC sensor (2 NTC)

Control unit settings with heat pump controlled by On/Off contact

Description of main settings Setting

Diagram no. 7

Option choice: Domestic Hot Water cylinder On

The type of tank NTC sensor (2 NTC)

0020096321_01 - 02/11 - Glow-worm

EN

- 11 -

Page 14

INSTALLATION

INSTALLATION

In the case of a multi-zone installation, fi ll the heating

i

3 Confi guring the installation

• Enter the installer code 96 into the Systempro control unit.

• Refer to the “System description” section for your diagram

1 Choose diagram number.

circuit using the “Filling” mode when commissioning

the control unit. “Filling” mode ensures fi lling by

automatically opening all of the circuit. Refer to the

chapter “Commissioning the Systempro control unit ▸

Commissioning ▸ Filling the heating circuit".

number.

2 Did you installed

a multi-zone kit?

4 The control unit

summarizes your installation.

5 Check the connections you

made to the control unit.

4 "Thermostat / sensor" menu

4.1 Thermostat(s)

1 Select Rmstat/sensor on

the screen.

2 Select Roomstat(s) on the

screen.

2.1 Select number of

heating zones present on the

system.

3 Select DHW cylinder on

the screen, if the option is

installed.

- Z20 kit = 2 heating zones

- Z11 kit = not available

- Z30 kit = 3 heating zones

3.1 Select the corresponding

DHW cylinder.

3 Select the area controlled

by the room thermostat.

4 Via the room thermostat

installer menu, select > RF >

pairing.

EN

0020096321_01 - 02/11 - Glow-worm

- 12 -

Page 15

INSTALLATION

4.2 Outdoor sensor

1 Select Rmstat/sensor on

the screen.

3 Select Connection on the

screen.

2 Select Outdoor sensor on

the screen.

4 Press the button on the

outdoor sensor to connect.

5 Self check

e

The automatic test allows you to check EBUS inputs, NTC inputs,

the RF connection with the room thermostat, the outdoor sensor

radio connection.

i

1 Select Self check on the

Do not modify the cables when connected to the mains.

The other connections are not tested and should be

visually inspected during installation or confi guration

modifi cations.

2 The automatic test will

screen.

start.

The sensor is operational after 24h of exposure to

b

Key

1 Outdoor sensor button

i

light and will therefore not function immediately after

being unpacked.

1

The External T°C Correction allows you to correct the

temperature measured by the outdoor sensor

(+/- 5 ° C, at intervals of 1 ° C - factory setting: 0).

- If the connection is correct, the message "OK" appears

opposite the component.

- If the connection is not correct, the message "Not OK" appears

opposite the component.

In this case, check the connections (wired and wireless) .

ON

0020096321_01 - 02/11 - Glow-worm

EN

- 13 -

Page 16

INSTALLATION

6 Settings

This menu allows you to adjust diff erent functions in accordance

with the connected appliances and to reset all the parameters.

6.1 Heating

The maximum heating output temperature must be

b

1 Select Settings on the

6.1.1 Max. heating fl ow temperature

b

adjusted in accordance with the characteristics of

your installation.

2 Select Heating on the

screen.

Ensure that the heating curve setting is compatible

with the installation.

screen.

1 Select Htg curve settings

on the screen.

2B With the Automatic htg

curve deactivated, you must

choose a heating curve.

2B.2 Choose the heating

curve (see curve and

explanations after).

2A With Automatic htg curve

activated.

2B.1 Select Htg curve setting

on the screen.

3 Select max. heating fl ow T°

on the screen.

4 Adjust the installation's

max. heating fl ow

temperature.

6.1.2 Heating curve

The following menu allows you to select the heating curve (value

adjustable between 0.2 and 4 - factory setting: 0.5), which allows

you to obtain the maximum heating demand for the usual minimum

outdoor temperature for the region in which the sensor is installed.

The automatic heating curve function continually and automatically

seeks the most suitable value to ensure your comfort and

the effi ciency of your heating system. The optimum value is

obtained approximately 24 hours after the system is started. It is

recommended to activate this function.

EN

Ensure that the heating curve setting is compatible

b

Key

1 Older properties with radiators

2 Standard/modern house with radiators

3 Highly insulated modern house with low temperature radiators or

with the installation.

A

underfl oor heating

Heating curve

1 2

B

3

- 14 -

A Heating fl ow temperature (°C)

B External temperature

0020096321_01 - 02/11 - Glow-worm

Page 17

INSTALLATION

Case of a heat pump controlled by On/Off contact

• Refer to the heat pump installation notice to access the “aftersales” parameters listed below.

• Set the heat pump heating curves complying with the

correspondences with the Systempro control unit heating

curves (see table below).

Incorrectly setting these parameters may signifi cantly

b

- Setting of the heat pump parameter 112:

Heating curve of the Systempro

- Example: Setting of the heat pump parameter 112:

Heating curve of the Systempro

impact the system effi ciency.

control unit

0.1 ▸ 02 7

0.3 ▸ 0.4 8

0.5 ▸ 0.7 9

0.8 ▸ 0.9 10

1.0 ▸ 1.2 11

1.3 ▸ Max. 12

control unit

0.1 ▸ 0.2 7

0.3 ▸ 0.4 8

0.5 ▸ 0.7 9

0.8 ▸ 0.9 10

1.0 ▸ 1.2 11

1.3 ▸ Max. 12

Heating curve

of the heat pump

Heating curve

of the heat pump

6.2 Domestic hot water

The lower the temperature of the hot water, the more

i

1 Select Hot water on the

economical the heat pump.

screen.

2 Set max.Domestic Hot

Water temperature.

6.3 Cooling

Function not active for the UK.

6.4 HP Management

This menu is used to set the outside temperature from which the

heat pump must turn off (value adjustable from -20°C to 20°C,

factory setting: 0°C).

To take full advantage of the heat pump, we recommend you to set:

- "-5°C" for 5 kW heat pump because it can not operate below -5°C.

- "-20°C" for the other heat pumps.

In the case where the MODUZONE Z20 or Z30 option is installed:

if the curve setting is "1.2" on the control unit, the curve setting

will be "11" for heat pump parameter 112.

6.1.3 Pre heating

The control unit manages the heating by anticipating the change

in temperature setting between two programmed time ranges.

This function allows it to reach the programmed temperature

more rapidly (factory setting: active). It acts at the fi rst morning

setting change for each zone.

1 Select Pre heating on the

screen.

2 Confi rm your choice.

1 Select HP Management on

the screen.

3 Set the outside

temperature from which the

heat pump must turn off .

2 Select Heat pump stop

temp. on the screen.

0020096321_01 - 02/11 - Glow-worm

EN

- 15 -

Page 18

INSTALLATION

6.5 Resetting parameters

This feature allows you to reset the parameters of the control unit

(factory setting).

The resetting of factory settings is irreversible. Any

b

1 Select Settings reset on

customised confi guration of the control unit will be lost.

the screen.

2 Confi rm your choice.

7 Commissioning

Refer to the hydraulic module instructions for fi lling

i

the heating and glycol water circuits.

7.1 Filling and venting the heating circuit

Filling the heating circuit allows the system to be pressurised.

Venting the heating circuit purges the air present in the heating

circuit.

Suitable external fi lling systems are shown diagrammatically, see

diagram below.

3

2

1

A C

B

5

4

This menu allows you to carry out the necessary operations on

the appliances following installation.

1 Select Commissioning on

the screen.

3

2

1

Key

1 Heating fl ow isolating valve

2 Heating return isolating valve

3 Hydraulic module

4 Temporary fi lling loop (remove immediately after fi lling)

5 Drain point

6 Back fl ow prevention device

7 Tundish

A Heating return circuit

B Heating fl ow circuit

C Domestic cold water supply in

A

B

6

7

C

5

EN

0020096321_01 - 02/11 - Glow-worm

- 16 -

Page 19

INSTALLATION

A - Case of a mono-zone installation :

• Open the diff erent heating circuit air vent (on the pump and

the hydraulic module tank...).

1 Select Air venting on the

screen.

• Open the taps on the module hydraulic jig and the installation

domestic cold water inlet tap.

• Fill the installation until the control unit shows 1.5 bar of

pressure.

• Close the cold water inlet shutoff tap.

• Vent each radiator until normal water fl ow then close the

venting valves.

• Vent the hydraulic module tank.

• Repeat the operation until all the radiators and the module

tank are vented.

2 Select Vent heating circuit

on the screen.

3 The screen displays the

2 Select Begin fi lling

procedure from the screen.

• To stop fi lling press the button .

• Close the fi lling loop.

• Vent each radiator until normal water fl ow then close the

venting valves.

• Vent the hydraulic module tank.

• Repeat the operation until all the radiators and the module

tank are vented.

• Open the diff erent heating circuit air vent (on the pump and

the hydraulic module tank...).

3 Select Air venting on the

screen.

pressure measured in the

system and that installation

fi lling is in progress.

4 Select Vent heating circuit

on the screen.

3 Select Begin manual

venting on the screen.

The venting process is carried

out for 15 minutes. You

can simultaneously run the

venting of the HP circuit.

• Check that the pressure

has not reduced (1.5

bar). If it has, repeat the

previous operations.

When venting is complete, close the diff erent heating

b

The heating circuit can only be fi lled via the control unit if you

have chosen the multi-zone kit option. It is used to open the valves

of each zone.

circuit air vent.

B - Case of a multi-zone installation :

1 Select Fill htg circuit

on the screen

The screen shows the

pressure measured in the

system.

• Open the taps on the

module hydraulic jig and the

installation domestic cold

water inlet tap.

5 Select Begin manual

venting on the screen.

When venting is complete, close the diff erent heating

b

circuit air vent.

The venting process is carried

out for 15 minutes. You

can simultaneously run the

venting of the HP circuit.

• Check that the pressure

has not reduced (1.5

bar). If it has, repeat the

previous operations.

EN

0020096321_01 - 02/11 - Glow-worm

- 17 -

Page 20

INSTALLATION

7.2 Venting the HP circuit

The venting of the HP circuit allows you to purge any air in the HP

circuit.

After fi lling the heat pump circuit with glycol water (following the

instructions of the hydraulic module and heat pump installation

manuals), you can start the heat pump venting function.

1 Select from the screen

▸ Air venting

▸ Vent HP circuit

2 Start the venting

procedure.

7.3 Adjustment of HP circuit fl ow

This function can only be activated for an eBus heat pump. The

fl ow display is not possible with the heat pump on / off .

8 Status reports

This menu enables real-time access to:

- the status of the appliances responding to a request (ON/OFF)

- the information available from the appliances (temperature,

pressure, fl ow, ...),

- register of last 5 faults recorded for each appliance (failure

code and description)

- to reset the report for each appliance.

Information on the heat pump

In the case of an On/Off heat pump, the forcing and information

reading modes are available from the command unit supplied

with the heat pump.

1 Select Status reports on

the screen.

2 Select Heat pump on the

screen.

1 Select Glycol circuit fl ow

on the screen.

3 Start the reading of the

heat pump circuit fl ow rate.

2 Select HP → Module on

the screen.

System information

1 Select Status reports on

the screen.

2 Select System on the

screen.

EN

0020096321_01 - 02/11 - Glow-worm

- 18 -

Page 21

INSTALLATION

Information on heating zone

1 Select Status reports on

the screen.

3 Select the zone you want to

consult.

2 select Heating zones on

the screen.

4 Consult the heating zones

information.

9 Re-check and restart

• Once the system is installed, check the operation of each appliance.

• Start the system to ensure that any adjustments operate correctly

and check that the appliances operate safely.

• Reset the fault reports for all appliances. To do this, refer to

the "Component info." section.

• Check the water-tightness of the appliances and eliminate any

leaks.

• Check the entire control and safety system, settings and operation.

• Start the "Self check" procedure to test the system connections.

10 User information

At the end of the installation, the installer must:

- explain the operation of the appliances and its safety devices

to the user, if necessary provide a demonstration and answer

any questions;

- hand over to the user all the required documentation,

Information about the domestic hot water cylinder option

This menu is only available if you have chosen the domestic hot

water cylinder option.

1 Select Status reports on

the screen.

2 Select DHW cylinder on the

screen.

- advise the user of the precautions necessary to prevent

damage to the system, appliances and the building;

- remind the user to service the appliances annually.

The user shall not interfere with or adjust sealed components.

Any servicing must be carried out by a competent person

approved at the time by the Health and Safety Executive.

0020096321_01 - 02/11 - Glow-worm

EN

- 19 -

Page 22

MAINTENANCE

MAINTENANCE

11 Trouble-shooting

11.1 Fault diagnosis

The following checks should be performed before proceeding

onto specifi c diagnostics:

- Make sure that the electricity supply has not been interrupted

and that the appliance is connected correctly.

- Ensure that the isolating valves are open.

- Check that all external controls are connected correctly.

11.2 System fault codes

The faults described in this chapter should be carried

i

out by a qualifi ed engineer and if needed by the After

Sales Service.

• Refer to the instructions for each element making up the

system for their fault codes.

Fault

Description Cause Solution

codes

Failure in Ebus communication

002

between with the heat pump

Failure in Ebus communication

003

between with the hydraulic module

Heating circuit fl ow temperature sensor

010

failure (open circuit)

Heating circuit fl ow temperature sensor

011

failure (short circuit)

Heating circuit fl ow temperature sensor

012

failure low temperature (open circuit)

Heating circuit fl ow temperature sensor

013

failure low temperature (short circuit)

Domestic water tank temperature

014

sensor failure (open circuit)

Domestic water tank temperature

015

sensor failure (short circuit)

021 Pressure too low <0.5 bar

Failure in communication with the zone

030

1 wireless room thermostat.

Failure in communication with the zone

031

2 wireless room thermostat.

Failure in communication with the zone

032

3 wireless room thermostat.

Failure in communication with the zone

033

4 wireless room thermostat.

Failure in communication with the zone

034

EN

5 wireless room thermostat.

Failure in communication with the zone

035

6 wireless room thermostat.

Failure in communication with the

036

wireless outdoor sensor

The heat pump is not connected to the

control unit.

The heat pump is off .

The hydraulic module is not connected

to the control unit.

The hydraulic module is off .

The sensor is defective or not

properly connected to the control unit

management or hydraulic module.

The sensor is shorted.

The sensor is defective or not properly

connected to the control unit.

The sensor is shorted.

The sensor is defective or not properly

connected to the control unit.

The sensor is shorted.

There is a leak in the heating circuit.

The venting was not carried out

correctly.

The room thermostat is too far from the

control unit.

There is a problem with the batteries in

room thermostat.

The wireless outdoor sensor is too far

from the control unit.

Make sure the heat pump is connected to the control unit.

Ensure that there is no interruption to the electricity network

and that the heat pump is properly connected and turned on.

Make sure that the hydraulic module is connected to the

control unit. Ensure that there is no interruption to the

electricity network and that the hydraulic module is properly

connected and turned on.

Check the sensor’s connections.

Verify that the position and the operation of the sensor are

correct.

Check the sensor’s resistance.

Check the sensor’s connections.

Verify that the position and the operation of the sensor are

correct.

Check the sensor’s resistance.

Check the sensor’s connections.

Verify that the position and the operation of the sensor are

correct.

Check the sensor’s resistance.

Check that there are no leaks.

Drain the heating circuit. Remove air.

Fill the installation.

Check the RF signal quality via the Climapro2 RF installer

menu.

Check the location of the thermostat.

Check that the thermostat’s batteries are installed in their

compartment.

Make sure the battery polarity is not reversed.

Make sure the batteries are not dead.

If so, replace them with new batteries

Check the location of the outdoor sensor. Check that the

sensor’s power supply is correctly provided by a photovoltaic

cell.

- 20 -

0020096321_01 - 02/11 - Glow-worm

Page 23

MAINTENANCE

12 Servicing

• Consult each of the system component’s instructions for more

information about the corresponding maintenance operations.

13 Control unit maintenance menu

• Enter the installer maintenance access code (35) into the

control unit.

13.1 Test menu

This menu allows you to test the operation of all appliances and

the system (HP, zone valves,) present in the installation.

Heat pump test

1 Select System tests on the

screen.

2 Select Heat pump on the

screen.

System test

1 Select System tests on the

screen.

3 Activate the hydraulic

module pump.

2 Select System on the

screen.

4 Activate the Forced module

resistors.

This menu allows you to:

- issue a heating demand to the heat pump (*),

- activate the pump (**)

- activate the fan (**)

- activate the 4-way valve (**)

- activate the crankcase heater (**)

- activate the electrical resistance heater (**)

- activate the heat exchanger’s resistance heater (**)

- activate the defrosting (**)

(*) In the case of a heat pump controlled by an On/Off contact,

switch off the power to the heat pump at the electrical panel for a

few seconds before starting the heating demand.

(**) Only available with an eBus heat pump

Heating zones test

The heating zones can only be tested if you have

i

1 Select System tests on the

3 Activate the multi-zone kit

installed multiple zone valves.

screen.

valve for each zone.

2 Select Zones on the

screen.

0020096321_01 - 02/11 - Glow-worm

EN

- 21 -

Page 24

MAINTENANCE

The domestic hot water cylinder test is only possible

i

if you have selected the domestic hot water cylinder

option.

DHW cylinder test

1 Select System tests on the

screen.

3 Select DHW cylinder

demand on the screen.

2 Select DHW cylinder on the

screen.

4 Select DHW cylinder elec.

resist. on the screen.

13.2 Aftersales information

This menu provides access to Aftersales Service information.

1 Select Parameters on the

screen.

3 Display or modify the

following information:

EN

2 Select After sales info on

the screen.

- date of last access to

installer menus,

- the name of the company

which provides the after

sales service if entered,

- the telephone number

of the company which

provides the after sales

service if entered.

- 22 -

0020096321_01 - 02/11 - Glow-worm

Page 25

Page 26

Page 27

Page 28

GLOW-WORM

0020096321_01 - 02/11 Subject to engineering changes

Nottingham Road,

Belper, Derbyshire.

DE56 1JT

www.glow-worm.co.uk

Because of our constant endeavour for

improvement, details may vary slightly

from those shown in these instructions.

Loading...

Loading...