Page 1

Supplied By www.heating spares.co Tel. 0161 620 6677

Instructions for Use

Installation and Servicing

T o be left with the user

BBU Fire Front

For use with

56/3e, 56/3pp, 45/2 and56/2

221793A. 06. 00

7441

specially designed

Back Boiler Units only

G.C. No. 37 047 08

BS 6332

BS 5258

This is a Cat I

Reference in these instructions to British Standards and Statutory

Regulations/Requirements apply only to the United Kingdom.

For Ireland the rules in force must be used.

The instructions consist of three parts, User, Installation and Servicing Instructions, which includes the Guarantee Registration

Card. The instructions are an integral part of the appliance and must, to comply with the current issue of the Gas Safety

(Installation and Use) Regulations, be handed to the user on completion of the installation.

Appliance

2H

Guarantee Registration

Thank you for installing a new Glow-worm appliance in your home.

Glow-worm appliances' are manufactured to the very highest standard so we are pleased

In the centre pages are to be found your Guarantee Registration Card, which we recommend you complete and

If this card is missing you can obtain a copy or record your registration by telephoning the Heatcall Customer

Our Guarantee gives you peace of mind plus valuable protection against breakdown by covering the cost of:

to offer our customers' a Comprehensive First Year Guarantee.

return as soon as possible.

Service number 01773 828100.

✔

All replacement parts

❏

✔

All labour charges

❏

All call-out charges

✔

❏

One Contact Local Service

REGISTER YOUR GLOW-WORM APPLIANCE

FOR 1ST YEAR GUARANTEE PROTECTION

CALL 0181 380 2555

Customer Services:

Tel: (01773) 828100

Fax: (01773) 828070

Hepworth Heating Ltd.,

Nottingham Road, Belper, Derbyshire. DE56 1JT

General/Sales enquiries:

Tel: (01773) 824141 Fax: (01773) 820569

Page 2

Supplied By www.heating spares.co Tel. 0161 620 6677

Important Information

CE Mark

The CE mark on this appliance shows compliance with:

1. Directive 90/396/EEC on the approximation of the laws of the Member States relating to appliances burning gaseous fuels.

2. Directive 73/23/EEC on the harmonization of the Laws of the Member States relating to electrical equipment designed for use

within certain voltage limits.

3. Directive 89/336/EEC on the approximation of the Laws of the Member States relating to electromagnetic compatibility - Boiler

and Fire.

INFORMATION FOR THE INSTALLER AND SERVICE ENGINEER.

Under Section 6 of the Health and Safety at Work Act 1974, we are required to provide information on substances hazardous to health.

The Adhesives and sealants used in this appliance are cured and give no known hazard in this state.

FUELBEDS, ARTIFICIAL FUEL

This product uses fuel effect Pieces containing Refractory Ceramic Fibre (RCF), which are man-made vitreous silicate fibres.

Excessive exposure to these materials may cause temporary irritation to eyes, skin and respiratory tract, consequently, it makes

sense to take care when handling these articles to ensure that the release of dust is kept to a minimum.

To ensure that the release of fibres from these RCF articles is kept to a minimum, during installation and servicing we recommend

that you use a HEPA filtered vacuum to remove any dust and soot accumulated in and around the fire before and after working on

the fire. When replacing these articles we recommend that the replaced items are not broken up, but are sealed within heavy duty

polythene bags, clearly labelled as RCF waste. This is not classified as “hazardous waste” and may be disposed of at a tipping site

licensed for the disposal of industrial waste. Protective clothing is not required when handling these articles, but we recommend you

follow the normal hygiene rules of not smoking, eating or drinking in the work area and always wash your hands before eating or

drinking.

INSULATION and SEALS

Ceramic fibre and glass fibre used in insulation panels rope and gaskets.

These can cause irritation to skin, eyes and the respiratory tract.

If you have a history of skin complaint you may be susceptible to irritation. High dust levels are usual only if the material is broken.

Normal handling should not cause discomfort, but follow normal good hygiene and wash your hands before eating, drinking or going

to the lavatory.

If you do suffer irritation to the eyes or severe irritation to the skin seek medical attention.

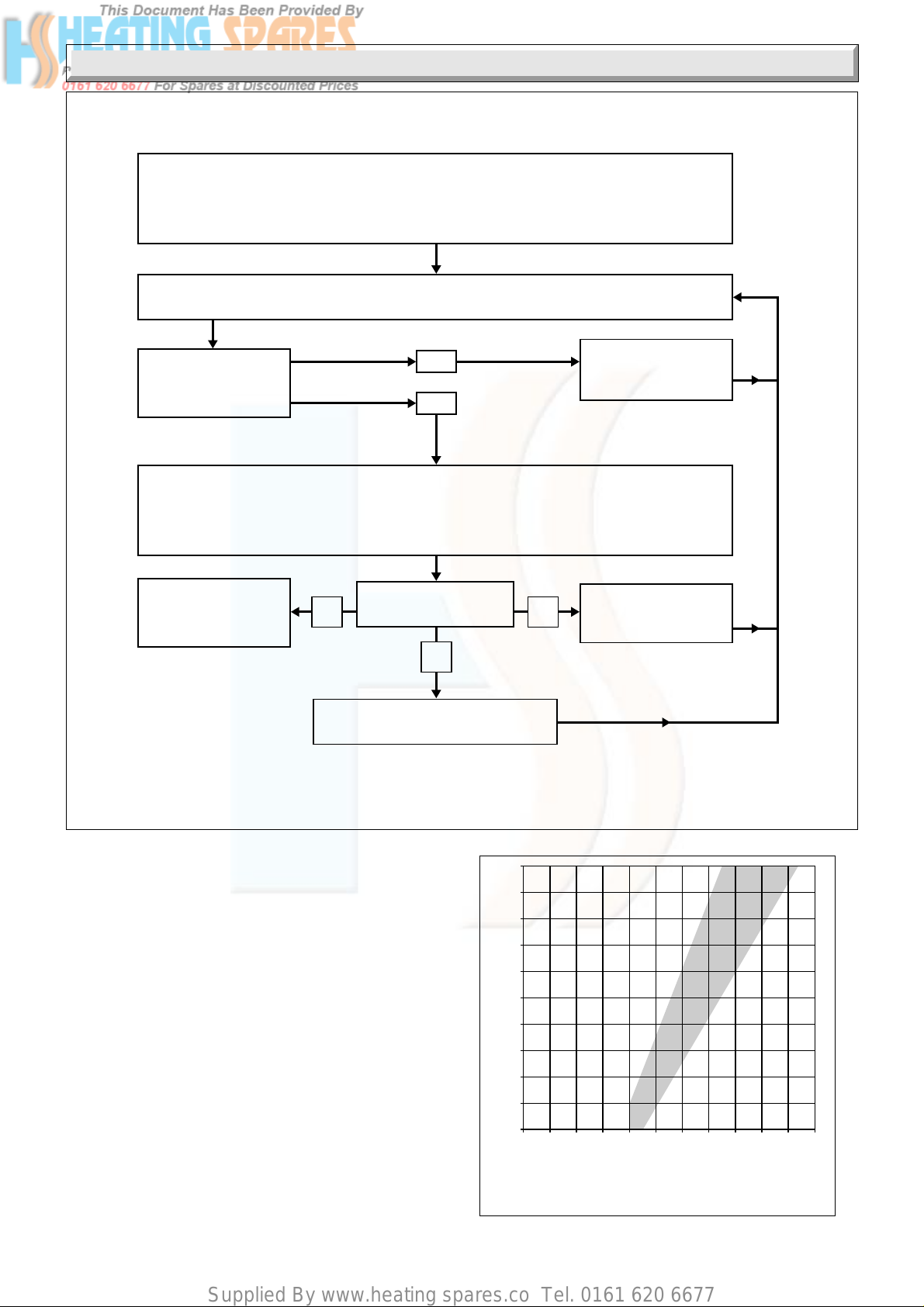

CONTENTS DESCRIPTION SECTION PAGE No.

Introduction 3

INSTRUCTIONS

FOR USE

INSTALLATION

INSTRUCTIONS

Lighting the Boiler 5

Lighting the Fire Front 9

Cleaning 9

General Data 1 13

Types of Flue Installation 2 15

Fire Front Preperation 3 16

Installation 4 20

Lighting, Testing and Fitting Internal Parts 5 24

Instructions for Use 6 28

SERVICING

INSTRUCTIONS

Servicing and Replacement of Parts 7 28

Fault Finding 8 33

Replacement Parts 9 36

2221793A

Page 3

Supplied By www.heating spares.co Tel. 0161 620 6677

FLAT AREA

FIRE FIXING

FACE

Instructions for Use

890mm

150mm

MAXIMUM

SHELF

DEPTH

840mm

7409

150mm

The Gas Safety (Installation and Use)

Regulations

In your interests and that of safety it is the Law that ALL gas

appliances are installed by a competent person in accordance

with the current issue of the above regulations.

General

These notes should be read and carefully followed for the safe

and economical use of your back boiler and fire front.

Important Notice

If this fire is fitted to a Glow-worm Back Boiler WITHOUT a flue

blockage safety device refer to the Supplementary Installations

in the Instructions for Use.

This appliance is for use only on G20 gas.

The Glow-worm Black Ash 3 BBU gas fire front is to be used

with specially designed Glow-worm 56/3e, 56/3pp, 45/2, 56/2,

45, 56, 45R or 56R Back Boiler Units only.

The fire front and back boiler must be fitted as a complete

appliance.

This is a combined central heating back boiler and gas fire

front. The back boiler and fire front can be operated either

together or independently.

In the event of a power or ignition system failure the fire front can

still be used on its own, instructions on how to do this are given

under “Lighting the Fire Front with a Match or Spill”.

Diagram 1

A slight smell may occur, for a short time, after initial lighting, this

is quite normal and will quickly disappear.

With a little use the interior of the fire front will discolour and

acquire the appearance of a solid fuel fire.

Combustible furniture must not be placed closer than 1metre in

front of the fire front.

Clothing or other flammable materials must not be placed on the

fire front casing.

The convection air openings at the top of the fire front and air

inlet grilles at the sides and base must never be obstructed.

Important: Soft wall coverings, for example, blown vinyl

wallpaper, are easily affected by heat, they may therefore,

scorch or become discoloured when close to a heating appliance.

This should be borne in mind when having a heating appliance

fitted and when redecorating.

The glass panel on this fire front conforms to the requirements

of the current issue of BS1945 and satisfies the Heating

Appliance (Fireguard) Regulations.

The fire front must not be used if this panel is broken or missing.

WARNING. The glass panel gets very hot when the fire front is

on and MUST NOT be touched.

The glass panel does not provide full protection for the young,

elderly or infirm. In such cases extra security must be provided

by fitting a fireguard which complies with the current issue of

BS6539 “Fireguards for use with solid fuel appliances” or the

current issue of BS6778 “Fireguards for use with portable, free

standing or wall mounted heating appliances”.

3

221793A

Page 4

Supplied By www.heating spares.co Tel. 0161 620 6677

Instructions for Use

Maintenance

To ensure the continued efficient and safe operation of the

appliance it is recommended that it is checked and serviced at

regular intervals. The frequency of servicing will depend upon

the particular installation and usage, but in general once a year

should be enough.

If this appliance is installed in rented property there is a duty of

care imposed on the owner of the property by the current issue

of the Gas Safety (Installation and Use) Regulations, Section

35.

It is the Law that servicing is carried out by a competent person.

To obtain service, please call your installer or Heatcall (Glow-

worm’s own service organisation) using the telephone number

given on the fire plinth.

Please be advised that the ‘Benchmark’ logbook should be

completed by the installation engineer on completion of

commissioning and servicing.

All CORGI Registered Installers carry a CORGI ID card, and

have a registration number. Both should be recorded in your

boiler Logbook. You can check your installer is CORGI registered

by calling CORGI direct on :- 01256 372300.

Heat Input - Fire Front

This gas fire front will run for about 4.4hrs at full on rate on one

therm of gas. The price of a therm of gas will vary according to

the tariff in your area.

At tap position 1 - centre section flame effect

At tap position 2 - centre section flame effect with

outer section fuel bed glow

At tap position 3 - centre and outer sections flame

effect with fuel bed glow

At tap position 4 - (full on) full flame effect and fuel

bed glow

Gas Leak or Fault

If a gas leak or fault exists or is suspected the appliance must

be turned off, including the electrical supply and must not be

used until the fault has been put right. Advice/help should be

obtained from your installation/servicing company or the local

gas undertaking.

183mm

Diagram 2

Electrical Supply

WARNING The boiler must be earthed.

Connection of the appliance and any system controls to t h e

mains (230V~50Hz) must be through one unswitched shuttered

socket outlet and a 3A fused 3 pin plug, both to the current issue

of BS1363. Alternatively, a fused 3A fused double pole isolating

switch may be used, having a minimum double pole contact

separation of 3mm, serving only the appliance and system

controls.

The colours of three core flexible cable are, blue - neutral, brown

- live, green and yellow - earth.

As the markings on your plug may not correspond with these

colours, continue as follows:The wire coloured blue must be connected to the terminal mark

“N” or black.

The wire coloured brown must be connected to the terminal

marked “L” or red.

The wire coloured green and yellow must be connected to the

terminal marked “E”, green or the earth symbol

.

7410

Clearances

A shelf or surround of a maximum depth of 150mm may be

fitted, provided clearances are as diagram 1, however, for every

extra 25mm above the fire front the depth of the shelf may be

increased by 25mm.

On no account may carpet or other combustible material be laid

directly under the fire front, unless the minimum clearances

shown in diagram 2 is achieved.

The dimension is taken from the bottom of the fire front casting

to the top of the carpet pile or other floor covering.

Frost

CAUTION. If the back boiler is to be out of use for any long

period of time during severe weather conditions we recommend

that the whole of the system, including the back boiler be

drained off to avoid the risk of freezing up.

If an immersion heater is fitted in the domestic hot water cylinder

make sure that it is switched off.

If in doubt your installation/servicing company or the local gas

undertaking should be contacted

4221793A

PLINTH

7444

Diagram 3

Page 5

Supplied By www.heating spares.co Tel. 0161 620 6677

Instructions for Use

Lighting the Boiler (BBU 56/3e ONLY)

This appliance is fitted with a flue blockage safety device which

will shut down the appliance in the event of abnormal flue

conditions. This device is NOT a substitute for an independently

mounted Carbon Monoxide detector.

If the boiler shuts down frequently for no apparent reason the

first things to be checked are the chimney and air inlets into the

room. Any problems found must be put right, by a competent

person, before the boiler is used again.

If the burner does go out, wait three minutes before relighting.

For any other reason, wait two minutes before relighting the

burner.

The boiler controls are situated behind the fire front plinth, see

diagram 3.

To remove the plinth grasp each side and pull it gently forwards

until it disengages.

Refer to diagram 4 to identify the controls.

Turn off the electrical supply at the mains supply outside the

unit.

See that all other controls are set for heating. The clock, room

thermostat and programmer, if fitted, will be situated away from

the unit. See manufacturers’ instructions supplied with these

items.

Turn the control thermostat knob “A” to the Off position "O", that

is, fully anti-clockwise (“O” to be against the pointer “B”).

Switch on the electrical supply to the back boiler unit. After a 30

second delay the pilot will automatically light.

This is indicated by the green light illuminating on the lockout

reset button “C”.

Note: Should the red light on the lockout reset button “C” come

on, it indicates that the pilot light is not operating correctly, or the

flue blockage safety device has been activated.

When the fault has been corrected the lockout reset button “C”

must be depressed.

NO ATTEMPT SHOULD BE MADE TO RELIGHT THE BOILER

UNTIL ANY FAULT HAS BEEN CORRECTED. EXPERT

ADVICE SHOULD BE SOUGHT.

Adjust the control thermostat knob “A” to the required setting

between "MIN" and “MAX”.

“MAX” is approximately 82°C.

The temperature of the hot water cylinder should be periodically

raised to 60°C.

Check that all external controls are also set to your requirements.

If the burner goes out for no apparent reason it is IMPORTANT

that the advice given under “Safety Device” is followed.

To Turn the Boiler Off

For short periods, turn control thermostat knob “A”

anti-clockwise until Off position "O" is opposite setting point.

The pilot will remain alight if there is a call for heat. To relight the

main burner turn control thermostat knob “A” clockwise to the

desired setting between "MIN" and “MAX”.

For longer periods, turn control thermostat knob “A” anticlockwise to Off position "O". Switch off the electrical supply to

the appliance.

To relight follow the full lighting instructions given above.

CONTROL BOX

GAS CONTROL VALVE

POINTER

“B”

MAX

0

MIN

GREEN

RED

CONTROL

THERMOSTAT

KNOB “A”

OVERHEAT CUTOFF DEVICE

(sealed systems only)

LOCKOUT

RESET

BUTTON “C”

BBU 56/3e ONLY

5

6821

Diagram 4

221793A

Page 6

Supplied By www.heating spares.co Tel. 0161 620 6677

Instructions for Use

Lighting the Boiler (BBU 56/3pp ONLY)

This appliance is fitted with a flue blockage safety device which

will shut down the appliance in the event of abnormal flue

conditions. This device is NOT a substitute for an independently

mounted Carbon Monoxide detector.

If the boiler shuts down frequently for no apparent reason the

first things to be checked are the chimney and air inlets into the

room. Any problems found must be put right, by a competent

person, before the boiler is used again.

If the burner does go out, wait three minutes before relighting.

For any other reason, wait two minutes before relighting the

burner.

The boiler controls are placed behind the fire front plinth, see

diagram 3.

To remove the plinth, pull it gently forwards until it is free.

Refer to diagram 4a to identify the controls.

Turn off the electrical supply at the mains supply outside the

appliance.

See that all other controls are set for heating. The clock, room

thermostat and programmer, if fitted, will be situated away from

the unit. See manufacturers’ instructions supplied with these

items.

Turn the control thermostat knob “D” to the Off position "O", that

is, fully anti-clockwise (“O” to be against the pointer “E”).

Push in and slightly turn gas control knob “F” clockwise until

” is against its setting point, that is, set to “Off”.

“

Push in slightly and turn gas control knob “F” anticlockwise until

“

” is against its setting point “G”, then push fully in and hold

in. At the same time press and release piezo button “H” until

pilot burner lights.

At initial lighting of the boiler air may be present and several

attempts may be needed to light the pilot. Keep the gas control

knob “F” pushed in whilst operating the ignition button.

When the pilot is alight and stable, keep knob “F” fully pushed

in for about 15 seconds then release. Check that the pilot is still

alight.

If the pilot burner fails to stay alight turn gas control knob “F” to

”, that is, fully clockwise. Wait three minutes. Repeat the

“

lighting operation, only now keep the gas control knob “F”

pushed in for a little longer than before after the pilot has lit.

NOTE. If the burner does go out, wait three minutes before

relighting. For any other reason, wait two minutes before

relighting the burner.

Push gas control knob “F” in slightly and turn anticlockwise until

” is against the setting point “G”.

“

Note. If gas control knob “F” is turned to until “

setting point “G”, a safety lock prevents it being turned on again.

No attempt should be made to turn the valve on again until at

least three minutes have elapsed.

Turn on the electrical supply to the unit.

Turn thermostat control knob “D” clockwise until “MAX” is

against the setting point, the main burner will light.

Adjust the thermostat to the required setting between “MIN” and

“MAX”. “MAX” is about 82

Check that all external controls are set to your requirements.

Refit the plinth by carefully locating the top edge of the plinth into

the sliders, then push gently back as far as it will go.

o

C.

” is against the

To Turn the Boiler Off

For short periods, turn thermostat control knob “D” anticlockwise

until “O” is against setting point "E". The pilot will stay alight, to

relight the main burner, turn thermostat control knob “D” clockwise

to the desired setting between “MIN” and “MAX”.

For longer periods, push in slightly gas control knob “F” fully

clockwise until '

thermostat control knob “D” anticlockwise to “O”.

Switch off the electrical supply the appliance. To relight follow

full lighting operation.

' is against the setting point “G”. Turn

CONTROL BOX

POINTER

“E”

CONTROL

THERMOSTAT

KNOB “D”

BBU 56/3pp ONLY

PIEZO UNIT

BUTTON “H”

GAS

CONTROL

KNOB “F”

SETTING

6822

POINT

“G”

Diagram 4a

6221793A

Page 7

Supplied By www.heating spares.co Tel. 0161 620 6677

Instructions for Use

Lighting the Boiler (45/2 and 56/2 ONLY)

This appliance is fitted with a flue blockage safety device which

will shut down the appliance in the event of abnormal flue

conditions. This device is NOT a substitute for an independently

mounted Carbon Monoxide detector. If the boiler shuts down

frequently for no apparent reason the first things to be checked

are the chimney and air inlets into the room.

An additional cause of the flue blockage safety device shutting

the fire down could be that the filter in the pilot port of the gas tap

has become blocked.

Any problems found must be put right, by a competent person,

before the boiler is used again.

The boiler controls are placed behind the fire front plinth.

To remove the plinth, pull it gently forwards until it is free, see

diagram 3.

Refer to diagram 4b to identify the controls.

Turn off the electrical supply at the mains supply outside the

unit.

Check that all controls are calling for heat.

The clock, room thermostat and programmer, if fitted, will be

remote from the appliance, refer to manufacturer’s instructions

supplied with them.

Turn the thermostat control knob “B” to Off position "O", that is,

fully anticlockwise, “O” to be against the pointer.

Push in and slightly turn gas control knob “A” clockwise until'

against its setting point, that is, set to “Off”.

Push in slightly and turn gas control knob “A” anticlockwise until

' is against its setting point, then push fully in and hold in. At

'

the same time press and release piezo button “D” until pilot

burner “E” lights. Look at flame through viewing window “F”.

At initial lighting of the boiler air may be present and several

attempts may be needed to light the pilot. Keep the control

knob “A” pushed in whilst operating the ignition button.

When the pilot is alight and stable, keep knob “A” fully pushed

in for about 15 seconds then release. Check that the pilot is still

alight, look through window “F”.

'is

If the pilot burner fails to stay alight turn gas control knob “A”

“Off”, that is, fully clockwise. Wait three minutes. Repeat the

lighting operation, only now keep the control knob “A” pushed

in for a little longer than before after the pilot has lit.

NOTE: If the burner does go out, wait three minutes before

relighting. For any other reason, wait two minutes before

relighting the burner.

Push control knob “A” in slightly and turn anticlockwise until

' is against the setting point.

'

Note. If gas control knob “A” is turned until '

setting point, a safety lock prevents it being turned on again. No

attempt should be made to turn the valve on again until at least

three minutes have elapsed.

Turn on the electrical supply to the unit.

Turn the boiler thermostat knob “B” clockwise until “MAX” is

against the setting point, the main burner will light.

Adjust the thermostat to the required setting between “MIN”

and “MAX”. “MAX” is about 82

Check that all external controls are set to your requirements.

Refit the plinth by carefully locating the top edge of the plinth

into the sliders, then push gently back as far as it will go.

o

C (180oF).

' is against the

To Turn the Boiler Off

For short periods, turn thermostat control knob “B” anticlockwise

until “O” is against setting point. The pilot will stay alight, to

relight the main burner, turn thermostat control knob “B”

clockwise to the desired setting between “MIN” and “MAX”.

For longer periods, push in slightly gas control knob “A” fully

clockwise until '

control knob “B” anticlockwise to “O”. Switch off the electrical

supply the appliance. To relight follow full lighting operation.

' is against the setting point. Turn thermostat

'D' PIEZO

UNIT BUTTON

SETTING

POINT

BBUs 45/2 and 56/2 ONLY

'E' PILOT BURNER

'B'

THERMOSTAT

CONTROL KNOB

'F' VIEWING

WINDOW

'A'

GAS VALVE

CONTROL KNOB

7

7997

SETTING

POINT

OFF

PILOT/IGNITION

MAIN BURNER

Diagram 4b

221793A

Page 8

Supplied By www.heating spares.co Tel. 0161 620 6677

Instructions for Use

Supplementary Instructions

NOTE: These supplementary instructions are only

applicable where the back boiler unit does not have a flue

blockage safety device and should otherwise be ignored.

As this fire front may be fitted to a Glow-worm 45, 56, 45R

or 56R back boiler unit WITHOUT a flue blockage safety

device, the following instructions on how to light the boiler

should be read and followed in place of those in the main

instructions for use.

To check if a flue blockage safety device is fitted, refer to the

inset in diagram 5, if one is fitted, this supplement MUST be

ignored.

Lighting the Boiler

The boiler controls are placed behind the fire front plinth.

To remove the plinth, pull it gently forwards until it is free.

Refer to diagram 5 to identify the controls.

Turn off the electrical supply at the mains supply outside the

appliance.

Check that all controls are calling for heat.

The clock, room thermostat and programmer, if fitted, will be

away from the unit, see manufacturer’s instructions supplied

with them.

Turn the thermostat control knob “B” to OFF Position "O", that

is, fully anticlockwise, “O” to be against the pointer.

Push in and slightly turn gas control knob “A” clockwise until'

against its setting point, that is, set to “Off”.

Push in slightly and turn gas control knob “A” anticlockwise until

'

' is against its setting point, then push fully in and hold in. At

the same time press and release piezo button “D” until pilot

burner “E” lights. Look at flame through viewing window “F”.

'is

At initial lighting of the boiler air may be present and several

attempts may be needed to light the pilot. Keep the control knob

“A” pushed in whilst operating the ignition button.

When the pilot is alight and stable, keep knob “A” fully pushed

in for about 15 seconds then release. Check that the pilot is still

alight, look through window “F”.

If the pilot burner fails to stay alight turn gas control knob “A”

“Off”, that is, fully clockwise. Wait three minutes. Repeat the

lighting operation, only now keep the control knob “A” pushed

in for a little longer than before after the pilot has lit.

NOTE: If the burner does go out, wait three minutes before

relighting. For any other reason, wait two minutes before

relighting the burner.

Push control knob “A” in slightly and turn anticlockwise until '

is against the setting point.

Note. If gas control knob “A” is turned until '

setting point, a safety lock prevents it being turned on again. No

attempt should be made to turn the valve on again until at least

three minutes have elapsed.

Turn on the electrical supply to the unit.

Turn the boiler thermostat knob “B” clockwise until “MAX” is

against the setting point, the main burner will light.

Adjust the thermostat to the required setting between “MIN” and

“MAX”. “MAX” is about 82

Check that all external controls are set to your requirements.

Refit the plinth by carefully locating the top edge of the plinth into

the sliders, then push gently back as far as it will go.

o

C (180oF).

' is against the

'

INSET: Showing a Flue Blockage

Safety Device fitted.

'E' PILOT BURNER

SETTING

POINT

'B'

THERMOSTAT

CONTROL

KNOB

'D' PIEZO

UNIT

BUTTON

45, 56, 45R or 56R Back Boiler Unit

WITHOUT a flue blockage safety device

'F' VIEWING

WINDOW

'A'

GAS VALVE

CONTROL

KNOB

5342

SETTING

POINT

OFF

PILOT/IGNITION

MAIN BURNER

Diagram 5

8221793A

Page 9

Supplied By www.heating spares.co Tel. 0161 620 6677

Instructions for Use

Lighting the Fire Front

CAUTION. If the glass panel or internal fire parts are damaged

do not light or use the fire front before replacement parts are

fitted.

The fire front is fitted with a flue blockage safety device which

will shut it down if there is a problem with the chimney. If the fire

front shuts down frequently, for no apparent reason the first

thing to be checked are the chimney and the air inlets into the

room. An additional cause could be that the filter, in the gas tap

has become blocked.

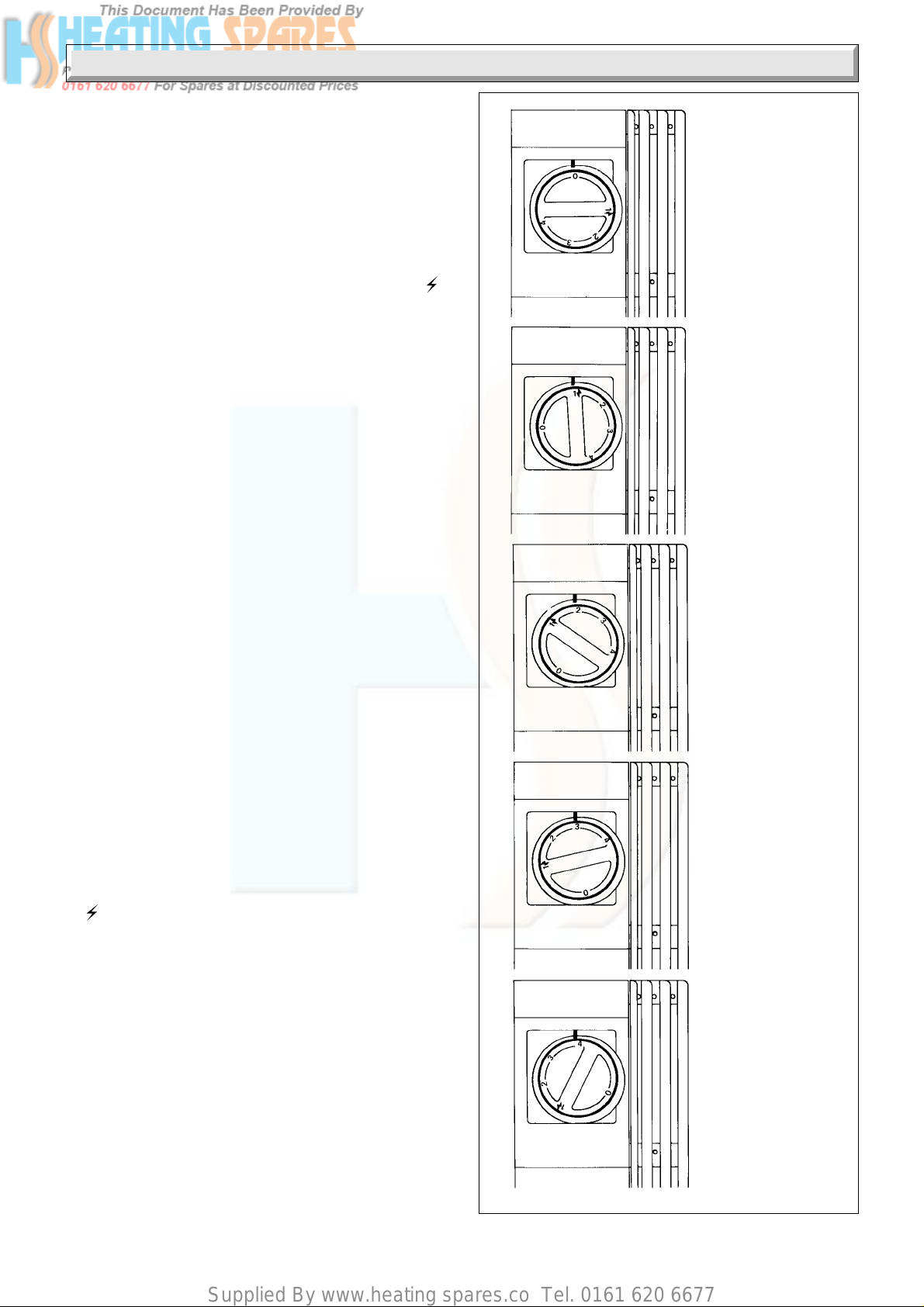

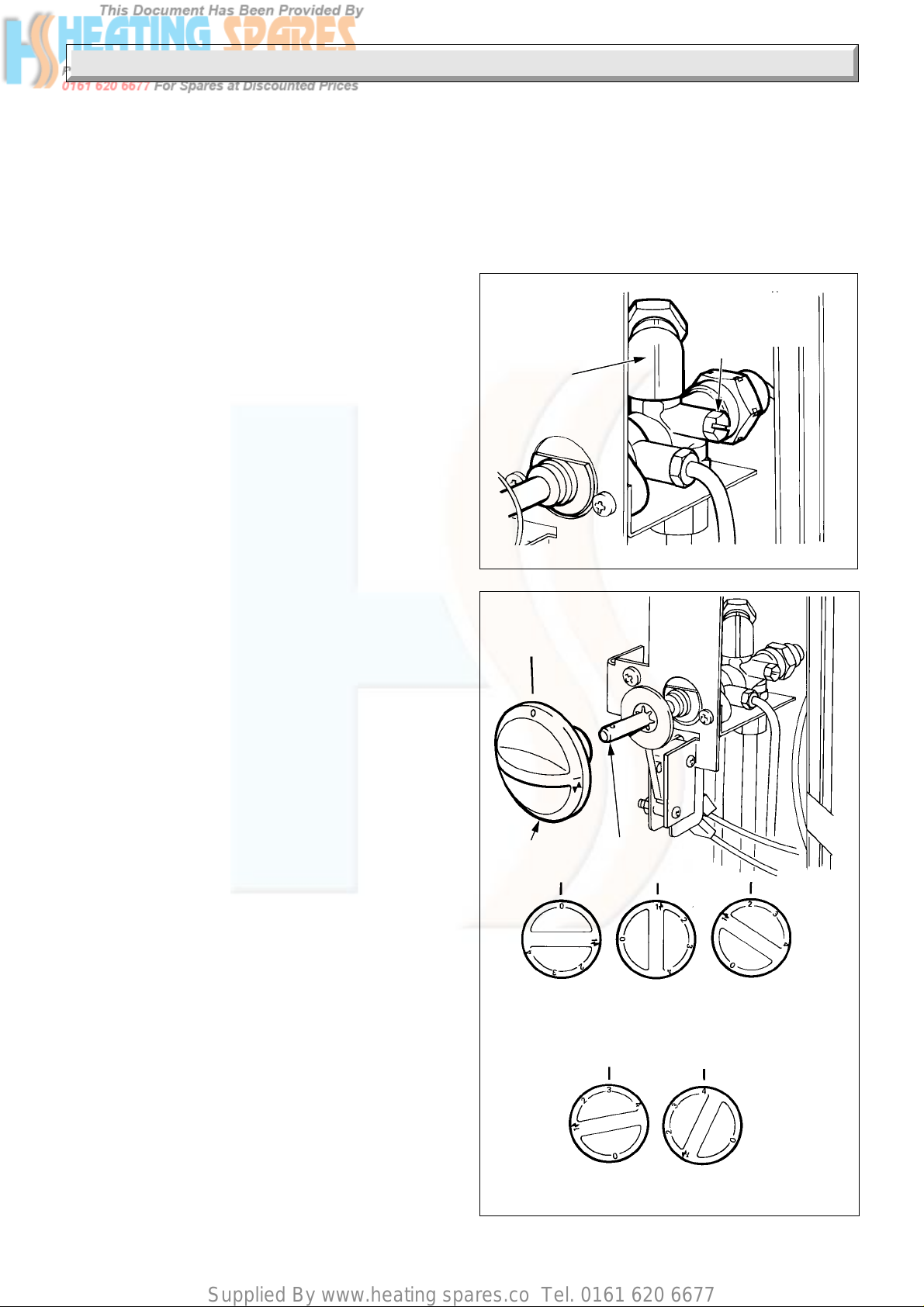

Push the control knob fully in and turn it anticlockwise to “1

ignition, clicking of the ignition will be heard and the burner will

light.

IMPORTANT. If the burner does not light within three seconds,

release the tap knob, wait ten seconds and repeat the lighting

operation.

Keep the knob pushed in for ten seconds, during which time the

ignition system will continue to operate, indicated by the clicking.

Air may be present in the supply to the fire front so that the initial

lighting operation may need to be repeated.

To change settings: Push in and turn. Refer to diagram 6.

If the burner goes out for any reason whilst the fire is turned on,

turn off.

Wait three minutes before relighting as above.

If relighting for any other reason wait two minutes before doing

so.

It can take several minutes for the fuel effect pieces to glow and

the flame effect to appear.

To turn off, turn the tap fully clockwise to “O” position and

release.

If there is a visible build up of soot on the fuel effect pieces follow

the instructions in Section on “Cleaning the Fire”.

7581

APPLIANCE OFF

“

IGNITION POSITION

AND CENTRE

SECTION

FLAME EFFECT

CENTRE SECTION

FLAME EFFECT

WITH OUTER

SECTIONS

FUELBED GLOW

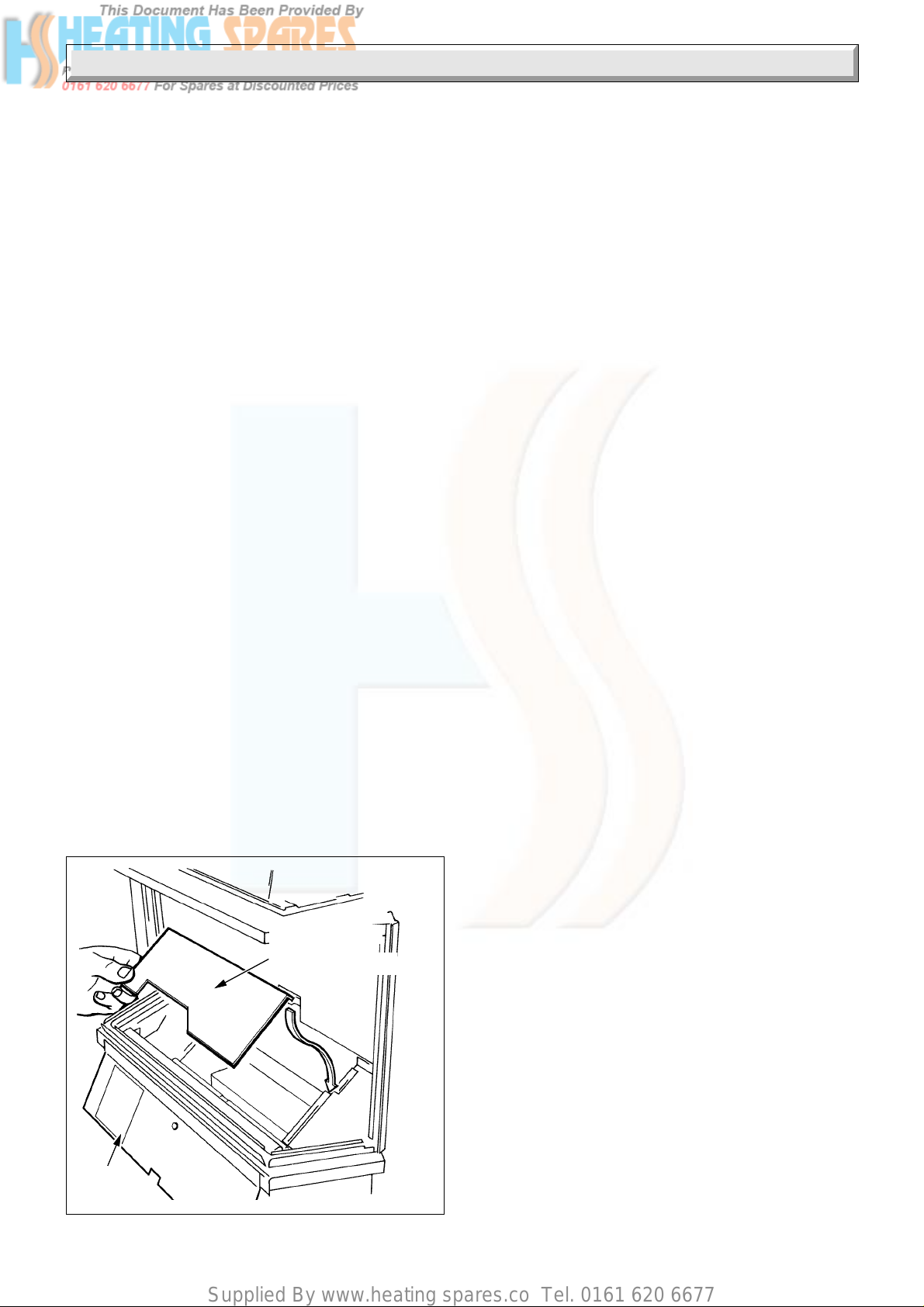

Lighting the Fire Front with a Match or Spill

This is a temporary measure, to be used only in the event of the

failure of the battery or the spark generator.

Make sure that the fire front is cold before starting.

Remove the front casting, see diagram 5.6. Take care as it is

made of cast iron.

Hold a lighted spill or long match and position it so that the flame

is over the burner, see diagram 7.

Keep the spill in position, push in and turn the gas tap to position

“1.

“ ignition and the burner will light. Keep the knob pushed

for about ten seconds and the burner will stay alight.

If the burner should go out, wait for 3 minutes, then repeat the

above, but now keep the knob pushed in for a little longer.

Once lit operate the gas tap normally.

This is a temporary measure only and the battery should be

replaced or the ignition system repaired as soon as possible.

Cleaning your Fire

WARNING. This appliance contains metal parts (components)

and care should be taken when handling and cleaning, with

particular regard to edges.

Any cleaning work must only be carried out when the fire front

is cold.

Under normal circumstances dusting should be enough. An

occasional wipe over with a damp cloth will help remove marks.

Do not use an abrasive cleaning powder or liquid.

CENTRE AND

OUTER SECTIONS

FLAME EFFECT

WITH FUELBED

GLOW

FULL FLAME

EFFECT WITH

FUELBED GLOW

Diagram 6

9

221793A

Page 10

Supplied By www.heating spares.co Tel. 0161 620 6677

Instructions for Use

Glass Panel and Internal Fire Front Parts

Remove the canopy as diagram 8. Take care as it is made of

cast iron. Remove the gas control knob, remove the retaining

screws, LH and RH sides, see diagram 19.

Swing the side panels open, see diagram 8.

Remove the glass panel, see diagram 9.

Clean the front glass panel inside and out with a proprietary

ceramic hob cleaner.

Should any soot accumulation become excessive, the fuel

effect pieces should be removed from the fire for cleaning.

Cleaning should be carried out in a well ventilated area or in the

open air, by gently brushing with the pieces held away from your

face so that you avoid inhaling the dust. We do not recommend

MATCH

EXTENSION

BURNER

the use of a normal domestic vacuum cleaner, which may blow

dust back into the air.

CAUTION. If replacing use only the fuel effect pieces approved

for this fire front.

When replacing fit as shown in diagram 10 to 17.

Note. Each fuel effect piece is numbered on its back.

DO NOT USE MORE FUEL EFFECT PIECES

THAN SHOWN.

5171

5094

GLASS

RETAINING

BRACKET

5mm

MATCH OR

SPILL

Diagram 7

5mm

7433

PULL FORWARDS

AND UP

GLASS

FRONT PANEL

FUEL EFFECT PIECES LOCATIONS

4

2

2

1

4

5

5

Diagram 9

4329 S

3

FUEL

EFFECT

BASE

Diagram 8

FUEL EFFECT PIECES 1 to 5

10221793A

2

31

Diagram 10

Page 11

Supplied By www.heating spares.co Tel. 0161 620 6677

Instructions for Use

Left

Side

NOTE:

Fuel Effect Base

seats behind

retaining brackets

FUEL EFFECT PIECE POSITION 1

FUEL

EFFECT

BASE

(see note)

RETAINING

BRACKETS

SUPPORT ANGLE FOR

FUEL EFFECT PIECES

1, 2 AND 3

Right

Side

FUEL

EFFECT

BASE

Diagram 11

5088

4331 S

FUEL EFFECT PIECE POSITION 3

LOCATION

LUG 3

NOTE:

FUEL EFFECT PIECE MUST

SIT ON SUPPORT ANGLE

FUEL EFFECT PIECE POSITION 4

4333 S4334 S4335 S

Diagram 14

NOTE:

FUEL EFFECT PIECE MUST

SIT ON SUPPORT ANGLE

FUEL EFFECT PIECE POSITION 2

LOCATION

RECESS 1

Diagram 12

LOCATION

RECESS 2

LOCATION

RECESS 4

Diagram 15

FUEL EFFECT PIECE POSITION 5

4332 S

LOCATION

RECESS 5

NOTE:

FUEL EFFECT PIECE MUST

SIT ON SUPPORT ANGLE

Diagram 13

11

Diagram 16

221793A

Page 12

Supplied By www.heating spares.co Tel. 0161 620 6677

Instructions for Use

To Replace the Battery

The battery supplied, should, under normal usage last for about

18 months.

The replacement is 9V and we recommend that it be of the

alkaline type which can be bought locally.

Remove the canopy as diagram 18. Take care as it is made of

cast iron. Remove the gas control knob, remove the securing

screw stop, swing open the right hand side panel as diagram 19.

Fit the battery as shown in diagram 20, make sure that the

terminals are correctly fitted.

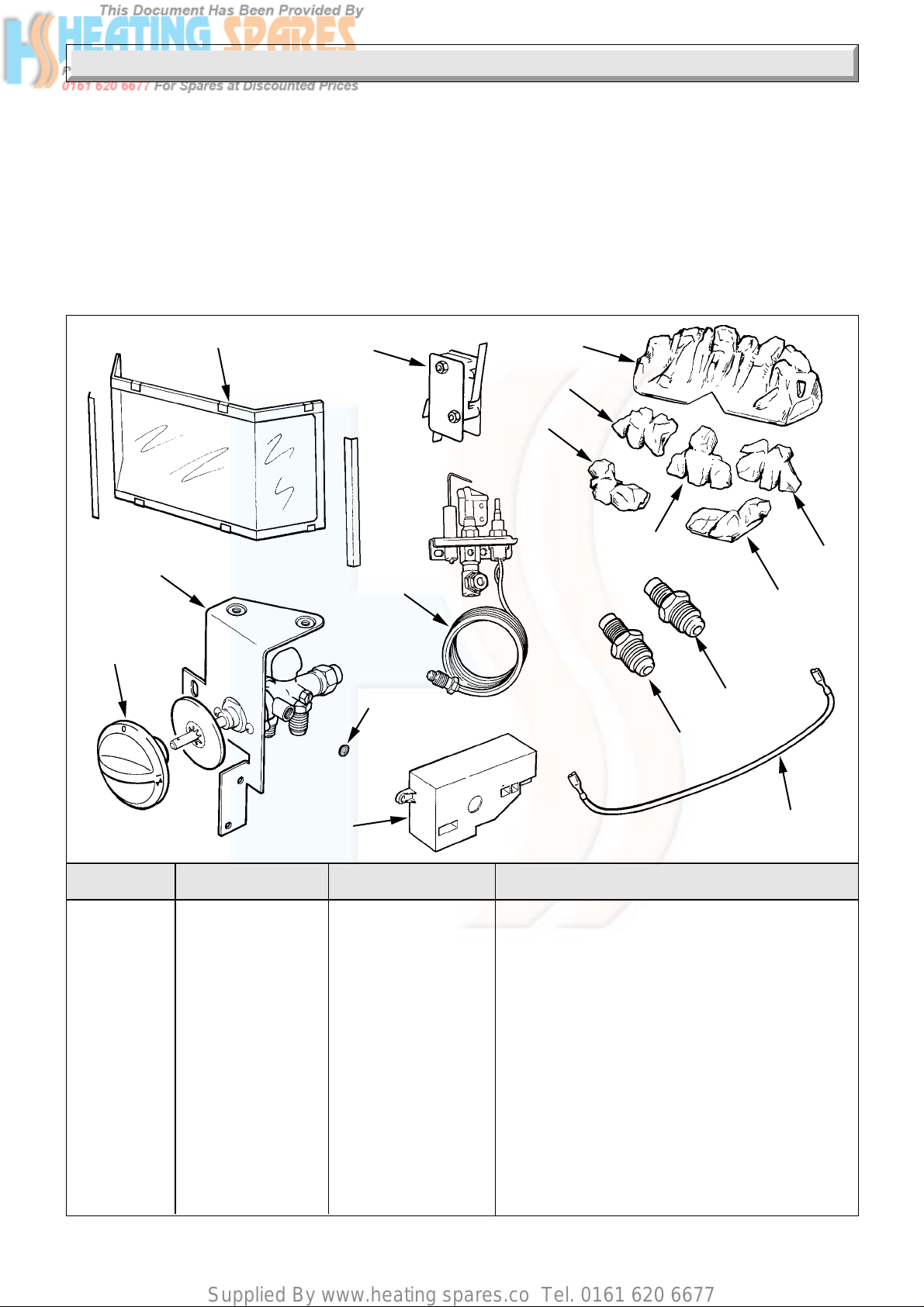

Replacement Parts

If replacement parts are required apply to your local supplier.

Please quote the name of the fire front, “Black Ash 3 BBU”, to

be found on the control knob bezel.

The back boiler serial number can be found on the base after

removal of the plinth.

The fire front serial number can be found on the chassis, visible

when the front casting is removed.

COMPLETED FUEL

EFFECT BED

This appliance is fitted with a flue blockage safety device which

will shut down the appliance in the event of abnormal flue

conditions. This device is NOT a substitute for an independently

mounted Carbon Monoxide detector.

Refit the plinth by carefully locating the top edge of the plinth into

the sliders, then push gently back as far as it will go.

UPPER SIDE

RETAINING

SCREW

3943 S

FIBRE

WASHER

7562

CANOPY

Ensure corners of fuel effect

pieces 4 and 5 are seated on

flat areas of fuel effect pieces

1, 2 and 3

LOCATING

Diagram 17

PIN

3947 S

SECURING

SCREW

SPARK

GENERATOR

ELECTRICAL

CONNECTIONS

R.H. SIDE

PANEL

LOCATING PIN

AND HOLE

Diagram 19

5283

9V ALKALINE

BATTERY

SECURING

SCREW

IGNITION

LEAD

LOCATING HOLE

Diagram 18

12221793A

Diagram 20

Page 13

Supplied By www.heating spares.co Tel. 0161 620 6677

1 General

FLAT AREA

FIRE FIXING

FACE

289mm

339mm

327mm

351mm

C

L

327mm

7595

690mm

351mm

Diagram 1.1

1 General Notes and Information

If this fire front is to be fitted to a Glow-worm Back Boiler

WITHOUT a flue blockage safety device refer to the

Supplementary Installation Instructions in the Instructions for

Use..

General Notes and Information

The Glow-worm Black Ash 3 BBU gas fire front is to be used with

specially designed Glow-worm 56/3e, 56/3pp, 45/2, 56/2, 45,

56, 45R or 56R Back Boiler Units only.

NOTE : If you are fitting the fire front to a 45/2 or 56/2 back boiler

unit you will have to use the additional kit No. 459319 supplied

with the fire front. If you are fitting the fire front to any of the other

back boiler units listed above, discard the kit as it not required.

This fire front and back boiler are NOT suitable for fitting to a

precast flue.

The fire front is delivered packed in two cardboard cartons,

which together contain all the parts necessary for the installation

of the fire front.

If the back boiler and fire front are to be installed at the same

please read both sets of instructions before starting.

Wherever possible, all materials, appliances and components

to be used shall comply with the requirements of applicable

British Standards.

Where no British Standards exist, materials and equipment

should be fit for their purpose and of suitable quality and

workmanship.

1.1 Important Notice

This fire front is for use only on G20 gas.

This fire front is fitted with a flue blockage safety device which

will shut down the fire if there is an unacceptable spillage of

products at the draught diverter. If the fire front shuts down

frequently for no apparent reason the first things to be checked

are the chimney and the air inlets into the room. An additional

cause could be that the filter, in the gas tap has become

blocked. Any problems found must be put right by a competent

person, before the fire front is used again.

Sheet Metal Parts

WARNING. When installing or servicing this fire front care

should be taken when handling metal parts (components) to

avoid any possibility of personal injury.

1.2 Statutory Requirements

The installation of this fire front must be carried out by a

competent person, in accordance with the current issue and

relevant requirements of:-

Manufacturer’s instructions, supplied.

The Gas Safety (Installation and Use) Regulations, The Building

Regulations, the Local Gas Undertaking, The Building Standards

(Scotland) Regulations (applicable in Scotland), The Health

and Safety at Work Act, Control of Substances Hazardous to

Health, The Electricity at Work Regulations and any applicable

local regulations.

Detailed recommendations are contained in the current issue of

the following British Standards and Codes of Practice:-

BS1251, BS5440 Part 1 and 2, BS5871, BS6891, BS7671.

Manufacturer’s notes must not be taken as overriding statutory

requirements.

13

221793A

Page 14

Supplied By www.heating spares.co Tel. 0161 620 6677

1 General

1.3 Data

Gas connection - from the service cock

Total weight - 49kg

Injector - upper - Bray 18/180

- lower - Bray 18/320

Burner pressure setting

- cold - 13.0mbar 5.2in wg

- hot - 13.2 mbar 5.3in wg

Heat input - gross 6.7kW - 22,750Btu/h

Heat output -nominal 4.4kW - 15,000Btu/h

Fire serial number - on chassis - visible when front

Data label - LH side of lower front baffle.

The fire front burner is lit by means of a battery operated

electronic spark generator unit.

All dimensions are given in millimetres (except as noted).

1.4 Fire Front Location

The back boiler must be correctly positioned in the builder’s

opening as the fire front is located by connection to it.

The back boiler air duct acts as a support for the fire front.

The top of the fire front must be secured to the vertical fire front

fixing wall face. This wall face may be a chimney breast or

surround, see diagram 1, (Instructions for Use).

The fire front flue spigot sticks out into the back boiler flue

collector assembly.

The gas supply is taken from the back boiler gas service cock.

casting is removed

1.5 Clearances

Restrictions must not be placed around the assembled fire

front, see diagram 1, (Instructions for Use).

A shelf or surround of a maximum depth of 150mm may be

fitted, provided clearances are as shown in

diagram 1, (Instructions for Use). However, for every extra

25mm above the fire front the depth of the shelf may be

increased by 25mm.

Combustible furniture or materials must not be placed closer

than 1metre in front of the fire front.

14221793A

Page 15

Supplied By www.heating spares.co Tel. 0161 620 6677

2 Types of Flue and Installation

Note. Refer to Section 2 in the Back Boiler Installation book

before starting.

2.1 With Hearth

A fireproof hearth under the fire front must have the minimum

dimensions as shown in diagram 2.1.

2.2 With Surround

See diagram 2.2. The fire front casing should cover the

opening.

A wider opening will require any opening left to be covered with

a non-combustible finished material, see diagram 2.3.

The surround must have a minimum clear, flat area as shown

in diagram 1, (Instructions for Use). Any projections on the

surround must be outside this area.

Any combustible material on the fire front fixing face area of the

surround must be removed, see diagram 2.3. This area, to the

depth removed, should then be rendered with a sand/cement

mixture.

2.3 Without Surround or Hearth

The fire front fixing wall face must be flat over an area as shown

in diagram 1, (Instructions for Use). This also shows the

minimum clearances for shelves or projections on the fire front

fixing wall face.

The information in the last two paragraphs of “With Surround”

should now be followed.

Under no account must carpet or other combustible material be

laid directly under the fire front, unless the minimum clearances

shown in diagram 2. (Instructions for Use) is achieved.

2.4 Flue

The back boiler flue collector assembly accepts the fire front flue

spigot.

Note. Provision must be made during the installation of the back

boiler for the total ventilation requirement for the combined

appliance. See relevant section in the Back Boiler Installation

Instructions.

7440

INSTALLATION CENTRE LINE

406mm to

460mm

FRONT

OPENING

280

C

L

280

220 220

7594

560mm

to

590mm

PREPARED

BASE

Diagram 2.2

3920s

1

50mm

2in. MIN.

/2in. 12mm

Noncombustible

material

760mm

30in

340mm

131/2in

Diagram 2.1

15

BUILDERS

OPENING

INSTALLATION

CENTRE LINE

REMOVE

COMBUSTIBLE

MATERIAL FROM

THIS AREA

C

L

PREPARED

BASE

680

560

135

Diagram 2.3

221793A

Page 16

Supplied By www.heating spares.co Tel. 0161 620 6677

3 Fire Front Preperation

FIRE BODY PACK

WALL

SEALING

PLATE

FIRE

BODY

ASSEMBLY

CASING PACK

FLUE SPIGOT

FUEL

EFFECT

BED

7880

COMBUSTION

CHAMBER

BOTTOM PLATE

7598

L.H. SIDE

PANEL

L.H. SIDE

CASTING

CANOPY

R.H. SIDE

PANEL

FRONT

CASTING

R.H. SIDE

CASTING

R.H. LEG

PLINTH

LOOSE

ITEMS

PACK

LITERATURE

L.H. LEG

16221793A

Diagram 3.1

Page 17

Supplied By www.heating spares.co Tel. 0161 620 6677

3 Fire Front Preperation

KEY

A

B

C

D

E

F

G

H

J

SCREW FRONT LEG

M5x30 LEVELLING SCREW

SCREW SIDE CASTINGS

M5x14 REAR FIXING

SCREW UPPER WALL

M5x40 MOUNTING

ANCHOR UPPER WALL

NUT MOUNTING

SCREW FRONT LEG

M4x8 FIXING

SCREW WALL SEALING

No. 10 x 11/2in. PLATE FIXING

WALL WALL SEALING

PLUG PLATE FIXING

KNURLED UPPER SIDE

SCREW RETAINING

SCREW FLUE SPIGOT

No. 8 x 3/8in. FIXING

BATTERY

7870

OLIVE (2)

CONTROL

KNOB

FIBRE WASHER (2)

TUBING

NUT

SIDE EXTENSION (2)

GAS

SUPPLY

PIPE

17

Diagram 3.2

221793A

Page 18

Supplied By www.heating spares.co Tel. 0161 620 6677

3 Fire Front Preperation

3.1 Unpacking

The fire front is delivered in two packs, one contains the body

assembly. The other contains the fire front castings, and loose

items pack. Refer to diagrams 3.1 and 3.2. to identify the parts.

To unpack carton 1, lift out the top fitting containing the fire

spigot and combustion chamber bottom plate, lift out the

cardboard front fitting, the supply tube pack and the two boxes

containing the fuel effect pieces.

Lift the outer carton clear to leave the fire front sitting in the base

tray.

To unpack carton 2, lift out the cardboard tray containing the

plinth and side panels. Lift out the loose items pack, legs box

and canopy. Remove the internal cardboard fitting and lift out

the lower front and side castings.

Put these items on one side until required. Check contents of

loose items pack against list.

Remove the glass front panel, see diagram 9. (Instructions for

Use).

It is suggested that the side extensions, from the castings pack,

be fitted at this time to the left and right hand side panels.

NOTE: These are a slide fit onto the louvres.

3.2 Flue Spigot Assembly

Note. This is marked “Homeglow BBU”

Leave the fire front sitting in the base tray.

Secure the spigot assembly to the fire front back with the self

taping screws provided, in the loose items pack, see diagram

3.3.

FLUE SPIGOT ASSEMBLY

7591

SECURING

SCREW (7)

J

Diagram 3.3

3.3 Battery

Remove the fire front from the base tray.

Take the battery from the fittings pack and fit as shown in

diagram 20, (Instructions for Use), make sure that the terminals

are correctly fitted.

18221793A

Page 19

Supplied By www.heating spares.co Tel. 0161 620 6677

3 Fire Front Preparation

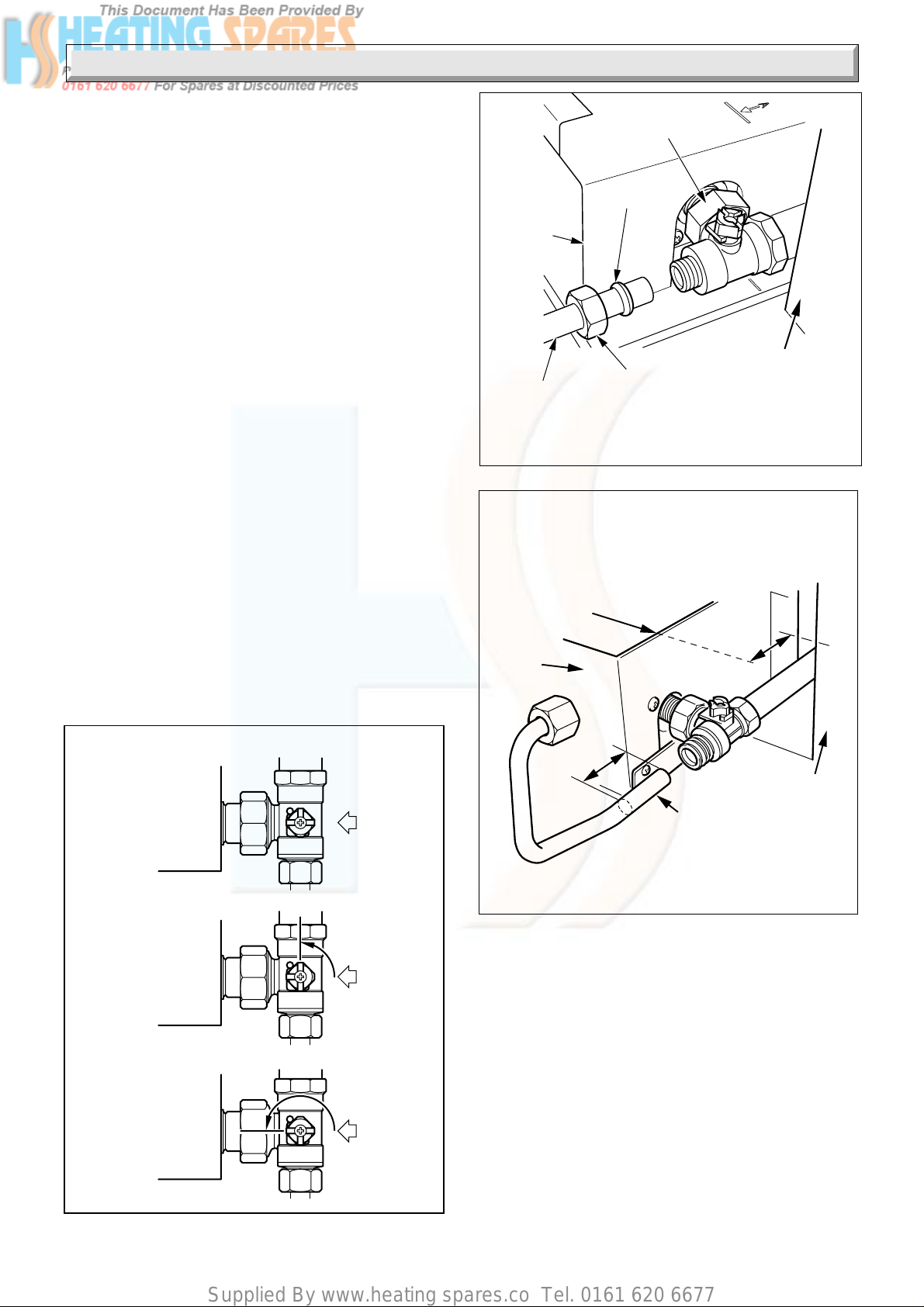

3.4 Gas Supply to Fire Front (Fitting to 56/3e

and 56/3pp Back Boiler Units ONLY)

Check that gas service cock on the boiler is in the Off position,

see diagram 3.4.

The inlet supply tube is packed with the fire front and will require

cutting to fit the gas service cock on the back boiler unit.

Remove glass panel, connect inlet supply tube to bulkhead, see

diagram 4.9. To measure the correct length of gas supply

tubing, the fire front will have to be temporarily positioned

against the fire fixing wall face, see diagram 3.5. Mark position

and cut, deburr the tube end inside and out. Replace glass

panel.

3.5 Gas Supply to Fire Front (Fitting to 45/2

and 56/2 Back Boiler Units ONLY)

Check that gas service cock on the boiler is in the Off position,

see diagram 3.4.

The inlet supply tube is packed with the fire front plinth in the

loose items pack.

This supply tube may need to be cut, at the plain end, dependent

on the model and position of the back boiler in the opening.

Measure the distance “C”, see diagram 3.6, from the front mark

“P” on the air duct to the fire front fixing wall face.

Use a straight edge across the opening.

Shorten the plain end of the gas supply tube by the distance “C”.

No shortening is required when “P” is level with the fire front

fixing wall face, “C” being zero.

The maximum distance for “C” will be 67mm.

Deburr the tube end inside and out.

GAS SERVICE

COCK

BACK

OLIVE

BOILER

AIR

DUCT

FIRE FIXING

GAS FIRE

UNION

NUT

WALL FACE

SUPPLY TUBE

56/3e and 56/3pp

Back Boiler Units ONLY)

*'C' = Distance from fire fixing wall face to datums

on back boiler air duct. This represents the

length of pipe that requires cutting off.

'P'

BACK

BOILER

AIR

DUCT

Diagram 3.5

*'C'

7163

BACK

BOILER

ONLY 'ON'

TURNED

FULLY

CLOCKWISE

BACK

BOILER &

FIRE FRONT

'ON' TURNED

TO MID

POSITION

'OFF'

TURN FULLY

ANTICLOCKWISE

90˚

180˚

Diagram 3.4

7595

*'C'

45/2 and 56/2

Back Boiler Units ONLY)

FIRE FIXING

WALL FACE

GAS FIRE

SUPPLY TUBE

Diagram 3.6

19

221793A

Page 20

Supplied By www.heating spares.co Tel. 0161 620 6677

4 Installation

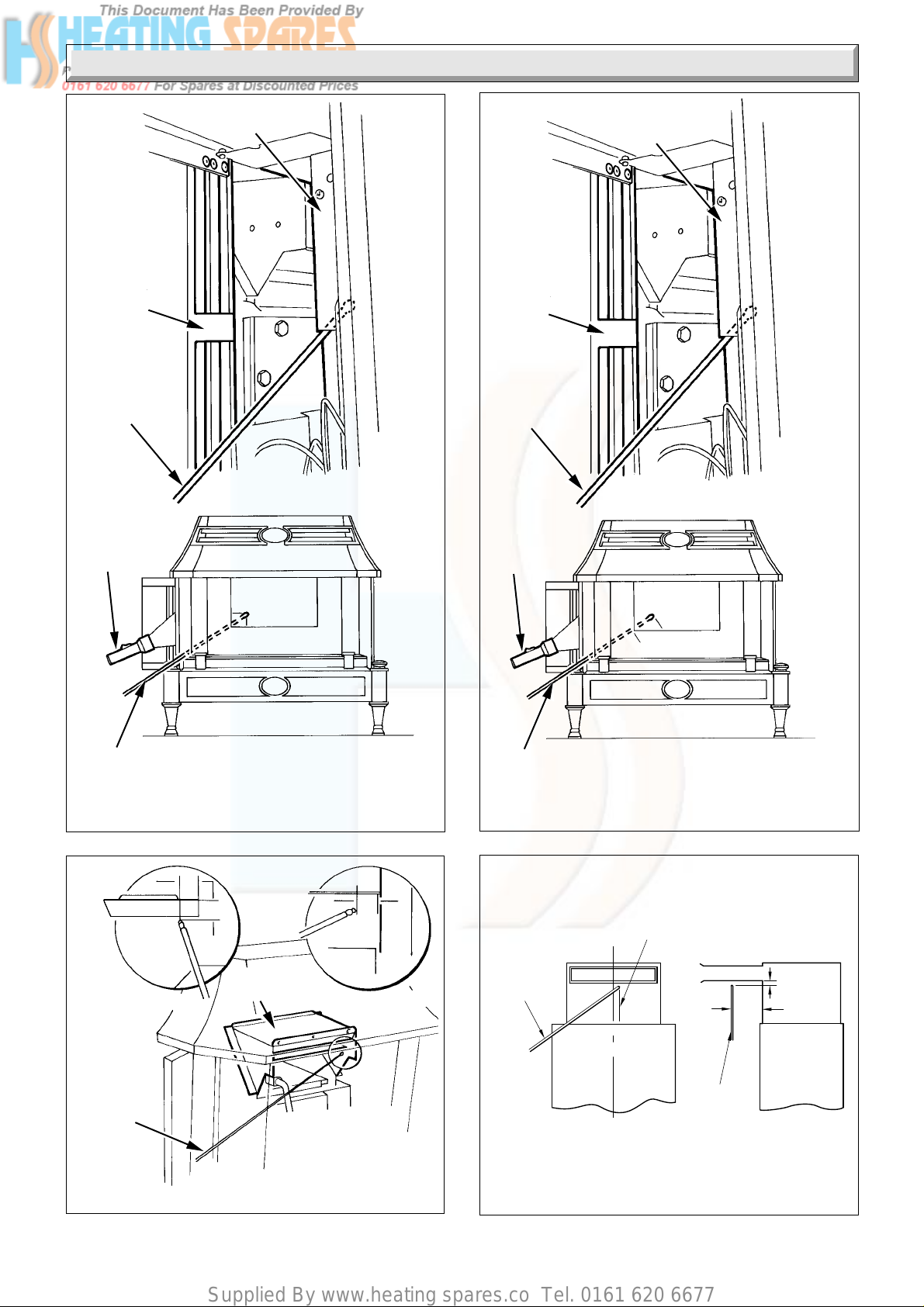

4.1 Positioning the Fire Front (Fitting to 56/3e

and 56/3pp Back Boiler Units ONLY)

Place the wall sealing plate onto the back boiler air duct, mark

the fixing holes, remove the plate and drill the holes to suit the

plugs and screws provided, in the supply tube pack, leave

sufficient screw proud to accept the wall sealing plate keyholes,

see diagram 4.1.

Fit the wall sealing plate and tighten the screws, making sure

that the “wings” are flush with the fire fixing wall face, see

diagram 4.1.

Place the fire front onto the back boiler air duct, check that the

fire front flue spigot is central in the flue collector assembly, push

into contact with the fire front fixing wall face.

Mark the fire front fixing points through the mounting bracket

holes, at the top, see diagram 4.2.

Pull the fire front forwards and remove.

Drill the fire front fixing wall face, using a 10mm masonry drill to

a minimum depth of 40mm to accept the anchor nuts and

screws, supplied in the loose items pack.

Place anchor nuts and screws into holes, screw up, but leave

sufficient thread proud the accept the fire front.

Note. If the fire front fixing face is not of a solid construction, to

a minimum depth of 40mm, that is, hollow brick or metal an

alternative and rigid form of fastening must be used and extra

care taken.

4.2 Securing (Fitting to 56/3e and 56/3pp Back

Boiler Units ONLY)

Refer to diagrams 4.2 and 4.3.

Offer the fire front up to engage fire front spigot, position

mounting bracket holes over the screws in fire front fixing wall

face.

Push back to locate flue spigot into flue spigot duct, lift slightly

to engage mounting bracket onto screws.

Tighten up securing screws.

MARK

FRONT

FIXING

HOLES

MOUNTING

BRACKET (2)

FLUE

COLLECTOR

ASSEMBLY

7868

SPIGOT

FIRE FRONT

Diagram 4.2

7593

G

F

56/3e and 56/3pp

Back Boiler Units ONLY)

FIRE FIXING

WALL FACE

FLUE

SPIGOT DUCT

BACK

BOILER

AIR DUCT

Diagram 4.1

7867

SECURING

SCREW (2)

C

SECURING

SCREW (2)

ANCHOR

NUT (2)

C

D

Diagram 4.3

20221793A

Page 21

Supplied By www.heating spares.co Tel. 0161 620 6677

4 Installation

4.3 Gas Connection (Fitting to 56/3e and

56/3pp Back Boiler Units ONLY)

Place the tubing nut and olive, from the loose items pack, onto

the prepared end of the gas supply tube, see diagram 4.9.

Connect the gas supply, as diagram 4.9, tighten the nut and

olive at the gas service cock.

To tighten the other end, use a spanner to hold hexagon locknut

(A) at the bulkhead fitting and make sure that it does not turn,

tighten union nut (B) on the supply tube in the usual manner, see

diagram 4.9.

Make sure that joint (B) is checked for gas soundness, by

checking it when carrying out the other gas soundness checks

as in Section 5.1.

Fit the left hand side panel, see diagram 4.10.

FILTER

SENSING

TUBE

FITTING

ASSEMBLY

3 mm

BACK

BOILER

SENSING TUBE

TUBING

NUT

BULKHEAD CONNECTION

BOILER AIR DUCT

45/2 and 56/2

Back Boiler Units ONLY)

THREAD CUTTING

SCREW(Taptite)

SENSING

TUBE

FITTING

ASSEMBLY

FRONT FACE

OF BOILER

CASTING

Diagram 4.4

4.4 Back Boiler Sensing Tubes (Fitting to 45/2

and 56/2 Back Boiler Units ONLY)

Note: The gas supply tube, see diagram 4.9, is supplied with the

fire. The back boiler sensing tube assembly is packed in the

additional kit no. 459319.

Remove and discard the plastic ferrule, if fitted, from the

bulkhead connection on the Back Boiler air duct.

Fix the flared end of the back boiler sensing tube to the bulkhead

connection on the boiler air duct with the tubing nut provided.

Slide the sensing tube fitting assembly over the back boiler

sensing tube and fix to the casting with the thread cutting screw

(taptite) provided, see diagram 4.4. Fit the sensing tube filter

onto the fitting assembly, see diagram 4.4. Take care not to

damage the filter.

IMPORTANT: Make sure that the sensing tube fitting assembly

is pushed back to the front face of the boiler casting and check

3mm. distance is achieved and back boiler sensing tube does

not extend above sensing tube fitting, see diagram 4.4.

6138

Note: After fitting the flue blockage safety device sensing tube

please refer to the 'Commissioning' section of the back boiler

unit and relight the boiler to test the device.

Check that the gas service cock on the boiler is in the Off

position, see diagram 3.5.

Using a suitable tool break off and discard the shaded section

of wall sealing plate shown in diagram 3.1.

Place the wall sealing plate onto the back boiler air duct, mark

the fixing holes, remove the plate and drill the holes to suit the

plugs and screws provided, in the supply tube pack, leave

sufficient screw proud to accept the wall sealing plate keyholes,

see diagram 4.5.

Fit the wall sealing plate and tighten the screws, making sure

that the “wings” are flush with the fire fixing wall face, see

diagram 4.5.

MARK

FRONT

FIXING

HOLES

SPIGOT

8000

7998

G

F

NOTE:

WINGS

FLUSH

WITH

WALL

Diagram 4.5

21

FLUE

COLLECTOR

ASSEMBLY

FIRE FRONT

Diagram 4.6

221793A

Page 22

Supplied By www.heating spares.co Tel. 0161 620 6677

4 Installation

4.5 Positioning the Fire Front (Fitting to 45/2

and 56/2 Back Boiler Units ONLY)

Place the fire front onto the back boiler air duct, check that the

fire front flue spigot is central in the flue collector assembly, push

into contact with the fire front fixing wall face, see diagram 4.6.

Mark the fire front fixing points through the mounting bracket

holes, at the top, see diagram 4.6.

Pull the fire front forwards and remove.

Drill the fire front fixing wall face, using a 10mm masonry drill to

a minimum depth of 40mm to accept the anchor nuts and

screws, supplied in the loose items pack.

Place anchor nuts and screws into holes, screw up, but leave

sufficient thread proud the accept the fire front.

Note. If the fire front fixing face is not of a solid construction, to

a minimum depth of 40mm, that is, hollow brick or metal an

alternative and rigid form of fastening must be used and extra

care taken.

4.6 Securing (Fitting to 45/2 and 56/2 Back

Boiler Units ONLY)

Offer the appliance up to the back boiler air duct and push back

into position, lift slightly to engage mounting bracket onto

screws, see diagram 4.7.

Tighten the fire front fixing screws, see diagram 4.8.

4.7 Gas Connection (Fitting to 45/2 and 56/2

Back Boiler Units ONLY)

Place the tubing nut and olive, from the loose items pack, onto

the prepared end of the gas supply tube, see diagram 4.9.

Connect the gas supply, as diagram 4.9, tighten the nut and

olive at the gas service cock.

To tighten the other end, use a spanner to hold the locknut (A)

at the bulkhead fitting and make sure that it does not turn,

tighten union nut (B) on the supply tube in the usual manner, see

diagram 4.9.

Make sure that joint (B) is checked for gas soundness, by

checking it when carrying out the other gas soundness checks

as in Section 5.1.

Fit the left hand side panel, see diagram 4.10.

FRONT

FIXING

SCREW

BACK

BOILER

AIR

DUCT

SPIGOT

8001

MOUNTING

BRACKET

C

SECURING

SCREW (2)

ANCHOR

NUT

7874

C

SECURING

SCREW (2)

M5 x 40mm

D

FLUE

COLLECTOR

FIRE FRONT

ASSEMBLY

Diagram 4.7

22221793A

Diagram 4.8

Page 23

Supplied By www.heating spares.co Tel. 0161 620 6677

4 Installation

LOCK

NUT (A)

JOINT (C)

3929 S

UNION

NUT (B)

GAS SUPPLY

PIPE

GAS SERVICE COCK

TUBING

NUT

FIBRE

WASHER

UPPER

SIDE

RETAINING

SCREW

H

LOCATING PIN

AND HOLE

UPPER

SIDE

RETAINING

SCREW

H

FIBRE

WASHER

OLIVE

Diagram 4.9

7588

R.H. SIDE

PANEL

GAS CONTROL

KNOB

L.H. SIDE

PANEL

LOCATING PIN

AND HOLE

23

R.H. SIDE PANEL

LOCATING PIN

AND HOLE

Diagram 4.10

221793A

Page 24

Supplied By www.heating spares.co Tel. 0161 620 6677

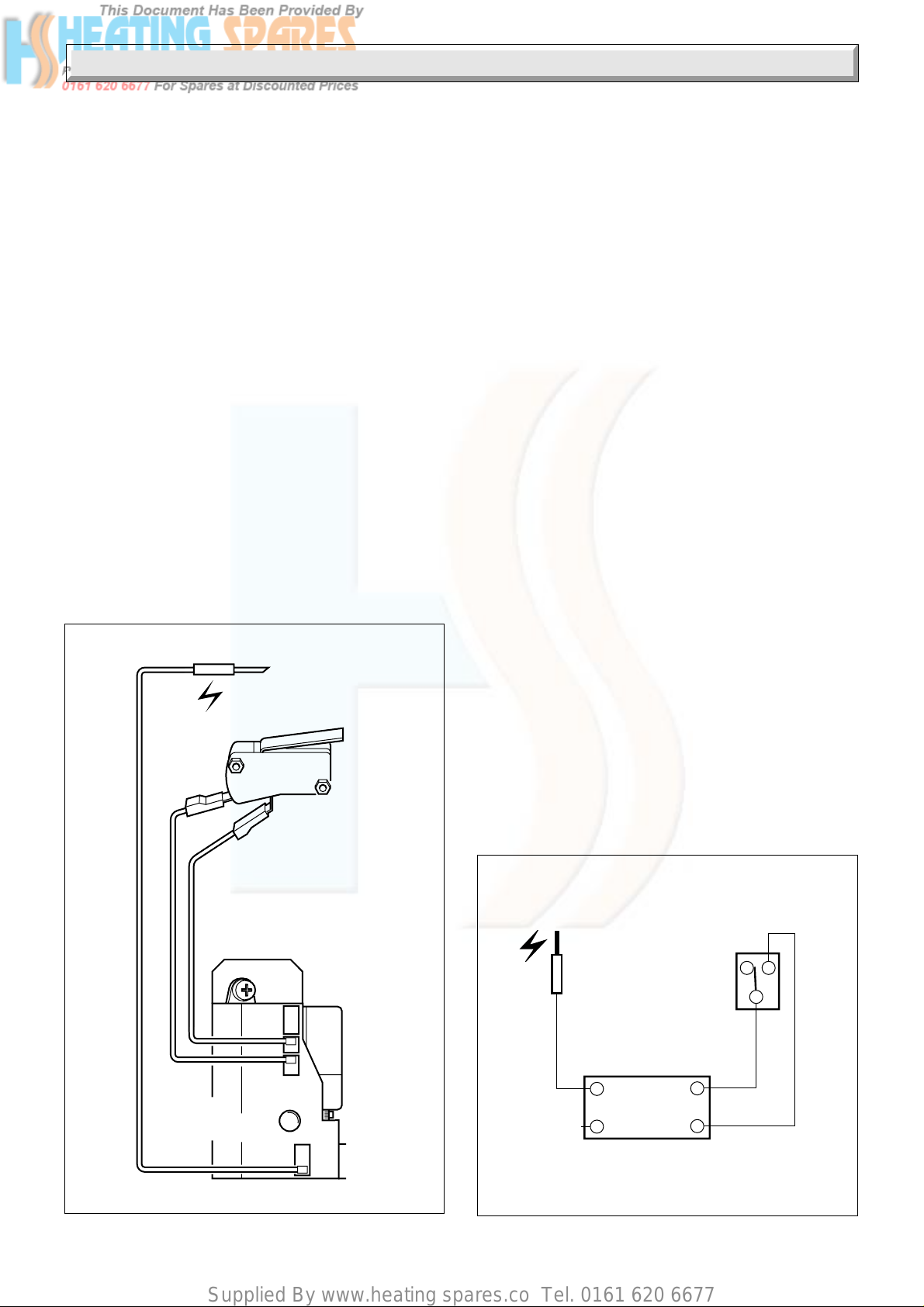

5 Lighting, Testing and Fitting Internal Parts

5.1 Lighting and Testing

Make sure that the electrical supply to the back boiler is isolated.

This fire front is fitted with a flue blockage safety device which

will shut down the fire if there is an unacceptable spillage of

products at the draught diverter. If the fire front shuts down

frequently for no apparent reason the first things to be checked

are the chimney and air inlets into the room. An additional cause

could be that the filter, in the gas tap, has become blocked. Any

problems found must be put right by a competent person before

the fire front is used again.

The flue blockage safety device MUST NOT be adjusted or

disconnected. If replacing use only the correct and approved

parts.

Remove the pressure test nipple screw and fit a suitable

pressure gauge, see diagram 5.1.

Place the right hand side panel onto the pins, see diagram 4.10,

but do not secure at this time.

Turn the gas service cock to back boiler and fire ON, see

diagram 3.5.

Using the pressure drop method check for gas soundness. If

necessary apply a suitable leak detection fluid to all joints,

replace glass panel, see diagram 9 (Instructions for Use).

Fit the control knob to the tap spindle, see diagram 5.2.

IMPORTANT NOTE. If the burner does not light within three

seconds, release the tap, wait ten seconds and repeat the

lighting operation.

Push the control knob fully in and turn it anti-clockwise to 1

- ignition, see diagram 5.2, clicking of the ignition will be heard

and the burner will light.

Keep the knob pushed in for ten seconds, to energise the flame

supervision device, during this time the ignition system will

continue to operate, indicated by the clicking.

Air may be present in the supply to the fire front so that the initial

lighting operation may need to be repeated.

With the burner lit, visually check for leaks whilst changing tap

settings.

To change settings:

0 - 1 Push in and turn

1 - 2 Push in and turn

2 - 3 Push in and turn

3 - 4 Push in and turn

If the burner goes out, wait three minutes before relighting, for

any other reason wait for two minutes.

Check that the gas pressure is as stated in the Data Section 1.3,

or on the Data Label on the left side lower front baffle, see

diagram 5.3.

If there is any doubt about the gas rate, check at the meter,

having first turned off all other gas appliances and pilot lights.

The rate for this fire front, after ten minutes, is about 2.7minutes

3

.

for 1ft

Turn the burner off, remove control knob, release right hand

side panel and pressure gauge, replace the test point screw and

make sure a gas tight seal is made.

Refit, close and secure the side panels, see diagram 4.10.

GAS

TAP

VERTICAL

5082

GAS

CONTROL

KNOB

APPLIANCE

OFF

FLAT DOWN

POSITION

IGNITION &

POSITION 1

PRESSURE

TEST

POINT

Diagram 5.1

POSITION 2

5081

24221793A

POSITION 4POSITION 3

Diagram 5.2

Page 25

Supplied By www.heating spares.co Tel. 0161 620 6677

5 Lighting, Testing and Fitting Internal Parts

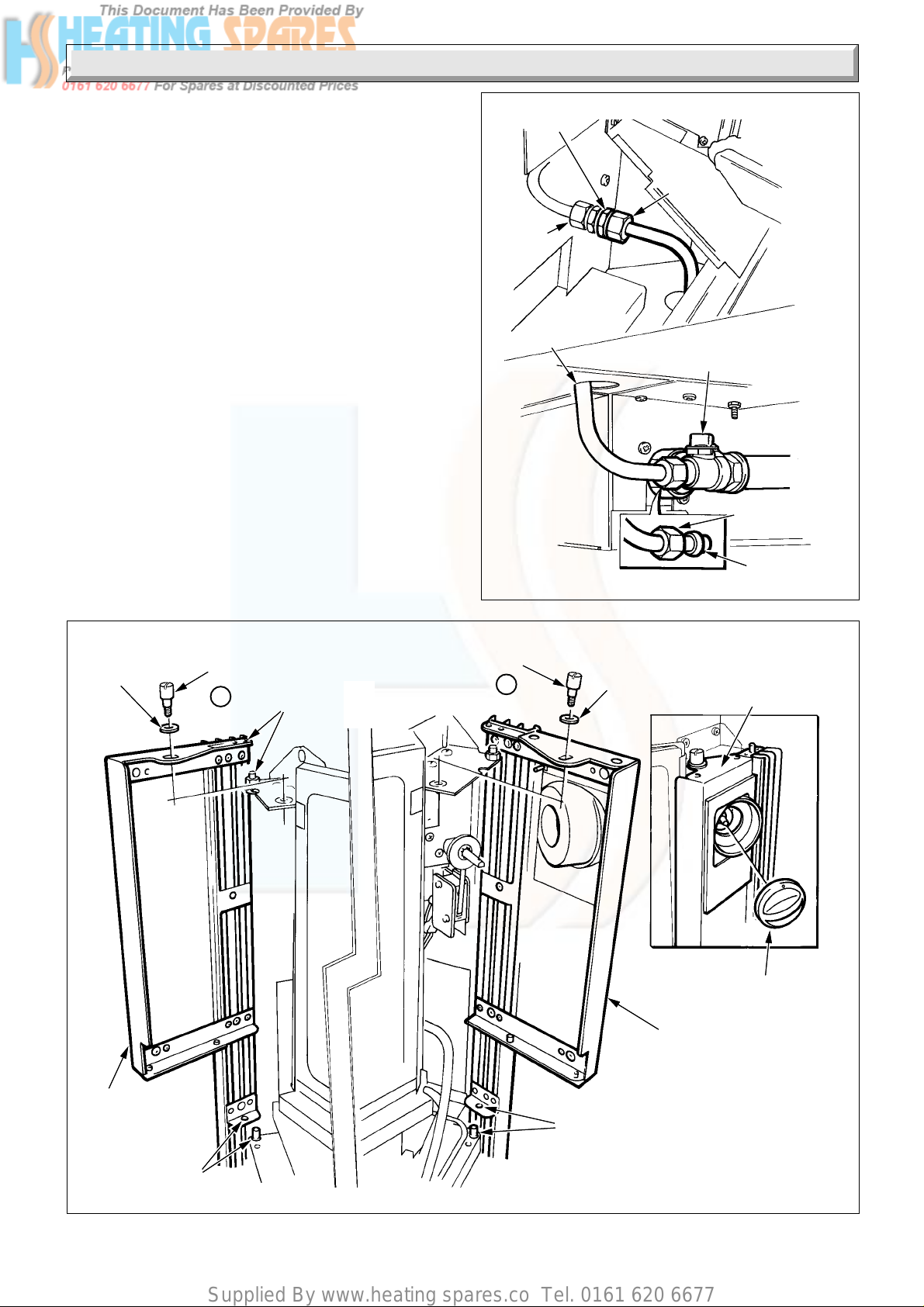

5.2 Internal Parts - Fitting

Caution. If any of the internal fire front parts are damaged DO

NOT light or further test the fire front until replacement parts are

fitted.

Refit gas tap control knob.

Swing the side panels out by about 5mm, to their stops.

Warning. The Glass panel can be hot.

Remove the glass panel, see diagram 9. (Instructions for Use).

Fit the combustion chamber bottom plate (inside base tray), see

diagram 5.3. Follow sequence in diagram 10 to 17. (Instructions

for Use) to fit fuel effect base and internal fire front parts.

Note. The fuel effect pieces are marked on their backs.

Replace front glass panel.

5.3 Decorative Castings

Fit the front legs as diagram 5.4.

Fit the decorative side castings as diagram 5.5, front casing as

diagram 5.6, replace glass panel assembly as diagram 9.

(Instructions for Use) and canopy as diagram 18. (Instructions

for Use).

5.4 Heat Settings

Light the fire front burner as the relevant part of

Section 6.1.

Refer to diagram 5. (Instructions for Use).

At tap position 1 - centre section flame effect.

At tap position 2 - centre section flame effect with

outer sections fuel bed glow.

At tap position 3 - centre and outer sections flame

effect with fuel bed glow.

At tap position 4 - (full on) full flame effect and fuel

bed glow.

In the unlikely event of the flame going out when the fire front

burner is on, then turn off. Wait three minutes before relighting.

If relighting for any other reason, wait two minutes before doing

so.

8055

COMBUSTION

CHAMBER

BOTTOM PLATE

5.5 Test for Clearance of Products

Notes

WARNING. Take care, the appliance will get hot during tests.

For the test you will need a smoke match, extension and a torch.

IN ALL CASES, if spillage continues after the specified test

periods steps must be taken to put the fault(s) right.

Possible causes include, flue obstruction, down draught or

restricted fresh air supply into the room.

If the problem cannot be put right the appliance must be

disconnected and expert advice sought.

Test Where No Fan is Present

Close all outside doors and windows in the room where the

appliance is installed.

Light the fire front only and set tap position to 4. After five

minutes apply a spillage test as shown in diagram 5.7 for the

45/2 and 56/2 or diagram 5.9 for the 56/3. During tests smoke

should be drawn into the fire draught diverter and the boiler

draught diverter.

If spillage occurs, leave the fire front alight for up to a further ten

minutes and repeat test. Turn the fire front burner off.

Next light the back boiler only. After ten minutes apply spillage

test as shown in diagram 5.8 for the 45/2 and 56/2 or diagram

5.10 for the 56/3. During tests smoke should be drawn into the

fire front draught diverter and boiler draught diverter.

If spillage occurs, leave the back boiler alight for up to a further

five minutes and repeat tests.

Leave the back boiler alight.

Now light the fire front. After ten minutes apply spillage tests as

shown in diagram 5.7 and 5.8 for the 45/2 and 56/2 or diagrams

5.9 and 5.10 for the 56/3. During tests smoke should be drawn

into the fire draught diverter and boiler draught diverter.

If spillage occurs leave back boiler and fire front alight for up to

a further five minutes and repeat tests.

Test Where a Fan is Present

A fan means an extract fan or a fan for other open flued

appliances or a circulating fan for a warm air unit, whether or not

gas fired. With the fan switched off carryout the appropriate

spillage test with all doors and windows closed, as Test Where

No Fan is Present.

If the above spillage test is satisfactory carry on as follows:

Open all doors connecting the room containing the appliance

and the room in which the fan is fitted.

Close all other doors and windows in the premises.

If the fan is in the same room as the appliance, close all doors

and windows in that room.

Switch the fan on and repeat the spillage test as above.

5.6 Plinth Fitting

Fit the controls cover plinth onto the guides and push it back as

far as it will go, see diagram 3. (Instruction for Use).

DATA

LABEL

Diagram 5.3

25

221793A

Page 26

Supplied By www.heating spares.co Tel. 0161 620 6677

5 Lighting, Testing and Fitting Internal Parts

LEG

SECURING

E

SCREW (2)

FOOT

LEVELLING

SCREW

Diagram 5.4

A

7564

3944S

LOCATION PIN

LOCATION

SLOT

VIEWED FROM REAR

3945S

SECURING

B

SCREW (3)

M5 x 14mm

SIDE CASTING

FRONT

CASTING

Diagram 5.6

Diagram 5.5

26221793A

Page 27

Supplied By www.heating spares.co Tel. 0161 620 6677

5 Lighting, Testing and Fitting Internal Parts

10mm

40/

45mm

15mm to right of centre

SMOKE

MATCH

AND

EMPLUME

TUBE

EMPLUME

TUBE

FRONT VIEW

SIDE VIEW

HEA T

EXCHANGER

L.H. SIDE

PANEL

SMOKE

MATCH

AND

EMPLUME

TUBE

DRAUGHT

DIVERTER

7876

L.H. SIDE

PANEL

SMOKE

MATCH

AND

EMPLUME

TUBE

DRAUGHT

DIVERTER

7879

TORCH

SMOKE MATCH

AND EMPLUME

TUBE

(45/2 and 56/2 ONLY)

10

10

SIDE VIEW

25

25

DIVERTER

PLATE

Diagram 5.7

10

FRONT VIEW

5176

TORCH

SMOKE MATCH

AND EMPLUME

TUBE

(56/3e and 56/3pp ONLY)

60

Diagram 5.9

7909

560 SMOKE

MATCH

AND

EMPLUME

TUBE

(45/2 and 56/2 ONLY)

FIRE SPIGOT NOT

SHOWN FOR CLARITY

Diagram 5.8

(56/3e and 56/3pp ONLY)

27

Diagram 5.10

221793A

Page 28

Supplied By www.heating spares.co Tel. 0161 620 6677

6 Instructions for Use

Hand these instructions the user and instruct in the safe and

economical use of the fire front and back boiler.

Advise the customer that they should read their Users

instructions before operating the fire and always follow the

advice in the Section headed “Cleaning your Fire”.

Advise that any smell which may be apparent on initial lighting

is quite normal and it will quickly disappear.

Important: Advise that soft wall coverings, for example, blown

vinyl wallpaper, are easily affected by heat, they may, therefore,

scorch or become discoloured when close to a heating appliance.

This should be borne in mind when having a heating appliance

installed and when redecorating.

Advise the user, to ensure the continued efficient and safe

operation of the appliance it is recommended that it is checked

and serviced as necessary at regular intervals. The frequency

of servicing will depend upon the particular installation and

usage, but in general once a year should be enough.

Draw attention, if applicable, to the current issue of the Gas

Safety (Installation and Use) Regulations, Section 35, which

imposes a duty of care on all persons who let out any property

containing a gas appliance.

It is the Law that servicing is carried out by a competent person.

Show how to light the fire front, in the event of a power or ignition

system failure, with a spill or long match.

Remove the front casting.

Hold a lighted spill or long match and insert it beneath the front

lighting assembly, position the spill so that the flame is over the

burner, see diagram 6.1.

Keep the spill in position, push in and turn the gas tap to position

1 and the burner will light keep knob pushed in for about 10

seconds and the burner will stay light.

If the burner should go out repeat the above operation, but now

keep the knob pushed in for a little longer.

Once lit operate the gas tap normally.

This is a temporary measure only and the fault must be put right

as soon as possible.

Advise the user of the precautions necessary to prevent damage

to the system, boiler and the building, in the event of the heating

system being out of use during frost or freezing conditions.

Advise that the fire front is fitted with a safety device and refer

to the instructions for use.

Reminder, leave these instructions with the user.

Advise the user that the ‘Benchmark’ logbook should be

completed by the installation engineer on completion of

commissioning or servicing.

MATCH OR

EXTENSION

BURNER

MATCH OR

SPILL

Diagram 6.1

7432

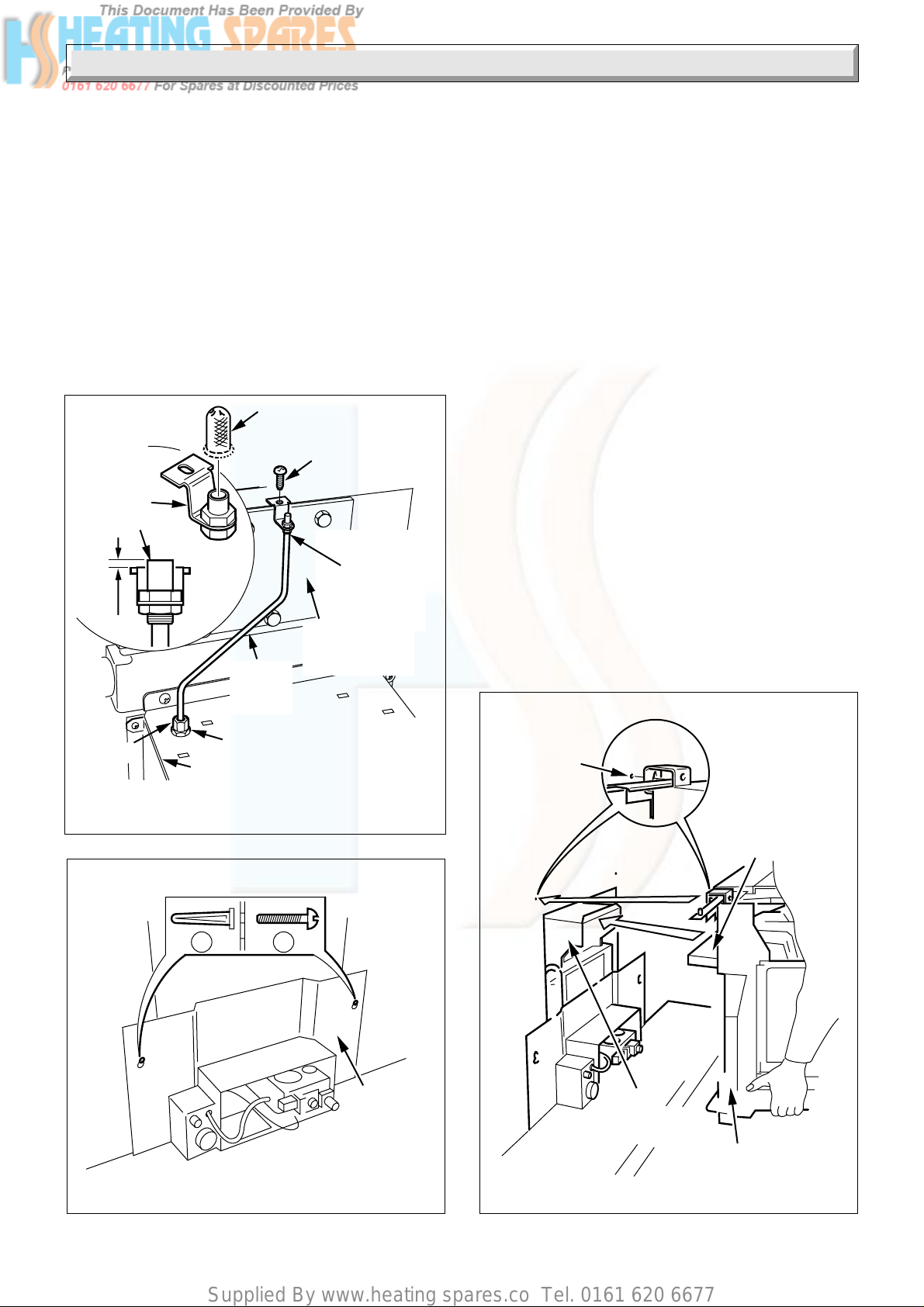

7 Servicing and Replacement of Parts

3 Flue Systems

Notes

To ensure the continued efficient and safe operation of the

appliance it is recommended that it is checked and serviced at

regular intervals. The frequency of servicing will depend upon

the particular installation and usage, but in general once a year

should be enough.

It is the Law that servicing is carried out by a competent person.

Make sure that the fire is cold before carrying out any servicing.

After servicing, or replacing parts, always test for gas soundness

with a suitable leak detection fluid. To test the gas tap, refix the

fire front and apply leak detection fluid to all joints, replace the

glass panel, light the burner and visually check all joints for

leakage whilst changing tap settings.

Carry out functional check on controls, see Section 4 and 5.

Other than for replacing the glass panel, internal fire front parts

and lighting the fire front should be removed from its fixings by

reversing the instructions in Section 4 and 5. Make sure that

the side panels and feet are removed. Refit controls cover plinth

so that the fire can stand upright.

Unless stated otherwise reassembly all parts in the reverse

order to removal.

The back boiler should be serviced at this time, refer to Back

Boiler Installation and Servicing Instructions.

The flue blockage safety device MUST NOT be adjusted or

disconnected. If replacing use only the correct and approved

parts.

7.1 Glass Panel

Lift canopy off, see diagram 18. (Instructions for Use). Take care

as it is made of cast iron.

Swing open side panels to their stops, about 5mm, as diagram

8 (Instructions for Use).

To remove the glass panel, refer to diagram 9. (Instructions for

Use).

7.2 Internal Fire Front Parts

Remove internal fire front parts as diagrams 17 to 10. (Instructions

for Use).

Examine these parts and replace as necessary.

28221793A

Page 29

Supplied By www.heating spares.co Tel. 0161 620 6677

7 Servicing and Replacement of Parts

4854

LOWER

FRONT

BAFFLE

SECURING SCREWS (3)

SECURING SCREWS (2)

BURNER

BAFFLE

7.3 Burner and Injectors

Remove the front casting, see diagram 5.6.

Remove the lower front baffle, see diagram 7.1.

Remove the burner baffle, see diagram 7.1.

Remove the RH. leg, see diagram 5.4.

Remove the side castings, see diagram 5.5.

Remove the RH. leg support bracket, see diagram 7.2.

Disconnect the supply pipe unions at the injectors also the union

connection at the front, see diagram 7.3.

Remove the two burner securing screws, see diagram 7.3.

Swing the burner out for access, see diagram 7.4.

Unscrew the injectors, inspect, clean or replace as necessary,

see diagram 7.5.

Do not clean the holes with a wire or sharp instrument.

Remove injector box cover screw and plate, see diagram 7.5,

clean out dust and debris. Brush away any lint and dust from the

burner and surrounds. Using a soft brush or vacuum cleaner.

Do not use a brush with wire bristles.

7.4 Flue blockage safety device

Remove the burner, refer to Section 7.3.

Check the condition of the electrode and thermocouple, clean

with a soft brush, see diagram 7.7.

Make sure the electrode is in line with the earth post and spark

gap is as in diagram 7.7.

7.5 Ignition Lead

Remove the burner, refer to Section 7.3.

Disconnect the tube nuts, remove the mounting bracket securing

screws and flue blockage safety device, see diagram 7.6.

Check the ignition lead, see diagram 7.7. Replace if required,

refer to Section 9.5.

Note. When refitting the flue blockage safety device, take care

not to trap the ignition lead under the mounting bracket.

7.6 Gas Tap and Micro Switch Assembly

Note. This item need not be serviced annually.

Remove micro switch electrical connections, see diagram 7.8

Disconnect all union connections and remove the tubes in the

order shown in diagram 7.9.

Take care as the filter in the pilot port may be loose, see diagram

7.11.

Disconnect the thermocouple nut, see diagram 7.10.

When replacing only tighten the nut a quarter turn beyond finger

tight.

Remove the gas tap bracket securing screws, see diagram

7.11.

Remove the gas tap assembly.

To service the gas tap remove the gas tap niting plate assembly

securing screws, see diagram 7.11. Take care as there is a

spring beneath the niting plate. Remove the plug, pin, spring

washer, plain washer and “O” ring, see diagram 7.11.

Clean and relubricate using a suitable grease.

When replacing make sure the operating disc, with retaining

washer and micro switch leads are correctly located, see

diagram 7.8 and 7.11.

29

Diagram 7.1

5080

Diagram 7.2

221793A

Page 30

Supplied By www.heating spares.co Tel. 0161 620 6677