Page 1

318504

Operation Manual

Contents subject to change without notice

Version 1.0

Issue AA

Page 2

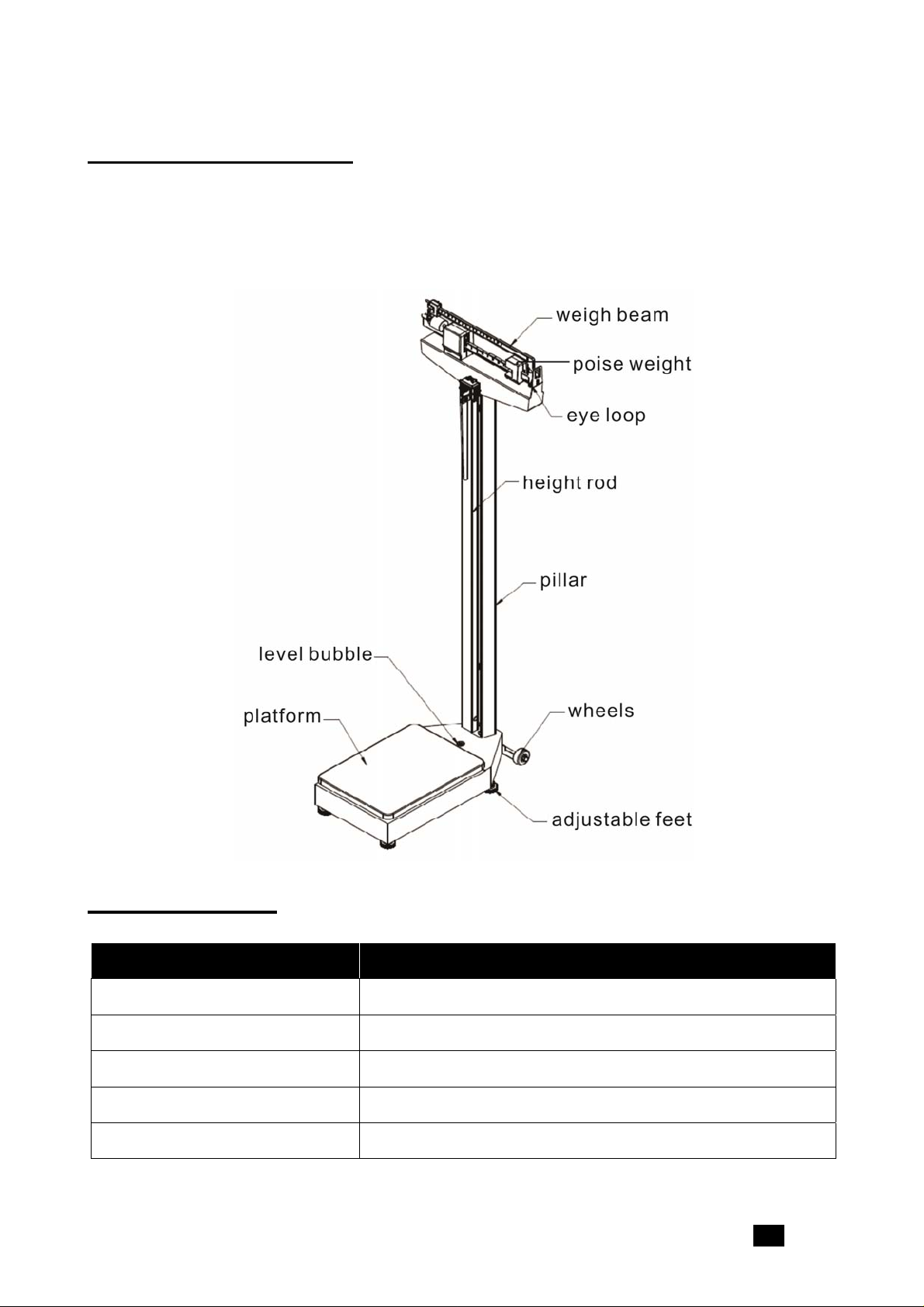

General Information

The 318504 Mechanical Physician Scale is ideal for use in health clinics and medical

practices for height and weight measurement. The scale is durable, having a sturdy

enameled steel body, removable slip-resistant plastic cover, a retractable aluminum height

rod, and rear wheels.

Specifications

Model 318504

Max Capacity 450lb

Weight Graduation 0.25lb

Height Measurement Range 24-84”

Height Graduation 0.125”

Platform Size 14.75” x 10.75”

318504 www.globalindustrial.com . 1 .

Page 3

Assembly

The 318504 Mechanical Physician Scale comes partially assembled. The following

components require assembly:

Pillar

Steel connection rod

Height rod

Wheels

Tools required:

Phillips head screwdriver

Wrench (included)

1. Set the scale base on a table or other assembly area free from traffic and obstructions.

2. Remove the tie that secures the steel rod during transit (shown in Figure 1).

Figure 1. Remove Cable Tie

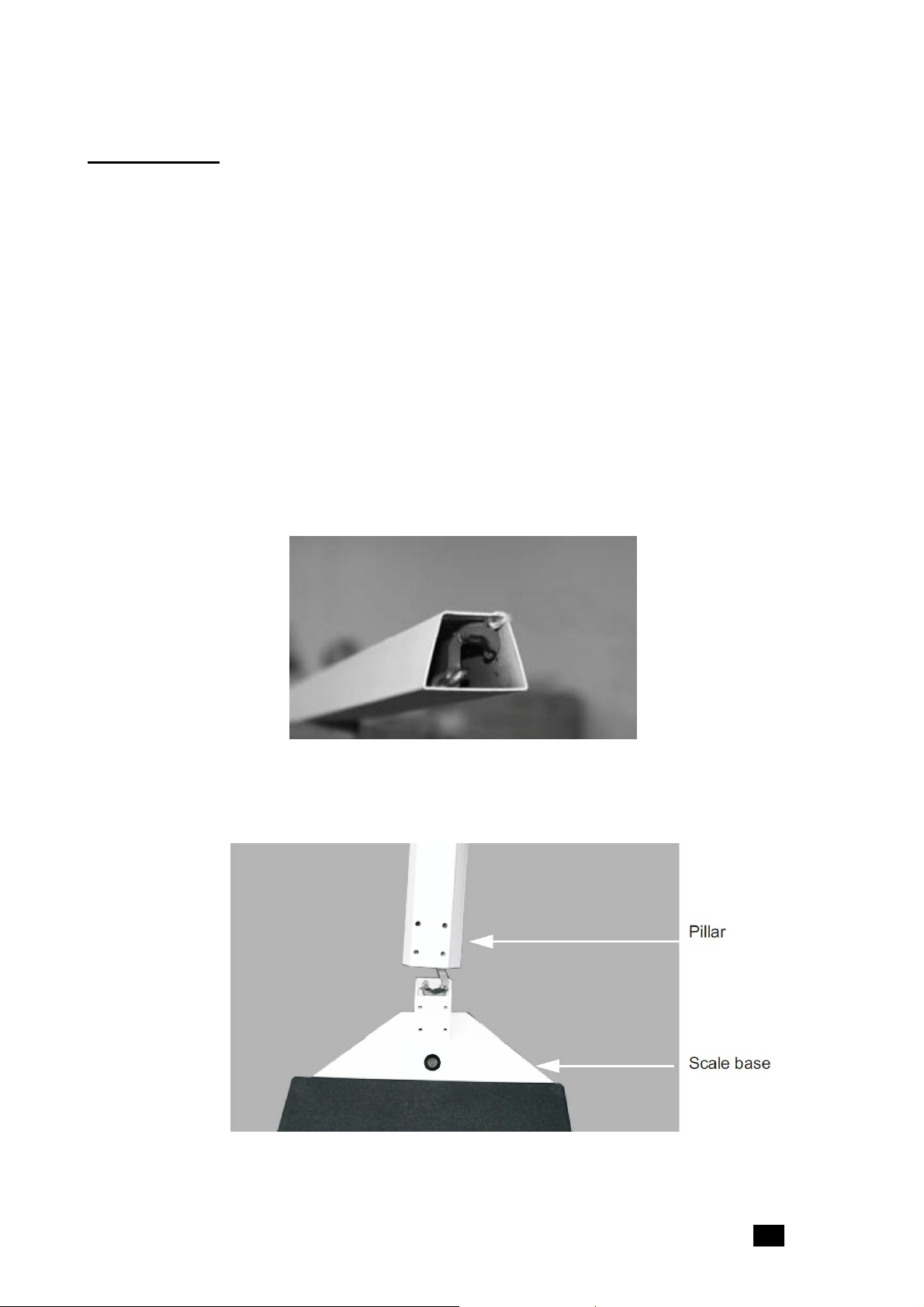

3. Insert the pillar into the scale base (shown in Figure 2), ensuring that the Global logo on

the weight beam faces the scale base.

Figure 2. Attach the Pillar to the Scale Base

318504 www.globalindustrial.com . 2 .

Page 4

4. Using a Phillips screwdriver, screw in the eight bolts and washers to secure the pillar to

scale base as shown in Figure 3.

Figure 3. Attach Eight Bolts and Washers to Secure the Pillar to the Base

5. Lay the scale on a table. Remove and discard the shipping tie wrap wires on the

underside of the scale carriage as shown in Figure 4.

Figure 4. Lay Scale on Table to Access Bottom of Scale

6. Insert the wrench (included) into the small hole in front of the steel rod and pull the rod

hook with the wrench to connect it to the scale base as shown in Figure 5. The steel rod

is located inside the scale pillar. Once the pillar is attached to the scale base, the steel

rod must be attached to the bottom of the scale.

318504 www.globalindustrial.com . 3 .

Page 5

Figure 5. Connect the Steel Rod to the Scale Base

7. Push the long lever forward and hook the steel rod’s bearing on the long lever pivot.

NOTE: During shipping, a plug is installed to ensure that the force lever assembly stays

aligned, but the linkage may still come out of alignment. Visually ensure that the force lever

assembly linkage is centered and properly aligned. The linkage must be free floating in order

for the scale to weigh properly. If the scale is slightly tipped to one side, the linkage can be

seen by looking up underneath the top weigh beam.

Figure 6. View of Linkage Underneath the Top Weigh Beam

8. Place the scale gently back on the floor.

318504 www.globalindustrial.com . 4 .

Page 6

Height Rod Assembly

1. Insert the slotted holes on the back of the height rod into the two bolts on the front of the

pillar as shown in Figure 7.

2. Use the enclosed wrench to tighten the two hex-head screws. Be sure not to

over-tighten.

3. To raise or lower the height rod, press the red button at the top of the height rod.

Figure 7. Attach the Slotted Screw Location onto the Pillar Bolt Location

318504 www.globalindustrial.com . 5 .

Page 7

Wheel Assembly

Mounting the wheels upside down can cause weighing errors.

1. Align the angle iron of the wheel base to the scale platform as shown in Figure 8.

2. Use the screws and washers that are included to affix the wheel assembly to the

platform. Adjust the angle iron at a level position and then tighten screws.

3. When moving the scale, hold the two side faces of the pillar to keep the front side of the

platform away from the ground.

Top

Bottom

Figure 8. Attach the Scale Wheels onto the Scale Base

318504 www.globalindustrial.com . 6 .

Page 8

Zero Adjustment

After assembly, the scale must be zeroed prior to use.

1. Ensure the scale is sitting on a level surface and slide the upper and lower weights

to the far left positions.

2. Gently hold the scale pointer with your finger so it is centered within the eye loop

area. Release the scale pointer and let it rise freely up or down.

3. If the pointer doesn’t remain centered, turn the zero adjustment screw (shown in

Figure 9) using a flathead screwdriver until the pointer remains centered within the

eye loop.

Zero

adjustment

screw

Weigh beam

Scale pointer

Eye loop area

Figure 9. Eye Loop Area and Zero Adjusting Screw Location (shown without height rod)

318504 www.globalindustrial.com . 7 .

Page 9

Troubleshooting

The Mechanical Physician Scale is factory-calibrated to within plus or minus 1/4 pound

accuracy. For the most accurate readings, always use the scale on a hard, level surface

and stand in the center of the scale platform with the weight evenly distributed. If an error

occurs or seems excessive, check the following:

Problem Possible Solution

Zero balance out of

adjustment

Beam does not move

freely

Platform rocks

excessively

Beam does not move at

all during weighing

The weighing beam must be balanced so the pointer comes

to a rest in the center of the eye loop (shown in Figure 9)

when both poise weights are set at zero (see page 1 for

poise weight location). Follow zero adjustment instructions

on page 7.

Make sure the pointer is not touching the side of the eye

loop, impeding its range of travel.

Visually ensure that the linkage is centered and properly

aligned. Occasionally during shipping, the alignment will

become skewed. The linkage must be free floating in order

for the scale to weigh properly. If the scale is slightly tipped

to one side, the linkage can be seen by looking up

underneath the top weigh beam.

Ensure scale is setting on a level surface. When you push

down on any corner of the platform, you should not feel any

significant rocking.

Weights are set higher than the person’s actual weight.

Reset the weights to a lower weight.

Make sure steel rod is properly connected and aligned as in

Figure 5.

Scale is out of

calibration

318504 www.globalindustrial.com . 8 .

Recalibrate the scale by placing a known weight on the scale

and turning the zero adjustment screw until the pointer

remains centered within the eye.

11 Harbor Park Drive Port Washington, NY 11050

Loading...

Loading...