Page 1

Best Value Standard Duty

Pallet Jack Truck

5500 lb. Capacity

User Manual

Model no. 989032 - 21 x 48 Forks

Model no. 989031 - 27 x 48 Forks

Globalindustrial.com

Customer Service

US: 1-800-645-2986

CA: 1-888-645-2986

Main Parameter pg. 2

Applicable Range pg. 2

Assembly pg. 3

Pallet Truck lift/lower adjustment pg. 6

Controls pg. 6

Operation pg. 8

Safety precautions pg. 9

Warning pg. 10

Oil type and proper oil disposal pg. 11

Maintenance pg. 11

Maintenance Record pg. 12

Troubleshooting pg. 13

Page 2

2

Main P

odel no

M

apacity 5500 lbs.

C

ar

ame

. 989032 989031

ter

Total lift height 7.75”

Lowered fork height 3.0”

Tow bar height 16.6”

Fork length 48.0”

Fork width 21” 27”

Steering wheel dia. 6.5”

Fork wheel dia. 3.0”

Truck weight 135 lbs 140 lbs.

Turning radius 50 - 52.5

Note

• The truck shall be used, serviced and repaired according to the

manufacturer’s requirements.

• The truck shall not be modied nor have attachments tted without

ensuring tha

t the truck is still safe.

Applicable Range

• Hand pallet truck is a low lift tr

move palletized cargo. This kind of truck possesses the feature of

stable lifting, easy operation, safety and reliability usage.

• The working place must be non-slip, hard, and at ground without

holes or obstacles.

• The ambient lighting for operational use is recommended to be 50 Lux.

ansportation tool which is limited to

Page 3

3

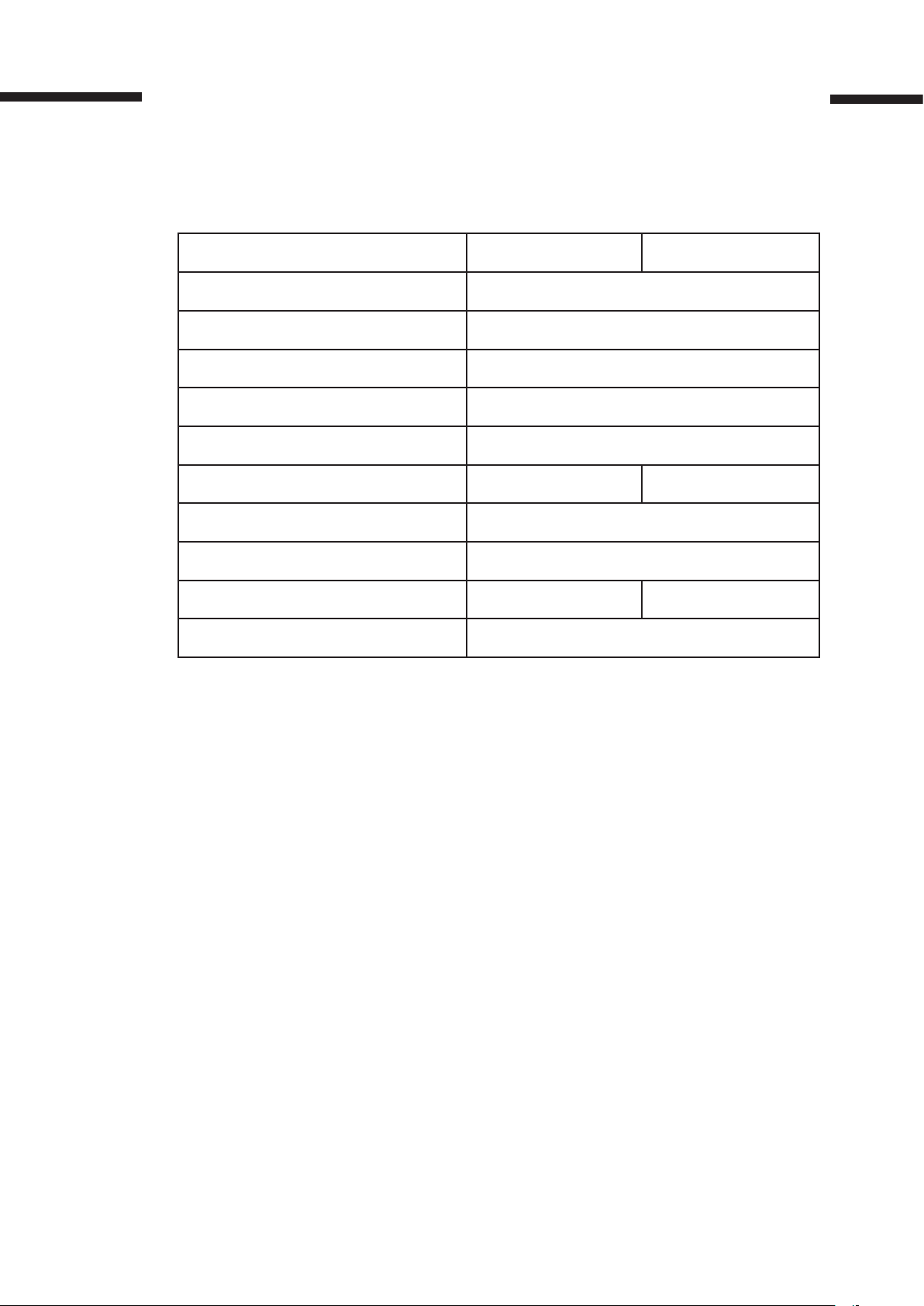

Assembly

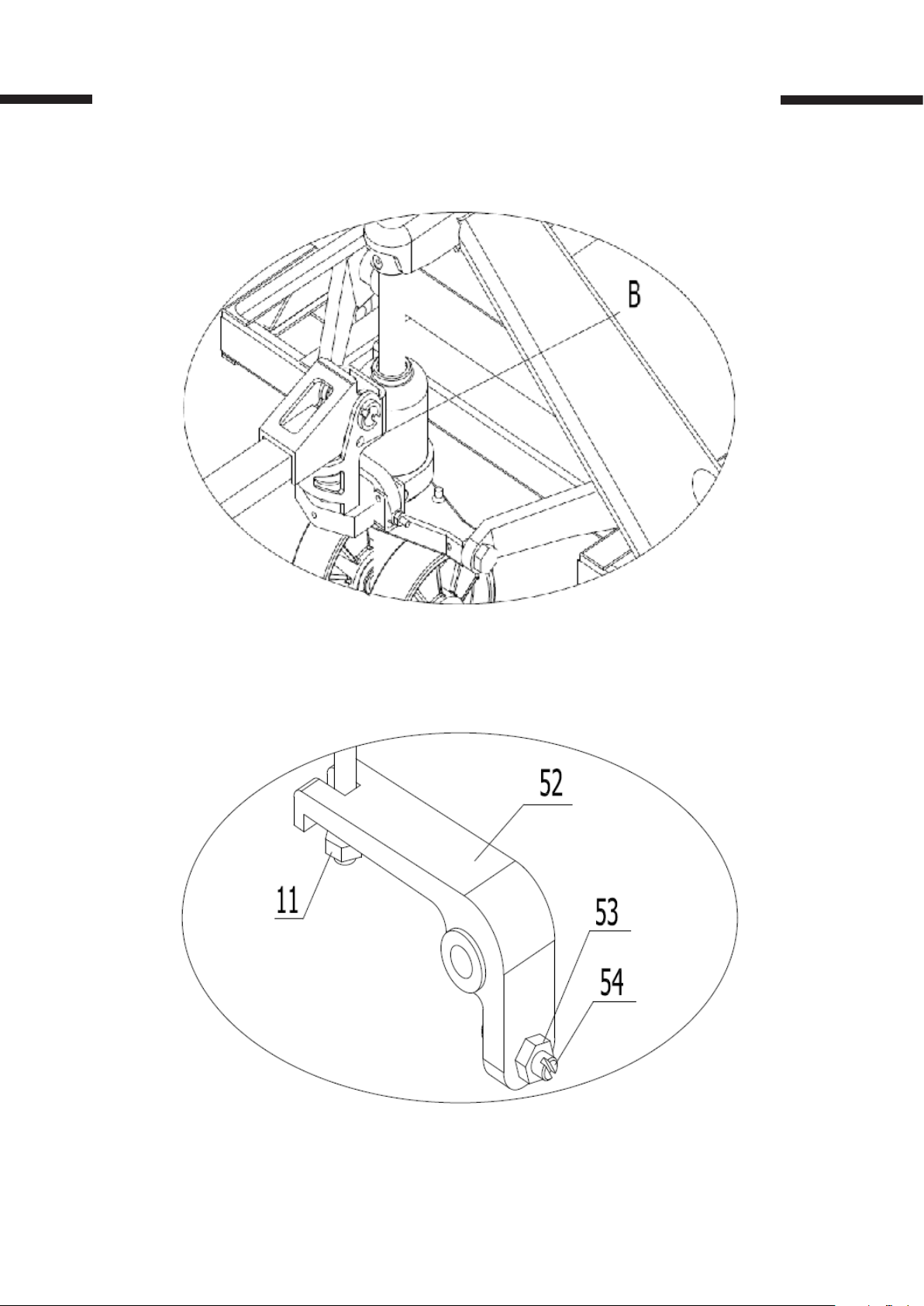

1. Pull the roll pin out(23). See figure 1

2. Insert the handle(8) into part (A). Connect the handle(8) and

pump body(31) with the roll pin(23).

3. Insert the spring pin(24) to secure the roll pin(23).

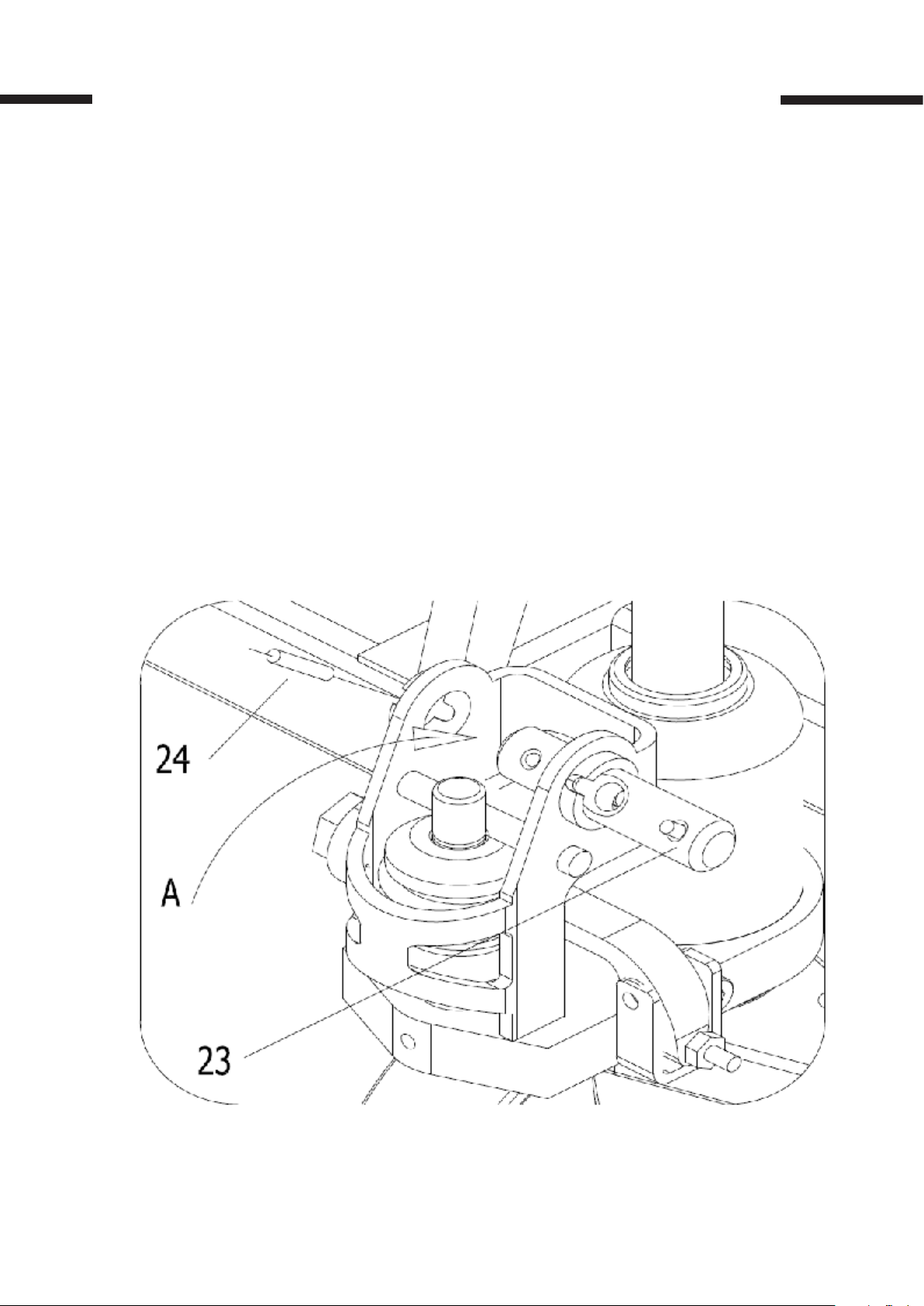

4. Connect the handle chain to the central hole of the roll

pin(23). See figure 2

5. Attach the nut, at the end of the chain(10), to the lever

plate(52). See figure 2 and 4

6. Pull the handle(8) and pull out the pin(B). See figure 3

Figure 1

Page 4

4

Figure 2

Page 5

5

Figure 3

Figure 4

Page 6

6

Pallet Truck lift/lower adjustment

1. Test the pallet jack truck controls to lift and lower a palletize

cargo. See figure 5

2. The screw(53), shown in gure 4, is used to adjust the truck

lift setting. If the truck drops the load, immediately after it is

lifted, you should turn the screw counter-clockwise. Vice versa,

if the truck could not return to the ground position after it’s lifted,

you should turn the screw clockwise. Once the proper tension

adjustment is made, the pallet jack truck is ready to be used.

Controls

See figure 5

1.

LIFT: Position the trigger downward and rock the tow bar to lift

the cargo.

NEUTRAL POSITION: When the trigger is in the middle position,

the truck will neither lower nor lift the truck when the tow bar is

rocking. The neutral position is used to move the cargo.

LOWER: Squeeze the trigger to lower the cargo to the ground.

2. Release brake

3. State of free walking

Page 7

7

Figure 5

Page 8

8

Operation

Before operating the pallet jack truck , make sure the cargo weight does

not exceed the rated 5500 lb. load capacity. The cargo should be

loaded in the middle of the truck forks. See Figure 6

Figure 6

Page 9

9

Safety precautions

• Untrained personnel are not allowed to use the pallet jack truck.

• The operators must put on work clothes, safety shoes,

and gloves during the operation of the pallet jack truck.

• When the pallet jack truck is not in use, the handle knob

should be in the brake position to make the truck stationary.

• In an emergency situation, trigger the brake handle

immediately and lower the cargo to the ground safely.

• Do not park the truck on the slope or in emergency

passages.

• When the pallet jack truck is used on the slope, the

operator is positioned on top of the slope and pulling the pallet

jack truck.

• Do not push the pallet jack truck on a slope.

• Do not stop the truck on a slope

• Do not make turns on a slope.

• When the pallet jack truck is not in use, the forks should be

lowered to the ground position..

• Do not park the truck in any area that will block trac or

cause an inconvenience.

• Do not use the truck in a rainy environment.

• Do not ever sit or stand on the pallet jack truck.

• Do not transport tall cargos that can potentially tip over.

• Before the pallet jack truck is pushed into the elevator, make

sure the elevator can bear the total load of pallet jack truck

and cargo, as well as the total weight of all personnel in the

elevator. When entering the elevator, allow the pallet jack truck to

enter the elevator rst.

• The pallet jack truck should be stored in dry and ventilated

environment.

Page 10

10

Warning

• Read the user manual carefully before you operate the

hand pallet truck.

• Slowly squeeze the handle to lower the cargo to the ground.

• Do not rock the tow bar at a high speed or in a high frequency.

• Do not transport the cargo at a high speed.

• Do not overload the forks. Overloading could damage the

pallet jack truck over time.

• The center of gravity of the cargo should be in the middle of truck

forks. The oset of cargo could make a pallet jack truck o

balance and possibly tip the load, if misused.

• Don’t load loose or unstable goods.

• When the pallet jack truck does not work, make sure that the truck’s

forks are on the lowest position.

• The truck shall be used, serviced and repaired according to the

manufacturer’s requirements. Do not modify the hand truck with

non-OEM parts.

• Do not use the pallet jack truck in areas with poor lighting.

• The fork arms should not be used as a lever to lift a load.

• Do not contact the fork arms directly with the goods or cargo.

• Do not use the hand pallet truck in a potentially explosive area.

• The operator should pay attention to their feet and any body parts

to avoid any injuries in use.

Page 11

Oil type and proper oil disposal

The oil tank capacity is about 250ml (or 0.25kg).

According to the ISO oil criterion, the choice of oil is

ISO 32 hydraulic oil between -31 °F to 104°F environment.

The waste of hydraulic oil shall be disposed in terms of

local laws. It is unlawful to dump oil without following

proper disposal standard.

Maintenance

11

The routine check should be carried out daily and every abnormal phenomenon should be dealt with immediately. Please

do not use a faulty truck in order to prolong the service life and

safety of the user. If there are any faults, please consult a

professional. It is recommended to replace any defected parts,

with new parts provided by the original manufacturer. The

rotary joints and motor oil should ne inspected every three

months. Keep all wheels clean to avoid any clogs in the wheel axle.

Record all maintenance and upkeep in the maintenance record.

Page 12

12

Maintenance Record

Maint. date Issues Part(s) replace

Page 13

Troubleshooting

Issues Causes Recommendation

The forks can’t be

lifted to the maximum

lift height.

Hydraulic oil is not enough. Rell oil.

Too much hydraulic oil.

Take out appropriate oil.

13

The forks can’t return

to the lowest position.

The forks can’t be

lowered after lifting.

Hydraulic oil

leakage.

The fork can’t be

lifted.

When the tow bar is

used, the forks drop

immediately. The valve of oil pump is clogged.

The forks drop after

the cargo is lifted.

The rotating parts are deformed

Or blocked. Replace the part(s).

The truck’s piston and guide bushing

are blocked.

The unloading mechanism is not

properly functional.

The parts are deformed or

damaged.

The oil seal is missing.

The surface of some parts

are damaged or worn.

Loosen parts Fasten the loosened parts.

The viscosity of the oil is too high, or

there is not enough oil.

There is impurity in the oil.

The unloading mechanism in not

properly functional.

See “Pallet Truck lift/lower

adjustment”

Replace the deformed or

damaged parts.

Replace the oil seal.

Replace the damaged parts.

Replace the oil.

Clear up the impurity and add

new oil.

See “Pallet Truck lift/lower

adjustment”

Open the valve and take out

the parts. Then re-install the

parts after the parts are cle-

aned.

Page 14

Loading...

Loading...