Page 1

Power Scissor Lift Table Model 989018, 989034, 989035, 989036, 989037

• All the electrical connection and disconnection

operations must be carried out by skilled and competent

personnel.

• While in operation, it is forbidden to contact the moving

parts of the lift table.

Do not lift or lower the load, if it is unstable or otherwise

•

could harm a person or other object.

• It is forbidden to lift the load, which perhaps does harm

to a person or other object.

• It is forbidden to operate the lift table while a person is

under the table.

• Do not adjust the safety valve of the hydraulic power

pack.

• It is forbidden to operate the lift table, if there is any

small structure distortion.

• Do not use in an explosive or flammable place.

II. CAUTION!

Note: This Manual has been prepared for skilled and

competent personnel. It provides instructions for using the

product correctly and parts list. This Manual cannot replace

the professional skills and expertise of the user.

I. WARNING!

If operating the li table improperly, a person may be seriously

injured. erefore, operate properly according to the following

instruction

• Read & thoroughly understand the Instruction Manual

completely before using. Follow all safety instructions

strictly.

• It is necessary to check all safety devices before operation.

• Make sure that there are no obstacles in the working area.

• Do not put a foot or hand in scissors mechanism or

through the frame.

• Engage the maintenance bars before working on the lift

table. See part VII

• Do not overload the lift table. The load should be distributed on the table according to relevant load distribution

chart.

• Pay attention if local voltage and frequency are the same

as the input specification of the lift table.

• Use the lift table on flat and solid ground.

If operating the lift table improperly, a person may be

injured. Therefore, operate properly according to the

following instruction.

• The lift table is a movable lifter designed to lift or lower

rated load. Do not use it for other purposes.

• It is forbidden to alter the lift table without

manufacturer’s written permission.

• It is necessary to use the replacement parts designated

by manufacturer.

• Make sure to keep some distance between the table and

ambient objects enough to operate the lift table safely.

• Keep the hydraulic system in clean and safe condition.

• The hydraulic power pack features an electric lowering

control. The coils must be fed with the required voltage

as described on those coils. The power supply voltage

should not exceed ±10% of the rated required voltage.

• Always do maintenance and routine checks while the

li table is unloaded.

• The lift table is not waterproof and should be used in a

dry environment.

1

Page 2

III. DAILY INSPECTION

2

1321

Daily inspection is effective to find the malfunction or fault on

the lift table. Before operation, check the lift table according to

the following points.

Do not use the lift table if any malfunction or fault is found.

• Check all the terms of WARNING and CAUTION.

• Check scratches, bending or crack on the lift table.

• Check smooth movement of the table.

• Check if there is any hydraulic oil leakage.

• Check for any imbalance on the table.

• Check if all the bolts and nuts are firmly tightened.

IV. OPERATING THE LIFT TABLE

1. LOADING

The maximum capacity of the lift table is 2200 lbs. The

load should be distributed on the lift table equally.

2. LIFTING THE TABLE

CAUTION!

Do not overload th

Ensure the balance of loading. Do not load partially or concentrically.

• Check to disengage the emergency stop switch.

• Push the UP button and power pack starts to work to li

the load.

• Release the UP button and power pack stops working.

e li table.

V.

WALL MOUNT BRACKET INSTRUCTION

•

Use M8 screws, adhesive tape, or velcro strips to attach

the wall mount bracket onto the mounting surface.

Note: Mounting hardware not included. Hardware type

and hardware size varies on wall thickness and material.

Safely store the hand pendant control on the wall

•

mount bracket, when not in use.

VI.

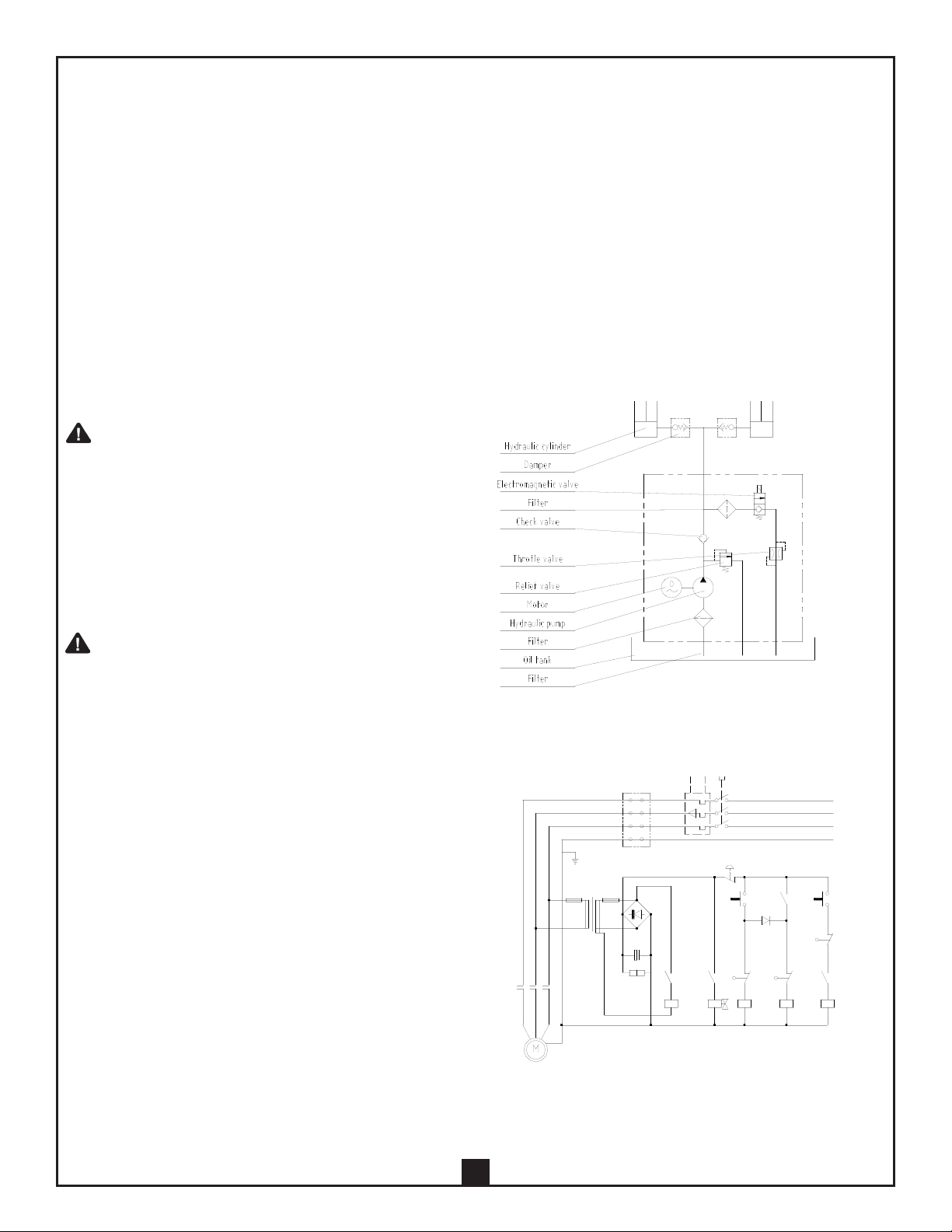

HYDRAULIC CIRCUIT & ELECTRIC

PRINCIPLE DIAGRAM

See Figure 1 & Figure 2.

3. LOWERING THE TABLE

Do not put foot o

WARNING!

• Push the DOWN button and the table will lower.

• Release the DOWN button and the table will stop.

Note: The table is equipped with an aluminum guard

to avoid accidental danger.

• If there is any interference while the table is descending,

_ the aluminum guard will stop the operation once it's in

_ contact with an object. Remove the interference and

_ press the UP button to resume operation.

4. EMERGENCY STOP

ere are tw

• Push down the emergency stop switch

• Interference when in contact with the table descending.

5. TRANSPORTATION

Use the attached ring bolts to safely transport the lift table to

the floor or installation surface, following the steps below.

•

Attach chain hooks such as sling hooks, S-hooks, pull chains

or similar hooking system onto each of the ring bolts.

•

Suspend the chain securely on a forklift or similar equipment

and move the suspended lift

installed. The installation area should be clean and located

near 110 Volt power.

r hand in scissors mechanism

o methods of emergency stop as follows.

.

table to the location it is to be

Fig. 1 Hydraulic circuit

Fig. 2 Electric Principle Diagram

Note: Using the RING BOLTS is the suggested manner of

moving the table; all other methods are not recommended.

2

Page 3

VII. MAINTENANCE BAR OPERATING INSTRUCTION

To engage the Maintenance Bars:

1. Remove all load from the platform and raise the lift table to its fully-raised position.

2. Rotate each maintenance bar until the bar contacts the surface of the base channel. Ensure both bars are positioned

correctly.

3. Lower the lift by depressing the DOWN button. The lift will lower slightly until the maintenance bars reach the corner of

the base. Release the DOWN button. ALWAYS check the position of both maintenance bars before going under the

platform or servicing the lift.

To Disengage The Maintenance Bars:

5. Depress the UP button to raise the platform to its fully-raised position. When the lift is fully raised, release the UP button.

6. Rotate each maintenance bar to its stored position. ENSURE both bars are in their stored position.

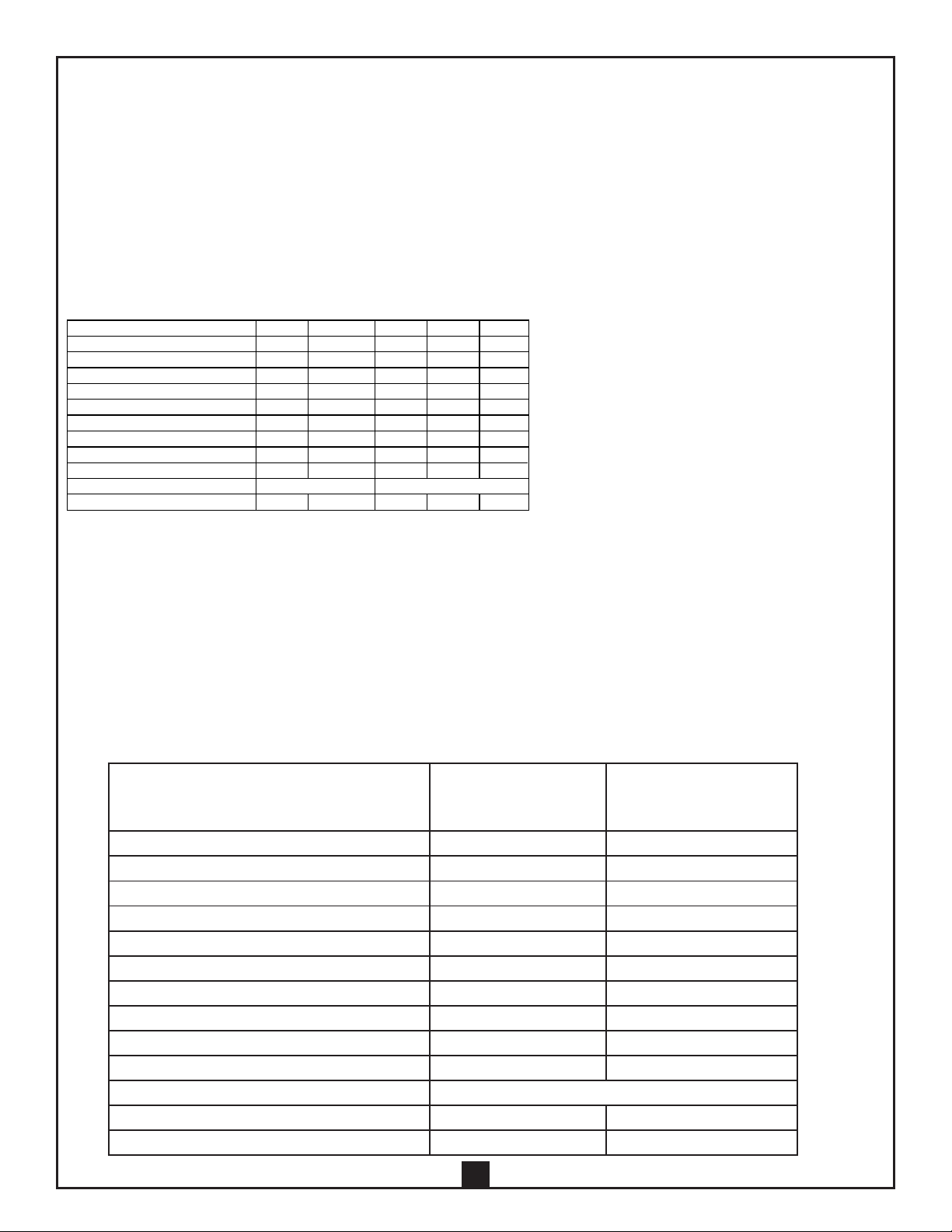

VIII.SPECIFICATIONS

Model 989018 989034 989035 989036 989037

Capacity

L ow ered Height 7-3/4” 7-3/4” 7-3/4” 8-5/8” 7-3/4”

Rai sed H eight 40” 40” 40” 40” 40”

Pl atf or m L engt h 48” 48” 48” 72” 48”

Platf orm Wi dth 28” 36” 48” 48” 48”

L i f t Ti me w i th rat ed l oad 17 17 25 30 30

Lowering time with rated load

Lif t Ti me wi thout load 16.5 16.5 24 27 27

Lowering time without load

Pow er Pack

Net W eight 448 lbs 484 l bs

2200 lbs 2200 l bs 3300 lbs 4840 l bs 4400 l bs

30 30 40 42 42

35 35 42 45 45

110V/60HZ,AC1.1KW 110V /60HZ ,AC1.5KW

638 lbs 750 lbs 638 l bs

IX. SERVICE INSTRUCTIONS

• Do a routine check of fasteners, packing and oil leaking.

• Do a routine check of the lift table functions.

• Before servicing the lift table, make sure to turn off the AC power supply.

• After servicing, it is necessary to check the function of the lift table again.

• ONLY a qualified personnel can do service work.

• Do a routine check of the micro-switches on the safety guard.

• Do routine check of the hydraulic system by listening to abnormal noise.

• Caution: It is required to turn off the AC power supply before touching the motor’s surface.

• Replace the oil filter after prolong usage.

• Appropriate lubrication is necessary to make the lift table work easily and have a prolonged service life.

• Following table is recommended to service the lift table periodically

Content

After every 500

hours’ working or

every 3 months later

Aer every 2000 hours’

working or every year

Check oil level of oil tank ✓

Check the cleanliness of oil lter ✓

Fasten all the connecting parts again ✓

Check wear and tear of pressure oil pipes ✓

Check hydraulic cylinder ✓

Fix main parts tightly again ✓

Check the function of micro-switches ✓

Check whole working state of the li table ✓

Lubricate all the joints and pivot points ✓

Check wear and tear of all axial bushes ✓

Replace hydraulic oil for the rst time Accumulated ten hours of usage

Replace hydraulic oil ✓

Check oil leaking ✓

3

Page 4

X. TROUBLE SHOOTING

Note: Before service, refer to part VII. and follow the maintenance bar operating instruction. It is

required to engage the maintenance bars to prevent the table from lowering accidentally.

Trouble Cause Solution

• Remove eyebolt

• Correct AC voltage phases

• Check the function of

electro-magnetic valve and

repair it

• Remove excessive load

Replace limi

t switch

Table cannot li while

motor works normally

Table cannot li and mo-

• Eyebolt has not been

removed

• AC voltage phases mistake

• Electromagnetic dysfunctions

• The table is overloaded

Lowering limit switch damaged

tor does not work

• Lowering limit switch or mi-

Table cannot lower

cro-switch on safety guard damaged

• Electromagnetic valve dysfunctions

• Safety guard works

• Something wrong with electric

• Replace lowering limit switch or

micro-switch.

• Check the function of electromagnetic valve and repair it

• Strike the UP button slightly

• Replace electric circuit board

circuit board

Table’s legs go over

limit position while table

lowers

Table cannot reach the

highest position

• Internal leaking in electromagnetic valve

• Packing damaged in hydraulic

cylinder

• Insufficient oil

• Limit switch damaged

• Repair electromagnetic valve

and if necessary replace it

• Check and replace packing

• Replenish oil

• Check and repair limit switch. If

necessary, replace it

4

Page 5

Optional

OPTIONAL: Bellows Package

(depending on size, 989019, 989038, 989039, 989040)

To install the bellow package, line up part #30

brackets with the holes on the table base and fasten

part #12 screws. Lift up the bellows package to the

table top and secure with screws.

Page 6

PARTS LIST

φφφφφ

Handle control

Check size

31

Foot Control

MDFS-65,

AC220V,3A

1

Page 7

HYDRAULIC POWER PACK (P1)

Page 8

Electric Control Box (E1)

Loading...

Loading...