Page 1

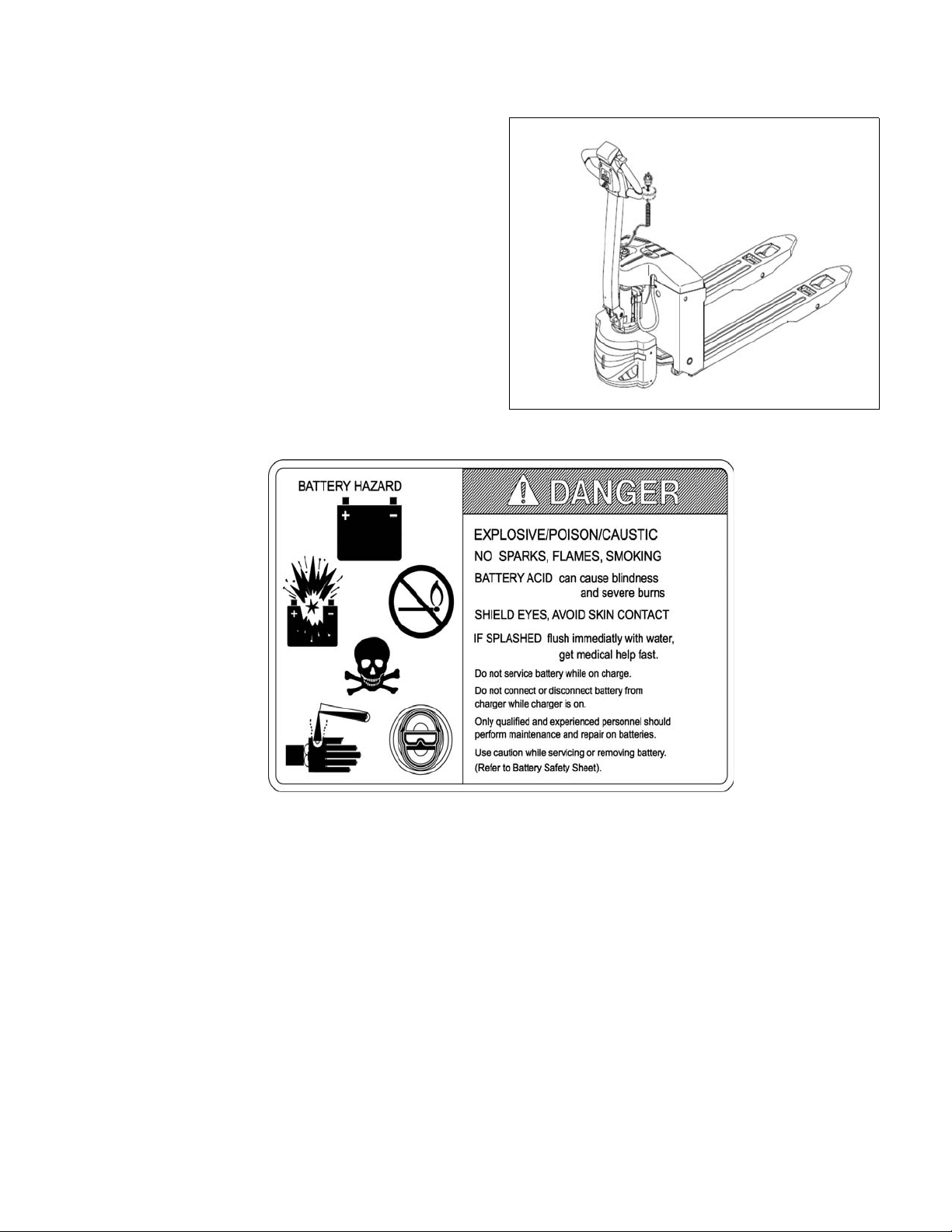

MODEL 988993

POWERED PALLET TRUCK

Operation

Maintenance

Repair Parts List

Global Industrial MANUAL NO. BL-GL33-0618 - 09-12-2019

globalindustrial.com

Page 2

WARNING

Do not operate this truck unless you have been authorized and trained to do so, and have read all warnings

and instructions in Operator’s Manual and on this

truck.

Do not operate this truck until you have checked its

condition. Give special attention to wheels, horn, battery, controller, lift system, brakes, steering mechanism, guards and safety devices.

Operate truck only from designated operating position.

Do not carry passengers. Keep feet clear of truck and

wear foot protection.

Observe applicable traffic regulations. Yield right of

way to pedestrians. Slow down and sound horn at

cross aisles and wherever vision is obstructed.

Start, stop, travel, steer and brake smoothly. Slow

down for turns and on uneven or slippery surfaces that

could cause truck to slide or overturn. Use special

care when traveling without load as the risk of overturn

may be greater.

Always look in direction of travel. Keep a clear view,

and when load interferes with visibility, travel with load

trailing.

Use special care when operating on ramps travel

slowly, and do not angle or turn. Travel with load

downhill.

Do not handle loads which are higher than the chassis

unless load is secured so that no part of it could fall

backward. Before lifting, be sure load is centered,

forks are completely under the chassis backrest.

When leaving truck, neutralize travel control, fully

lower lifting mechanism and set brake. When leaving

truck unattended, also shut off power.

BL-GL33-0618 - 09-12-2019

Page 3

TABLE OF CONTENTS

Section Page Section Page

DESCRIPTION..................................................................1-1

1-1 INTRODUCTION. .........................................1-1

1-2 GENERAL DESCRIPTION...........................1-1

1-3 SAFETY FEATURES....................................1-2

OPERATION.....................................................................2-1

2-1 GENERAL.....................................................2-1

2-2 OPERATING PRECAUTIONS......................2-1

2-3 BEFORE OPERATION .................................2-1

2-4 GENERAL CONTROL OPERATION............2-4

2-5 DRIVING AND STOPPING PROCEDURES 2-4

2-6 BELLY-BUTTON SWITCH............................2-4

2-7 STEERING ARM GAS SPRING...................2-5

2-8 LIFT AND LOWER CONTROLS...................2-5

2-9 LOADING AND UNLOADING.......................2-5

2-10 PARKING......................................................2-5

PLANNED MAINTENANCE ..............................................3-1

3-1 GENERAL.....................................................3-1

3-2 MONTHLY AND QUARTERLY CHECKS..... 3-1

3-3 BATTERY CARE .........................................3-1

3-3.1 GENERAL.....................................................3-1

3-3.2 SAFETY RULES...........................................3-2

3-3.3 BATTERY CARE AND CHARGING .............3-2

3-3.4 BATTERY CLEANING 2

3-3.5 MAINTENANCE FREE BATTERIES ............3-2

3-4 CHARGING BATTERIES..............................3-3

3-5 BATTERY REPLACEMENT .........................3-4

3-6 LUBRICATION..............................................3-5

TROUBLESHOOTING......................................................4-1

4-1 GENERAL.....................................................4-1

4-2 CONTROLLER TROUBLESHOOTING........4-4

4-2.1 FAULT DETECTION.....................................4-4

4-2.2 HAND HELD PROGRAMMER (OPTIONAL) 4-4

4-3.3 FAULT RECORDING....................................4-4

4-3.4 GENERAL CHECKOUT................................4-4

4-3.5 DIAGNOSTIC HISTORY...............................4-6

4-3.6 TEST THE FAULT DETECTION

CIRCUITRY ..................................................4-6

4-3.7 DIAGNOSTICS AND

TROUBLESHOOTING..................................4-6

4-3.7.1 LED Diagnostics ...........................................4-6

4-3.8 PROGRAMMER DIAGNOSTICS................4-16

STEERING ARM, CONTROL HEAD

AND COMPARTMENT .....................................................5-1

5-1 CONTROL HEAD .........................................5-1

5-1.1 CONTROL HEAD REMOVAL.......................5-1

5-1.2 CONTROL HEAD INSTALLATION...............5-3

5-1.3 CONTROL HEAD COVERS REMOVAL....... 5-3

5-1.4 CONTROL HEAD COVERS

INSTALLATION ............................................5-3

5-1.5 SPEED POTENTIOMETER

REPLACEMENT...........................................5-3

5-1.6 BELLY-BUTTON SWITCH REPLACEMENT5-4

5-1.7 HORN SWITCH REPLACEMENT................ 5-5

5-1.8 LIFT AND LOWER SWITCH

REPLACEMENT .......................................... 5-6

5-2 UPPER COMPARTMENT COVERS............ 5-7

5-2.1 REMOVAL....................................................5-7

5-2.2 INSTALLATION............................................ 5-7

5-3 LOWER COMPARTMENT COVERS........... 5-8

5-3.1 REMOVAL....................................................5-8

5-3.2 INSTALLATION............................................ 5-8

5-4 STEERING ARM.......................................... 5-9

5-4.1 RETURN SPRING REPLACEMENT............ 5-9

5-4.2 STEERING ARM REMOVAL ....................... 5-9

5-4.3 STEERING ARM INSTALLATION ............... 5-9

BRAKE SERVICING......................................................... 6-1

6-1 BRAKES.......................................................6-1

6-1.1 BRAKE ASSEMBLY REPLACEMENT......... 6-1

TRANSMISSION, DRIVE WHEEL, LOAD WHEEL.......... 7-1

7-1 DRIVE WHEEL ............................................ 7-1

7-2 TRANSMISSION.......................................... 7-1

7-3 LOAD WHEEL.............................................. 7-3

7-3.1 REMOVAL....................................................7-3

7-3.2 REPAIR....................................................

7-3.3

ELEVATION SYSTEM SERVICING................................. 8-1

8-1 LIFT LINKAGE ............................................. 8-1

8-1.1 REMOVAL....................................................8-1

8-1.2 REPAIR........................................................ 8-2

8-1.3 INSTALLATION............................................ 8-2

HYDRAULIC SYSTEM SERVICING ................................ 9-1

9-1 LINES AND FITTINGS................................. 9-1

9-2 HYDRAULIC AND ELECTRICAL

9-2.1 REMOVAL....................................................9-2

9-2.2 INSTALLATION............................................ 9-2

9-3 HYDRAULIC PUMP, MOTOR

9-3.1 REMOVAL....................................................9-2

9-3.2 DISASSEMBLY AND REASSEMBLY.......... 9-2

9-3.3 INSTALLATION............................................ 9-2

9-4 LIFT CYLINDER........................................... 9-5

9-4.1. REMOVAL.................................................... 9-5

9-4.2 REPAIR........................................................ 9-5

9-4.3 INSTALLATION............................................ 9-6

ELECTRICAL COMPONENTS....................................... 10-1

10-1 ELECTRICAL CONTROL PANEL.............. 10-1

10-1.1 MAINTENANCE ......................................... 10-1

10-1.2 CLEANING................................................. 10-1

10-1.3 CONTROLLER REMOVAL ........................ 10-1

10-1.4 CONTROLLER INSTALLATION ................ 10-1

LOAD WHEEL INSTALLATION ................... 7-3

ASSEMBLY REMOVAL ............................... 9-2

AND RESERVOIR ASSY............................. 9-2

.... 7-3

BL-GL33-0618 - 09-12-2019 1

Page 4

TABLE OF CONTENTS - CONTINUED

Section Page Section Page

10-1.5 CHARGER REMOVAL............................... 10-1

10-1.6 CHARGER INSTALLATION....................... 10-1

10-1.7 COOLING FAN REMOVAL........................ 10-3

10-1.8 COOLING FAN INSTALLATION................ 10-3

10-1.9 BUZZER REMOVAL .................................. 10-3

10-1.10 BUZZER INSTALLATION .......................... 10-3

10-1.11 KEY SWITCH REMOVAL .......................... 10-3

10-1.12 KEY SWITCH INSTALLATION .................. 10-3

10-1.13 BATTERY INDICATOR REMOVAL ........... 10-3

10-1.14 BATTERY INDICATOR INSTALLATION ... 10-3

10-1.15 EMERGENCY DISCONNECT REMOVAL. 10-3

10-1.16 EMERGENCY DISCONNECT INSTALL ....10-4

10-1.17 LIFT LIMIT SWITCH REMOVAL ................10-6

10-1.18 LIFT LIMIT SWITCH INSTALLATION ........10-6

10-2 PUMP MOTOR ...........................................10-7

10-3 DRIVE MOTOR ..........................................10-7

10-4 DEADMAN SWITCH...................................10-7

10-4.1 REPLACEMENT.........................................10-7

OPTIONAL EQUIPMENT ...............................................11-1

ILLUSTRATED PARTS BREAKDOWN .......................... 12-1

1-2 BL-GL33-0618 - 09-12-2019

Page 5

SECTION 1

R8548

DESCRIPTION

1-1. INTRODUCTION.

This publication describes the 24 volt 988993 lift truck

distributed by Global Industrial. Included are operating

instructions, planned maintenance instructions, lubrication procedures, corrective maintenance procedures

and a complete parts list with part location illustrations.

Users shall comply with all requirements indicated in

applicable OSHA standards and current edition of

A.N.S.I. B56.1 Part II. By following these requirements

and the recommendations contained in this manual,

you will receive many years of dependable service

from your 988993 lift truck.

1-2. GENERAL DESCRIPTION.

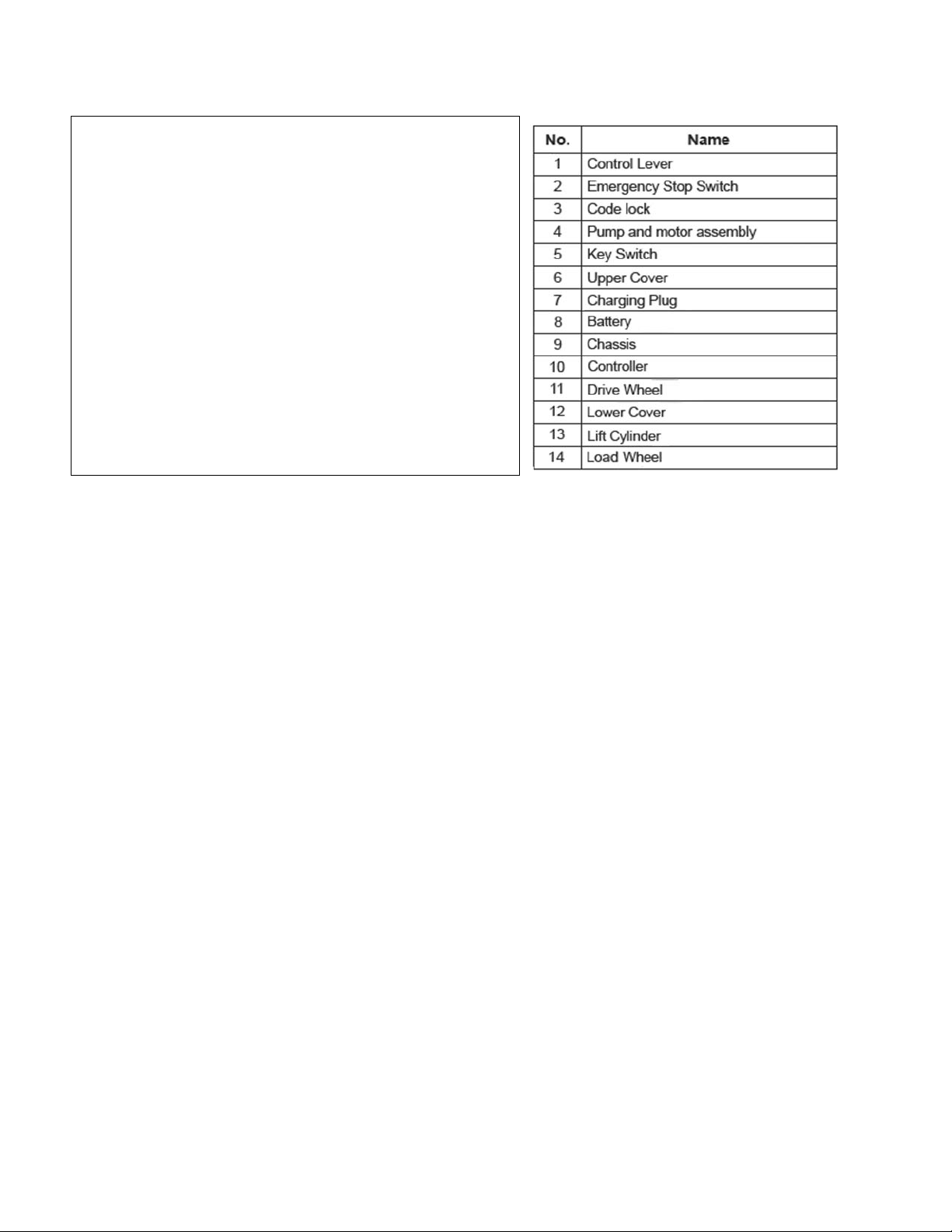

The self-propelled 988993 truck, Figure 1-2, lifts and

transports payloads up to 3300 pounds on rigid forks.

The forward and reverse motion is controlled by either

of two controller levers mounted on the control head.

Stopping and turning is controlled by the steering arm.

Lift and Lower is controlled by pushbuttons on the control head. The battery powered lift truck is quiet and

without exhaust fumes.

The reversible DC motor propels the lift truck in forward or reverse direction throughout the available

speed range. The 988993 lift truck can be driven with

forks raised or lowered. The lift truck must be protected from the elements.

The model number will be found on the name plate

(Figure 1-1) along with the serial number, lifting capacity, and load center. Figure 1-2 shows the locations of

the truck’s main components and controls.

BL-GL33-0618 - 09-12-2019 1-1

Figure 1-1 Name Plate

Page 6

Figure 1-2 Lift Truck

GL33-14

1-3. SAFETY FEATURES.

The 988993 is designed and engineered to provide

maximum safety for operator and payload. Some of

the safety features incorporated into the design are:

• Dead-man brake to apply the brake and cut off drive

power when the steering arm is released.

• Belly-button switch to reverse truck should the operator accidentally pin himself against a wall or

obstruction when backing up in slow speed.

• All control functions automatically return to “OFF”

when released.

• Emergency Disconnect within operator's reach.

• Readily accessible horn button.

• Handle to provide a firm hand hold for operator.

• Flow control valve regulates maximum lowering

speed within prescribed limits.

• Relief valve maintains hydraulic pressure within prescribed limits.

• High visibility color scheme of truck provides visual

alert of truck’s presence.

• Battery Indicator

1-2 BL-GL33-0618 - 09-12-2019

Page 7

SECTION 2

OPERATION

2-1. GENERAL.

This section gives detailed operating instructions for

the 988993 lift truck. The instructions are divided into

the various phases of operations, such as operating

lift, driving, and stopping. Routine precautions are

included for safe operation.

2-2. OPERATING PRECAUTIONS.

WARNING: Improper operation of the lift truck may

result in operator injury, or load and/or lift

truck damage. Observe the following

precautions when operating the 988993

lift truck.

The following safety precautions must be adhered to

at all times.

• Do not operate this truck unless you have been

trained and authorized to do so and have read all

warnings and instructions in this manual and on the

truck.

• All warnings and instructions must be read and

understood before using the equipment.

• Equipment must be inspected by a qualified person

on a regular basis.

• Do not operate this truck until you have checked its

condition. Give special attention to Wheels, Horn,

Batteries, Controller, Lift System, Brakes, Steering

Mechanism, Guards and Safety Devices

• Operate truck only from designated operation position. Wear foot protection. Do not carry passengers.

• Observe applicable traffic regulations. Yield right of

way to pedestrians. Slow down and sound horn at

cross aisles and wherever vision is obstructed.

• Start, stop, travel, steer and brake smoothly. Slow

down for turns and on uneven or slippery surfaces

that could cause truck to slide or overturn. Use special care when traveling without load as the risk of

overturn may be greater.

• Always look in direction of travel. Keep a clear view,

and when load interferes with visibility, travel with

load or lifting mechanism trailing.

• Do not overload truck. Check nameplate for load

weight and load center information.

• Before lifting, be sure load is centered, forks are

completely under load, and load is as far back as

possible against the chassis.

• Do not handle loads which are higher than the chassis unless load is secured so that no part of it could

fall backward.

• When leaving truck, neutralize travel control. Fully

lower lifting mechanism and set brake. When leaving

truck unattended, turn off key switch and disconnect

switch, and remove key.

2-3. BEFORE OPERATION

Table 2-1 covers important inspection points on the

988993 lift truck which should be checked prior to

operation. Depending on use, some trucks may

require additional checks.

Figure 2-1 shows a sample format for an Operator

Checklist, which can be modified as necessary to fit

your operation.

WARNING: Periodic maintenance of this truck by a

QUALIFIED TECHNICIAN is required.

CAUTION: A QUALIFIED SERVICE TECHNICIAN

should check the truck monthly for

proper lubrication, proper fluid levels,

brake operation, motor maintenance and

other areas specified in the SECTION 3.

WARNING: If the truck is found to be unsafe and in

need of repair, or contributes to an

unsafe condition, report it immediately to

the designated authority. Do not operate

it until it has been restored to a safe

operating condition. Do not make any

unauthorized repairs or adjustments. All

service must be performed by a qualified

maintenance technician.

BL-GL33-0618 - 07-16-2019 2-1

Page 8

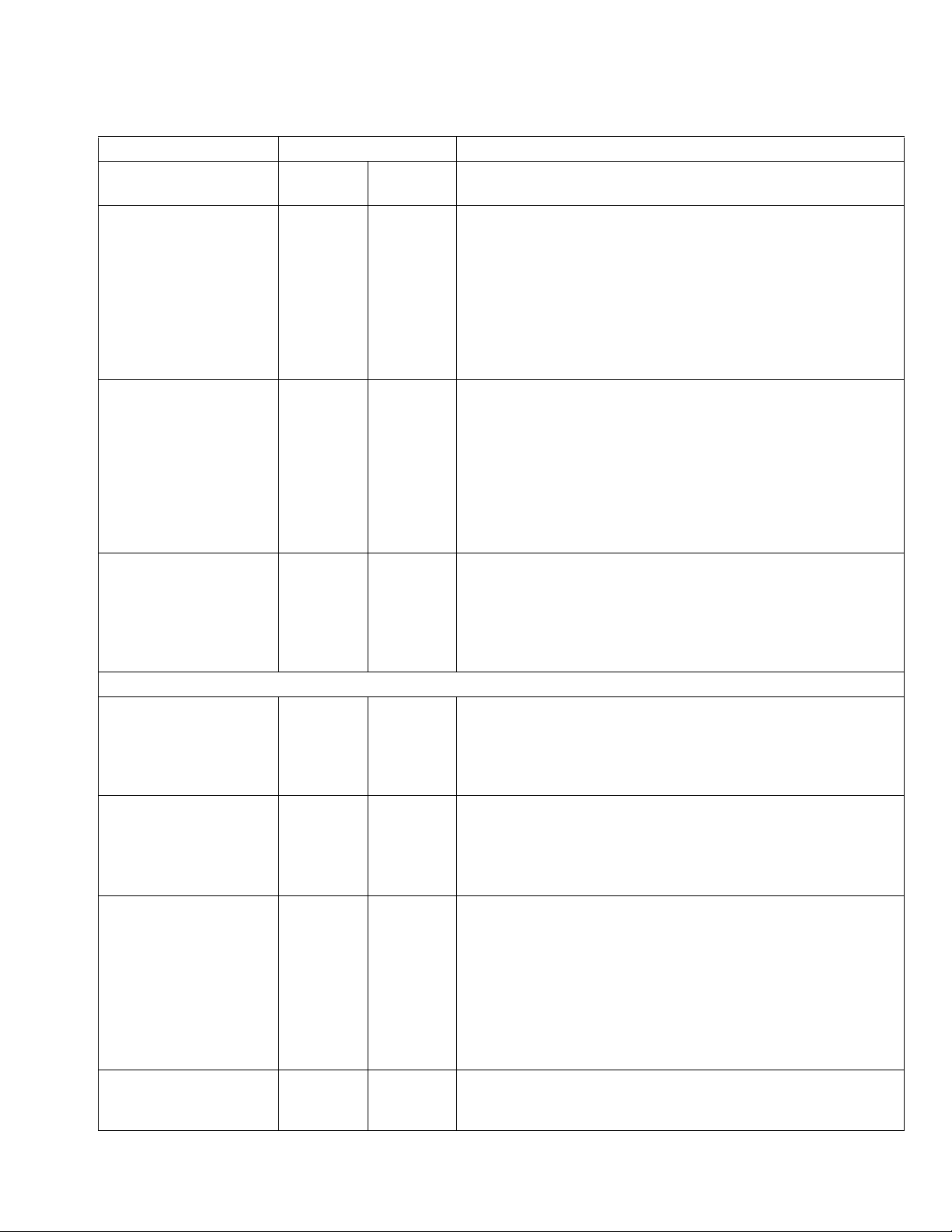

Table 2-1 Operator Checks

ITEM PROCEDURE

Transmission

and hydraulic

systems.

Forks Check for cracks and damage.

Safety signs Check that warning labels,

Horn Check that horn sounds when

Steering Check for binding or looseness in

Travel controls Check that speed controls on

Check for signs of fluid leakage.

nameplate, etc., are in good

condition and legible.

operated.

steering arm when steering.

control head operate in all

speed ranges in forward and

reverse and that belly button

switch functions.

ITEM PROCEDURE

Wheels Check drive wheel for cracks or

damage. Move truck to check

load for freedom of rotation.

Hydraulic

controls

Brake Check that brake actuates when

Deadman/

Parking brake

Battery

disconnect

Battery charge Check the battery indicator.

Check operation of lift and lower

to their maximum positions.

steering arm is raised to upright

position, and when lowered to

horizontal position.

Check that steering arm raises to

upright position when released

and brake applies.

Check that battery can be

disconnected and reconnected. Check for connector

damage.

2-2 BL-GL33-0618 - 07-16-2019

Page 9

R8549

Figure 2-1 Sample of Operator Check List

BL-GL33-0618 - 07-16-2019 2-3

Page 10

2-4. GENERAL CONTROL OPERATION.

R6617

R6618

R8505

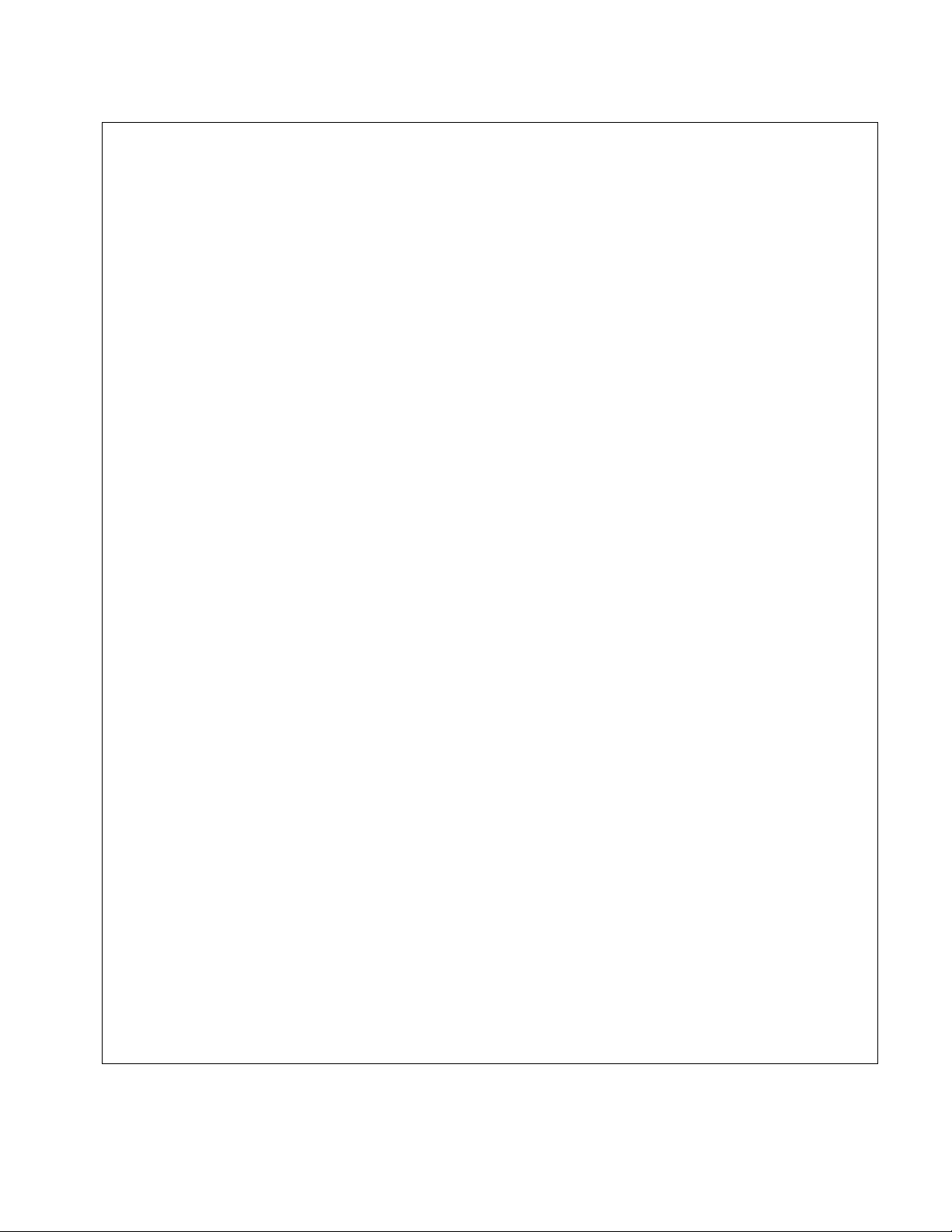

The speed control (See Figure 2-2) located on each

side of the control head provides fingertip control for

driving the truck. Rotate the control in the direction you

want to travel. The farther you rotate the control from

the neutral position, the faster the truck will travel.

Figure 2-2 Forward/Reverse Control

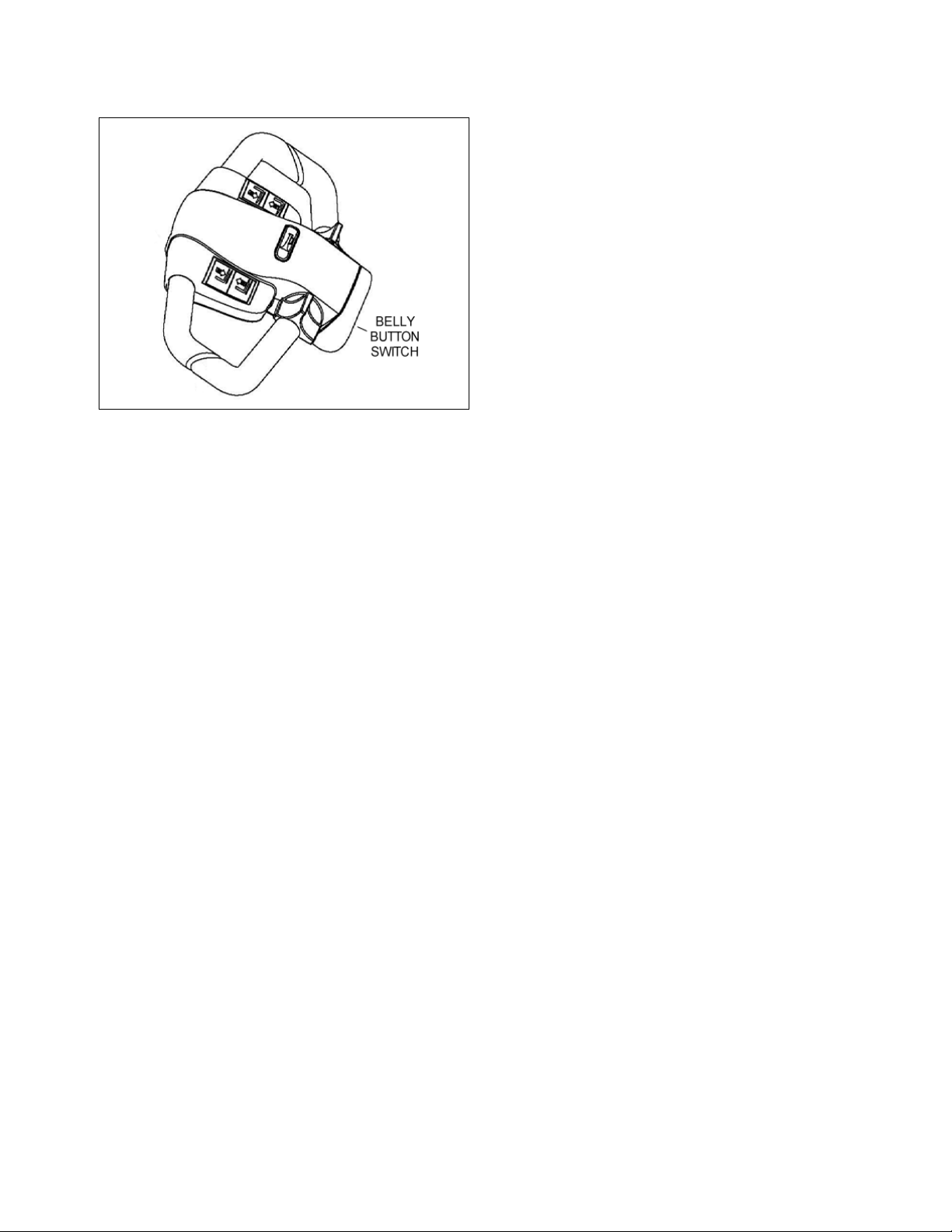

The pushbutton switches (See Figure 2-3), located on

the front of the control head activate the lift-lower controls and the horn.

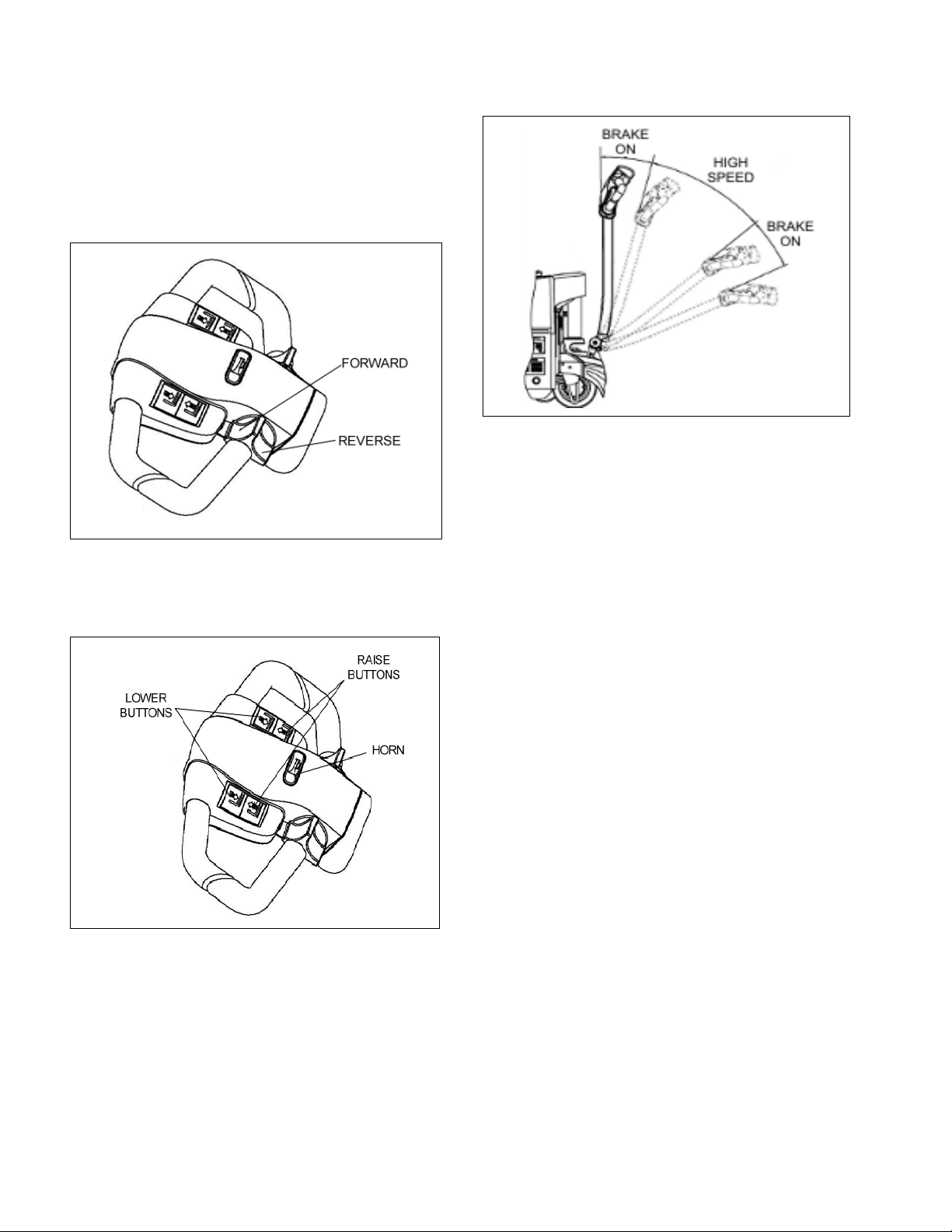

Figure 2-4 Brake Actuation

2-5. DRIVING AND STOPPING PROCEDURES.

1. Turn on the emergency disconnect and the key

switch. Grasp the grips of the steering head so

that the speed control can be comfortably operated by either thumb.

2. Lower the steering arm to a comfortable position

above horizontal to disengage the brake and to

energize the electrical circuits. If the truck is not

moved, the electrical circuits will time out and will

deenergize. See Figure 2-4.

3. To move forward (with load in front), slowly press

the speed control forward. See Figure 2-2. Press

the forward speed control farther to increase

speed.

4. To slow down or stop, release the speed control

and lower or raise the steering arm to the horizontal or vertical position. See Figure 2-4. In those

positions, the brake engages, slowing or stopping

the truck.

5. Procedures for movement in reverse are the

same as in the forward direction except slowly

press the speed control backward. See Figure 2-

2.

Figure 2-3 Pushbutton Switches

The brake is fully applied by lowering or raising the

steering arm. (See Figure 2-4) All traction control

power is shut off when the brake is engaged. When

the steering arm is in the upright position, the brake

acts as a parking brake. Deadman braking occurs

when the handle is released and spring action raises

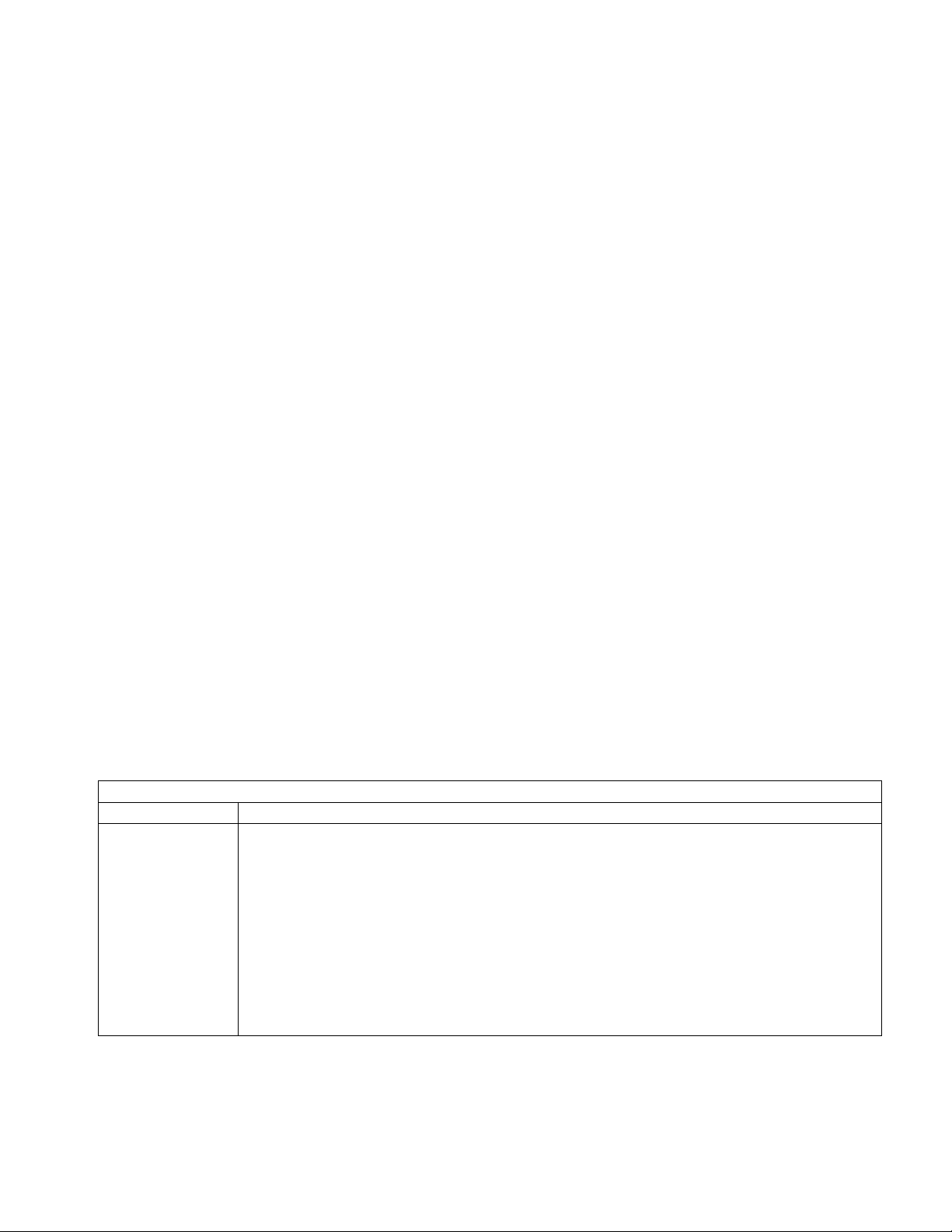

2-6. BELLY-BUTTON SWITCH.

The belly-button switch (Figure 2-5) minimizes the

possibility of the driver being pinned by the steering

arm while driving the lift truck in slow speed. If the

switch presses against the operator while the lift truck

is being driven toward the operator, the switch

changes the direction of the lift truck.

steering arm to the upright position.

2-4 BL-GL33-0618 - 07-16-2019

Page 11

Figure 2-5 Belly-Button Switch

R6619

2-7. STEERING ARM GAS SPRING.

The steering arm gas spring automatically raises the

steering arm to the upright position when the steering

arm is released. If the steering arm does not return

fully, the steering arm gas spring requires replacement. Return truck to maintenance for repair.

2-8. LIFT AND LOWER CONTROLS.

Lift/Lower Control buttons are located on the steering

control head. (Figure 2-3)

To lift forks, push in either LIFT button and hold until

forks reach desired height. To lower forks, push in

either LOWER button and hold until forks descend to

desired height.

2-9. LOADING AND UNLOADING.

1. Move truck to location where load is to be picked

up.

2. Move the truck into position so forks are within

pallet or skid, and the load is centered over the

forks and as far back as possible.

3. Raise forks to lift load.

4. Drive to area where load is to be placed.

5. Move truck to align load with its new position.

6. Lower the load until it rests squarely in place and

the forks are free.

7. Slowly move the truck out from under the load.

2-10.PARKING.

When finished with moving loads, return the truck to its

maintenance or storage area. Turn off the emergency

Disconnect and the key switch. Charge batteries as

necessary. Refer to battery care instructions, SEC-

TION 3.

BL-GL33-0618 - 07-16-2019 2-5

Page 12

NOTES

2-6 BL-GL33-0618 - 07-16-2019

Page 13

SECTION 3

PLANNED MAINTENANCE

3-1. GENERAL.

Planned maintenance consists of periodic visual and

operational checks, parts inspection, lubrication, and

scheduled maintenance designed to prevent or discover malfunctions and defective parts. The operator

performs the checks in SECTION 3, and refers any

required servicing to a qualified maintenance technician who performs the scheduled maintenance and

any required servicing.

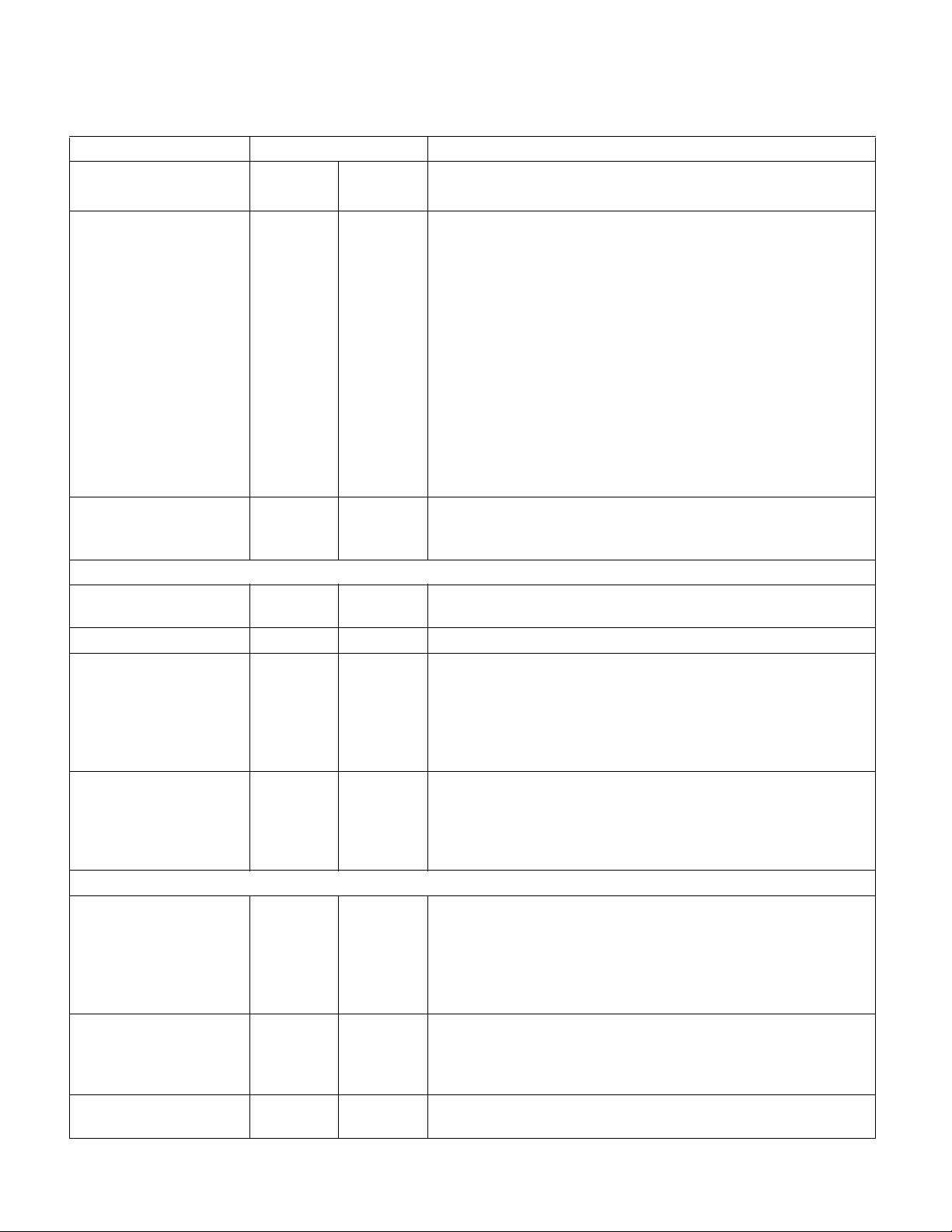

3-2. MONTHLY AND QUARTERLY CHECKS.

Table 3-1 is a monthly and quarterly inspection and

service chart based on normal usage of equipment

eight hours per day, five days per week. If the lift truck

is used in excess of forty hours per week, the frequency of inspection and service should be increased

accordingly. These procedures must be performed by

a qualified service technician or your Global Industrial

Service Representative.

3-3. BATTERY CARE.

3-3.1. General

The 988993 may be equipped with maintenance free

batteries.

The care and maintenance of the battery is very

important to obtain efficient truck operation and maximum battery life.

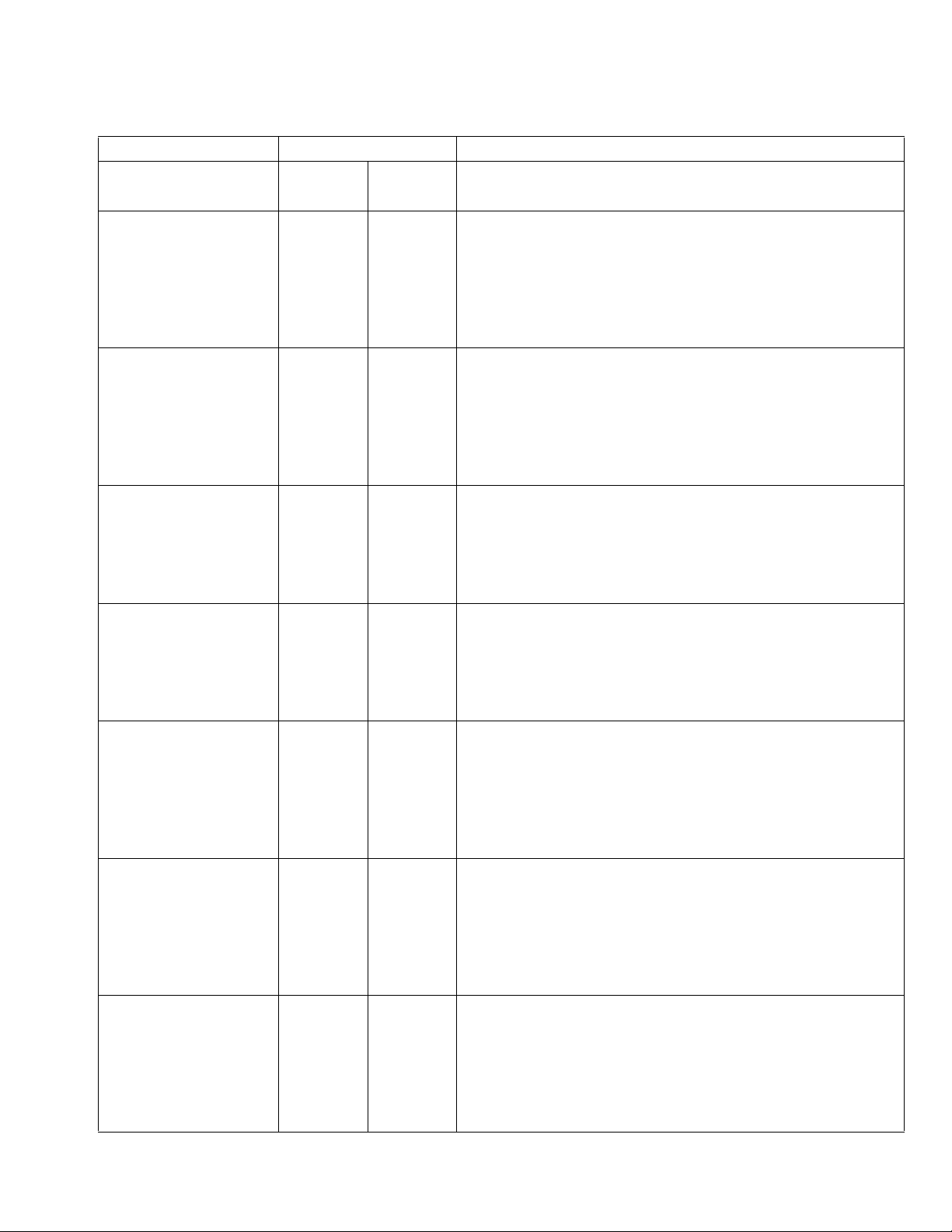

Table 3-1 Monthly and Quarterly Inspection and Service Chart

CAUTION: Gases produced by a battery can be

explosive. Do not smoke, use an open

flame, create an arc or sparks in the

vicinity of the battery. Ventilate an

enclosed area well when charging.

CAUTION: Batteries contain sulfuric acid which may

cause severe burns. Avoid contact with

eyes, skin or clothing. In case of contact,

flush immediately and thoroughly with

clean water. Obtain medical attention

when eyes are affected. A baking soda

solution (one pound to one gallon of

water) applied to spilled acid until bubbling stops, neutralizes the acid for safe

handing and disposal.

Leakage voltage from battery terminals to battery case

can cause misleading trouble symptoms with the truck

electrical system. Since components of the truck electrical system are insulated from truck frame, leakage

voltage will not normally affect truck operation unless a

short circuit or breakdown of circuit wire insulation to

truck frame occurs.

A voltage check from battery connector terminal to

battery case should indicate near zero volts. Typically,

however, the sum of the voltages at both terminals will

equal battery volts. This leakage voltage will discharge

the battery. As battery cleanliness deteriorates, the

usable charge of the battery decreases due to this self

discharge.

VISUAL CHECKS

INTERVAL INSPECTION OR SERVICE

Monthly Check electrical brake for proper operation.

Monthly Check load wheels for wear. A poly load wheel must be replaced if worn to within 1/16 inch

of hub. Check for separation from hub.

Monthly Check drive wheel for wear. A poly drive wheel must be replaced if worn to within 3/4 inch of

hub. Check for separation from hub.

Monthly Inspect wiring for loose connections and damaged insulation.

Monthly Inspect contactors for proper operation.

Monthly Check deadman brake switch for proper operation.

Quarterly Check lift cylinder for leakage.

Quarterly Check for excessive jerking of steering arm when stopping or starting.

BL-GL33-0618 - 09-12-2019 3-1

Page 14

Although a leakage voltage reading of zero volts may

not be possible, a cleaner battery will have more

usable charge for truck operation and not affect operation of electronic devices on the unit.

3-3.2. Safety Rules

• Wear protective clothing, such as rubber apron,

gloves, boots and goggles when performing any

maintenance on batteries. Do not allow electrolyte to

come in contact with eyes, skin, clothing or floor. If

electrolyte comes in contact with eyes, flush immediately and thoroughly with clean water. Obtain medical attention immediately. Should electrolyte be

spilled on skin, rinse promptly with clean water and

wash with soap. A baking soda solution (one pound

to one gallon of water) will neutralize acid spilled on

clothing, floor or any other surface. Apply solution

until bubbing stops and rinse with clean water.

• If truck is equipped with wet cell batteries, keep vent

plugs firmly in place at all times except when adding

water or taking hydrometer readings. Do not allow

dirt, cleaning solution or other foreign material to

enter cells. Impurities in electrolyte has a neutralizing effect reducing available charge.

• Do not bring any type of flame, spark, etc., near the

battery. Gas formed while the battery is charging, is

highly explosive. This gas remains in cell long after

charging has stopped.

• Do not lay metallic or conductive objects on battery.

Arcing will result.

• Do not touch non-insulated parts of DC output connector or battery terminals to avoid possible electrical shock.

• De-energize all AC and DC power connections

before servicing battery.

• Do not charge a frozen battery.

• Do not use charger if it has been dropped or otherwise damaged.

3-3.3. Battery Care and Charging

CAUTION: Never smoke or bring open flame near

the battery. Gas formed during charging

is highly explosive and can cause serious injury.

1. Charge the battery only in areas designated for

that use.

2. Battery terminals should be checked and cleaned

of corrosion regularly. Good battery terminal contact is essential not only for operation, but also for

proper charging of the battery.

3. The charging requirements will vary depending on

the use of the truck. The battery should be given

as equalizing charge on a weekly basis. This

charge should normally be an additional three

hours at the finish rate.

4. Make certain battery used meets weight and size

requirements of truck. NEVER operate truck with

an undersized battery.

3-3.4. Battery Cleaning

Always keep vent plugs tightly in place when cleaning

battery. When properly watered and charged, the battery will remain clean and dry. All that is necessary is

to brush or blow off any dust or dirt that may accumulate on them. However, if electrolyte is spilled or overflows from a cell, it should be neutralized with a

solution of baking soda and water, brushing the soda

solution beneath the connectors and removing grime

from the covers. Then rinse the battery with cool water

from a low pressure supply to remove the soda and

loosen dirt. If batteries stay wet consistently, they may

be either overcharged or over filled. This condition

should be investigated and corrected.

3-3.5. MAINTENANCE FREE BATTERIES

Some trucks may be equipped with maintenance free

batteries. These batteries are completely sealed, will

not require any watering and have a full 80% discharge available.

Sealed Maintenance Free batteries contain a pressure

release valve and under normal operating conditions

do not require any special ventilation.

CAUTION: Do not try to open this battery or remove

the pressure release valve.

Only under severe overcharging, such as connected

to an improperly sized charger, will any significant

amount of gasses be released from the battery. Also,

being a valve regulated battery, it never requires

watering.

3-2 BL-GL33-0618 - 09-12-2019

Page 15

3-4. CHARGING BATTERIES

GL33-16

R6115

Charging requirements will vary depending on depth of

discharge and temperature. Follow safety rules when

placing a battery on charge.

Proceed as follows:

1. Park truck at charging station with forks lowered

and turn the key switch off.

2. Check the condition of the AC cord and battery

cables. If there are any cuts in the cable, any

exposed wires, loose plugs or connectors, DO

NOT attempt to charge the batteries. Contact

appropriate personnel for repairs to be made.

3. Pull the charger cord out of the top cover (Figure

3-1) and connect to the appropriate power supply.

Figure 3-1 Battery Charging

BL-GL33-0618 - 09-12-2019 3-3

Page 16

3-5. BATTERY REPLACEMENT

GL33-17

R6761

R6762

Access to the batteries requires removing the cover.

Charging requirements will vary depending on depth of

discharge and temperature. Follow safety rules when

placing a battery on charge.

Proceed as follows:

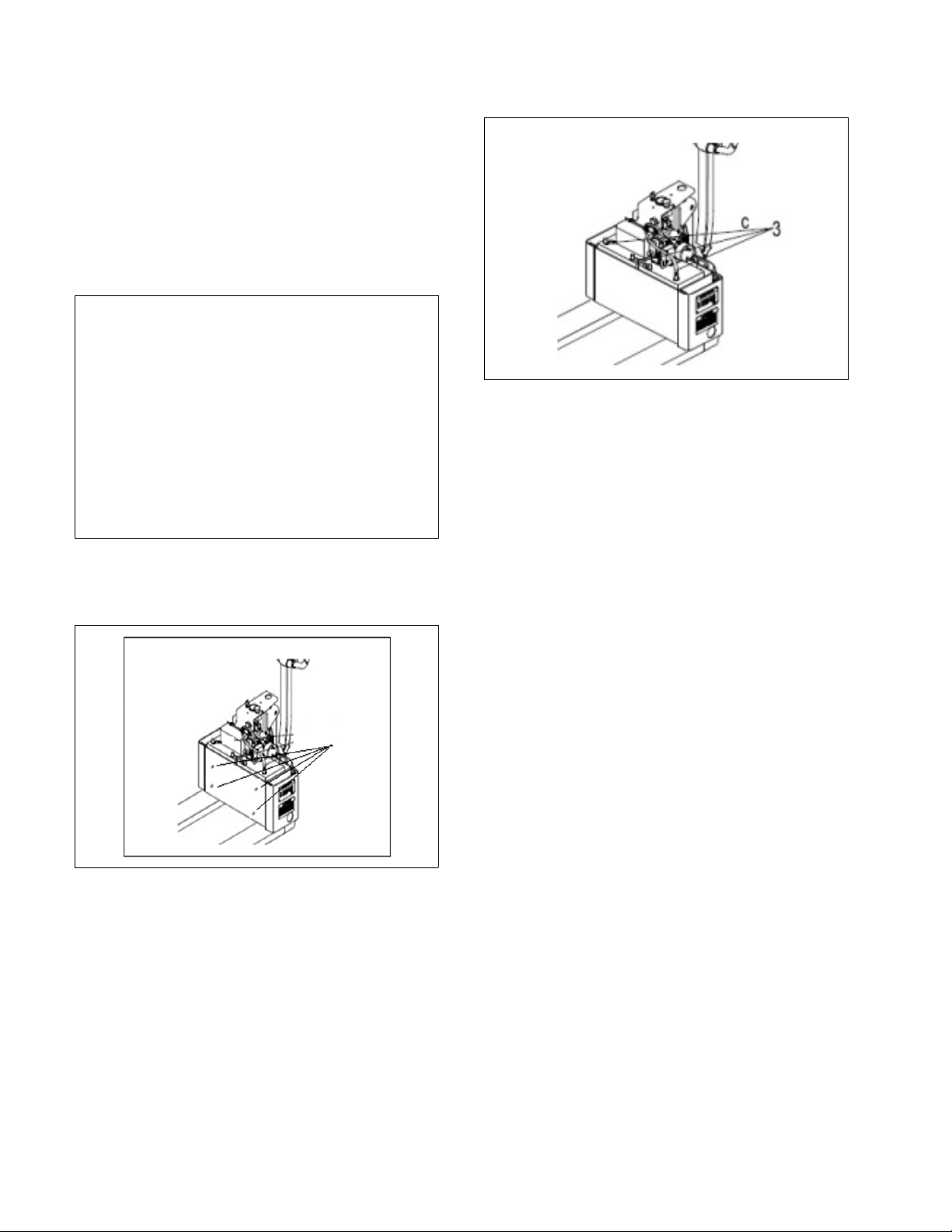

a. Remove top cover screws (1, Figure 3-2) and

remove the upper compartment cover (2).

Figure 3-2 Cover Removal

b. Remove four and front cover, this will expose

the 2 batteries. (Figure 3-3).

P

Figure 3-4 Disconnect Battery Cables

e. Install in the reverse order of remove.

Figure 3-3 Screw Removal

c. Tag and disconnect the three battery cables

(Figure 3-4).

d. To remove the batteries pull each one out

individually as required.

3-4 BL-GL33-0618 - 09-12-2019

Page 17

3-6. LUBRICATION.

Refer to Table 3-2 for the recommended types of

grease and oil. Table 3-3 in conjunction with Figure 3-5

identifies the items requiring lubrication.

Table 3-2 Recommended Lubricants

(See Table 3-3 for Application)

No. 1 Grease—Lithium base, general purpose

No. 2 (Note) Grease—Lithium base

No. 3 Hydraulic oil-Heavy duty with a viscosity of

150 SUS foam suppressing agent and

rust and oxidation inhibitors

Hydraulic oil-Heavy duty with a viscosity of

100 SUS foam suppressing agent and

rust and oxidation inhibitors (Note)

No. 4 SAE 30 or 40 Engine lubricating oil

BL-GL33-0618 - 09-12-2019 3-5

Page 18

Figure 3-5 Lubrication Diagram

GL33-18

Table 3-3 Lubrication Chart

FIG 3-2

INDEX

NO.

LOCATION METHOD OF

APPLICATION

TYPE

(Table

3-3)

1 Transmission Grease Can No. 1 Fill to level plug

2 Hydraulic Reservoir

Capacity-1 quarts

Can No. 3 With lift carriage fully lowered, fill

reservoir with hydraulic oil to 1

inch below opening

3 Lift Linkage Fittings* Gun No. 2 Pressure lubricate.

* Raise lift carriage to gain access to grease fittings.

APPLICATION

OF

LUBRICANT

3-6 BL-GL33-0618 - 09-12-2019

Page 19

SECTION 4

TROUBLESHOOTING

4-1. GENERAL

Use Table 4-1 and Figure 4-3 as a guide to determine

possible causes of trouble. The table is divided into

five main categories: Truck and Hydraulic System Will

Table 4-1 Troubleshooting Chart

MALFUNCTION PROBABLE CAUSE CORRECTIVE ACTION

TRUCK AND HYDRAULIC

SYSTEM WILL NOT OPERATE

Truck will not travel nor will lift sys-

tem operate.

TRUCK DOES NOT OPERATE

FORWARD OR REVERSE

Truck does not travel forward or

reverse. All other functions

operate normally.

Truck travels forward but not in

reverse.

Truck travels reverse but not in

forward.

Truck travels forward and in

reverse at lower speeds; will

not travel at high speed.

TROUBLE WITH BRAKING

Truck does not slow with brake, or

brake does not engage.

a. Fuse blown. Check fuse and replace if

b. Battery dead or disconnected. Check battery connections and

c. Keyswitch defective. Bypass keyswitch to determine if it

d. Defective wiring. Check for open circuit. Repair as

a. Check all wiring. A loose con-

nection may be the cause of

malfunction.

b. Defective deadman switch. Check and replace switch if

c. Defective controller. Check for proper operation and

d. Defective potentiometer. Check and replace potentiometer

Defective potentiometer in control

head.

Defective potentiometer in control

head.

Defective potentiometer in control

head.

a. Defective deadman switch. Check deadman switch for

b. Defective electric brake. Replace brake.

Not Operate: Truck Does Not Operate Forward or

Reverse: Trouble With Braking: Trouble With Lifting Or

Lowering, and Miscellaneous malfunctions.

necessary.

check battery voltage.

is malfunctioning.

required.

Tighten all loose connections

before further troubleshooting.

defective.

replace if necessary.

if defective.

Check and replace potentiometer

if defective.

Check and replace potentiometer

if defective.

Check and replace potentiometer

if defective.

continuity. If none found when

the control arm is in the brake

position, replace switch.

Brake will not release. a. Brake temperature above

281F (140C).

b. Open brake circuitry or wiring. Make voltage checks.

BL-GL33-0618 - 09-12-2019 4-1

Allow to cool.

Page 20

Table 4-1 Troubleshooting Chart - Continued

MALFUNCTION PROBABLE CAUSE CORRECTIVE ACTION

TROUBLE WITH BRAKING -

Continued

Brake drags. Defective electric brake. Replace.

Brake grabs. Defective electric brake. Replace.

Abnormal noise and chatter when

brake is applied.

TROUBLE WITH LIFTING OR

LOWERING

Oil sprays or flows from the top of

the lift cylinder.

Squealing sounds when lifting

forks.

Forks do not lift to top. Oil level too low. Add oil to reservoir.

Weak, slow or uneven action of

hydraulic system.

Forks do not lift, pump motor does

not run.

Forks do not lift, motor runs. Defect in hydraulic system. Check the oil level in the reservoir

Defective electric brake. Replace.

.

Defective packing in lift cylinder Repair lift cylinder.

a. Oil level too low. Identify oil leak.

b. Lift linkage binding. Apply grease.

a. Defective pump or relief valve. Check pressure. Adjust as

necessary.

b. Worn lift cylinder. Replace cylinder.

c. Load larger than capacity. Refer to I.D.plate for capacity.

d. Defective lift motor solenoid. Replace solenoid on electrical

panel.

e. Battery charge low. Charge battery.

a. Battery is dead or discon-

nected.

b. Defective wiring. Check and repair as required.

c. Defect in electrical system for

operating pump motor.

Check and recharge if required.

Check lift switch in control head,

as well as the solenoid.

and the oil lines to the lift cylinder, and repair as required. If

normal, check the hydraulic

pump, and relief valve. Repair,

or adjust.

4-2 BL-GL33-0618 - 09-12-2019

Page 21

Table 4-1 Troubleshooting Chart - Continued

MALFUNCTION PROBABLE CAUSE CORRECTIVE ACTION

TROUBLE WITH LIFTING OR

LOWERING - Continued

Forks lift, but will not go down. Defect in hydraulic system Check lowering control switch in

control head and lowering solenoid on valve assembly.

Replace as required.

Load will not hold a. Oil bypassing internally in con-

trol valve

b. Worn lift cylinder or packing. Repack cylinder.

Platform does not lift to top. Pump

motor runs.

Forks creep downward under load

when in a raised position.

MISCELLANEOUS

Steering arm does not return to

the upright position.

Truck moves forward when arm is

pulled down.

Steering arm jerks excessively

starting or stopping the truck.

Drive motor is jerky. Motor internally damaged or worn. Replace motor.

a. Oil level too low. Add oil to reservoir.

b. Load larger than capacity. Refer to nameplate on side of

c. Batteries need charging. Change batteries.

Leak in hydraulic system, lift cylin-

der or lowering valve.

a. Week return spring. Replace spring.

b. Binding. Check and free the binding item.

a. Belly-button switch defective. Check for short, and repair or

b. Short in control head. Check wiring and repair as

Drive wheel worn. Replace drive wheel if worn to

Replace valve assembly.

mast for maximum load capacity.

Check for leaking fitting in hydrau-

lic line and repair as required.

Repack lift cylinder or replace

valve assembly.

Verify that the cable has not

been damaged. Repair or

replace as needed.

replace as necessary.

required.

within 3/4 inch of hub.

BL-GL33-0618 - 09-12-2019 4-3

Page 22

4-2. CONTROLLER TROUBLESHOOTING

R6759

R7090

4-2.1. Fault Detection.

The controller provides diagnostics information to

assist technicians in troubleshooting drive system

problems. When a fault is detected, the appropriate

fault code is signaled via the panel mounted LED.

4-2.2. Hand Held Programmer (Optional)

The hand held programmer is available that is

designed specifically for use with the controller. The

programmer is available through your Global Industrial

dealer.

4-2.3. Fault Recording.

Fault events are recorded in the controller's memory.

However, multiple occurrences of the same fault are

recorded as one occurrence.

The fault event list can be loaded into the programmer

for readout. The Special Diagnostics mode provides

access to the controller's diagnostic history file. The

history file contains the entire fault event list created

since the diagnostic history file was last cleared. The

standard Diagnostics mode provides information about

only the currently active faults.

1. Disconnect the battery charger and connect the

programmer to the 4-pin connector (Figure 4-1)

on the controller.

Figure 4-1. Controller Terminals

2. Turn the lift truck key switch to the ON position.

The programmer should “power up” with an initial

display (2, Figure 4-2), and the controllers Status

LED should begin steadily blinking a single flash.

If neither happens, check for continuity in the key

switch circuit and controller ground.

4-2.4. General Checkout.

Carefully complete the following checkout procedure.

If you find a problem during the checkout, refer to

paragraph 4-2.7. for further information.

The checkout can be conducted with or without the

handheld programmer (See Paragraph 4-2.2.). However, the checkout procedure is easier with a programmer. To evaluate the system without a programmer,

observe the LED and note the flashing pattern and

refer to for the code description.

CAUTION: Put the vehicle up on blocks to get the

drive wheel off the ground before beginning these tests.

Turn the keyswitch off and make sure the

brake is applied, the throttle is in neutral,

and the forward/reverse switches are

open.

Do not stand, or allow anyone else to

stand directly in front of or behind the

vehicle during the tests.

Figure 4-2. Hand Held Programmer

4-4 BL-GL33-0618 - 09-12-2019

Page 23

3. Put the controller into the diagnostic mode by

pressing the “Menu Navigation Key” (1, Figure 4-

2). Using the Navigation key, select the Faults

menu. Display the Faults menu by pressing the

Right side of the Navigation key. Press the Right

side of the Navigation key again to display the list

of System Faults. The display should indicate “No

Known Faults.”

Release the brake by pulling down the steering

arm into the operating position. The controllers

LED should continue blinking a single flash and

the programmer should continue to indicate no

faults. If there is a problem, the LED will flash a

diagnostic code and the programmer will display a

diagnostic message. If you are conducting the

checkout without a programmer, look up the LED

diagnostic code in Table 4-3.

When the problem has been corrected, it may be

necessary to cycle the brake in order to clear the

fault code.

4. With the brake released, select a direction and

operate the throttle. The motor should begin to

turn in the selected direction. If it does not, verify

the wiring to the forward/reverse switches and

motor. The motor should run proportionally faster

with increasing throttle. If not, refer to Paragraph

4-2.7.

5. Put the controller into the test mode by using the

Navigation key (1) to select the "Monitor" menu.

Select the Monitor mode by pressing the "Right"

arrow on the Navigation key. Press the Navigation

key "Down" arrow to scroll down to observe the

status of the forward, reverse, brake, emergency

reverse, and mode switches. Cycle each switch in

turn, observing the programmer. Each input

should show the correct state on the programmer.

6. Check the controller's fault detection circuitry as

described in Paragraph 4-2.5.

7. Take the vehicle off the blocks and drive it in a

clear area. It should have smooth acceleration

and good top speed.

8. Test the plug braking of the vehicle. The vehicle

should smoothly slow to a stop and reverse direction, with the audible plugging tone.

9. Verify that all options, such as high pedal disable

(HPD), static return to off (SRO), and anti-tiedown, are as desired.

10. Check to see whether the emergency reverse

(belly button) feature is working correctly. Verify

that the circuit is operational by momentarily disconnecting one of the emergency reverse wires.

The vehicle should be disabled and a fault indicated.

BL-GL33-0618 - 09-12-2019 4-5

Page 24

4-2.5. Diagnostic History

The handheld programmer can be used to access the

controller's diagnostic history file. When the programmer is connected to the unit, the error log file is automatically uploaded into the handheld programmer.

To see the present status of the unit, use the Menu

Navigation Key (1, Figure 4-2) to select:

Faults->System Faults.

To access this log, use the Menu Navigation Key to

select:

Faults->Fault History

The faults are shown as a code and descriptive text. If

there are multiple faults, you have to scroll through the

list using the Up and Down Buttons on the Menu Navigation Key

The faults may be intermittent faults, faults caused by

loose wires, or faults caused by operator errors. Faults

such as HPD or over-temperature may be caused by

operator habits or by overloading.

After a problem has been diagnosed and corrected,

clearing the diagnostic history file is recommended.

This allows the controller to accumulate a new file of

faults. By checking the new diagnostic history file at a

later date, you can quickly determine whether the

problem has been completely fixed.

To clear the diagnostic history file, select:

Faults->Clear Fault History.

You will be asked to confirm your actions. Use the

"plus" arrow (+) for yes to clear the menu and the

"minus" arrow (-) (3) to cancel your selection and not

clear the Fault History.

4-2.6. Test the Fault Detection Circuitry

1. Put the vehicle up on blocks to get the drive wheel

off the ground.

1. Turn off the key switch and emergency disconnect.

2. Using an inline fuse holder fitted with a 10 amp

fuse and alligator clips, connect the controller's M

and B- terminals.

3. Turn on the emergency disconnect (17) the key

switch (20). Release the brake and apply the

throttle. The motor should not operate.

4. Leave the key switch on and remove the in-line

fuse wire. The vehicle status should continue to

remain off.

5. Cycle the key switch off and on. Release the

brake and apply the throttle. The vehicle should

now operate normally.

4-2.7. Diagnostics and Troubleshooting.

The motor controller provides diagnostics information

to assist in troubleshooting drive system problems.

The diagnostics information can be obtained in two

ways:

• Reading the appropriate display on the programmer

• Observing the fault codes issued by the panel

mounted Status LED.

4-2.7.1. LED Diagnostics

During normal operation with no faults present, the

Status LED is steady on. If the controller detects a fault

the Status LED flashes a fault identification code continuously until the fault is corrected.

NOTE: The Status LED can only indicate one fault at

a time. If multiple faults are detected, the

highest priority fault code flashes until it is

cleared.

With Fault Code Type parameter is set to 0, the status

LED uses the fault codes listed in . Six single-digit

codes are used: 2, 3, 5, 6, 7, and 9.

For suggestions about possible causes of the various

faults, refer to Table 4-3 Troubleshooting Chart.

4-6 BL-GL33-0618 - 09-12-2019

Page 25

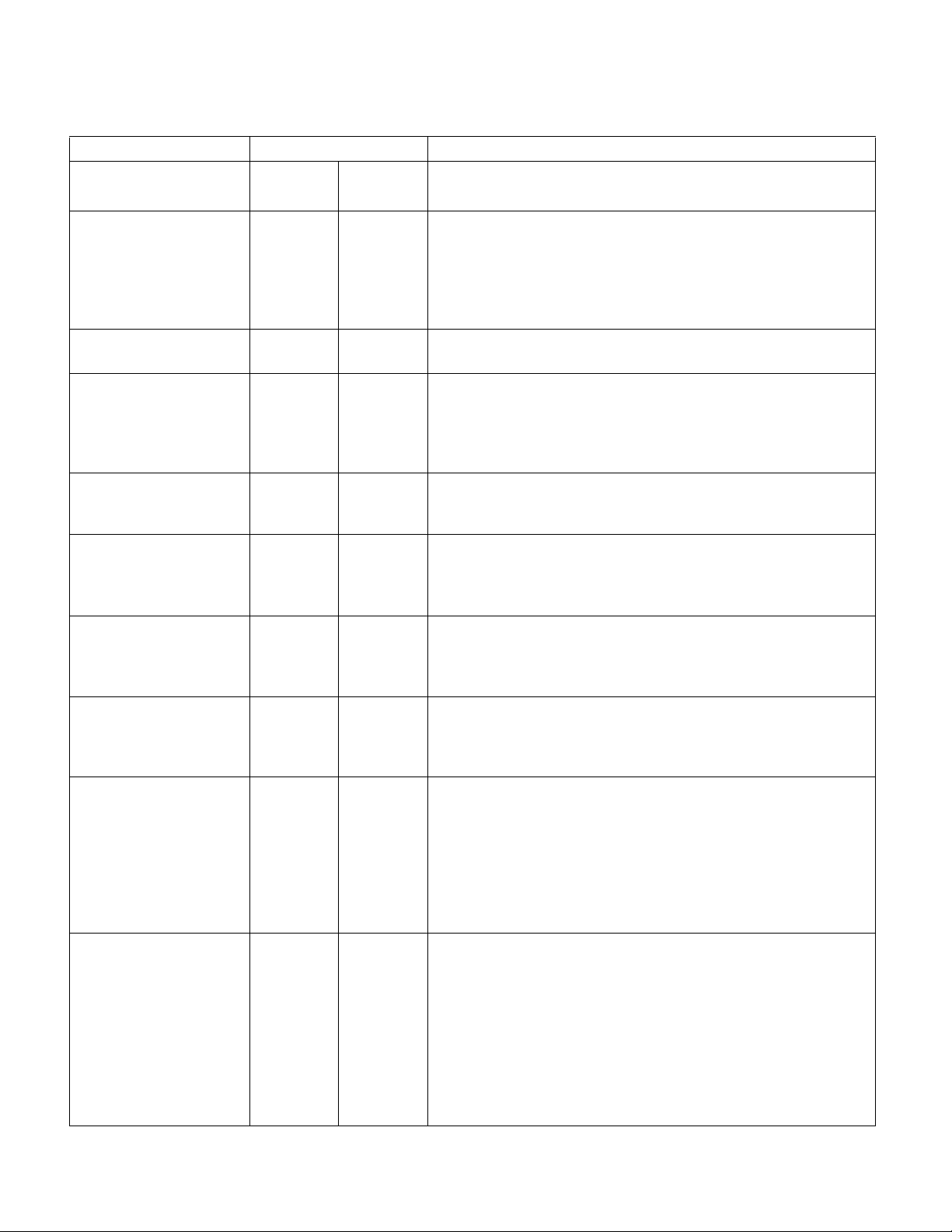

Table 4-2 Programmable Parameters

Parameter Factory Setting Description

DRIVE MENU

Accel Max Speed 1.5 sec.

Accel Min Speed 5.0 sec.

Decel High Speed 0.6 sec.

Decel Low Speed 1.5 sec.

90A

Sets the rate (in seconds) at which the speed command

increases when throttle is applied with the speed limit pot is

in its maximum speed position, and the vehicle is traveling

forward. Larger values represent slower response.

Note: Allowable range is restricted by the Accel Min Speed set-

ting.

Sets the rate (in seconds) at which the speed command

increases when throttle is applied while the speed limit pot is

in its minimum speed position, and the vehicle is traveling

forward. Larger values represent slower response

Note: Allowable range is restricted by the Accel Max Speed

setting.

Sets the rate (in seconds) that is used to slow down the vehicle

when it is traveling forward at high speed and throttle is

reduced. Larger values represent slower response.

Note: Allowable range is restricted by the Decel Low Speed

setting.

Sets the rate (in seconds) that is used to slow down the vehicle

when it s traveling forward at low speed and throttle is

reduced. Larger values represent slower response.

Rev Accel Max Speed 1.5sec.

Rev Accel Min Speed 5.0 sec.

Rev Decel High Speed 0.5 sec.

Note: Allowable range is restricted by the Decel High Speed

setting.

Sets the rate (in seconds) at which the speed command

increases when throttle is applied while the speed limit pot is

in its maximum speed position, and the vehicle is traveling in

reverse. Larger values represent slower response.

Note: Allowable range is restricted by Rev Accel Min Speed

setting.

Sets the rate (in seconds) at which the speed command

increases when throttle is applied while the speed limit pot is

in its minimum speed position, and the vehicle is traveling in

reverse. Larger values represent slower response.

Note: Allowable range is restricted by Rev Accel Max Speed

setting.

Sets the rate (in seconds) that is used to slow down the vehicle

when it is traveling in reverse at high speed and throttle is

reduced. Larger values represent slower response.

Note: Allowable range is restricted by Rev Decel Low Speed

setting.

BL-GL33-0618 - 09-12-2019 4-7

Page 26

Table 4-2 Programmable Parameters - Continued

Parameter Factory Setting Description

DRIVE MENU Cont.

Rev Decel Low Speed 1.5 sec.

Key Off Decel 0.7 sec.

E Stop Decel 0.6 sec.

E Stop Pause 0.5 sec.

Soft Start 25%

Gear Soften 15%

Creep Speed 7%

Push Max Speed N/A

90A

Sets the rate (in seconds) that is used to slow down the vehicle

when it is traveling in reverse at low speed and throttle is

reduced. Larger values represent slower response.

Note: Allowable range is restricted by Rev Decel High Speed

setting.

Sets the rate (in seconds) that is used to slow down the vehicle

at key-off or in the event of a major fault.

Sets the rate (in seconds) that is used to slow down the vehicle

during emergency reverse, i.e., when a throttle command

>80% in the reverse direction is given while the vehicle is

moving forward. This gives the operator a way to stop more

quickly when unexpected conditions arise.

Sets a pause before reversing direction after an emergency

reverse stop. This gives the operator time to return the throttle to neutral without moving backwards

This parameter can be used to soften the bump associated

with gear slack in the transaxle when throttle is applied from

the neutral state. Larger values provide a softer slack takeup.

This parameter is intended to soften the bump associated with

gear slack in the transaxle when throttle is released and then

reapplied while the vehicle is still moving. Larger values provide a softer slack take-up.

Creep Speed helps to prevent vehicle rollback on inclines

when the brake is released with very little throttle applied. It is

activated when the throttle request exceeds the throttle deadband threshold.

Sets the maximum speed at which the vehicle can be pushed.

When the vehicle is powered on and in neutral, it enters the

push mode when the push button is activated. The electromagnetic brake is released, driving is inhibited, and speed is

limited to Push Max Speed. When the vehicle is not powered

on and the brake is mechanically released to enable pushing,

Push Max Speed still applies. Once sufficient voltage is generated by the motor, speed will be limited by the controller

Sets the speed at which a gentler deceleration is initiated when

the throttle is released to neutral; larger values start the soft

stop deceleration sooner.

Soft Stop Speed 13%

4-8 BL-GL33-0618 - 09-12-2019

Page 27

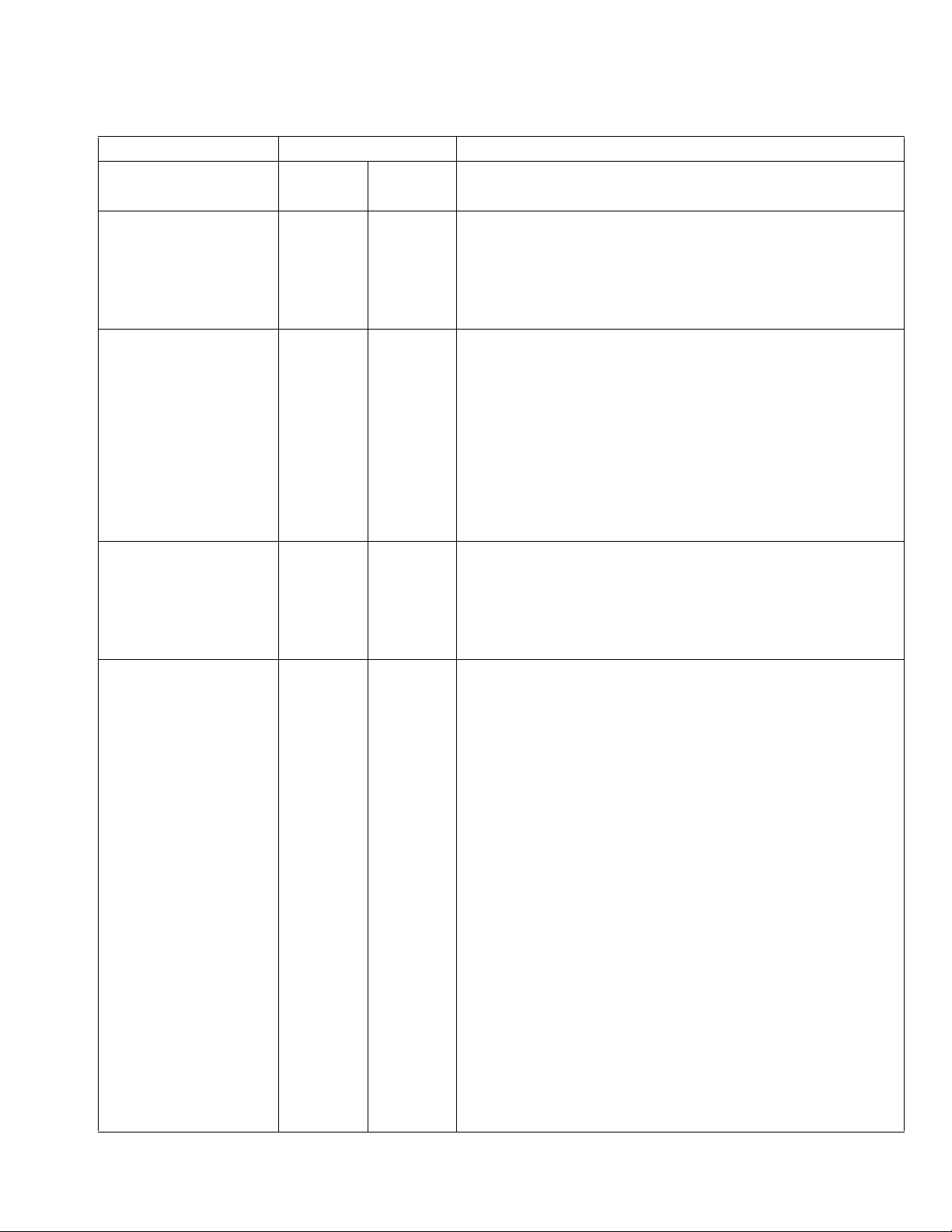

Table 4-2 Programmable Parameters - Continued

Parameter Factory Setting Description

SPEED MENU

Max Speed

Mode 1

Mode 2

Min Speed

Mode 1

Mode 2

Rev Max Speed

Mode 1

Mode 2

90A

100%

30%

20%

20%

100%

30%

During forward operation, defines the requested speed at full

throttle when the speed limit pot is in its maximum speed

position.

Note: Allowable range is restricted by the M1/M2 Min Speed

setting.

During forward operation, defines the requested speed com-

mand at full throttle when the speed limit pot is in its minimum

speed position. Min Speed cannot be set higher than the programmed Max Speed.

Note: Allowable range is restricted by the M1/M2 Max Speed

setting.

Note: For this parameter to apply, a speed limit pot must be

installed in parallel with the throttle and the Speed Limit Pot

parameter must be programmed On (see Throttle menu).

During reverse operation, defines the requested speed at full

throttle when he speed limit pot is in its maximum speed position.

Note: Allowable range is restricted by M1/M2 Rev Min Speed

setting.

During reverse operation, defines the requested speed com-

mand at full throttle when the speed limit pot is in its minimum

speed position. Rev Min Speed cannot be set higher than the

programmed Rev Max Speed.

Note: Allowable range is restricted by M1/M2 Rev Max Speed

setting.

Note: For this parameter to apply, a speed limit pot must be

Rev Min Speed

Mode 1

Mode 2

BL-GL33-0618 - 09-12-2019 4-9

10%

10%

installed in parallel with the throttle and the Speed Limit Pot

parameter must be programmed On (see Throttle menu).

Page 28

Table 4-2 Programmable Parameters - Continued

Parameter Factory Setting Description

THROTTLE MENU

Type 7

PotHigh 5V

PotLow 0V

Neutral Deadband 5%

Throttle Max 90%

HPD ON

90A

The 1212 controller can accept inputs from both 5k, 3-wire

pot throttles and voltage throttles. Set the throttle type parameter to match the throttle used in your application.

5k, 3-wire pot throttles

0 = wigwag

1 = inverted wigwag

2 = single-ended; neutral when wiper at PotLow

3 = inverted single-ended; neutral when wiper at PotHigh

4 = unipolar.

Voltage throttles

5 = wigwag

6 = inverted wigwag

7 = single-ended; neutral when wiper PotLow

8 = inverted single-ended voltage; neutral when wiper

PotHigh

9 = unipolar

Sets the maximum voltage for voltage throttles (Types 5–9).

For 5k, 3-wire pot throttles, PotHigh is determined by the

throttle itself.)

Sets the maximum voltage for voltage throttles (Types 5–9).

For 5k, 3-wire pot throttles, PotLow is determined by the

throttle itself.)

Sets the throttle range the controller interprets as neutral.

Increasing the parameter setting increases the neutral range.

This parameter allows the neutral deadband to be defined

wide enough to ensure the controller goes into neutral when

the throttle is released.

Sets the pot wiper voltage required to produce 100% controller

output. Increasing the Throttle Max setting reduces the wiper

voltage required, and therefore reduces the stroke necessary

to produce full output. This feature allows reduced-range

throttle assemblies to be used.

When programmed On, vehicle drive is inhibited if a throttle

command outside the neutral deadband is issued before the

controller is powered up. Drive will continue to be inhibited

until the throttle is returned to within the neutral deadband. If

the HPD fault is not cleared within 10 seconds, a wiring fault

is declared and a power cycle is required.

This parameter is used to enable/disable the speed limit pot. If

no speed limit pot is used, set Speed Limit Pot to Off.

Speed Limit Pot OFF

4-10 BL-GL33-0618 - 09-12-2019

Page 29

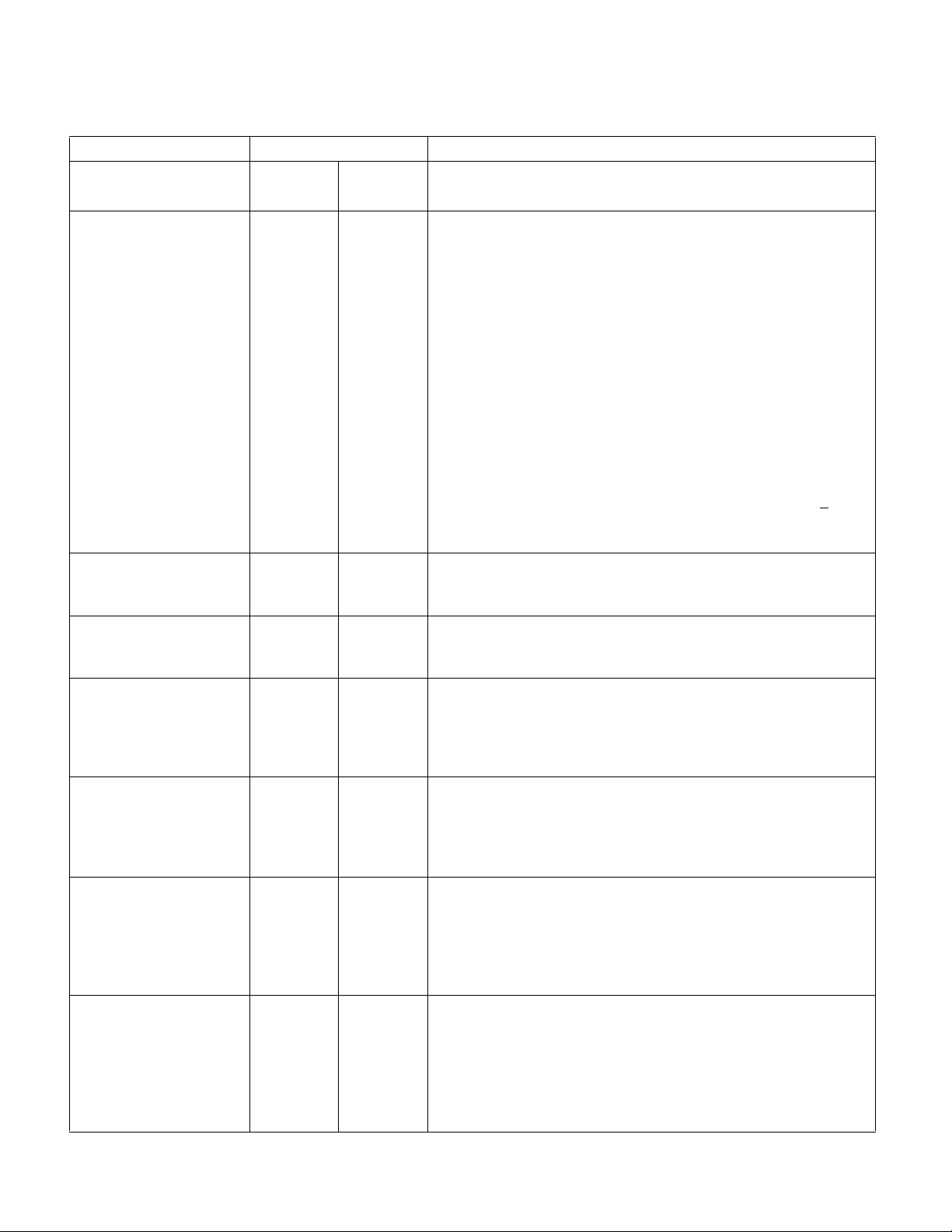

Table 4-2 Programmable Parameters - Continued

Parameter Factory Setting Description

THROTTLE MENU Continued

90A

The throttle map parameter adjusts the static throttle map. The

parameter setting corresponds to the throttle command at

half throttle.

Throttle Map 50%

Tremor Suppression 50%

Calibration OFF

CURRENT MENU

Main Current Limit 90A

Braking Current Limit 90A

Boost Current 90A

A setting of 50% provides linear response. Values below 50%

reduce the throttle command at low throttle positions, providing enhanced slow speed maneuverability. Values above

50% give the vehicle a faster, more responsive feel at low

throttle positions.

This parameter can be used to limit the controller’s response

to sharp throttle movements, such as movements resulting

from hand tremors.

Larger values will provide a steadier ride, but they also result in

more sluggish response to throttle request. There is thus a

trade-off between crispness of response (low Tremor Suppression settings) and steady speed in the presence of tremors (high settings).

Wigwag and unipolar throttle pots should be centered. Setting

this parameter to On inhibits driving and puts the controller

into throttle autocalibration mode.

Setting the parameter Off returns the controller to normal oper-

ation.

Sets the maximum current the controller will supply to the

motor during normal driving. By limiting the current supplied,

this parameter can be used to protect the motor from potentially damaging currents or to reduce the maximum torque

applied to the drive system.

Sets the maximum current the controller will supply to the

motor during braking. By limiting the current supplied, this

parameter can be used to protect the motor from potentially

damaging currents or to reduce the maximum braking torque

applied to the drive system.

Boost current gives a brief boost of current that greatly

improves performance with transient loads, such as starting

on a hill, crossing a threshold, climbing obstacles, etc. When

the controller recognizes that the motor needs more current

to respond to a drive request, it provides a current boost of a

set amount for a set time.

The Boost Current parameter defines the motor current limit

the boost period

d.

Boost Time 0.0 sec.

during

This parameter sets the maximum time that the boost current is

allowe

BL-GL33-0618 - 09-12-2019 4-11

Page 30

Table 4-2 Programmable Parameters - Continued

Parameter Factory Setting Description

INHIBIT MENU

Type 2

Speed 0%

BRAKE MENU

Delay 0.3 sec

Fault Check ON Enables/disables the fault detection on the EM brake.

Hold Voltage 18V

Brake Light OFF

HORN MENU

Fault Beep N/A

Reverse Beep ON

Beep Constant OFF

90A

The flexible speed input at J1 Pin 6 can be used to limit or to

inhibit speed under certain conditions. For example, a switch

could be installed under the seat so that if the operator drives

the scooter while they are standing the max speed will be limited.

The Inhibit Type parameter is used to select how the inhibit

function will be implemented. Depending on how the inhibit

switch is wired into the system, set this parameter to:

0 = B- active

1 = B+ active

2 = Open circuit active

3 = B- inactive

4 = B+ inactive

5 = Open circuit inactive.

This parameter limits the maximum speed allowed during

speed inhibit mode. A setting of 0 prevents drive during

inhibit mode.

Sets the length of delay between when zero speed is com-

manded and the electromagnetic brake is engaged.

A high initial voltage is applied to the brake coil when the brake

is first released. After approximately 1 second, this peak voltage drops to the programmed Hold Voltage. The parameter

should be set high enough to hold the brake released under

all the shock and vibration conditions the vehicle will be subjected to.

When set to On, the horn output (J1 Pin 3) will act as a brake

light driver. The brake light must be driven by a relay. The

brake light will be turned on when the throttle is returned to

neutral and will remain on for about 2 seconds after the EM

brake is engaged.

When programmed On, the horn will be used to provide audi-

ble fault codes whenever faults are present. These are the

same fault codes that are flashed by the status LED. If a fault

should occur while the vehicle is driving in reverse with the

reverse beep active, the fault signal will take precedence. If

this audible fault alarm is not wanted, set Fault Beep to Off.

When programmed On, the horn will sound whenever the vehi-

cle is being driven in reverse. On vehicles with reverse

switches, the horn will sound when the reverse switch is activated.

Sets the reverse beep to be a constant tone (when pro-

grammed On) or a 1Hz pulse (when programmed Off).

4-12 BL-GL33-0618 - 09-12-2019

Page 31

Table 4-2 Programmable Parameters - Continued

Parameter Factory Setting Description

MOTOR MENU

System Resistance

Resistance Auto Comp ON

Auto Comp Current

Limit

Speed Scaler 27V

Current Rating 25A

Max Current Time 120 sec.

Cutback Gain 0%

BDI MENU

Full Voltage 24.4V

Empty Voltage 20.8V

90A

80 mΩ

73 mΩ

20%

Sets the system resistance (motor + brushes + wiring + con-

nections) used for load compensation and speed estimation.

Control system performance depends on this parameter

being set correctly; it must be set to the actual cold motor

resistance.

Resistance is automatically measured under a preset low cur-

rent before the brake is released. The measured motor resistance plays an important role in IR compensation.

The Resistance Auto Comp parameter enables/disables this

automatic function.

Sets the current limit used for automatic resistance testing, as

a percentage of the Main Current Limit (see Current menu).

The Speed Scaler parameter sets the maximum voltage that

can be applied to the motor. It can be used to eliminate variations in maximum speed that would otherwise result when

driving with a fully charged battery vs. a partially discharged

battery. If Speed Scaler is set to 23 volts, for example, the

maximum vehicle speed will be the same whether the actual

battery voltage is 27 volts or 23 volts or any value in between.

This parameter should be set to the current rating provided by

the motor 0–70 A manufacturer.

Sets the maximum amount of time the motor is allowed to run

at the main current limit.

When the motor overheats, the drive current is cut back until it

reaches the programmed Current Rating. The Cutback Gain

determines how quickly this cutback will occur, once the programmed Max Current Time has expired.

Voltage when the battery is fully charged. Note: Allowable

range is restricted by the Empty Voltage, Start Charge Voltage, and Reset Voltage settings.

Voltage when the battery is fully discharged.

Note: Allowable range is restricted by the Full Voltage setting.

Voltage, when a charger is connected, above which the battery

is considered finished charging.

Note: Allowable range is restricted by the Start Charge setting.

Full Charge Voltage 28.2V

BL-GL33-0618 - 09-12-2019 4-13

Page 32

Table 4-2 Programmable Parameters - Continued

Parameter Factory Setting Description

BDI MENU - Cont. 90A

Voltage above which the battery is considered to start

Start Charger

Voltage

Reset Voltage 25.0V

25.2V

charging.

Note: Allowable range is restricted by the Full Voltage and Full

Charge Voltage settings.

Voltage at which the BDI calculator will be reset to 100%, after

the charger is disconnected and the controller is powered up.

Note: Allowable range is restricted by the Full Voltage setting.

Discharge Factor 2.0

Charge Factor 2.0

Low BDI Level 40%

Low BDI Max Speed 15%

COMPENSATION MENU

IR Comp 70%

Discharge rate of the battery. Larger values are for larger bat-

teries, which discharge more slowly.

Charge rate of the battery. Larger values are for larger batter-

ies, which charge more slowly.

Sets the battery charge level at which maximum vehicle speed

will be limited in order to protect the battery from deep discharge. Setting Low BDI Level to zero disables this function

and allows the battery to discharge completely.

Sets the maximum allowed vehicle speed when the battery

charge falls below the programmed Low BDI Level.

Sets the motor load compensation. Higher values provide

stronger disturbance rejection, while lower values provide

smoother operation.

Note: Allowable range is restricted by the Anti-Rollback Comp

setting.

Sets the motor load compensation after the throttle is released

to neutral and the speed is estimated to be near zero. Higher

values provide more hill-holding force.

Anti-Rollback Comp 90%

Note: Allowable range is restricted by the IR Comp setting.

4-14 BL-GL33-0618 - 09-12-2019

Page 33

Table 4-2 Programmable Parameters - Continued

Parameter Factory Setting Description

EMERGENCY

REVERSE MENU

Speed (90A Only) 30%

Time Limit (90A Only) 3 sec.

Decel Rate (90A Only) 0.6 sec.

Accel Rate (90A Only) 1.5 sec.

Max Braking Current

(90A Only)

Switch Normally

Closed (90A Only)

MISCELLANEOUS MENU

Sleep 0

Fault Code Type 0

Reset Drive Time

Emergency Stop

(90A Only)

90A

90A

OFF

OFF

ON

Defines the maximum reverse speed of the motor when emer-

gency reverse is active.

Defines how long emergency reverse is allowed to be active

after the vehicle is moving in reverse direction. Setting this

parameter to zero means there is no time limit.

Sets the rate at which the vehicle brakes to a stop when emer-

gency reverse is activated and the vehicle is moving forward.

If the vehicle is already moving in the reverse direction above

the programmed EMR speed, it will be brought down to the

EMR speed.

Sets the rate at which the vehicle accelerates in the reverse

direction when emergency reverse is activated. speed.

Defines the maximum allowed motor current when the vehicle

brakes to a stop when emergency reverse is activated.

Defines the emergency reverse switch (belly button switch)

type.

On = BB switch is normally closed when it is not pressed.

Off = BB switch is normally open when it is not pressed.

Sets the delay time between the last throttle request or serial

communication and when the controller goes into sleep

mode. Setting the delay to zero disables the sleep function

This parameter selects which set of fault identification codes

(Type 0,1, or 2) will be flashed by the status LED.

The controller’s hourmeter logs the total drive time since the

last reset; this record is accessible through the Monitor

menu. Setting this parameter ON zeroes the hourmeter and

starts a new log; this is typically done when the vehicle is ser-

viced. Reset Drive Time is automatically set to Off after the

hourmeter is reset.

Defines how the vehicle will respond when the emergency stop

button is pressed.

On =The EM brake will be engaged rapidly when the emer-

gency stop button is pressed; the battery is disconnected and

the vehicle will stop abruptly.

Off =When the emergency stop button is pressed, the battery

is disconnected and the vehicle will decelerate for a short dis-

tance before it fully stops.

BL-GL33-0618 - 09-12-2019 4-15

Page 34

4-2.8. Programmer Diagnostics

With a programmer, diagnostics and troubleshooting is

more direct than with the LED alone. The programmer

presents complete diagnostic information in plain language - no code to decipher. Faults are displayed in

the Diagnostic Menu, and the status of the controller

inputs/outputs is displayed in the Test Menu.

The following 4-step process is generally used for

diagnosing and troubleshooting an inoperative vehicle

using the programmer:

1. Visually inspect the vehicle for obvious problems:

2. Diagnose the problem:

3. Test the circuitry with the programmer:

4. Correct the problem.

Repeat the last three steps as necessary until the

vehicle is operational.

Refer to the Table 4-3 for suggestions covering a

wide range of possible faults.

4-16 BL-GL33-0618 - 09-12-2019

Page 35

Table 4-3 Troubleshooting Chart

BL-GL33-0618 - 09-12-2019 4-17

Page 36

Figure 4-3 Wiring Diagram

R8507

4-18 BL-GL33-0618 - 09-12-2019

Page 37

SECTION 5

GL33-1

STEERING ARM, CONTROL HEAD AND COMPARTMENT

5-1. CONTROL HEAD

5-1.1. Control Head Removal

1. Turn off the key switch and emergency disconnect.

2. Remove the control head Covers as described in

paragraph 5-1.3.

3. Disconnect harness from potentiometer.

Figure 5-1 Steering Arm

BL-GL33-0618 - 09-12-2019 5-1

Page 38

4. Disconnect harness from emergency reverse

GL33-3

switch.

5. Remove two screws, two washers and two flat

washers.

WARNING: When removing the control head in the

following steps, be sure to hold it in place

until the control harness is disconnected.

6. Remove two screws, two washers and two flat

washers.

7. Remove the control head and handle.

Figure 5-2 Control Head

5-2 BL-GL33-0618 - 09-12-2019

Page 39

5-1.2. Control Head Installation

1. Secure control head and handle with two screws,

two washers and two flat washers.

2. Install two screws, two washers and two flat

washers.

3. Reconnect harness to emergency reverse switch.

4. Reconnect harness to potentiometer.

5. Install the control Head Covers as described in

paragraph 5-1.4.

6. Turn on the key switch and emergency disconnect.

5-1.3. Control Head Covers Removal.

1. Turn off the key switch and emergency disconnect.

2. Remove four screws and lift up control head Covers.

3. Disconnect harnesses from each other and

remove control head Covers.

5-1.4. Control Head Covers Installation.

1. Hold control head Covers in place and connect

harnesses together.

2. Position control Head Covers on control head and

secure with four screws.

3. Turn on the key switch and emergency disconnect.

5-1.5. Speed Potentiometer Replacement.

1. Remove the control Head Covers as described in

paragraph 5-1.3.

2. Disconnect harness from potentiometer.

3. Remove screw, washer and control knob from

potentiometer.

4. Remove screw, washer and control knob from

other side of potentiometer.

BL-GL33-0618 - 09-12-2019 5-3

Page 40

5. Remove screws, two lock washers and two flat

washers and remove potentiometer and switch

assembly from bracket.

6. Position new potentiometer and switch assembly

in bracket and secure with screw, screw, two lock

washers and two flat washers.

7. Install control knob on potentiometer and secure

with screw, and washer.

8. Install control knob on the other side of potentiometer and secure with screw, and washer.

9. Reconnect harness to potentiometer.

10. Install the control Head Covers as described in

paragraph 5-1.4.

5-1.6. Belly-Button Switch Replacement.

1. Remove the control Head Covers as described in

paragraph 5-1.3.

2. Disconnect harness from emergency disconnect

switch.

3. Remove screws, two lock washers and two flat

washers and remove potentiometer and switch

assembly from bracket.

4. Remove pin, bracket, and spring from button.

5. Remove two pins and switch assembly from

bracket.

6. Position the new switch assembly in bracket and

secure with two pins.

7. Position bracket and springs in button and install

pin.

8. Position potentiometer and switch assembly in

bracket and secure with screws, two lock washers

and two flat washers.

9. Reconnect harness to emergency reverse switch.

10. Install the control head Covers as described in

paragraph 5-1.4.

5-4 BL-GL33-0618 - 09-12-2019

Page 41

Figure 5-3 Emergency Reverse Switch Assembly

GL33-3

5-1.7. Horn Switch Replacement.

1. Remove the control head Covers as described in

paragraph 5-1.3.

2. Remove three screws, bracket and two springs.

3. Remove two pins and switch from bracket.

4. Position new switch in bracket and secure with

two pins.

5. Position bracket with two springs in cover and

secure with three screws.

6. Install the control head Covers as described in

paragraph 5-1.4.

BL-GL33-0618 - 09-12-2019 5-5

Page 42

Figure 5-4 Control Head Covers

GL33-2

5-1.8. Lift and Lower Switch Replacement.

1. Remove the control Head Covers as described in

paragraph 5-1.3.

2. Remove switch assembly from the cap

3. Remove pin securing buttons to bracket and

remove the buttons.

4. Remove two pins, two switches and four springs

from bracket.

5. Position switches and four springs in bracket and

secure with two pins.

6. Position switch assembly in cover and secure with

pin.

7. Install the control head Covers as described in

paragraph 5-1.4.

5-6 BL-GL33-0618 - 09-12-2019

Page 43

5-2. UPPER COMPARTMENT COVERS

GL33-5

5-2.1. Removal.

1. Turn off the key switch and emergency disconnect.

2. Pull cable up and remove cap from the cable. Let

cable back down into cover.

3. Remove two screws and cover.

4. Disconnect cable from the battery charger.

5-2.2. Installation.

1. Reconnect cable to the battery charger.

2. Feed cable through cover and position cover on

frame. Secure with two screws.

3. Install cap on cable and position the cap on cover.

4. Turn on the key switch and emergency disconnect.

Figure 5-5 Compartment Cover

BL-GL33-0618 - 09-12-2019 5-7

Page 44

5-3. LOWER COMPARTMENT COVERS

GL33-1

5-3.1. Removal.

1. Turn off the key switch and emergency disconnect.

2. Remove four screws and washers from lower

cover.

3. Remove lower cover from back frame.

5-3.2. Installation.

1. Position lower cover on back frame and secure

with four screws and washers.

2. Turn on the key switch and emergency disconnect.

Figure 5-6 Steering Arm

5-8 BL-GL33-0618 - 09-12-2019

Page 45

5-4. STEERING ARM

5-4.1. Return Spring Replacement.

The steering arm gas return spring is replaced while

the steering arm is in the upright position.

1. Secure the steering arm in the upright position.

2. Remove screw and free the gas return spring

from bracket.

3. Pull downward on the gas return spring to free it

from its seat inside steering arm.

4. Position the new gas return spring inside the

steering arm being sure it fully engages its seat.

5. Position the opposite end of the gas return spring

on bracket and install screw.

5-4.2. Steering Arm Removal.

1. Remove steering arm gas return spring as

described in paragraph 5-4.1.

2. Disconnect the harnesses from each other.

3. Attach a hoist to steering arm.

4. Remove shaft and the steering arm.

5-4.3. Steering Arm Installation.

1. Position steering arm over bracket and secure

with shaft.

2. Reconnect harnesses to each other.

3. Install steering arm gas return spring as described

in paragraph 5-4.1.

BL-GL33-0618 - 09-12-2019 5-9

Page 46

5-10 BL-GL33-0618 - 09-12-2019

Page 47

SECTION 6

BRAKE SERVICING

6-1. BRAKES.

The brake system consists of a transmission mounted

brake. This brake is spring applied and electrically

released.

6-1.1. Brake Assembly Replacement

1. Block load wheels.

2. Remove the lower compartment covers as

described in paragraph 5-3.

3. Disconnect electric brake from harness.

4. Remove the three mounting screws and the

brake.

5. Place the new brake into position and secure with

the three mounting screws.

6. Reconnect electric brake to harness.

7. Remove load wheel blocks and check operation.

8. Install the lower compartment covers as

described in paragraph 5-3.

BL-GL33-0618 - 09-12-2019 6-1

Page 48

Figure 6-1 Transmission, Motor, Brake Mounting

GL33-4

6-2 BL-GL33-0618 - 09-12-2019

Page 49

SECTION 7

TRANSMISSION, DRIVE WHEEL, LOAD WHEEL

7-1. DRIVE WHEEL.

1. Turn off the key switch and emergency disconnect.

2. Remove the lower compartment covers as

described in paragraph 5-3.

3. Jack up the truck so the drive wheel is off the

ground; then securely block the truck to prevent

movement.

4. Disconnect cables from drive motor.