Global Industrial 988955 User Manual

globalindustrial.ca

Distribucion Industrial Globales S DE RL DE CF

User's manual Manual del usuario Manuel de l'utilisateur

Customer Service

US: 1-800-645-2986

Servicio de atención al Cliente

México: 01.800.681.6940

Powered Drive Straddle Trucks

Model 988955

CAPACITY

2650 lbs.

INTEGRAL BATTERY / CHARGER

24-volt maintenance free batteries with direct connect

110A 110VAC plug-in automatic charger.

HH1216JW (2)12V 95AH

SPEED

Transistor travel controller

LIFT

Up to 45 fpm empty.

Up to 31 fpm loaded

LOWERING

Up to 18.5 fpm empty.

Up to 26 fpm loaded

TIRES / WHEELS

DRIVE 10" x 3" polyurethane

DUAL LOAD (2) 3" x 2.7" polyurethane

HYDRAULICS

Lift cylinder is hard chrome. Permanent magnet pump

motor and chrome plated lift cylinder provides smooth

lifting and lowering. Pump unit includes DC motor,

solenoid, and gear pump.

DRIVE

24-Volt permanent magnet DC drive motor with rare earth

neodymium magnets increases efficiency and duty cycle.

ELECTRICAL

C

urtis travel control provides smooth step less travel.

Quick disconnect EPD power cut off and battery

discharge indicator are standard equipment.

BRAKES

Electronic neutral braking function provides smooth and

safe control. Electro-magnetic disc brake provides safe and

secure stops under all conditions.

TILLER ARM CONTROLS

Offset steering arm provides excellent line of sight for

operators. Right angle stacking in aisles as narrow as 60".

Travel, lift, and lower functions are located in the ergonomic

operator handle. All operator controls are accessible

without having to lift the hand from the handle. Angle grips

are designed to allow easy operation with either hand.

Wrap around guard, reversing switch, thumb control, and

horn are standard. Low mounted tiller arm offers excellent

operator comfort and minimum steering effort.

@ 24" Load Center

Service à la clientèle

Canada: 888-645-2986

• Narrow Aisle Stacker

• General Material Handling

• Stacking

• Work Positioning in

Tight Areas

• Step-Up From Manual

Push Stacker

FRAME AND MAST

All steel construction welded rigid steel chassis for added

durability. Adjustable forks on pin style carriage. Forks are

adjustable from 9" ID to 31" OD. Standard fork is 42" long x

4" wide x 1.25" thick

HH1216JW non-telescoping mono mast with single lifting

chain, adjustable mast rollers. Chrome plated lift cylinder

provides smooth lift/lower operation and long life. Three

inch wide adjustable straddle legs for ease of operation in

racked aisles. 47.5 to 59.5 inch adjustment allows for preset

outrigger dimensions to fit various sized pallets. Straddle

leg inside dimension (ID) can be set at 38" to 50" any

position. Fully enclosed wheel guard and flush mounted

axles prevent wheel and axle damage during normal use.

SERVICEABILITY

Removable one piece power head cover allows for

easy maintenance.

1

072117

Powered Drive Straddle Trucks

TABLE OF CONTENTS

1. Introduction ...................................................... 2

User’s Manual

2. Safety Warnings

3. Main Parameters

............................................... 2

.............................................. 4

4. Operation Instructions

5. Battery Charging

.............................................. 7

6. Inspection And Maintenance

1.

INTRODUCTION

Become familiar with the location and function of all

controls before operating the truck. Do not use this truck

unless you have been trained and authorized to do so.

All information, specifications, a nd i llustrations i n t his

manual are based on the latest data available at the time

of publication. Our company reserves the right to make

changes or improvements at any time without notice.

The machine is certified to ANSI: B56.1 standards.

Controller is certified to UL. Charger is certified to UL and

CSA standards.

With proper operation and scheduled maintenance, this

truck should provide years of productive service.

1.1 Modifications and Additions

Any changes, additions or modifications will void the

warranty. Do not cover or remove safety decals.

2. SAFETY WARNINGS

Safe operation of the truck depends upon the

following:

• The operator’s knowledge, skill and training

• Equipment maintenance

• The operator’s high regard for personal safety and

the safety of others

• A safe and suitable working environment

2.1 Safety Guidelines

Read and understand the following safety guidelines

for maximum safe operation of this electric truck.

• Read and obey all warnings

and instructions contained in

this manual.

• Operate this truck only from

the designated operating

position.

• Never carry passengers.

• Never let anyone stand on or under the forks.

• Drive the truck safely. Always keep it under

control.

• If you lose control of the truck, let go of the control

handle and quickly move away from the truck.

•

Elevate the lifting mechanism only to pick up a

load. Stunt driving and horseplay are dangerous to

personnel and equipment, and are not permitted.

• Do not overload the truck. Check the capacity

plate for load weight information.

................................. 5-7

.......................... 8

• Operate on a flat, smooth surface.

• Start, stop, change direction, travel, and brake

smoothly. Slow down for turns and uneven or

slippery surfaces that could cause the

truck slide or tip. In any application,

always approach and leave the aisle

slowly.

• Be aware of objects protruding from

racks, shelves and walls that can

cause injury or come into contact with the truck.

• Operate the truck slowly and in an open area until

you become thoroughly familiar with the truck

controls.

• Use extreme care when traveling without a load.

Excessive speed with abrupt turns or on uneven

surfaces may cause the truck to tip when empty

as well as when loaded.

• Examine the load before moving to ensure that it

is securely and safely loaded.

•

Always look in the direction of travel. Keep a clear view.

• When the load interferes with visibility, face the

direction of travel with the load trailing.

• Do not handle unstable or loosely-stacked loads.

Use special care when handling long, high, or

wide loads.

• Obey all applicable traffic regulations. Yield the

right-of-way to pedestrians. Drive on the right

unless your work area follows different rules.

• Always stop the truck and sound the horn when

approaching crossing aisles, when entering or

exiting an aisle, or when visibility is obstructed.

• Keep your hands and fingers inside the protected

area of the control handle.

• Ensure there is enough light.

• Do not operate unit near personnel.

• If you leave the electric truck unattended, fully

lower the forks, shut the power off, remove the

key from the optional key switch (if your truck has

this option), and disconnect the battery.

2

NO

SLOPE

Powered Drive Straddle Trucks

User’s Manual

2.2 Power Equipment Can Be Hazardous

• Any power equipment can be hazardous.

•

Accidents may occur when power industrial equipment

is in the hands of untrained or unauthorized operators.

This electric truck is no exception.

• Before operating this truck, read and understand

this manual. Notify your supervisor if you have

any concerns or questions. Carefully review all

safety decals on the truck.

2.3 Pedestrians

Pay attention to pedestrians at all times. Many other

people in your area of facility might not be familiar

with this truck and how it operates. Always yield the

right-of-way to pedestrians. Never drive this truck up

to anyone, particularly someone standing next to a

solid object like a wall or workbench.

2.4 Travel

Operate this electric truck at an authorized speed

consistent with conditions. Always maintain a safe

distance from other trucks. Keep the truck under

control at all times so you can stop in an emergency.

Look in the direction of the path of travel, and keep a

clear view. Stop the truck and sound the horn when

crossing aisles or when visibility is obstructed. Keep

to the right unless conditions dictate otherwise. Do

not pass another truck traveling in the same direction

at intersections, blind spots, or other dangerous

locations. Avoid making sudden starts, quick stops

or turns, particularly when operating with stacked

loads. Slow down for rough, wet or slippery floors,

and avoid running over any objects on the floor.

2.5 Power Equipment

Dockboards must be strong enough to carry the weight

of the truck, the weight of the operator and the load.

The carrying capacity should be plainly marked on the

dockboards. Dockboards should be securely anchored

or equipped with devices to prevent slipping. The sides

of the dockboards should be turned up at right angles

to prevent the electric truck from running over the edge.

Dockboards should be designed and maintained so the

edges have substantial contact with the carrier and the

dock or loading platform to prevent rocking or sliding.

Handholds, or other effective means, should be provided

to permit safe handling. Positive positioning, such as

wheel chocks, should be provided to prevent railroad cars

or highway trucks from being moved while dockboards

are in position.

2.6 Elevators

Check with your supervisor before you use this electric

truck near or in an elevator.

2.7 Lifting And Loading

Follow these instructions when lifting and loading:

• Move only loads that are securely and safely

loaded

• Place forks under the load as far as possible

• When the electric truck is empty, travel with the

forks fully lowered

• When moving bulky loads that block rearward

visibility, drive the electric truck with the load

trailing

• Carry the load as low as is safely possible

2.8 Moving the Stacker With a Forklift

As with all large loads, always maintain a safe

speed while transporting the stacker. When finished,

reattach the forklift pocket covers before operating.

Exposed pockets may catch equipment and injure

pedestrians or cause property damage.

3

Powered Drive Straddle Trucks

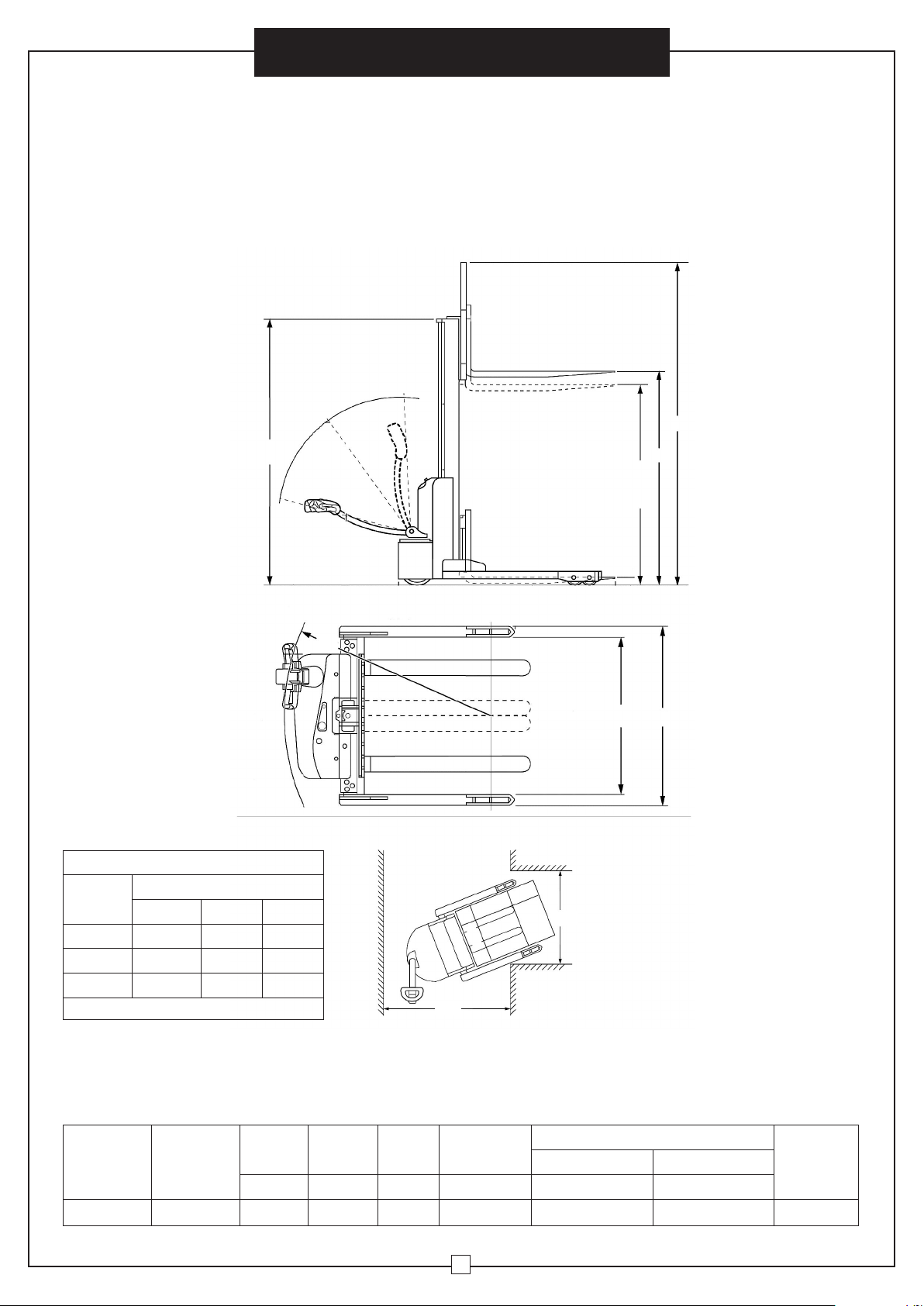

3. MAIN PARAMETERS

3.1 Capacity Plate

Capacity plate information:

The capacity plate is on the truck. It contains:

• Capacity information

• Truck weight (without battery or load)

• Truck dimensions

Mono Mast

User’s Manual

E

C

52.5"

Aisle Guide - Right Angle Stacking

Lift

Width

36"

40"

48"

For ease of use add 8" to aisle dimension listed

Load Length

36" 40" 48"

57.3 57.3 57.3

57.5 58.6 58.6

63 63 63

Aisle

Length

Bay

A

D

Free

Lift

F

G

Aisle dimensions listed above assume

the minimum bay width to be straddle

OD plus 5" (2.5" on either side of straddle

leg). Straddle OD is the load width plus

8". Truck performance may vary due to

application requirements' and changes

in model design.

Model Mast

Lift

Height

Col

Height

A

988955 Mono

3

Complete weight includes truck, battery and charger

62"

85" 55.6" 92" 38" to 50"

Free

Lift

Ext Height

w/LBR

Adjust Straddle Leg 4" Increments

ID OD

C D E F G

47.5" to 59.5"

4

3

Weight

Complete

1400lb.

Powered Drive Straddle Trucks

User’s Manual

4. OPERATION INSTRUCTIONS

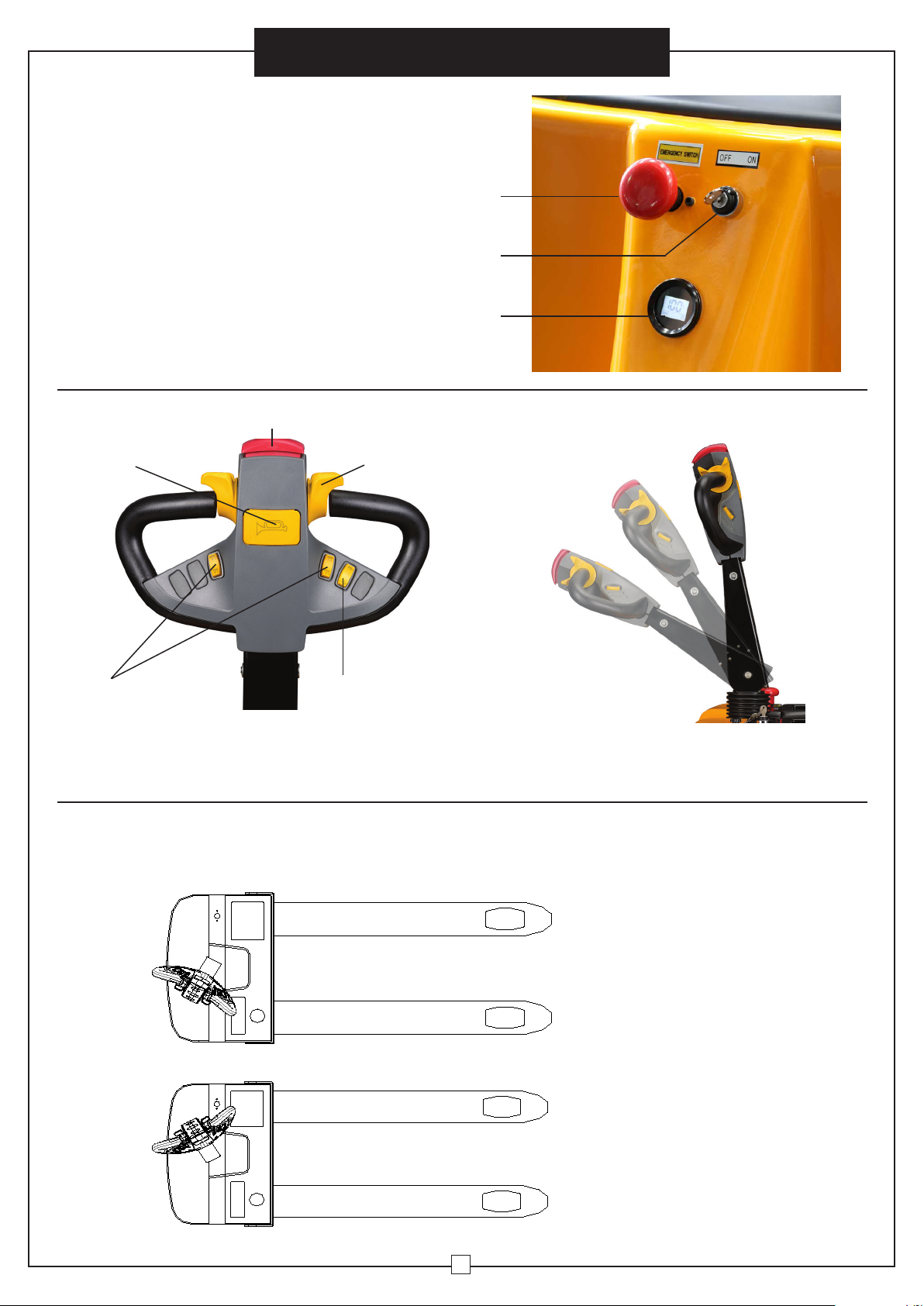

4.1 Power On and Off

• Turn on the truck by turning the key

to right: Power on

• Turn off the truck by turning the key

to left: Power off

• Always turn off the truck when

leaving the truck

Reverse

Horn

Travel

Rotator

Emergency

Switch

Key

Switch

Battery

Indicator

STOP

WORK

STOP

Lift/Lower

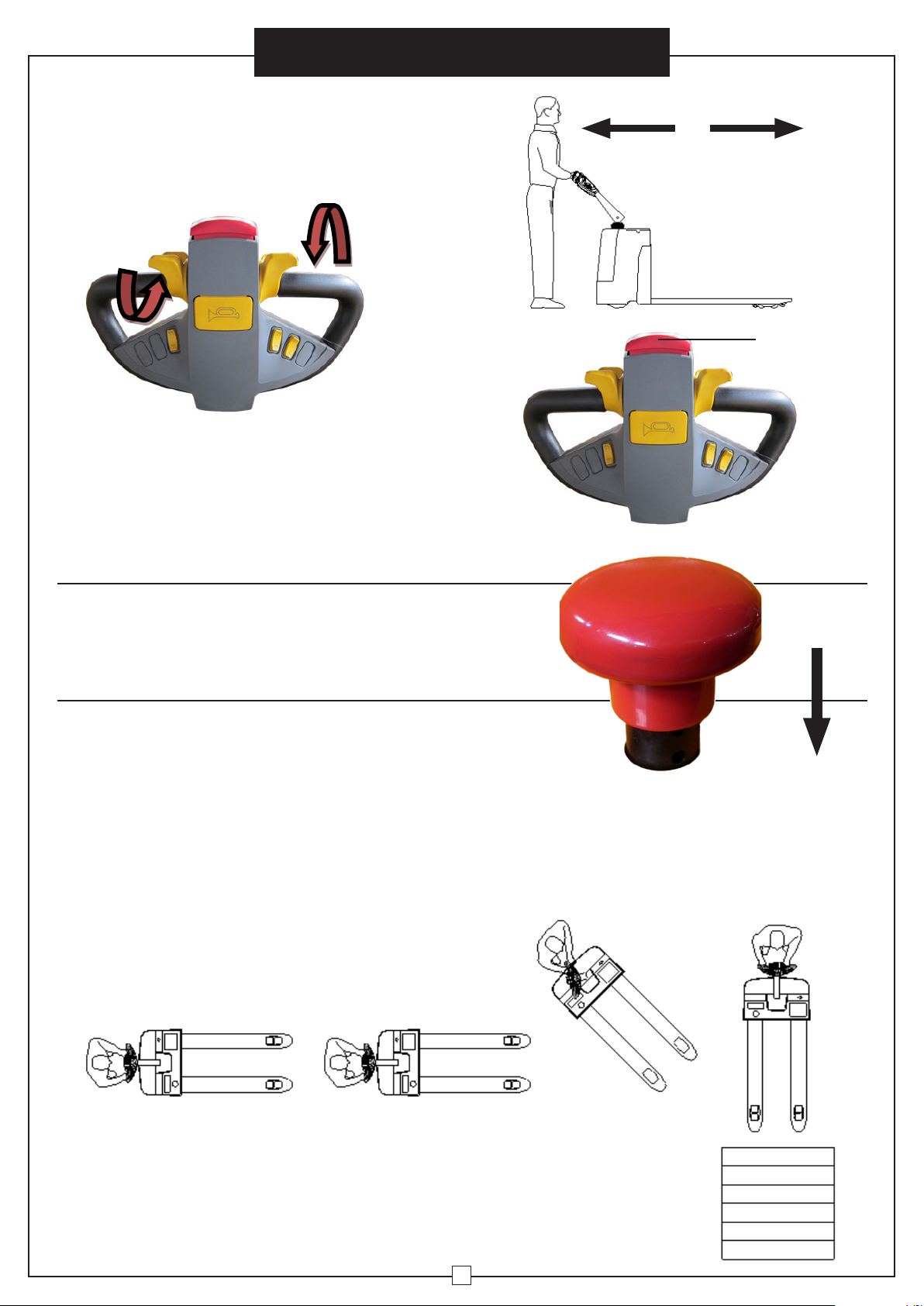

4.2 Operation Handle

• Move the handle all the way down or all the way up to apply the brake

4.3 Steering

Control steering by moving the control handle from side to side

Fast/Slow

Steer Right

Steer Left

5

Powered Drive Straddle Trucks

4.4 Traveling

Rotate the throttle button in the direction you want to

travel. The farther you rotate the throttle button from

the neutral position, the faster the truck will travel.

Forward

Backward

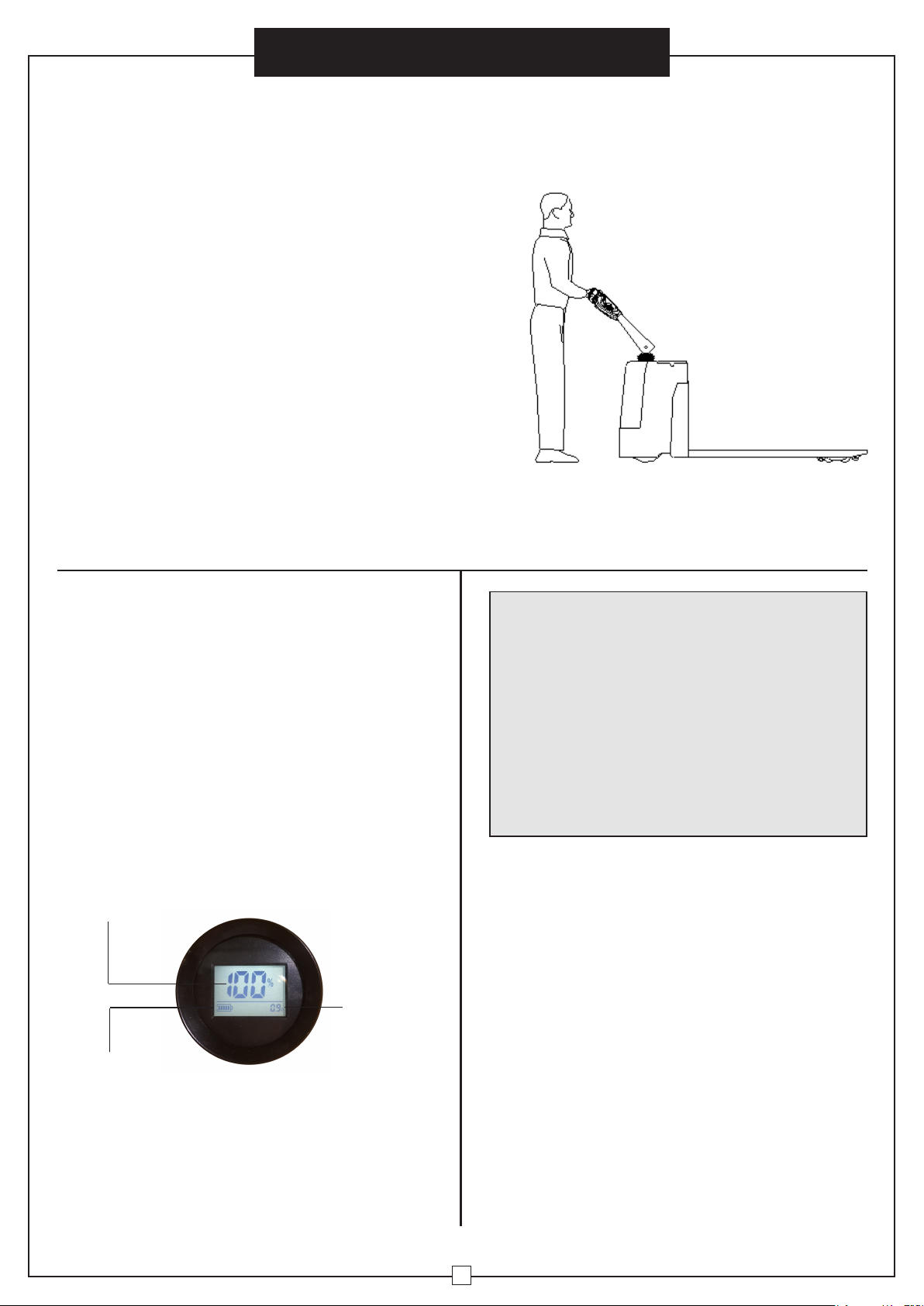

4.5 Emergency Reverse Button

If you accidentally hit the reverse button while working, the

truck will stop and then move in the direction of the forks.

Be careful-the reverse button cannot prevent injuries.

User’s Manual

Backward Forward

Emergency

Reverse

Button

4.6 Emergency Switch

Pushing down the emergency switch will cut the power

source of the machine, making it stop immediately.

4.7 Entering A Pallet

Follow these steps when entering a pallet with a truck:

1. Approach the pallet from either side with the nearest

fork about 3 in (76mm) out in the aisle.

2. When the fork is just forward of the pallet edge, stop.

3. Turn the control handle to swing the front of the truck

out into the aisle until the forks begin to enter the

pallet at an angle.

4. Continue maneuvering the truck, gradually returning

the control handle straight ahead until the truck faces

the pallet squarely.

5.

Drive the truck forks-first until the pallet is completely on

the forks. Ensure that the load wheels are not resting on

any of the boards on the bottom of the pallet.

6. Lift the pallet just enough to raise it off the floor.

7. Change direction and carefully swing the truck out into

the aisle.

Press down

to cut off

power

6

Powered Drive Straddle Trucks

4.8 Traveling With a Load

Always look in the direction of travel. When transporting loads

over a long distance, always travel in a forward direction with the

forks trailing. Never enter a trailer unless its wheels are checked

and the trailer is properly jacked.

When traveling with a load, follow these instructions:

• Ensure the load on the forks is stable

• Travel at the safest speed that conditions allow, and always

within authorized facility speed limits. Operate the truck only

at a speed that permits the truck to stop safely at all times and

under all travel conditions.

• Start, steer, change direction, and brake smoothly. Slow down

for turns and uneven or slippery surfaces to avoid causing the

truck to slide or tip.

• Keep a clear view and watch out for obstructions. When the

load interferes with visibility, travel with the load trailing.

• Check the condition of all floors, dockboards, semi-trailer beds,

ramps, elevators, and so on, to ensure they can safely support

the truck and its load.

• Observe all traffic regulations. Yield the right-of-way to

pedestrians. Stop and sound the horn at crossing aisles and

whenever vision is obstructed.

• When operating in narrow aisles, stay as far away from

stockpiles as possible in order to allow the truck to swing clear.

• Never cross railroad tracks except at approved floor grade

crossings. Cross at an angle perpendicular to the tracks.

User’s Manual

4

.9 Positioning And Unloading

To position and unload the truck, follow these steps:

1. Slowly maneuver the truck with the load to the

required area.

2. Place the load squarely and evenly to make use of

all available space.

3. Lower the forks completely.

4. Drive the truck slowly away to withdraw the forks.

4

.10 Moving The Stacker Without Power

If the stacker is inoperable or needs to be moved on/off

a pallet, remove bottom rear covers to expose forklift

pockets. Do not operate the vehicle until both covers

are reattached.

5. BATTERY CHARGING

5.1 Battery Indicator

The lighted bar and percentage indicator show how much

charge is left in the battery. Check battery indicator regularly.

Percentage indicator

Total running

time(h)

Lighted bar

indicator

5.2 Battery Procedures

The truck is mounted with two maintenance-free 12V

batteries. The battery charger is mounted inside the

battery box which is located above the controls. For

your safety, observe the following precautions when

working with or around truck batteries:

• Read, understand and follow procedures,

recommendations, and specifications in the

battery and battery charger manufacturers’

manuals.

• Do not smoke, use open flames, or use sparkproducing devices near batteries.

• Charge batteries in a well-ventilated area to avoid

hydrogen gas concentration.

• Do not break live circuits at the battery terminals,

because a spark usually occurs at the point where

a live circuit is broken.

• To avoid shorts and sparks, keep plugs, terminals,

cables, and receptacles in good condition.

5.3 Battery Removal And Installation

Take precautions not to jam or cut the battery cables

during installation of the battery, as this could result in a

short that may cause a fire or a battery explosion.

• Disconnect the battery connectors/cables from

the truck.

• Ensure the removed battery is properly stored.

• When installing a battery, always ensure that it is

fully charged before operating the truck

5.4 Charging Process

1. Press down the emergency switch on the keypad and

turn the key switch to OFF.

2. Open the battery box cap board and find the input

power cord of the charger.

3. Connect the power plug of the charger into

the outlet of the local power supply. This will

automatically turn the charger on, and it will run at

a rate commensurate with the requirements of the

batteries. The charger will automatically control the

procedure. When the batteries are fully charged,

the charger will only supply enough current to

maintain the batteries’ charge.

7

Powered Drive Straddle Trucks

6. INSPECTION AND MAINTENANCE

User’s Manual

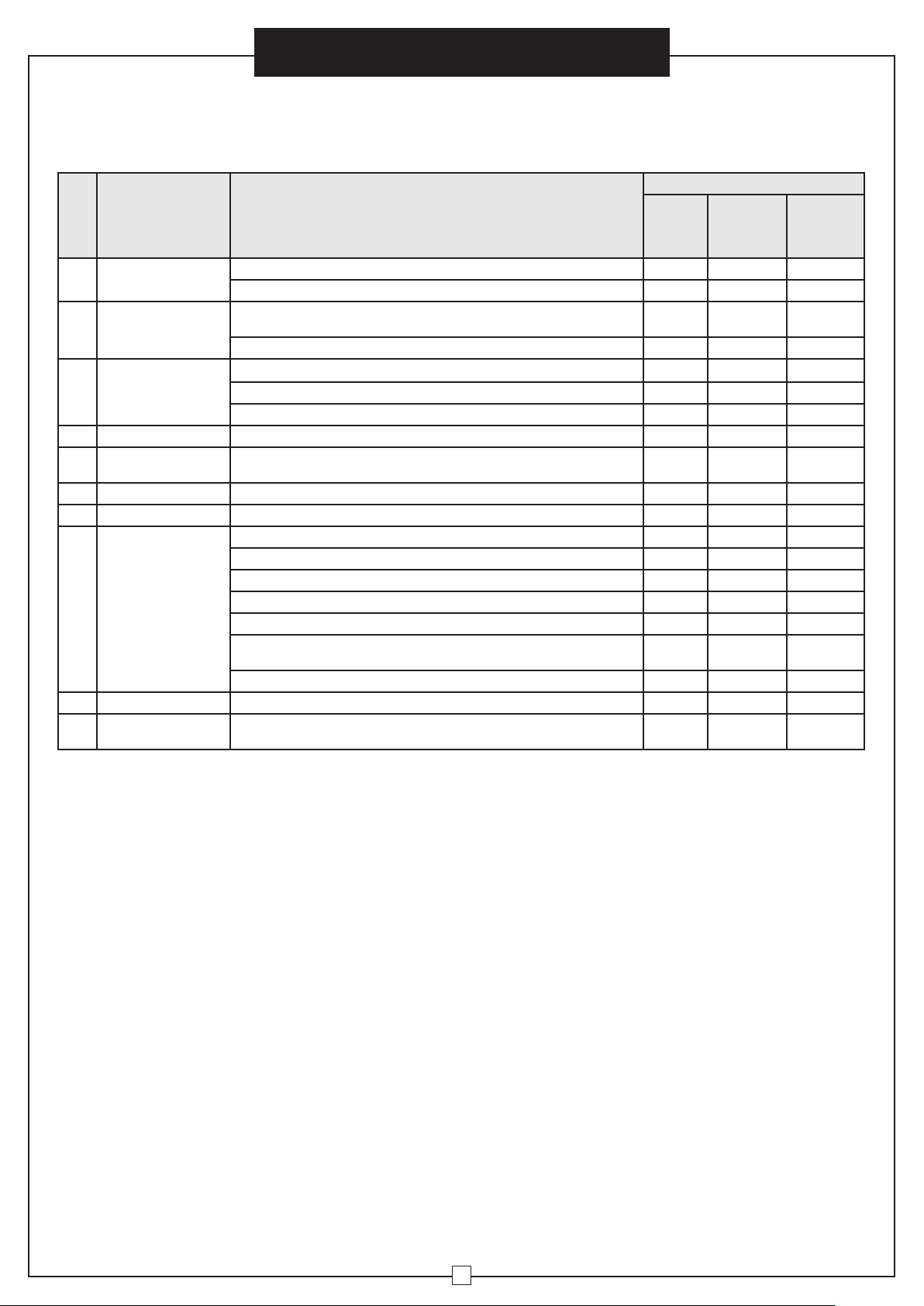

6.1 Inspection And Maintenance Schedule

Item Component Check

1 Battery

2 Battery Connector

3 Brake

4 Decals All decals must be in place and legible. √

5 Drive Unit

6 Drive Wheel Check the tightness of the screws on the drive wheel. √

7 Electrical System Visually inspect all cable for damage and replace as needed. √

9 General

10 Lift Cylinder Check the lift cylinder for leaks. √

11 Wheels

Check cleanliness and exterior. √

Check charging condition. √

Check connector. Ensure all powered functions shut down when

disconnected.

Ensure the battery is properly installed. √

Verify the drive motor does not run while the brake is applied. √

Check that the control handle returns to the vertical position when released.

Check the brake disc for wear. Replace if necessary. √

Check for oil leaks. If leaks are present, check to see if the oil level is

low. If so, identify the cause and fill to appropriate level.

Check the speed and directional controls. √

Check the steering operation. √

Check the lifting and lowering functions. √

Check the operation of the Emergency Reverse Button. √

Check the Operation of the Key Switch. √

Note any unusual noises during operation, and report it to a super-

visor or maintenance personnel right away.

Check for loose hardware. Tighten if necessary. √

Check the condition of the drive wheel and load wheels. Remove

any steel chips and foreign material to prevent wheel damage.

Daily or

8 Hours

√

√

√

√

√

Time Interval

Two

Months

or 250

Hours

Annually

or

1500

Hours

6.2 Change Oil

It is advised to change the hydraulic oil every 6 months or every 600 hours. Change the oil

every 6 months even if the hours of use are less than 600. To change the oil: Make sure the

forks are at the lowest position. Disassemble the tube joint at the lower part of cylinder and

put it in a container. Operate the lift handle to work the pump and exhaust the oil. If the truck

is used in a low-temperature environment, lift and lower two or three times after adding

hydraulic oil to purge the system. If the lift height is insufficient, replenish oil. Check the

hydraulic oil level again and add more if needed.

8

Loading...

Loading...