Global Industrial 988295, 988940 User Manual

globalindustrial.ca

Distribucion Industrial Globales S DE RL DE CF

Assembly Instructions Instrucciones de Ensamblaje Directives d’assemblage

Customer Service

US: 1-800-645-2986

Servicio de atención al Cliente

México: 01.800.681.6940

Service à la clientèle

Canada: 888-645-2986

Spring-Actuated Pallet Carousel Skid Positioner

READ & SAVE THESE INSTRUCTIONS

INTRODUCTION

The Spring-Actuated Pallet Carousel Skid

Positioner is a simple device which will

automatically maintain a load at the ideal

height for manual loading and unloading.

If a palletized load is placed on the unit,

the unit gradually rises as boxes or parts

are removed. This automatically maintains

the top of the load at the correct working

height.

If an empty pallet is placed on the unit,

it gradually lowers as boxes or parts are

added. Again, this keeps the top of the load

at the correct height. Completed pallets

may be loaded or unloaded using a fork lift.

Each unit includes a steel scissor

lift mechanism and at least one large

compression spring. The springs are

chosen to match the weight and height of

a fully loaded pallet. Springs are available

for a wide range of weight and height

combinations. The unit also includes

a shock absorber. This eliminates any

tendency for the load to bounce on the

springs.

This manual contains information to help

you to learn about the safe and proper

installation, use, and upkeep of your unit.

Please be sure that this manual is available

to anyone who uses or services the unit.

These units may be used in a wide variety of

industrial settings. The instructions in this

manual are not necessarily all-inclusive,

as Global Industrial cannot anticipate all

conceivable or unique situations. In the

interest of safety, please read this whole

manual carefully. Be familiar with the

contents of this manual before you install

or use this unit. If you are not sure of the

1

proper procedure to be followed, please

call Global Industrial Customer Service for

more information.

This instruction manual is not intended to

be or to create any other warranty, express

or implied, including any implied warranty

of merchantability or fitness for a particular

purpose, all of which are hereby expressly

excluded. As set forth more specifically in

the product warranty, Global’s obligation

under that warranty is limited to the repair

or replacement of defective components,

which shall be the buyer’s sole remedy,

and Global Industrial shall not be liable

for any loss, injury, or damage to persons

or property, nor for any direct, indirect,

or consequential damage of any kind

resulting from the unit.

052715

Spring-Actuated Pallet Carousel Skid Positioner

Assembly Instructions

RESPONSIBILITY OF OWNERS

AND USERS

INSPECTION AND MAINTENANCE

The device shall be inspected and maintained

in proper working order in accordance with this

user’s owner’s manual.

REMOVAL FROM SERVICE

Any device not in safe operating condition such

as, but not limited to, missing rollers, pins,

or fasteners, any bent or cracked structural

members, damaged safety devices, etc. shall

be removed from service until it is repaired to

the original manufacturer’s standards.

SAFETY

The unit has been carefully designed to be as safe

as possible for operators and service workers. If

you take a few common-sense precautions, you

will be able to use the unit safely. However, this is

a powerful unit with moving parts, and is capable

of causing personal injury if proper precautions

are not taken.

Therefore, throughout this manual, there have

been identified certain hazards which may occur

in the use and servicing of the unit, and provided

appropriate instructions or precautions which

should be taken to avoid these hazards.

DEFLECTION

It is the responsibility of the user/purchaser to

advise the manufacturer where deflection may

be critical to the application.

REPAIRS

All repairs shall be made by qualified personnel.

OPERATORS

Only trained and authorized personnel shall be

permitted to operate the positioner.

BEFORE OPERATION

Before using the device, the operator shall have:

• Read and/or had explained, and understood,

the manufacturer’s operating instructions and

safety rules.

In some cases, it has also been pointed out

the consequences which may occur if the

instructions or precautions are not followed.

Please read and follow this instruction

manual, including all safety instructions and

precautions, carefully and completely.

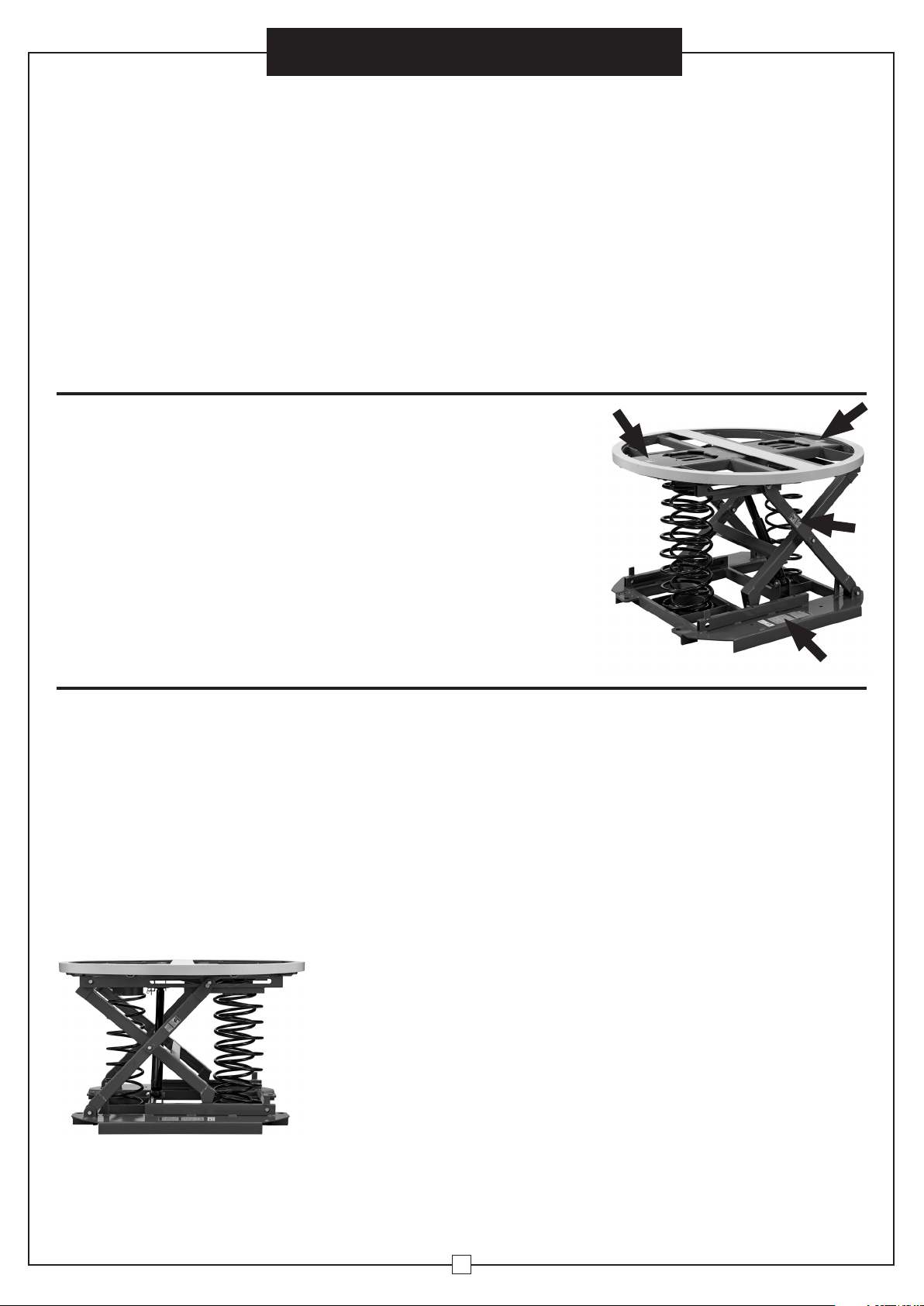

Figure 1 shows the safety labels on this unit. Please

be sure that all of the labels are in place, and are

visible to the machine operators. Never paint over

the labels. If any of the labels are missing, please

contact Global Industrial for replacements. The

safety labels help to protect your workers.

• Inspected the device for proper operation and

condition. Any suspect item shall be carefully

examined and a determination made by a

qualified person as to whether it constitutes

a hazard.

DURING OPERATION

The device shall only be used in accordance

with this user’s manual.

• Do not overload.

• Ensure that all safety devices are operational

and in place.

MODIFICATIONS OR ALTERATIONS

Modifications or alterations are not permitted.

Fig. 1

INSTALLATION NOTES

NOTICE

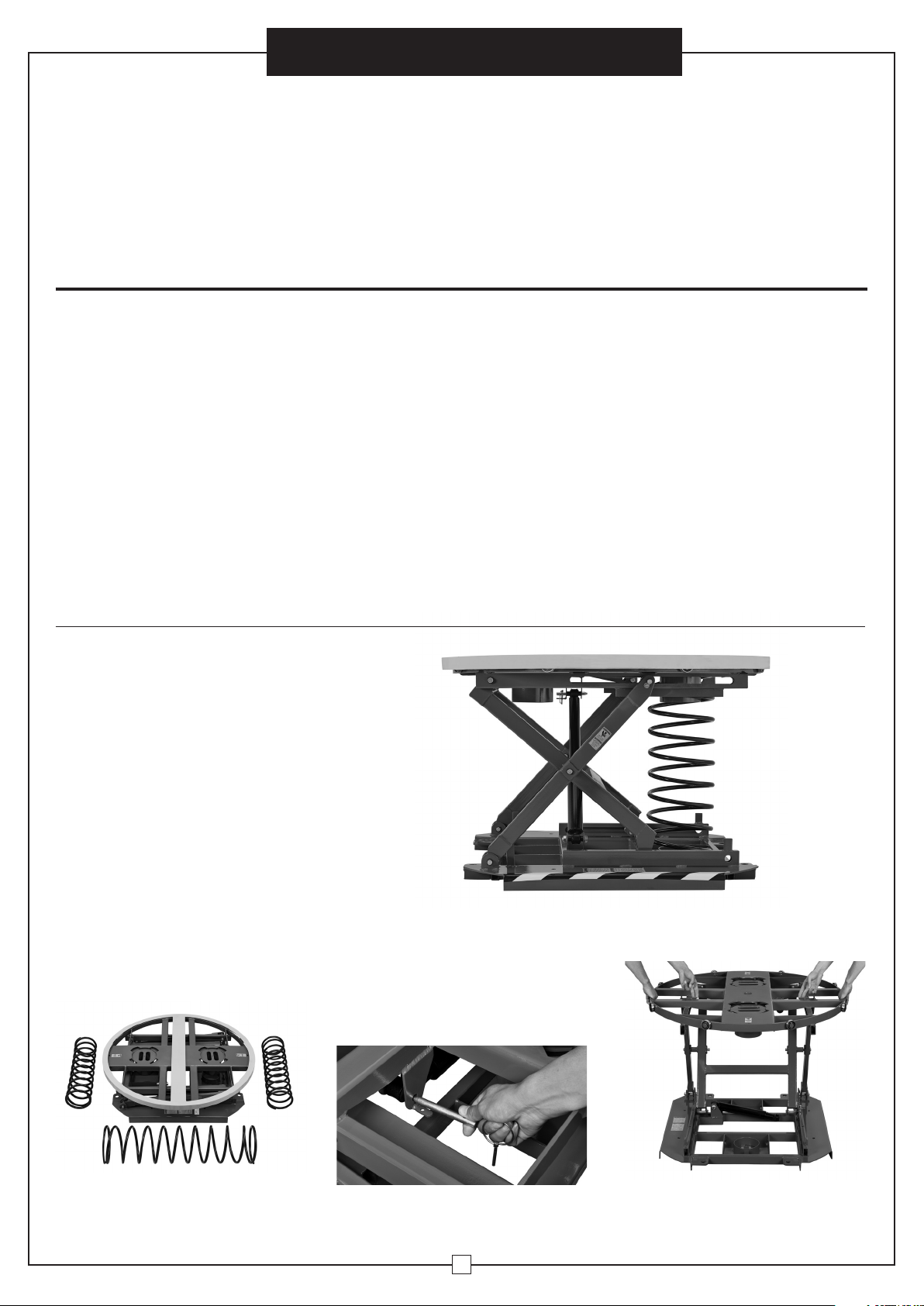

The unit must be installed on a firm, nearly level

surface. The frame of the unit must sit firmly on the

floor, and the floor must be level. If the frame is not

supported correctly, stresses may develop in the

frame. The unit may bind or not work easily. The

rotating ring may not rotate correctly.

After the springs are installed, if the springs are

not seated correctly, or the twist-lock caps are

not tightened, the parts may pop loose when

the unit is used. You may be hurt, or the load

may be damaged.

Fig. 2

OPERATION NOTES – MANUAL USE

WARNING!

• Never operate the unit if anyone is sitting or

riding on the rotating ring.

• Never operate the unit if the load is off center.

The load may shift, and you may be injured.

This can also damage the unit.

• As the unit moves, keep away from the “pinch

points” where metal parts meet.

•

Keep the area around the unit clean. Do not allow

any dirt, debris, spilled oil, or excess grease to

collect. These materials may cause you to slip

while the unit is operating, and you may be injured.

• Stay clear of the rotating ring when it is

moving. As the pallet turns, a part of the load

may rotate around and hit you. Never turn the

load when anyone is standing beside the unit.

• Do not try to use this unit with damaged

or broken pallets. Broken pallets may have

boards or nails which hang down below the

main part of the pallet. As the pallet is turned,

these boards or nails may catch on the

frame of the unit. This can cause the pallet

to stop turning suddenly, causing the load to

shift. You may be injured, and the unit may be

damaged. The boards or nails on the bottom of

the pallet should not extend down more than

1/8 inch.

OPERATION NOTES - WHEN LOADING

USING A FORK LIFT OR STACKER

WARNING!

•

When adding a load to the unit, lower

the forks completely before removing the

fork lift. The pallet must be completely

supported by the unit. If you do not do

this, the load may be dropped when you

remove the fork lift. The unit or the load

may be damaged, or you may be hurt.

OPERATION NOTES - WHEN UNLOADING

USING A FORK LIFT OR STACKER

WARNING!

•

When removing a load from the unit, lift

the load clear before backing out the

fork lift. If you do not do this, the top of

the unit may jump up when you remove

the fork lift. The unit or the load may be

damaged, or you may be hurt.

OPERATION NOTES THE UNIT -

NOTICE

Do not move the unit while it is loaded. This will

damage the base frame of the unit. The pockets

on the base frame are designed to support an

unloaded unit, they cannot support any extra

weight.

WHEN MOVING

2

Spring-Actuated Pallet Carousel Skid Positioner

SPECIFICATIONS

Load capacity ...............................400 to 4500 lbs., depending on springs

Load size ......................................50” wide x 50” long x 72” high (max.)

Length ..........................................45-1/4”

Width (base frame) .......................36-3/4”

Compressed height ......................9-1/2”

Extended height ...........................27-3/4”

Rotating ring, outside diameter ....43-5/8”

Rotating ring, inside diameter ......40-5/8”

Net weight ....................................380 lbs., with (3) springs installed

INSTALLATION INSTRUCTIONS

UNPACKING THE UNIT

1. Before you start to install the unit, check

for local codes and ordinances which may

apply. It is your responsibility to obtain any

necessary permits.

2. Please read all of these instructions carefully.

Be sure to read and understand all of the

warnings.

3. Inspect the shipping pallet carefully for any

damage which may have affected the unit.

If you see signs of damage, tell the trucker.

Also make a note of this on the shipping

papers which you are asked to sign.

4. Choose the place where you want to use the

unit. It is very important that the unit be set

up on a smooth and flat surface. Check the

floor surface carefully and make sure that it

is free of all loose debris and dirt.

The unit must be installed on a smooth flat

surface. If the floor is not flat, this can create

stresses in the frame of the unit. The unit

may not work properly, or parts of the

unit may wear more quickly than they

should. You may be hurt or the load may

be damaged.

5. Position the unit beside the point where

the unit will be set up.

6. Remove the banding which secures the

unit to the pallet. Remove all packing

material. Shift the unit to the floor. Support

the base as you do this.

7. Check to see that the frame of the unit is

sitting firmly on the floor. Try to move or

rock the frame of the unit. The base frame

CAUTION!

Assembly Instructions

should be stable, and should not move.

Check to see that the base frame is level.

8. Remove the springs and lay them out on

the floor.

9. If you have any questions about the steps

in the installation process, please call

Global Industrial Customer Service.

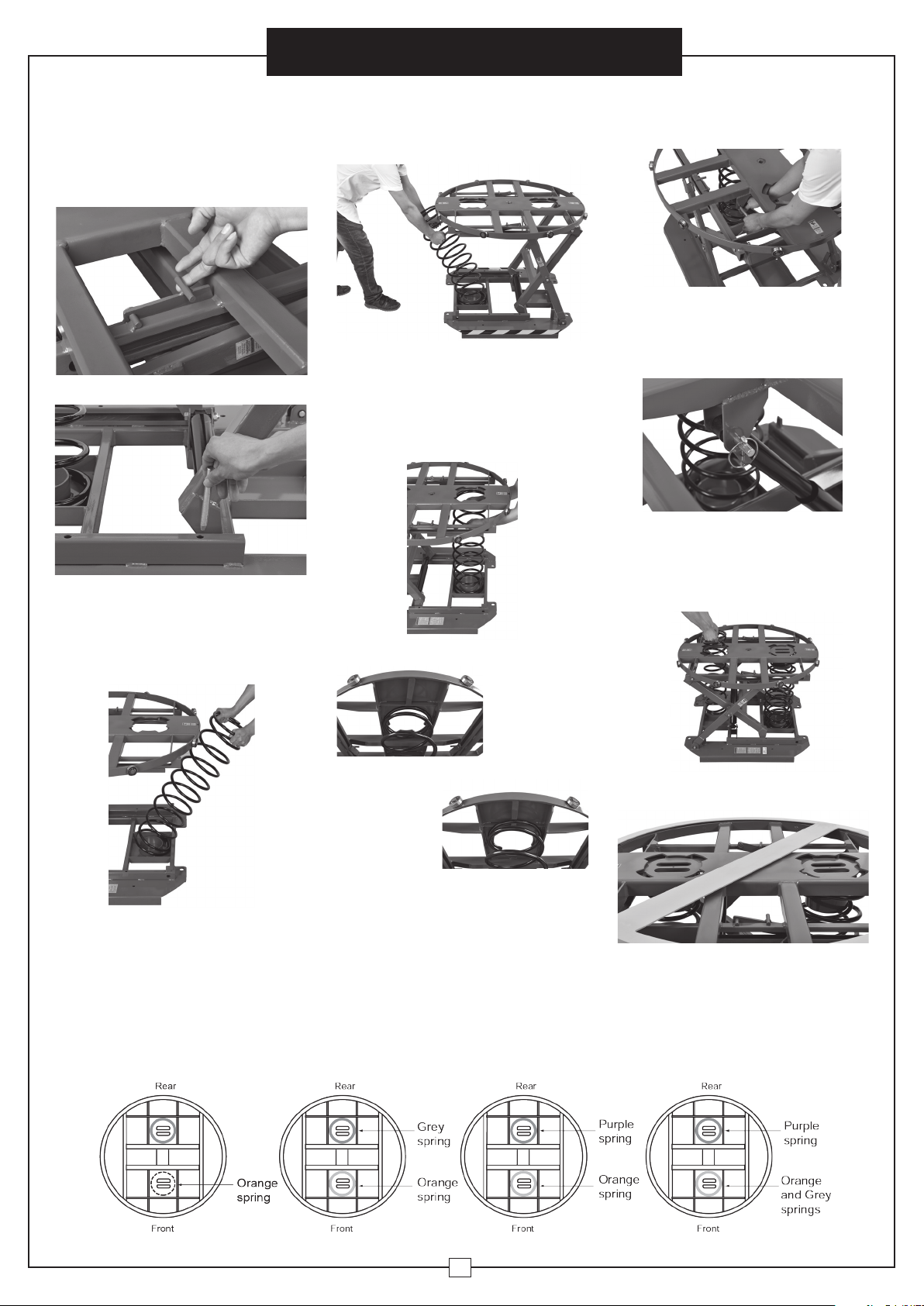

SETTING UP AND INSTALLING THE SPRINGS

1. The unit will always have at least one spring.

This spring has an orange mark, and is

larger in diameter than the others. This large

orange spring is always placed in the front of

the unit. Figure 3 shows the position of the

first spring. The frame of the unit can handle

loads of up to 4500 lbs. In order to adapt the

unit for different pallet loads, the springs are

changed. The springs are chosen to match

the weight and height of a fully loaded pallet.

A unit may have one to three springs. Each

time the pallet weight or pallet height is

changed, the springs may also need to be

changed. Table 1 shows how the springs

are selected.

2. The unit is shipped without springs installed.

The installation of the first spring (orange)

requires two people. Lift off rotating ring and

both yellow bayonets. Set them aside, they

will be installed later.

Fig. 3

Back

(Hinged End)

3. The shock absorber is attached to the top

frame of the unit with a pivot pin, and this

is held in place by a linch pin. The pivot pin

is used to hold the table frame in the raised

position. Take a look at the mechanism and

note the positions of the parts. Remove the

linch pin and remove the pivot pin. Lay the free

end of the shock absorber down.

Front

(Roller End)

4. With the help of an assistant, lift the top

frame until it hits the upper latch stops.

Fig. 4

Fig. 6

Fig. 5

3

Spring-Actuated Pallet Carousel Skid Positioner

5. While holding both latches up, lift the top

frame past the latches until it is at its full,

uppermost position. Have the assistant hold

the weight and insert the pivot pin in the hole

in the base frame. See Fig. 8. With the unit

in this full upper most position the orange

spring can be installed.

Fig. 7

7. Grasp the spring by the second or third coil

down from the top (DO NOT grasp the top

coil or rung) and push the spring down and

under the edge of the top frame.

Fig. 10

8. While pushing down to compress the spring,

push it forward into the pocket up under the

top frame. It will “snap” into position when

completely in the pocket.

9. Remove the shock absorber pivot pin. Push

down on top frame until latches engage.

(Both latches will drop into place).

Fig. 14

10. Reinstall the shock absorber pivot pin and

linch pin.

Fig. 15

Fig. 8

6. Insert either end of the large orange

spring into the lower pocket. Be sure

the bottom spring coil is positioned

outside the alignment tab as shown.

Fig. 9

13. Figure 18 shows the position of additional springs if needed. Double-check to be sure

you have the correct springs. Refer to Table 1 and see that you have the correct springs

for your application.

Fig. 11

Fig. 13

INCORRECT

Spring not

fully inserted into

pocket

Fig. 12

CORRECT

Fully inserted into

pocket

11. Install additional springs as needed through

the bayonet openings. Reinsert the yellow

bayonets and twist to lock them in place.

Fig. 16

12. Reinstall the rotator ring.

Fig. 17

Range #1 Range #2 Range #3 Range #4

Fig. 18 Spring Mounting Positions

4

Spring-Actuated Pallet Carousel Skid Positioner

Assembly Instructions

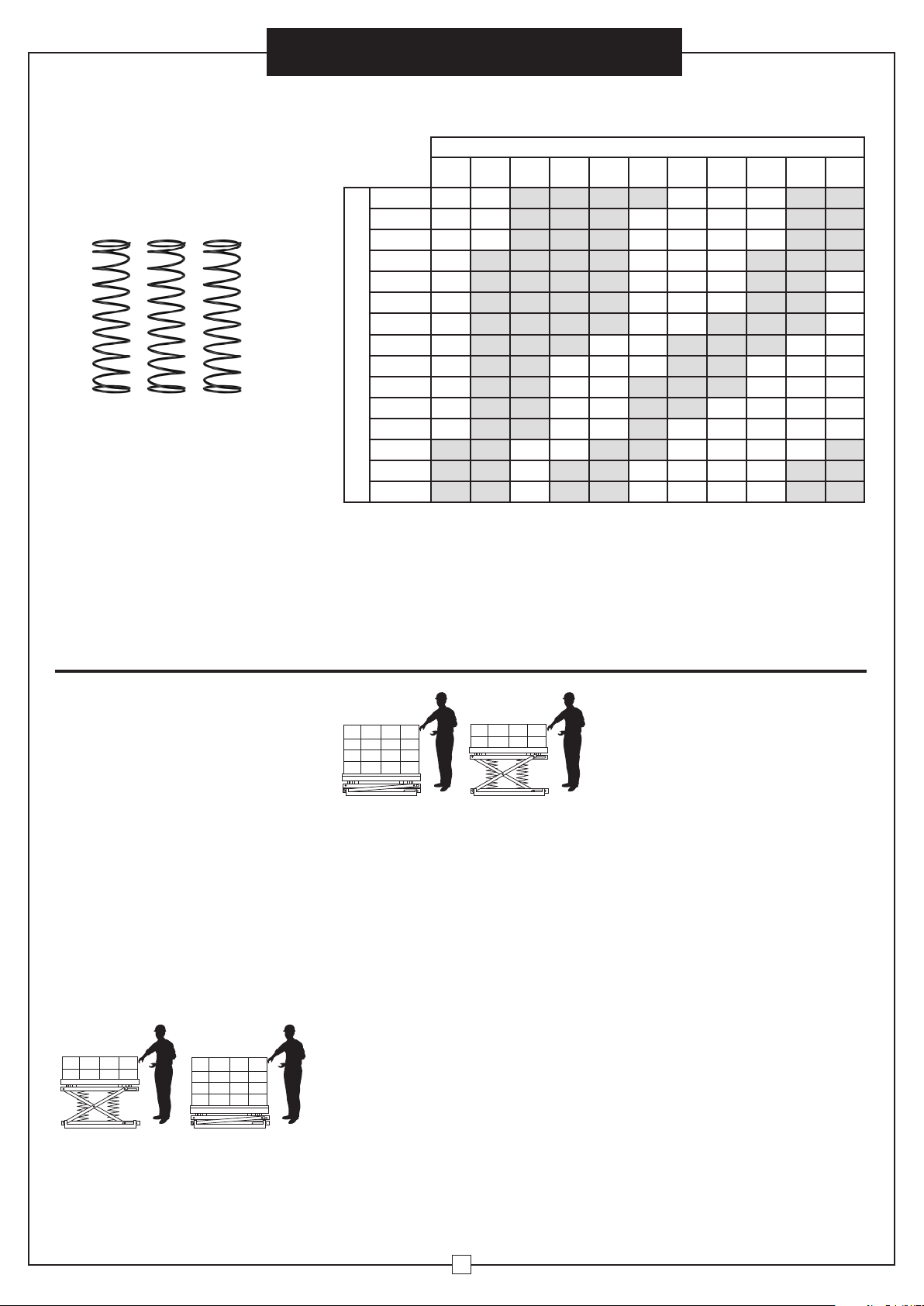

SPRING SELECTION GUIDE

In order to make sure your unit functions

properly you must have the proper spring

configuration. Table 1 will allow you to

pick the right spring configuration for your

application based on the weight and the

height of your pallet load.

Unit comes complete with rotator ring, fork

truck pockets in base and selected range

spring package.

1. Fill in the weight of a fully loaded pallet

here: _____________________

(Do not guess. Get actual weight from

prospect or have a pallet weighed)

2. Fill in the height of a fully loaded pallet

here: _____________________

(Do not guess. Get actual height from

prospect or measure a loaded pallet)

3. Using table 1, select the correct range:

_____________________

1

1

Table 1 - Spring selection chart

Weight of Fully Loaded Pallet (lbs.)

400-

800-

1200-

1600-

2000-

2400-

2800-

3200-

3600-

0-400

800

1200

1600

2000

2400

2800

3200

3600

58-60” - - 1 1 1 1 2 2 2 3 3

56-58” - - 1 1 1 2 2 2 2 3 3

54-56” - - 1 1 1 2 2 2 2 3 3

52-54” - 1 1 1 1 2 2 2 3 3 3

50-52” - 1 1 1 1 2 2 2 3 3 4

48-50” - 1 1 1 1 2 2 2 3 3 4

46-48” - 1 1 1 1 2 2 3 3 3 4

44-46” - 1 1 1 2 2 3 3 3 4 4

42-44” - 1 1 2 2 2 3 3 4 4 4

40-42” - 1 1 2 2 3 3 3 4 4 4

38-40” - 1 1 2 2 3 3 4 4 4 4

Height of Fully Loaded Pallet

36-38” - 1 1 2 2 3 4 4 4 4 4

34-36” 1 1 2 2 3 3 4 4 4 4 -

32-34” 1 1 2 3 3 4 4 4 4 - -

30-32” 1 1 2 3 3 4 4 4 4 - -

1 = Range 1 – Orange Spring (1 Spring)

2 = Range 2 – Orange and Gray Springs (2 Springs)

3 = Range 3 – Orange and Purple Springs (2 Springs)

4 = Range 4 – Orange, Gray, and Purple Springs (3 Springs)

(1) CAUTION: The springs are precisely calibrated and will work best within the load weight and height ranges selected.

Selection based on higher or lower than actual weight will result in restricted raising or lowering capability. Should pallet weight

or height weight requirements dramatically change, the unit can be adapted in the field at any time by simply changing the

spring combination used.

4000

4000-

4500

WARNING!

Before using the unit, do a safety check. Be

sure that each of the spring bayonet caps is

in place and rotated to their locked position.

Check the top and bottom of each spring

to be sure it is seated correctly. Check the

linch pin at the top of the shock absorber.

These checks are very important.

OPERATING INSTRUCTIONS

LOADING MANUALLY

Add boxes or parts until the pallet is full. Load

he pallet in layers. Use the rotating ring to

position the pallet to eliminate walking around.

The unit will gradually lower the pallet until it

reaches the bottom. See Fig. 19.

CAUTION!

ROTATE THE PALLET LOAD. NEVER PLACE

YOUR HANDS ON THE ROTATOR RING.

YOU MAY BE HURT.

Fig. 19

REMOVING LOADS MANUALLY

Remove boxes or parts until the pallet is empty.

Unload the pallet in layers. Use the rotating ring

to position the pallet to eliminate walking around.

The unit will gradually raise the pallet. See Fig. 20.

Fig. 20

OPERATING SAFETY

1. Do not use this unit with a load greater than

the rated load. This includes the weight of the

payload and the weight of the pallet. Table 1

shows how to be sure you have the correct

spring combination for your application.

2. Never push the load off of the side of the

unit. If you do this, the frame of the unit may

jump upward.

3. Never use the unit when anyone is sitting or

riding on the rotating ring.

4.

Do not try to use this unit with damaged

or broken pallets. Broken pallets may have

boards or nails which hang down below

the main part of the pallet. As the pallet is

turned, these boards or nails may catch

on the frame. The pallet may stop turning

suddenly and this can cause the load to

shift. You may be injured and the unit may

be damaged. If the boards or nails on the

bottom of the pallet extend down more than

1/8 inch, they will interfere with the turning

action.

5. Stay clear of the rotating ring when it is

moving. As the pallet turns, a part of the load

may rotate around and hit you.

6. Keep the area around the unit clean. Do not

allow any dirt, debris, spilled oil, or excess

grease to collect. These materials may cause

you to slip while the unit is operating and you

may be injured.

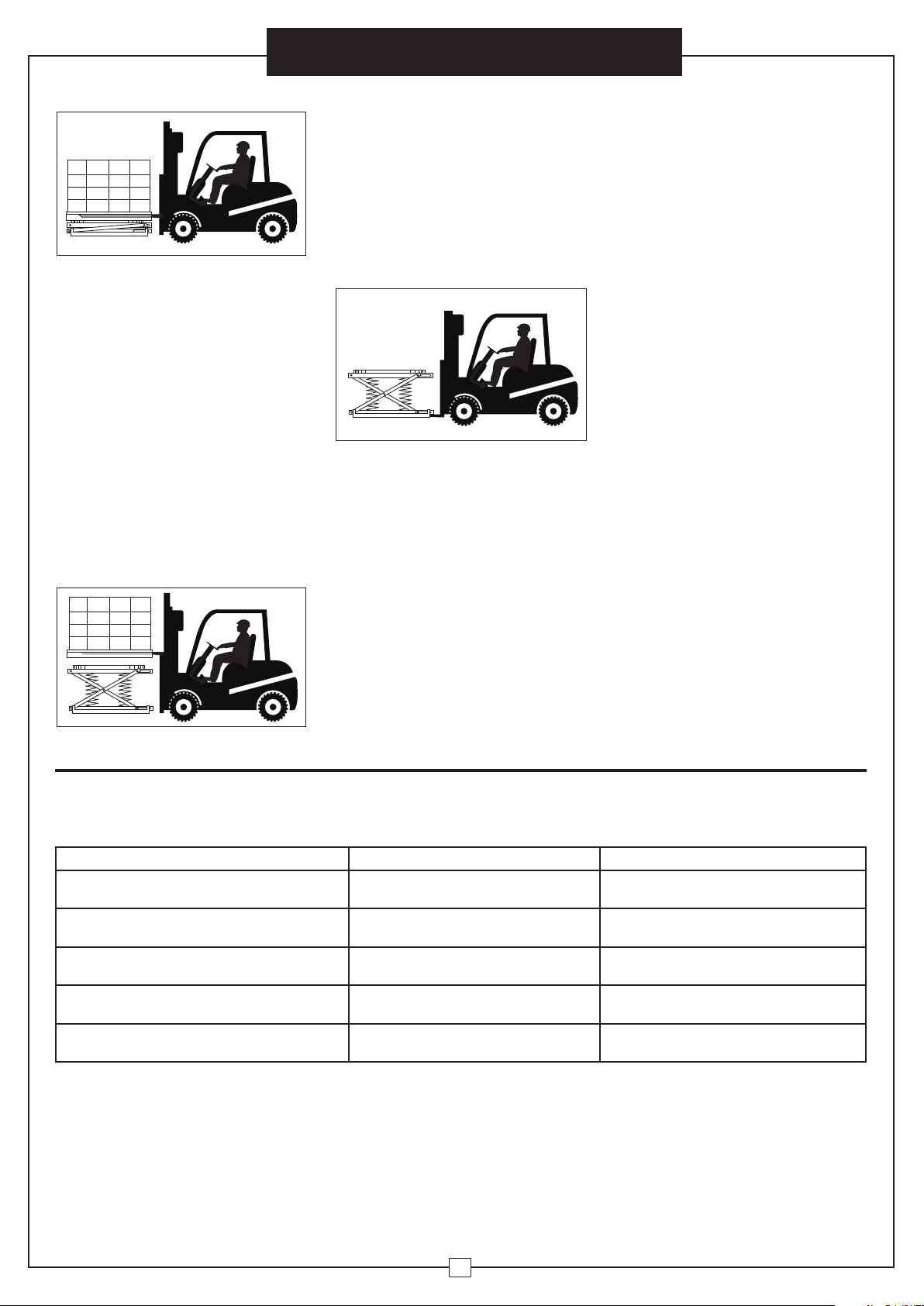

LOADING WITH A FORK LIFT

1. Place the load on the fork lift, then lower the

fork lift. Before removing the load, be sure

the unit is carrying the weight, not the fork

lift. See Fig. 21.

• Lower the load until the springs on the

unit are fully compressed.

• Be sure the forks on the lift are clear of

the inside of the pallet.

WARNING!

If you skip these steps, the load may drop

suddenly when you remove the fork lift. You

may be hurt or the unit or load may be

damaged.

WARNING!

Never drop the load on the rotating ring. If you

do this while the rotating ring is moving, the

load may shift. You may be injured or the unit

may be damaged.

5

Spring-Actuated Pallet Carousel Skid Positioner

Assembly Instructions

Fig. 21

2. Be sure the load is centered on the unit.

WARNING!

If the load is off-center, it may shift when the

rotating ring is turned. You may be hurt or

the unit or load may be damaged.

UNLOADING WITH A FORK LIFT

1. Insert the forks fully into the pallet, and lift he

pallet straight up and clear of the top of the

unit. See Fig. 22.

• Raise the pallet until the springs on the unit

are fully extended.

• Be sure the pallet clears the top of the rotating

ring before you move the fork lift.

WARNING!

If you skip these steps, the unit may jump up

suddenly when you remove the pallet. You may

be hurt or the unit or load may be damaged.

MOVING THE UNIT

NOTICE

Do not move the unit while it is loaded. This

will damage the base frame of the unit. The

pockets on the base frame are designed

to support an unloaded unit, but cannot

support any extra weight.

1. Remove any load from the top of the unit.

2. Insert the forks into the pockets in the base

frame. See Fig. 23.

Fig. 22

MAINTENANCE

Routine Periodic Maintenance every 90 days

• Check for loose hardware and signs of

excessive wear.

• Check to be sure that the unit is placed

on a firm level surface.

Fig. 23

TROUBLESHOOTING

Troubleshooting Check List

Problem Possible Cause Check This

The unit lowers too easily (too early).

The unit does not lower enough (too late).

The top of the unit rotates away from you.

The top of the unit bounces.

Excessive “rumble” when the ring rotates

The spring combination may be too

weak for the load.

The spring combination may be too

strong for the load.

The frame of the unit may not be

level.

The shock absorber may be

damaged.

Wear or lack of lubrication to

bearings under rotating ring.

Check the spring ratings.

See Table 1.

Check the spring ratings.

See Table 1.

Move the unit to a level surface.

Contact Customer Service.

Contact Customer Service.

6

Loading...

Loading...