Page 1

globalindustrial.ca

Distribucion Industrial Globales S DE RL DE CF

User's manual Manual del usuario Manuel de l'utilisateur

Customer Service

US: 1-800-645-2986

Best Value Lift Stacker

Model 988934 (47" Lift) & 988935 (59" Lift) Optional Platform 988936

Servicio de atención al Cliente

México: 01.800.681.6940

Service à la clientèle

Canada: 888-645-2986

FOR OPERATION SAFETY, please read

and understand instructions carefully prior

to assembling, installing, operating, or

performing maintenance on the product. Be

sure to observe all safety information. Failure

to comply with instructions could result in

personal injury and/or property damage.

Retain instructions for future reference.

1

021017

Page 2

Best Value Lift Stacker

User’s Manual

WARNING:

1. Be sure to operate lift stacker within rated load. Do

not overload. Overloading will cause damage.

2. Do not exceed rated capacity of 880 lbs.

3. Do not sit or stand on lift stacker.

4. Inspect unit prior to use and do not operate if

damaged or in poor condition.

5. Do not abuse or mishandle unit.

6. Protect all extremities including hands, feet, and

other body parts while operating or transporting lift.

7. Do not place hands or feet near lowering forks/

platform.

8. Apply brakes and/or chock tires when lifting,

loading, or unloading unit to prevent movement.

9. Verify stability and even distribution of loads prior to

handling. DO NOT handle unsecure loads.

10. Do not leave loads on lift stacker for extended

periods of time.

11. Lift stacker cannot be moved during operation.

12. Operate lift stacker on level, durable surfaces away

from traffic.

13. When placing items on raised fork/platform, item

weight should be loaded lightly and total weight

must be within rated load.

14. When loading and unloading items on raised fork/

platform, do not drag content in cross direction.

This may cause risk stability and off-set loading.

15. Please operate strictly according to “notes

(warning)”. The warnings, precautions, and

instructions discussed cannot cover all possible

conditions and situations that may occur. Failure

to heed these warnings may result in property

damage, personal injury, and/or death.

16. Do not modify or alter this lift table. Modifications

may cause improper functionality resulting in

possible injury or death.

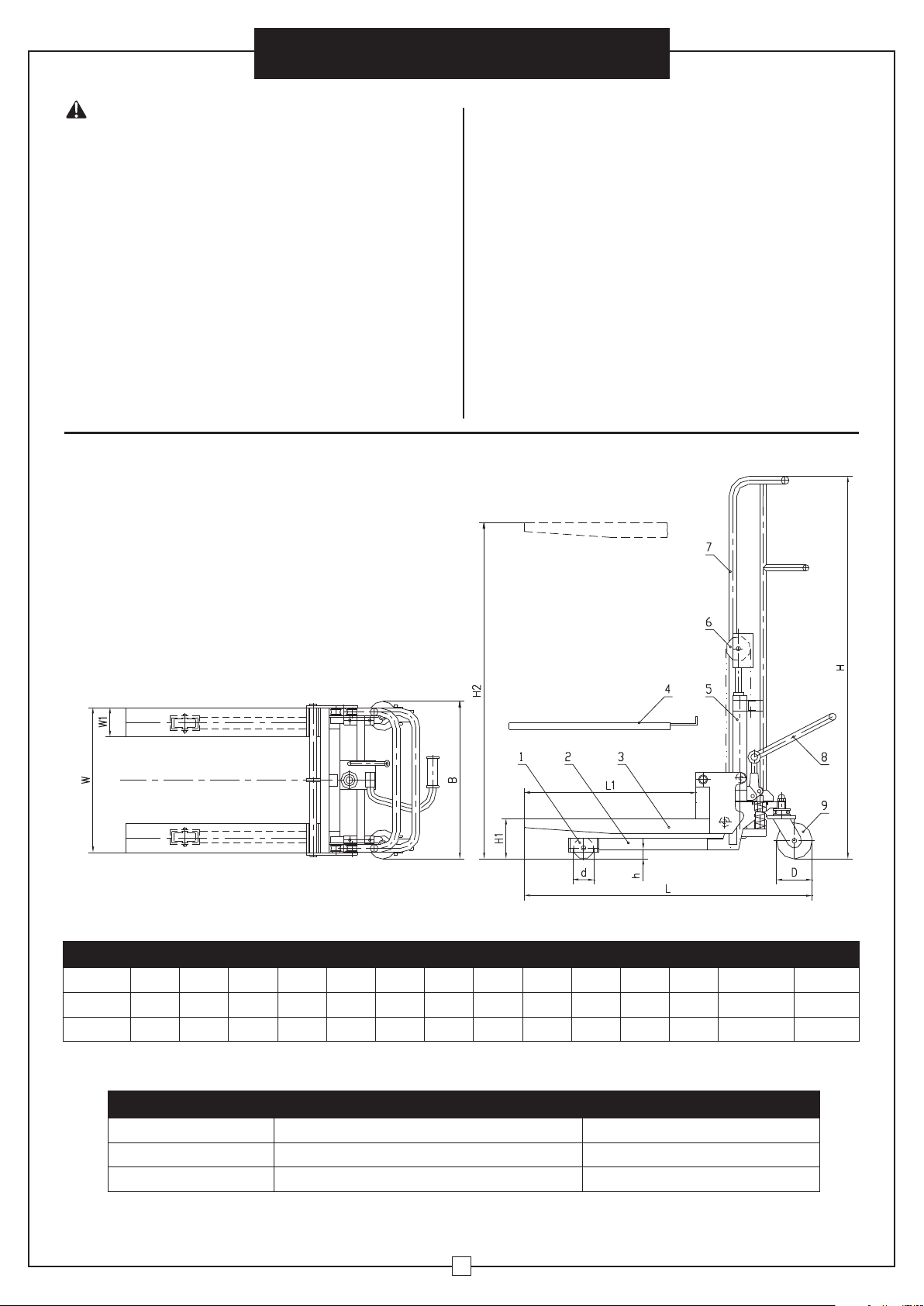

Fig. 1

SPECIFICATIONS

Model H H1 H2 L L1 W1 W B d D h Load Work No. NW

988934 56" 3.5" 47" 47" 26" 4.4" 22" 23" 3" 5" 0.9" 880 48 180 lbs.

988935 67" 3.5" 59" 59" 26" 4.4" 22" 23" 3" 5" 0.9" 880 60 190 lbs

PARTS LIST

1. Front Wheel 4. Work Platform (sold separately 988936) 7. Slideway Handrail Assembly

2. Chassis Assembly 5. Cylinder Assembly 8. Footstep Lever

3. Fork Assembly 6. Chains and Wheel 9. Back Wheel

2

Page 3

Best Value Lift Stacker

User’s Manual

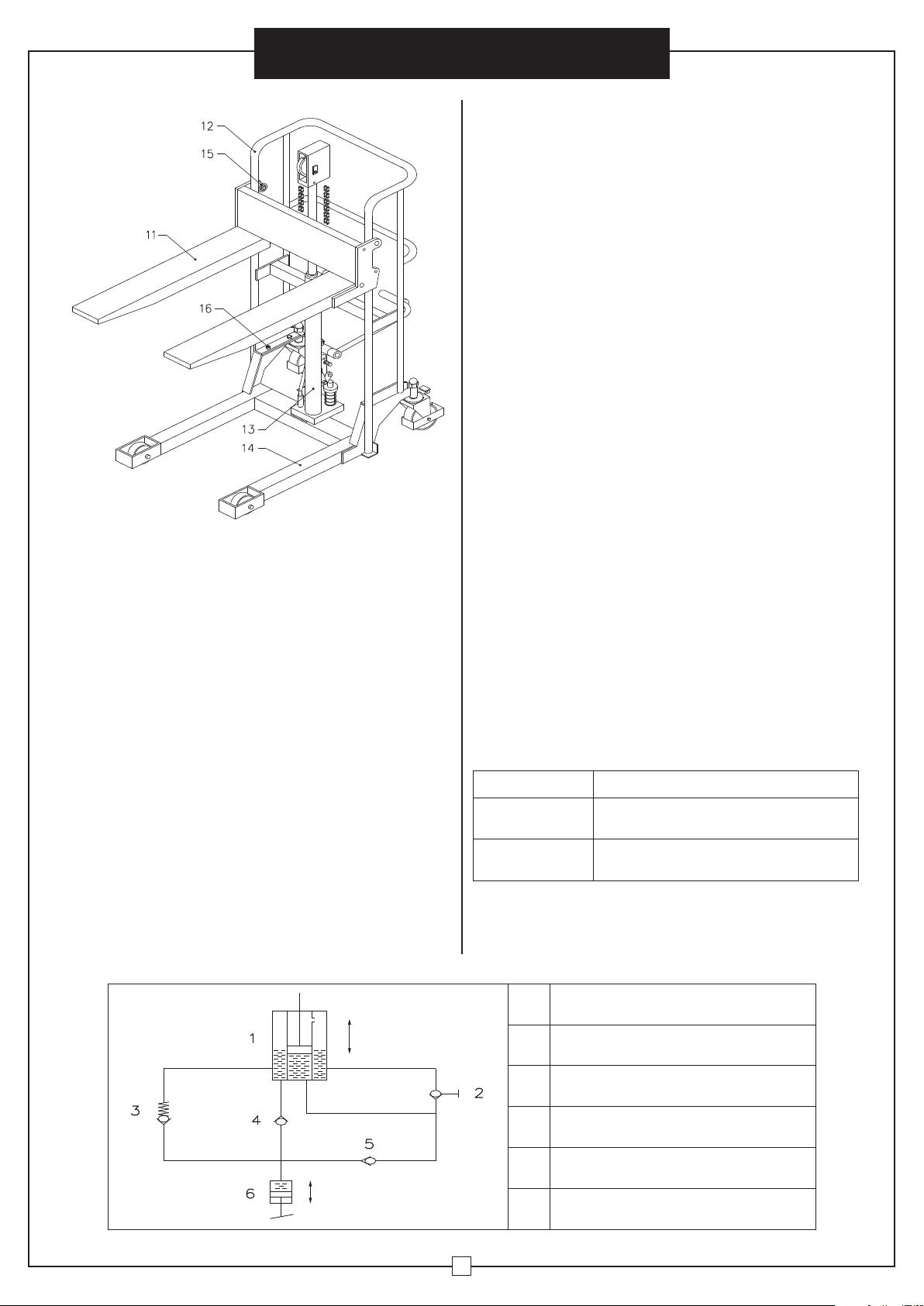

Installation

Required tools for assembly two 17mm wrenches

Part identification #11 fork assembly, #12 handrail

#13 cylinder assembly, #14 Chassis assembly, #15

Handrail guide and #16 connecting bolts; 4 sets.

1. On an even surface, place the fork assembly #11 on

the chassis #14 as in the drawing.

2. Insert the handrail #12 through fork assembly #11

and Handrail guide # 15; until it meets with the

chassis #14., aligning the bottom hole of cylinder

pump with the chassis #14.

3. Remove the lower nut on both sides of the chain

assembly, being careful not to let the chain slip

through. Connect the upper portion of the chain to

the handrail #12 and then the lower portion to the

chassis #14. Tighten the bolts and using the cotter

pins supplied to secure.

4. The forklift height can be adjusted after installation

via the chain bolt.

5. Connect the handrail #12 and Chassis #14 using the

connecting bolts #16 supplied.

6. Make sure all parts are connected properly and

bolts are tight.

7. Make sure operation is steady without and with a

rated load.

Attention & Warning

1. Use lift stacker on flat, hard surfaces.

2. Do not exceed maximum load capacity. Transport

goods according to load curve ensuring

load balance.

Operational Instructions

1. Lock wheel brakes and confirm height release valve

is closed.

2. Footstep pole adjusts fork pump height. To lower

forks, turn height release valve slowly until reaching

desired height.

3.

When the load exceeds 1.2 times of the load capacity

the safety will lock so that the forks cannot rise. This is

to ensure safe operation.

4. During transport, forks must be in the lowest

position for safety.

5. Descending speed may be adjusted by modifying

the positioning ring angle on the release valve pole.

6. WARNING! When raising fork, do not pump

footstep pole too quickly as this may cause cylinder

to deplete.

7. WARNING! When handling heavy loads, turn release

valve slowly for stability.

8. WARNING! When rising operation ceases, verify

release valve is securely closed for fork stability.

Daily Maintenance & Inspection

1. Inspect forklift prior to use. Do not operate if

damaged or in poor condition. Inspect all moving

parts for issue or noise.

2. Inspect hydraulic system for oil leakage.

3. Perform monthly inspection of forks, wheels, chains,

and more.

4.

Perform recommended lifting cylinder maintenance.

Replace hydraulic oil at 20 hours of run time and once

every 18 months or 300 hours whichever comes first.

Please fill in the specified hydraulic oil at the following

temperatures listed below:

Temperature Hydraulic Oil

23°F~ 113°F

5°F~ -41°F

When replacing oil, adjust pillar piston pole to

lowest position.

L-HM68 hydraulic oil

(equivalent to ISOVG68)

L-HM46 hydraulic oil

(equivalent to ISOVG46)

Hydraulic Principle

Drawing

1 Out-pushing Cylinder

2 Turning Lifting and Falling Valve

3 Safety Valve

4 Oil Returning Valve

5 Work Valve

6 Work Cylinder

3

Page 4

User’s Manual

Best Value Lift Stacker

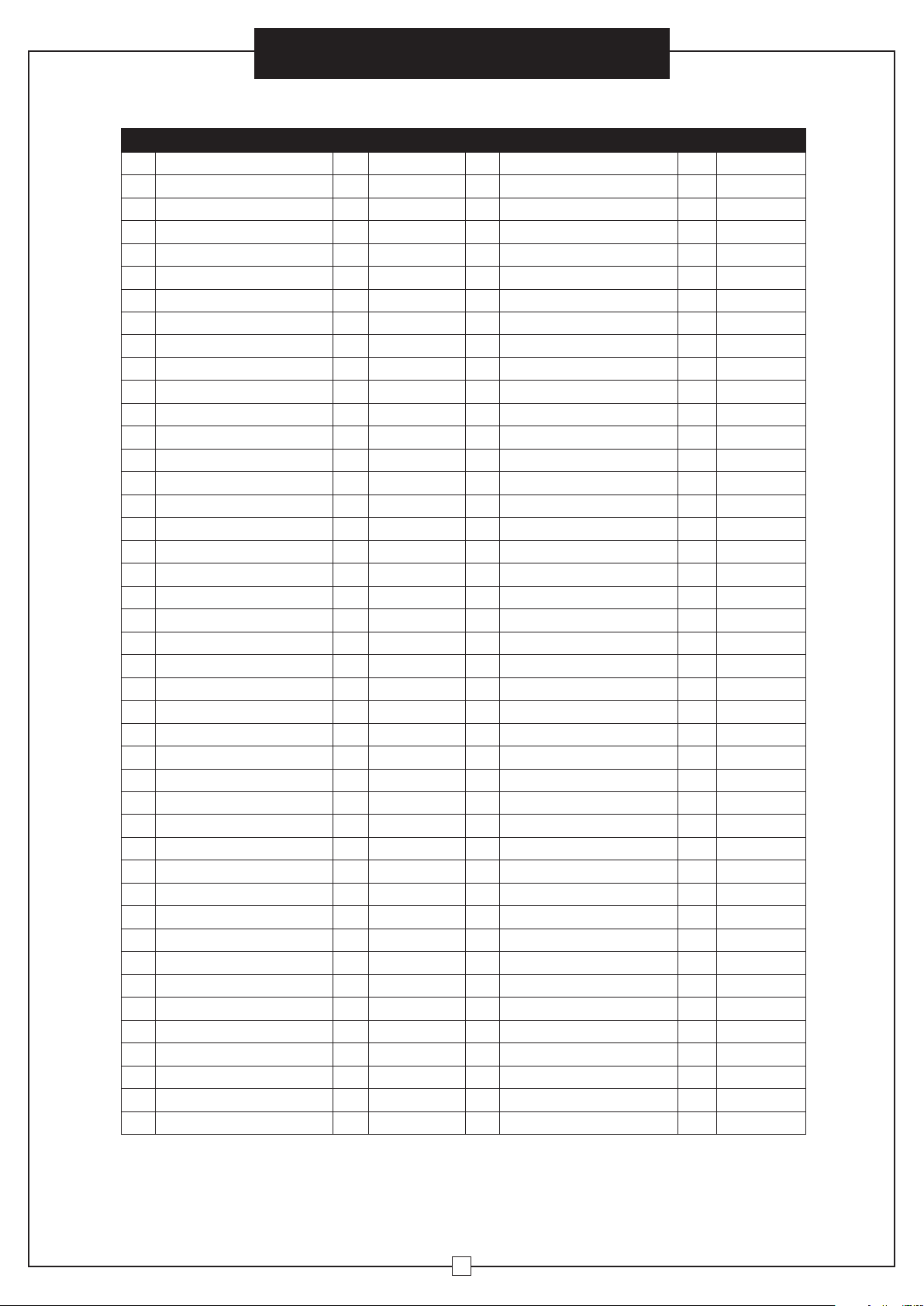

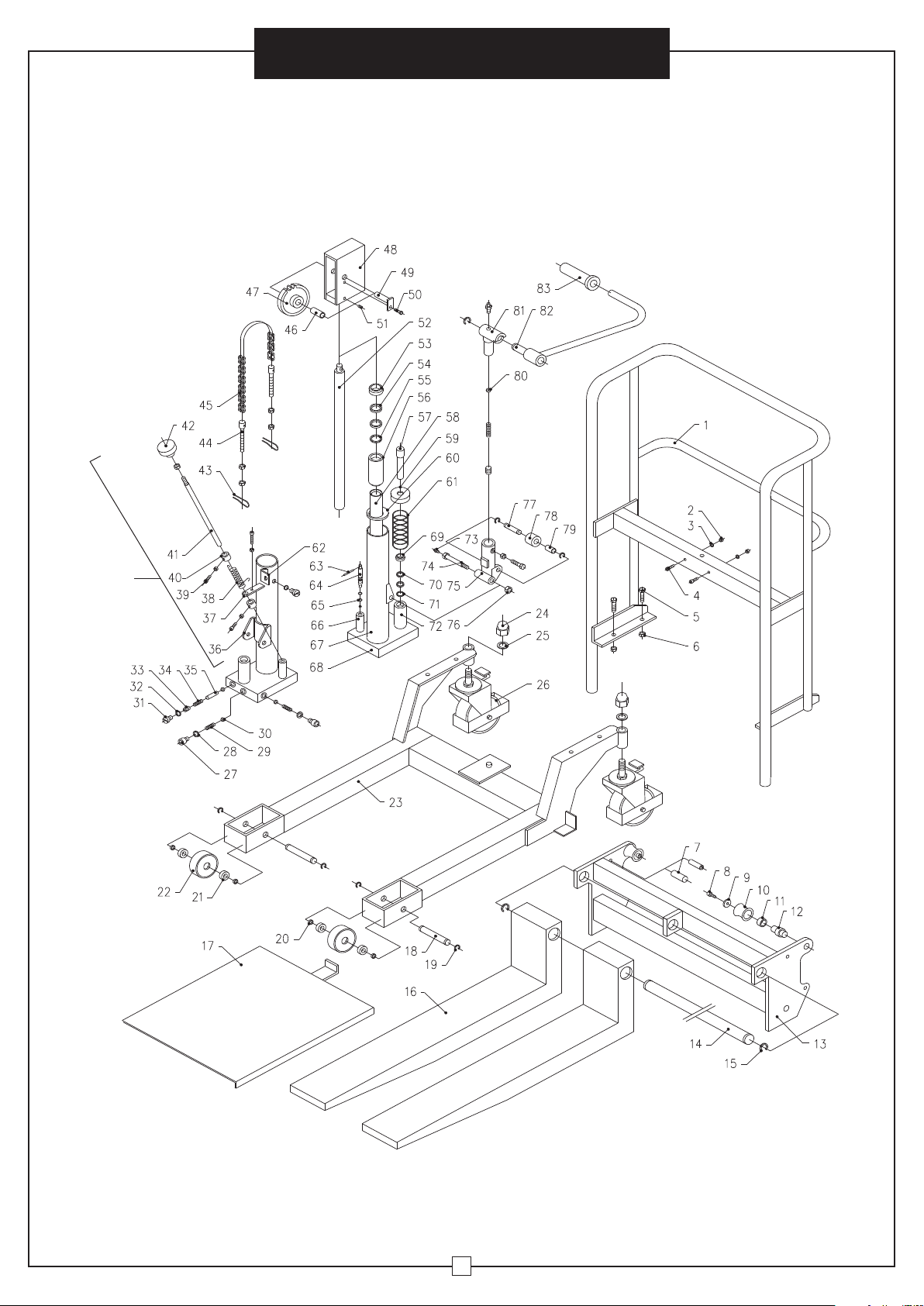

PARTS LIST

No. Description Qty. Remark No. Description Qty. Remark

1 Slideway handrail 1 43 Split pin 2

2 Nut 2 44 Chains bolt 2

3 Washer 2 45 Roller chains 1

4 Internal hex bolt 2 46 Oil-free bearing 1

5 Hex bolt 4 47 Chain & wheel 2

6 Nut 4 48 Chain cover 1

7 Shield pin 4 49 Axle 1

8 Hex bolt 4 50 Bolt 1

9 Washer 4 51 Bolt 2

10 Rolling wheel 4 52 Piston pole 1

11 Oil-free bearing 4 53 Dust-proof ring 1 Damageable

12 Rolling wheel axle 4 54 O-ring 1 Damageable

13 Fixed rack 1 55 Nylon ring 1

14 Long axle 1 56 Inside piston glove 1

15 Split ring 2 57 Pump pole 2

16 Adjustable fork 2 58 Inside cylinder 1

17 Optional platform 1 59 Pump lid 1

18 Front wheel axle 2 60 Eccentric sealing plate 1

19 Split ring 4 61 Oil pump spring 1

20 Washer 4 62 Fixed ear 1

21 Bearing 4 63 Round pillar pin 1

22 Front wheel 2 64 Valve inner 1

23 Chassis assembly 1 65 O-ring 2 Damageable

24 Nut 2 66 Valve pole glove 1

25 Internal tooth lock washer 2 67 Outside cylinder 1

26 Back wheel 2 68 Pump plate 2

27 Internal hex bolt 2 69 Dust-proof ring 1 Damageable

28 Copper washer 2 70 O-ring 1 Damageable

29 Cone spring 2 71 Nylon ring 2

30 Steel ball 4 72 Pump glove 1

31 Bolt plug 2 73 Oil cup 2

32 O-ring 2 Damageable 74 Pump axle 1

33 Bolt 1 75 Pump base 1

34 Spring 1 76 Nut 1

35 Short pin 1 77 Pump ring axle 1

36 Base connecting 1 78 Pump ring 8

37 Positioning plate 1 79 Oil-free bearing 2

38 Torsion spring 1 80 Steel ball 1

39 Positioning bolt 2 81 Axle sleeve 1

40 Positioning ring 2 82 Foot step lever 1

41 Single-direction valve pole 1 83 Rubber glove 1

42 Handle 1

4

Page 5

Best Value Lift Stacker

Exploded View

User’s Manual

Release

valve lever

5

Page 6

globalindustrial.ca

Distribucion Industrial Globales S DE RL DE CF

User's manual Manual del usuario Manuel de l'utilisateur

Customer Service

US: 1-800-645-2986

Servicio de atención al Cliente

México: 01.800.681.6940

Service à la clientèle

Canada: 888-645-2986

Apiladora de Calidad

Modelo 988934 (elevación 47") y 988935 (elevación 59") Plataforma Opcional 988936

PARA LA OPERACIÓN DE SEGURIDAD,

por favor leer y entender las instrucciones

cuidadosamente antes de montar, instalar,

operar o realizar el mantenimiento del

producto. Asegúrese de cumplir toda la

información de seguridad. El incumplimiento

de las instrucciones podría resultar

en lesiones personales y/o daños a la

propiedad. Conserve las instrucciones para

futuras referencias.

1

021017

Page 7

Apiladora de Calidad

Manual del usuario

ADVERTENCIA:

1. Asegúrese de operar la apiladora bajo la carga

nominal. No sobrecargue. La sobrecarga puede

causar daños.

2. No exceda la capacidad nominal de 880 libras.

3. No se siente ni se pare sobre la apiladora.

4. Inspeccione la unidad antes de usarla y no la

utilice si está dañada o en mal estado.

5. No abuse de la unidad ni le dé mal uso.

6. Proteja todas sus extremidades incluyendo las

manos, los pies y otras partes del cuerpo mientras

opere o transporte carga.

7. No coloque las manos o los pies cerca de las

horquillas o plataforma cuando bajen.

8. Aplique los frenos o bloquee las ruedas al levantar,

cargar o descargar la unidad para evitar el

movimiento.

9. Verificar la estabilidad y la distribución uniforme de

cargas antes de su uso. NO manipule cargas no

aseguradas.

10. No dejar las cargas en la apiladora por largos

períodos de tiempo.

11. La apiladora no puede moverse durante la

operación.

12. Operar la apiladora en superficies planas y

resistentes lejos del tráfico.

13. Al colocar elementos en horquillas/plataformas

elevadas, el peso del artículo debe colocarse

ligeramente y el peso total debe estar dentro de la

capacidad nominal.

14. Cuando cargue o descargue elementos en

horquillas/plataformas, no arrastre el contenido en

dirección transversal. Esto podría provocar riesgo

de estabilidad y desbaratar la carga.

15. Por favor opere estrictamente según las "notas

(advertencia)". Las advertencias, precauciones e

instrucciones provistas no pueden cubrir todas

las posibles condiciones y situaciones que

puedan ocurrir. No seguir estas advertencias

puede resultar en daños a la propiedad, lesiones

personales o la muerte.

16.

No modificar o alterar esta tabla de elevación.

Cualquier modificación puede causar el funcionamiento

inadecuado terminando en lesiones o muerte.

Fig. 1

ESPECIFICACIONES

Modelo H H1 H2 L L1 W1 W B d D h Carga Tarea No. NW

988934 56 in 3.5 in 47 in 47 in 26 in 4.4 in 22 in 23 in 3 in 5 in 0.9 in 880 48 180 lb

988935 67 in 3.5 in 59 in 59 in 26 in 4.4 in 22 in 23 in 3 in 5 in 0.9 in 880 60 190 lb

LISTA DE PARTES

1. Rueda Delantera 4. Plataforma de Trabajo (se vende por separado 988936) 7. Montaje de Barandilla deslizante

2. Montaje de Chasis 5. Montaje de Cilindro 8. Caballete

3. Montaje de Horquilla 6. Cadenas y Ruedas 9. Rueda Trasera

2

Page 8

Best Value Lift Stacker

Manual del usuario

Instalación

Herramientas necesarias para el montaje de dos llaves

de 17mm. Identificador de parte #11 montaje de horquilla, #12

barandilla #13 montaje de cilindro, #14 montaje de chasis, #15

guía de Barandilla y #16 pernos de conexión; 4 sets.

1. En una superficie plana, coloque el montaje de horquilla

#11 en el chasis #14 como se muestra en el dibujo.

2. Inserte la barandilla #12 a través del montaje de horquilla

#11 y la Barandilla guía # 15; hasta que se encuentre con

el chasis #14., alineando el orificio inferior de la bomba del

cilindro con el chasis #14.

3. Extraiga la parte inferior de ambos lados del montaje de la

cadena, cuidando que la cadena no se deslice. Conecte la

parte superior de la cadena a la barandilla #12 y luego la

parte inferior con el chasis #14. Ajuste los pernos y use los

pasadores suministrados para asegurarlos.

4. La altura del montacargas puede ajustarse después de la

instalación con el perno de la cadena.

5. Conecte la barandilla #12 y el Chasis #14 con los tornillos

de conexión #16 suministrados.

6. Asegúrese de que todas las piezas estén conectadas

correctamente y que los pernos están bien apretados.

7. Asegúrese que la operación sea constante con o sin una

capacidad nominal.

Atención y Advertencia

1. Use la apiladora en superficies planas y duras.

2. No exceda la capacidad máxima de carga. Transporte los

artículos según la curva de carga garantizando el equilibrio

de la carga

Instrucciones de Operación

1. Aplique los frenos y confirme que la válvula de altura

esté cerrada.

2. El caballete ajusta la altura de la bomba de la horquilla.

Para bajar las horquillas, gire la válvula de altura

lentamente hasta llegar a la altura deseada.

3. Cuando la carga supera 1,2 veces la capacidad de carga, la

seguridad se bloqueará para que las horquillas no puedan

elevarse. Esto es para garantizar una operación segura.

4. Durante el transporte, las horquillas deben estar en la

posición más baja por seguridad.

5. La velocidad de descenso puede ajustarse modificando

el posicionamiento del ángulo del anillo en la vara de la

válvula de liberación.

6. ¡ADVERTENCIA! Al elevar la horquilla, no accione la vara de

la bomba demasiado rápido ya que puede agotar el cilindro.

7. ¡ADVERTENCIA! Al manipular cargas pesadas, gire la

válvula lentamente para mayor estabilidad.

8. ¡ADVERTENCIA! Al terminar la operación de elevación,

verifique que la válvula de liberación esté bien cerrada

para mayor estabilidad de la horquilla.

Mantenimiento Diario e Inspección

1. Inspeccione el montacargas antes de utilizar. No lo use si está

dañado o en mal estado. Inspeccione todas las piezas móviles

en busca de problemas o ruidos.

2. Inspeccionar el sistema hidráulico en busca de fugas de aceite.

3. Realice una inspección mensual de las horquillas, ruedas,

cadenas y lo demás.

4.

Realice el mantenimiento de cilindros de levantamiento

recomendado. Cambie el aceite hidráulico a las 20 horas

de ejecución y una vez cada 18 meses o 300, horas lo que

ocurra primero

Por favor, rellene el aceite hidráulico especificado a las

temperaturas a continuación:

Temperatura Aceite Hidráulico

23°F~ 113°F

5°F~ -41°F

Al cambiar el aceite, ajuste el eje del pistón a la posición más baja.

aceite hidráulico L-HM68

(equivalente a ISOVG68)

aceite hidráulico L-HM46

(equivalente a ISOVG46)

Dibujo del

Principio

Hidráulico

1

2

Válvula de Giro, Elevación y Descenso

3

4

5

6

3

Cilindro Desplazador

Válvula de Seguridad

Válvula de retorno de aceite

Válvula de Trabajo

Cilindro de Trabajo

Page 9

Manual del usuario

Apiladora de Calidad

LISTA DE PARTES

No. Descripción Cant. Observación No. Descripción Cant. Observación

1 Barandilla deslizante 1 43 Clavija partida 2

2 Tuerca 2 44 Perno de cadenas 2

3 Arandela 2 45 Cadenas de rodillos 1

4 Perno interno hexagonal 2 46 Rodamiento libre de aceite 1

5 Tornillo hexagonal 4 47 Cadena y rueda 2

6 Tuerca 4 48 Cubierta de la cadena 1

7 Perno protector 4 49 Eje 1

8 Tornillo hexagonal 4 50 Tornillo 1

9 Arandela 4 51 Tornillo 2

10 Rueda de balanceo 4 52 Pistón 1

11 Rodamiento libre de aceite 4 53 Anillo a prueba de polvo 1 Deteriorable

12 Eje de la rueda de balanceo 4 54 Junta tórica 1 Deteriorable

13 Estante fijo 1 55 Anillo de nylon 1

14 Eje largo 1 56 Guante interior del pistón 1

15 Anillo de división 2 57 Vara de la bomba 2

16 Horquilla ajustable 2 58 Cilindro interior 1

17 Plataforma opcional 1 59 Tapa de la bomba 1

18 Eje de la rueda frontal 2 60 Placa de cierre excéntrica 1

19 Anillo de división 4 61 Resorte de la bomba de aceite 1

20 Arandela 4 62 Espiga fija 1

21 Soporte 4 63 Perno redondo del pilar 1

22 Rueda delantera 2 64 Válvula interna 1

23 Montaje de chasis 1 65 Junta tórica 2 Deteriorable

24 Tuerca 2 66 Guante de vara de la válvula 1

25 Arandela dentada interna de bloqueo 2 67 Cilindro exterior 1

26 Rueda trasera 2 68 Placa de la bomba 2

27 Perno interno hexagonal 2 69 Anillo a prueba de polvo 1 Deteriorable

28 Arandela de cobre 2 70 Junta tórica 1 Deteriorable

29 Resorte del cono 2 71 Anillo de nylon 2

30 Bola de acero 4 72 Guante de la bomba 1

31 Anclaje del perno 2 73 Copa de aceite 2

32 Junta tórica 2 Deteriorable 74 Eje de la bomba 1

33 Tornillo 1 75 Base de la bomba 1

34 Resorte 1 76 Tuerca 1

35 Perno corto 1 77 Eje del anillo de la bomba 1

36 Conexión de la base 1 78 Anillo de la bomba 8

37 Placa de posicionamiento 1 79 Rodamiento libre de aceite 2

38 Resorte de torsión 1 80 Bola de acero 1

39 Perno de posicionamiento 2 81 Camisa del eje 1

40 Anillo de posicionamiento 2 82 Palanca del caballete 1

41

42 Manija 1

Vara unidireccional de la Válvula

1 83 Guante de goma 1

4

Page 10

Apiladora de Calidad

Vista Ampliada

Manual del usuario

Palanca

de la

válvula de

liberación

5

Page 11

globalindustrial.ca

Distribucion Industrial Globales S DE RL DE CF

User's manual Manual del usuario Manuel de l'utilisateur

Customer Service

US: 1-800-645-2986

Servicio de atención al Cliente

México: 01.800.681.6940

Service à la clientèle

Canada: 888-645-2986

L’empileur de valeur optimale

Modèle 988934 (élévateur de 47 po.) et 988935 (élévateur de 59 po.) plate-forme optionnelle 988936

POUR UN FONCTIONNEMENT SÉCURITAIRE,

bien lire et comprendre toutes les instructions

avant d’assembler, installer, faire fonctionner

ou entretenir le produit. S’assurer de bien

respecter toutes les directives de sécurité.

Le non-respect de ces directives pourrait

entraîner des blessures corporelles graves

et/ou dommages matériels. Conserver ces

instructions pour référence ultérieure.

1

021017

Page 12

L’empileur de valeur optimale

Manuel de l'utilisateur

AVERTISSEMENT :

1. Assurez-vous d'exploiter l’empileur dans la portée

de la charge nominale. Ne pas surcharger. Une

surcharge peut provoquer des endommages.

2. Ne pas dépasser la capacité nominale de 880 lb.

3. Ne pas s'asseoir ou se tenir debout sur l’empileur.

4. Inspectez l’unité avant de l'utiliser ; ne pas utiliser si

endommagé ou en mauvais état.

5. Ne pas abuser ou altérer l'unité.

6. Protéger toutes les extrémités, y compris les mains,

les pieds, et d'autres parties du corps lors de

l'utilisation ou le transport de l'ascenseur.

7. Ne pas mettre les mains ou les pieds près des

fourches/plate-forme d’abaissement.

8. Appliquer les freins et/ou caler des pneus lors du

levage, du chargement ou du déchargement de l’unité

pour éviter tout mouvement.

9. Vérifier la stabilité et que la distribution des charges

soit parfaitement distribuée avant de manipuler. NE

PAS manipuler des charges non sécurisé.

10. Ne laissez pas de charge sur l’empileur pendant de

longues périodes de temps.

11.

L’empileur ne peut pas être déplacé au cours de l'opération.

12. Utiliser l'empileur seulement sur des surfaces durables

et lisse, loin de la circulation.

13. Lorsque vous placez des articles sur les fourches/

plate-forme une fois élevées, le poids de l'article doit

être chargé à la légère et le poids total doit être à la

portée de la charge nominale.

14. Lors du chargement et du déchargement des articles

des fourches/plate-forme une fois élevées, ne faites

pas glisser le contenu transversalement. Cela peut

impliquer des risques de stabilité et une charge

déséquilibrée.

15.

Veuillez utiliser strictement en fonction de «

remarques (avertissement) ». Les avertissements,

précautions et instructions discuté ne peut pas

couvrir toutes les conditions et situations qui

peuvent se produire. Le non-respect de ces

avertissements peut entraîner des dommages

matériels, des blessures corporelles et/ou la mort.

16. Ne pas modifier ou altérer cette table de levage.

Les modifications peuvent causer un mauvais

fonctionnement qui peut résulter en des blessures ou

la mort.

Fig. 1

SPÉCIFICATIONS

Modèle H H1 H2 L L1 W1 W B d D h Load Work No. NW

988934 56 po 3.5 po 47 po 47 po 26 po 4.4 po 22 po 23 po 3 po 5 po 0.9" 880 48 180 lbs.

988935 67 po 3.5 po 59 po 59 po 26 po 4.4 po 22 po 23 po 3 po 5 po 0.9" 880 60 190 lbs

LISTE DES PIÈCES

1. Roue avant 4. Plate-forme de travail (988936 vendu séparément) 7. Assemblage de garde-fou Slideway

2. Assemblage du châssis 5. Assemblage du vérin 8. Levier de pieds

3. Assemblage de la fourche 6. Chaînes et roues 9. Roue arrière

2

Page 13

L’empileur de valeur optimale

Manuel de l'utilisateur

Installation

Outils requises pour l'assemblage des deux clés plates de

17 mm Identification de la pièce #11 de l’assemblage de la

fourche, # 12 pour le garde-fou, #13 pour l’assemblage du

vérin, #14 pour l’assemblage du châssis, #15 pour le guide

du garde-fou et #16 pour les boulons de connexion; 4 jeux

1. Sur une surface plane, placez l'assemblage de la fourche

# 11 sur le châssis # 14 comme illustré.

2. Sur une surface plane, placez l'assemblage de la fourche

# 11 sur le châssis # 14 comme illustré.

3. Retirez l'écrou inférieur des deux côtés de l'assemblage

général de la chaîne, en veillant à ne pas laisser la chaîne

glisser dans celui-ci. Connecter la partie supérieure de

la chaîne au garde-fou #12, puis la partie inférieure dans

le châssis # 14. Serrer les vis et en utilisant les goupilles

fendues fournies pour unir le tout.

4. La hauteur du chariot élévateur est réglable après

l'installation via le boulon de la chaîne.

5. Branchez le garde-fou # 12 et le châssis #14 en utilisant

les boulons de connexion # 16 fournies.

6. S'assurer que toutes les pièces sont correctement

connectées et que les boulons soient bien serrés.

7. Assurez-vous que l'opération soit régulière avec et sans

charge nominale.

Attention et Avertissement

1. Utiliser l’empileur sur des surfaces planes et dures.

2. Ne pas dépasser la capacité de charge maximale.

Transporter des marchandises en fonction de la courbe de

charge assurant.

Instructions d’utilisations

1. Verrouillez les freins des roues et confirmer que la soupape

de relâche de hauteur soit fermée.

2.

Le poteau du marchepied ajuste la hauteur de la pompe de

la fourche. Pour abaisser la fourche, tourner la soupape de

relâche de hauteur lentement jusqu'à la hauteur désirée.

3. Lorsque la charge dépasse 1,2 fois la capacité de charge, la

sécurité se verrouille de sorte que les fourches ne puissent

pas monter. Il s'agit d'assurer un fonctionnement sûr.

4. Pendant le transport, les fourches doivent être dans la

position la plus basse pour une sécurité accrue.

5. La vitesse de descente peut être réglée en modifiant

l'angle de l'anneau de positionnement sur le poteau de la

soupape de relâche.

6. ATTENTION! Lors de la montée de la fourche, ne pompez

pas le marchepied trop rapidement puisque cette action

peut entrainer un appauvrissent du vérin.

7.

ATTENTION! Lors de la manipulation de charges lourdes, tourner

la soupape de relâche lentement pour une stabilité accrue.

8. ATTENTION! Lorsque les opérations d’élévation cessent,

vérifier que la soupape de relâche est correctement fermée

pour la stabilité de la fourche.

Inspection et Entretien quotidien

11. Inspectez le chariot élévateur avant l'utilisation. Ne pas

utiliser si endommagé ou en mauvais état. Inspecter toutes

les pièces mobiles contre tout problème ou bruit.

2. Inspecter le système hydraulique contre toute fuite d'huile.

3. Effectuer une inspection mensuelle des fourches, des

roues, des chaînes, et plus encore.

4. Effectuez un entretien recommandé du vérin de levage.

Remplacer l'huile hydraulique après 20 heures d’utilisation

et une fois tous les 18 mois ou à tous les 300 heures, selon

selon la première éventualité.

Veuillez remplir avec l’huile hydraulique spécifiée aux

températures énumérées ci-dessous :

Température ambiante Huile hydraulique

23°F~ 113°F

5°F~ -41°F

Lors du remplacement de l'huile, régler la position du

poteau du piston à la position la plus basse.

Huile hydraulique L-HM68

(équivalent à ISOVG68)

Huile hydraulique L-HM46

(équivalent à ISOVG46)

Schéma du principe

hydraulique

1 Vérin de sortie

2 Tourner la soupape de levage et d’abaissement

3 Soupape de sécurité

4 Soupape de retour d’huile

5 Soupape de travail

6 Cylindre de travail

3

Page 14

Manuel de l'utilisateur

L’empileur de valeur optimale

LISTE DES PIÈCES

Non. Description Qté. Remarque Non. Description Qté. Remarque

1 Garde-fou Slideway 1 43 Goupille fendue 2

2 Écrou 2 44 Boulon de chaînes 2

3 Rondelle 2 45 Chaînes à rouleaux 1

4 Boulon interne hexagonale 2 46 Roulement à bille sans huile 1

5 Boulon hexagonal 4 47 Chaine et roue 2

6 Écrou 4 48 Couvre-chaine 1

7 Broche bouclier 4 49 Essieu 1

8 Boulon hexagonal 4 50 Boulon 1

9 Rondelle 4 51 Boulon 2

10 Roue de roulement 4 52 Pôle de piston 1

11 Roulement à bille sans huile 4 53 Anneau anti-poussière 1 Dommageable

12 Essieu de roue 4 54 Rondelle en ‘O’ 1 Dommageable

13 Rack stable 1 55 Anneau en nylon 1

14 Essieu long 1 56 Jante de piston intérieure 1

15 Anneau fendue 2 57 Pôle de la pompe 2

16 Fourche réglable 2 58 Cylindre interne 1

17 Plate-forme optionnelle 1 59 Couvercle de pompe 1

18 Essieu de roue avant 2 60 Plaque d'étanchéité excentrique 1

19 Anneau fendue 4 61 Ressort de pompe à huile 1

20 Rondelle 4 62 Oreille fixe 1

21 Roulement à bille 4 63 Goupille de pilier ronde 1

22 Roue avant 2 64 Soupape intérieure 1

23 Assemblage du châssis 1 65 Rondelle en ‘O’ 2 Dommageable

24 Écrou 2 66 Jante de poteau de soupape 1

25 Rondelle de blocage à dent interne 2 67 Cylindre extérieur 1

26 Roue arrière 2 68 Plaque de pompe 2

27 Boulon interne hexagonale 2 69 Anneau anti-poussière 1 Dommageable

28 Rondelle en cuivre 2 70 Rondelle en ‘O’ 1 Dommageable

29 Ressort conique 2 71 Anneau en nylon 2

30 Bille en acier 4 72 Jante de la pompe 1

31 Bouchon de boulon 2 73 Cuvette d'huile 2

32 Rondelle en ‘O’ 2 Dommageable 74 Essieu de la pompe 1

33 Boulon 1 75 Base de la pompe 1

34 Ressort 1 76 Écrou 1

35 Goupille courte 1 77 Essieu de l’anneau de la pompe 1

36 Connexion à la base 1 78 Anneau pour pompe 8

37 Plaque de positionnement 1 79 Roulement à bille sans huile 2

38 Ressort de torsion 1 80 Bille en acier 1

39 Bille en acier 2 81 Boulon de positionnement 1

40 Essieu à manchon 2 82 Anneau de positionnement 1

41 Poteau de soupape unidirectionnelle 1 83 Gant en caoutchouc 1

42 Poignée 1

4

Page 15

L’empileur de valeur optimale

Vue éclatée

Manuel de l'utilisateur

Levier de

libération

5

Loading...

Loading...