Page 1

Page 2

Page 3

Page 4

Instruction Manual

Mobile-Karrier

For 55 gallon (210 liters) steel drum

Note: Owner/Operator must read and understand this instruction

manual before using the Mobile-Karrier.

Page 5

Contents

Ⅰ. Structure and Relevant Parts Description

Ⅱ. Specifications

Ⅲ. Precaution

Ⅳ. Operation

Ⅴ. Maintenance

Ⅵ. Assembly

VII. Exploded View & Spare Parts

Page 6

THANK YOU FOR CHOOSING OUR MOBILE-KARRIER. FOR

YOUR SAFETY AND CORRECT OPERATION, PLEASE

CAREFULLY READ THE MANUAL BEFORE USE.

NOTE: All of the information reported herein is based on data

available at the time of printing. The factory reserves the right to

modify its own products at any time without notice or incurring in

any sanction. Please verify with the factory for possible updates.

Ⅰ. Structure and Relevant Parts Description

Item No. Description Remark

1 Chassis

2 Mast

3 Supporting hoop

4 Handle

5 Location pin

6 Fastening lever

7 Chain

8 Wheel

9 Caster

Page 7

10 Location lever

11 Lifting arm

12 Hanger plate

13 Adjustment hole

14 Pawl

15 Mobile hoop

16 Adjustment hole

17 Hook

Ⅱ. Specifications

Capacity

Drum dimension

Net Weight

800lbs

1/2” x 36”

22-

50kg

Ⅲ. Precaution

1. Always use the Mobile-Karrier on firm and flat floor.

2. Do not overload.

3. Only after chain firmly holds drum and location pin is correctly

positioned can the Mobile-Karrier be moved.

4. Do not pull location lever (Part No. 10) while moving the

Mobile-Karrier.

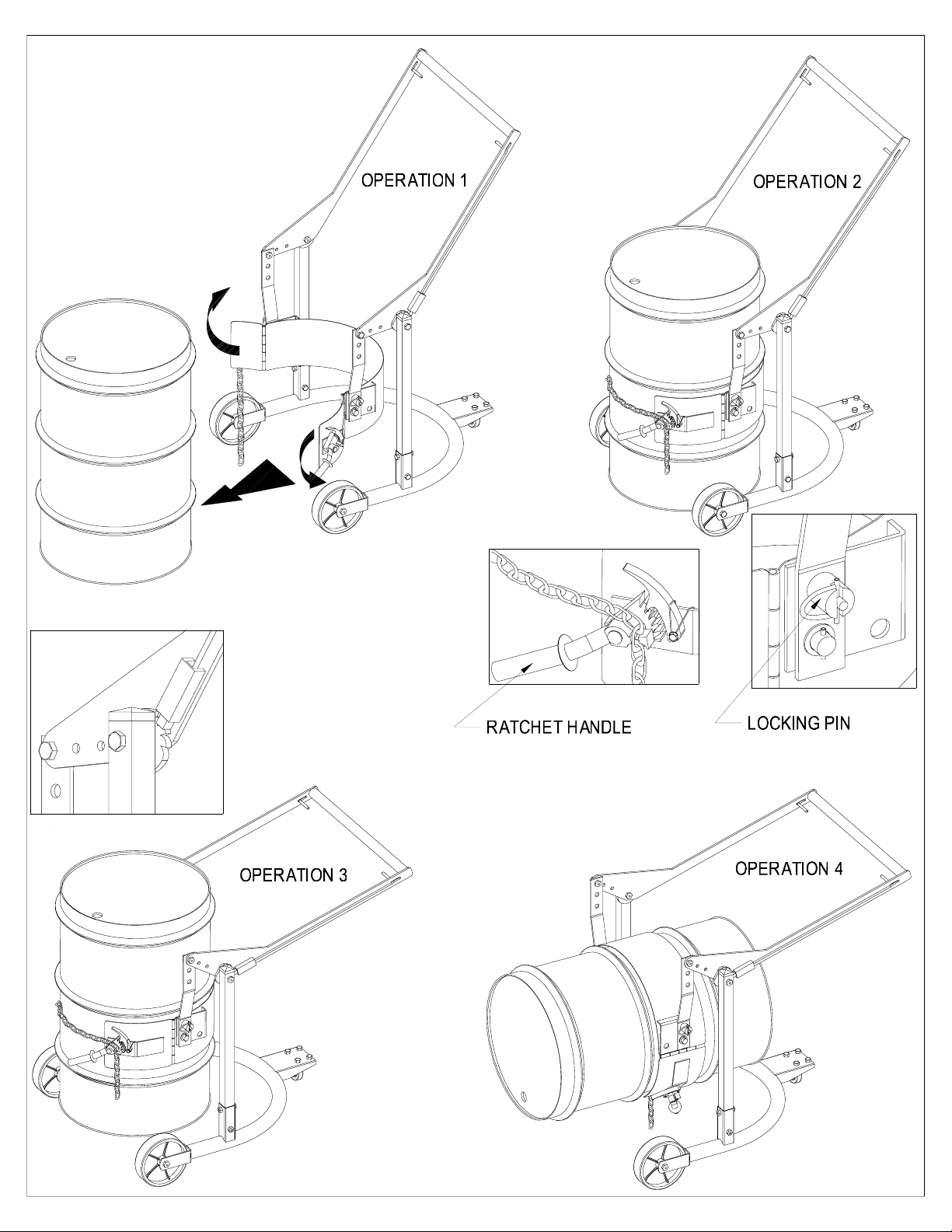

Ⅳ. Operation

1. Clamping drum

The mobile hoop (Part No. 15) is usually open due to being

supported by a spring. This does help to accepting the drum.

Push the Mobile-Karrier near to the drum that shall be lifted. While

pulling the location levers (Part No. 10), turn the handle (Part No. 4)

to locate supporting hoop (Part No. 3) in the middle of the drum.

Page 8

Release the location levers (Part No. 10) to lock the handle at this

appropriate position.

Turn the fastening lever (Part No. 6) counter-clockwise to make its

teeth upward. Fasten the chain (Part No. 7) and insert the chain

into the groove on the fastening lever (Part No. 6). Then turn the

lever (Part No. 6) clockwise quickly to make chain (Part No. 7)

embay the drum. Please make sure that the fastening lever (Part

No.6) is firmly locked by the pawl (Part No. 14).

2. Lifting drum

Press the handle (Part No. 4) and the drum will be lifted. When the

drum is lifted to the required position, release the handle (Part No. 4)

and the drum will be locked.

3. Transportation

Push/haul the handle (Part No. 4) to move the Mobile-Karrier to the

destination. (Of course, if necessary, operator can turn the handle

to change the Mobile-Karrier’s moving direction.)

4. Lower & release the drum

Press the handle (Part No. 4) slightly, and pull the location levers

(Part No. 10) at the same time. Then slowly lift the handle (Part No.

4) so as to lower the drum. When the drum reaches a firm surface

release the location levers (Part No. 10).

Page 9

Turn the fastening lever (Part No. 6) clockwise slightly so that the

pawl (Part No 14.) disengages. Release the fastening lever (Part

No. 6). Take the chain (Part No. 7) out the groove on the fastening

lever and hang it on the hook (Part No. 17).

Move away the Mobile-Karrier.

5. Rotate the drum

The Mobile-Karrier can rotate the drum from vertical to horizontal

position according to actual demand. Do the operation as follows.

Disengage the location pins (Part No. 5) and in the meantime turn

the drum by 90° by hand.

Turn the location pins so as to insert them into the corresponding

holes to lock the drum in the horizontal position.

Note: Before rotating the drum, press/lift the handle (Part No. 4) to

an appropriate height in case the drum bumps the ground.

6. Adjustment

If the supporting hoop is too high to hold the middle of the drum

while the handle (Part No. 4) is lifted to its max. height, it is

necessary to choose another appropriate hole on the handle.

If the drum cannot be lifted to required height while the handle (Part

Page 10

No. 4) is pressed to reach its min. height, it is necessary to choose

another appropriate hole on the lifting arm (Part No. 12).

Pull the location levers (Part No. 10) and slowly lift the handle (Part

No. 4) so as to lower the drum. When the drum reaches a firm

surface release the small levers (Part No. 10).

Remove the chain and move the Mobile-Karrier away from the

drum.

Ⅴ. Maintenance

1. Do routine check of the wearing condition of location pins (Part

No. 5) and replace the worn pins in time.

2. Do routine check of chassis, front wheel and rear caster.

3. Do routine check of clamping reliability of chain.

4. Do routine check of all the connecting parts such as pins and

fasteners.

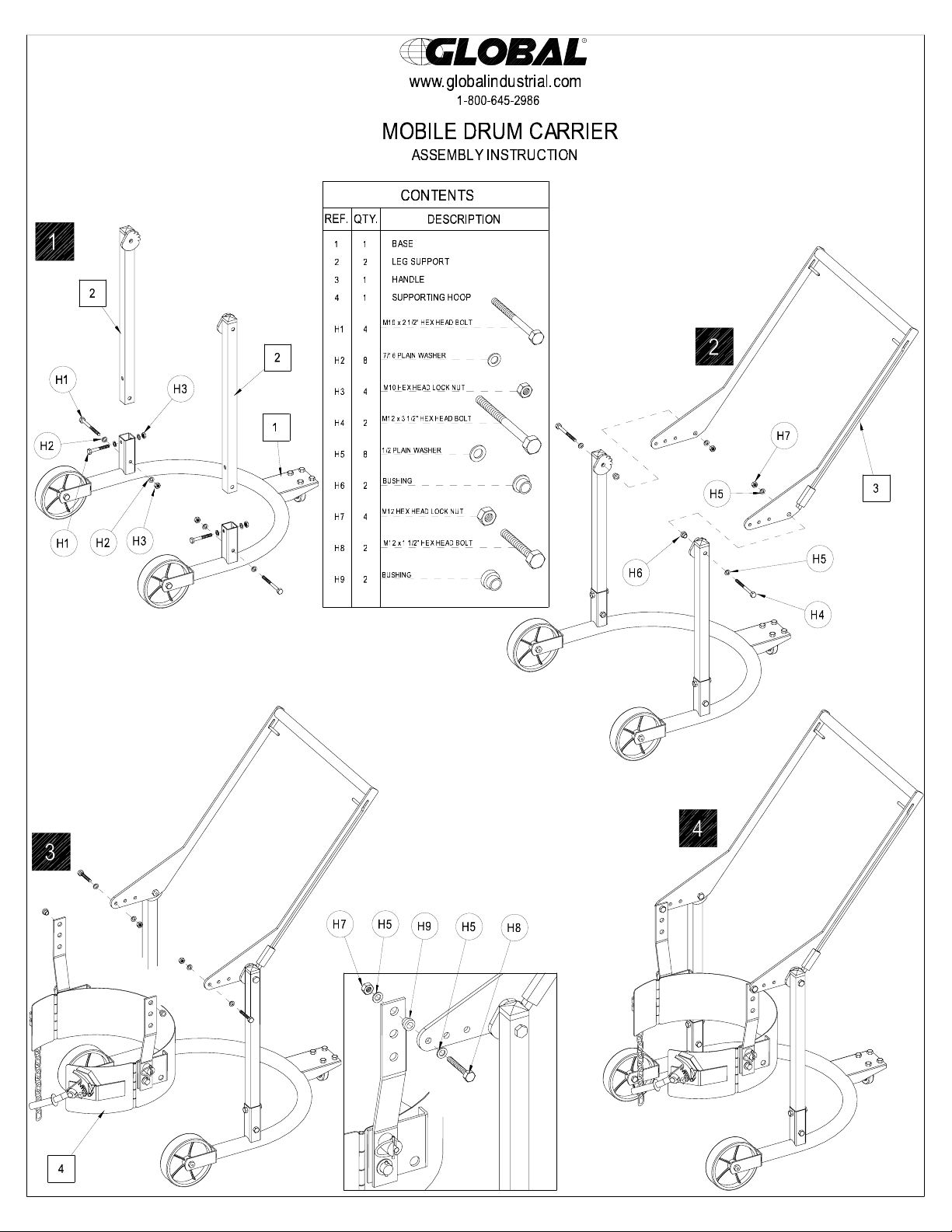

Ⅵ. Assembly

Some necessary tools must be prepared before assembly.

1. Take out all the subassemblies in following turns from carton.

a

b

c

d

e

Steel harness, washers, nuts and clamp

Chassis

Mast

Supporting hoop

Handle

collars

2. Assemble mast (b) on chassis (a) with screws, washers and

nuts.

3. Put steel harness (e) through the holes on the outsides of the

lifting arms (Part No 11.) and then fix it with fasteners (e).

Page 11

4. Put steel harness (e) through the holes on the hanger plates

(Part No 12.) and then fix it with fasteners (e).

VII. Exploded View & Spare Parts

Page 12

No. Description Qty No. Description Qty

1. Pin 2 26. Pin 1

2. Retaining ring 4 27. Retaining pin 1

3. Separate ring 4 28. Supporting hoop 1

4. Front wheel 2 29. Hanger plate 2

5. Bearing 4 30. Sliding pin

6. Chassis 1 31. Spring

7. Bolt 4 32. Sliding bush

8. Lock nut 4 33. Retaining ring

9. Rubber bush 1 34. Extension ring

10. Pawl

11. Retaining ring

12. Bolt

13. Spring

14. Dentation clip

15. Pin

16. Chain

17. Mobile hoop

18. Nut

1

35. Bolt

1

36. Separate ring

1

37. Bolt

1

38. Separate ring

1

39. Sliding block

1

40. Spring

1

41. Lever

1

42. Lifting arm

1

43. Tapper pipe

19. Hub for chain 2 44. Dentation claw

20. Door 1 45. Square plug

21. Bolt 1 46. Bolt

22. Pin 1 47. Lock nut

23. Lock nut 2 48. Mast

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

24. Spring 1 49. Back wheel 1

25. Washer 1 50.

Loading...

Loading...