Gerber P2C 600 Owner's Manual

Gerber P2C™ 600

User’s Manual

IMPORTANT

Before you begin...

Please complete the attached Warranty Registration Card and

return it to Gerber today, or go through the online registration at

http://www.gspinc.com/products/registration/index.html

Failure to register may result in delayed responses to your warranty

and service inquiries.

FCC NOTICE

Warning: Changes or modifications to this unit not expressly approved by the

party responsible for compliance could void the user’s authority to operate the

equipment.

Note: This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC rules. These limits are

designed to provide reasonable protection against harmful interference when

the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user

will be required to correct the interference at his own expense.

RS-232 shielded cables must be used with this unit to ensure compliance with

the Class A FCC limits.

This Class A digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du

Canada.

Gerber P2C™ 600 User’s Manual

NOTICE

Gerber Scientific Products reserves the right to modify the information

contained in this User Manual at any time without prior notice. Unauthorized

copying, modification, distribution or display is prohibited. All rights reserved. All

queries, comments or suggestions concerning this and other Gerber manuals

should be directed to:

Gerber Scientific Products

83 Gerber Road

South Windsor, CT 06074 USA

860-643-1515

Customer Service: (800) 222-7446

Technical Support: 800-828-5406 / 860-644-6971

Fax 800-227-6228 / 860-871-3862

www.gspinc.com

Copyright 2005, Gerber Scientific International, Inc.

Notice

Gerber P2C™ 600 User’s Manual

TRADEMARK ACKNOWLEDGEMENTS

GERBER EDGE, EDGE and Gerber Scientific Products are registered trademarks

and Gerber P2C, GerberGlow, Gerber ImageCast, Gerber HoloGraphix,

Gerber AutoMag, GerberMag, LexEdge, EDGE Positive, Gerber ImageCal,

Gerber PermaGrip, Gerber PlastiGraphix, Gerber QUANTUM, Gerber Vision, and

FastFacts are trademarks of Gerber Scientific Products Corporation.

3M, Scotchcal, Scotchlite, Controltac, Comply and Panaflex are trademarks of

the 3M Corporation.

DM/PL and Houston Instrument are trademarks of Summagraphics Corporation.

HP-GL is a trademark of Hewlett-Packard Company.

IBM PC, IBM PC/XT, and IBM AT are trademarks of International Business

Machines Corp.

Macintosh, Macintosh Plus, Macintosh SE, and Macintosh II are trademarks of

Apple Computer.

Table of contents

Gerber P2C™ 600 User’s Manual

TABLE OF CONTENTS.................................................................................. PAGE

SECTION 1 .................................................................................................................. 1-1

INTRODUCTION............................................................................................ 1-1

1.1.

1.1.1. PRODUCT FEATURES .....................................................................................1-1

1.1.2. GERBER P2C 600 USER’ S MANUAL .............................................................1-3

1.2. SPECIFICATIONS.......................................................................................... 1-4

1.2.1. CUTTER ..........................................................................................................1-4

1.2.2. MEDIA ...........................................................................................................1-4

1.2.3. KNIFE, PEN, AND POUNCING TOOL ............................................................1-5

1.2.4. INTERFACE ....................................................................................................1-6

1.2.5. FIRMWARE ....................................................................................................1-6

1.2.6. PERFORMANCE............................................................................................1-6

1.2.7. CERTIFICATIONS............................................................................................1-7

1.2.8. ENVIRONMENTAL .........................................................................................1-7

1.2.9. ELECTRICAL...................................................................................................1-7

1.3. CUTTER ACCESSORIES AND CONSUMABLES.............................................. 1-8

1.4. POSITIONING THE 600 CUTTER ON A TABLE ............................................... 1-9

1.5 CUTTER COMPONENTS.............................................................................. 1-10

1.5.1 REAR PANEL CONTROLS ............................................................................1-10

1.5.2 FRONT PANEL CONTROLS ......................................................................... 1-12

1.6. POWERING UP THE CUTTER........................................................................ 1-14

1.6.1. EARTHING (“GROUNDING”)......................................................................1-14

1.6.2. POWER-UP PROCEDURE ............................................................................1-15

1.7. LOADING MEDIA....................................................................................... 1-16

1.7.1. POSITIONING THE PINCH ROLLERS ............................................................1-16

1.7.2. FEEDING AND POSITIONING MEDIA .........................................................1-17

1.8. INSTALLATION OF A KNIFE, PEN OR POUNCING TOOL ........................... 1-21

1.8.1. KNIFE INSTALLATION ...................................................................................1-21

1.8.2. PEN INSTALLATION......................................................................................1-25

1.8.3. INSTALLATION OF A POUNCING TOOL......................................................1-26

SECTION 2 .................................................................................................................. 2-1

THE CONTROL PANEL .................................................................................. 2-1

2.1.

2.1.1. THE LIQUID CRYSTAL DISPLAY ......................................................................2-1

2.1.2 THE MENU KEY ..............................................................................................2-2

2.1.3 THE EXIT KEY ................................................................................................2-3

2.1.4 THE V KEY ....................................................................................................2-3

Table of contents TOC-i

Gerber P2C™ 600 User’s Manual

2.1.5 THE TEST KEY..................................................................................................2-3

2.1.6 THE JOGGING KEYS...........................................................................................2-3

2.2. COMMON MENU ITEMS .............................................................................. 2-4

2.2.1 VELOCITY......................................................................................................2-4

2.2.2 PEN PRESSURE...............................................................................................2-4

2.2.3 KNIFE PRESSURE ............................................................................................2-4

2.2.4 KNIFE OFFSET.................................................................................................2-5

2.2.5 POUNCING PRESSURE..................................................................................2-5

2.2.6 POUNCING GAP ..........................................................................................2-5

2.2.7 USER CONFIGURATION (“USER CONFIG”)..................................................2-6

2.2.8 RESET .............................................................................................................2-7

2.2.9 RECUT............................................................................................................2-7

2.2.10 LOAD ............................................................................................................2-7

2.2.11 ALIGN LOAD.................................................................................................2-7

2.2.12 SYSTEM SETUP................................................................................................2-7

2.3 SYSTEM SETUP....................................................................................................... 2-8

2.3.1. CONFIDENCE ...............................................................................................2-9

2.3.2. DIN CUT.........................................................................................................2-9

2.3.3. TOOL.............................................................................................................2-9

2.3.4. FLEX-CUT .......................................................................................................2-9

2.3.5. OVERCUT....................................................................................................2-10

2.3.6. OPTICUT ......................................................................................................2-11

2.3.7 EMULATE .....................................................................................................2-11

2.3.8. BAUD RATE..................................................................................................2-12

2.3.9. PARITY .........................................................................................................2-12

2.3.10. RTS/DTR .......................................................................................................2-13

2.3.11. RS 232 TEST..................................................................................................2-13

2.3.12. ALIGN MODE..............................................................................................2-13

2.3.13. AUTOLOAD .................................................................................................2-14

2.3.14. LANGUAGE.................................................................................................2-14

2.3.15. MENU UNITS ................................................................................................2-14

2.3.16. ROM REVISION ...........................................................................................2-14

2.3.17. MEDIA SENSOR...........................................................................................2-15

2.3.18. SENSOR SETUP.............................................................................................2-15

2.3.19. CALIBRATE X/Y............................................................................................2-15

2.3.20. COIL SETUP..................................................................................................2-16

SECTION 3 .................................................................................................................. 3-1

3.1.

MAINTENANCE & CLEANING...................................................................... 3-1

3.1.1. CLEANING THE DRIVE SYSTEM.....................................................................3-1

3.1.2. CLEANING THE SENSOR ...............................................................................3-2

3.2. OPERATING VOLTAGE................................................................................. 3-1

SECTION 4 .................................................................................................................. 4-1

Table of contents TOC-ii

Gerber P2C™ 600 User’s Manual

4.1. INTRODUCTION............................................................................................ 4-1

4.2. RS232 INTERFACE NOTES............................................................................. 4-1

4.2.1. SYSTEM SETUP................................................................................................4-1

4.2.2. SERIAL INTERFACE CONNECTOR ON THE CUTTER.......................................4-2

4.2.3. AVAILABLE SERIAL SIGNALS.........................................................................4-2

4.3 USB INTERFACE NOTES ................................................................................ 4-3

4.3.1 USB SPECIFICATIONS ....................................................................................4-3

4.3.2 INSTALLING THE USB SOFTWARE ON A WINDOWS OPERATING SYSTEM....4-3

MEDIA CERTIFICATION ..............................................................................................A-1

GERBER SCIENTIFIC PRODUCTS.................................................................................A-3

Table of contents TOC-iii

Gerber P2C™ 600 User’s Manual

APPENDIX A:

MEDIA CERTIFICATION................................................................................. A-1

ADDRESSES ................................................................................................... A-3

LIST OF ILLUSTRATIONS........................................................................................... PAGE

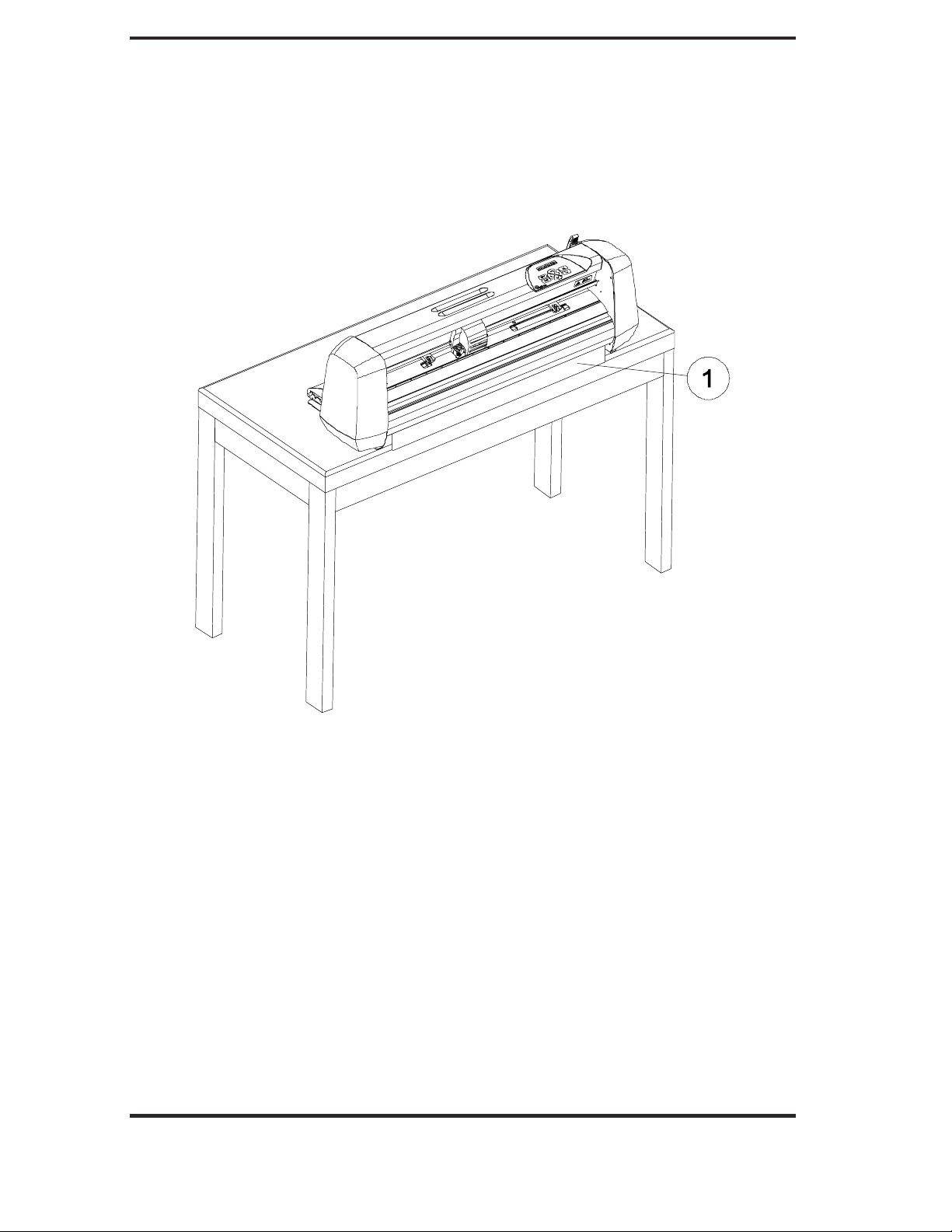

1-1 CORRECTLY POSITIONING THE CUTTER ON A FLAT SURFACE…......……….1-9

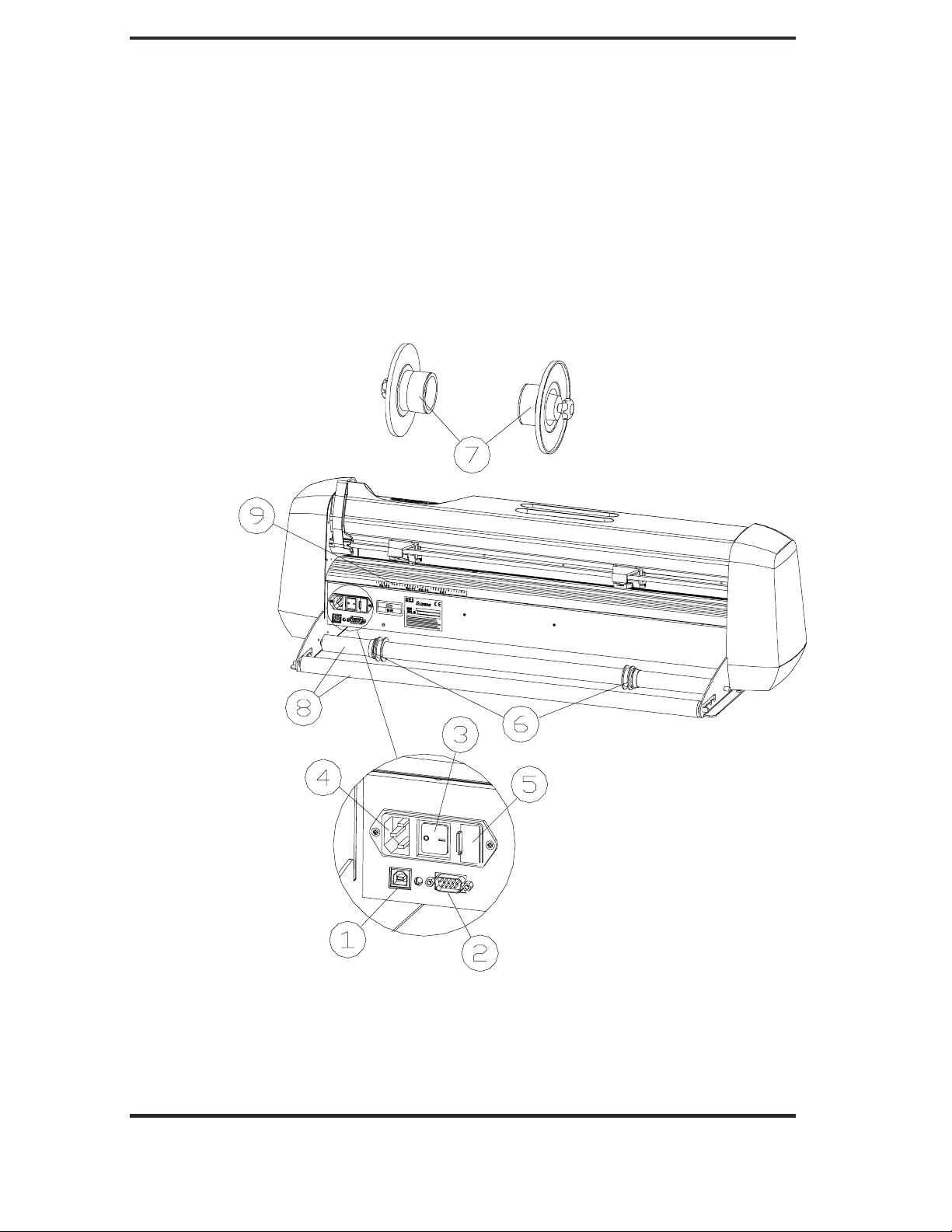

1-2 GERBER P2C 600 CUTTER, REAR VIEW........................................................1-10

1-3 GERBER P2C 600 CUTTER, FRONT VIEW......................................................1-12

1-4 GROUND CONNECTION.............................................................................1-15

1-5 MEDIA POSITIONING...................................................................................1-17

1-6 FEEDING ROLL MEDIA WITH USING FLANGES........................................... 1-18

1-7 FEEDING ROLL MEDIA WITHOUT USING FLANGES .................................... 1-19

1-8 PINCH ROLLER POSITIONING......................................................................1-19

1-9 BLADE INSERTION ........................................................................................1-21

1-10 BLADE LENGTH ADJUSTMENT......................................................................1-22

1-11 SETTING KNIFE DEPTH...................................................................................1-22

1-12 KNIFE DEPTH TEST PATTERN..........................................................................1-23

2-1 GERBER P2C 600, CONTROL PANEL.............................................................2-1

2-2 GERBER P2C 600, MAIN MENU.....................................................................2-2

2-3 GERBER P2C 600, SYSTEM SETUP ..................................................................2-8

3-1 CLEANING OF THE FRICTION DRIVE SYSTEM................................................3-2

3-2 POWER ENTRY MODULE................................................................................3-3

LIST OF TABLES........................................................................................................ PAGE

1-1 GERBER P2C 600 CUTTER SPECIFICATIONS..................................................1-4

1-2 GERBER P2C MEDIA SPECIFICATIONS..........................................................1-4

1-3 GERBER P2C 600 KNIVES, PENS AND POUNCING TOOLS...........................1-5

1-4 GERBER P2C 600 INTERFACE SPECIFICATIONS ............................................1-6

1-5 GERBER P2C 600 FIRMWARE........................................................................1-6

1-6 GERBER P2C 600 PERFORMANCES..............................................................1-6

1-7 GERBER P2C 600 ENVIRONMENTAL SPECIFICATIONS.................................1-7

1-8 GERBER P2C 600 ELECTRICAL SPECIFICATIONS ..........................................1-7

1-9 GERBER P2C 600 ACCESSORIES AND CONSUMABLES...............................1-8

Table of contents TOC-iv

Gerber P2C™ 600 User’s Manual

SECTION 1

GENERAL INFORMATION

1.1. INTRODUCTION

Gerber P2C™ 600 cutters have been designed to reproduce computergenerated graphic images on sheets or rolls of vinyl media. By replacing the

knife with a fiber tip pen, the cutter can also be used to render previews of new

designs on inexpensive paper.

This manual covers the Gerber P2C 600, which can accommodate media

widths from 70mm up to 770mm (2.7" to 30.5").

1.1.1. PRODUCT FEATURES

The following are some of the main features of the Gerber P2C 600 cutters:

• The ability to accommodate various media widths

• An interchangeable pen for producing preview plots of designs on paper

• An interchangeable pouncing tool

• Adjustable knife pressure and offset settings that are microprocessor-

controlled

• Communication with the host computer via Universal Serial Bus (USB) or

standard serial RS-232-C

• Plug-and-play compatibility for Windows 95, Windows 98 and Windows NT

• An 8-key control panel

• A convenient 16-character liquid crystal display (LCD)

• Metric or English units of measurement

• Microprocessor-controlled menu mode that allows for the selection of a

standard start-up configuration

General Information 1-1

Gerber P2C™ 600 User’s Manual

• A wide variety of axial cutting speeds (in metric or English units)

• Up to four separate user configurations that are stored in the non-volatile

memory

• Automatic pull from media roll

• A sensor that detects the end of the media

• The ability for the user to reposition the origin

• Concatenation and curve smoothing that result in better cuts

• A slitter knife for cutting the finished graphic off the media roll

• Knife depth and offset tests

• An adjustable overcut for easy weeding

• User-selected DM/PL, HP-GL,

• The ability to recut a graphic multiple times

• An optional stand

and HP-GL/2 software protocols

General Information 1-2

Gerber P2C™ 600 User’s Manual

1.1.2. GERBER P2C 600 USER’ S MANUAL

The Gerber P2C 600 User’s Manual contains the following information:

• Complete technical specifications for the Gerber P2C 600 cutters and

compatible media

• A complete description of the Gerber P2C 600's main components

• Step-by-step instructions for knife and pen installation and the loading of

media

• Information about control panel operation and how to use it to set the

cutter’s parameters

• Information about the interface cables used to connect the cutter to IBM,

IBM-compatible, Macintosh, and Macintosh-compatible host computers

• Maintenance and cleaning instructions

General Information 1-3

Gerber P2C™ 600 User’s Manual

1.2. SPECIFICATIONS

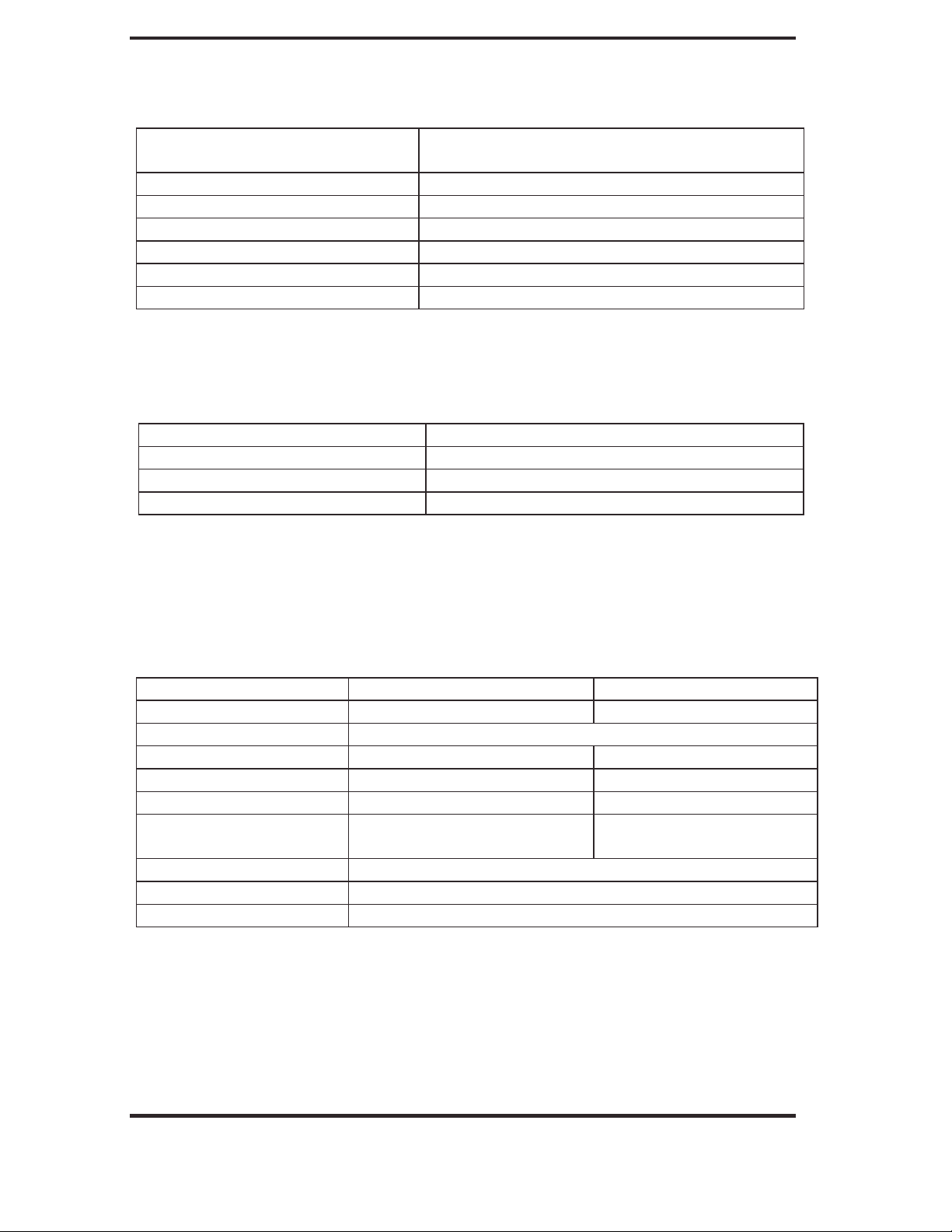

1.2.1. CUTTER

P2C 600

HEIGHT

WIDTH

DEPTH

WEIGHT

1.2.2. MEDIA

Width Roll 70 to 660 2.8 to 26

Sheet 70 to 770 2.8 to 30.3

Tracking

performance

Thickness

Max.Cutting/

Plotting area

Minimum

Margins**

Front margin

Rear margin Sensor on 42 1.7

Sensor off

* Media lengths larger than 8m (26 feet) can be accommodated, but adherence to

specifications is not guaranteed. Rather, performance will depend on the type and size of the

media used in addition to other parameters not mentioned here.

** For positioning of the pinch rollers (see section 1.7)

MM INCH

300 11.8

1000 39.4

350 13.8

15 KG 33 LBS

TABLE 1-1:

Gerber P2C 600 SPECIFICATIONS

Gerber P2C 600

mm inch

8m/26 feet max. within

guaranteed specifications*

0.05 to 0.25

0.8mm with optional

sandblast knife

600mm x 50m. 23.6” x 164 ft.

25

18 0.7

25 1

TABLE 1-2:

GERBER P2C MEDIA SPECIFICATIONS

-8 m/26 feet max. within

guaranteed specifications* for

media less than 750mm (30" wide).

-4m/13 feet max. within

guaranteed specifications** for

media larger than 750 mm (30").

0.002 to 0.01 0.03 inch with optional

sandblast knife

1

General Information 1-4

Gerber P2C™ 600 User’s Manual

Vinyl Types

Different types of vinyl have been evaluated and tested on Gerber P2C 600

cutters. When using duly certified media, operation in accordance with the

functional specifications of the model is warranted. Contact Gerber before

using uncertified media to ensure performance in compliance with

specifications.

See Appendix A for a complete list of duly certified media suitable for friction

drive operation.

Plotting Paper

Bond paper (120g/m² recommended)

1.2.3. KNIFE, PEN, AND POUNCING TOOL

Gerber P2C 600 cutters are shipped with two standard knife blades for vinyl

media and a black fiber tip pen.

Knife

Standard knife Standard, reflective,

Knife for masking stencil Masking stencil &

Pen

Fiber tip pen Black 1 included

Pouncing tool

GERBER P2C KNIVES, PENS, AND POUNCING TOOLS

To order replacement knives, pens, and/or pouncing tools, contact your local

dealer.

The Gerber P2C 600 cutters are only warranted to perform in accordance with

specifications if a genuine Gerber knife, pen or pouncing tool is installed. Do

not replace any of these tools with products from other manufacturers.

Medium Quantity

2 included

& fluorescent vinyl

types

Optional

thick material

Color Quantity

Paper Optional

TABLE 1-3:

General Information 1-5

Gerber P2C™ 600 User’s Manual

1.2.4. INTERFACE

Communication

Serial : I/O Port connector

Mating connector

Byte format

Baud rate

USB : I/O Port connector

Mating connector

GERBER P2C 600 INTERFACE SPECIFICATIONS

1.2.5. FIRMWARE

Language

Supported character sets

Supported fonts

ROM-based plots

GERBER P2C 600 FIRMWARE

Standard asynchronous RS-232-C and

Universal Serial Bus (USB)

DB-9P

DB-9S

8 data bits, 2 stop bits, no parity

38400, 19200, 9600, 4800, 2400 bps

USB series “B” receptacle

USB series “B” plug

TABLE 1-4:

DM/PL, HP-GL (758x emulation), HP-GL/2

Standard ASCII

Sans serif (single stroke & medium)

Confidence plot, DIN plot

TABLE 1-5:

1.2.6. PERFORMANCE

Cutting specifications for 0.05mm (0.002") wax-backed vinyl where the total

media thickness does not exceed 0.25mm (0.010")

Axial speed

Default speed

Acceleration

Addressable resolution

Default resolution

Mechanical resolution

Accuracy

Knife pressure

Pen pressure

Pouncing pressure

*

Excludes differences due to media expansion, stretching, etc.

50 to 800 mm/s 2 to 32 ips

700 mm/s 28 ips

Up to 2 G

0.025 mm, 0.1 mm 0.001", 0.005"

0.025 mm 0.001"

0.0127 mm 0.0005"

0.2% of move or 0.25 mm,

whichever is greater*

0.2% of move or 0.010",

whichever is greater*

0 to 400 gr.

0 to 400 gr.

0 to 250 gr.

TABLE 1- 6:

GERBER P2C 600 PERFORMANCE

General Information 1-6

Gerber P2C™ 600 User’s Manual

1.2.7. CERTIFICATIONS

CE-Certification for electrical light industrial environment

FCC Class A

Comply with UL1950, CSA 950

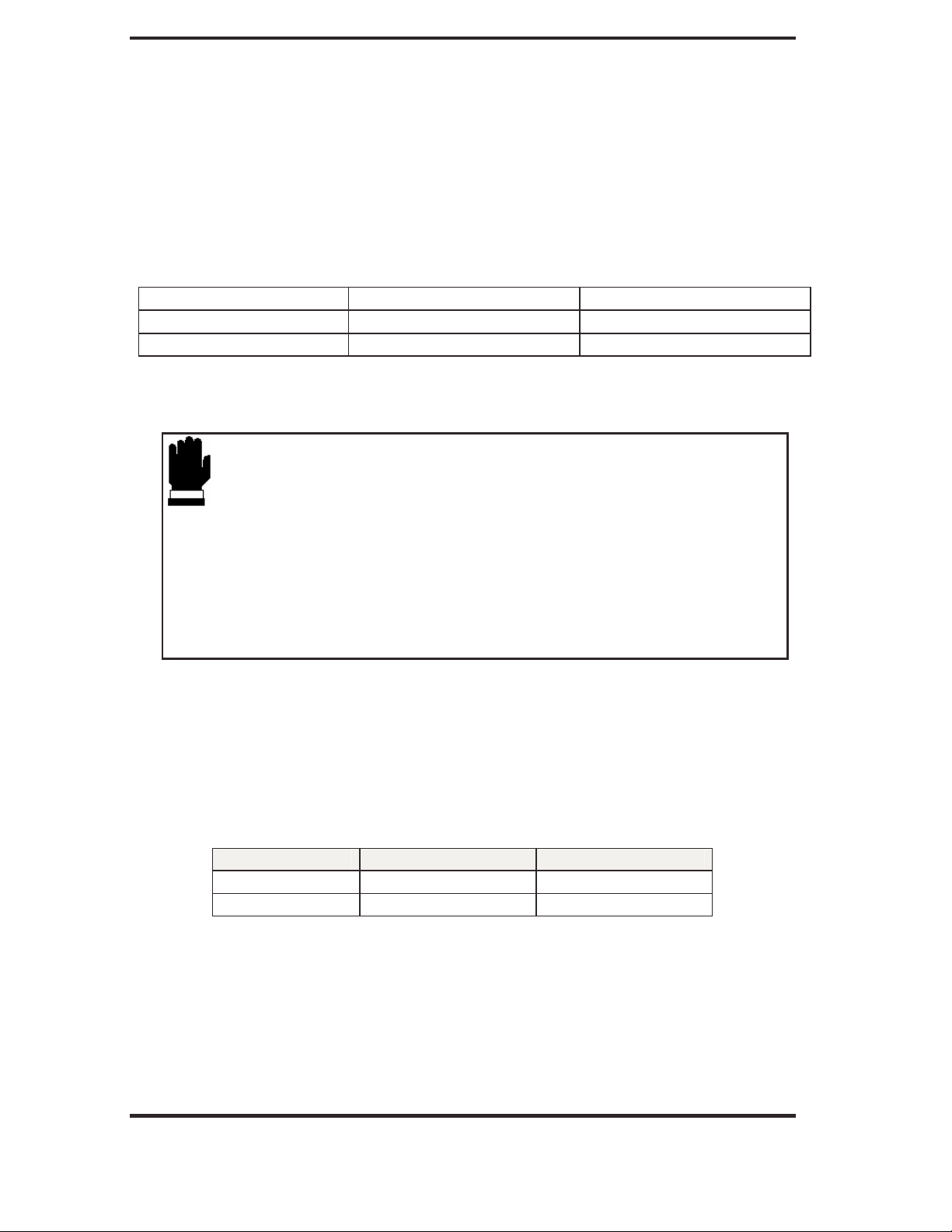

1.2.8. ENVIRONMENTAL

(Cutter without media)

Operating Temperature

Storage temperature

Relative humidity

GERBER P2C 600 ENVIRONMENTAL SPECIFICATIONS

15 to 35° C 59 to 95° F

-30 to 70° C -22 to 158° F

35 - 85%, non-condensing 35 - 85%, non-condensing

TABLE 1-7:

IMPORTANT HINT

The use of dimensionally stable media is essential for obtaining high cut

quality. Additionally, media expansion or contraction may occur as a

result of temperature variations.

To improve the dimensional stability of media, allow it to acclimate to the

environment in which it will be used for at least 24 hours prior to use.

1.2.9. ELECTRICAL

The power entry module detects the line voltage and alternates automatically

between 110V and 230V.

Main Supply: 48-62 Hz, single phase.

Nominal line Min./Max. line Fuse

110 V AC 88 - 132 V AC 2.0 A, Slo-Blo

230 V AC 176 - 264 V AC 2.0 A, Slo-Blo

TABLE 1-8:

GERBER P2C 600 ELECTRICAL SPECIFICATIONS

General Information 1-7

Gerber P2C™ 600 User’s Manual

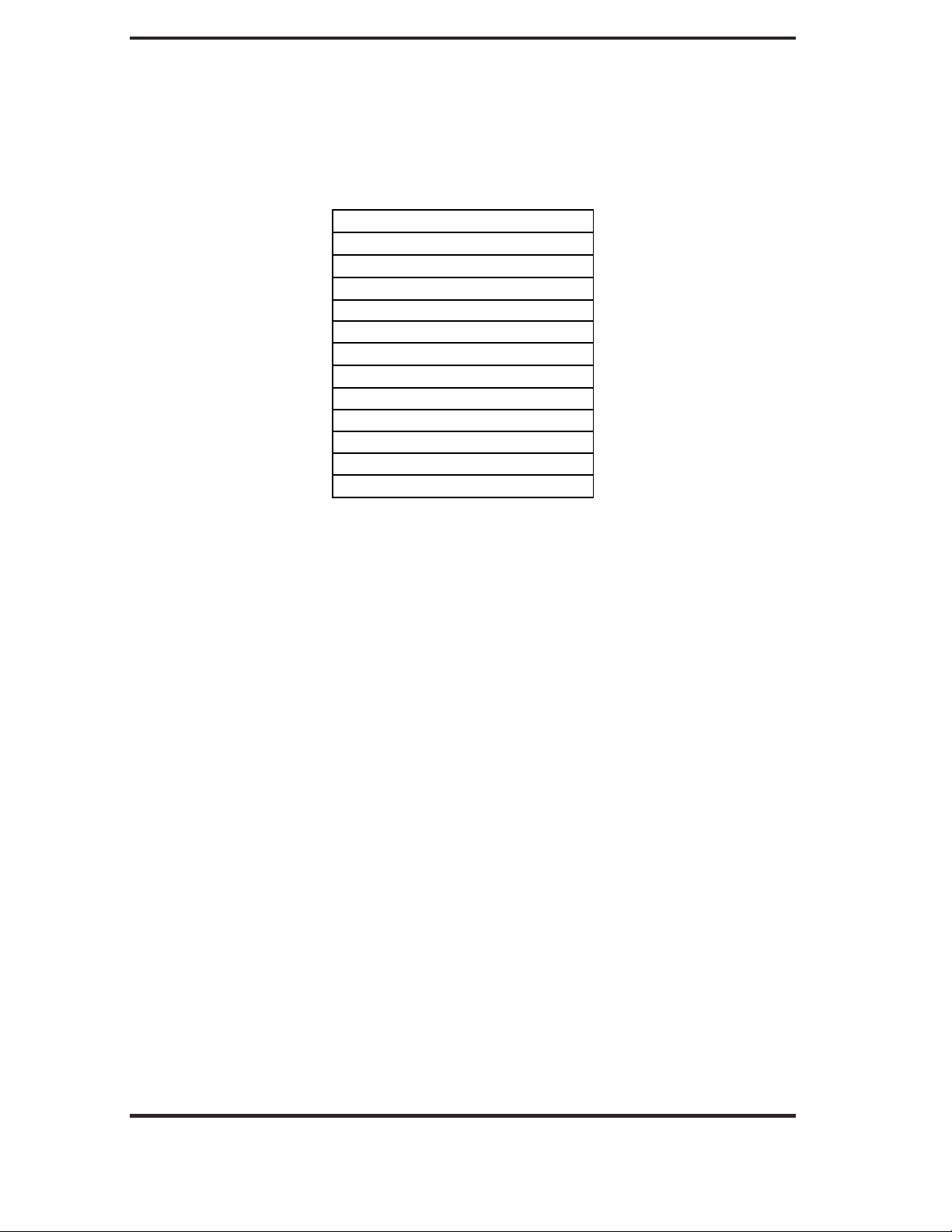

1.3. CUTTER ACCESSORIES AND CONSUMABLES

The following accessories and consumables are available for your Gerber P2C

600 cutter:

CD-ROM (manuels + drivers)

Power Supply Cables

Serial Interface Kit

Contents:

- 9 pin to 9 pin cable

- 9 pin to 8 pin DIN conv.

Standard knife

Standard knife holder

Sandblast knife

Sandblast knife holder

Fiber tip pen black

Razor blade & holder

Pouncing tool

TABLE 1-9:

GERBER P2C 600 ACCESSORIES AND CONSUMABLES

General Information 1-8

Gerber P2C™ 600 User’s Manual

1.4. POSITIONING THE 600 CUTTER ON A TABLE

The cutter is equipped with a front media deflection flap. Do not damage this

flap when placing the cutter on a surface. Figure 1-1 illustrates how the cutter

should be positioned on a flat surface with its flap (1) hanging freely over the

edge.

FIG 1-1

CORRECTLY POSITIONING THE CUTTER ON A FLAT SURFACE

General Information 1-9

Gerber P2C™ 600 User’s Manual

1.5 CUTTER COMPONENTS

In order to get better acquainted with your Gerber P2C 600 cutter, examine

the following illustrations and read the accompanying descriptions of its

components.

1.5.1 REAR PANEL CONTROLS

Figure 1-2 shows the location of the main components.

FIGURE 1-2:

GERBER P2C 600, REAR VIEW

General Information 1-10

Gerber P2C™ 600 User’s Manual

1. USB interface: - This interface is based on the standards specified in

Universal Serial Bus Specifications Revision 1.1. USB connectivity can be

used to establish high-speed bi-directional communication serially

between the host computer and the cutter. Use either the USB cable or

the 9-pin serial cable, but not both simultaneously.

2. RS-232-C Port: - This DB-9P connector uses a 9-pin serial cable to establish

bi-directional communication between the cutter and a host computer.

Use either the 9-pin serial cable or the USB cable, but not both

simultaneously.

3. Power ON/OFF switch: - This rocker switch sets the cutter’s power to ON or

OFF. To switch the power ON, press the “I” side of the rocker switch. To

switch the power OFF, press the “O” side of the rocker switch.

4. Power Entry Module: - The fuse box and the AC power cord receptacle

are located in the power entry module.

The power-up procedure is explained in detail in Section 1.6.

5. Fuse box: - For information about changing the fuse, see Section 4.2.

6. Roll Media Guides: - The two guides keep the media roll in place as the

cutter pulls media from the roll.

7. Media Flanges: - The media flanges ensure proper routing of the media as

it is pulled from the roll.

8. Media Support Roller: - The rotating rollers support the media roll.

9. Alignment Strip: - The rear alignment strip facilitates proper media loading

and should be used in conjunction with the front alignment strip.

General Information 1-11

Loading...

Loading...