Page 1

FasTrack

Cutter

Owner's Guide

TM

Page 2

COPYRIGHT NOTICE

COPYRIGHT 1999 Gerber Scientific Products, Inc. All Rights Reserved.

This document may not be reproduced by any means, in whole or in part, without written permission of the

copyright owner.

This document is furnished to support the FasTrack™ Cutter. In consideration of the furnishing of the

information contained in this document, the party to whom it is given assumes its custody and control and

agrees to the following:

1. The information herein contained is given in confidence, and any part thereof shall not be copied or

reproduced without written consent of Gerber Scientific Products, Inc.

2. This document or the co nt ents herein under no circumstances sh all be used in the manufacture or

reproduction of the article shown and the delivery of this document shall not constitute any right or

license to do so.

Information contained in this document is subject to change without notice.

Printed in USA

GRAPHIX ADVANTAGE and GSP are registered trademarks and FasTrack is a trademark of Gerber

Scientific Products, Inc. HPGL is a trademark of Hewlett-Packard Company. Windows is a registered

trademark of Microsoft Corporation in the U.S. and other countries. MS-DOS and Microsoft are registered

trademarks of Microsoft Corporation. HPGL is a trademark of Hewlett-Packard Company.

Page 3

FCC WARNING

This equipment has been tested and found to comply with the limits for a Class A digital device, pursu ant to

Part 15 of the FCC rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates, uses,

and can radiate radio frequ ency energy and, if not installed and used in accordance with the inst ruction

manual, may cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user will be required to correct the

interference at his own risk.

This digital apparatus does no t exceed the Class B limits for radio noise emissions from digital apparatus set

out in the Radio Interference Regulations of the Canadian Department of Communications.

Le present appareil numerique n'emet pas de bruits radioelectriques depassant les limites applicables aux

appareils numeriques de la classe B prescrites dans les Reglements sur le brouillage radioelectrique edicte par

le Ministere des Communications du Canada.

Page 4

Page 5

TABLE OF CONTENTS

INTRODUCTION............................................................................................................. 1

ATTENTIONS AND CAUTIONS............................................................................................................ 1

CUSTOMER SUPPORT ........................................................................................................................ 2

CHAPTER 1 INSTALLATION PROCEDURES .............................................................. 4

PREPARING THE CUTTER ENVIRONMENT....................................................................................... 4

UNPACKING AND SETTING UP THE CUTTER................................................................................... 5

Cutter box contents.......................................................................................................................... 6

CUTTER PARTS and COMPONENTS.................................................................................................. 7

CONTROL PANEL................................................................................................................................. 9

CONNECTING THE CUTTER TO THE COMPUTER ......................................................................... 10

Serial interface............................................................................................................................... 10

To connect the serial interface....................................................................................................... 10

CONNECTING THE POWER CABLE ................................................................................................. 11

INSTALLING KNIFE HOLDERS OR PENS......................................................................................... 12

LOADING MATERIAL .......................................................................................................................... 13

To load cut-sheet material............................................................................................................. 13

To load roll material....................................................................................................................... 15

To straighten the material edge using the auto-sheet-off utility..................................................... 17

CHAPTER 2 CUTTER CONTROLS............................................................................. 18

UNDERSTANDING THE CONTROL PANEL...................................................................................... 18

Online and Offline modes.............................................................................................................. 18

Slew keys....................................................................................................................................... 19

ORIGIN key.................................................................................................................................... 19

PAGE key ...................................................................................................................................... 20

ENTER key.................................................................................................................................... 20

Menu keys...................................................................................................................................... 21

VALUE keys................................................................................................................................... 21

GENERAL PROCEDURE TO CHANGE SETTINGS ON THE CUTTER............................................ 22

TOOL SELECTION .............................................................................................................................. 23

TOOLKIND SELECTION...................................................................................................................... 24

To change the TOOLKIND ............................................................................................................ 24

FORCE SELECTION ........................................................................................................................... 25

First Range (15 - 100 grams)......................................................................................................... 26

Second Range (110 - 190 grams) ................................................................................................. 26

Third Range (200 - 500 grams) ..................................................................................................... 26

SPEED SELECTION............................................................................................................................ 27

ACCELERATION SELECTION............................................................................................................ 27

PAGE LENGTH.................................................................................................................................... 27

To set the PAGE LENGTH............................................................................................................ 28

RESET and CLEAR FUNCTION.......................................................................................................... 29

AVAILABLE VALUES/SETTINGS FOR PARAMETERS - IMPERIAL SYSTEM.................................30

AVAILABLE VALUES/SETTINGS FOR PARAMETERS, METRIC SYSTEM..................................... 31

CHAPTER 3 CUTTER SETTINGS and SPECIAL FUNCTIONS.................................. 32

INTRODUCTION.................................................................................................................................. 32

CHANGING THE USER LANGUAGE.................................................................................................. 32

MENU MODE OPERATION................................................................................................................. 32

To plot a complete setup sheet...................................................................................................... 33

To plot a single line and change settings ...................................................................................... 33

Page 6

Example of a FasTrack Cutter Setup Sheet.................................................................................. 34

GENERAL SETTINGS ......................................................................................................................... 35

TOOLKIND SELECTION...................................................................................................................... 35

To select a TOOLKIND.................................................................................................................. 35

SHEET-OFF / PAGE MODE ................................................................................................................ 36

Page commands............................................................................................................................ 36

To set the SHEET-OFF / PAGE MODE......................................................................................... 37

REPLOT FACTOR ............................................................................................................................... 38

To set the replot factor...................................................................................................................38

SMOOTHING ....................................................................................................................................... 39

To change the smoothing settings................................................................................................. 39

COMMUNICATION SETTINGS...........................................................................................................40

To change the serial communication settings ............................................................................... 41

LANGUAGE SETTINGS ...................................................................................................................... 42

To change language settings......................................................................................................... 43

RESET TO FACTORY DEFAULTS..................................................................................................... 43

CHAPTER 4 FINE TUNING THE CUTTER .................................................................. 44

ADJUSTING THE KNIFE DEPTH........................................................................................................ 45

To adjust the knife depth of the standard tool holder .................................................................... 45

To adjust the knife depth of the optional knife holder.................................................................... 47

FEATURES OF THE OPTIONAL KNIFEHOLDER.............................................................................. 48

SETTING THE CUTTING PRESSURE / TEST SQUARES................................................................. 49

SETTING THE OFFSET ...................................................................................................................... 49

ADJUSTING THE OFFSET.................................................................................................................. 50

SETTING UP FOR POUNCING (PUNCHING) APPLICATIONS......................................................... 52

Method 1. Pen-Up / Pen-Down sent by cutting software............................................................... 52

Method 2. Use the incorporated pouncing (punching) capability of the cutter .............................. 52

To adjust the pouncing tool............................................................................................................ 53

PERFORMING A TEST CUT............................................................................................................... 54

GENERATING A PARAMETER SETTINGS PLOT............................................................................. 55

CHAPTER 5 CUTTER MAINTENANCE and TROUBLESHOOTING.......................... 56

CLEANING and DAILY MAINTENANCE ............................................................................................. 56

To clean the pressure rollers and drive rollers .............................................................................. 56

To remove material particles from the cutter blade in a standard knife holder ............................. 57

To remove material particles from the cutter blade in an optional knife holder with vernier ......... 57

To clean the cutter......................................................................................................................... 58

PARTS REPLACEMENT ..................................................................................................................... 58

To replace the cutting mat............................................................................................................. 58

To replace the knife blade in the standard knife holder................................................................. 59

To replace the knife blade in the optional knife holder with vernier............................................... 60

To replace the auto-sheet-off knife................................................................................................ 61

TROUBLESHOOTING ......................................................................................................................... 62

To check the communication settings............................................................................................ 63

ERROR MESSAGES ........................................................................................................................... 65

Unrecoverable system errors......................................................................................................... 65

Recoverable system errors............................................................................................................ 68

Communication errors ................................................................................................................... 69

Language errors............................................................................................................................. 71

CHAPTER 6 CUTTER OPTIONS and ACCESSORIES,.............................................. 72

OPTIONS and ACCESSORIES FOR FasTrack CUTTERS................................................................ 72

CHAPTER 7 MATERIAL COMPATIBILITY and DIMENSIONS................................... 74

Page 7

MATERIAL COMPATIBILITY............................................................................................................... 74

PHYSICAL DIMENSIONS FasTrack Series ........................................................................................ 75

Imperial dimensions in inches and pounds (*Desk-Top model).................................................... 75

Metric dimensions in millimeters and kilograms (*Desk-Top model)............................................. 75

Page 8

Page 9

INTRODUCTION

Congratulations on purchasing a FasTrack™ cutter, one of the most

versatile single-tool cutters on the market. It is fast, reliable, of high

quality, and easy to use. You can find information on setting up and

operating your FasTrack cutter as follows:

The

FasTrack Cutter Quick Reference

: a booklet designed to help you

get your cutter operating as quickly as possible.

The

FasTrack Cutter Owner’s Guide

: a reference manual that provides

more detailed information on the FasTrack cutter. Refer to the

FasTrack Cutter Owner’s Guide

for further explanations on cert ain

aspects of your cutter.

This guide contains information on the topics below. For a further listing of

topics, please refer to the Table of Contents and the Index.

Unpacking and setting up the cutter

Making the necessary power connections

Learning to use the control panel

Installing tools and loading material

Changing cutter settings

Fine tuning the cutter

Cleaning and maintaining the cutter

Troubleshooting

ATTENTIONS AND CAUTIONS

When you see the CAUTION symbol at the left, c arefully read

the messages next to the symbol. Caution means that you

may harm yourself or the cutter by performing or not

performing certain actions.

When you see the check mark graphic at the left, read the messages

to find helpful information or specific details about the cutter and its

functions.

Introduction 1

Page 10

CUSTOMER SUPPORT

Gerber is pleased to provide you with excellent system support. Refer to

the information below to determine which group to call for service. If

possible, please use a phone that is close to your system.

If you require assistance installing or operating your FasTrack cutter,

contact your Gerber distributor, or contact Gerber Field Service at:

phone: 800-828-5406

fax: 860-648-8376

For Hardware

e-mail: gspservice@gspinc.com

www.gspinc.com

For Software

If you require assistance installing or ope ra ting your GRAPHIX

ADVANTAGE system, contact your Gerber distributor, or contact GSP

Technical Systems Support Department at:

phone: 860-528-1028

fax: 860-290-5568

e-mail: gsptech@gspinc.com

www.gspinc.com

Before calling, please have th e following information and items availa ble

(if applicable):

Cutter installation date

Cutter serial number (located at rear of the cutter)

The graphics package and version number you are using

MS-DOS® and Microsoft® Windows® version numbers

GSP System ID number (gasysid)

2 Introduction

Page 11

GRAPHIX ADVANTAGE serial number (6-digit bolded number on the

security block)

GRAPHIX ADVANTAGE, Windows, MS-DOS, and hardware utilities

disks

GRAPHIX ADVANTAGE, Windows, and MS-DOS user manuals

The names of any output devices, such as a printer

Note: To find the GSP system ID number and the serial number, open GSP Setup,

click on System Information, and select System Id. The system Id number is at the

bottom left of the message box; the serial number is at the upper right.

Introduction 3

Page 12

CHAPTER 1

INSTALLATION PROCEDURES

PREPARING THE CUTTER ENVIRONMENT

The location where you set up your equipment is very important. Please

ensure that it meets the following conditions:

Power supply of 100 to 120 VAC 50/60 Hz or 200 to 240 VAC 50/60

Hz.

Ambient Conditions

Operating environment

•

- Temperature: 41°F to 104°F (5°C to 40°C)

- Humidity: 35% - 75% non-condensing

Recommended environment

•

- Temperature: Room temperature 61°F to 90°F (16°C to 32°C)

- Humidity: 50% to 65%, non-condensing

Variation rate

•

- Temperature: 3.6°F (2°C) per hour

- Humidity: 5% per hour

Storage environment

•

- Temperature: 32°F to 122°F (0°C to 50°C)

Protect your cutter from moisture, dust, drafts, and direct sunlight. It is

best to keep your machine away from air-conditioners and open

windows.

Ensure that there is an adequate space around the cutter to ensure

proper ventilation.

Avoid unnecessary vibrations and set up your cutter on a level surface.

When selecting a place for your cutter, leave at least 35.5" (900 mm) in

front and 35.5" (900 mm) at the rear, as shown in the illustration on the

next page.

4 Chapter 1, Installation

Page 13

UNPACKING AND SETTING UP THE CUTTER

When unpacking the cutter, check whether all parts described below in

Cutter box contents

are included. Consult your distributor if anything is

missing. See Chapter 7 for dimensions.

Lifting the machine out of the box should be done by two people.

Protect the cutter from firm shocks.

Do not dismantle the unit

.

35.5"

Tool Head

(remove foam)

1. Lift the cutter unit out of the box and put it on a flat and stable surface.

Chapter 1, Installation 5

Page 14

2. Remove all plastic wrapping materials.

3. Remove the pieces of foam, which protect the tool head during

transportation.

4. If you had your cutter delivered with a stand, please refer to the

mounting instructions that came with it.

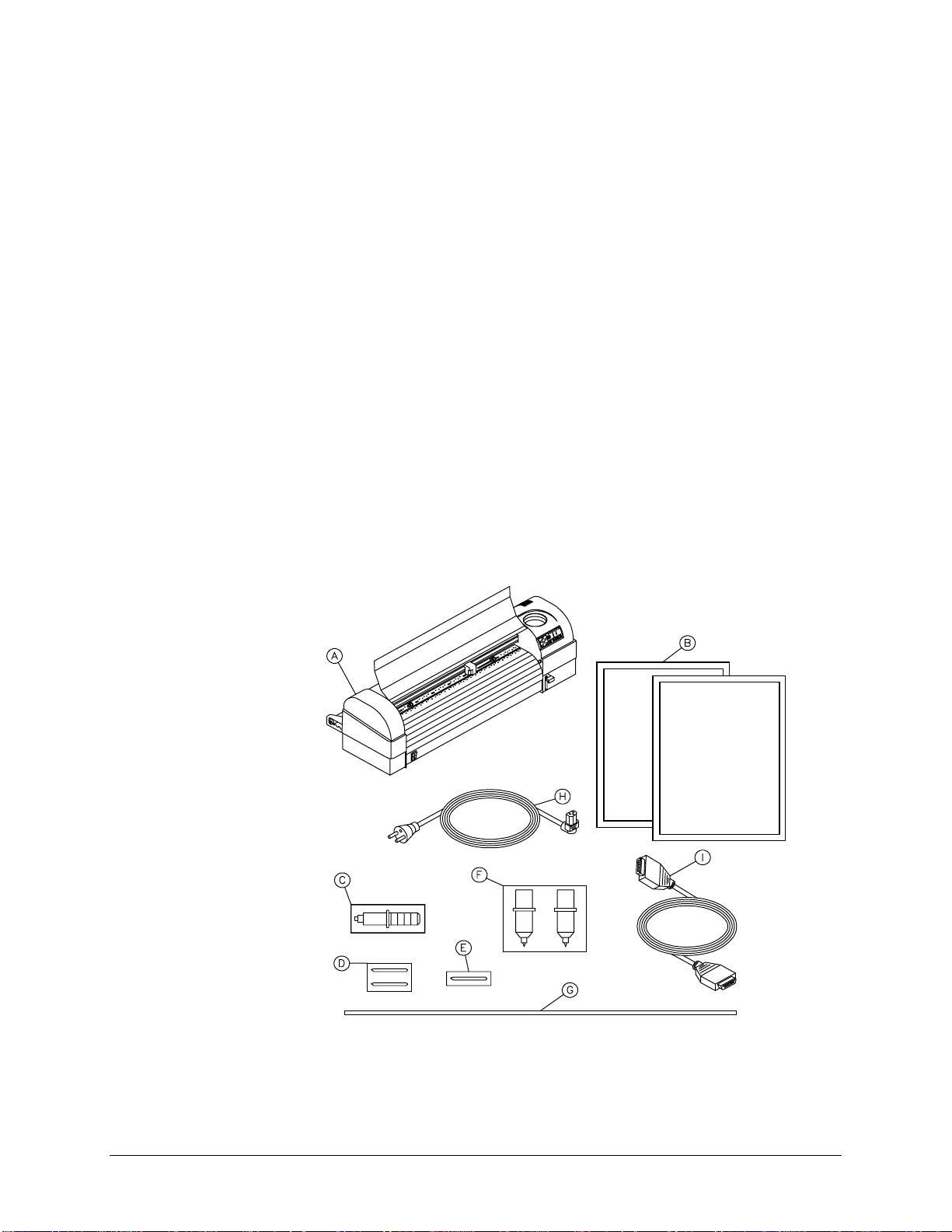

Cutter box contents

A. Cutter unit with roll support system, conveyor rolls, and small flanges.

B. Owner’s Guide and Quick Reference

C. One knife holder

D. Set of 2 blades and 1 spring for cutting jobs (45°/Offset 0.50 mm)

E. Blade for auto-sheet-off (1 pc–installed in tool head)

F. Set of fiber-tip pens (2 pcs)

G. Spare cutting mat (1 pc)

H. Power cord

I. RS-232C serial interface cable

6 Chapter 1, Installation

Page 15

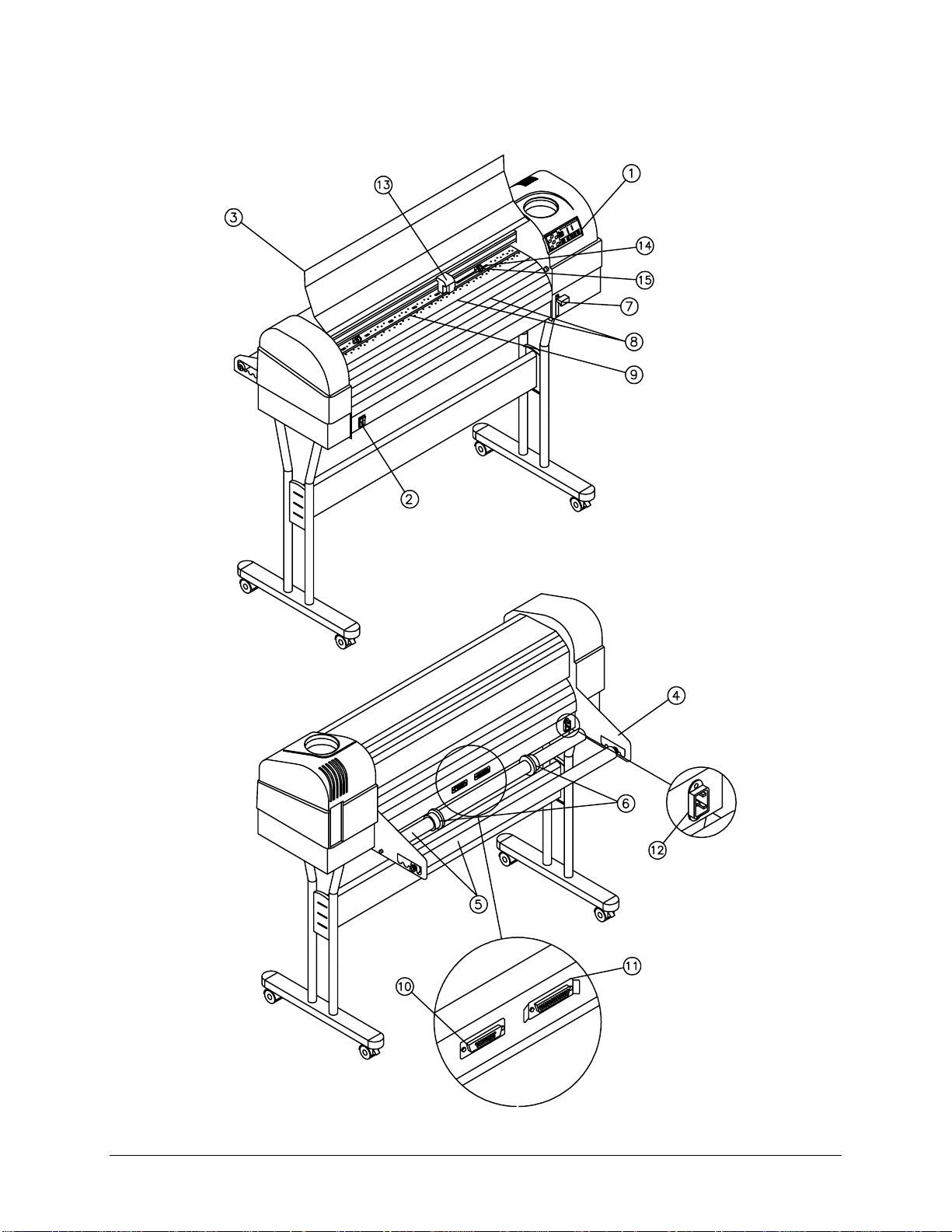

CUTTER PARTS and COMPONENTS

Chapter 1, Installation 7

Page 16

The numbers in the diagram match the parts described below.

1.

Control Panel

2.

Power Switch

3.

Carriage Cover

: Indicator LEDs and control keys.

: Turns the cutter on or off.

: For safety reasons, the cutter will not work with the

cover open. The cover also prevents objects from falling into the

cutting zone.

4.

Roll Support System

5.

Conveyor Rolls

6.

Guiding Flanges

: Carries the conveyor rolls.

: Hold roll material.

: Located on the conveyor rolls, prevent the roll of

material from shifting to the left or right when material is pulled from the

roll.

7.

Material Hold Lever

: Raises and lowers the pressure rollers. Lowering

the pressure rollers holds the material in place.

8.

Platen and Drive Roller Cover

: Supports the cutting material and

guides the movement of the material along the X-axis.

9.

Cutting Mat

: Provides a reliable cutting surface and prevents damage

to the knife tip.

10.

Serial Interface Connector

: RS-232C serial interface connector to

connect the cutter to the host computer.

11.

Parallel Interface Connector

: Centronics parallel connector to

connect the cutter to the host computer's printer port for fast data

transfer.

12.

Power Connector

: Connector for the power cord, which plugs into the

main power supply of the cutter.

13.

Tool head with Tool Mounting Bracket

: All available tools such as

knife holders, drawing pens, and painting pens can be secured into the

tool head using the locking screw. The tool head moves along the Yaxis to the exact cutting position.

14.

Drive Rollers

15.

Pressure Rollers

: Move the cutting material along the X-axis.

: Hold the material against the drive rollers during

cutting.

8 Chapter 1, Installation

Page 17

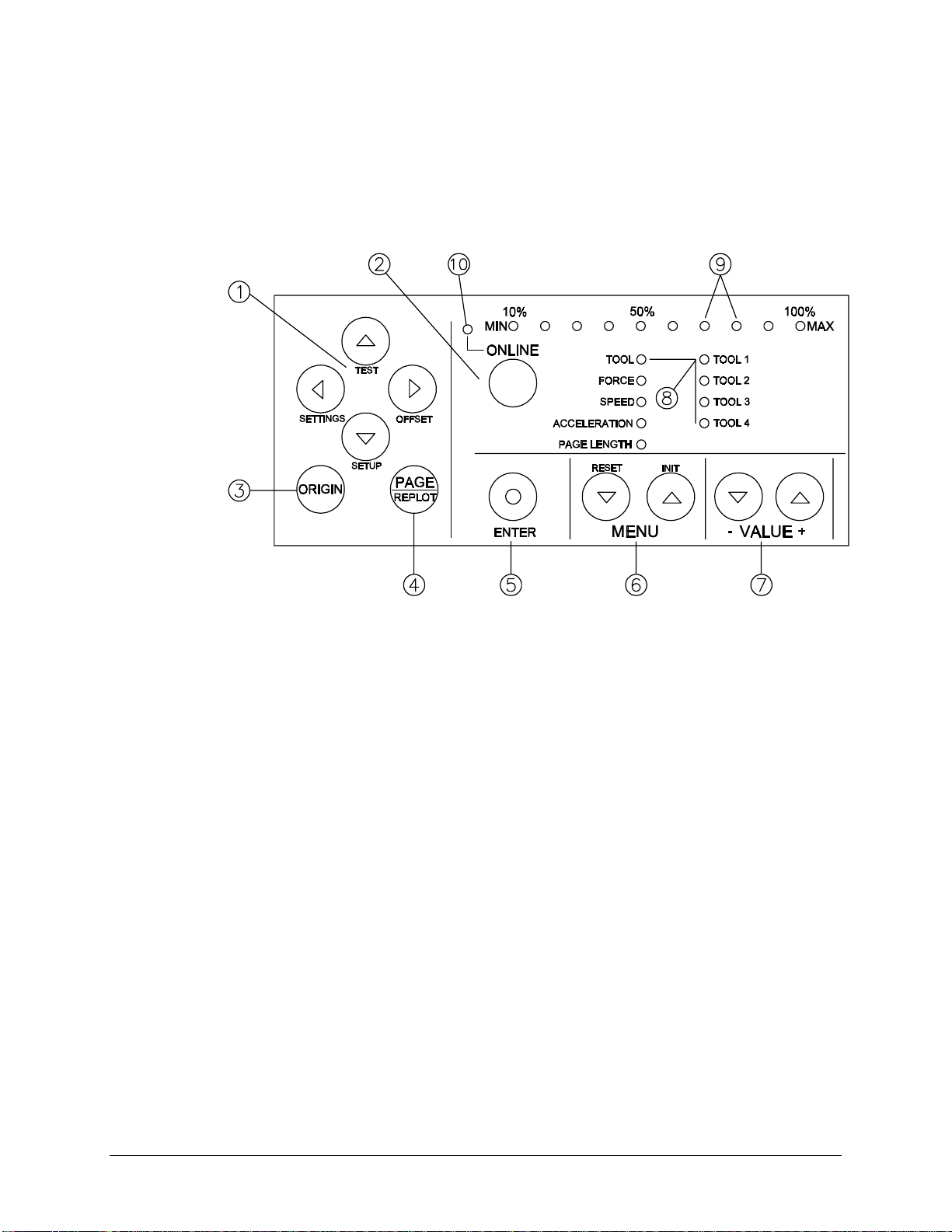

CONTROL PANEL

Use the control panel to access different modes and alter several settings

in order to fine tune the cutter for your needs. The numbers in the diagram

match the keys described below. For detailed information on the functions

of the keys, see

Understanding the Control Panel

on page 18.

1.

Slew:

Manually move the tool head or the material, slew also has

secondary functions when used with enter key.

2.

ONLINE:

3.

ORIGIN:

Switches between online and offli ne modes.

Sets a new origin at the present location of the

tool head.

4.

PAGE:

5.

ENTER:

Performs auto-sheet-off.

■

Gives access to the replot/copy function.

■

Confirms changes and accepts settings.

■

Gives access to special functions indicated by the blue

■

text on the control panel. This is what the blue dot on the

ENTER key signifies.

6.

MENU Selection:

7.

VALUE + and –:

8.

LED indicators:

9.

LED bar:

Indicates values, error messages, and function

confirmation.

10.

ONLINE LED indicator:

Selects the parameter you want to change.

Changes a parameter’s value or setting.

Show cutter parameters and tool selections.

Shows cutter mode (lit when cutter is

online).

Chapter 1, Installation 9

Page 18

Do not use sharp or pointed tools like pens or pencils to press control

panel keys. Press the keys with your fingertips only.

CONNECTING THE CUTTER TO THE COMPUTER

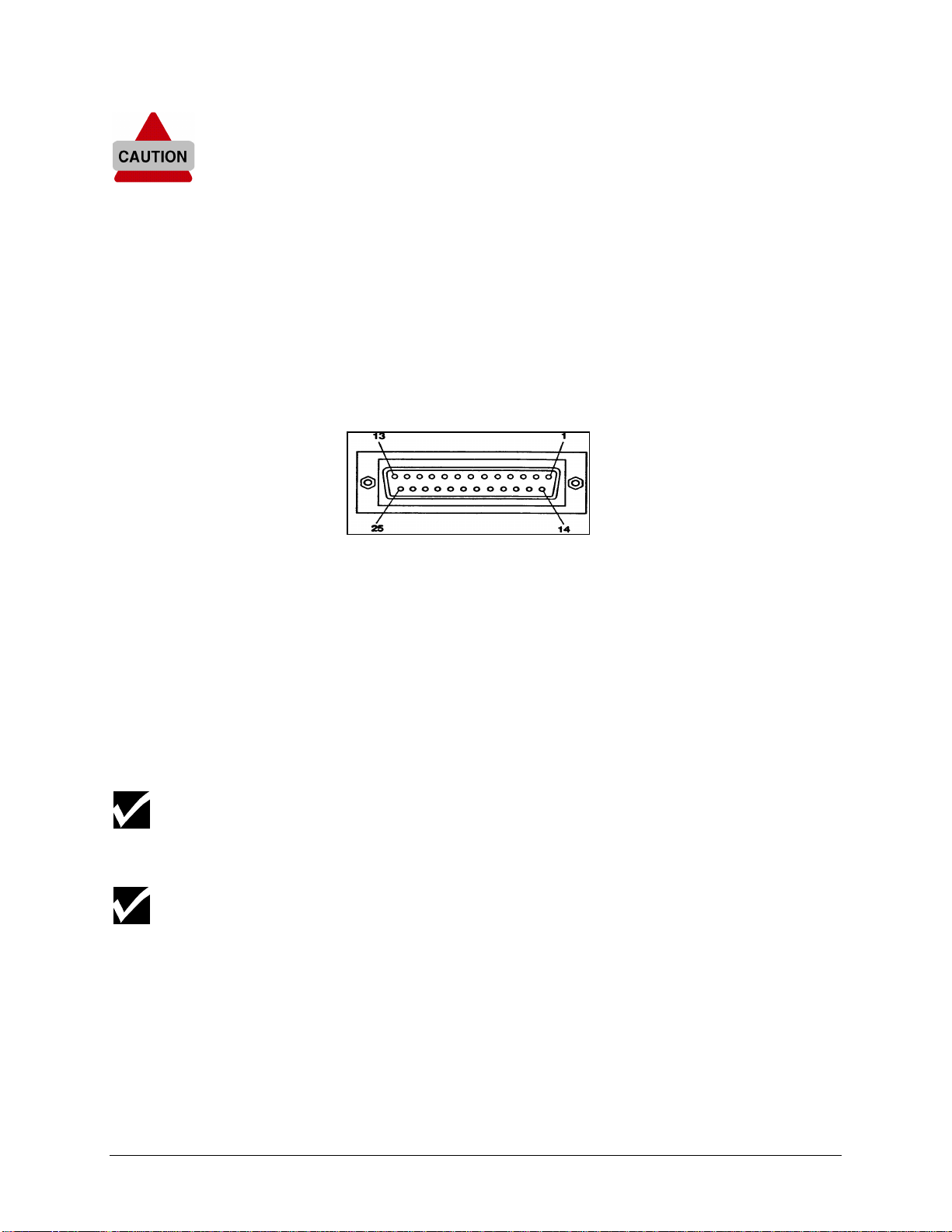

Serial interface

The serial RS-232C interface enables the cutter to be connected to and

controlled by an RS-232C compatible host computer system. The cutter is

equipped with a standard RS-232C - DB-25P connector on the rear panel

and requires a standard RS-232C dB-25S mating connector.

To connect the serial interface

1. Make sure both the cutter and the computer are turned off.

2. Connect one end of the serial interface cable to the serial interface

connector at the back of the cutter.

3. Fasten the screws to secure the connector.

4. Connect the other end of the serial cable to your computer.

For proper operation of the serial communication, it is necessary to match the

computer settings to the cutter settings. For instructions, refer to

Communication Settings, Page 40, in Chapter 3.

Using the serial communication, your cutter will have two-way communication.

It can receive data from the computer and also send information to the

computer, material size, for example.

10 Chapter 1, Installation

Page 19

CONNECTING THE POWER CABLE

1. Make sure the cutter’s power switch is turned off.

2. Plug the cutter end of the power cable into the connector at the back of

the cutter.

3. Plug the other end of the power cable into an electrical outlet of the

correct voltage and with a proper grounding.

The illustration above shows an international AC plug.

Chapter 1, Installation 11

Page 20

INSTALLING KNIFE HOLDERS OR PENS

At the right side of the cutter head, you will find a pivoting mounting

bracket. Opening this bracket will enable you to install a full range of

cutting and drawing tools.

Because you will be performing a test cut with a knife, make sure that you install

a knife with a well-adjusted depth as described in Adjusting the Knife Depth,

page 44 in Chapter 4.

1. Turn the thumbscrew counterclockwise to unlock the tool head

mounting bracket (figure 1).

2. Hold back the clip of the tool head and slide the tool into position,

making sure that the tool collar fits into the groove just beneath the

locking screw (figure 2).

3. Tighten the thumbscrew by turning it clockwise to secure the tool in

position (figure 3).

12 Chapter 1, Installation

Page 21

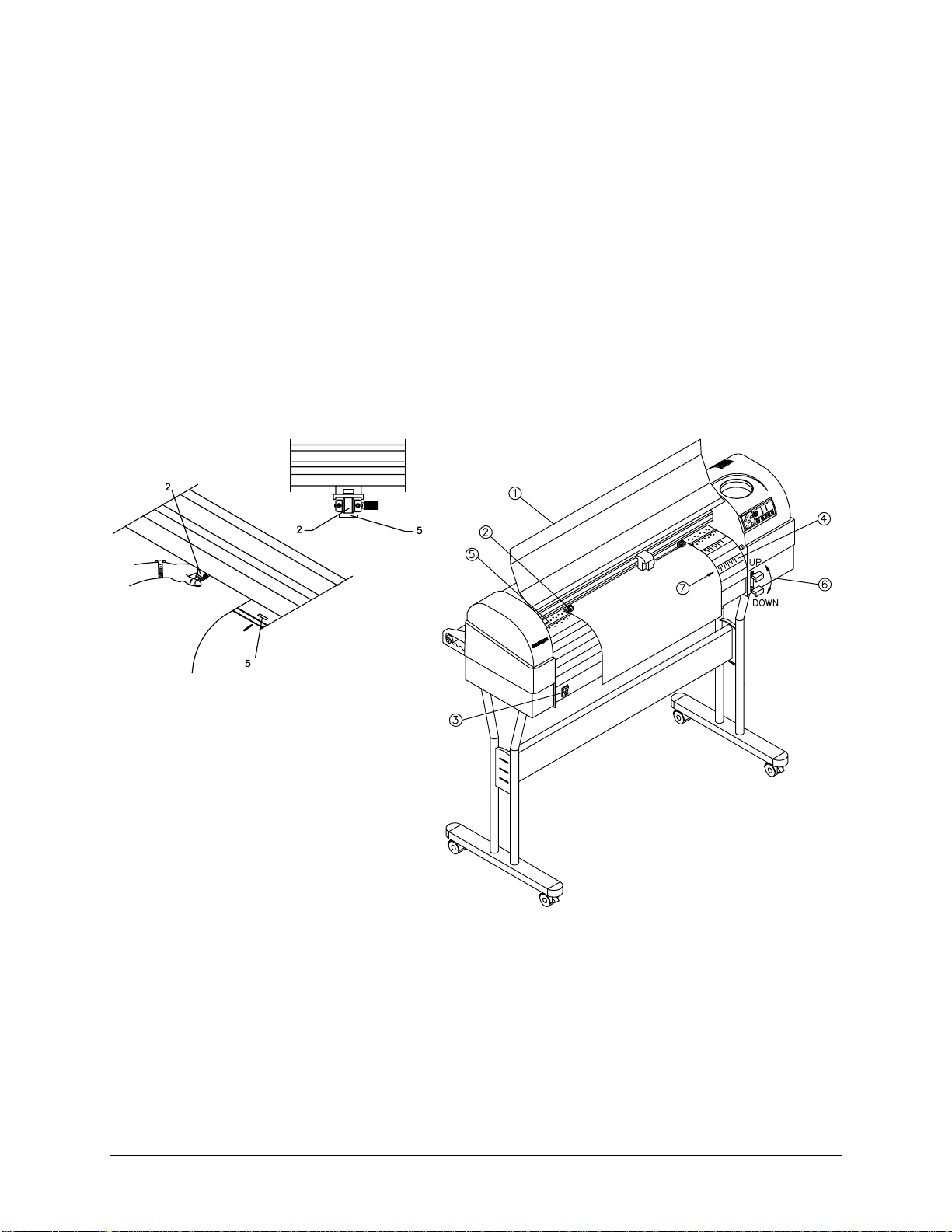

LOADING MATERIAL

You can load either cut-sheet or roll material. Follow the procedure below

for the type of material you are loading.

To load cut-sheet material

1. Close the protective cover (1).

2. Make sure the pressure rollers (2) are up. If they are not lift them up

using the material hold lever (6 ).

3. Turn on the power switch (3).

The cutter performs its start-up routine and moves the tool head to the

rightmost position.

4. Open the protective cover (1).

5. Insert the material into the cutter, using the two sets of alignment

markers (4) to make sure the right edge of the material is straight.

Position the material so that half of it hangs in front and half of it hangs

in back of the cutter.

6. Adjust the position of the pressure rollers (2) so that they align with the

drive rollers (5). When the left pressure roller is moved into proper

alignment with one of the drive rollers, you will feel and hear it click into

Chapter 1, Installation 13

Page 22

place. The right pressure roller’s movement is limited so that it can

never be positioned incorrectly.

7. Always make sure that all pressure rollers are completely inside the

sheet of material you want to load, so that the rollers do not run on the

very edge of the material. When you use a cut-sheet that does not

have perfectly square corners, it is best to put the pressure rollers at

least ¼" inside the material edge as the width of the sheet may vary.

If you are using a FasTrack 1000 or larger, you have the option of using either

two or three pressure rollers, depending on the width of the material you are

using. When not using the left pressure roller (i.e. when loading material of a

small width), the left pressure roller should be placed at the extreme left of the

cutter (not on top of a drive roller).

The middle pressure roller should always be placed on top of a drive roller.

8. Put the material hold down lever (6) down and close the cover.

The material loading sequence begins, during which the cutter will

measure the loaded sheet. The cutter shuffles the material back and

forth, determining its size and allowing you to ensure that the material

moves easily through the cutter.

Do not try to move the pressure rollers when the material hold lever is

down, as this may damage the system.

After the material loading sequence, the tool head is parked at the

origin position and the cutter is

online

, ready to receive data from the

host computer.

14 Chapter 1, Installation

Page 23

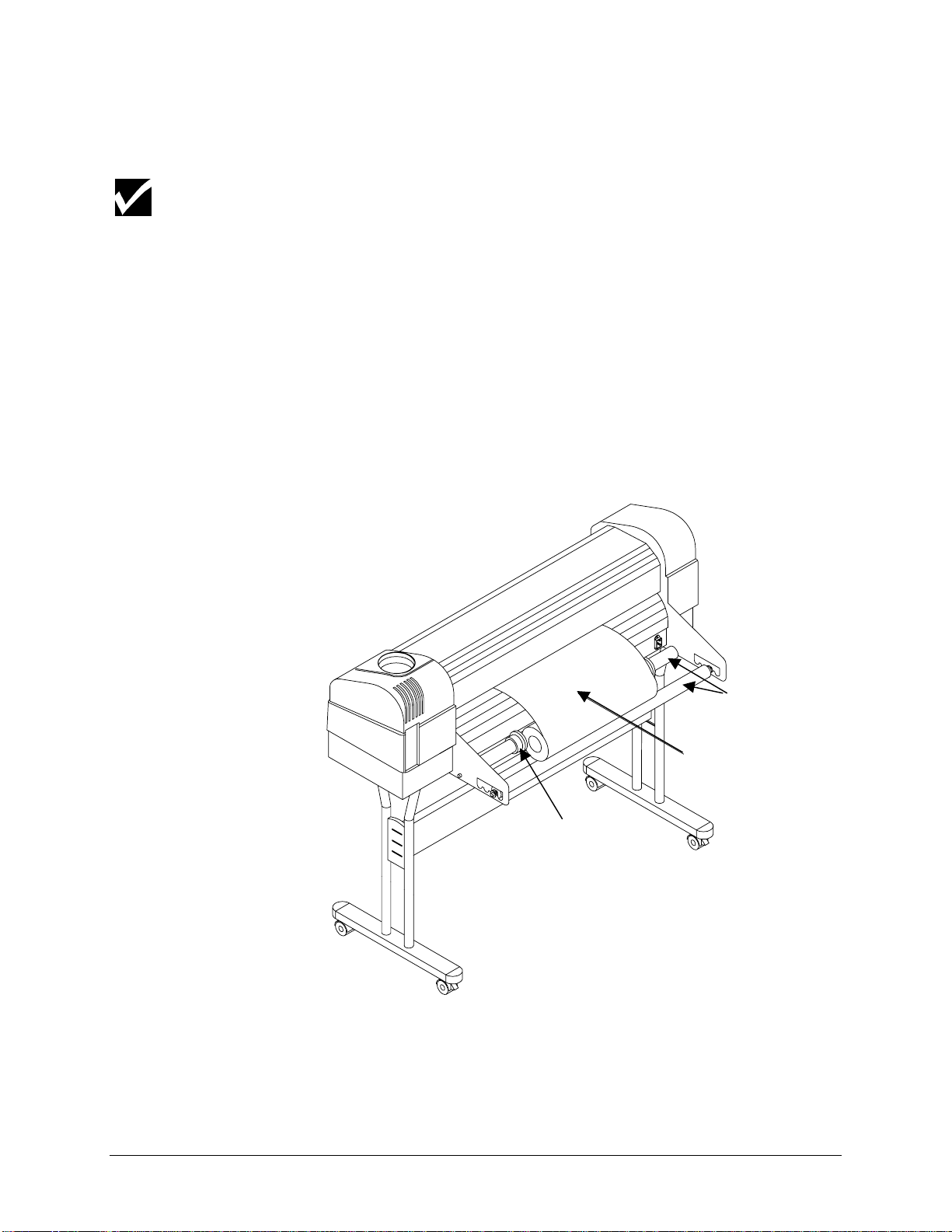

To load roll material

1. Close the protective cover (1).

The numbers in parentheses refer to the numbers on the illustration on page 13.

2. Make sure the pressure rollers (2) are up. If they are not, put them up

using the material hold lever (6 ).

3. Turn on the power switch (3).

The cutter performs its start-up routine and moves the tool head to the

rightmost position.

4. Position the roll of material onto the conveyor rolls. Open the

protective cover, pull the material through, and position the material for

optimal cutting by locating the right edge of the material over the

rightmost drive roller, and the left edge of the material over one of the

other drive rollers.

Conveyor

rolls

Roll

Guiding

flange

5. Adjust the position of the pressure rollers (2) so that they align with the

drive rollers (5) and can accommodate the roll of material. When the

left pressure roller is moved into proper alignment with one of the drive

Chapter 1, Installation 15

Page 24

rollers, you will feel and hear it click into place. The right pressure

roller's movement is limited so that it can never be positioned

incorrectly. Always make sure that both pressure rollers are at least

0.2" (5 mm) inside the edge of the material. Do not let the rollers run on

the very edge of the material.

Do not use the marker lines to align a roll of material! They are for use with cutsheets only! Rolls can only be correctly installed using the EQUAL TENSION

METHOD!

If you are using a FasTrack 1000 or larger, you can use either two or three

pressure rollers, depending on the width of the material used. When not using

the left pressure roller (i.e. when loading material of a small width), the left

pressure roller should be placed at the extreme left of the cutter (not on top of a

drive roller).

The middle pressure roller should always be placed on top of a drive roller.

6. Hold the front edge of the material in the middle with one hand and

with the other hand, the roll itself. As you are holding the roll firmly in

position, pull the front edge of the material forward so that there is an

even tension across the whole width of the roll (= Equal Tension

method.)

The material must be rolled tightly and not telescoped.

7. Adjust the position of the guiding flanges so that they are just

alongside the roll of material, but not directly against it.

8. Close the protective cover.

9. This action starts the material loading sequence, during which the

cutter shuffles a pre-set length of material. The material will be shuffled

back and forth allowing you to make sure the material mov es easil y

through the cutter. The shuffle length is factory-set to 40" (1 m), but

you can adjust the setting if desired. (See

Page Length,

page 27, in

Chapter 2).

10. After the material loading sequence, the tool head is parked at the

origin position and the cutter is

online

, ready to receive data from the

host computer.

16 Chapter 1, Installation

Page 25

To straighten the material edge using the auto-sheet-off utility

The auto-sheet-off mechanism of the cutter can easily cut the front edge

of a new roll of material straight as well as cut off a sheet of material from

a roll, to be used as a separate sheet.

To do this, proceed as follows:

1. Insert the material to be cut (straight) into the cutter as if you were

loading either a roll or a cut sheet, as described above.

2. Make sure the material hold lever is up.

3. Press the PAGE key to request a sheet-off sequence. You will get

visual confirmation of your request by the LED bar, which shows a

flashing sequence of LEDs.

4. Lower the material hold lever and close the cutter’s cover to start the

sequence.

The cutter sheets off the material, producing a neat edge.

The default FORCE used for automatic sheet-off is 300 grams. To adjust this

force, see Force Selection, page 25, in Chapter 2.

Chapter 1, Installation 17

Page 26

CHAPTER 2

CUTTER CONTROLS

UNDERSTANDING THE CONTROL PANEL

The control panel contains 12 keys that perform one or more functions,

such as positioning the tool head, selecting online mode, performing test

cuts, changing settings, and more. All of the keys and their functions are

described in detail below.

There are also 20 LEDs that provide information about the status of the

cutter. Ten of them constitute the LED bar on top of the control panel,

indicating values or showing error messages. All the other LEDs show the

online status of the cutter, which tool selection is in use and which

parameter has been selected.

Online and Offline modes

The ONLINE key is used to switch between the online and the offline

modes of your cutter. Each operating mode allows you to perform a

different set of tasks from the control panel as described below.

When you f i rst switch the cutter on

with no material loaded, the cutter is in offline mode and the

ONLINE LED is off.

with material already loaded, the cutter is automatically in online

mode and the ONLINE LED is lit.

After you load material, the cutter automatically goes online.

18 Chapter 2, Cutter Controls

Page 27

Slew keys

In online mode you can:

Set a new origin

Initiate a sheet-off action

Browse through the parameter settings without changing them

In offline mode, you are in control of the cutter and can alter the cutter

settings such as

Tool Force Speed

Accelerations Page Length Origin

TEST

SETTINGS

ORIGIN key

OFFSET

SETUP

With the slew keys, you can move the tool head and the material so you

can examine specific details of the job or set a new origin (start point). The

slew keys are always active, whether the cutter is online or offline.

When you press the

(left) or ¾ (right) slew key, the tool head moves in

½

the Y-axis, slowly for 2 seconds and then speeds up.

When you press the ¿ (up) or À (down) slew key, the material (if loaded)

moves in the X-axis, slowly for 2 seconds and then speeds up.

The ORIGIN key allows you to register a new origin (start) point if material

has been loaded. A new origin point can be set in offline as well as in

online mode.

To register a new start point

1. Using the slew keys, place the tool head at the desired origin point.

2. Press the ORIGIN key. LEDs on the LED bar will flash to confirm your

action.

If the tool head Is located beyond the borders of the material, the new origin

point will be rejected.

Chapter 2, Cutter Controls 19

Page 28

PAGE key

T

PAGE

REPLO

The PAGE key is available only in online mode. It has two functions:

Function 1:

To perform the Auto-Sheet-Off function. The position

where the auto-sheet-off occurs depends on the situation. If no design

has been cut at the spot where the tool head is parked when pressing

the PAGE key, the cutter will auto-cut at the present location. When a

design has already been cut, the tool head will move to a location 0.2"

(5 mm) beyond the job and will perf orm an auto-cut.

Function 2:

To start the automatic replot/sheet-off function of the last

file that was sent to the cutter—all data that was sent since the last

INITIALIZATION (“IN”) command. Proceed as follows:

1. Press the PAGE key for about two seconds.

On the LED bar, an LED will start blinking. Its position in the bar

indicates the number of copies to be cut. For example, 60% means

6 copies.

2. Using the VALUE +/- keys, select the desired number of copies.

The factory default settings allow a maximum of 10 copies.

3. Press ENTER.

The cutter starts cutting. A new part of the material will be loaded

automatically after every replot.

ENTER key

It is possible to request up to 100 copies by changing the REPLOT

MULTIPLICATION FACTOR in the cutter setup. (See Replot Factor, page 38,

in Chapter 3.

You must press the ENTER key to confirm requested changes to the

cutter settings. A requested change will always be shown by one or more

flashing LEDs for the parameter to be changed. Pressing ENTER will

stop the flashing, indicating that the new setting has been accepted.

The ENTER key also carries a blue dot, indicating it can be pressed

together with another key to access one of the special functions indicated

in blue on the control panel.

20 Chapter 2, Cutter Controls

Page 29

Menu keys

VALUE keys

The MENU selection keys allow you to cycle through the various cutter

parameters to view or change them.

The parameters that can be modified are TOOL, FORCE, SPEED,

ACCELERATION, and PAGE LENGTH. Each is listed on the control panel.

The selected parameter is shown with an LED.

In online mode, pressing the MENU selection keys allows you to verify the

actual settings, though you will not be able to change them

In offline mode, you can select a parameter and then change the value or

the tool selection using the VALUE keys.

Use the VALUE keys to change either settings or parameter values.

To change tools or values:

1. Switch to

offline

mode.

2. Select the parameter you wish to change.

3. Press one of the value keys once to change the parameter.

The LED bar or LED indicating the value or the tool will blink.

4. Press the ENTER key to save the new setting. (Pressing one of the

menu keys again before pressing ENTER will exit without saving the

change.)

Chapter 2, Cutter Controls 21

Page 30

GENERAL PROCEDURE TO CHANGE SETTINGS ON THE CUTTER

1. Make sure you have power to the cutter and that the cutter is in the

offline

If you start with the cutter off (no power),

mode.

and there is no material loaded, the cutter will be in

offline

mode,

which is indicated by the ONLINE LED being off.

and there is material loaded, the cutter will be in

online

mode,

which is indicated by the ONLINE LED being lit. Press the ONLINE

key to take the cutter

offline

, which will be indicated by the ONLINE

LED going out.

If you start with the cutter on (power to the cutter), look at the ONLINE

LED,

if it is lit, press the ONLINE key to put the cutter in the

offline

mode.

The ONLINE LED will go off.

if it is off, the cutter is already in the

offline

mode.

2. Using the MENU keys, select one of the five different parameters

(TOOL, FORCE, SPEED, ACCELERATION, or PAGE LENGTH).

3. Using the VALUE keys, adjust the settings for the selected parameter.

The + key increases the value or selects the next parameter. The - key

decreases the value or selects the previous parameter. A requested

change is indicated by one or several blinking LEDs.

4. Press ENTER to confirm the requested change. (To exit without a

change, press one of the menu keys.)

The blinking stops, indicating that the new setting has been saved.

22 Chapter 2, Cutter Controls

Page 31

TOOL SELECTION

The four tools listed on the control panel are actually four different sets of

tool parameters. For each of the four tools you can register and store

specific values for

TOOLKIND (knife, drawing pen, or pounce)

FORCE

SPEED

ACCELERATION

OFFSET (knives only)

POUNCING GAP (pouncing only).

Switching from tool to tool allows you to switch from one complete setup to

another without having to change any individual value.

Furthermore, to fit your application, you can change the settings in each of

the four setups. This allows you to save the settings for your most popular

material or job types. Then you can swiftly change to a different material

type or application without having to change any of the settings.

(Offset values and correction routines are applied only if a tool is selected

that is defined as a knife. The pouncing gap is only adjustable and active if

a tool is selected that is defined as a pouncing tool.)

There is a fifth tool parameter, TOOL-UP, which is not listed on the control

panel. When tool-up is selected, you can adjust speed and acceleration

for tool-up movements as well as the force used to perform automatic

sheet-off. (The force and acceleration settings included in the four tool

settings are for tool-down movements.)

The procedure below tells you how to choose the tool (setup). The

following sections explain how to change the settings in the setup.

To select which set of tool parameters to use or change

1. Switch the cutter

2. Using the MENU selection keys, select the TOOL option.

The LED next to TOOL must go on.

3. Using the VALUE + or – key , select TOOL 1, TOOL 2, TOOL 3, TOOL

4 or TOOL-UP.

TOOL-UP is selected when all TOOL LEDs are out. The other tools

are indicated by blinking of the associated LED.

4. Press ENTER to confirm your selection or press one of the menu keys

to exit. To access the TOOL-UP status, you also need to press

ENTER, although no flashing LED is visible at that time!

offline

.

Chapter 2, Cutter Controls 23

Page 32

For cutting jobs, use only tools set to KNIFE.

For plotting jobs, use only tools set to PEN.

For pouncing jobs, use only tools set to POUNCE.

When TOOL-UP is selec ted, the FORCE adjustment refers to

the FORCE that will be used for automatic sheet-off.

TOOLKIND SELECTION

Your cutter has 3 different types of tools: knives, drawing pens and a

pouncing (punching) tool. The TOOLKIND selection makes it possible to

change the type of tool that is linked to a specific set of tool parameters

(Tool 1–Tool 4). This is possible using the setup sheet.

The factory default toolkind selection setup is:

TOOL 1 acts as a KNIFE

TOOL 2 acts as a KNIFE

TOOL 3 acts as a PEN

TOOL 4 acts as a PEN

Note that you can always verify the toolkind of the selected tool. When the

tool menu is selected (LED next to Tool is ON), the Led bar on top shows

the current tool type

To change the TOOLKIND

See setup sheet (page 35) Toolkind Selection

Drag Knife

Pen

Pounce

10 20 30%

24 Chapter 2, Cutter Controls

Page 33

FORCE SELECTION

Force is the amount of downward pressure applied by a tool. You are able

to adjust the amount of tool pressure applied by an individual tool so that

you can cut varying thicknesses of material correctly or set the correct

amount of pressure for a pen.

1. Switch the cutter

2. Using the MENU selection keys, select the FORCE option (LED next to

FORCE must be on).

The actual FORCE setting for the selected tool will now be shown on

the LED bar. You can view the value in both offline and online modes.

3. Using the VALUE +/- keys, you can now alter the FORCE settings.

The force is adjustable in three ranges:

15-100 grams, 110-190 grams, and 200-500 grams.

(See explanation on the next page.)

4. Press ENTER to confirm and store, or press one of the menu keys to

exit.

For the procedure to test the force, see Cutting a Test Square To Test Cutting

Pressure (Force), page 49, in Chapter 4.

offline

.

Chapter 2, Cutter Controls 25

Page 34

Force settings are shown by one LED for the first range and combinations

of LEDs for the second and third ranges. Since the actual numbers are not

on the control panel, consult these tables to find the numerical equivalent

of the LEDs shown.

First Range (15 - 100 grams)

Force settings in the first range are indicated by one blinking LED to

indicate the cutting force. The example below shows 80 grams.

15 20 30 40 50 60 70 80 90 100

Second Range (110 - 190 grams)

Force settings are indicated by blinking of the

combination with one of the other LEDs. The example below shows a

setting of 150 grams.

110 120 130 140 150 160 170 180 190

Third Range (200 - 500 grams)

Force settings are indicated by blinking of the

bar in combination with other LEDs in 50-gram increments.

Example showing a 200-gram setting.

200 200 200 200 250 300 350 400 - -

Example showing a 250-gram setting.

200 200 200 200 250 300 350 400 - -

Example showing a 400-gram setting.

LED of the LED bar in

last

first four

LEDs of the LED

200 200 200 200 250 300 350 400 450 500

All available values are shown in the tables at the end of this chapter.

When TOOL-UP is selected, the force adjustment refers to the force

that will be used for the automatic sheet-off.

26 Chapter 2, Cutter Controls

Page 35

SPEED SELECTION

The speed selection allows you to set the tool-down speed, the speed at

which the tool moves through the material.

1. Switch the cutter

2. Using the MENU selection keys, select the SPEED option (LED next to

SPEED must be on).

The current SPEED setting for the selected tool is shown on the LED

bar. You can view the value both offline as and online modes.

3. Use the VALUE +/- keys to change the SPEED setting.

4. Press ENTER to confirm and store, or press one of the menu keys to

exit.

The indicated value only refers to the tool-down speed of the selected tool.

The tool-up speed can be set separately (See Tool Selection page 23, in

this Chapter.

All values being used or available are shown in the tables at the end of

this chapter.

offline

ACCELERATION SELECTION

1. Switch the cutter

2. Using the MENU selection keys, select the ACCELERAT ION opt ion

(LED next to ACCELERATION must be on).

offline

.

.

The current ACCELERATION setting for the selected tool is shown on

the LED bar. You can view the value in both offline and online modes.

3. Use the VALUE +/- keys to change the ACCELERATION settings.

4. Press ENTER to confirm and store, or press one of the menu keys to

exit.

All values being used or available are shown in the tables at the end of

this chapter.

PAGE LENGTH

This parameter is related to loading roll material. The PAGE LENGTH

must be set before a roll is loaded. Set the PAGE LENGTH to a value at

least as large as the job you are going to cut.

Chapter 2, Cutter Controls 27

Page 36

There are three reasons for using a PAGE LENGTH:

The length of material set for the PAGE LENGTH is pulled off the roll

before the cutting job starts, thus preventing material from being pulled

off the roll at high speed and acceleration. High speed movements—

up to 40 ips, (1000 mm/s) and 4.0 G—can be achieved only when the

material can move freely without having to be pulled off the roll during

a job.

Before cutting starts, the complete length of the material is shuffled

back and forth through the cutter, ensuring that the pressure rollers

have a clear path while you have the time to verify that the material

moves easily through the cutter

The Auto-Sheet-Off feature automatically cuts off material at the end of

a cutting sequence. Following an automatic PAGE command or a

manual PAGE command from the control panel, the cutter shuffles

through the pre-set PAGE LENGTH of material to ensure that there is

enough material left for a possible replot. If there is not enough

material left, the cutter will stop before the end of the assigned material

length.

To set the PAGE LENGTH

1. Switch the cutter

offline

.

2. Using the MENU selection keys, select the PAGE LENGTH optio n

(LED next to PAGE LENGTH must be on).

The current PAGE LENGTH setting is shown on the LED bar. You can

view the value in both offline and online modes.

3. Use the VALUE +/- keys to change the PAGE LENGTH settings. Set

the PAGE LENGTH to a value that is at least as large as the sign you

want to cut. The available values for PAGE LENGTH are:

in 0 16 24 32 40 80 120 160 200 400

cm 0 40 60 80 100 200 300 400 500 1000

Each value corresponds with the indications shown on the LED bar.

The default PAGE LENGTH is 40" (1 m).

4. Press ENTER to confirm and store, or press one of the menu keys to

exit.

The use of the PAGE LENGTH should not be regarded as a waste of time. If the

shuffle movement completes without difficulty, the job to be cut will be executed

with very little risk of material tracking problems. In the long run, this saves

time because you won't have to re-cut a complex design because of bad

material alignment.

28 Chapter 2, Cutter Controls

Page 37

The cutting range is not limited by the Page Length that you have set. If a

design that exceeds the shuffle length is sent to the cutter, it will react as

follows:

The first vector that exceeds the limit will be cut using reduced speed for the

distance exceeding the limit.

An additional 8" (20 cm) of material will be pulled from the roll in order to

eliminate any possible snagging at the roll.

After the additional 8" (20 cm) pre-feed, the cutter will continue at the

requested speed until the new limit is exceeded.

These protective measures should not be a reason to avoid changing the page

length, since by not changing it, you will be unable to check the full material

transport before the job is launched.

RESET and CLEAR FUNCTION

In some cases it might be necessary to reset your cutter and/or clear its

buffer while a cutting job is in progress. To do this:

1. Cancel the cutting job in your cutter software so that the data flow is

stopped.

2. Press the ENTER and the MENU down key (RESET) at the same time

for about two seconds.

A sequence of flashing LEDs on the LED bar will indicate that the

cutter has cancelled the current job. The buffer is now empty and the

cutter has stopped cutting.

This reset procedure reinstalls the default original.

Chapter 2, Cutter Controls 29

Page 38

AVAILABLE VALUES/SETTINGS FOR PARAMETERS - IMPERIAL

SYSTEM

All speeds are given in inches per second.

SPEED

TOOL 1

TOOL 2

TOOL 3

TOOL 4

Tool-Up

ACCEL.

TOOL 1

TOOL 2

TOOL 3

TOOL 4

Tool-Up

10% 20% 30% 40% 50% 60% 70% 80% 90% 100%

4 8 12 16 20 24 28 32 36 40

4 8 12 16 20 24 28 32 36 40

24 6 81012 14 16 18 20

4 8 12 16 20 24 28 32 36 40

4 8 12 16 20 24 28 32 36 40

All accelerations are given in G (m/s²).

10% 20% 30% 40% 50% 60% 70% 80% 90% 100%

0.5 1 1.5 2 2.5 3.0 3.5 4 - -

0.5 1 1.5 2 2.5 3.0 3.5 4 - -

0.5 1 1.5 2 2.5 3.0 3.5 4 - -

0.5 1 1.5 2 2.5 3.0 3.5 4 - -

0.5 1 1.5 2 2.5 3.0 3.5 4 - -

All forces are given in grams (1 g = 0.01 Newton)

FORCE

Range 1

Range 2

Range 3

Defaults: TOOL 1 (Knife1) (100 g) TOOL 2 (Knife2) (100 g)

SHUFFLE

Length

Factory Default Settings: TOOL 1 = Knife 1 TOOL 2 = Knife 2

10% 20% 30% 40% 50% 60% 70% 80% 90% 100%

15 20 30 40 50 60 70 80 90 100

110 120 130 140 150 160 170 180 190

200 200 200 200 250 300 350 400 450 500

TOOL 3 (Pen1) (20 g) TOOL 4 (Pen2) (80 g) Sheet-Off (300 g)

All distances are given in inches

10% 20% 30% 40% 50% 60% 70% 80% 90% 100%

0162432

TOOL 3 = Pen 1 TOOL 4 = Pen 2

= Factory default

40 80 120 160 200 400

N/A

30 Chapter 2, Cutter Controls

Page 39

AVAILABLE VALUES/SETTINGS FOR PARAMETERS, METRIC

SYSTEM

All speeds are given in centimeters per second.

SPEED

TOOL 1

TOOL 2

TOOL 3

TOOL 4

Tool-Up

ACCEL.

TOOL 1

TOOL 2

TOOL 3

TOOL 4

Tool-Up

10% 20% 30% 40% 50% 60% 70% 80% 90% 100%

10 20 30 40 50 60 70 80 90 100

10 20 30 40 50 60 70 80 90 100

51015202530 35 40 45 50

10 20 30 40 50 60 70 80 90 100

10 20 30 40 50 60 70 80 90 100

All accelerations are given in G (m/s²).

10% 20% 30% 40% 50% 60% 70% 80% 90% 100%

0.5 1 1.5 2 2.5 3.0 3.5 4 - -

0.5 1 1.5 2 2.5 3.0 3.5 4 - -

0.5 1 1.5 2 2.5 3.0 3.5 4 - -

0.5 1 1.5 2 2.5 3.0 3.5 4 - -

0.5 1 1.5 2 2.5 3.0 3.5 4 - -

All forces are given in grams (1 g = 0.01 Newton)

FORCE

Range 1

Range 2

Range 3

Defaults: TOOL 1 (Knife1) (100 g) TOOL 2 (Knife2) (100 g )

SHUFFLE

Length

Factory Default Settings: TOOL 1 = Knife 1 TOOL 2 = Knife 2,

10% 20% 30% 40% 50% 60% 70% 80% 90% 100%

15 20 30 40 50 60 70 80 90 100

110 120 130 140 150 160 170 180 190 N/A

200 200 200 200 250 300 350 400 450 500

TOOL 3 (Pen1) (20 g) TOOL 4 (Pen2) (80 g) Sheet-Off (300 g)

All distances are given in centimeters

10% 20% 30% 40% 50% 60% 70% 80% 90% 100%

0406080100 200 300 400 500 1000

TOOL 3 = Pen 1 TOOL 4 = Pen 2

= Factory default

Chapter 2, Cutter Controls 31

Page 40

CHAPTER 3

CUTTER SETTINGS and SPECIAL FUNCTIONS

INTRODUCTION

Most of the frequently-used settings are available directly from the

keyboard. However, when setting up the cutter, you must fine tune it to

match the computer setup. Furthermore, the MENU mode operation gives

you access to the setup sheet, allowing you to change special functions

that are not used frequently.

This chapter contains information on how to enter the MENU mode, plot

the setup sheet, and use it to change 32 different settings.

CHANGING THE USER LANGUAGE

It is possible to change the user language of your cutter, thus changing

the setup sheet language. This can be done by pressing two keys

simultaneously during power-up. The combinations are:

LANGUAGE KEY COMBINATION

American (Def ault)

German

French

English

Japanese

MENU MODE OPERATION

1. Install a PEN in the tool head.

2. For optimum plot quality, set the tool selection to a PEN (factory

default TOOL3 and 4).

3. Load a B-size (11" X 17") sheet of paper or larger into the cutter with

the short side on the Y-axis.

4. Switch the cutter to

The ONLINE LED indicator should go off.

offline

ENTER + SLEW DOWN

ENTER + SLEW UP

ENTER + SLEW RIGHT

ENTER + SLEW LEFT

ENTER + ONLINE

by pressing the ONLINE key.

5. Enter the MENU mode by pressing ENTER and slew À (SETUP).

32 Chapter 3, Cutter Settings and Special Functions

Page 41

The cutter now plots a menu selection line (example below).

MENU: xx.xx:

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 SHOW

You can now plot a complete setup sheet with all the settings and options

or any of the 32 lines, each showing a single setting and its options. See

the next page for a sample setup sheet.

To plot a complete setup sheet

1. Using the ½ or ¾ (left or right slew) key, park the tool head above the

SHOW function.

2. Press ENTER.

After your selection is plotted, the tool head is returned to the menu

selection line.

To plot a single line and change settings

The column of 32 numbers at the left of the sample setup sheet

correspond to the row of 32 numbers in the menu selection line.

1. Using the ½ or ¾ (left or right slew) key, park the tool head above your

selection in the menu selection line.

2. Press ENTER.

After the line is plotted, the tool head is parked above the current

setting, which is also underlined in the plot.

3. To keep the current setting, use the ¿ or À (up or down) slew key to

return to the menu selection line.

4. To chan ge the setting, use the ½ or ¾ (left or right slew) key to position

the tool head above the desired setting.

5. Press ENTER to save the new setting.

The tool then returns to the menu selection line.

6. To return the cutter to its normal operating mode, put the material hold

lever up and remove the setup sheet from the cutter.

Switching the machine off will not undo any changes that have already been

saved, even if the cutter is still in MENU mode operation when you switch it off.

To reset the cutter to factory defaults, there is a special key code sequence. See

Reset to Factory Defaults, page 43, in this chapter.

When you view a parameter in the setup sheet, the current selection of that

particular parameter is underlined when ENTER is pushed or exit is chosen via

the slew keys.

Chapter 3, Cutter Settings and Special Functions 33

Page 42

Example of a FasTrack Cutter Setup Sheet

p

. Toolkind Tool 1: Knife Pen Pounce

1

2. Toolkind Tool 2: Knife Pen Pounce

3. Toolkind Tool 3: Knife Pen Pounce

4. Toolkind Tool 4: Knife Pen Pounce

5. SheetOff/Pgmode: On/PMO On/PM1 On/PM2 Off/PMO Off/PM Off/PM2

6. Replot factor : x1 x2 x5 x10

7. Smoothing : Off On

8. Communication :

Default 1 Default 2 Default 3 Default 4 Default 5 User Def.

Baudrate: 1200 2400 4800 9600 19200b

9.

10. Data Bits: 7 bits 8 bits

11. Parity: None Odd Even

12. Stop Bits: 1 bit 2 bits

13. Handshake: Off Xon Ack

14. DTR Control: Off On

15. CTS Control: Off On

16. RTS Pin: On Off RTS

17. Command Set: MH-GL2 MC-GL

18. Origin: Center L. Rght L. Lft U. Rght U. Lft

19. Plot Unit: 0.025mm 0.01mm

20. VS, AS, FS: Ignore Accept

s

21. Format: 907 PCI

22. Plot Unit: 0.010mm 0.0125mm 0.025mm

23. SYNC Count: 1 2

24. SYNC Code Hundred: 0 1

25. SYNC Code Ten: 0 1 2 3 4 5 6 7 8 9

26. SYNC Code One: 0 1 2 3 4 5 6 7 8 9

27. Sum Check: No Yes

28. Radix Hundred: 0 1 2

29. Radix Ten: 0 1 2 3 4 5 6 7 8 9

30. Radix One: 0 1 2 3 4 5 6 7 8 9

31. EOB Code Ten: 0 1 2 3

32. EOB Code One: 0 1 2 3 4 5 6 7 8 9

MENU: Firmware Version xx.xx

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 SHOW

34 Chapter 3, Cutter Settings and Special Functions

Page 43

GENERAL SETTINGS

The general setting parameters, lines 1 through 7 on the setup sheet,

influence the cutter’s reactions to commands given by the computer or

initiated at the control panel. In the general settings menu, you can set

TOOLKIND, PAGE MODE, REPLOT FACTOR and SMOOTHING. Here's

an example from the setup sheet on the previous page:

1. Toolkind Tool1: Knife Pen Pounce

2. Toolkind Tool2: Knife Pen Pounce

3. Toolkind Tool3: Knife Pen Pounce

4. Toolkind Tool4: Knife Pen Pounce

5. SheetOff/Pgmode: On/PM0 On/PM1 On/PM2 Off/PM0 Off/PM1 Off/PM2

6. Replot Factor: x1 x2 x5 x10

7. Smoothing: Off On

TOOLKIND SELECTION

Lines 1 to 4 of the setup sheet allow you to redefine the toolkind for each

of the four tools. By factory default TOOLS 1 and 2 are defined as knives,

while TOOLS 3 and 4 are defined as pens.

For an explanation of the complete setup for the four tools, which is done

from the control panel, see

Selection, and Acceleration Selection,

To select a TOOLKIND

The example is for Tool 1.

1. Using the ½ and ¾ (left and right slew) keys, position the pen above

selection 1, 2, 3, or 4 in the menu selection line.

2. Press ENTER to confirm this choice.

The cutter plots the following line

1. Toolkind Tool1: Knife Pen Pounce

after which the tool head parks above the current setting.

3. To keep the current setting, use the ¿ and À (up and down) slew keys

to return to the menu selection line.

4. To chan ge the setting, use the ½ and ¾ (left and right slew) keys to

position the tool head above the desired setting.

5. Press the ENTER key to save the new setting into memory.

At the same time, the tool head returns to the menu selection line,

allowing a new selection.

Tool Selection, Force Selection, Speed

starting on page 23, in Chapter 2.

Chapter 3, Cutter Settings and Special Functions 35

Page 44

SHEET-OFF / PAGE MODE

This is a combination of two parameters: sheet-off and page mode. You

can select any one of three page modes with the auto sheet-off feature

turned on or off.

With the auto-sheet-off part, you can enable or disable the automatic

sheet-off facility. When the auto-sheet-off function is disabled, no

sheeting off will occur.

The page mode part determines the cutter’s reaction to a PAGE

command as sent by the cutting software. The PAGE command is

used to relocate the origin after a job is finished and can take control

remotely of the cutter’s automatic sheet-off feature. Sheeting-off

automatically, without user intervention, is a unique feature of

FasTrack cutters that enhances the cutter’s versatility and overall

performance enormously.

Page commands

A PAGE command is sent to the cutter by the host computer software as

either a “PG;”, or “Pgn;”, where “n” is a number in millimeters.

If the PAGE command “PG;” is sent, the cutter will automatically sheet off

regardless of the Page Mode, minimizing the loss of material.

If the PAGE command “Pgn;” is sent, the number after the PG command

will be interpreted differently, depending on the page mode you have

chosen:

Page Mode 0 (PM0): The number after the PAGE command is ignored.

The material will be cut 0.2" (0.5 cm) after the furthest vector and the

new cutting limit will be located 0.2" (0.5 cm) from the lower material

border.

Page Mode 1 (PM1): The new origin is located “n” millimeters beyond

the last vector that was sent.

Page Mode 2 (PM2) = default: The new origin is located “n” millimeters

beyond the previous origin position.

Refer to the manual for your software to find out what kind of page mode your

software sends to the cutter.

36 Chapter 3, Cutter Settings and Special Functions

Page 45

: Original origin.

A

: End point last vector

B

: New origin with

C

: New origin with

D

To set the SHEET-OFF / PAGE MODE

1. Using the ½ and ¾ (left and right slew) keys, position the pen above

selection 5 in the menu selection line.

2. Press ENTER to confirm this choice.

The cutter will plot the following line:

5 SheetOff / PGmode: PM0 PM1 PM2

after which the tool head will park above the current setting. The

factory default is Page Mode 2.

Page Mode 1

Page Mode 2

3. To keep the current setting, use the ¿ and À (up and down) slew keys

to return to the menu selection line leaving the original setting

unchanged.

4. To chan ge the setting, use the ½ and ¾ (left and right slew) keys to

position the tool head above the desired setting.

5. Press the ENTER key to save the new setting into memory.

At the same time, the new selection is underlined and the tool head

returns to the menu selection line, allowing a new selection.

Chapter 3, Cutter Settings and Special Functions 37

Page 46

REPLOT FACTOR

If you want to make multiple copies of a design, the easiest way is to send

the job from your computer. However, you can also use the replot factor in

the cutter. Using the replot factor, it is possible to request more than 10

copies when the automatic replot utility is used. The replot factor indicates

the multiplication factor (2,5, or 10) that the cutter will use to determine

how many copies are requested.

EXAMPLE: If the replot factor is (times) 5 and the third LED is selected to

indicate the number of copies, a total of 15 copies will be generated.

To set the replot factor

1. Using the ½ and ¾ (left and right slew) keys, position the pen above

selection 6 in the menu selection line.

2. Press ENTER to confirm this choice.

The cutter will plot line 6.

6) Replot Factor: x1 x2 x5 x10

after which the tool head will park above the current setting. The

factory default is times 1.

3. To keep the current setting, use the ¿ and À (up and down) slew keys

to return to the menu selection line leaving the original setting

unchanged.

4. To chan ge the setting, use the ½ and ¾ (left and right slew) keys to

position the tool head above the desired setting.

5. Press the ENTER key to save the new setting into memory.

At the same time, the new selection is underlined and the tool head

returns to the menu selection line.

38 Chapter 3, Cutter Settings and Special Functions

Page 47

SMOOTHING

Smoothing rounds sharp corners. It can be set on or off. Depending on

your choice, the cutter cuts obtuse angles differently.

If the complementary angle (n) between two consecutive vectors A and B

is larger than the smoothing angle, the cutter will slow down and cut a

sharp corner (1). If the angle is smaller, the cutter will maintain its speed

and cut a rounded corner (2). The optimum smoothing angle is calculated

internally.

When smoothin g is turned off, all corners will be cut sharply. The time

difference between cutting a job with smoothing on and cutting it with

smoothing off is negligible.

To change the smoothing settings

1. Using the ½ and ¾ (left and right slew) keys, position the pen above

selection 7 in the menu selection line.

2. Press ENTER to confirm this choice.

The cutter plots line 7:

7) SMOOTHING: Off On

after which the tool head parks above the current setting. The factory

default is on.

3. To keep the current setting, use the ¿ and À (up and down) slew keys

to return to the menu selection line.

4. To chan ge the setting, use the ½ and ¾ (left and right slew) keys to

position the tool head above the desired setting.

5. Press the ENTER key to save the new setting into memory.

At the same time the new selection is underlined and the tool head

returns to the menu selection line, allowing a new selection.

Chapter 3, Cutter Settings and Special Functions 39

Page 48

COMMUNICATI O N SETTINGS

For your cutter to communicate with your host computer, the

communication settings on both machines must match exactly. In the

Setup sheet, they can be found in lines 8 to 16:

8 Communication: Default 1 Default 2 Default 3 Default 4 Default 5 User Def

9 Baudrate: 1200 2400 4800 9600

10 Data Bits: 7 bits 8 bits

11 Parity: None Odd Even

12 Stop Bits: 1 bit 2 bits

13 Handshake: Off Xon ACK

14 DTR Control: Off On

15 CTS Control: Off On

16 RTS Pin: On Off RTS

In the factory, several commonly used sets for items 9 through 16 have

been preinstalled. (See below.) Refer to your software manual to

determine if you can use the default setting (in which case you don't have

to make any changes), use one of the other preinstalled sets, or need to

make changes to some of the items in lines 9 through 16.

19200 bps

Menu selection options 9 to16 are only available if the parameter User Defined

is selected in line 8. If you use one of the default settings, all other

communication parameters are automatically set.

Factory default

DEFAULT1DEFAULT2DEFAULT3DEFAULT4DEFAULT

5

BAUDRATE 9600 9600 9600 9600 9600

DATABITS 7 8788

PARITY EVEN NONE EVEN NONE EVEN

STOPBITS 1 1 112

HANDSHAKE OFF OFF X-ON X-ON OFF

DTR ON ON OFF OFF ON

CTS OFF OFF OFF OFF OFF

RTS ON ON ON ON ON

40 Chapter 3, Cutter Settings and Special Functions

Page 49

To change the serial communication settings

In line 8, choose one of the preinstalled sets or the User Defined selection.

If you need to use the User Defined option, alter the settings one by one

until they match the desired values.

6. Using the ½ and ¾ (left and right) slew keys, position the tool head

above the desired selection (between 8 and 16) in the menu selection

line.

7. Press ENTER to confirm this choice.

The cutter plots the corresponding line and the tool head parks above

the current setting. The factory default setting is default 2.

8. To keep the current setting, use the ¿ and À (up and down) slew keys

to return to the menu selection line leaving the original setting

unchanged.

9. To chan ge the setting, use the ½ and ¾ (left and right slew) keys to

position the tool head above the desired setting.

10. Press the ENTER key to save the new setting into memory.

At the same time, the new selection is underlined and the tool head

returns to the menu selection line, allowing a new selection.

Chapter 3, Cutter Settings and Special Functions 41

Page 50

LANGUAGE SETTINGS

Your cutter can understand two different graphic languages, MH-GL/2

(HPGL™/2 - compatible) and MC-GL (Ca lcomp Compatible). So that you

can fully use them, settings for them are available in the cutter setup

mode. In the setup sheet, the language settings are in lines 17 to 32.

17) Command Set: MH-GL/2 MC-GL

18 Origin: Center L. Right

19 Plot Unit: 0.025mm 0.010mm

20 VS-AS-FS: Ignore Accept

21 Format: 907 PCI

22 Plot Unit: 0.010mm 0.0125mm 0.025mm

23 SYNC Count: 1 2

24 SYNC Code

Hundred:

25 SYNC Code Ten: 0 1 2 34 56 7 89

26 SYNC Code One: 0 1 2 34 56 7 89

27 Sum Check: No Yes

28 Radix Hundred: 0 12

29 Radix Ten: 0 1 2 3 4 5 6 789

30 Radix One: 0 1 2 3 4 56789

31 EOB Code Ten: 0 1 23

32 EOB Code One: 0 1 2 3 4 56789

0 1

L. Left U. Right U. Left

When MH-GL/2 is activated in menu option 17, the menu options 21-32 will

NOT be available.

When MC-GL is activated in menu option 17, menu-options 18-20 will NOT be

available.

The first choice to make is the language type: MH-GL/2 or MC-GL. The

factory default is MH-GL/2.

When using MH-GL/2, three setti ngs are available:

1. Origin: Center, Lower Right, Lower Left, Upper Right and Upper Left.

Lower Right is factory default.

2. Plot Unit: 0.025 mm or 0.01 mm. Factory default is 0.010mm. If these

values are not set correctly, all your jobs will be too large or too small.

3. VS-AS-FS: Several cutting software packages enable your to send

SPEED, ACCELERATION and FORCE commands to the cutter from

42 Chapter 3, Cutter Settings and Special Functions

Page 51

the software. The cutter can be set up to ACCEPT or IGNORE these

commands.

When using MC-G L, twelve se ttings are available. Please refer to your

software manual to look for the necessary values if this language is

needed.

To change language settings

1. Using the ½ and ¾ (left and right slew) keys, position the pen above

one of the selections 17 to 32 in the menu selection line.

2. Press ENTER to confirm this choice.

The cutter plots the corresponding line and the tool head parks above

the current setting.

3. To keep the current setting, use the ¿ and À (up and down slew) keys

to return to the menu selection line.

4. To chan ge the setting, use the ½ and ¾ (left and right slew) keys to

position the tool head above the desired setting.

5. Press the ENTER key to save the new setting into memory.

At the same time, the new selection is underlined and the tool head

returns to the menu selection line, allowing a new selection.

RESET TO FACTORY DEFAULTS

If it is necessary to reset your cutter to its factory default settings, switch

the cutter on while pressing the ORIGIN and the PAGE keys at the same

time.

The LED bar confirms this action. The LEDs display a running light from

the outside to the inside several times.

Using this function will fully re-initialize your unit. All previously stored

language and communication settings will be reset.

In case of doubt, first plot out a setup sheet using the show option of the menu

selection line.

It is also possible to set the factory default settings when in "STANDALONE

MODE" by pressing the ENTER + MENU up keys. An LED sequence confirms

the settings to factory default. This procedure is equivalent to pressing the

ORIGIN and PAGE keys during startup.

Chapter 3, Cutter Settings and Special Functions 43

Page 52

CHAPTER 4

FINE TUNING THE CUTTER

The FasTrack cutter provides a step-by-step method to help beginning

users achieve excellent cutting quality. Once you have more experience

with your cutter, you will be able to fine tune your cutter quickly and

accurately.

There are several knife types available, each designed for cutting specific

material.

Cutting Blade 1 Cutting Blade 2 Cutting Blade 3

Top Angle 45º 30º 60º

Typical Offset 0.50 mm 0.50 mm 0.50 mm

Default Speed 50 cm/s (20"/s) 50 cm/s (20"/s) 50 cm/s (20"/s)

Default Force 100 g 100 g 100 g

Default

3.0 G 3.0 G 3.0 G

Acceleration

There are three factors to consider when setting up your cutter for a

demanding cutting job:

The knife depth

The cutting pressure

The offset

This section covers

Adjusting the knife depth

Setting the cutting pressure

Adjusting the offset

Performing a test cut

44 Chapter 4, Fine Tuning the Cutter

Page 53

ADJUSTING THE KNIFE DEPTH

Two types of high quality knife holders are available for FasTrack cutters,