Page 1

Elite

Page 2

ENGLISH

ELITE AUTOMATION

The ELITE automation system for swing gates comprises an

electromechanical operator which drives the gate leaves by

means of a worm screw.

The ELITE operator is irreversible and locks mechanically when the

motor is not in use. Therefore a lock does not need to be fitted.

Its manualoveride is activated by a customised key.

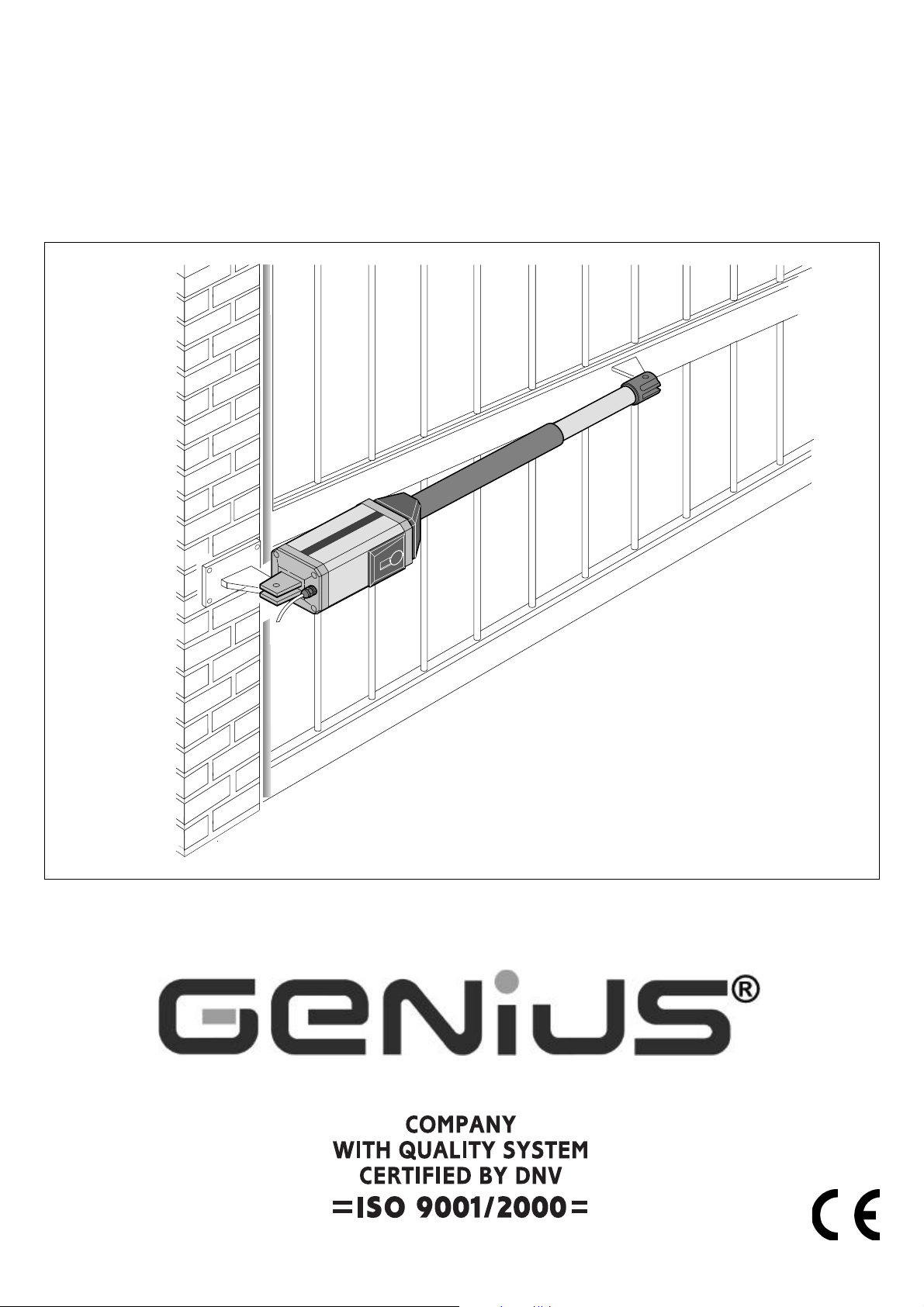

1. DESCRIPTION AND TECHNICAL SPECIFICATIONS

Fig. 1

4

3

5

1) Motor Unit

2) Power cable

1

2

Table 1:

Model

Power supply

Absorbed power

Current drawn

Electric motor rpm

Thermal cutout

Capacitor

Max. thrust/traction force

Rod stroke

Rod speed

Temperature range

Operator weight

Housing protection

Duty cycle (cycles/hour)

Maximum leaf length

Operator technical specifications

ELITE 300

ELITE 400

230V~ - 50Hz 230V~ - 50Hz

10 µF / 400V 8 µF / 400V

400 daN 320 daN300 daN

3) Worm screw

4) Front bracket

5) Rear bracket

ELITE 324

ELITE 424

24Vdc

350W 280W70W

1,5A 1,2A3A

1400 900

140°C 140°C

300 mm / 400 mm

1,6 cm/sec

-20°C +55°C

6,5 Kg

IP 44

20 2050

3 m / 4 m

ELITE

LENTO

400 mm

1,1 cm/sec

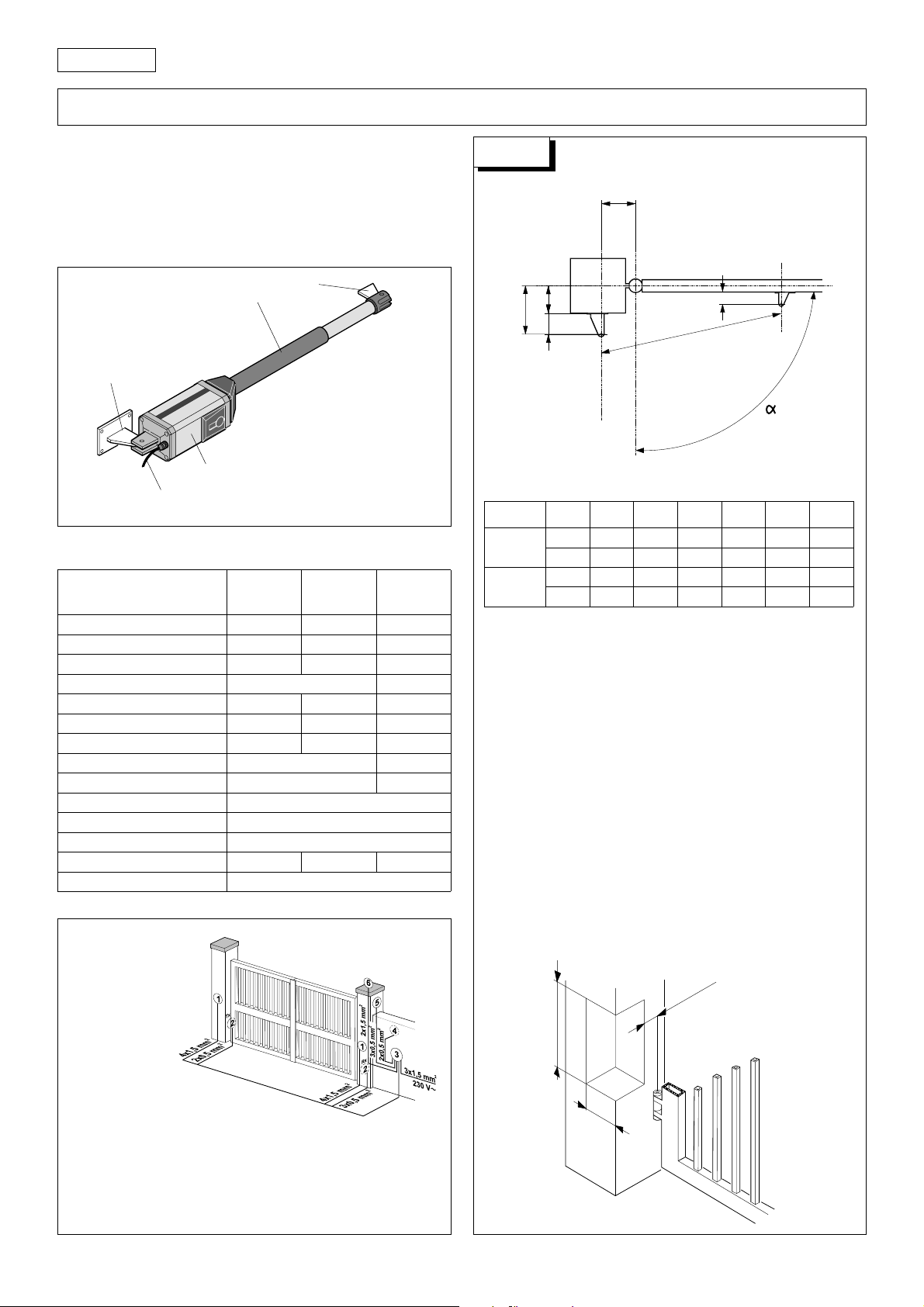

2. STANDARD INSTALLATION LAYOUT

Fig. 2

Drawing A

A

INSTALLATION DIMENSIONS

B

D

Z

L

45 min.

Fig. A

Table A: Recommended dimensions (in mm)

Model

300

400

(¹) useful rod stroke (²) max. dimension (³) min. dimension

αα

α

αα

90°

110°

90°

110°

A B C (¹) D (²) Z (³) L

145 145

125 125

195 195

165 165

290

290

390

390

70

50

120

90

45

45

45

45

970

970

1170

1170

CALCULATING INSTALLATION DIMENSIONS:

GENERAL RULES

If the dimensions specified in Table A cannot be used,

calculate different dimensions as follows:

- For 90° leaf opening: a + b = c

- For leaf opening over 90°: a + b < c

- The lower the dimensions of a and b the higher the

gate speed. Ensure that current standards are

observed.

- Make sure that the difference between a and b is

no more than 4 cm: larger differences cause large

variations in speed during opening and closing.

- Due to the dimensions of the operator, the minimum

value for Z is 45 mm (fig. A)

If the dimensions of the gate post or the position of

the hinge do not allow a to be kept within the

required value, make a recess in the gate post as

shown in fig. B.

1) Operators

2) Photocells

3) Control unit

4) Keyswitch

5) Receiver

6) Flashing light

Notes:1) Use suitable rigid/flexible pipes for laying power cables.

2) Always keep low voltage accessory cables separate from 230V~ power

cables. To avoid interference, use separate sheaths.

4

70 mm

200 mm

150 mm

Fig. B

Page 3

3. INSTALLATION OF THE AUTOMATION SYSTEM

3.1. PRELIMINARY CHECKS

To ensure trouble-free operation, make sure that the gate (whether

existing or to be installed) has the following specifications:

• max. length of each gate leaf: 3 metres (with operator with

300 mm stroke);

• maximum length of each gate leaf: 4 metres (with operator

with 400 mm stroke);

• strong and rigid leaf frame

• smooth movement of leaves during entire travel; no stiff points

• hinges in good condition

• mechanical travel limit stops present

• electric lock present in reversible version.

If any welding or brazing has to be done on the gate, this must

be done before installing the automation system.

Good condition of the structure is essential for reliability and

safety of the automation system.

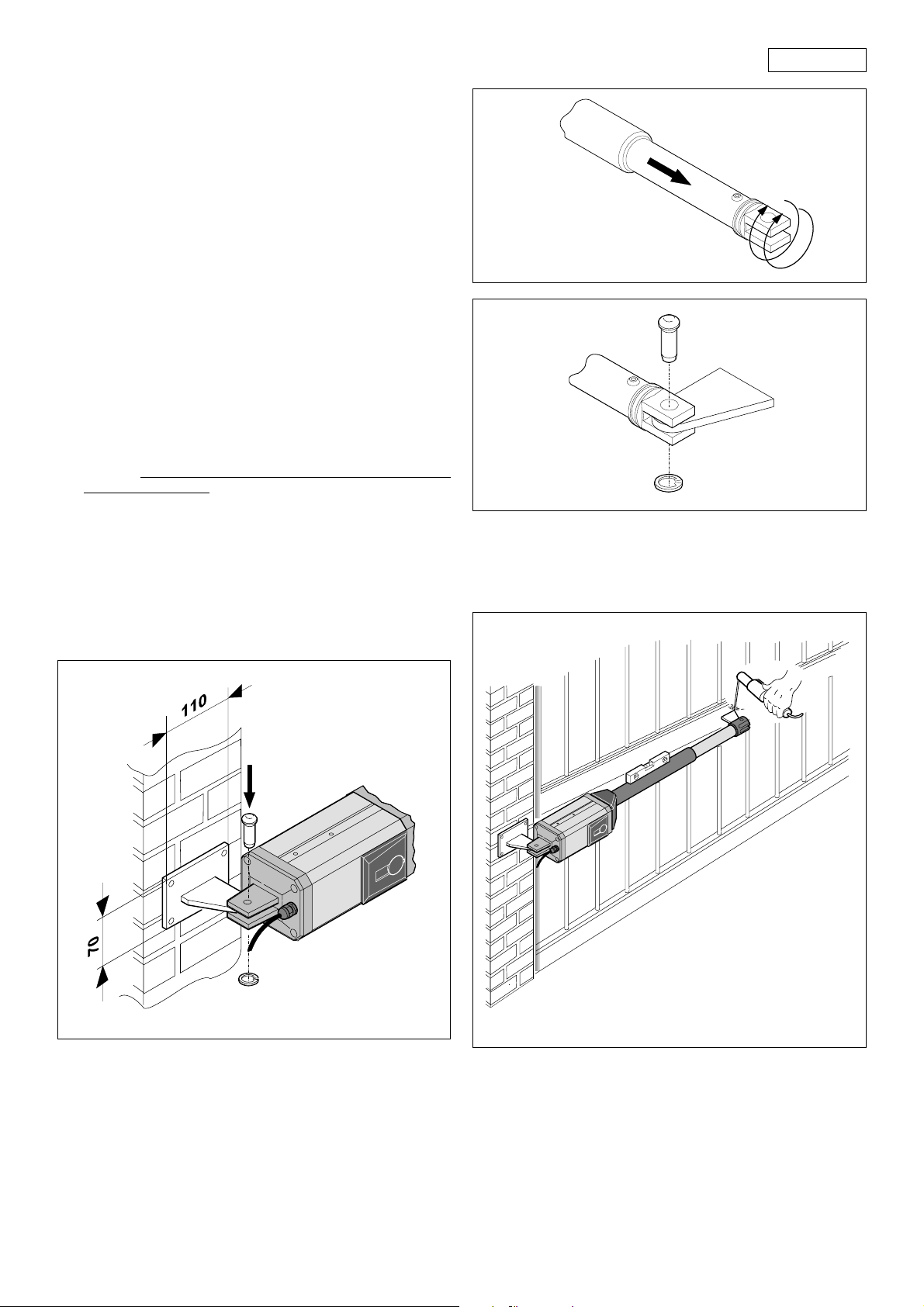

3.2. INSTALLATION OF THE OPERATORS

1) Fix the rear bracket to the gate post according to the

instructions in Table A. Adjust the length of the bracket if

necessary.

Warning:

operator operation.

In the case of iron gate posts, weld the bracket directly onto

the gate post.

In the case of brick/concrete gate posts, flush-mount a wall

plate (fig. 3), and weld the bracket to the plate.

2) Fix the operator to the rear bracket by means of the screws

supplied (fig. 3).

Observe the specified dimensions to ensure correct

ENGLISH

Fig. 4

Fig. 5

7) Fit the front bracket onto the rod as shown in fig. 5.

8) Close the gate leaf and, keeping the operator perfectly

horizontal, locate the leaf attachment position on the front

bracket (fig. 6).

Fig. 3

3) Release the operator (see paragraph 6).

4) Extend the rod to the end of its stroke (fig. 4).

5) Lock the operator (see paragraph 7).

6) Rotate the operator rod two full turns clockwise (fig. 4).

Fig. 6

9) Fix the front bracket temporarily to the leaf by two welds.

N.B.: If the gate frame does not allow for secure fixing of the

bracket, add a support plate.

10) Release the operator and ensure that the gate opens

smoothly with no stiff points and that it stops on the mechanical

travel stops.

5

Page 4

ENGLISH

11) Completely weld the front bracket to the leaf. When doing

this, detach the operator temporarily from the bracket to

prevent damage from welding scale.

N.B.:

1) Grease all pivots on brackets

2) If welding is not possible, the front and rear bracket plates

can be fixed using screws and screw anchors.

12) Attach the metal tag to the slot in the top section of the motor

in order to blank off the holes present as shown fig.7. On the

other hand, do not block the holes to be found in the lower

section.

1

2

3

4

5

Fig. 8

Fig. 7

13) Repeat the above operations to install the second operator,

if required.

14) Install the control unit box according to the dimensions given

in the relevant instructions.

4. STARTING THE AUTOMATED UNIT

1) Program the control unit according to your requirements as

described in the relevant instructions.

2) Power up the system and check the state of the LEDs

according to the table in the control unit instructions.

5. TESTING THE AUTOMATED UNIT

Carefully check operation of the operator and all

accessories connected to it.

Give the customer the page entitled "End-User Guide". Describe

how the operator works and explain how it is to be used correctly.

Inform the customer of the potential hazard areas of the

automation.

6. MANUAL OPERATION

The gate can be operated manually in the event of a power

failure or malfunction by removing the plug and inserting the

special release key as shown in fig. 8.

To release the operator, turn the key as shown in fig. 8.

Open or close the leaves manually.

7. RETURNING TO NORMAL OPERATION

Turn off the electricity supply to the system before re-locking the

operators to avoid all risk of starting them accidentally.

To re-lock the operator, turn the key as shown in fig. 9.

2

1

5

3

4

Fig. 9

8. SPECIAL APPLICATIONS

There are no special applications.

9. MAINTENANCE

Carry out periodic checks of the gate structure and ensure in

particular that the hinges are in perfect working condition.

Check periodically that the electronic anti-crushing system is

adjusted correctly and that the release mechanism for manual

movement is fully operative (see relevant paragraph).

Safety devices installed on the system must be checked every six

months.

10.REPAIRS

For repairs, contact authorised service centres.

6

Page 5

DICHIARAZIONE CE DI CONFORMITÁ PER MACCHINE

(DIRETTIVA 89/392 CEE, ALLEGATO II, PARTE B)

Fabbricante: GENIUS S.p.a.

Indirizzo: Via Padre Elzi, 32

Dichiara che: L'Attuatore mod. ELITE

• è costruito per essere incorporato in una macchina o

• è conforme ai requisiti essenziali di sicurezza

e inoltre dichiara che non è consentito mettere in servizio il

macchinario fino a che la macchina in cui sarà incorporata o

di cui diverrà componente sia stata identificata e ne sia stata

dichiarata la conformità alle condizioni della Direttiva 89/392/

CEE e successive modifiche trasposta nella legislazione

nazionale dal DPR n° 459 del 24 Luglio 1996.

Grassobbio, 01-06-2005

24050 - Grassobbio

BERGAMO - ITALIA

per essere assemblato con altri macchinari per

costituire una macchina ai sensi della Direttiva 89/

392 CEE, e successive modifiche 91/368/CEE, 93/44/

CEE, 93/68/CEE;

delle seguenti altre direttive CEE:

73/23 CEE e successiva modifica 93/68/CEE.

89/336 CEE e successiva modifica 92/31 CEE e

93/68/CEE

L’Amministratore Delegato

D. Gianantoni

EC MACHINE DIRECTIVE COMPLIANCE DECLARATION

(DIRECTIVE 89/392 EEC, APPENDIX II, PART B)

Manufacturer: GENIUS S.p.a.

Address: Via Padre Elzi, 32

Hereby declares that: the ELITE

• is intended to be incorporated into machinery, or to

• complies with the essential safety requirements in the

and furthermore declares

until the machinery into which it is incorporated or of which it

is a component has been identified and declared to be in

conformity with the provisions of Directive 89/392 ECC and

subsequent amendments enacted by the national

implementing legislation.

Grassobbio, 01-06-2005

24050 - Grassobbio

BERGAMO - ITALY

be assembled with other machinery to constitute

machinery in compliance with the requirements of

Directive 89/392 EEC, and subsequent amendments

91/368 EEC, 93/44 EEC and 93/68 EEC;

following EEC Directives:

73/23 EEC and subsequent amendment 93/68 EEC.

89/336 EEC and subsequent amendments 92/31 EEC

and 93/68 EEC.

that unit must not be put into service

Managing Director

D. Gianantoni

DÉCLARATION CE DE CONFORMITÉ

(DIRECTIVE EUROPÉENNE "MACHINES" 89/392/CEE,

ANNEXE II, PARTIE B)

Fabricant: GENIUS S.p.a.

Adresse:

Déclare d’une part

et d’autre part

qu’il est formellement interdit de mettre en fonction l'automatisme en

question avant que la machine dans laquelle il sera intégrée ou dont

il constituera un composant ait été identifiée et déclarée conforme

aux exigences essentielles de la directive européenne "machines"

89/392/CEE, et décrets de transposition de la directive.

Grassobbio, le 01-06-2005

Via Padre Elzi, 32

24050 - Grassobbio

BERGAMO - ITALIE

que l'automatisme mod. ELITE

• est prévue soit pour être incorporée dans une machine,

soit pour être assemblée avec d’autres composants ou

parties en vue de former une machine selon la directive

européenne "machines" 89/392 CEE, modifiée 91/368

CEE, 93/44 CEE, 93/68 CEE.

• satisfait les exigences essentielles de sécurité des

directives CEE suivantes:

73/23 CEE, modifiée 93/68 CEE.

89/336 CEE, modifiée 92/31 CEE et 93/68 CEE.

L’Administrateur Délégué

D. Gianantoni

DECLARACIÓN DE CONFORMIDAD CE PARA MÁQUINAS

(DIRECTIVA 89/392 CEE, ANEXO II, PARTE B)

Fabricante: GENIUS S.p.a.

Dirección: Via Padre Elzi, 32

Declara que: El equipo automático mod. ELITE

Asimismo, declara que

equipo si la máquina en la cual será incorporado, o de la cual

se convertirá en un componente, no ha sido identificada o no

ha sido declarada su conformidad a lo establecido por la

Directiva 89/392 CEE y sus sucesivas modificaciones, y a la ley

que la incorpora en la legislación nacional.

Grassobbio, 01-06-2005

24050 - Grassobbio

BERGAMO - ITALIA

• Ha sido construido para ser incorporado en una

máquina, o para ser ensamblado con otros

mecanismos a fin de constituir una máquina con

arreglo a la Directiva 89/392 CEE y a sus sucesivas

modificaciones 91/368 CEE, 93/44 CEE y 93/68 CEE.

• Cumple los requisitos esenciales de seguridad

establecidos por las siguientes directivas CEE:

73/23 CEE y sucesiva modificación 93/68 CEE,

89/336 CEE y sucesivas modificaciones 92/31 CEE y

93/68 CEE.

no está permitido poner en marcha el

Administrador Delegado

D. Gianantoni

EG-KONFORMITÄTSERKLÄRUNG ZU MASCHINEN

(gemäß EG-Richtlinie 89/392/EWG, Anhang II, Teil B)

Hersteller: GENIUS S.p.a.

Adresse: Via Padre Elzi, 32

erklärt hiermit, daß: der Antrieb Mod. ELITE

und erklärt außerdem, daß die

untersagt ist, bis die Maschine, in welche diese Maschine

eingebaut wird oder von der sie ein Bestandteil ist, den

Bestimmungen der Richtlinie 89/392 EWG sowie deren

nachträglichen Änderungen entspricht.

Grassobbio, 01-06-2005

24050 - Grassobbio

BERGAMO - ITALIEN

• zum Einbau in eine Maschine oder mit anderen

Maschinen zu einer Maschine im Sinne der Richtlinie

89/392 EWG und deren Änderungen 91/368 EWG,

93/44 EWG, 93/68 EWG vorgesehen ist.

• den wesentlichen Sicherheitsbestimmungen

folgender anderer EG-Richtlinien entspricht:

73/23 EWG und nachträgliche Änderung 93/68 EWG

89/336 EWG und nachträgliche Änderung 92/31 EWG

sowie 93/68 EWG

Inbetriebnahme solange

Der Geschäftsführer

D. Gianantoni

Timbro rivenditore: / Distributor’s stamp: / Timbre de l’agent: /

Sello del revendedor: / Fachhändlerstempel:

Le descrizioni e le illustrazioni del presente manuale non sono

impegnative. GENIUS si riserva il diritto, lasciando inalterate le

caratteristiche essenziali dell’apparecchiatura, di apportare in

qualunque momento e senza impegnarsi ad aggiornare la

presente pubblicazione, le modifiche che essa ritiene convenienti per miglioramenti tecnici o per qualsiasi altra esigenza di

carattere costruttivo o commerciale.

The descriptions and illustrations contained in the present

manual are not binding. GENIUS reserves the right, whils leaving the main features of the equipments unaltered, to undertake any modifications to holds necessary for either technical

or commercial reasons, at any time and without revising the

present publication.

Les descriptions et les illustrations du présent manuel sont

fournies à titre indicatif. GENIUS se réserve le droit d’apporter à

tout moment les modifications qu’elle jugera utiles sur ce

produit tout en conservant les caractéristiques essentielles,

sans devoir pour autant mettre à jour cette publication .

Las descripciones y las ilustraciones de este manual no

comportan compromiso alguno. GENIUS se reserva el derecho,

dejando inmutadas las características esenciales de los

aparatos, de aportar, en cualquier momento y sin

comprometerse a poner al día la presente publicación, todas

las modificaciones que considere oportunas para el

perfeccionamiento técnico o para cualquier otro tipo de

exigencia de carácter constructivo o comercial.

Die Beschreibungen und Abbildungen in vorliegendem

Handbuch sind unverbindlich. GENIUS behält sich das Recht

vor, ohne die wesentlichen Eigenschaften dieses Gerätes zu

verändern und ohne Verbindlichkeiten in Bezung auf die

Neufassung der vorliegenden Anleitungen, technisch bzw,

konstruktiv / kommerziell bedingte Verbesserungen

vorzunehmen.

GENIUS S.p.a.

Via Padre Elzi, 32

24050 - Grassobbio

BERGAMO-ITALY

tel. 0039.035.4242511

fax. 0039.035.4242600

info@geniusg.com

www.geniusg.com

I0010EL REV.3

Loading...

Loading...