Genie GS-1530, GS-1532, GS-1930, GS-1932, GS-2032 Repair Manual

...

Service and Repair Manual

Serial Number Rang

e

GS™-1530/1532

he

inside cover

This manual includes:

Repair procedures

Fault Codes

Electrical and

Hydraulic Schematics

GS™-1930/1932

GS™-2032/2632/3232

GS™-2046/2646/3246

GS™-4047

For detailed maintenance

procedures, refer to the

appropriate Maintenance

Manual for your machine.

Part No. 1272217GT

Rev E

March 2021

Refer to t

Service and Repair Manual March 2021

GS

GS-2032, GS-2632, GS-3232

GS

GS-4047

from SN GS4712C

from SN GS4714D

from SN GS4716P

from SN GS47C

from SN

from SN GS47P

Introduction

Introduction Introduction

Serial Number Range

Compliance

Machine Classification

Group A/Type 3 as defined by ISO 16368

Machine Design Life

Unrestricted with proper operation, inspection and

scheduled maintenance.

Contact Us:

Internet: www.genielift.com

E-mail: awp.techpub@terex.com

Find a Manual for this Model

Go to http://www.genielift.com

Service Manuals, Maintenance Manuals, Service

and Repair Manuals, Parts Manuals and

Operator's Manuals.

Copyright © 2016 by Terex Corporation

1272215GT Rev E, March 2021

First Edition, Fifth Printing

Genie is a registered trademark of Terex South Dakota, Inc. in

the U.S.A. and many other countries.

“GS” is a trademark of Terex South Dakota, Inc.

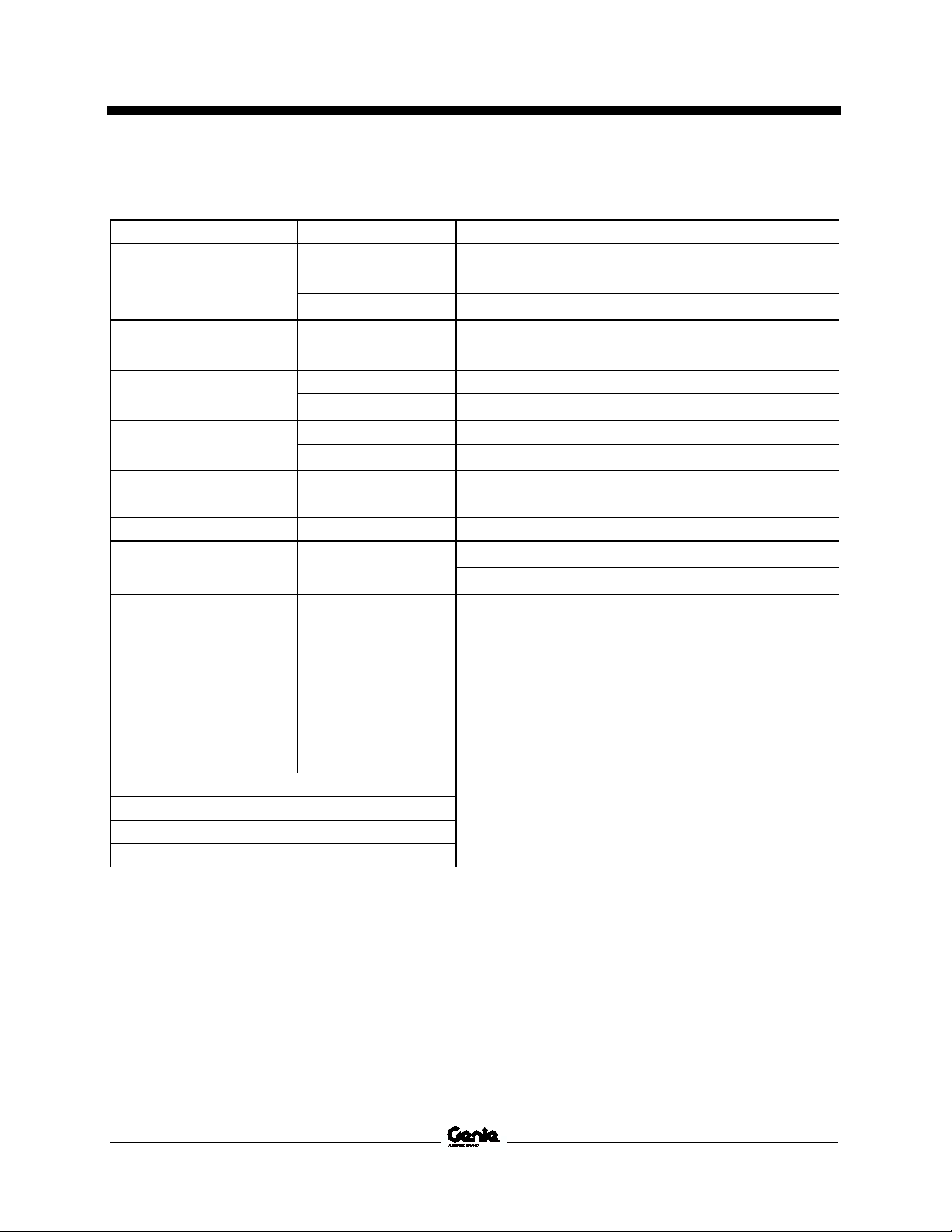

Use the following chart to identify the specific

serial number for models included in this manual.

-1530, GS-1532, GS-1930, GS-1932

from SN GS3010A-110000 to GS3016A-142280

from SN GS3011C-10000 to GS3016C-23999

from SN GS3014D-101 to GS3016D-6079

from SN GS3016P-151487 to GS3016P-160599

from SN GS30C-24000

from SN GS30D-6080 to GS30D-40100

from SN GS30P-160600 to GS30P-200100

from SN GS3211A-110000 to GS3216A-142675

from SN GS3212C-10000 to GS3216C-17299

from SN GS3216P-142676 to GS3216P-148699

from SN GS32C-17300

from GS32D-101 to GS32D-10100

from SN GS32P-148700 to GS32P-200100

-2046, GS-2646, GS-3246

from SN GS4612A-110000 to GS4616A-138361

from SN GS4612C-10000 to GS4616C-18099

from SN GS4614D-101 to GS4616D-5029

from SN GS4616P-138362 to GS4616P-141799

from SN GS46C-18100

from SN GS46D-5030 to GS46D-20100

from SN GS46P-141800 to GS46P-200100

-101 to GS4716C-4499

-101 to GS4716D-3959

-101 to GS4716P-999

-4500

GS47D-3960

-1000

i

i GS

™

-30 • 32 • 46 • 47 Part No. 1272217GT

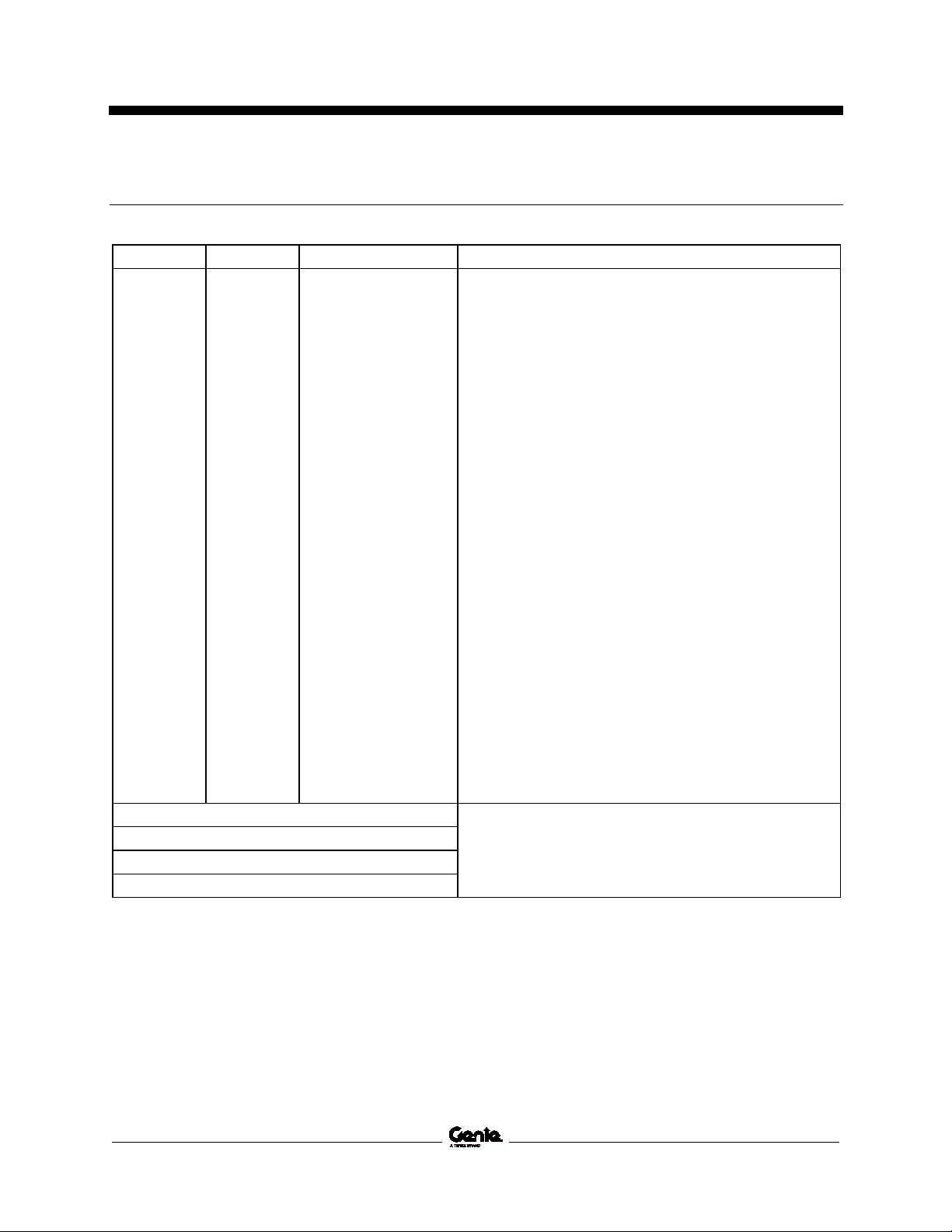

March 2021 Service and Repair Manual

Introduction

Revision History

Revision Date Section Procedure / Page / Description

A 3/2016

A1 5/2016 Repair Procedures 2-3, 2-4, 9-11

Diagnostics H067 fault

A2 5/2016 Repair Procedure 2-6

Diagnostics Type CXXX and UXXX fault codes

A3 9/2016 Introduction Serial Number Legend

Specifications Add drive speed stowed parameters

B 4/2017 Repair Procedure 11-1

Diagnostics Battery charger and fault codes

B1 12/2017 Schematics GS46, GS47 AS/CE

C 1/2019 All Sections Added GS-1330m

D 8/2019 All Sections Added GS-4655

E 3/2021

Initial Release

Add ending serial break

All Sections Remove GS-1330m, GS-4655

Reference Examples:

Section – Repair Procedure, 4-2

Section – Fault Codes, All charts

Section – Schematics, Legends and schematics

Electronic Version

Click on any content or procedure in the Table of Contents to view

the update.

Part No. 1272217GT GS

™

-30 • 32 • 46 • 47 iii

Service and Repair Manual March 2021

Introduction

Revision History(continued)

Revision Date Section Procedure / Page / Description

Reference Examples:

Section – Repair Procedure, 4-2

Section – Fault Codes, All charts

Section – Schematics, Legends and schematics

Electronic Version

Click on any content or procedure in the Table of Contents to view

the update.

iv GS

™

-30 • 32 • 46 • 47 Part No. 1272217GT

March 2021 Service and Repair Manual

To August 31, 2016

From September 1, 2016

Introduction

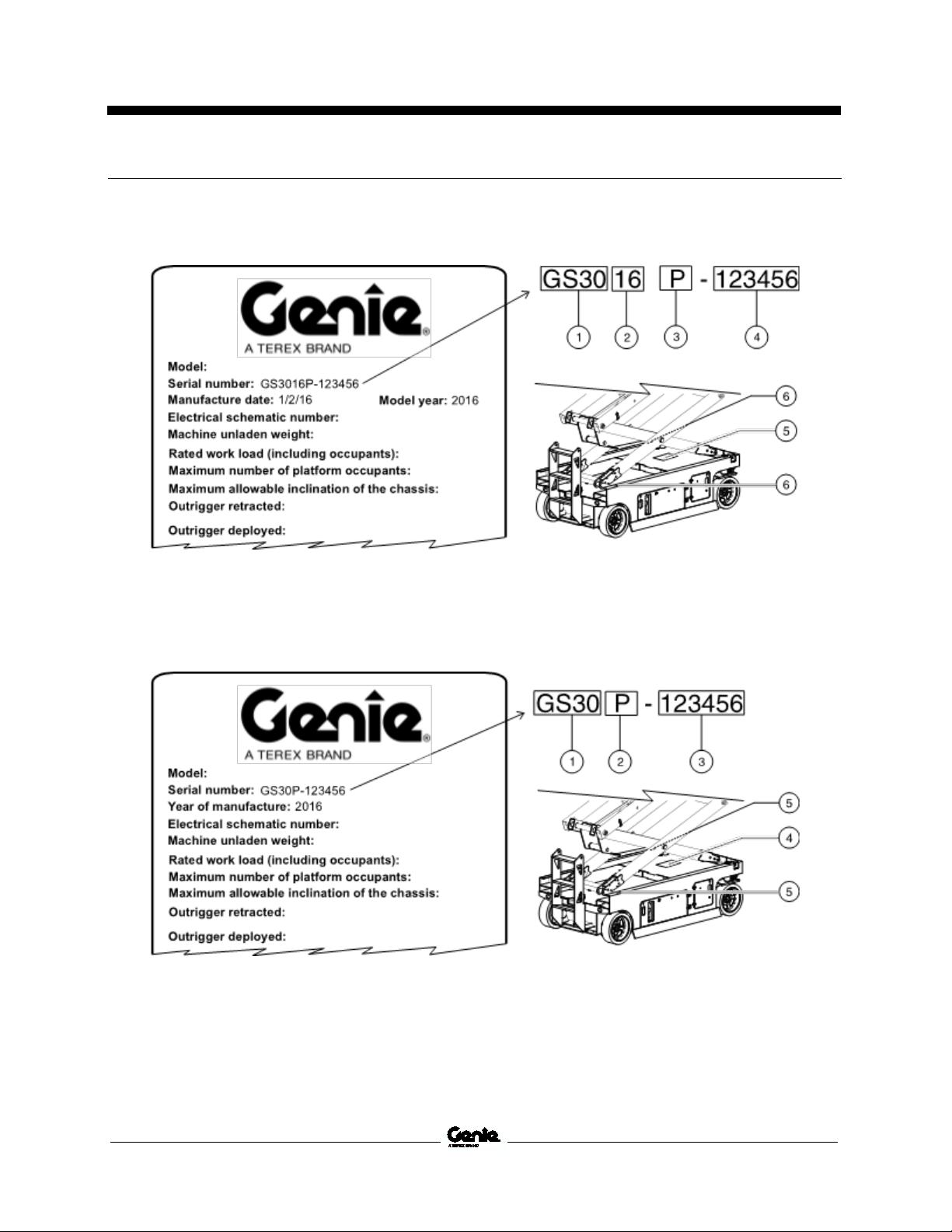

Serial Number Legend

1. Model

2. Model year

3. Facility code

1. Model

2. Facility code

3. Sequence number

4. Sequence number

5. Serial label located on chassis

6. Serial number (stamped on chassis)

4. Serial label located on chassis

5. Serial number (stamped on chassis)

Part No. 1272217GT GS

™

-30 • 32 • 46 • 47 v

Service and Repair Manual March 2021

Safety Rules

Section 1 Safety Rules

Danger

Failure to obey the instructions and safety rules in

this manual and the appropriate Operator's Manual

on your machine will result in death or serious

injury.

Many of the hazards identified in the operator's

manual are also safety hazards when

maintenance and repair procedures are

performed.

Do Not Perform Maintenance

Unless:

You are trained and qualified to perform

maintenance on this machine.

You read, understand and obey:

• manufacturer's instructions and safety rules

• employer's safety rules and worksite

regulations

• applicable governmental regulations

You have the appropriate tools, lifting

equipment and a suitable workshop.

vi GS

™

-30 • 32 • 46 • 47 Part No. 1272217GT

March 2021 Service and Repair Manual

Read each proced

manual and the decals on the machine,

use signal words to identify the following:

Safety alert symbol

alert personnel to potential

personal injury hazards. Obey all

safety messages that follow this

symbol to avoid possible injury or

death.

Indicates a imminently hazardous

situation which, if not avoided,

will result in death or serious

injury.

Indicates a potentially hazardous

situation which, if not avoided,

could result in death or serious

injury.

Indicates a potentially hazardous

situation which, if not avoided,

may cause minor or moderate

injury.

Indicates a potentially hazardous

situation which, if not avoided,

may result in property damage.

Be sure to wear protective eye wear and

other pro

warrants it.

Be aware of potential crushing hazards

such as moving parts, free swinging or

unsecured components when lifting or

placing loads. Always wear approved

steel

Be sure to keep sparks, flames and

lighted tobacco away from flammable and

combustible

and engine

approved fire extinguisher within easy

reach.

Be sure that all tools and working areas

are properly maintained and ready for

use. Keep work surfaces clean and free

of debris that could get

components and cause damage.

Be sure any forklift, overhead crane or

other lifting or supporting device is fully

capable of supporting and stabilizing the

weight to be lifted. Use only chains or

straps that are in good condition and of

ampl

Be sure that fasteners inte

time use (i.e., cotter pins and self-locking

nuts) are not reused. These components

may fail if they are used a second time.

Be sure to properly dispose of old oil or

other fluids. Use an

Please be environmentally safe.

Be sure that your workshop or work area

is properly ventilated and well lit.

Safety Rules

Personal Safety

Any person working on or around a machine must

be aware of all known safety hazards. Personal

safety and the continued safe operation of the

machine should be your top priority.

ure thoroughly. This

—used to

Workplace Safety

Any person working on or around a machine must

be aware of all known safety hazards. Personal

safety and the continued safe operation of the

machine should be your top priority.

e capacity.

materials like battery gases

fuels. Always have an

into machine

nded for one

tective clothing if the situation

-toed shoes.

Part No. 1272217GT GS

approved container.

™

-30 • 32 • 46 • 47 vii

March 2021

Table of Contents

Introduction Introduction .......................................................................................................... ii

Find a Manual for this Model ................................................................................... ii

Serial Number Range ............................................................................................. ii

Revision History ..................................................................................................... iii

Serial Number Legend ........................................................................................... v

Section 1 Safety Rules ......................................................................................................... vi

General Safety Rules ............................................................................................. vi

Section 2 Specifications ....................................................................................................... 1

Machine Specifications .......................................................................................... 1

Performance Specifications (models without proportional lift function) ................. 3

Performance Specifications (models with proportional lift) .................................... 5

Hydraulic Oil Specifications ................................................................................... 7

Hydraulic Component Specifications ................................................................... 10

Manifold Component Specifications..................................................................... 11

Hydraulic Hose and Fitting Torque Specifications ............................................... 12

Torque Procedure ................................................................................................ 13

viii GS

™

-30 • 32 • 46 • 47 Part No. 1272217GT

March 2021

Table of Contents

Section 3 Repair Procedures ............................................................................................. 15

Introduction ........................................................................................................... 15

Platform Controls ............................................................................................... 17

1-1 Circuit Board................................................................................................... 19

1-2 Joystick ........................................................................................................... 20

1-3 Platfrom Controls Alarm ................................................................................. 20

1-4 Platform Emergency Stop Button ................................................................... 21

Ground Controls ................................................................................................. 22

2-1 Software Revision Level ................................................................................. 23

2-2 Machine Setup ............................................................................................... 24

2-3 Loading or Updating Machine Software ......................................................... 25

2-4 Using a Wi-Fi Router to Connect to the SmartLink Web Service Tool .......... 30

2-5 Service Override Mode .................................................................................. 32

2-6 Level Sensors ................................................................................................ 34

2-7 Manual Platform Lowering Cable ................................................................... 49

2-8 Outrigger Calibration ...................................................................................... 50

Hydraulic Tank .................................................................................................... 51

3-1 Hydraulic Tank ............................................................................................... 51

Hydraulic Pump .................................................................................................. 52

4-1 Hydraulic Pump .............................................................................................. 52

How to Remove the Hydraulic Pump .............................................................. 53

Part No. 1272217GT GS

™

-30 • 32 • 46 • 47 ix

March 2021

Table of Contents

Manifolds ............................................................................................................ 54

5-1 Function Manifold Components – GS-1530, GS-1532,

GS-1930 and GS-1932 ................................................................................ 54

5-2 Function Manifold Components – GS-2032, GS-2632, GS-3232,

GS-2046, GS-2646 and GS-3246 ................................................................ 56

5-3 Function Manifold Components – GS-4047 .................................................. 58

5-4 Check Valve Manifold Components – GS-1530, GS-1532,

GS-1930 and GS-1932 ................................................................................ 60

5-5 Lift Pressure Selector Manifold Components – GS-4047 .............................. 61

5-6 Outrigger Function Manifold Components – GS-3232 .................................. 62

5-7 Outrigger Cylinder Manifold Components – GS-3232 ................................... 63

5-8 Valve Adjustments – Function Manifold ........................................................ 64

5-9 Valve Coils ..................................................................................................... 70

Steer Axle Components .................................................................................... 72

6-1 Yoke and Drive Motor .................................................................................... 72

6-2 Steer Cylinder ................................................................................................ 73

6-3 Steer Bellcrank .............................................................................................. 74

Non-Steer Axle Components ............................................................................ 75

7-1 Drive Brake .................................................................................................... 75

Brake Release Hand Pump Components ........................................................ 76

8-1 Brake Release Hand Pump Components ...................................................... 76

x GS

™

-30 • 32 • 46 • 47 Part No. 1272217GT

March 2021

Table of Contents

Scissor Components ......................................................................................... 77

9-1 Scissor Assembly, GS-1530 and GS-1532 .................................................... 78

9-2 Scissor Assembly, GS-1930 and GS-1932 .................................................... 84

9-3 Scissor Assembly, GS-2032 and GS-2046 .................................................... 92

9-4 Scissor Assembly, GS-2632 and GS-2646 .................................................... 99

9-5 Scissor Assembly, GS-3232 and GS-3246 .................................................. 107

9-6 Scissor Assembly, GS-4047 ........................................................................ 116

9-7 Scissor Arm Wear Pads ............................................................................... 124

9-8 Platform Height Sensor ................................................................................ 126

9-9 Lift Cylinder .................................................................................................. 128

9-10 Pressure Transducer .................................................................................. 139

9-11 Platform Overload System ......................................................................... 141

9-12 Platform Overload Recovery ...................................................................... 146

Platform Components ...................................................................................... 148

10-1 Platform ...................................................................................................... 148

10-2 Platform Extension Deck ............................................................................ 149

Battery Charger ................................................................................................ 150

11-1 Battery Charger .......................................................................................... 150

Selecting a Charge Profile ............................................................................ 151

Part No. 1272217GT GS

™

-30 • 32 • 46 • 47 xi

March 2021

Table of Contents

Section 4 Diagnostics ....................................................................................................... 152

Introduction ........................................................................................................ 152

GCON I/O Map without Load Sense (all machines except GS-3232) ............... 155

GCON I/O Map with Load Sense (all machines except GS-3232) .................... 156

GCON I/O Map without Load Sense GS-3232 only) ......................................... 157

GCON I/O Map with Load Sense (GS-3232 only) ............................................. 159

Operation Indicator Codes (OIC) ....................................................................... 161

Diagnostic Trouble Codes (DTC) ....................................................................... 162

Troubleshooting "HXXX" and "PXXX" Faults ..................................................... 163

Fault Inspection Procedure ................................................................................ 164

Type "HXXX" Faults ........................................................................................... 166

Type "PXXX" Faults ........................................................................................... 170

Type "UXXX" Faults ........................................................................................... 171

Type "FXXX" Faults ........................................................................................... 174

Type "CXXX" Faults ........................................................................................... 177

Battery Charger .................................................................................................. 179

Charger Fault Codes .................................................................................... 180

Charger Error Codes .................................................................................... 181

xii GS

™

-30 • 32 • 46 • 47 Part No. 1272217GT

March 2021

Table of Contents

Section 5 Schematics ........................................................................................................ 185

Introduction ......................................................................................................... 185

Electrical Component and Wire Color Legends ................................................. 186

Wiring Diagram Ground and Platform Controls .................................................. 189

Limit Switch Legend ........................................................................................... 190

Electrical Symbol Legend ................................................................................... 191

Hydraulic Symbols Legend ................................................................................. 192

Hydraulic Component Abbreviation Legend ....................................................... 193

Hydraulic Schematics ...................................................................................... 195

Hydraulic Schematic, GS-1530, 1532, 1930, 1932 (from serial number GS3010A-

110000, GS3011C-10000, GS3014D-101, GS3016P-142281) ................. 195

Hydraulic Schematic, GS-2032, 2632, 3232, 2046, 2646, 3246 (from serial

number GS3211A-110000 to GS3214A-119070, GS3212C-10000 to

GS3214C-11873, GS4612A-110000 to GS4614A-117177,

GS4614C-10000 to GS4614C-12073) ....................................................... 196

Hydraulic Schematic, GS-2032, 2632, 3232, 2046, 2646, 3246 (from serial

number GS3214A-119071, GS3214C-11874, GS4614A-117178,

GS4614C-12074, GS4614D-101) .............................................................. 197

Hydraulic Schematic, GS-3232 (from serial number GS3211A-110000,

GS3212C-10000, GS3216P-142677) ........................................................ 198

Hydraulic Schematic, GS-4047 (from serial number GS4712C-101

to GS4714C-1459) ..................................................................................... 199

Hydraulic Schematic, GS-4047 (from serial number GS4714C-1460,

GS4714D-101, GS4716P-101) ................................................................... 200

Part No. 1272217GT GS

™

-30 • 32 • 46 • 47 xiii

March 2021

Table of Contents

Electrical Schematics – ANSI / CSA Models ................................................. 201

Electrical Schematic GS-1530 / GS-1930, ANS / CSA (from serial number

GS3010A-110000 to GS3011A-110827) ................................................... 202

Electrical Schematic, GS-1530 / GS-1930, ANSI / CSA (from serial number

GS3011A-110828 to GS3014A-136972,

GS3014D-101 to GS3015D-1113) ............................................................. 206

Electrical Schematic, GS-1530 / GS-1930, ANSI / CSA (from serial number

GS3014A-136973, GS3015D-1114 to GS3016D-5426,

GS3016P-142281 to GS3016P-158208) ................................................... 210

Electrical Schematic, GS-1530/1930, ANSI/CSA (from serial number

GS3016D-5427, GS3016P-158209) .......................................................... 214

Electrical Schematic, GS-3232, ANSI / CSA (from serial number

GS3211A-110000 to GS3214A-135714) ................................................... 216

Electrical Schematic, GS-3232, ANSI / CSA (from serial number

GS3214A-135715 to GS3215A-141898) ................................................... 220

Electrical Schematic, GS-3232, ANSI / CSA (from serial number

GS3215A-141899, GS3216P-142677 to GS3216P-146462) .................... 224

Electrical Schematic, GS-3232, ANSI / CSA (from serial number

GS3216P-146463) ..................................................................................... 228

Electrical Schematic, GS-2032, 2632, 2046, 2646, ANSI / CSA (from serial

number GS3211A-110000 to GS3214A-135714, GS4612A-110000 to

GS4614A-135366, GS4613D-101 to GS4615D-1303) .............................. 232

Electrical Schematic, GS-2032, 2632, 2046, 2646, ANSI/CSA (from serial number

GS3214A-1135715 to GS3215A-141898, GS4614A-135367 to

GS4615A-137959, GS4615D-1304) .......................................................... 236

Electrical Schematic, GS-2032, 2632, 2046, 2646, ANSI / CSA (from serial

number GS3215A-141899, GS3216P-142676 to GS3216P-146462,

GS4615A-137960, GS4615D-1305 to GS4616D-4432,

GS4616P-138362 to GS4616P-139710) ................................................... 240

xiv GS

™

-30 • 32 • 46 • 47 Part No. 1272217GT

March 2021

Table of Contents

Electrical Schematic, GS-2032, 2632, 2046, 2646, ANSI / CSA (from serial

number GS3216P-146463, GS4616D-4433, GS4616P-139711) .............. 244

Electrical Schematic, GS-3246 / GS-4047, ANSI / CSA (from serial number

GS4612A-110000 to GS4614A-135366, GS4614D-101 to

GS4615D-1303, GS4714D-101 to GS4715D-749) .................................... 246

Electrical Schematic, GS-3246 / GS-4047, ANSI / CSA (from serial number

GS4614A-135367 to GS4615A-137959, GS4615D-1304 to GS4616D-4432,

GS4616P-138362 to GS4616P-139710,

GS4715D-750 to GS4716D-3101) ............................................................. 250

Electrical Schematic, GS-3246, GS4047 ANSI / CSA (from serial number

GS4616D-4433, GS4616P-139711, GS4716D-3102, GS4716P-101) ...... 254

Electrical Schematics – CE and Australia Models ........................................ 255

Electrical Schematic GS-1530, 1532, 1930, 1932, AS / CE (from serial number

GS3010A-110000 to GS3011A-110827) .................................................... 256

Electrical Schematic, GS-1530/32_GS-1930/32, AS / CE (from serial number

GS3011A-110828 to GS3014A-136972, GS3011C-10000 to GS3015C-

18038, GS3014D-101 to GS3015D-1113) ................................................. 260

Electrical Schematic, GS-1530, 1532, 1930, 1932, AS / CE (from serial number

GS3014A-136973, GS3015C-18039, GS3015D-1114 to GS3016D-5426,

GS3016P-142281 to GS3016P-158208) .................................................... 264

Electrical Schematic, GS-1530, 1532, 1930, 1932, AS / CE (from serial numbers

GS3015D-5427, GS3016P-158209) .......................................................... 268

Electrical Schematic, GS-3232, AS / CE (from serial number GS3211A-110000 to

GS3214A-135714, GS3212C-10000 to GS3215C-14503) ........................ 270

Electrical Schematic, GS-3232, AS / CE (from serial number GS3214A-135715 to

GS3215A-141898, GS3215C-14504) ........................................................ 274

Electrical Schematic, GS-3232, AS / CE (from serial number GS3215A-141899,

GS3216P-142676 to GS3216P-146462) .................................................... 278

Electrical Schematic, GS-3232, AS / CE

(from serial number GS3216P-146463) ..................................................... 282

Electrical Schematic, GS-2032, 2632, 2046, 2646, AS / CE (from serial number

GS3211A-110000 to GS3214A-135714, GS3212C-10000 to GS3215C14377, GS4612A-110000 to GS4614A-135366, GS4612C-10000 to

GS4615C-14503, GS4613D-101 to GS4615D-1303) ................................ 286

Part No. 1272217GT GS

™

-30 • 32 • 46 • 47 xv

March 2021

Table of Contents

Electrical Schematic, GS-2032, 2632, 2046, 2646, AS / CE (from serial number

GS3214A-135715 to GS3215A-141898, GS3215C-14378, GS4614A-

135367 to GS4615A-137959, GS4615C-14504, GS4615D-1304) ............ 290

Electrical Schematic, GS-2032, 2632, 2046, 2646, AS / CE (from serial number

GS3215A-141899, GS3216P-142676 to GS3216P-146462, GS4615A-

137960, GS4616P-138362 to GS4616P-139710) ..................................... 294

Electrical Schematic, GS-2032, 2632, 2046, 2646, AS / CE (from serial number

GS3216P-146463, GS4616P-139711) ...................................................... 298

Electrical Schematic, GS-3246, AS / CE (from serial number GS4612A-110000 to

GS4614A-135366, GS4612C-10000 to GS4615C-14503, GS4614D-101 to

GS4615D-1303) ......................................................................................... 300

Electrical Schematic, GS-3246, AS / CE (from serial number GS4614A-135367 to

GS4615A-137959, GS4615C-14504, GS4615D-1304) ............................. 304

Electrical Schematic, GS-3246, AS / CE (from serial number GS4615A-137960,

GS4616P-138362, GS4616P to GS4616P-139710).................................. 308

Electrical Schematic, GS-3246, AS / CE (from serial number GS4616D-4433,

GS4616P-139711) ..................................................................................... 312

Electrical Schematic, GS-4047, AS / CE (from serial number GS4712C-101 to

GS4715C-2130, GS4714D-101 to GS4715D-749) .................................... 314

Electrical Schematic, GS-4047, AS / CE (from serial number GS4715C-2131,

GS4715D-750 to GS4716D-3101) ............................................................. 318

Electrical Schematic, GS-4047, AS / CE

(from serial number GS4716D-3102) ......................................................... 322

Electrical Schematic – Foot Switch (option) All Models .............................. 323

Foot Switch (option) All Models ......................................................................... 324

xvi GS

™

-30 • 32 • 46 • 47 Part No. 1272217GT

March 2021 Service and Repair Manual

Batteries, Standard

All models except GS

Voltage 6V DC

Group

GC2

Type

105

Quantity

4

Battery capacity, maximum

C20 = 225AH

Reserve capacity @ 25A rate

inutes

Weight, each

lbs

kg

Batteries, Standard, GS

Voltage 12V DC

Group

GC2

Type

1275

Quantity

4

Battery capacity, maximum

C20 = 150AH

Reserve

inutes

Weight, each

bs

g

Batteries, Maintenance

All models except GS

Voltage

DC

GC2

Type

AGM

Quantity

4

Battery capacity, maximum

200AH

Reserve capacity @ 25A rat

inutes

Weight, each

lbs

kg

(if equipped) All models except GS-3232, GS-4047

Input voltage

o 30 VDC

Signal voltage

o 5 V

Platform Overload Pressure Transducer

(if equipped) GS

Input

o 30 VDC

Signal voltage

o 6.25 V

Angle Sensor (if equipped)

Input voltage

o 30 VDC

Signal voltage

o 4 V, PMW output

Outrigger Pressure Transducer, GS-3232 only

Input voltage

o 30 VDC

Signal voltage

o 5 V

Fluid capacities

Hydraulic tank

All models except GS

allons

iters

allons

iters

Hydraulic system (including tank) GS

1530, GS

allons

iters

allons

iters

Hydraulic system (including tank) GS

3232, GS

allons

iters

Hydraulic system (including tank) GS

4047

allons

iters

Specifications

Section 2 Specifications

Machine Specifications

Platform Overload Pressure Transducer

For operational specifications, refer to the

Operator's Manual.

-4047

T-

447 m

-4047

T-

capacity @ 25A rate 280 m

82 l

-free (option)

-4047

6V

Group

6V-

e 380 m

62

62

28

37 k

28

8 t

1 t

-3232, GS-4047

voltage 8 t

0.25 t

8 t

3 t

8 t

1 t

-4047

3.4 g

12.9 l

Hydraulic tank, GS-4047 5.9 g

22.4 l

-

-1532, GS-1930, GS-1932

Hydraulic system (including tank) GS-

3.8 g

14.2 l

4.5 g

2032, GS-2632, GS-2046, GS-2646

-

-3246

-

5.5 g

20.8 l

7.5 g

28.4 l

17 l

Part No. 1272217GT GS

™

-30 • 32 • 46 • 47 1

Service and Repair Manual March 2021

Tires and wheels

GS

Ti

in

cm

Tire contact area

q in

2

Castle nut torque, dry

lbs

406.7 Nm

Castle nut torque, lubricated

lbs

305 Nm

GS

3246, GS-4047

Tire size (soli

n

m

Tire contact area

q in

2

Castle nut torque, dry

lbs

406.7 Nm

Castle nut torque, lubricated

lbs

305 Nm

Specifications

-1530, GS-1532, GS-1930, GS-1932

re size (solid rubber) 12 x 4.5

30.5 x 11.4

9 s

58 cm

300 ft-

225 ft-

-2032, GS-2632, GS-3232, GS-2046, GS-2646, GS-

d rubber)

15 x 5 i

38.1 x 12.7 c

15 s

96.7 cm

300 ft-

225 ft-

2 GS

™

-30 • 32 • 46 • 47 Part No. 1272217GT

March 2021 Service and Repair Manual

Drive speed, maximum

GS

Platform stowed, fast

ph

ec

m/h

ec

Platform raised

ph

ec

m/h

ec

GS

3246

Platform stowed, fast

t

GS3216P

GS4616P

ph

ec

m/h

ec

Platform stowed, fast

from serial

GS3216P

GS4616P

ph

ec

m/h

ec

Platform raised

ph

ec

m/h

ec

GS-4047

Platform stowed, fast

ph

ec

m/h

ec

Platform raised

ph

ec

m/h

ec

Braking

High range on paved surface

t

m

Gradeability

GS

3232, GS

25%

GS

GS

30%

Airborne noise emissions

Sound pressure level at ground

work

BA

Sound pressure level at platform

workstation

BA

Specifications

Performance Specifications

(models without proportional lift)

-1530, GS-1532, GS-1930, GS-1932

12.2 m / 10.9 s

-2032, GS-2632, GS-3232, GS-2046, GS-2646, GS-

o serial number:

-145830

-139575

12.2 m / 12.4 s

number:

-145831

-139576

12.2 m / 12.4 s

0.5 m

2.5 m

40 ft / 10.9 s

4 k

0.5 m

40 ft / 55 s

0.8 k

12.2 m / 55 s

2.2 m

40 ft / 12.4 s

3.5 k

2.0 m

40 ft / 12.4 s

3.2 k

40 ft / 55 s

0.8 k

12.2 m / 55 s

2.0 m

40 ft / 13.6 s

3.2 k

12.2 m / 13.6 s

0.5 m

40 ft / 55 s

0.8 k

12.2 m / 55 s

distance, maximum

1 - 3 f

0.3 - 0.9

-1930, GS-1932, GS-2632,GS-

-3246 and GS-4047

-1530, GS-1532, GS-2032,

-2046 and GS-2646

< 70 d

station

< 70 d

Part No. 1272217GT GS

™

-30 • 32 • 46 • 47 3

Service and Repair Manual March 2021

Function speed, maximum from platform controls

(with

GS-1530 and GS-1532

Platform up (fast

Platform up (slow mode)

Platform down

econds

econds

econds

GS-1930 and GS-1932

Platform up (fast

Platform up (slow mode)

Platform down

econds

econds

econds

GS-2032 and GS-2632

Plat

Platform up (slow mode)

Platform down

econds

econds

econds

GS-2046 and GS-2646

Platform up (fast mode)

Platform up (slow mode)

Platform down

econds

econds

econds

GS

Platform up (fast mode)

Platform up (slow mode)

Platform down

econds

econds

econds

GS-4047

Platform up (fast mode)

Platform up (slow mode)

Platform down

econds

econds

econds

Rate

GS

600 lbs

kg

GS

263

lbs

kg

GS

bs

g

GS

bs

g

GS

bs

g

GS

bs

g

GS

(CE and AS models)

bs

g

GS

(ANSI and CSA models)

bs

g

GS-3232 Outrigger leveling capacity, maximum

Side to side

Front to rear

5°

3°

Specifications

Performance Specifications

(without proportional lift), continued

1 person in platform)

form up (fast mode)

-3232 and GS-3246

mode)

mode)

15 to 17 s

30 to 32 s

28 to 30 s

15 to 17 s

30 to 32 s

28 to 30 s

28 to 32 s

58 to 62 s

32 to 36 s

28 to 32 s

58 to 62 s

32 to 36 s

55 to 59 s

108 to 112 s

33 to 37 s

d work load at full height, maximum

-1530 and GS-1532

-1930, GS-1932, GS2 and GS-3232

-2032

-2046

-2646

-3246

-4047

-4047

71 to 76 s

83 to 87 s

41 to 46 s

272

500

227

800 l

363 k

1200 l

544 k

1000 l

454 k

700 l

317 k

770 l

350 k

550 l

250 k

4 GS

™

-30 • 32 • 46 • 47 Part No. 1272217GT

March 2021 Service and Repair Manual

Drive speed, maximum

GS

Platform stowed

ph

ec

m/h

ec

Platform raised

ph

ec

m/h

ec

GS

3246

Platform s

t

GS3216P

GS4616P

ph

ec

m/h

ec

Platform stowed

from serial number

GS3216P

GS4616P

ph

ec

m/h

ec

Platform raised

ph

ec

m/h

ec

GS-4047

Platform stowed

ph

ec

m/h

ec

Platform raised

ph

ec

m/h

ec

Braking distance, maximum

High range on paved surface

t

m

Gradeability

GS

GS

GS

25%

GS

2046, GS

30%

Airborne noise emissions

Sound pressure level at ground

workstation

BA

Sound pressure level at platform

workstation

BA

Specifications

Performance Specifications (models with proportional lift)

-1530, GS-1532, GS-1930, GS-1932

12.2 m / 10,9 s

-2032, GS-2632, GS-3232, GS-2046, GS-2646, GS-

towed

o serial number:

-145830

-139575

:

-145831

-139576

0.5 m

12.2 m / 12,4 s

12.2 m / 12,4 s

2.5 m

40 ft / 10.9 s

0.5 m

40 ft / 55 s

0,8 k

12.2 m / 55 s

2.2 m

40 ft / 12.4 s

3,5 k

2.0 m

40 ft / 12.4 s

3,2 k

40 ft / 55 s

0,8 k

12.2 m / 55 s

4 k

2.0 m

40 ft / 13.6 s

3,2 k

12.2 m / 13,6 s

0.5 m

40 ft / 55 s

0,8 k

12.2 m / 55 s

1 - 3 f

0,3 - 0,9

-1930, GS-1932,

-2632, GS-3232, GS-3246,

-4047

-1530, GS-1532, GS-2032, GS-

-2646

< 70 d

< 70 d

Part No. 1272217GT GS

™

-30 • 32 • 46 • 47 5

Service and Repair Manual March 2021

Function speed, maximum from platform controls

(with

GS-1530, GS-1532

econds

econds

GS-1930, 1930PAR, GS-1932

econds

econds

GS

econds

econds

GS-2046, GS-2646

econds

econds

GS

econds

econds

GS-4047

econds

econds

Rated work load at full height, maximum

GS

lbs

kg

GS

2632, GS

lbs

kg

bs

g

GS

bs

g

bs

g

bs

g

GS

bs

g

GS

(CE and AS models)

bs

g

GS-3232 Outrigger leveling capacity, maximum

Side to side

Front to rear

5°

3°

Specifications

Performance Specifications

(with proportional lift), continued

1 person in platform)

Platform up

Platform down

Platform up

Platform down

-2032, GS-2632

Platform up

Platform down

Platform up

Platform down

-3232, GS-3246

Platform up

Platform down

Platform up

Platform down

15 to 17 s

18 to 25 s

15 to 17 s

18 to 25 s

28 to 32 s

24 to 28 s

28 to 32 s

28 to 32 s

55 to 59 s

28 to 32 s

71 to 76 s

41 to 46 s

-1530, GS-1532 600

272

-1930, GS-1932, GS-

-3232

500

227

GS-1930PAR 400 l

181 k

-2032 800 l

363 k

GS-2046 1200 l

544 k

GS-2646 1000 l

454 k

-3246 700 l

317 k

-4047

770 l

350 k

6 GS

™

-30 • 32 • 46 • 47 Part No. 1272217GT

March 2021 Service and Repair Manual

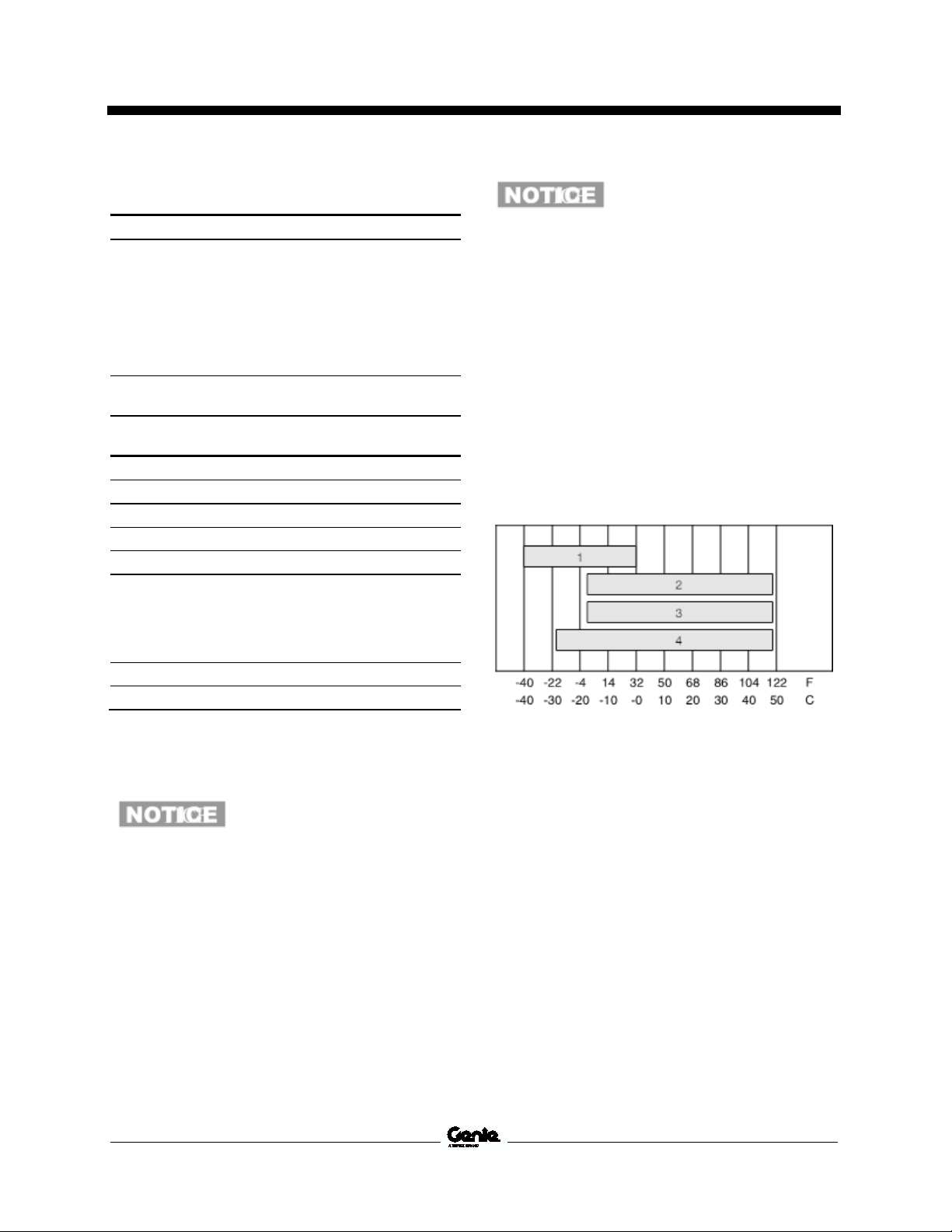

Hydraulic Fluid Specifications

Genie specifications require hydraulic oils which are

designed to give maximum protection to hydraulic

systems, have the ability to perform over a wide

temperature range, and the viscosity index s

exceed 140. They should provide excellent antiwear,

oxidation prevention, corrosion inhibition, seal

conditioning, and foam and aeration suppression

properties.

Cleanliness level,

minimum

ISO 15/13

Water content,

maximum

pm

Recommended Hydraulic Fluid

Hydraulic oil type

Chevron Rando HD Premium

Viscosity grade

32

Viscosity index

200

Optional Hydraulic Fluids

Mineral based

Shell Tellus S2 V 32

Shell Tellus S2 V 46

Shell Tellus S4 VX 32

Shell Donax TG (Dexron III)

Chevron 5606A

Biodegradab

46

Fire resistant

5046

Optional flui

the same hydraulic lifespan and

may result in component

damage.

Do not top off with incompatible

hydraulic fluids. Hydraulic fluids

may be incompatible due to the

differences in base additive

chemistry. When incompatible

fluids are mixed,

materials may form and deposit

in the hydraulic system,

plugging hydraulic lines, filters,

control valves and may result in

component damage.

Specifications

Hydraulic Oil Specifications

hould

250 p

insoluble

Note: Do not operate the machine when the

ambient air temperature is consistently above

120°F / 49°C.

Hydraulic Fluid Temperature

Range

le Petro Canada Environ MV

UCON Hydrolube HP-

Note: Genie specifications require additional

equipment and special installation instructions for

the approved optional fluids. Consult Genie

Product Support before use.

Note: Extended machine operation can cause the

hydraulic fluid temperature to increase beyond its

maximum allowable range. If the hydraulic fluid

temperature consistently exceeds 200°F / 90°C an

optional oil cooler may be required.

Part No. 1272217GT GS

ds may not have

™

Ambient air temperature

1 Chevron hydraulic oil 5606A

2 Petro-Canada Environ MV 46

3 UCON Hydrolube HP-5046D

4 Chevron Rando HD premium oil MV

-30 • 32 • 46 • 47 7

Service and Repair Manual March 2021

ISO Grade

32

Viscosity index 200

Kinematic Viscosity

cSt @ 200°F / 100°C

cSt @ 104°F / 40°C

7.5

33.5

Brookfield Viscosity

cP @

cP @

1040

3310

Flash point 375°F / 190°C

Pour point

50°C

Maximum continuous operating

temperature

171°F / 77°C

ISO Grade

15

Viscosity index 300

Kinematic Viscosity

cSt @ 200°F / 100°C

cSt @ 104°F / 40°C

cSt @

5.5

15.0

510

Flash point 180°F / 82°C

Pour point

63°C

Maximum continuous

temperature

124°F / 51°C

Continued use of Chevron

5606A

equivalent, when ambient

temperatures are consistently

above

component damage

Specifications

Chevron Rando HD Premium Oil

MV Fluid Properties

Chevron 5606A Hydraulic Oil

Fluid Properties

-4°F / -20°C

-22°F / -30°C

-58°F / -

Note: A hydraulic oil heating system is

recommended when the ambient temperature is

consistently below 0°F / -18°C.

Note: Do not operate the machine when the

ambient temperature is below -20°F / -29°C with

Rando HD Premium MV.

-40°F / -40°C

-81°F / -

operating

Note: Use of Chevron 5606A hydraulic fluid, or

equivalent, is required when ambient temperatures

are consistently below 0°F / -17°C unless an oil

heating system is used.

hydraulic fluid, or

32°F / 0°C may result in

8 GS

™

-30 • 32 • 46 • 47 Part No. 1272217GT

March 2021 Service and Repair Manual

ISO Grade

46

Viscosity index 154

Kinematic Viscosity

cSt @ 200°F / 100°C

cSt @

8.0

44.4

Flash point 482°F / 250°C

Pour point

45°C

Maximum c

temperature

180°F / 82°C

ISO Grade

32

Viscosity index 300

Kinematic Viscosity

cSt @ 200°F / 100°C

cSt @

9

33.8

Brookfield Viscosity

cSt @

cSt @

cSt @

481

702.4

2624

Flash point >100

Pour point

60°C

Maximum continuous operating

temperature

103°F / 75°C

ISO Grade

46

Viscosity index 192

Kinematic Viscosity

cSt @ 149°F / 65°C

cSt @ 104°F / 4

cSt @ 0°F /

22

46

1300

Flash point None

Pour point

63°C

Maximum continuous operating

temperature

189°F / 87°C

Specifications

Petro-Canada Environ MV 46

Fluid Properties

UCON Hydrolube HP-5046 Fluid

Properties

104°F / 40°C

-49°F / -

ontinuous operating

Shell Tellus S4 VX Fluid

Properties

104°F / 40°C

-4°F / -20°C

-13°F / -25°C

-40°F / -40°C

-76°F / -

0°C

-18°C

-81°F / -

Part No. 1272217GT GS

™

-30 • 32 • 46 • 47 9

Service and Repair Manual March 2021

Function Pump

1932

Type

Gear

Displacement per revolution

u in

c

Flow rate @ 250

pm

11,3 L/min

Hydraulic tank return filter

10 micron

ar

bypass

Function Pump

2046, GS

Type

Gear

Displacement per revolution

u in

c

Flow rate @ 250

pm

15 L/min

Hydraulic tank return filter

icron

ar

bypass

Function manifold

System relief valve pressure,

maximum

si

ar

Lift relief valve pressure

si

ar

Steer relief valve pressure

si

ar

Function manifold

System relief valve pressure,

maximum

si

ar

Platform relief valve pressure

si

ar

St

si

ar

Outrigger manifold

Relief valve pressure, maximum

si

Check valve manifold

GS

Check valve pressure, maximum

si

Lift pressure selector manifold - GS-4047

Platform relief valve pressure,

maximum

si

Specifications

Hydraulic Component Specifications

– GS-1530, GS1532, GS-1930, GS-

0 psi / 172 bar

– GS-2032, GS-2632, GS-3232, GS-

-2646, GS-3246, GS-4047

0.355 c

0 psi / 172 bar 4 g

10 m

0.244 c

3 g

25 psi / 1.7 b

5,5 c

25 psi / 1,7 b

4 c

-

-1530, GS-1532, GS-1930. GS-1932

3500 p

241 bar

200 p

13,8 bar

2000 p

138 bar

– All models except GS-4047

3700 p

255 b

1800 to 3700 p

142 to 241 b

1500 p

103 b

– GS-4047

3500 p

241 b

3000 p

206 b

eer relief valve pressure 1500 p

103 b

10 GS

™

-30 • 32 • 46 • 47 Part No. 1272217GT

March 2021 Service and Repair Manual

Plug torque

SAE No. 2

lbs / 6 Nm

SAE No. 4

lbs / 18 Nm

SAE No. 6

lbs / 24 Nm

SAE No. 8

/ 68 Nm

SAE No. 10

lbs / 75 Nm

SAE No. 12

lbs / 102 Nm

Valve coil resistance

Note: The following coil resistance specifications are at

an ambient temperature of 68°F / 20°C. As valve coil

resistance is sensitive to change in air tempera

coil resistance will typically increase or decrease by 4%

of each 18°F /

increases or decreases from 68°F / 20°C.

Description

Specification

Solenoid valve,

20V DC with diode

(schematic items F,

Ω

Solenoid valve,

20V DC with diode

(schematic item E)

Ω

Solenoid valve,

20V DC with diode

(schematic items H, AI or DI)

Ω

Solenoid valve,

N.C. 20V DC with diode

(schematic item N)

Ω

Solen

20V DC with diode

(schematic item AE or DE)

Ω

Solenoid valve,

20V DC with diode

(schematic item AG or DG)

Ω

Solenoid valve,

20V DC with diode

(schematic items CA, CB, CC and

CD)

Ω

Solenoid valve,

20V DC

(schematic item BA)

Ω

Solenoid valve,

20V DC with diode

(schematic item DN)

Ω

Solenoid valve,

24V DC with diode

(schematic item EA)

Ω

Solenoid valve,

24V DC with diode

(schematic

Ω

Solenoid valve,

20V DC with diode

(schematic item GC)

Ω

Solenoid valve,

20V DC with diode

(schematic item GA)

Ω

Specifications

Manifold Component Specifications

50 in-

13 ft-

18 ft-

50 ft-lbs

55 ft-

75 ft-

-7.7°C that your air temperature

3 position 4 way,

AC or DC)

3 position 4 way,

2 position 4 way,

2 position 2 way,

oid valve, 2 position 4 way,

3 position 5 way,

2 position 2 way,

ture, the

27.2

19

19

25

19

19

27.2

Part No. 1272217GT GS

3 position 4 way,

with diode

2 position 2 way,

23.9

3 position 4 way

33.75

2 position 4 way

33.75

item EC)

2 position 4 way,

3 position 4 way,

™

-30 • 32 • 46 • 47 11

19

24

24

Service and Repair Manual March 2021

SAE Dash Size

Torque

SAE Dash Size

Torque

Specifications

Hydraulic Hose and Fitting Torque Specifications

Your machine is equipped with Parker Seal-Lok™

ORFS or 37° JIC fittings and hose ends. Genie

specifications require that fittings and hose ends

be torqued to specification when they are removed

and installed or when new hoses or fittings are

installed.

Seal-Lok™ Fittings

(hose end - ORFS)

-4 18 ft-lbs / 25 Nm

-6 30 ft-lbs / 41 Nm

-8 40 ft-lbs / 55 Nm

-10 60 ft-lbs / 81 Nm

-12 85 ft-lbs / 115 Nm

-16 110 ft-lbs / 150 Nm

-20 150 ft-lbs / 205 Nm

-24 230 ft-lbs / 315 Nm

SAE O-ring Boss Port

(tube fitting - installed into Aluminum)

(all types)

SAE Dash Size Torque

-4 14 ft-lbs / 19 Nm

-6 23 ft-lbs / 31,2 Nm

-8 36 ft-lbs / 49 Nm

-10 62 ft-lbs / 84 Nm

-12 84 ft-lbs / 114 Nm

-16 125 ft-lbs / 169,5 Nm

-20 151 ft-lbs / 204,7 Nm

-24 184 ft-lbs / 249,5 Nm

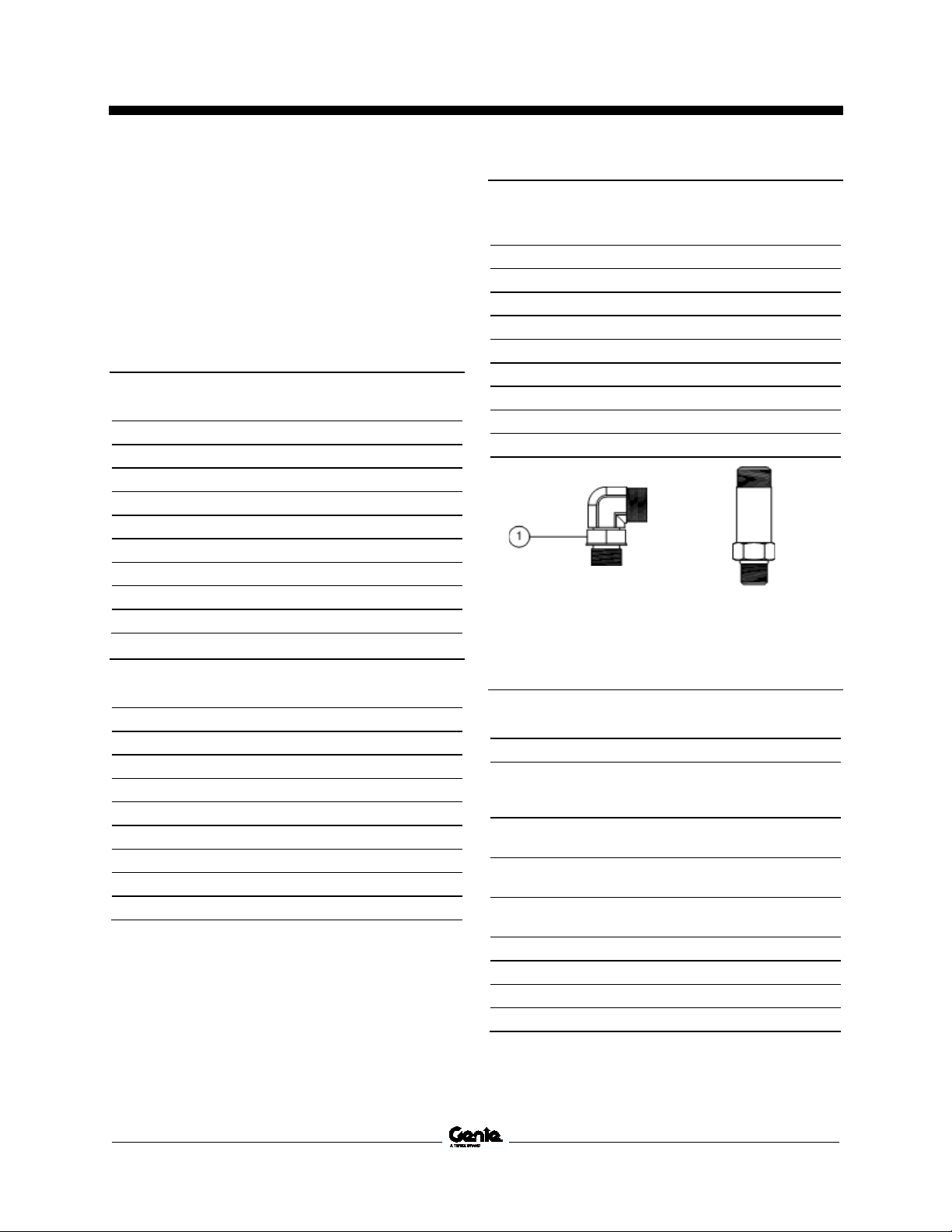

Adjustable Fitting Non-adjustable fitting

1 jam nut

JIC 37° Fittings

(swivel nut or hose connection)

SAE Dash Size Thread Size Flats

-4 7/16-20 2

-6 9/16-18 1 1/2

-8 3/4-16 1 1/2

-10 7/8-14 1 1/2

-12 1 1/16-12 1 1/4

-16 1 5/16-12 1

-20 1 5/8-12 1

-24 1 7/8-12 1

SAE O-ring Boss Port

(tube fitting - installed into Steel)

-4 ORFS / 37° (Adj)

ORFS (Non-adj)

37° (Non-adj)

-6 ORFS (Adj / Non-adj)

37° (Adj / Non-adj)

-8 ORFS (Adj / Non-adj)

37° (Adj / Non-adj)

-10 ORFS (Adj / Non-adj)

37° (Adj / Non-adj)

-12 (All types) 135 ft-lbs / 183 Nm

-16 (All types) 200 ft-lbs / 271,2 Nm

-20 (All types) 250 ft-lbs / 339 Nm

-24 (All types) 305 ft-lbs / 413,5 Nm

15 ft-lbs / 20,3 Nm

26 ft-lbs / 35,3 Nm

22 ft-lbs / 30 Nm

35 ft-lbs / 47,5 Nm

29 ft-lbs / 39,3 Nm

60 ft-lbs / 81,3 Nm

52 ft-lbs / 70,5 Nm

100 ft-lbs / 135,6 Nm

85 ft-lbs / 115,3 Nm

12 GS

™

-30 • 32 • 46 • 47 Part No. 1272217GT

March 2021 Service and Repair Manual

Specifications

Torque Procedure

Seal-Lok™ fittings

1 Replace the O-ring. The O-ring must be

replaced anytime the seal has been broken.

The O-ring cannot be re-used if the fitting or

hose end has been tightened beyond finger

tight.

Note: The O-ring in Parker Seal Lok™ fittings and

hose end are custom-size O-rings. They are not

standard size O-rings. They are available in the Oring field service kit (Genie part number 49612).

2 Lubricate the O-ring before installation.

3 Be sure the O-ring face seal is seated and

retained properly.

4 Position the tube and nut squarely on the face

seal end of the fitting, and tighten the nut

finger tight.

5 Tighten the nut or fitting to the appropriate

torque. Refer to the appropriate torque chart

in this section.

6 Operate all machine functions and inspect the

hose, fittings and related components to

confirm there are no leaks.

JIC 37° fittings

1 Align the tube flare (hex nut) against the nose

of the fitting body (body hex fitting) and

tighten the hex nut to the body hex fitting to

hand tight, approximately 30 in-lbs / 3.4 Nm.

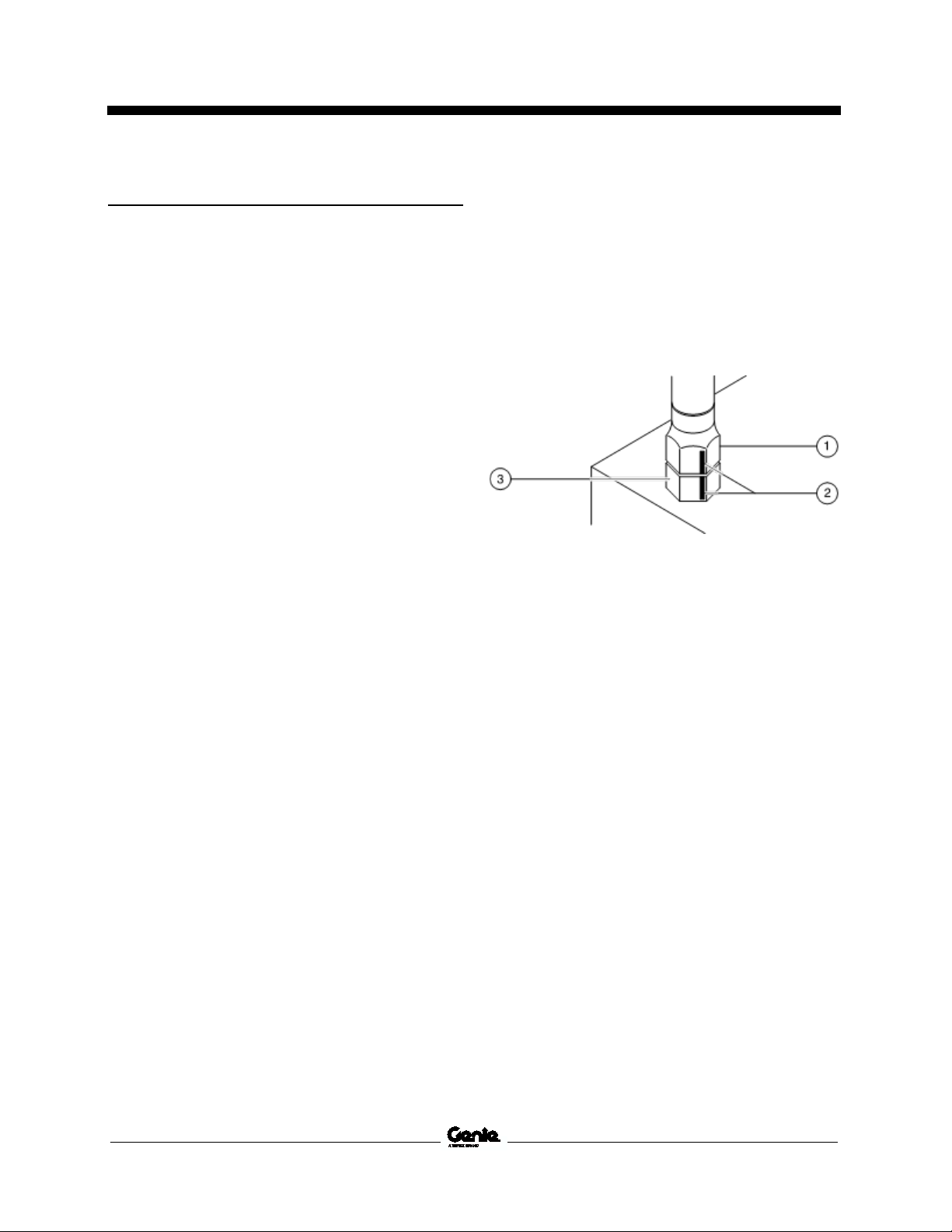

2 Using a permanent ink marker, make a

reference mark on one the flats of the hex nut

and continue the mark onto the body of the

hex fitting. Refer to Illustration 1.

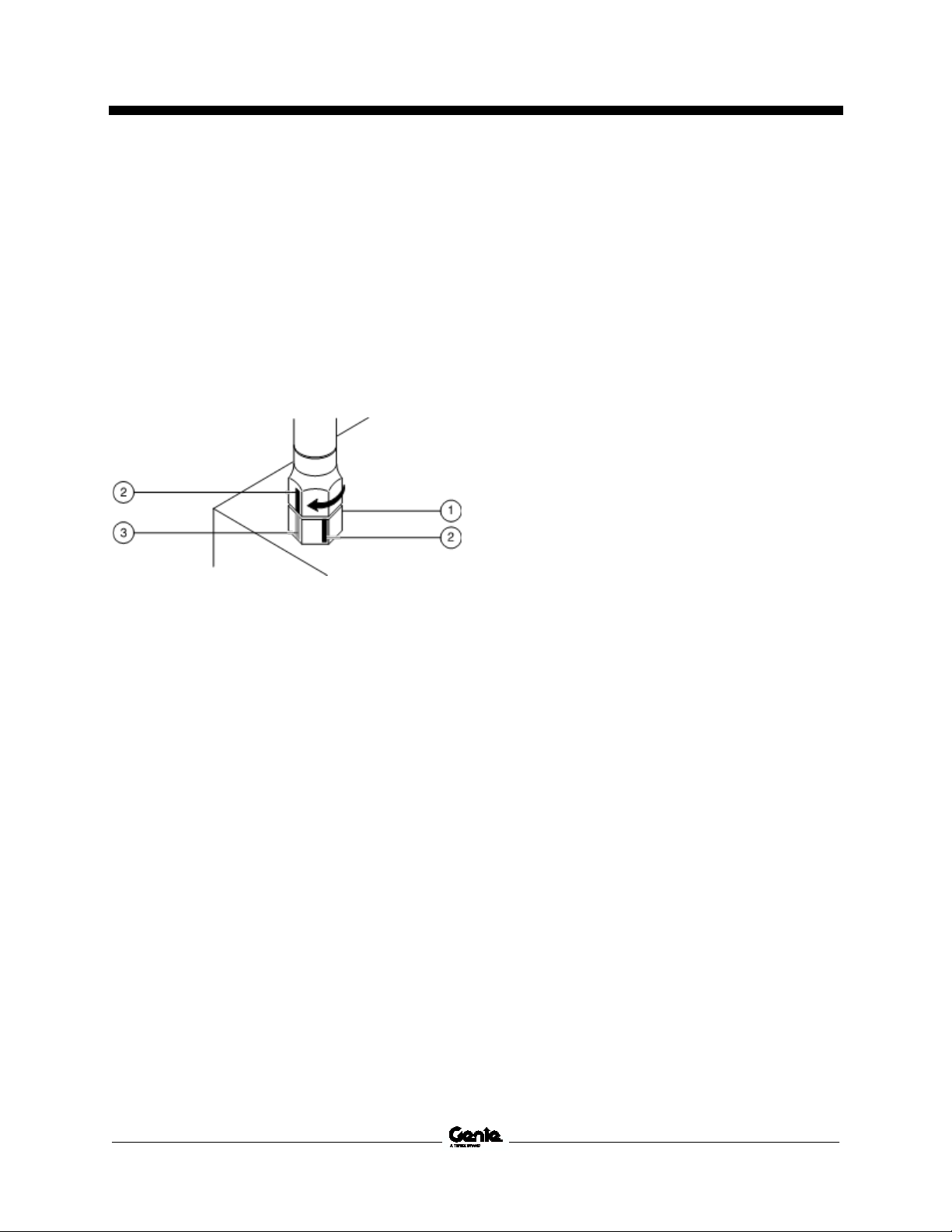

Illustration 1

1 hex nut

2 reference mark

3 body hex fitting

Part No. 1272217GT GS

™

-30 • 32 • 46 • 47 13

Service and Repair Manual March 2021

Specifications

3 Working clockwise on the body hex fitting,

make a second mark with a permanent ink

marker to indicate the proper tightening

position. Refer to Illustration 2.

Note: Use the JIC 37° Fitting table in this section

to determine the correct number of flats, for the

proper tightening position.

Note: The marks indicate the correct tightening

positions have been determined. Use the second

mark on the body hex fitting to properly tighten the

joint after it has been loosened.

Illustration 2

1 body hex fitting

2 reference mark

3 second mark

4 Tighten the hex nut until the mark on the hex

nut is aligned with the second mark on the

body hex fitting.

5 Operate all machine functions and inspect the

hose, fittings and related components to

confirm there are no leaks.

14 GS

™

-30 • 32 • 46 • 47 Part No. 1272217GT

Loading...

Loading...