Page 1

3531835447

f

Kaimm

——

Safety Information...............................................2

Important Installation Instructions

Safety Features....................................................2

Pre-installation Checklist....................................3

Garage Door Opener Assembly

Record Data (for Service)

Garage Door Opener Installation

Accessories.......................................................22

Maintenance

.....................................................

..................................

—

......................

...........................

.......................

11

12

25

2

For

7'

6" Doors. Extension Kit is available for

Included Wall Control MUST be installed prior to Operation

of this Garage Door Operator.

9

Safe-T-Beam® Safety Reverse System Must be Installed and

the Force Controls MUST be Properly Set to close door.

This Equipment meets or exceeds all Federal, State and UL325

Safety Requirements.

Will not operate twice as fast on a one-piece door.

8'

Doors

Troubleshooting................................................26

Wiring Diagram

Warranty information

.................................................

........................................

29

30

Please call us: 1-800-35-GENIE (354-3643)

www.geniecompany.com

Please have Model information ready when calling.

Page 2

Garage Doors are heavy objects that move with the help of springs

under high tension and electric opening equipment. Since moving

objects, springs under tension, and electric opening equipment

may cause injuries, your safety and the safety of others depend on

you reading and understanding the information in this manual.

EFFECT

If you have garage door related questions or do not understand the

information presented, call your nearest Genie Factory Authorized

Dealer listed at

www.geniecompany.com, or customer Service at

1-800-35-GENIE..

• Keep people clear of opening while door is moving.

• Do Not allow children to play with the door operator.

• Do Not operate a door that jams or one that has a broken spring.

• Turn off power before removing operator cover.

• When replacing cover, make sure wires are not pinched or near

moving parts.

• Operator must be properly grounded.

• Do Not try to remove, repair or adjust springs or anything to

which door spring parts are fastened, such as, wood blocKS,

steel brackets, cables or other like items.

• Repairs and adjustments must be made by a trained service

person using proper tools and instructions.

MOVING DOOR

>illli

ELECTRICAL SHOCK

HIGH SPRING TENSION

WARNING:

Can Cause Serious

Injury or Death

WARNING:

Can Cause Serious

Injury or Death

WARNING:

Can Cause Serious

Injury or Death

;tallatiom

A WARNING:

To REDUCE THE RISK OF SEVERE INJURY OR DEATH:

1 READ AND FOLLOW ALL SAFETY, INSTALLATION AND

OPERATION INSTRUCTIONS. If you have any

questions or do not understand an instruction, call

your service representative.

2 Do Not install operator on an improperly balanced

door. An improperly balanced door could cause

severe injury. Repairs and adjustments to cables,

spring assembly, and other hardware must be made

by a trained service person using proper tools and

instructions.

3 Remove all ropes, and disable all locks connected to

the door before installing operator.

4 Install door operator 7 feet or more above the floor.

Mount the emergency release knob 6 feet above

the floor.

5 Do Not connect the operator to the source of power

until instructed to do so.

6 Locate the control button:

• Within sight of door.

• At a minimum height of 5 feet, so small children

cannot reach it.

• Away from all moving parts of the door.

7 Install the entrapment WARNING label next to the

wall button or console. Install the emergency release

tag on, or next to, the emergency release

8 The operator must reverse when the door contacts a

1-1/2 inch high object on the floor at the center of

the doorway.This is about the size of a 2" x 4" board

laid flat.

Safe-T-Beam" (STB) Non-Contact Reversing System

Places an invisible beam across door opening, that reverses

the door during down travel to the fully open position if

anything passes through beam.

Safe-T-Reverse Contact Reversing System

Automatically stops and reverses a closing door within 2

seconds of contact with an object.

Safe-T-Stop Timed Reversed System

®

Automatically opens a closing door, if door does not close

within 30 seconds.

Force Guard Control

®

Used to set the force required for opening and closing

door. For maximum safety, set the minimum force required

to fully open and close door.

Automatic Lighting System

Two light bulbs up to 60 Watts max. each, are used for safer

entries and exits.The light turns on when door is activated

and automatically turns off 4.5 minutes later.

Manual Emergency Release

Allows the garage door to be opened or closed manually

for emergencies or maintenance.

FcM' Help, call 1-S00HJS4SEÍÍE or visit %wi»i.ferilecornparif.ccirn

Page 3

This Opener includes parts and supplies needed to install in most garages and

connect to most garage doors. There are many variations of garages and garage

doors. A few additional parts and supplies may be needed to install Opener into

your garage and connect to your garage door. While checking items listed

below, note any additional items you will need.

Tools used in tfils sticticin:

• 12'+Tape Measure • Pencil • Ladder • Level

Check condition of vertical stile in center of door, and its connection to door's

top and bottom beams.

A If door frame is nailed together and not a solid connection, door frame

must be braced or reinforced before installing Opener.

B If door is "lightweight" (made with frame and skin - not solid), door

(including door frame) must be braced or reinforced before

installing Opener.

C A door opener reinforcement bracket may also be needed to connect

garage door to Opener's Door Bracket. This Opener is designed for

installation on a properly braced sectional door or solidly braced

one-piece door.

D Contact your Genie Factory Authorized Dealer or dealer of your garage

door for any necessary bracing and a door opener reinforcement

bracket (if needed) before proceeding.

E If you have a wooden door, measure door's thickness. (1/4" x 2") Lag

Screws are included for installing Door Bracket onto door. If your door

is less than 2" thick, brace door or use shorter Door Bracket Lag

Screws (1/4"

X 11/4" - not included)

A WARNING:

If your door sticks, binds, or is out of

balance, have it adjusted by a Genie Factory

Authorized Dealer. Door springs, cables,

pulleys, brackets and associated hardware

are under extreme tension and can cause

serious injury or death.

NOTE

The Excelerator Opener is equipped with

an automatic Garage Door Balance

Detection System. See Troubleshooting

Guide on page 27.

KEEP FEET CLEAR OF DOOR

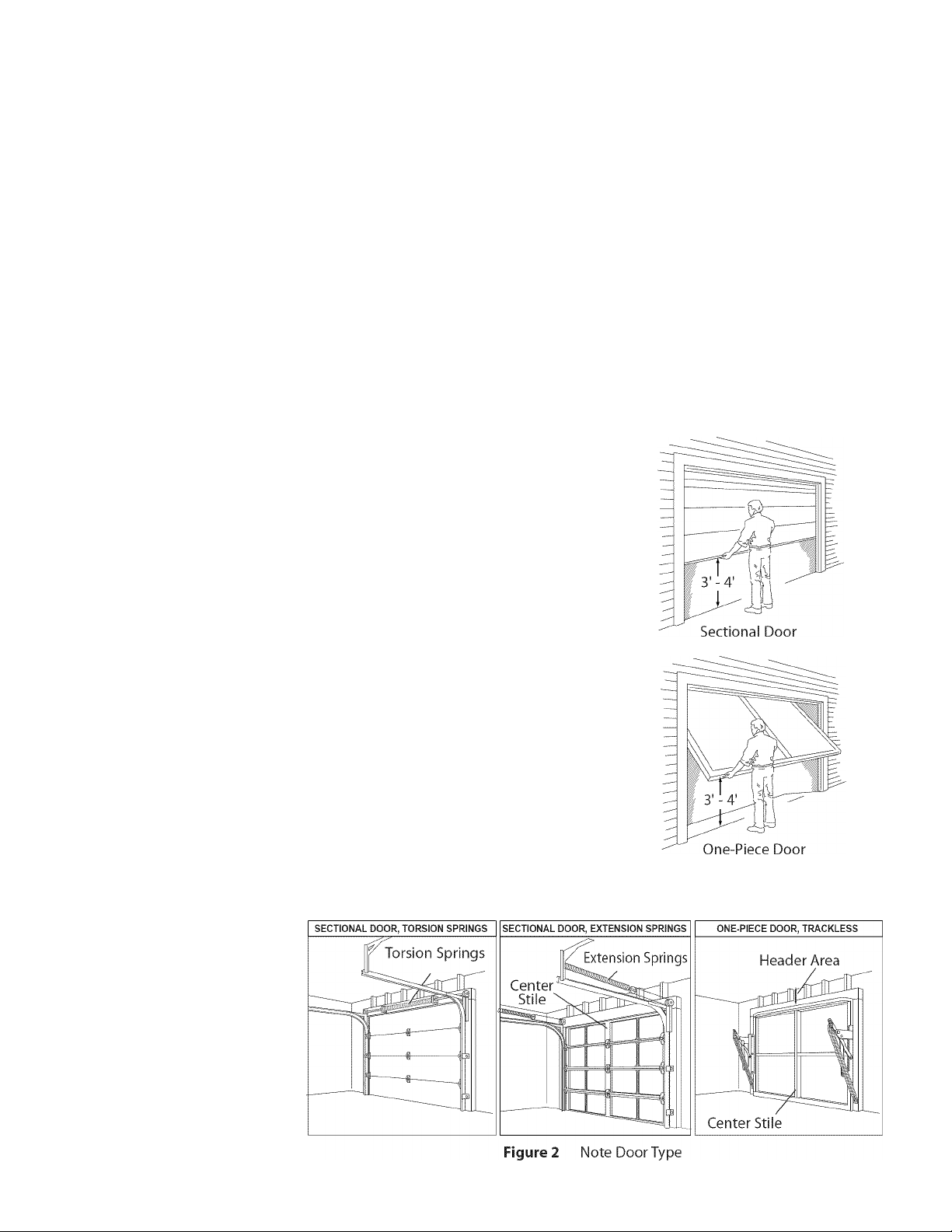

Raise door, check alignment and see if it moves freely (Figure 1). If door

appears out of alignment, binds, or does not move smoothly, contact a

Genie Factory Authorized Dealer or dealer of your garage door for repairs

and adjustments to door mechanism.

Raise door to 3' - 4' above ground and carefully let go. Door should stay

stationary. Slight movement is acceptable. More than slight movement

means door is out of balance. Contact a Genie Factory Authorized Dealer

or dealer of your garage door

for repairs and adjustments

to door mechanism.

Check door type. Make

a note of whether it is a

sectional or a one-piece

door (Figure 2).

FcM' Help, call 1-800-3S4SEiiE or ¥islt www.gBmet€ompanf.t,om

Figure 1 Checking door balance

Page 4

Measure garage door height (7'-6", 8'-0", or taller) with

tape measure.

A If door height is 7'-6" or less, continue with Check Step 4.

B If your door height is above 7'-6", make sure your rail is long

enough to open the garage door. If there is any question

contact your Customer Service Representative at

1-800-35-GENIE.

NOTE

The header is a heavily reinforced section of the wall just

above the top of the garage door opening.

Find vertical center line of door and header:

• Close door.

• Measure door width at top.

• Mark a point at center of door and on header directly

above door. Draw a center line to connect points.

Find Header Bracket mounting height (Figure 4):

(Do not attach Header Bracket).

• Raise door, watching top edge of door and stop door

when its edge reaches its highest point.

• Measure distance ("H") from top edge of door to floor.

- For sectional doors, add 2-1/2" to"H" Mark a point

on center line. Bottom of Header Bracket will be

installed here.

- For one-piece doors, add 6" to "H" Mark this point on

center line. Bottom of Header Bracket will be

installed here.

SECTIONAL DOOR

ONE-PIECE DOOR

NOTE

For both types of doors:

- If the ceiling in your garage is so low that there is

not at least a 3" space above the Header Bracket

mounting point, contact a Genie Factory

Authorized Dealer.

If a door spring is in the way, place the Header

Bracket avove the spring. Do Not move the door spring.

C Check wall for a stud or a solid header at your mark:

(If checking a finished wall, a stud finder may be helpful).

• If location is above Header, a 2" x 6" board must be

screwed to studs beside your mark with at least two Lag

Screws and Flat Washers (not provided).

• Transfer your mark to new mounting board.

Figure 4 Find Highest Point of Travel

FcM' Help, call 1-S00-3S4SEiiE or visit %wi»i.ferilecornparif.ccirn

Page 5

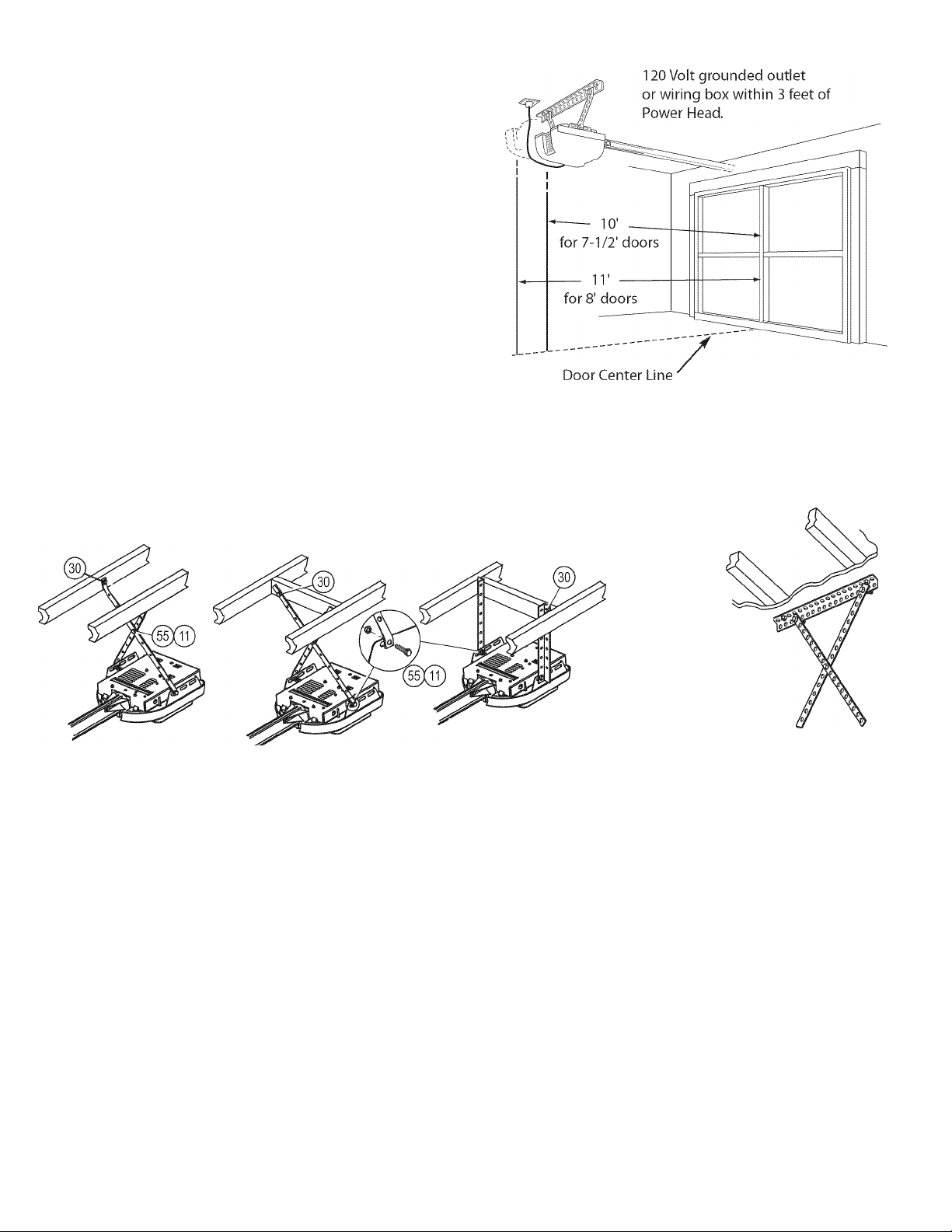

Check ceiling or space above where Opener Power Head will be

mounted (Figure 5):

A Measure from garage door center line mark toward rear

of garage:

• Approximately 10' back if garage has a 7' 6" door.

• Approximately 11' back if garage has an 8' 0" door.

• Approximately 13' back if garage has an 10' 0" door.

• Approximately 14' back if garage has an 12' 0" door.

NOTE

Mounting Straps are included to attach the Opener to most

garage ceilings. Garage construction varies widely.

Additional mounting straps or angle iron may be needed for

your installation.

B Find location of ceiling joist or truss above where Opener

Power Head will be and estimate type and quantity of

materials needed for your installation

(Figure 6).

Figure 5 Check Power Head location

OPEN BEAM CEILING EXAMPLES

Mounting Straps Support board added

for longer spans

Figure 6 Mounting methods for open beam and finished ceilings

Check that there is a 15 Amp 120 Volt grounded electrical

outlet or grounded permanent wiring box (per building code)

within 3' of Opener Power Head:

• If not, an outlet or wiring box must be installed. Contact

a licensed electrician for installation.

• If building codes require permanent wiring, Power Head

must be partially disassembled to install appropriate

wiring in place of Power Cord. See page 19

Perforated

Angle Iron

(Angle iron not included)

FINISHED CEILINGS

Locate ceiling joists or

trusses using

a stud finder

or similar

device.

Attach angle iron

(not included) to

joists or trusses

through finish material

using Lag Screws.

NOTE

Permanent wiring must be installed by a Licensed

Electrician. Not all Genie Factory Authorized Dealers are

Licensed Electricians. Contact someone who is a Licensed

Electrician.

FcM' Help, call 1HI00HJS4SEÌÌE or visit svswi.ferileccirnpiirif.corn

Page 6

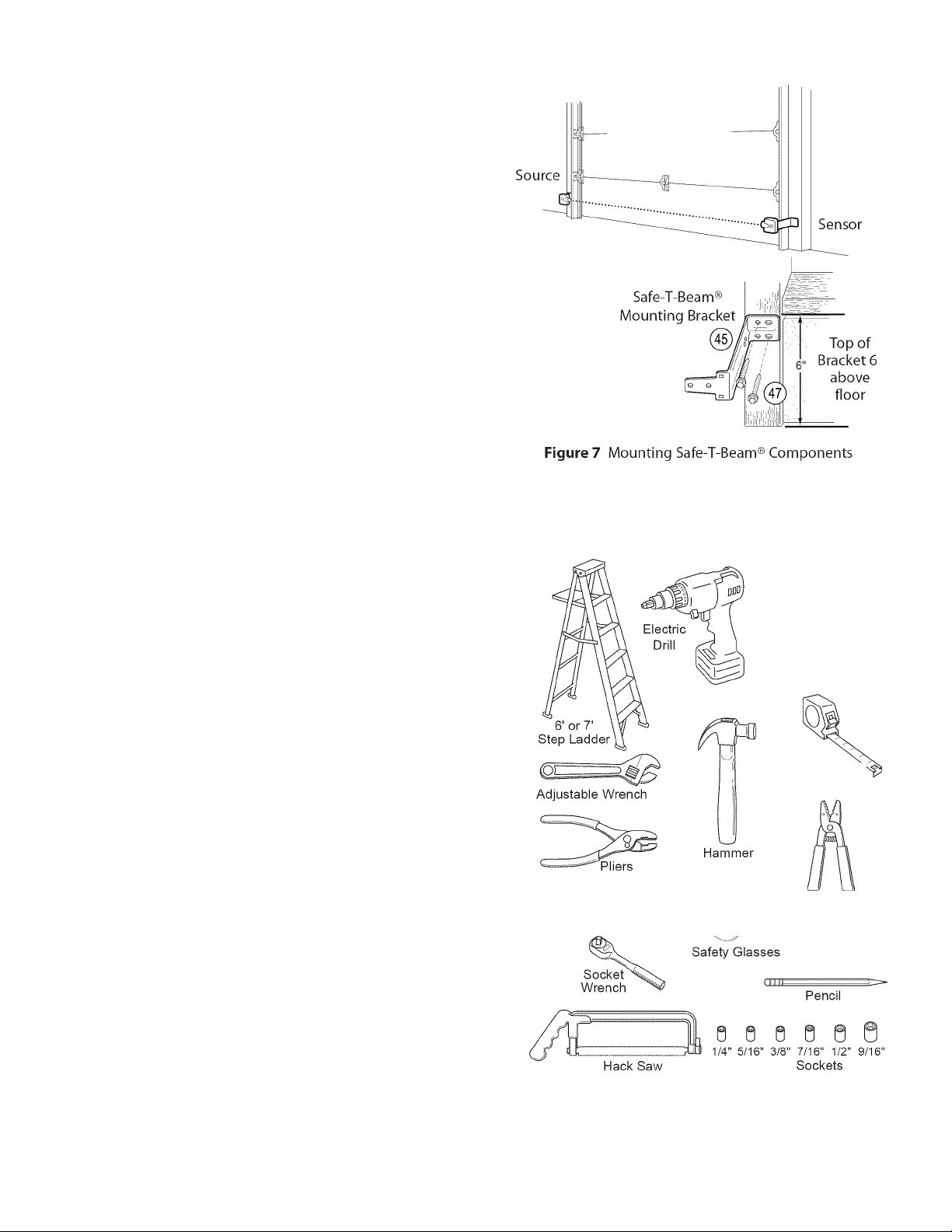

Check for wood garage frame, jamb, or masonry at mounting location

(6" above floor) with attachment tabs facing away from garage door

(Figure 7).

A If you cannot mount Safe-T-Beam® Mounting Bracket to

wood frame:

• Concrete screws and concrete anchors (not included)

must be used to mount Brackets on masonry with

attachment tabs facing away from garage door.

• Safe-T-Beam® Mounting Bracket Extensions may be used

(not included - available from a Genie Factory Authorized

Dealer or through Accessories Order Form on pages 31/32).

A Tools (Figure 8):

B Additional tools to make installation easier:

• Slotted and phillips screw-driver bits

• Stud finder

• Sheet-metal cutting snips

* •

Check that the garage door locks, rope, and T-Handles are removed

from the garage door before starting the installation.

A If your garage does not have a separate entry door, it is highly

recommended to install a Genie Emergency Release Kit (GER-2).

Emergency Release Kit lets you open garage door from outside if

there is a power failure. (Please see Accessories Order Form on

pages 31/32.)

□ Safe-T-Beam® Sensor Mounting Bracket Extensions (dealer)

□ Garage door opener reinforcement bracket (dealer)

□ Garage door frame reinforcement brackets, screws, bracing

or reinforcement kits (dealer)

□ Lag Screws (11/4") for a wood door less than 2" thick (store)

□ Electrical outlet and/or wiring (supplied by a

licensed electrician)

□ Excelerator Extension Kit (for 8' garage doors) (store)

□ Sufficient angle iron or strapping for hanging Power Head

(store)

□ Two 60 Watt light bulbs

(Rough service bulbs recommended)(store)

□ GER-2 Emergency Release Kit for entry during power failure

(store)

□ Wood for header, ceiling, and/or door bracing reinforcement

(if needed)

□ Masonry fasteners for Safe-T-Beam® Bracket installation,

(if needed)

□ Masonry drill bit (if needed)

Phillips Screwdriver

Figure 8 Recommended Tools

1/16" 5/32"

Drill Bit Drill Bit

12' +

Tape Measure^

Wire

Stripper

Carpenter's Level

FcM' Help, call 1-S00-3S4SEiiE or visit %wi»i.ferilecornparif.ccirn

Page 7

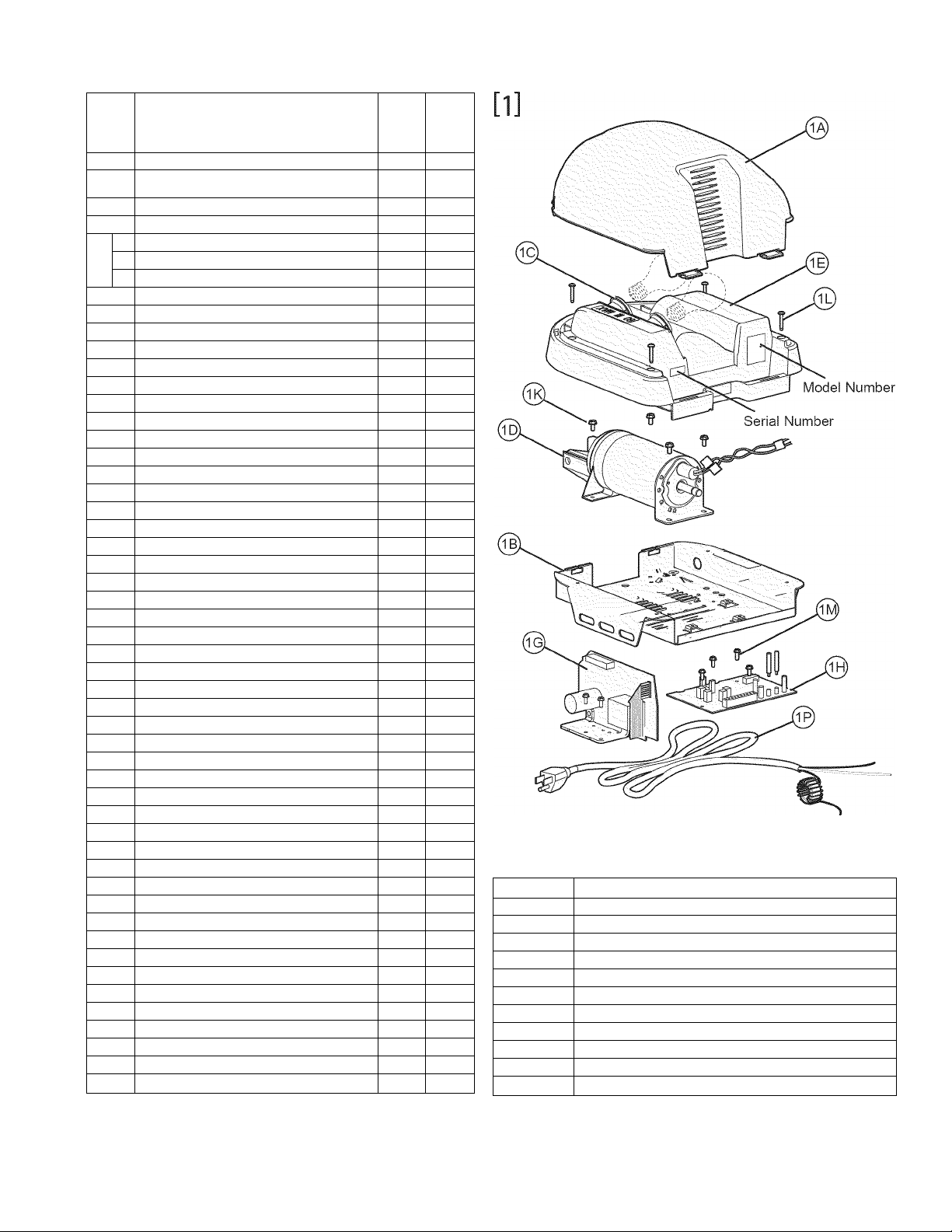

Item Part Name Qua

1 Power Head Assembly (main carton) 1 1

2 1 /4"-20 X13/16" Hex Head Shoulder Bolt (blue bag)

(yellow bolt)

3 Rail Assembly (1 piece)(packaged separately) 1

4 Rail Assembly (3 piece)(main carton) 1

4A First Rail Section 1

4B IVliddle Rail Section 1

4C End Rail Section 1

8 l/4"-20 Hex Serrated Flange Nut (blue bag) 4 4

9 Rail Clamps (blue bag) 4

10 5/16"-l 8 X11 /16" Hex Head Shoulder Bolt (blue bag) 8

11 5/16"-l 8 Hex Serrated Flange Nut (blue & orange bags)

12 (Vlagnetic Carriage Assembly (main carton) 1 1

13 Collar (blue bag) 3

14 Retaining Clip (blue bag) 3

15 Rail Strap (blue bag) 1 1

16 l/4'-20 Hex Head Bolt (blue bag) 2 2

18 Open Limit Switch Assembly (White)(green bag) 1 1

19 Close Limit Switch Assembly (Brown) (green bag) 1 1

21 N0.8-32x1' Hex Head Screw (green bag) 2 2

22 Emergency Release Cord (green bag) 1 1

23 Emergency Release Cord (long)(yellow)

24 Emergency Release Knob (green bag) 1 1

25 Emergency Release Tag (green bag) 1 1

26 Header Bracket (orange bag) 1 1

28 Door Bracket (orange bag) 1 1

30 1/4'x 2' Lag Screw (orange bag)

31 Straight Door Arm (main carton) 1 1

32 Clevis Pin,3/8" X15/16" (yellow bag) 2 2

33 Cotter Pin, .073" dia. (yellow bag) 2 2

34 Curved Door Arm (main carton) 1 1

35 3/8' X 7/8' Hex Head Bolt (yellow bag) 2 2

36 3/8" Hex Serrated Flange Nut (yellow bag) 2 2

37* 2-Conductor Wire (main carton) 1 Roll 1 Roll

38* Insulated Staple (red bag) approx. 30 approx. 30

40* Wall Console (main carton) 1 1

41* #6 X1-1/4" Pan Head Screw (red bag) 2 2

42* Entrapment Warning Label (manual)(main carton) 1 1

43* Safe-T-Beam (STB) Sensor (Green LED)(main carton) 1 1

44* Safe-T-Beam (STB) Source (Red LED)(main carton) 1 1

45* Safe-T-Beam (STB) Bracket (yellow bag) 2 2

46 Coupler (blue bag) 1 1

47* No.10 xl 1/4" Phillips Hex Head Screw (yellow bag) 4 4

48* 1 Button Remote Control (main carton)

49* 3 Button Remote Control (main carton)

50* Wireless Keypad (main carton)

51* 2 Button Remote Control (main carton)

52* Safety & (Vlaintenance Guide (manual)(main carton) 1 1

53 Wire Clip (green bag) 7

54 Bumper (blue bag) 1 1

55* 5/16"-18x 3/4' Hex Head Bolt (orange bag) 3

56 1/4-20 X 3/4" Self-drilling Screw (orange bag) 3 3

57 Mounting Straps (main carton) 2 2

low

utity

lired

Reqi

1-Pc Rail

3-Pc Rail

2 2

“"“/model

12’only

“"“/model

“"“/model “"“/model

“"“/model “"“/model

“"“/model “"“/model

varies/

/model

12

8

“"“/model

Denotes items not shown on page 8. These items will be Illustrated

throughout the manual as required.

Item Part Name

lA Lens

IB Top Plate Assembly

1C Light Socket (2)

ID Motor Assembly

IE Cover

1G Motor Drive Board

1H Controller Board

IK No. 10-24 X 3/8" Hex Head

1L No.8-32 X 1" Phillips Screw

1M No. 8-32 X 3/8" Slotted Hex Head Screw

IP Power Cord

t-ar Heii: ‘lit or ¥ISIC ' sri lecci rn pa riy. co rri

Page 8

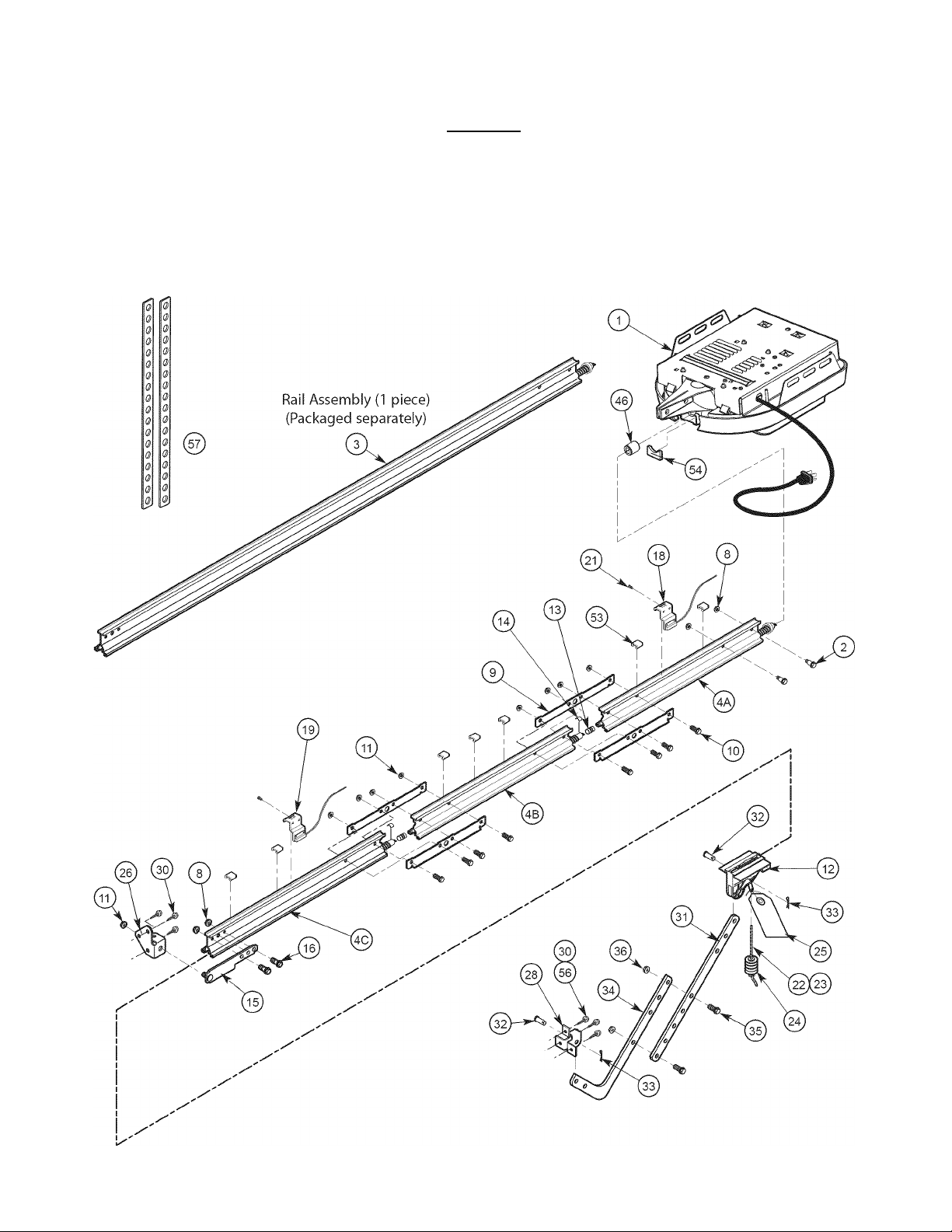

_________________________NOTE

Opener will not function unless Safe-T-Beam® System is installed and Force Controls are properly set.

One-Piece Rail Assembly (Genie Pro only) for 10' or 12' door includes;

• Special "Close" Limit Switch with longer Wires.

• 96" Emergency Release Cord (yellow).

• Rail Support Kit.

________________

FcM' Help, call l-SOOHJSHSEiiE or ¥isit %wi»i.ferilecornparif.ccirn

Page 9

Rail Strap

(15

5/16"-l8 Hex Head Shoulder Bolts

5/16"-l 8 Hex Serrated Flange Nuts

A Turn Power Head upside down and place on a flat

level surface.

B Install Bumper (Figure 9).

C Install Coupler on Motor Shaft (Figure 9).

A CAUTION

The Drive Screw and Rail Liner can slide out of Rail Sections.

Keep Rail Sections level until the Opener is fully assembled.

Connect first Rail Section to Opener Power Head. Connect

with 2 (l/4"-20) (yellow) Hex Head Shoulder Bolts and

2 (1/4" -20) Hex Serrated Flange Nuts (Figure 10).

Finger-tighten until later.

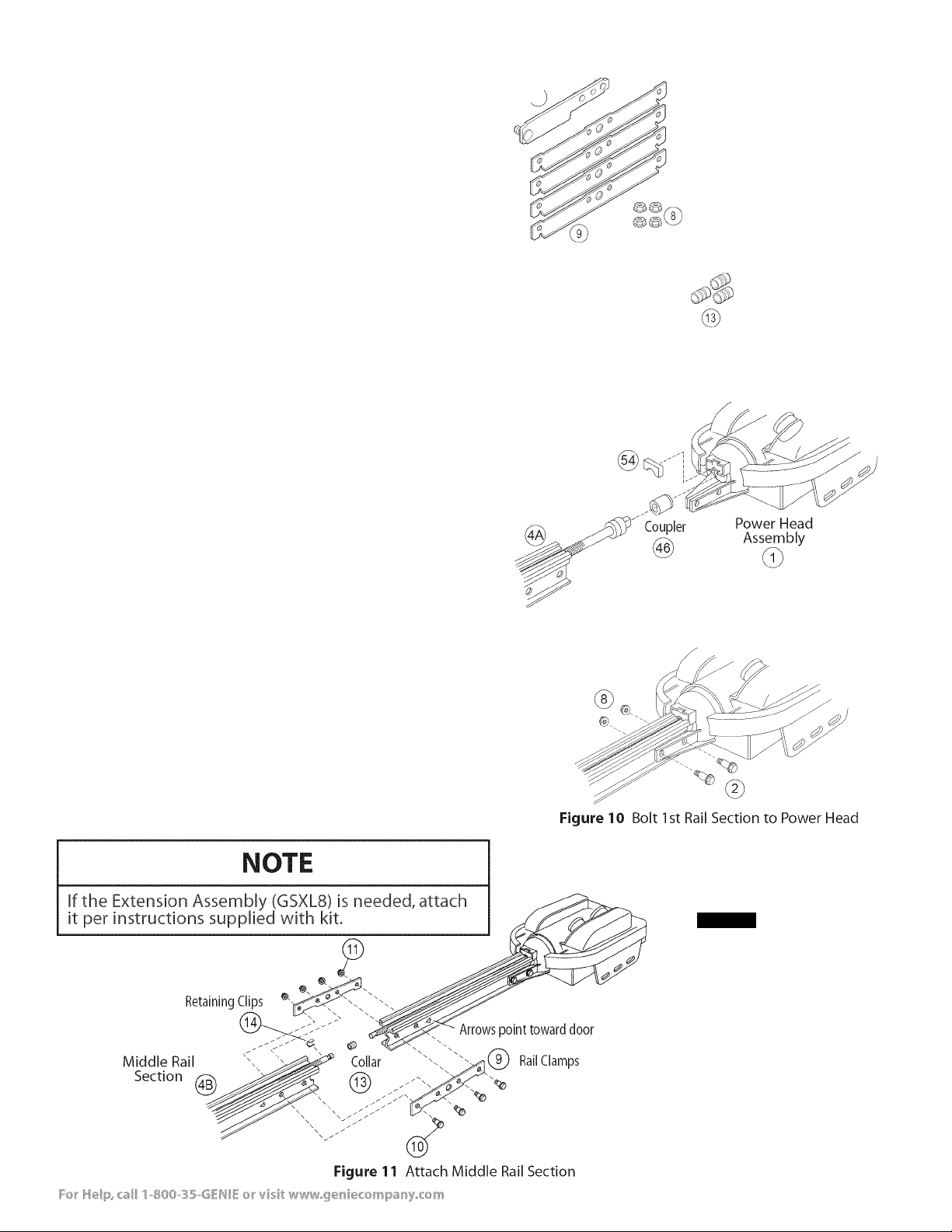

If you have a 1 -piece rail unit, skip Assembly Step 2.

Arrange arrows on Rail Sections to point in same direction

and away from Power Head:

• Push Middle Drive Screw out about 2" toward Power Head.

• Slide Collar over Middle Drive Screw Hook (Figure 11 A).

• Turn Middle Screw by hand to align Drive Screw Hooks

between First and Middle Rail Sections.

• Latch two Hooks together and slide Collar over them

(Figure 11B) and (Figure 11C).

• Snap Clip on Drive Screw next to Collar (Figure 11D).

Attach Middle Rail Section to First Rail Section, using 2 Rail

Clamps, 4 (5/16"-18) Hex Shoulder Bolts, and 4 (5/16"-18) Hex

Head Serrated Flange Nuts onto Bolts (Figure 11).

Finger-tighten until later. (Middle Rail Section looks the

same on both ends. See page 8.)

Attach End Rail Section to Middle Rail Section following

procedures in step A & B.

flt© ¥¥(16:

Rail Clamps Serrated Flange Nuts Shoulder Bolts Head Bolts

%

Coupler

(remove backing)

First Rail

Section

Figure 9 Install Bumper, Coupler and 1st Rail Section

l/4"-20Hex l/4"-20 Hex Head l/4"-20Hex

(yellow)

0

Bumper Collars -r spare Retaining Clips -r spare

Hardware (blue bag)

Bumper

0

f©,

11 A. Slip on collar

11B. Engage Hooks

lie. Slide Collar over Hooks

11D. Snap on Retaining Clip

Ehnm

Page 10

Magnetic Carriage

Assembly ^

Release

Position

A Place Magnetic Carriage Assembly Lever in "release" position.

B Slide Magnetic Carriage Assembly into slot on End Rail

Section with arrow pointing away from the Power Head

(Figure 12).

A Attach Rail Strap to End Rail Section with 2 (l/4"-20) Hex

Head Bolts and 2 (l/4"-20) Serrated Flange Hex Nuts

(Figure 13).

B Tighten snugly but Do Not over-tighten.

A Align all Rail Sections so Magnetic Carriage Assembly can

slide freely along length of Rail.

B Securely tighten all fasteners now. Do Not over-tighten.

Engaged Position

Toward Power Head End Rail Section

^ 0

Figure 12 Slide Magnetic Carriage onto Rail

Rail Strap

® © ®_

0 0

8^

Figure 13 Attach Rail Strap

White

n Limit

S

Ij

Wire

As^^mbly

I 21

#8-32 X 1

Hex Head Screws

Toward door

and header

\ End Rail Section

(ic)

Wire Clips

5^

10

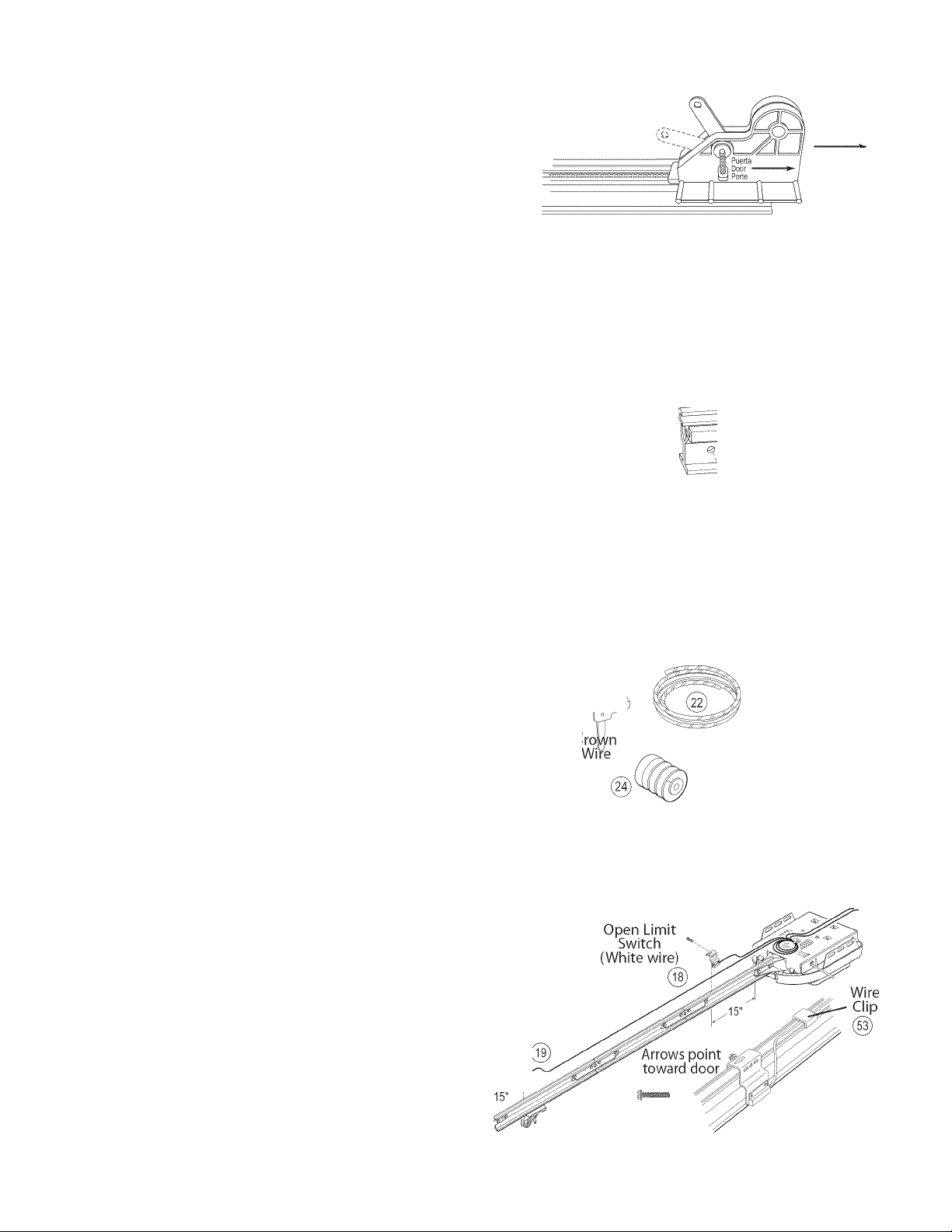

Turn Opener right side up and support Power Head to avoid

damaging the Light Bulb Sockets.

Uncoil Limit Switch Wires and retain Twist Ties.

Place Switches on Rail with arrows pointing away from

Power Head (Figure 14).

Place Close Limit Switch (Brown Wire) 15" from Rail Strap.

Insert (#8-32 X 1") Hex Head Screw into Switch hole and

finger-tighten until later.

Place Open Limit Switch (White Wire) 15" from Power Head.

Insert (#8-32 X 1") Hex Head Screw into Switch hole and

finger-tighten until later.

Emergency

Release Core

25

Close Limit

Switch Assembly

Emergency

Release Knob

Emergency

Release Tag

Hardware (green bag)

Close Limit

Switch

(Brown wire)

#8-32 X 1"

Hex Head^

Screws 0

Figure 14 Install Limit Switches on Assembled Rail

FcM' Help, call 1-S00-3S4SEiiE or visit %wi»i.ferilecornparif.ccirn

Page 11

NOTE

Loosen (Do Not Remowe) Terminal Block Screws.

Limit Switch adjustments and securing the Wires

will be done later.

F Lay Wires in channel on top of Rail and secure with Wire Clips

(Figure 14).

G Coil and bundle excess Limit Switch Wires on top of Power

Head with Twist Ties. Leave just enough Wire to reach

Terminals on back of Power Head (Figure 14).

H Turn Opener upside down, and connect Limit Switch Wires to

Power Head Terminal Block (Figure 15):

• Terminal 4: OPEN Limit Switch Wire (white).

• Terminal 5: OPEN Limit Switch Wire (white) and

CLOSE Limit Switch Wire (brown).

• Terminal 6: CLOSE Limit Switch Wire (brown).

Tie overhand knot at one end of Emergency Release Cord.

Thread opposite end of Cord through Knob and hole in

Magnetic Carriage Assembly Release Lever (Figure 16).

C

Tie overhand knot at this end of Emergency Release Cord.

D

Attach Emergency Release Tag to Magnetic Carriage

Assembly Release Lever.

Figure 15 Connect Limit Switch Wires to Power

Head Terminal Block

Please note the following information so it is available if you need

to call us:

Date purchased: ____

Serial number (Figure 17):

Model number (Figure 17):

Dealer Name:

Dealer Address:

City:

State:

Zip:

Phone:

/ /

NOTE

Please keep original or photocopy of your sales receipt with

this manual for future reference should service ever be

required.

Figure 17 Model and Serial Numbers

FcM' Help, call IHIOOHJSHSEiiE or visit svswi.ferileccirnpiirif.corn

11

Page 12

NOTE

For lightweight garage doors, make sure you have installed

the proper reinforcement (See Check Door Condition and

Thickness on page 3).

A CAUTION

The Header Bracket must be fastened to the garage

framing. Do Not fasten the Header Bracket to drywall,

particle board, plaster, or other such material.

It may be necessary to attach a 2" x 6" board across the

wall studs above the door header to serve as a

mounting plate for the Header Bracket. The Bracket can

then be mounted at the proper location and have

sufficient support.

If a door spring is in the way, place the Header Bracket

above the spring. Do Not move the door spring.

Mount directly

into header

Alternative Header Bracket orientations

Figure 18 Attach Header Bracket above Garage Door

Use of Header Bracket

support board

If needed, attach a 2" x 6" board (Figure 18) (also see page 4)

with at least two (four is recommended) Lag Screws and Flat

Washers (not supplied).

B Attach Header Bracket to header at mark above door.

NOTE

Mounting variations are shown in Figure 18. Any of these

may be used depending on space. However, it is critical that

the point where the Rail attaches to the Header Bracket be

on the center line of the door.

Mark 3 hole positions.

Drill 3 (5/32") pilot holes.

Attach Header Bracket with 3 (1/4" x 2") Lag Screws.

12

FcM' Help, call 1-SOOHJS4SEiiE or ¥isit %wi»i.ferilecornparif.ccirn

Page 13

A CAUTION

Doors made of masonite, lightweight wood, fiberglass, metal,

or other lightweight materials must be properly braced

before mounting door Opener.

(28

(5^ or (g)

(28)

SECTIONAL DOORS ONE-PIECE DOORS

Center Line of dooL,-::;:=:gi J Center Line of door .

For stictional doors;

A Place Door Bracket on door center line, no lower than top

roller, and mark holes (Figure 19).

B Attach Door Bracket:

• For metal doors, use 3 (1/4" -20 x 3/4") Self-Drilling

Screws (provided).

• For wood doors, use 3 (1/4" x 2") Lag Screws or

3 (1/4" X 11 /4") Lag Screws (not provided).

NOTE

Before installing, check length of the included Lag Screws vs.

the thickness of your garage door. For doors thinner than 2",

use 11/4" Lag Screws. Check door condition and thickness.

See page 3.

For ontf-plecef doors:

A Position Door Bracket on door's center line, as high as

possible or on top of door.

B Attach Door Bracket:

• For metal doors, use 3 (1/4" -20 x 3/4") Self-Drilling

Screws.

• For wood doors, use 3 (1/4" x 2") Lag Screws.

/. I OR

Attach no "

lower than.1

top rollers

Optional Door Operator Bracket (not included)

Figure 19 Attach Door Bracket

■'Attach at j

highest point j

on door

A While supporting the Power Head, place threaded end of Rail

Strap Bolt through Header Bracket hole (Figure 20).

B Attach (5/16"-18) Flange Nut to Rail Strap Bolt.

Finger-tighten until later.

FcM' Help, call 1-800-3S4SEiiE or visit svswi.ferileccirnpiirif.corn

13

Page 14

A Raise and support Opener Power Head (along door center

line) higher than highest point of door travel (using step

ladder, etc.) (Figure 21).

B Measure distance from Opener to garage ceiling.

A CAUTION

Mounting Brackets must be fastened to garage framing.

Do Not fasten to drywall, particle board, plaster, or other

such materials.

NOTE

SECTIONAL DOORS

Rail Should be level or dip down slightly.

Make sure the rail of your supported Power Head is

slightly higher than tne highest point of door travel

by raising the door to check. Adjust as needed.

Materials needed for mounting Opener Power Head

to garage may vary. Read all instructions completely.

Garage constructions differ. Extra material may be

needed. See Check Power Head Mounting Area on

page 5.

Install Mounting Straps and/or support brackets (angle iron

not included) to joists or trusses and to mounting slots in

Opener. Use (5/16"-18 x 3/4") Hex Head Bolt, (5/16"-18)

Serrated Flanged Nut, and (1/4" x 2") Lag Screws as needed

(Figure 22).

Securely tighten all fasteners now. Do Not over-tighten.

OPEN BEAM CEILING EXAMPLES

Mounting Straps Support board added

for longer spans

ONE-PIECE DOORS

Set clearance at 1 "-1V2" between Rail and door at

Figure 21 Checking Power Head position

FINISHED CEILINGS

Perforated

Angle Iron

Locate ceiling joists or

trusses using

a stud finder

or similar

device.

14

Attach angle iron

(not included) to

joists or trusses

through finish material

using Lag Screws.

(Angle iron not included)

Figure 22 Mounting methods for open beam and finished ceilings

FcM' Help, call 1-S00-3S4SEiiE or visit %wi»i.ferilecornparif.ccirn

Page 15

For stictiorial cii3ors:

A Attach Curved Door Arm to Door Bracket with Clevis Pin and

Cotter Pin (Figure 23).

B Attach Straight Door Arm to Magnetic Carriage Assembly.

C Attach both Arms together with 2 (3/8" x 7/8") Hex Head

Bolts and 2 (3/8") Serrated Flange Hex Serial Number

Nuts so overall length is as short as pos

sible. Securely tighten fasteners.

D Adjust height of Emergency Release Cord Knob to 6' above

floor:

• Pull Cord through Magnetic Carriage Assembly Lever

until Knob is 6' from floor.

• Tie a new overhand knot in Cord at Magnetic Carriage

Assembly Lever.

For one-piece cli3cirs:

A Attach Straight Arm to Door Bracket with Clevis Pin and

Cotter Pin (Figure 24).

B Attach Curved Arm to Magnetic Carriage Assembly.

C Attach both Arms together with 2 (3/8" x 7/8") Hex Head

Bolts and 2 (3/8") Serrated Flange Hex Nuts so overall length

is as long as possible. Securely tighten fasteners.

D Adjust height of Emergency Release Cord Knob to 6' above

floor:

• Pull Cord through Magnetic Carriage Assembly Lever

until Knob is 6' from floor.

• Tie a new overhand knot in Cord at Magnetic Carriage

Assembly Lever.

Safe-T-Beam® (STB) Brackets

#10-16 X 11/4"

Phillips Hex Head Screw

Hardware (yellow bag)

As short as

possible

32

Clevis Pins Cotter Pins

3/8"X 7/8"

Hex Head Bolts

3/8" Hex Serrated

Flange Nuts

A WARNING

Do Not skip Step D above!

Failure to comply may leave Emergency Release Knob within

reach of children. If the Knob is pulled with garage door fully

or partially open, garage door may close without warning!

FcM' Help, call 1-800CJS4SEÌÌE or visit svswi.ferileccirnpiirif.corn

^(3^ @Door Arm

^ Curved

Figure 24 Assemble Arms (ONE-PIECE)

15

Page 16

^ ELECTRICAL WARNING

Ensure there is No power to the Opener before installing

Safe-T-Beam® System Wires. If Opener is plugged into outlet,

Unplug it now.

Safe-T-Beam® Sensor

(Green LED)

@)

Safe-T-Beam® Source

(Red LED)

NOTE

The Opener will not close the door automatically unless the

Safe-T-Beam® System is installed.

Install Safe-T-Beam® Source and Sensor (Figure 25):

• Mark both sides of garage door frame or wall 6"

above floor.

• Hold Bracket against door frame or wall. Check if Bracket

extends out from wall far enough so tongue of Bracket is

beyond door, tracks, or any door hardware. If not, Safe-T-

Beam® Mounting Bracket Extensions are available from a

Genie Factory Authorized Dealer or through the

Accessories Order Form.

- Blocks of wood, etc. may be substituted

for extensions.

• Position top of Mounting Bracket at 6" mark and fasten

with 2 (#10-16 X 1-1/4") Phillips Hex Head Screws

per Bracket.

NOTE

Mounting Brackets can be attached to brick walls or concrete

floor using masonry anchors (not included).

Slide onto

tongue of

Bracket until^

it clicks into (45)

place

Figure 25 Install Safe-T-Beams®

Top of

Bracket 6"

above

floor

B Attach Safe-T-Beam® Source (Red LED) and Sensor (Green

LED) to Brackets (Figure 25):

• For single-door garages.

- Determine which side of garage receives the most

direct sunlight, and place Source (Red LED) on this

side whenever possible.

• For multiple-door garages see (Figure 26).

- Preventing crossed signals is critical.

- Place Source and Sensor modules on adjacent doors

facing in opposite directions.

NOTE

To help prevent interference from the sun, the Safe-T-Beam®

Sensor (Green LED) may be placed further away from the

door opening, where it will spend more time in the shadows.

Slide the Safe-T-Beam® Source and Sensor onto the

tongues of the Brackets until they click into place.

Check final height of Lens (Figure 27).

16

Top edge of Lens

5" - 6" above floor

Figure 27 Final Check Safe-T-Beams®

FcM' Help, call 1-S00HJS4SEÍÍE or visit %wi»i.ferilecornparif.ccirn

Page 17

^ CAUTION

Staples which are too tight may cut or pinch Wires. Cut or

pinched Wires can cause the Safe-T-Beam® System to stop

working. When installing the Insulated Staples, make sure

you fasten them only as tightly as needed to hold the

Wire securely.

Install Safe-T-Beam® Wiring (Figure 28):

• Route Wire and Insulated Staples

(Figure 29 and Figure 30).

- Securely fasten Wires with Insulated Staples as

you go. Staples should be snug only.

- Wires between garage wall and Power Head should

be run on top of Rail and underneath Wire Clips.

• Attach Wires to Safe-T-Beam® Sensors.

- Split and strip Wire ends to be connected as shown.

- Loosen Terminal Screws.

- Insert each Wire under flat plate and tighten Screw.

It does not matter which Wire, white or striped, goes

on which Terminal.

• Attach Wires at Power Head.

- Wires are connected to Terminals #2 and #3 on

Power Head Terminal Block. It does not matter which

Wire, white or striped, goes on which Terminal.

• Check the following.

- Ensure that no part of door or its hardware is in path

between Source or Sensor Lenses.

• Ensure that tops of Lenses are between 5" - 6" above

floor. Brackets are flexible and can be adjusted slightly

if needed.

NOTE

The Safe-T-Beam® alignment check will be performed

following connection to electrical power.

Do Not plug in yet!

Wire Clips

) B /[

i iji)pjpi|i|ejfl| 11

■) ! i r

\ \l ! STB I 1/ /

' Terminal '

attachments

at Power Head

Figure 29 Wiring Method A

Insulated

Staples

1(38)

Terminal i

- attachments " . . ,

at Safe-T-Beam® Leave slack for

¡ÎÎ s

adjustment

//

0

FcM' Help, call 1-800HJS4SEiiE or visit svswi.ferileccirnpiirif.corn

Wire Clips 0

Terminal '

attachments

at Power Head

Figure 30 Wiring Method A

.

.....

Insulated

Staples

(Ss)

• M S’

Leave slack for

adjustment

17

Page 18

A WARNING

Security

Vacation

Verify there is no power to the Opener before installing Wall

Console Wires.

* •

NOTE

More than one lighted Wall Control per Opener will cause

a malfunction.

Wall Console (Figure 31):

• Has a Security Vacation Lock Switch which disables

all controls.

• LED Indicator shows whether system is powered, locked,

or unlocked. Makes Console easy to find in dark.

• Controls door Opener from inside garage.

• Independent Light Control allows convenient manual

control of Opener Lighting System.

Find a convenient mounting location;

• Within direct sight of garage door.

• At least S' above floor (to prevent small children from

operating garage door).

• Away from any moving garage door or Opener parts (you

should not be able to reach door while standing at

Wall Console).

c

Ensure Vacation Lock Switch is in UNLOCKED position.

D

Wire Wall Console to Opener (Figure 32):

• On Power Head, connect Striped Wire to Terminal #1 and

White Wire to Terminal #2.

• On back of Wall Console, connect Striped Wire to

terminal "B"and White Wire to Terminal "W"

Attach Wall Console onto wall at location found above with 2

(#6 X 11/4") Pan Head Screws.

Remove protective backing from Entrapment Warning Label,

and attach it to wall near Wall Console.

Figure 31 Wall Console

18

A CAUTION

Use of any wall consoles other than the type included

will prevent the light from working properly and could

cause the door to operate on its own.

Cut or pinched Wires can cause the Wall Console to stop

working. When using the Insulated Staples, be sure to

only tap them in as far as needed to hold the

Wire snugly.

FcM' Help, call l-SOOHJSHSEiiE or visit %wi»i.ferilecornparif.ccirn

Page 19

A electrical warning

To reduce the risk of electrical shock, this equipment has

a grounding type Plug that has a third (grounoing) Pin.

This Plug will only fit into a grounding type outlet. If the

Plug does not fit into the outlet, contact a qualified

electrician to install the proper outlet. Do Not change

the Plug in any way.The door Opener must be properly

grounded to prevent personal injury and damage to the

components.

The electrical power to the door Opener Must Be removed

when the Motor Cover is removed. Electrical power must

remain off while making electrical connections.

A Check building codes:

• If building code requires Opener be permanently wired

to building, have a licensed electrician perform step B.

• If you are not installing permanent wiring, go to step C.

B Instructions for licensed electrician - connecting power

with permanent wiring (Figure 33):

• Remove power from circuit.

• Remove Motor Cover.

• Remove and discard Power Cord.

- Cut off Power Cord inside Power Head as near Strain

Relief as possible.

- Remove Knock-Out Plug, Strain Relief, and Power

Cord. (Cut Ground Wire on line side ofToroid).

- Dispose of Plug, Strain Relief, and Power Cord.

• Install required entrance bushing.

• Connect permanent wiring to Power Head Wires.

- White supply line to Opener White Wire.

- Black supply line to Opener Black Wire.

- Ground to Opener Green Wire.

- Replace Motor Cover.

•

NOTE

Use only Underwriters Laboratories, Inc. (U.L.)

recognized wire nuts.

The Circuit Boards are light sensitive. Ensure the

Motor Cover is installed before energizing

the Opener.

Knockout

- Restore Power to circuit.

Connecting Power with Plug:

• Plug Opener into a grounded outlet as stated in previous

electrical warning.

Perform Safe-T-Beam® alignment check:

• Check if Safe-T-Beam® Source Red LED is glowing

continuously (OK) or blinking (problem).

• If Red LED is blinking twice, adjust Sensor Brackets as

needed to make Red LED glow continuously. (Refer to

page 26.)

FcM' Help, call 1-800-3S4SEiiE or ¥islt i«%wi.ferileccirnpiirif.corn

19

Page 20

Setting Close Limit Switch (Figure 34):

• Check that Magnetic Carriage Assembly is disengaged.

• With garage door fully closed, slide Close Limit Switch

until it is aligned with Carriage Assembly Magnet.

• Tighten Set Screw. Do Not over-tighten.

Setting Open Limit Switch:

• Manually open garage door to full open position.

• Slide Open Limit Switch until it is aligned with Carriage

Assembly Magnet.

• Tighten Set Screw. Do not over-tighten.

• Re-engage Magnetic Carriage Assembly.

of

NOTE

Little effort is required to turn the Force

Adjusting Knobs.

If the door stops moving while opening or

closing, adjust the Open Force or Close Force

Controls

increase the force) and retry the step.

The Open Force and Close Force Controls are to

be set to the minimum force necessary to

ensure the door smoothly opens fully and

closes completely.

The garage door will move slowly the first

time it runs, until the Opener "learns" the

type of door.

Ensure the Magnetic Carriage Assembly is

engaged and is between the two Limit

Switches before operating the Opener.

slightly clockwise (to slightly

A WARNING

The garage door opens rapidly, and can cause serious

injury or death.

Keep the path clear.

Position the ladder to the side of the Power Head so it is

clear of all moving parts of the Opener and the door.

Set the door Opener to use the minimum force needed

to open the door.

A Pre-set Force Controls to midpoint between fully counter

clockwise and fully clockwise (Figure 35).

B Adjust the Close Limit Switch:

• Press Wall Console to close garage door.

- If door does not close completely, measure distance

from bottom of door to floor. Move Limit Switch

same amount toward door and try again.

- If door reverses after contacting floor, move Limit

Switch toward Power Head and try again.

- If door reverses before contacting floor, increase

Close force and try again.

- If door fails to move, check Safe-T-Beam® System. See

Safe-T-Beam® Troubleshooting Guide on pg. 26, and

Opener System Self-diagnostic Troubleshooting

on pg.27.

• Tighten Limit Switch Set Screw. Do not over-tighten

(strip) Limit Switch Set Screw.

C Adjust Open Limit Switch:

• Press Wall Console to open garage door.

- If door does not open completely, move Limit Switch

toward Power Head.

- If door opens completely, but motor continues to

run, move Limit Switch toward door.

• Tighten Limit Switch Set Screw. Do not over-tighten

(strip) Limit Switch Set Screw.

Close Limit Switch

(door fully closed)

Carriage

(disengaged)

Open Limit Switch Switch

(door fully open)

Carriage

(disengaged)

Figure 34 Setting Limit Switches

Figure 35 Making Force Adjustments

Switch

Magnet

Magnet

20

FcM' Help, call 1-S00-3S4SEiiE or visit %wi»i.ferilecornparif.ccirn

Page 21

________

NOTE

____________

NOTE

To protect your new investment, your Excelerator® is

equipped with a Timer and Cycle Counter which work

together to prevent any chance of heat damage to

electrical circuits caused by too many cycles in too short

a time. If your Opener suddenly stops responding to the

Wall Console -

Do Not Unplug the Unit - simply wait

10 minutes for theTimer/CycIe Counter to reset itself

and try again.

Unplugging the unit will prevent the Timer/Cycle

Counter from resetting.

Test Door Opener:

Run door up and down a few times using Wall Console

and observe door travel.

Repeat steps above as needed to set Limit

Switch positions.

Adjust Open Force to minimum needed:

Place door in closed position using Wall Console.

Gently adjust Open Force fully counterclockwise

(minimum force).

Run Opener using Wall Console.

Observe that door runs to Open Limit Switch.

- If not, adjust Open Force Control slightly clockwise,

close garage door, and open it again.

Repeat steps above until garage door runs smoothly

from Close Limit Switch to Open Limit Switch.

Adjust Close Force to minimum needed:

Place door in open position using Wall Console.

Gently adjust Close Force fully counterclockwise

(minimum force).

Run Opener using Wall Console.

Observe that door runs to Close Limit Switch.

- If not, adjust Close Force Control slightly clockwise,

open garage door, and close it again.

Repeat steps above until garage door runs smoothly

from Open Limit Switch to Close Limit Switch.

The door must contact the 2" x 4" board before the

Carriage activates the Close Limit Switch. If not,

readjust the Close Limit Switch.

NOTE

Limit Switch and Force Adjustments must be completed

before checking the contact reverse function (Figure 36).

A Open garage door using Wall Console.

B Lay a 2" x 4" board flat in center of doorway.

C Close door using Wall Console.

D Check that door stops and reverses within 2 seconds after it

contacts board:

• If door does not reverse, decrease Close Force until

door reverses.

• If door still does not reverse, move Limit Switch

toward door.

E Check Safe-T-Beam® System operation:

• If beam is blocked, door will not close.

FcM' Help, call IHIOOHJSHSEiiE or ¥islt i«%wi.ferileccirnpiirif.corn

21

Page 22

A To program one Button of a Remote Control (Figure 37):

• Locate Learn Button and Learn Indicator Light near

Terminal Block on Power Head (Figure 38).

• Press and release Learn Button. Red Learn Indicator Light

will blink 2 times per second.

• Press Remote Control Button once within 30 seconds.

Red Learn Indicator Light will stay lit.

• Press Remote Control Button again. Red Learn Indicator

Light will go out, indicating that memory is stored.

B Program each additional Remote using step A above.

To Erase All ieiricites froiri Power H<?aci Memory

A Press and hold Learn Button on Power Head for 10 seconds or

until Learn Indicator Light goes out. Memory is erased:

• Program Remotes again as needed.

To ieplacts ierriote Control iattery

A Push in on Battery Cover Latch at base of Remote Control

(Figure 39):

• Use coin, pen, screwdriver or any similar device.

- Cover snaps open.

• Replace old Battery with new ^EVEREAD% A23,

12 Volt Battery.

B Snap Battery Cover closed.

NOTE

Each Remote Control must be programmed

separately.

The Remote Controls will not cause the door

Opener to close the garage door if the Safe-T-

Beam® System is malfunctioning.

When programming the Remote Controls, they

must be at least 24'Arom the Antenna Wire.

If the red Learn Indicator Light blinks

approximately 4 times per second,

programming has stopped. If programming

has stopped, repeat the above steps.

Each Button on a 2 or 3 Button Remote Control

is for a different Opener. You cannot use more

than one Button per Remote, per Opener.

A maximum of seven Remote Controls or

Wireless Keypads can be stored into the

Receiver at one time. If a Remote Control

becomes lost, or if you want to delete a Remote

Control or Wireless Keypad, see "To Erase All

Receiver Memory."

05

1 Button

Remote

48

2 Button

Remote

3 Button

Remote

A WARNING

A moving garage door may cause serious injury or death.

• Keep people clear of opening while door is moving.

• Do not allow children to play with the Remote Controls.

If the Safety Reverse does not work properly:

• Close the door and disconnect the Opener using the

Emergency Release Cord.

• Do not use the door Opener, Remote Controls, or

Wireless Keypad.

• Refer to the door and door Opener Owner's Manuals

before attempting any repairs.

Press Button on Remote Control. Garage door will move.

Press Button again. Garage door will stop:

• The door automatically stops at the end of the open or

close cycle.

Press Button again. Garage door will reverse.

Figure 37 Genie Remote Controls

Figure 38 Learn Code Button and Indicator Light

.... Visor Clip

Push to open

Battery Cover

Model

Number

iiJO'

I

Figure 39 Remote Control Battery Replacement

22

FcM' Help, call 1-SOOHJS4SEÌÌE or visit www.gBmstompsmi.mm

Page 23

A WARNING

A Moving door can cause serious injury or death.

1 Keep people clear of opening while door is moving.

2 Do Not allow children to play with Wireless Keypad.

3 During programming, the door opener could begin

to run, so stay away from the moving door and its

parts.To keep the door from moving, close the door

and disconnect it from the Opener oy pulling the

Emergency Release.

If Safety Reverse does not work properly

1 Close door and disconnect the Opener using

Emergency Release Cord.

2 Do not use door Opener, Remote Controls, or

Wireless Keypad.

3 Refer to Door and Door Opener Owner's Manuals

before attempting any repairs.

NOTE

FOR CONVENIENCE — Program Keypad BEFORE mounting.

A Set Wireless Keypad PIN (Personal ID Number):

• Activate programming mode.

- Press (in order)

- Red LED blinks - once per second.

• Enter your PIN (3 to 8 characters).

• Press

- Red LED blinks - twice per second and turns off.

B Programming One Door Operator:

• Find the Learn Code Button and Learn Code

Indicator LED on your door opener.

- If your door opener has a black antenna

wire, the Learn Code Button and Indicator

LED are located near the antenna.

(The light lens may need to be opened)

- If your door opener does not have an

antenna,you have an external receiver.

The external receiver cover must be

removed to access the Learn Code

Button and Indicator LED.

• Press the Learn Code Button.

- Learn Code Indicator LED (on Opener)

will blink.

• Enter your PIN and press

- Learn Code Indicator LED stays on.

• Press again.

- Learn Code Indicator LED turns off

C Operating One Door Operator:

• To move the garage door:

- Enter your PIN.

- Press(

__________

If the door does not move, check the red LED on

Keypad. If the LED is blinking rapidly, the PIN was

entered incorrectly. After the LED stops blinking,

re-enter your PIN and try again.

Any keypad button will control the door for

30 seconds after the door starts moving.

Rapid Blinking of the red LED indicates an error.

After a few seconds the LED will turn off. Start over.

NOTE

___________

Proceed to"iloijritirig Ifireless ICef fjac!."

Pri3graii'iirJri§ for 2 or 3 Door Operi<?rs

A Set Wireless Keypad PIN (Personal ID Number):

• Activate programming mode.

- Press (in order) ©©©^P-

- Red LED blinks - once per second.

• Enter your PIN (3 to 8 characters).

• Press

- Red LED blinks - twice per second and turns off

B Programming the Keypad for Multiple Door openers:

All sJcicir openers will use the same PIN.

• Enter your PIN and press

- Red LED blinks - once per second.

• Press again.

- Red LED blinks - twice per second.

• Press the number of doors (total) you wish

to control ( or

• Press 1^^^).

- Red LED blinks several times and turns off

Programming Door Openers:

• Decide which door will be door #1, #2 and #3.

• Press the Learn Code Button (see Figure 1).

- Learn Code Indicator LED (on Opener) blinks.

• Enter your PIN and press .

- Learn Code Indicator LED stays on.

• Press the number you have picked for this

door Opener (© or ^ or @).

- Learn Code Indicator LED stays on.

• Press

- Learn Code Indicator LED turns off.

Repeat step A above for each door opener.

Each door opener must be programmed to receive the

signal from the Wireless Keypad.

FcM' Help, call IHIOOHJS.GEiiE or visit svswi.ferileccirnpiirif.corn

23

Page 24

(Continued)

Operating 2 or 3 Door Openers:

• To move one of the doors.

• Enter your PIN.

• Press ,

Press door opener number (C1J or or

Mount Keypad. (Mounting screws located inside

battery compartment.)

• Remove Battery Cover. See Figure 3.

• Drill a 1/16" pilot hole for the top mounting screw.

• Install a screw into the drilled hole,

leaving a 1/8" gap between the

screw head and the wall.

See Figure 2.

• Hook the Keypad over the screw.

• Mark,drill pilot hole and fasten

bottom screw.

• Reinstall Battery Cover.

A Enter your PIN

• Press

B Enter theTemporary PIN (from 3 to 8 characters).

• Press .

Erase old PIN:

Press and hold in order

- Red LED will blink once and turn off.

• Release all buttons.

Programming Door Opener(s).

• Return to "Programming for 1 Door Opener"or

"Programming for 2 or 3 Door Openers."

DO NOT reprogram the Door Opener(s).

Temporary PIN remains active until the next time your

normal PIN is entered.

24

FcM' Help, call l-SOOHJSHSEiiE or visit www.gBmstompsmi.mm

Page 25

Snap Lens Hinges into

slots on back of Motor Cover

60 Watts

maximum

Figure 41 Install Lens Cover and Light Bulbs

Install two 50 Watt light bulbs (not included) into Light

Sockets (Figure 41):

• Rough service, 130 Volt bulbs are recommended.

Install Lens into slots in Motor Cover.

B

C

Install Genie Emergency Release Kit (GER-2) accessory,

if purchased.

Installation is now complete.

Trarisiriitter Cöinpliarice 5Jtatemerit

Transmitters comply with all United States and Canadian legal requirements

as of the date of manufacture. No warranty is made that they comply with all

legal requirements ofany other jurisdiction. If transmitters are to be used in

another country, the importer must determine compliance with any local

laws and regulations which may differ from United States and Canadian

requirements prior to use.

Los transmisores cumplen con todas las reglamentaciones legales de los

Estados Unidos y del Canadá, en la fecha de fabricación. Ninguna garantía

se da que cumplan con todas as reglamentaciones legales de ninguna otra

jurisdicción. Si los transmisores se van a utilizar en otro país, el importador

debe determinar si cumplen con las reglamentaciones y leyes locales que

puedan ser diferentes a las reglamentaciones de los Estados Unidos y del

Canadá, antes de usar los mismos.

Les émetteurs sont conformes à la réglementation américaine et canadienne

à compter de leur date de fabrication. Aucune garantie n'est stipulée

indiquant qu’ils sont conformes à toutes les prescriptions juridiques d'autres

autorités. Si les émetteurs sont utilisés dans d'autres pays, il incombe à

l'importateur d'en déterminer leur conformité aux lois et règles locales

pouvant différer de celles des États-Unis et du Canada avant toute

utilisation desdits émetteurs.

Sendegeräte entsprechen allen gesetzlichen Bestimmungen in den USA und

Kanada zum Zeitpunkt der Herstellung. Wir übernehmen keine

Gewährleistung für die Einhaltung aller gesetzlichen Bestimmungen in

anderen Ländern. Sollen Sendegeräte in anderen Ländern eingesetzt werden,

so muss der Importeur vor dem Gebrauch sicherstellen, dass die Sendegeräte

auch solchen lokalen Bestimmungen entsprechen, welche von den

Bestimmungen der USA und Kanadas abweichen,

«ihTtœ 01. « T'ÄÄft

I' 7 >X 5 -Vó'-H. u

spsff a* »»íe

Push in

Latches

to

close Lens

A Monthly:

• Door springs and door hardware:

- Oil door roller, bearings, and hinges using silicone

lubricant or light oil.

A WARNING

Do not operate door automatically or manually if springs

are broken. Contact a Genie Factory Authorized Dealer for

service or call Customer Service at 1-800-35-GENIE.

• Balance Door.

- Close door.

- Release Magnetic Carriage Assembly from Rail Assembly

by pulling down on Emergency Release Knob.

- Raise door manually 3'- 4' and verify that door stays at

that position. See Check Step 2 on page 3.

NOTE

When the door is 3' - 4' above the ground, the door

should stay open. Slight movement is acceptable. If

the door moves too much, contact a Genie Factory

Authorized Dealer for service or call Customer Service at

1-800-35-GENIE.

- Reattach Magnetic Carriage Assembly to Rail Assembly:

a. Pull the Emergency Release Knob toward Power Head.

b. Close door.

Contact Reverse Test.

- Perform Installation Step 10 on page 21.

If the door fails to reverse on contact with the board,

adjust the Close Force Control as specified in Set Limit

Switches and Force Controls on page 20. If the Opener

still fails, contact a Genie Factory Authorized Dealer for

service or call Customer Service at

Yearly:

• Wipe off old excess lubricant from Drive Screw.

• Lubricate Drive Screw with Genie Lubricant (GLU-3)

NOTE

Use ONLY Genie Lubricant

may damage the Opener.

GLU-3

Lubricant

1-800-35-GENIE.

GLU-3). Other lubricants

LfnSüft. |lISÍ,a0ttJl(C56ÍI®ffifi§Wíbnb0IMAr¿;#|7S?,f:

¿ s, 5 fc 0. «1 A# H nnáf, átfi A B 0 W A 2ptM A A b ¿ S «

fgbítíttliíAUÍ-a'A,

E0j^D|Ejse DRuf nm aeioiiAi «5 w»» gzisiioj s^aiikhi

ttjEjof SMcf 7|Ej c\E awasi Hë gsjoj s.^ aUJOii tcjEjof Sfe aiêJ

ë siôMEK eia MazsDiEjgoi 7|E| CB xigoiiAf Afsa ëSJSAfe

A®5|7|0|| o>A1 nR3t 7imq.fijo| SëAfîfafe CUXlEaëë n A|«°|

gm 5BII0II n|E|0| IfA|°| 01^1 igsiiot îfMcK

FcM' Help, call 1-800-35-GEiîE or visit LVLWi.ferilsccirnpiirif.corn

FCC AND IC CERTIFIED

All devices comply with Part 15 of the FCC Rules.

Operation is subject to the following two conditions: (1)

this device may not cause harmful interference, and (2)

this device must accept any interference received, includ

ing interference that may cause undesired operation.

25

Page 26

^WARNING

TO REDUCE THE RISK OF SEVERE INJURY OR DEATH

1 READ AND FOLLOW ALL INSTRUCTIONS.

2 Never let children operate or play with the Door Controls. Keep the Remote Control away from children.

3 Always keep the moving door in sight and away from people and objects until the door is completely closed.

NO ONE SHOULD CROSS THE PATH OF THE MOVING DOOR.

4 NEVER GO UNDER A STOPPED, PARTIALLY OPEN DOOR.

5 Test Opener monthly. The door MUST reverse on contact with a 1-1/2" high object (or a 2" x 4" board laid flat)

at the center of the doorway on the floor. After adjusting either the Force or the Limit of travel, retest the Door

Opener. Failure to adjust the Opener properly may cause severe injury or death.

6 When possible use the Emergency Release only when the door is closed. Use caution when using this Release

with the door open. Weak or broken springs are capable of increasing the rate of door closure and increasing

the risk of severe injury or death.

7 KEEP GARAGE DOORS PROPERLY BALANCED. See Owner's Manual. An improperly balanced door increases the

risk of severe injury or death. Have a Genie Factory Authorized Dealer make repairs to cables, spring

assemblies, and other hardware.

8 SAVE THESE INSTRUCTIONS.

^WARNING

Use the Wall Console included with Opener. Any other wall console can cause the Opener to operate unexpectedly and

the light to stop working.

1 So'r i ■ i iED) insor (Green LED) 1 i ■ . .iible Problem Solution 1

26

tl' "

OFF OFF

OFF ON

2 BLINKS, Pause

(Repeat) , ON

2 BLINKS, Pause

(Repeat)

3 BLINKS, Pause

(Repeat)

4 BLINKS, Pause

(Repeat)

OFF

ON

ON

|_ Normal operation ^

1 • Power Head not powered i

• Wiring from Power Head bad

• Wiring to Source missing or bad

• Power has been interrupted

• Beam not aligned

1 • Beam obstructed

• Sensor defective

• Wire to Sensor missing or bad

• Sensor defective

• Sensor receiving interference • Determine source of interference

• Source not sending pulses

• Source defective

FcM' Help, call l-SOOHJSHSEiiE or ¥isit %wi»i.ferilecornparif.ccirn

None required

• Check breakers, fuses, plugs 1

• Check wiring for obvious shorts

• Check wiring

• Remove power and reapply

• Check Source, Sensor alignment

• Check for obstruction i

• Contact Customer Service

• Check wiring

• Contact Customer Service

• Contact Customer Service

• Contact Customer Service

• Contact Customer Service

Page 27

Of

See Status Light on FigureSS, page 22)

u See ablem /Vhat to Do Reference

1 BLINK, 1 Motor Drive

1 Pause Board back in (reapply power), and activate from Wall Console.

(Repeat) Interrupt

Normal

. operation

restored

If the problem

recurs automatic garage door balance detection system. An improperly

Operation not

restored

1

INKS, Controller

Pause Board back in (reapply power), and activate from Wall Console.

(Repeat) 1 Interrupt

3 BLINKS, Opener

Pause Overheated for internal clock to provide additional cycles. Cycles are restored

(Repeat) or at a rate of 5 cycles per 10 minutes of rest.

Over-cycled

4 BLINKS, Force Settings

Pause Incorrect

(Repeat)

5BLINKS, Safe-T-Beam®

Pause Malfunction

6 BLINKS, Wall Console

Pause does not work

(Repeat)

INKS, Limit Switches

Pause not working

(Repeat)

8 BLINKS, Wall Console

Pause , locked Unlock switch.

(Repeat)

J

__________

e

Reset Opener—unplug (or disconnect power), wait 5 seconds, plug

«

First Cycle will run at slow speed.

«

Check door condition. NOTE: This Opener is equipped with an See Door

balanced door, damaged or worn counter-balance spring, binding

Joor hardware or rollers may result in a "ONE-BLINK" signal.

lontact Customer Service for further assistance.

«

Check door condition. l.See page 3.

«

Have a Genie Factory Authorized Dealer check: 2. See door

- Fuse on Motor Drive Board.

- Ribbon Cable on Motor Drive Board is properly inserted into

Connector on Controller Board.

«

Contact Customer service for further service.

«

Reset Opener — unplug (or disconnect power), wait 5 seconds, plug

«

Have a Genie Factory Authorized Dealer check that Ribbon Cable on

Motor Board is properly inserted into connector on Controller Board.

e

Contact Customer Service for further assistance.

«

Do not unplug or disconnect power from Opener. Wait 10 minutes

«

Contact Customer Service for further assistance.

«

Check Force Settings. NOTE: Force Settings are not pre-set at factory. l.See page 20.

«

Check door condition. 2. See Door

«

Contact Customer service for further assistance. Safety Guide

«

Check Safe-T-Beam® Self-diagnostic System. NOTE: Safe-T-Beam® See page 16.

System must be installed and operational to enable door to close.

e

Contact Customer Service for further assistance.

«

Check Wall Console Wiring for shorts, tight Staples, or pinched Wires. See page 18.

«

Check Wiring Connections at Power Head and Wall Console.

e

Contact Customer Service for further assistance.

«

Check Limit Switch Wire connections to Terminals on Power Heac See page 20.

«

Check for shorted or pinched Wires under Limit Switch Brackets.

«

Contact Customer Service for further assistance.

«

Vacation Locking Switch on Wall Control is in "Lock" mode. See page 18

Contact Customer Service for further assistance.

•

1

1

Safety Guide

Safety Guide

: i

1 1

The status LED Indicator Light is located under the Lens Cover.The Green LED light will turn ON, then OFF when

power is applied to the Opener. If LED stays ON, have a Genie Factory Authorized Dealer check the Controller

Board, or call Customer Service at 1-800-35-GENIE.

If Safe-T-Beam® problems exists, the door can be closed electrically by holding the Wall Console Button down

until door is fully closed.

The Remote Controls and Wireless Keypad will not work without a working Safe-T-Beam® System.

FcM' Help, call IHIOOHJSHSEiiE or ¥islt i«%wi.ferileccirnpiirif.corn

27

Page 28

Problem

Opener does not run

from Remote Control

Door Opener starts

for no apparent reason

Door starts down, then

stops before it is

completely closed

Door starts down, then

stops and goes back up

Door will only run closed

Door will only run open

Lights will not turn off

Door starts up, but stops

before it is

completely open

Operator runs, but door

does not move

Wall Console Vacation

Lock function does

not work

What To Do

1. Check power source.

A. If Opener is connected to an outlet:

• Plug a working lamp into outlet used for Power Head.

• If lamp glows, power source and outlet are OK.

• If not, check fuse or circuit breaker or non-compatible GFCI.

NOTE: A licensed electrician must replace non-compatible GFCI's.

B. If Opener is connected to a wiring box:

• Check fuse is not blown, or circuit breaker is "Closed" (not tripped).

• If still no power, have a licensed electrician check circuit and wiring.

2. If power is OK:

• Check connections at Power Head Terminals (see Wall Console Installation page 18), tightening any

loose connections.

Have a Genie Factory Authorized Dealer check that Ribbon Cable between Controller Board and Motor Drive

Board is properly connected to Connectors on Circuit Boards,or call Customer Service at 1-800-35-GENIE.

Check Wires to ensure that they are not cut (Stapes can cut insulation and short Wires).

Replace any shorting Staples and shorted Wires.

Was Remote Control lost or stolen? If so, erase all Remote Control codes from Receiver's memory

and reprogram for remaining remote controls. (See Erase All Receiver Memory on page 22).

Ensure that no Buttons are stuck"pushed-in"on Wall Console or any Remote Controls.

Check Close Limit Switch setting (see Set Limit Switches and Force Controls on page 20).

I

I

Adjust as needed.

Check for shorted Wires.

Check garage door for binding.

If a new installation, check Door Arm position.

Check operation of Contact Reverse function.

Check Safe-T-Beam® System for beam obstruction or misalignment of Lenses.

Check Safe-T-Beam® System diagnostic code.

Check Close Force adjustment (see Set Limit Switches and Force Controls on page 20). Adjust as needed.

Check garage door for binding.

Check Open Limit Switch for a short circuit and for proper wiring.

Check Open Force adjustment (see Set Limit Switches and Force Controls on page 20). Adjust as needed.

Check condition of garage door and doorspring(s).

: If you suspect a problem with the garage door hardware or springs, contact a Genie

Factory Authorized De aler for service, or contact Customer Service at 1-800-35-GENIE.

Check Safe-T-Beam® System as detailed in the Safe-T-Beam® System Self-diagnosticTroubleshooting Chart

(see Safe-T-Beam® System Self-diagnosticTroubleshooting Section on page 26).

Check Close Limit Switch for a short circuit and for proper wiring.

Check Close Force adjustment (see Set Limit Switches and Force Controls on page 20). Adjust as needed.

Disconnect Wires connecting Wall Console to Power Head (see Wall Console Installation on page 18).

Check their condition and either replace or reconnect.

Until a replacement Wall Console can be obtained,disconnectWall Console and use only Remote Controls

or Wireless Keypad to operate Opener.

Check (ensure) that garage door and Opener are in good repair, properly lubricated, and properly

balanced as detailed in Maintenance Section.

liCî: If you suspect a problem with the garage door hardware or springs, contact a Genie

Factory Authorized De aler for service, or contact Customer Service at 1-800-35-GENIE.

Check Open Limit Switch for a short circuit and for proper wiring.

Check Open Force adjustment (see Set Limit Switches and Force Controls on page 20). Adjust as needed.

Ensure Magnetic Carriage Assembly is engaged to Rail Drive Screw (see Install Magnetic Carriage Assembly

onto Rails on page 10).

Check Force adjustment (see Set Limit Switches and Force Controls on page 20). Adjust as needed.

Check that all sections of Rail Drive Screw are turning when Motor runs. If not:

- Check condition (not cracked, split, or broken) and placement of Coupler. Replace as needed.

- Check condition (not cracked, split, or broken) and placement of Collar and Clip. Replace them

as needed.

Ensure Magnetic Carriage Assembly is in contact with Close Limit Switch.

Check when door is fully closed, that Carriage activates Close Limit Switch. If not,adjust position of Close

Limit Switch (See page 19).

28

FcM' Help, call 1-SOO-3S-GEiiE or ¥isit %wi»i.ferilecornparif.ccirn

Page 29

C5eri<iral Troubleshooting (Al'imafs Chtick th<i Steitus LED UghtMCoritIriuecll

Li'Oblc.iV; What To Do

Remote Control has less

than 25'operating range

Opener works from Wall

Control, but not from

Remote Control

Noisy operation

Safe-T-Beam® System

Door closes, and Opener

: «

: «

: «

«

Relocate Remote Control inside car.

«

Ensure Remote Control is pointing toward garage door when pressing Control Button.

«

Replace Remote Control Battery ^EVEREJWY, type"A23." (See page 22).

«

Reposition Opener Antenna Wire.

«

Do Not attempt to retune Remote Controls or Receiver.

: «

Program code for each Remote Control into Receiver memory (See Programming the Remote

Control on page 22.

Replace Remote Control Battery ^jtEVERERDY, type"A23." (See page 22).

Check Safe-T-Beam® System for beam obstruction or misalignment of Lenses.

Check Safe-T-Beam® System for any diagnostic codes. If present, troubleshoot as detailed in

Safe-T-Beam® System Self-Diagnostic Troubleshooting Chart (See page 26).

i «

Ensure all fasteners are tightened.

Check that the garage door and Opener are in good repair, properly lubricated,and properly j

balanced. (See Maintenance page 25). i

•

e

Factory Authorized Dealer for service, or contact Customer Service at 1-800-35-GENIE.

% «

If an operational problem exists, Opener will not run closed.

«

Check Safe-T-Beam® System for beam obstruction or misalignment of Lenses.

£ «

Check Safe-T-Beam® System for any diagnostic codes. If present, troubleshoot as detailed in Safe-T-Beam®

System Self-DiagnosticTroubleshooting Chart (See page 26).

£ «

Check position ofWall Console Vacation Lock Switch. It must be in UNLOCKED position for Opener to

1 shuts down open door.

: If you suspect a problem with garage door hardware or springs, contact a Genie

FcM' Help, call IHIOOHJSHSEiiE or ¥islt i«%wi.ferileccirnpiirif.corn

SECONDARY GROUND

29

Page 30

To get warranty service for your Genie product, you must

provide proof of date, and place of purchase of the product.

What is Cmemd

Any defect in material and workmanship from personal, normal

household use in accordance with the Owner’s Manual.

For How Long:;

H8000D Series — Lifetime* on motor, on parts and service.

ISD990 Series — Lifetime* on motor, 5 years* on parts.

ISD990-2 Series — Lifetime* on motor and all parts.

ISD99S Series — Lifetime* on motor and all parts.

ISD99S-2WKM Series — Lifetime* on motor and all parts.

ISDIOOO Series — Lifetime* on motor,aII parts and service.

CMD9900 Series — Lifetime* on motor, 5 years* on parts.

PR099 Series — Lifetime* on motor and all parts.

* for as long as you own your home.This warranty is non-transferable.

This warranty applies only to the consumer who originally purchased

the product.

G <iog ra ph ic Scope:

This warranty applies only to Genie products purchased in the United

States and Canada.

If your Genie product is defective, we will send replacement parts or, at

our option, a replacement unit at no charge to you, excluding shipping,

handling and labor costs. If we send replacement parts for your Genie

product, we may use new or reconditioned parts. If we choose to send

a replacement unit, we may use a new or reconditioned one of the

same or similar design.

LliTiitations;

IMPLIED WARRANTIES, INCLUDING THOSE OF FITNESS FOR A

PARTICULAR PURPOSE AND MERCHANTABILITY (AN UNWRITTEN

WARRANTYTHATTHE PRODUCT IS FIT FOR ORDINARY USE) ARE

LIMITED TO ONE YEAR FROM DATE OF PURCHASE. GENIEWILL NOT PAY

FOR: LOSS OF USE OF YOUR GENIE PRODUCT OR PROPERTY DAMAGE

CAUSED BY YOUR GENIE PRODUCTOR ITS FAILURETO WORK; ANY

SPECIAL INCIDENTAL OR CONSEQUENTIAL DAMAGES; ANY DAMAGES

RESULTING FROM MISUSE OR MODIFICATION OF YOUR GENIE PRODUCT.

Some states and provinces do not allow limitations on how long an

implied warranty lasts or the exclusion of incidental or consequential

damages, so the above exclusions and limitations may not apply.

This warranty is the oniy one we will give on your Genie product, and

it sets forth all our responsibilities regarding your Genie product.

There are no other expressed warranties.

State and Province Rights: This warranty gives you specific legal rights,

and you may also have other rights that vary from state to state and

province to province.

1. Do-It-Yourself Serwice:

Call Genie Customer Service toll free at 1-800-354-3643, or visit

our website at

representatives will assist in diagnosing the problem and will

arrange to supply you with the required parts for do-it-yourself

repairs.Trained service representatives are available Monday Friday, 8:00 AM -11:00 PM,and on Saturday, 11:00 AM - 8:00 PM

Eastern Time (subject to holidays).

You can obtain the name of a Genie Factory Authorized Dealer

by calling the Genie Dealer Locator Service at 1-800-654-3643.

If an Authorized dealer provides warranty service, Genie will not

reimburse you or otherwise be responsible for any labor

charges. Your choice of one of the above described service

options is your remedy under this warranty.

Batteries (which are considered replacement parts)

Installation

Commercial use

Defects resulting from accidents

Damage while in transit to our service location or damage

from alterations

Misuse or Abuse

Lack of proper maintenance

Unauthorized repairs or modifications of the product

Affixing of any attachment not provided with the product

Programming of Remote Control Devices

Programming of Keypads

Safe-T-Beam® adjustment/cleaning

Staples through wiring

Pinched or broken wires

Carriage disengaged

Force Control adjustments

Door out of balance

Broken springs or cables

Power outages

Use of extension cords

Missing or damaged parts on discounted, clearanced, final

sale or taped cartons

Phantom operations

Fire

Flood

Acts of God

Failure to follow the Owner's Manual

www.geniecompany.com.Trained Genie

30

For Help, call l-SOO-35-GEiiE or ¥isit %wi»i.ferilscornparif.ccirn

Page 31

ài

(GIT-1) Deluxe Remote Control with Intellicode®- Allows remote operation of garage door

Controlador remoto de lujo con Intellicode®- Proporcionar operación remoto de la puerta del garaje

Télécommande de luxe avec Intellicode®- Permettre opération éloign"de porte de garage