Page 1

Name

Barrel

Volume

(L)

Power

(KW)

Weight

(Kg)

Speed of stirring shaft (r/min)

Overall

Dimensions(mm)

1stSpeed

2ndspeed

3rdspeed

10

0.5

75

108

195

355

485*410*635

20

1.1

90

108

195

355

600*600*780

30

1.5

180

91

166

282

700*620*1200

FOOD Mixer Operation Instruction

General Description

This is a kind of changing speed gear mixer. With its planetary stirring design, it has a compact

structure, high efficiency, power saving and easy operation. It will be provided to you as an ideal

assistant for bread and cake making.

Technical parameters

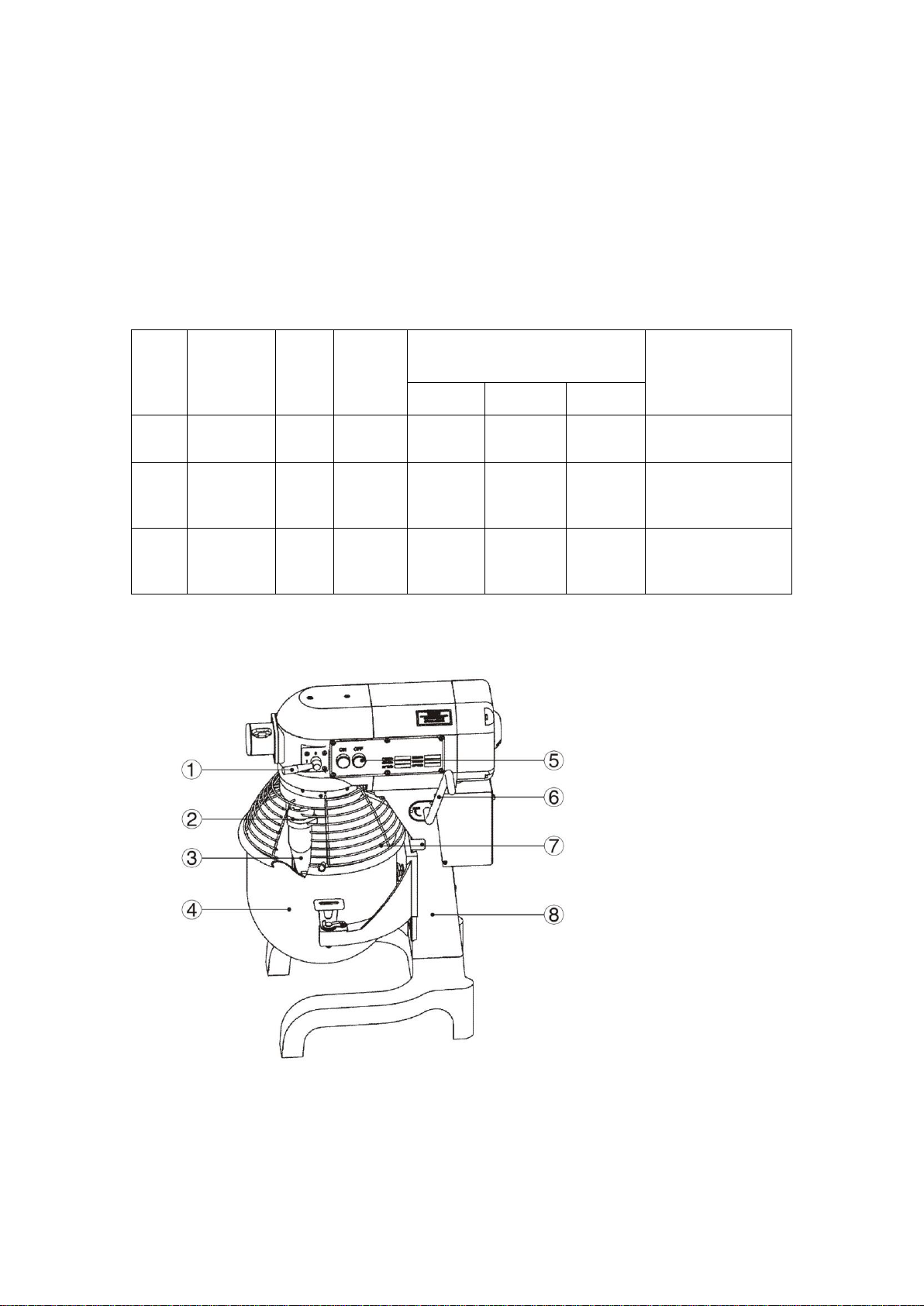

Main External Parts of Mixer

1. Gear change hand lever

2. Stirring shaft

3. Mixer

4. Stainless barrel

5. Power switch

Page 2

6. Bent lever

7. Safety guard(may choose the fitting)

8. Support

Operation Instruction

① Standard power supply V/ Hz AC. (Please use a plug with 3 wide contacts and

good grounding.)

② Installation of Mixer: Put the stirring shaft 2 in Mixer 3 and rotate it in clockwise direction.

③Starting procedure: Pull the gear change hand lever 1 to position 1 before staring, then turn

on the power switch 5 and set the speed required. After the mixer is in normal operation, pull

the hand lever6 to the highest point and lift the support 7 to the highest position.

④Speed transformation: if you want to change the speed, please turn off the power switch 5

first, and then pull the gear change hand lever 1 to the position required.

⑤Shutting down: hen the operation is completed, turn off the power switch 5 first, then pull the

gear change hand lever 1 to position 1,and pull back the hand lever 6to the lowest point and

finally disconnect power supply.

Accessories and Functions

① Spherical mixer: Used for stirring of liquid materials, such as cream and egg.

Recommended speed: mid or high speed.

② Plate mixer: Used for stirring of paste, powder, and fragmental materials, such as stuffing,

cake dough. Recommended speed: Start with low speed, end with mid speed.

③ Hook mixer: Used for stirring of more sticky materials, such as dough. Recommended

speed: low speed.

Notes

① The power socket must be provided with a good ground wire to guarantee the mixer’s

good grounding through it .There will be a electric shock if no ground wire or an

improper grounding mounted. The ground wire can never be connected with gas pipe,

water pipe, lightning rod or telephone line. Electric leakage should be checked after

installation. Once the power line damaged, the user must replace them in the special

maintain Service Company.

② Don’t put your hand into the stirring barrel during operation. Power supply should be

disconnected before the mixer is going to be installed.

③ Don’t operate the mixer beyond the time limit to prevent reduction of its service life.

④ The mixer should be mounted on a stable and clean place, Keep it away from overheated

or over wet places and away from equipment which has strong electromagnet or can

produce strong electromagnet.

⑤ Keep the machine clean constantly. Disconnect power supply before maintenance. Clean

it with a piece of soft and a bit wet cloth. Don’t clean it with liquid or spraying detergent.

Page 3

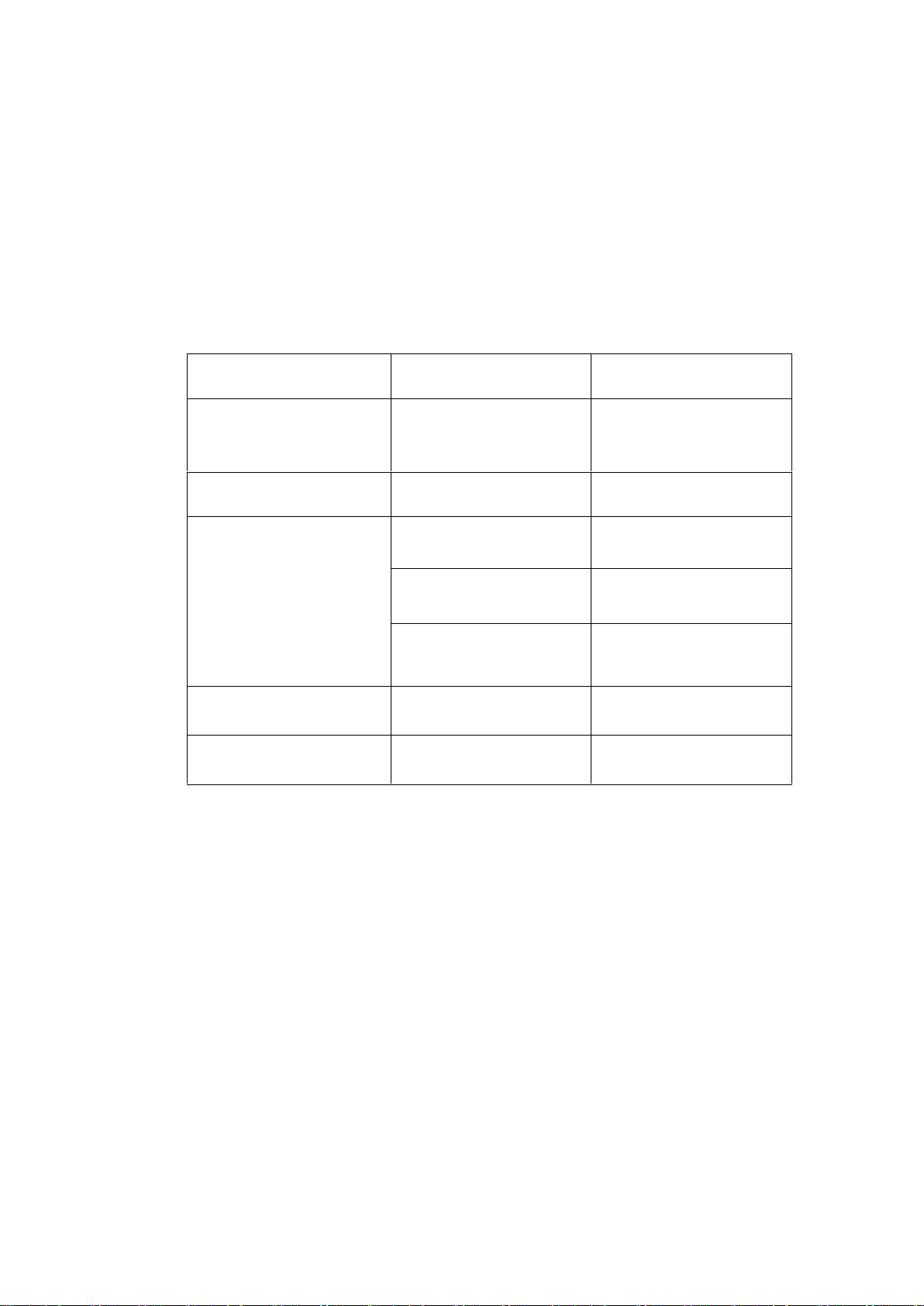

Problems

Causes

Solutions

Tool shaft does not rotate

after starting the machine

Loosen electric wiring

Check electric wiring

tighten those loose

connects

Oil leakage

The seal rings are worn out

Replace seal rings

Motor temperature raises

while reduced output speed

Too low voltage

Check the power supply

Over-loaded

Reduce load

The speed of mixing is too

high or use a wrong stirrer

Select a suitable speed and

stirrer

The mixing knocks with the

bowl

The stirrer or bowl is

deformed

Repair of replace the stirrer

or bow

Abnormal noise and high

temperature from gearbox

Insufficient lubrication

Add or replace the grease

Maintenance

Clean the bowl and stirrer daily or after use to maintain hygiene standard. Clean the

mixer with wet soft cloth. Do not use liquid or corrosive spraying detergent to clean the

mixer.

The transmission gear box is greased in factory. Check the greasing each 6 months. To

add or refill grease, open the top cover, then fill grease from aperture or replace the grease

directly.

TROUBLE SHOOTING

Warning!

If the equipments out of function, please make sure be serviced by professional person of

please turn to special service point!

Page 4

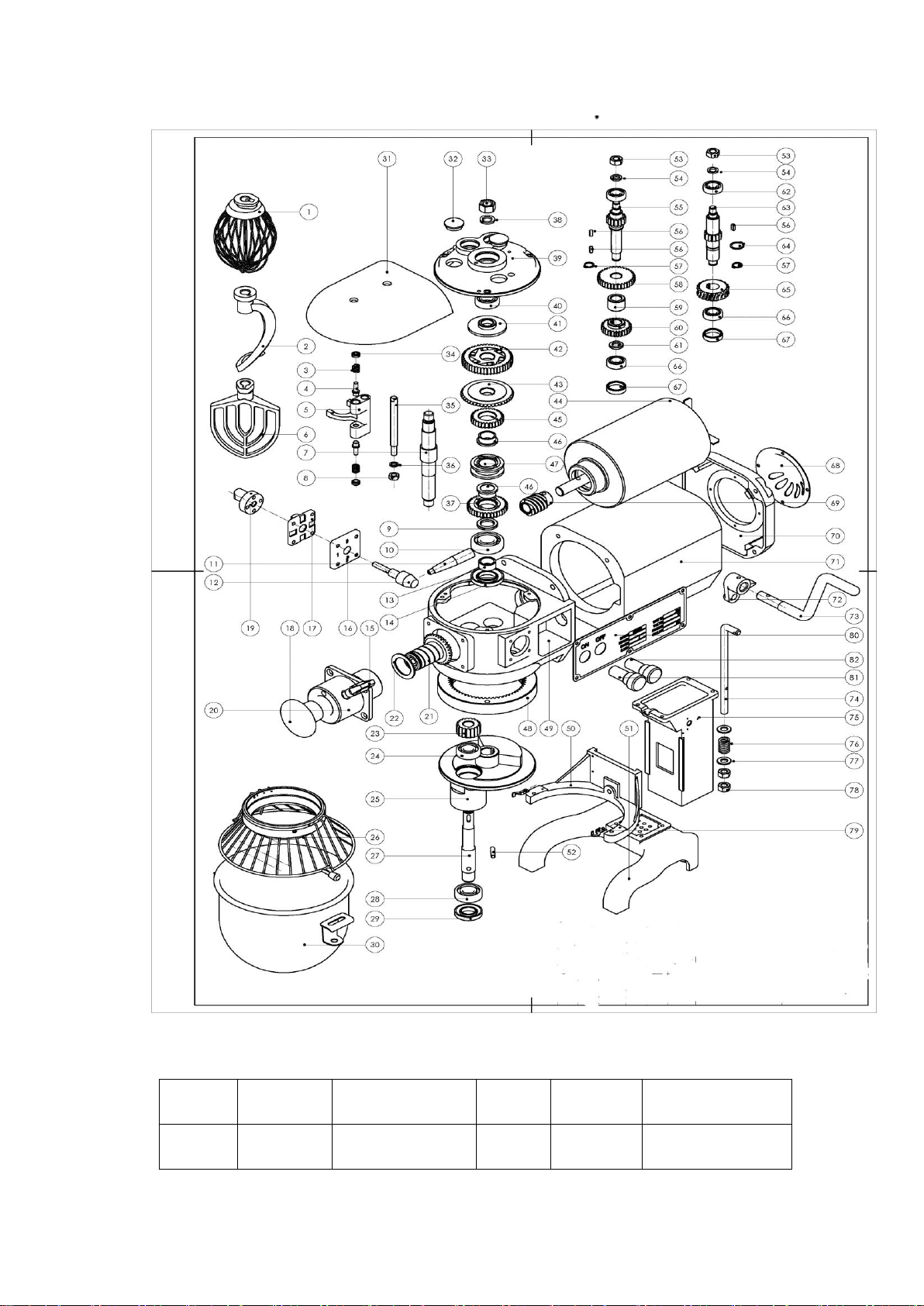

SER.NO.

PART.NO

PART NAME

SER.NO

PART.NO

PART NAME

1

40306000

Wire whip

42

40301200

Super machine parts

PARTS OF 10 L MIXERS

Page 5

2

40305900

Hook

43

40307400

Taper gear

3

50406002

Spring

44

50501010

Motor

4

50405020

Pin shaft

45

40301400

Combination of

gear

5

40303500

Shifting yoke

46

50405019

Bushing

6

40305800

Flat Beater

47

40301500

Claw-type clutch

7

40301900

Main shaft

48

40302600

Inner gear

8

50304005

Nut

49

40302500

Gear box

9

40301800

Lining ring

50

40304200

Support

10

50301006

Bearing 6204

51

40304400

Base

11

40303300

Speed handle

52

50306023

Retainer-spring

12

40303100

Handle shaft

53

50304018

Nut

13

40303800

Lining ring

54

50308006

Spring washer 10

14

50310006

Oil seal

55

40300600

Gear shaft

15

50405065

Locking bolt

56

50313012

Key 4x12

16

40303200

Block handle

57

50312002

Circlips for shaft 12

17

50405016

Block handle cover

58

40300700

Gear

18

50405015

Plug

59

40300800

Lining ring

19

40303000

Cam-gear shifter

60

40300900

Gear

20

50601005

Attachment hub

61

40301000

Ring

21

40307200

Taper gear wheel

62

50301001

Bearing 6001

22

40302400

Circlips for shaft

63

40300400

Shaft worm gear

23

40302700

Planet gear

64

50312006

Circlips for shaft

24

50301004

Bearing 6202

65

40300500

Worm gear

25

40302900

Operating shelf

66

50312006

Bearing 6001

Page 6

26

40306400

Safety guard

67

40300500

Nausea cover

27

40302800

Working shaft

68

50301001

Back guard

28

50301005

Bearing 6203

69

40303600

Worm pole

29

50310003

Oil seal 20x40x7

70

40300100

Back cover

30

50401003

Bowl

71

40300200

Motor box

31

50603045

Cover

72

40305501

Crank lever

32

50405032

Plug

73

40305600

Handle

33

50304020

Nut

74

40305200

Connecting rod

34

50405021

Control nut

75

40303900

Stud

35

40303400

Declutch shift shaft

76

50406001

Spring

36

50308005

Spring washer 8

77

50307006

Clamp plate 10

37

40301700

Gear

78

50304006

Nut M10

38

40301200

Spring washer 14

79

50405074

Press board

39

40307400

Support

80

50402109

Brand

40

50501010

6003

81

50506026

Start switch

41

40301400

Spindle boring

cover

82

50506029

Stop switch

Page 7

SER.NO.

PART.NO

PART NAME

SER.NO

PART.NO

PART NAME

1

40506300

Wire whip

42

50312002

Circlips for shaft 12

PARTS OF 20 L MIXERS

Page 8

2

40506500

Spiral dough hook

43

40507200

Taper gear wheel

3

40506200

Flat Beater

44

40501700

Gear

4

40506700

Safety guard

45

50405041

Bushing

5

50401006

Bowl assembly

46

40501800

Sleeve

6

50405064

Plunger-shifter yoke

47

40502000

Claw type gear

wheel

7

50406021

Spring

48

40502100

Ring

8

50405029

Pin shaft

49

50301007

Bearing 6205

9

40503600

Shifting yoke

50

40502200

Bushing

10

40502900

Cam-gear shifter

51

50310010

Oil seal 30X52X10

11

40503100

Plate-shifter index

52

50405074

Press board

12

50405016

Handle-shifter cover

53

50601026

Support

13

40503300

Handle-shifter

54

50601027

Case

14

40303300

Speed handle

55

50304018

Nut

15

50405015

Plug

56

50301003

Bearing

16

40507100

Attachment hub

57

40501100

Mid-gear wheel

17

50405065

Tighten handle

58

50313013

Key 4*14

18

50405026

Ring

59

50312006

Circlips for shaft 18

19

40506600

Taper gear wheel

60

40501000

Gear

20

50403009

Top cover

61

40500600

Bushing

21

50304020

Nut

62

40500500

Gear

22

50405052

Pressing plate

63

40503800

Plug cover

23

50405032

Plug cover

64

50405025

Worm pole

24

40501500

Super machine parts

65

50310002

Oil seal

25

40503500

Declutch shift shaft

66

50506026

Green button

Page 9

26

50308006

Spring washer 10

67

50506029

Red button

27

50304006

Nut M10

68

50402024

Brand

28

40501400

Main shaft

69

40500300

Motor box

29

40502300

Gear box

70

50313015

Key 5*14

30

40502400

Internal gear

71

40500900

Shaft worm gear

31

40502600

Gear

72

40500800

Worm wheel

32

40502700

Operating shalf

73

50501016

Motor

33

50301006

Bearing

74

40500200

Back housing

34

50310008

Oil seal 28X47X10

75

40500100

Back Cover

35

40502800

Working shaft

76

40505600

Handle-shifter

36

50306030

Retainer-pin 8x35

77

40505400

Crank lever

37

50308008

Spring washer 14

78

40505200

Connecting rod

38

50405051

Pressing plate

79

40504100

Stud

39

40500700

Transmission shaft

support

80

50307008

Clamp plate

40

50301005

Bearing 6203

81

50307006

Clamp plate

41

40501300

Spacer-lower

82

50406005

Spring

Page 10

SER.NO.

PART.NO

PART NAME

SER.NO

PART.NO

PART NAME

1

40705900

Hook

47

40704000

Body housing

2

40705800

Beater

48

40704200

Bowl hold kits

PARTS OF 30 L MIXERS

Page 11

3

40706000

Wire Whip

49

40705100

Support

4

40708200

Safety guard

50

50307009

Clamp plate 18

5

50401008

Bowl

51

50304012

Nut M8*1.5

6

40707300

Top cover

52

50405038

Base

7

50405064

Screw

53

50301005

Bearing 6203

8

50406021

Spring

54

40700500

Transmission shaft

support

9

50405029

Pin shaft

55

50313016

Key 5*16

10

40703400

Shifting yoke

56

50312005

Circlips for shaft 17

11

40502900

Cam-gear shifter

57

40701700

Gear

12

40503100

Plate-shifter index

58

50405042

Bushing

13

40700200

Handle-shifter

59

40701400

Gear box

14

40700300

Handle set

60

50405025

Worm pole

15

50405044

Turn set M6

61

50402037

Brand

16

40700100

Speed handle

62

40700400

Motor

17

50405015

Plug attachment hub

63

50405037

Back housing

18

40701900

Attachment hub

64

40702400

Internal gear

19

50405065

Spring

65

50305075

Tighten yoke M8x25

20

50405026

Circlips

66

50405049

Crank lever

21

40701800

Gear

67

40700900

Handle-shifter

22

50405033

Hood ring

68

40700800

Gear

23

50312007

Circlips for shaft 19

69

40703200

Bushing

24

40702600

Planet gear

70

40700700

Worm wheel

25

40702700

Operating shelf

71

40702900

Mid-gear wheel gear

26

50301007

Bearing 6205

72

40703100

Washer

27

50310009

Oil seal

73

40703000

Plug cover 1

28

50306036

Pin 10*38

74

50304007

Nut M12

29

40702800

Working shaft

75

50308007

Spring washer 12

30

40703600

Declutch shift shaft

76

50301004

Bearing 6202

31

50307006

Plate 10

77

40700600

Gear wheel

Page 12

32

40701300

Main shaft

78

50313016

Key 5x15

33

50304006

Nut M10

79

50312008

Circlips for shaft 20

34

40701100

Top batter valve cap

80

50312003

Circlips for shaft 15

35

50405032

Flat valve cap

81

40703300

Plug cover 2

36

50301006

Bearing 6204

82

50501031

Motor

37

40701200

Main shaft plug

cover

83

50405050

Rubber set

38

40701500

Super machine parts

84

50506026

Green button

39

40701000

Gear

85

50506030

Red button

40

50405041

Bushing

86

40705500

Crank lever

41

40702000

Sleeve

87

40705700

Handle-shifter

42

40702100

Gear

88

40705300

Connecting rod

43

40702200

Clamp plate

89

50307008

Clamp plate 14

44

50301008

Bearing 6206

90

50406022

Spring

45

40702300

Bushing

91

50307007

Clamp plate 12

46

50310015

Oil seal 40*62*8

Loading...

Loading...