SERVICE MANUAL

Service, Repair & Replacement Parts Information

RIP-R-STRIPPER Floor Covering Stripper

Model: FCS16

Form: PGSM4240301EU, Version 1.1, Original Instructions

• Do not discard this manual.

• Keep manual readily available for reference during operation or when servicing product.

• Before operation, read and comprehend operator manual content.

• Customer Service: 001 507 451 5510

• Customer Service Telefax: 001 507 451 5511

Note: There is no charge for Customer Service.

Internet Address: http://www.generalequip.com

•

Email: general@generalequip.com

•

Mailing Address:

•

General Equipment Company, 620 Alexander Dr. S.W., P.O. Box 334, Owatonna, MN 55060, USA

EUROPEAN REPERESENTATIVE

• Customer Service: ( + 31) 5 23 63 82 86

• Internet Address: http://www.eurogate-international.com

Email: info@eurogate-international.com

•

• Mailing Address: Eurogate International, Galilieistraat 6, 7701 SK Dedemsvaart, The Netherlands

Product covered by this manual complies with mandatory requirements o f 2006/42/EC.

Copyright 2016, General Equipment Company, All rights reserved.

FCS16 RIP-R-STRIPPER FLOOR COVERING STRIPPER

Symbol

Meaning

Symbol

Meaning

Warning,

Material

Material

damage, personal injury and/or death.

FORM PGSM4240301EU, VERSIO N 1.1

TABLE OF CONTENTS

No Food Or

Drink

1 INTRODUCTION ……………………….…………… 1

2 SAFETY SYMBOLS………………………..……….. 1

3 SAFETY INSTRUCTIONS ………….……………… 1

4 SERVICE/REPAIR INSTRUCTIONS ….………….. 1

5 END OF LIFECYCLE ……………………………….. 2

6 DECLARATION OF CONFORMITY ..……………... 2

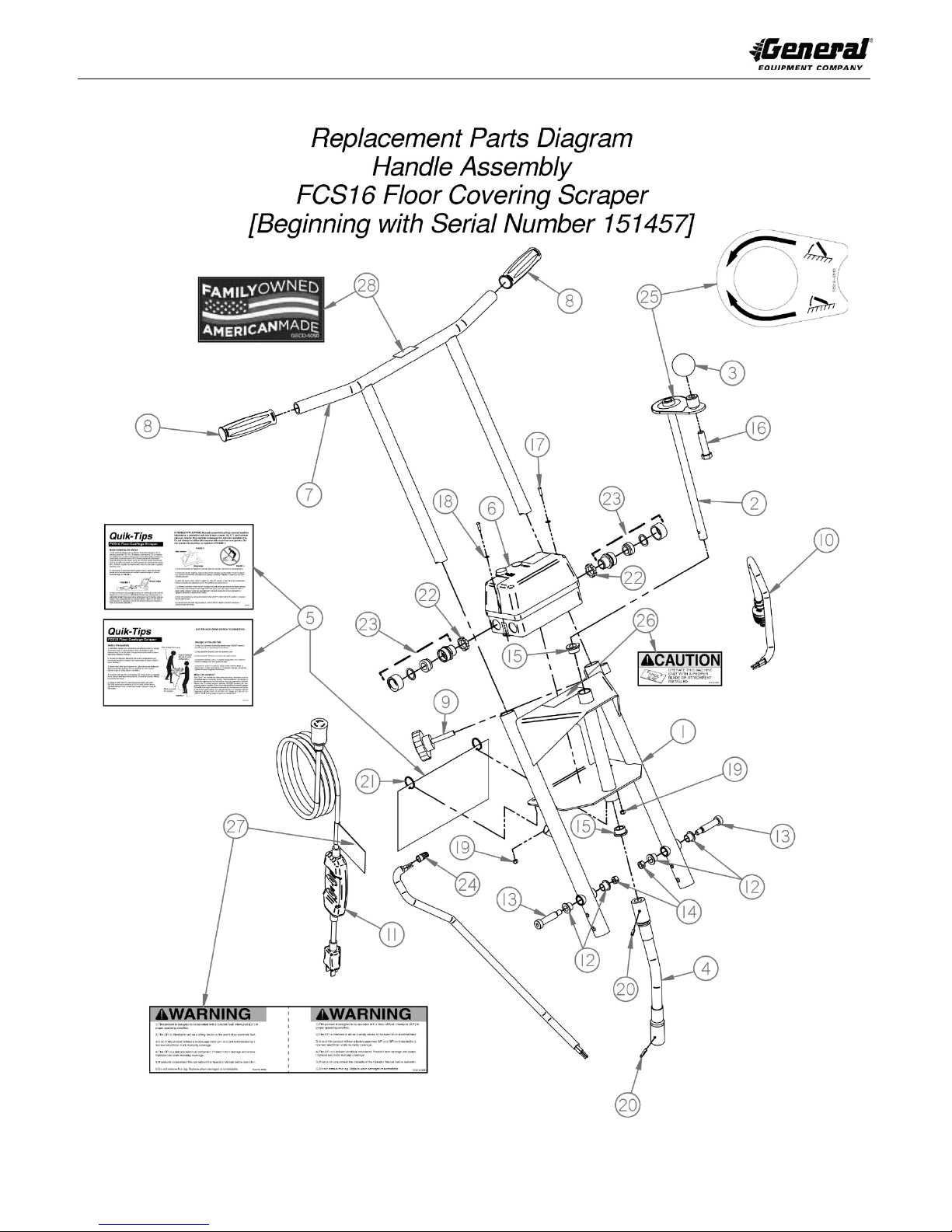

7 REPLACEMENT PARTS .……………….….……… 4

1 INTRODUCTION

The RIP-R-STRIPPER is intended for use in removing a variety of floor

covering materials in a non-explosive atmosphere. This manual is provided to

assist in the service of specific, longer term service items and replacement of

parts when repairs are required. Contents of this manual must be used in

conjunction with the latest version Operator’s Manual GOM4240301EU for

products sold within European Union countries and GOM4240301 for all

other destina ti on s .

You have access to a team of dedicated, knowledgeable, support personn el

that ready to provide field support assistance. Our personnel readily ans wer

your questions or concerns regarding proper applications, service requirements

and warranty related pro blem s.

Please feel free to contact our European Representative or Customer Service

Department during normal business hours using the contact information located

on the front cover of this manual.

Sincerely,

The General Equipment Team

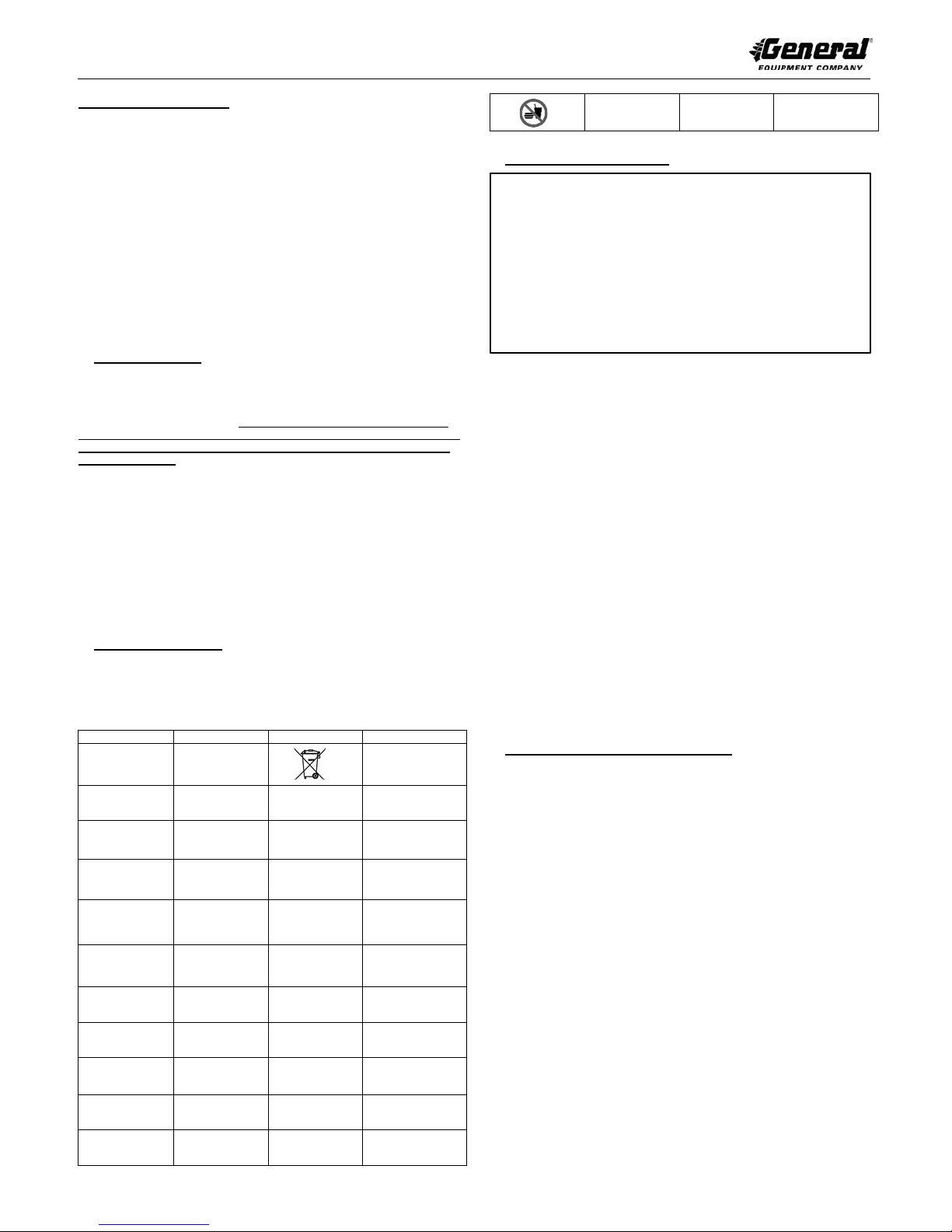

2 SAFETY SYMBOLS

The following safety alert symbols identify important safety messages in this

manual. When you see these symbols, be alert to the possibility of personal

injury and carefully read the message that follows.

SAFETY SYMBOLS & MEANINGS

Action Required

Read Manual

Wear Ear

Protection

Wear Eye

Protection

Wear Protective

Gloves

Wear Safety

Shoes

Wear Breathing

Protection

Disconnect

From Power

No Open Flame

No Smoking

No Active

English-EN 1

Mobile Phone

No Trash

Containers

General Warning

Flammable

Warning,

Explosive

Warning, Toxic

Material

Warning,

Electricity

Warning, Body

Entrapment

Warning, Sharp

Element

Warning, Floor

Level Obstacle

Warning, Drop Off

Warning, Slippery

Surface

3 SAFETY INSTRUCTIONS

• These safety instructions provide guidelines to promote safety

and efficiency in servicing/repairi ng the RIP-R-STRIPPER.

• No warranty, guarantee or representation is made by

manufacturer as to abs olute c or r ect ne ss or suf fic ie nc y of an y

information or statement.

• Safety instructions are intended to deal wit h common practices

and conditions encountered in servicing/repairing of RIP-RSTRIPPER and are not intended to be all inclusive.

• Not following instructions in this manual can result in property

BEFORE SERVICING/MAKING REPAIRS

1. BEFORE servici ng an d/o r rep ai ri ng the RIP-R-STRIPPER, read this

manual and appro pri ate O p er ato r’s Ma nual to gai n fam il iarization with

correct procedures. DO NOT service/repair RIP-R-STRIPPER unless

designated service/repair technician has received adequate, professional

instruction regarding proper procedures.

2. Visually inspect RIP-R-STRIPPER per Operator Manual MAINTENANCE

INSTRUCTIONS STEPS 5 through 10.

3. Determine RIP-R-STRIPPER is in original, factory configuration and has

not been modified in any manner. If questions arise about possible

modifications, contact the European Representative or Customer Service

Department BEFORE utilization. There is no charge for this service.

NOTE: Specifica ti on s and des i gn ar e subj ec t t o chan ge wi th out notice or

obligation. All specifications are general in nature and are not intended for

specific application purposes. General Equipment Company reserves the right

to make changes in design, engineering or specifications and to add

improvements or discontinue manufacture at any time without notice or

obligation. General Equipment Company and its agents accept no responsibility

for variations which may be evident in actual products, specifications, pictures

and descriptions contained in this publication.

4 SERVICE/REPAIR INSTRUCTIONS

The following information is intended for specific service/repair situations for the

RIP-R-STRIPPER. Information is for reference only and is not intended to be all

inclusive.

1. Use only factory approved replacement parts/accessories only for

servicing/repair.

2. All service/repairs not described in this manual must be done by a

dedicated service center following a specific service/repair manual.

3. STOP RIP-R-STRIPPER BEFORE performing service and repair per

STOPPING RIP-R-STRIPPER in OPERATING INSTRUCTIONS section

of Operator’s Manual.

4. Remove ac c essory blade per INSTALLING & RE MOVING ACCESSORY

IMPORTANT: Use safety type solvent. DO NOT use thinner, benzene, or

other volatile solvents that will attack rubber/plastic components when cleaning

RIP-R-STRIPPER. Provide adequate ventilation. Dispose of rags/solvents per

international and local regulations.

BLADE in MACHINE SET-UP section of Oper ato r Man ual and inspect for

sharpness and cracking. Sharpen blade per SHARPENING

ACCESSORY BLADE in SERVICE/REPAIR INSTRUCTIONS section of

this manual. Replace blade if severely worn or damaged.

FCS16 RIP-R-STRIPPER FLOOR COVERING STRIPPER

FORM PGSM4240301EU, VERSIO N 1.1

NOTE: Properly dispose of all accumulated floor covering materials according

to international and local environmental standards.

LUBRICATION

Grease intervals will vary dependent on machine use and operating

environments. In general, lubrication should be performed after every 8 hours

of continuous use.

Tools Required:

1each, standard greas e gu n

Lubricants Required:

1 each, (for standard grease gun) fill with one of the following:

a) ESSO Beacon 325

b) Shell Alvana #2

c) Chevron SRI or equivalent

1 each, container dry film lubricant

1. Lubricate caster wheel bearings using dry film lubricant. Lubricant dries

immediately.

IMPORTANT: DO NOT lubricate caster wheel bearings with other than dry film

type lubricants or over lubricate to prevent foreign material attraction and

reduced bearing service life. Use sparingly.

2. Zerk type fittings are provided at two locations. Using grease gun,

lubricate pivot plate bushings.

a) Lubricate Back-Saver™ Blade Control system jackscrew to

minimize blade control friction during operation. FIGURE 1

ACCESSORY BLADE SHARPENING

1. Blades can be sharpened using a file designed for use on metal

materials. This method will not duplicate original blade sharpening

process, but can significantly increase overall productivity rates versus

use of a dull blade.

a) Remove blade from RIP-R-STRIPPER.

b) Properly secure blade in suitable vice.

c) Use file to sharpen blade edge using similar method to

sharpening rotary lawnmower blade. FIGURE 3

FIGURE 3

ELECTRIC MOTOR SERVICE

The motor is designed for long service life with minimal maintenance. The

motor is equipped with higher capacity ball bearings and seals intended for

dust-filled atmospheres that should not require lubrication for many years.

1. If bearing lubrication or seal replacement is necessary, contact local

motor manufacturer representative for specific information.

FIGURE 1

b) Lubricate exciter plate shielded bearing and bearing housing

casting. Zerk fitting lubricates bearing balls and self-aligning

feature of bearing. FIGURE 2

FIGURE 2

IMPORTANT: DO NOT over lubricate to prevent foreign material

accumulations and accelerated wear/reduced bearing service life. Grease

accumulation on bearing/bearing housing indicates excessive lubrication.

NOTE: Sleeve bearings for operator handle are self-lubricating plus ball

bearings are shielded or sealed. Both will not require lubrication during normal

service life.

5 END OF LIFECYCLE

If the machine comes to the end of its lifecycle, destruction of the machine must

be conducted according to international and local environmental regulations.

6 DECLARATION OF CONFORMITY

We, General Equipment Company, 620 Alexander Drive SW, P.O. Box 334,

Owatonna, MN 55060, USA declare under our sole responsibility that the

portable floor covering stripper product: FCS16

To which this declaration relates is in conformity with the following standards or

standardization documents:

- EN-ISO 12100:2010

According to the provisions of the European directive:

- 2006/42/EC

Manufactured at: Owatonna, Minnesota 55060, USA

Beginning with serial num b er: 141071

Signature: Dennis Von Ruden

Position: President

Date: April 4, 2016

English-EN 2

FCS16 RIP-R-STRIPPER FLOOR COVERING STRIPPER

PAGE INTENTIONALLY LEFT BLANK

FORM PGSM4240301EU, VERSIO N 1.1

English-EN 3

FCS16 RIP-R-STRIPPER FLOOR COVERING STRIPPER

FORM PGSM4240301EU, VERSIO N 1.1

English-EN 4

FCS16 RIP-R-STRIPPER FLOOR COVERING STRIPPER

FORM PGSM4240301EU, VERSIO N 1.1

English-EN 5

Loading...

Loading...