Generac LP3250-6000-0, 006000-0 Owner’s Manual

MODEL:006000-0

GENERAC

i I

S

Generator

introduction.............................................................1

ReadthisiVlanualThoroughly.................................1

Safety Rules...........................................................1

StandardsIndex.............................................................3

Generalinformation................................................4

1.1 Unpacking......................................................................4

1.1.1 Accessory Box..................................................4

1.2 Assembly.......................................................................4

1.2.1 Assemblingthe AccessoryKit............................4

Operation................................................................5

2.1 Knowthe Generator.......................................................5

2.2 ConnectionPlugs...........................................................6

2.2.1 120 VAC,20Amp, DuplexReceptacle...............6

2.2.2 120/240VAC,20 Amp,Receptacle....................6

2.3 Howto Usethe Generator..............................................6

2.3.1 Groundingthe Generator....................................6

2.3.2 SystemGround..................................................7

2.3.3 ConnectingElectricalLoads...............................7

2.4 Don'tOverloadthe Generator..........................................7

2.5 WattageReferenceGuide...............................................8

2.6 BeforeStartingtheGenerator.........................................8

2.6.1 Adding EngineOil..............................................8

2.6.2 ConnectingLPFuelTank....................................8

2.7 Starting Pull StartEngines..............................................9

2.8 Stoppingthe Engine.....................................................10

2.9 LowOil LevelShutdownSystem..................................10

2.9.1 SensingLow Oil Level......................................10

Maintenance.........................................................10

3.1 MaintenanceSchedule.................................................10

3.2 ProductSpecifications..................................................10

3.2.1 GeneratorSpecifications..................................10

3.2.2 EngineSpecifications.......................................10

3.2.3 EmissionsInformation.....................................10

3.3 GeneralRecommendations...........................................11

3.3.1 GeneratorMaintenance....................................11

3.3.2 ToCleanthe Generator.....................................11

3.3.3 EngineMaintenance.........................................11

3.3.4 CheckingOil Level...........................................11

3.3.5 Changingthe Oil..............................................11

3.3.6 Replacingthe SparkPlug.................................11

3.4 ServiceAir Filter...........................................................12

3.5 ValveClearance............................................................12

3.6 General........................................................................12

3.7 Long TermStorage....................................................... 13

3.8 OtherStorageTips....................................................... 13

Troubleshooting....................................................14

4.1 TroubleshootingGuide..................................................14

Notes....................................................................15

Warranty...............................................................16

iNTRODUCTiON

Thankyou for purchasingthis model by GeneracPowerSystems,

Inc. This model is a compact, high performance, air-cooled,

engine driven generatordesigned to supply electrical power to

operateelectrical loads where no utility power is available or in

placeof utility dueto apoweroutage.

READTHiSMANUALTHOROUGHLY

If any portion of this manual is not understood, contact the

nearest Authorized Dealer for starting, operating and servicing

procedures.

The operator is responsible for proper and safe use of the

equipment.We strongly recommendthat the operator readthis

manualandthoroughlyunderstandall instructions beforeusingthe

equipment.Wealsostronglyrecommendinstructingotherusersto

properlystart andoperatethe unit.This preparesthem if they need

to operatetheequipmentin anemergency.

Thegeneratorcan operatesafely,efficiently and reliably only if it

is properlylocated, operatedand maintained.Before operatingor

servicingthe generator:

• Becomefamiliar with and strictly adhereto all local, state and

nationalcodes andregulations.

• Study all safety warnings in this manual and on the product

carefully.

• Becomefamiliarwith this manualandthe unit beforeuse.

Themanufacturercannot anticipateevery possible circumstance

that might involvea hazard.Thewarnings inthis manual,andon

tags and decals affixedto the unit are, therefore,not all inclusive.

If usinga procedure,work method oroperatingtechniquethat the

manufacturerdoes not specifically recommend,ensurethat it is

safe for others. Also makesure the procedure,work method or

operatingtechniqueutilizeddoes not renderthe generatorunsafe.

THE INFORMATIONCONTAINEDHEREIN WAS BASED ON

MACHINESIN PRODUCTIONAT THE TIME OF PUBLICATION.

GENERACRESERVESTHERIGHTTO MODIFYTHISMANUALAT

ANYTIME.

Save these instructionsfor future reference,if you loan this

device to someone,ALWAYSloan these instructionsto the

individualas well.

SAFETYRULES

Throughoutthis publication,and ontags anddecalsaffixedto the

generator,DANGER,WARNING,CAUTIONand NOTEblocks are

usedto alert personnelto special instructionsabout a particular

operation that may be hazardousif performed incorrectly or

carelessly. Observe them carefully. Their definitions are as

follows:

iNDICATESA HAZARDOUSSiTUATiONORACTIONWHICH,IF

NOTAVOIDED,WILLRESULTIN DEATHORSERIOUSINJURY.

Indicatesa hazardoussituationor action which,if not

avoided, couldresultin deathorseriousinjury.

,ACAUTION!

Indicatesa hazardoussituationoraction which,if not

avoided, couldresultin minorormoderateinjury.

NOTE:

Notescontainadditionalinformationimportantto aprocedure

and will be foundwithin the regulartextbody of thismanual.

These safety warnings cannot eliminate the hazards that they

indicate. Common sense and strict compliancewith the special

instructionswhileperformingtheaction orserviceareessentialto

preventingaccidents.

Four commonly used safety symbols accompanythe DANGER,

WARNINGand CAUTIONblocks. The type of information each

indicatesis asfollows:

,_This symbol points out important safety

information that, if not followed, could

endanger personal safety and/or property of

others.

This symbol points out potential explosion

hazard.

i/_This symbol points out potential fire hazard.

/i_This symbol points out potential electrical

shock hazard.

GENERAL HAZARDS

• NEVERoperatein an enclosed area, in a vehicle, or indoors

EVENIFdoors and windows areopen.

• For safety reasons, the manufacturer recommends that the

maintenanceof this equipmentis carried outby an Authorized

Dealer.Inspectthe generatorregularly,and contactthe nearest

AuthorizedDealerfor parts needingrepairor replacement.

• Operategeneratoronly on levelsurfacesandwhereit will notbe

exposedto excessivemoisture,dirt, dust orcorrosivevapors.

• Keephands, feet, clothing, etc., away from drive belts, fans,

and other moving parts. Neverremoveany fan guardor shield

whilethe unit is operating.

• Certain parts of the generator get extremely hot during

operation. Keep clear of the generator until it has cooled to

avoidsevereburns.

• Do NOToperategeneratorinthe rain.

• Do not alter the construction of the generator or change

controlswhich might createan unsafeoperatingcondition.

• Neverstart or stop the unit with electrical loads connected

to receptaclesAND with connected devices turned ON. Start

the engine and let it stabilize before connecting electrical

loads. Disconnect all electricalloads beforeshutting downthe

generator.

• Do notinsert objectsthrough unit's cooling slots.

• When working on this equipment, remain alert at all times.

Never work on the equipment when physically or mentally

fatigued.

• Neverusethe generatoror anyof its parts as a step. Stepping

on the unit can stress and break parts, and may result in

dangerousoperating conditions from leakingexhaust gases,

fuel leakage,oil leakage,etc.

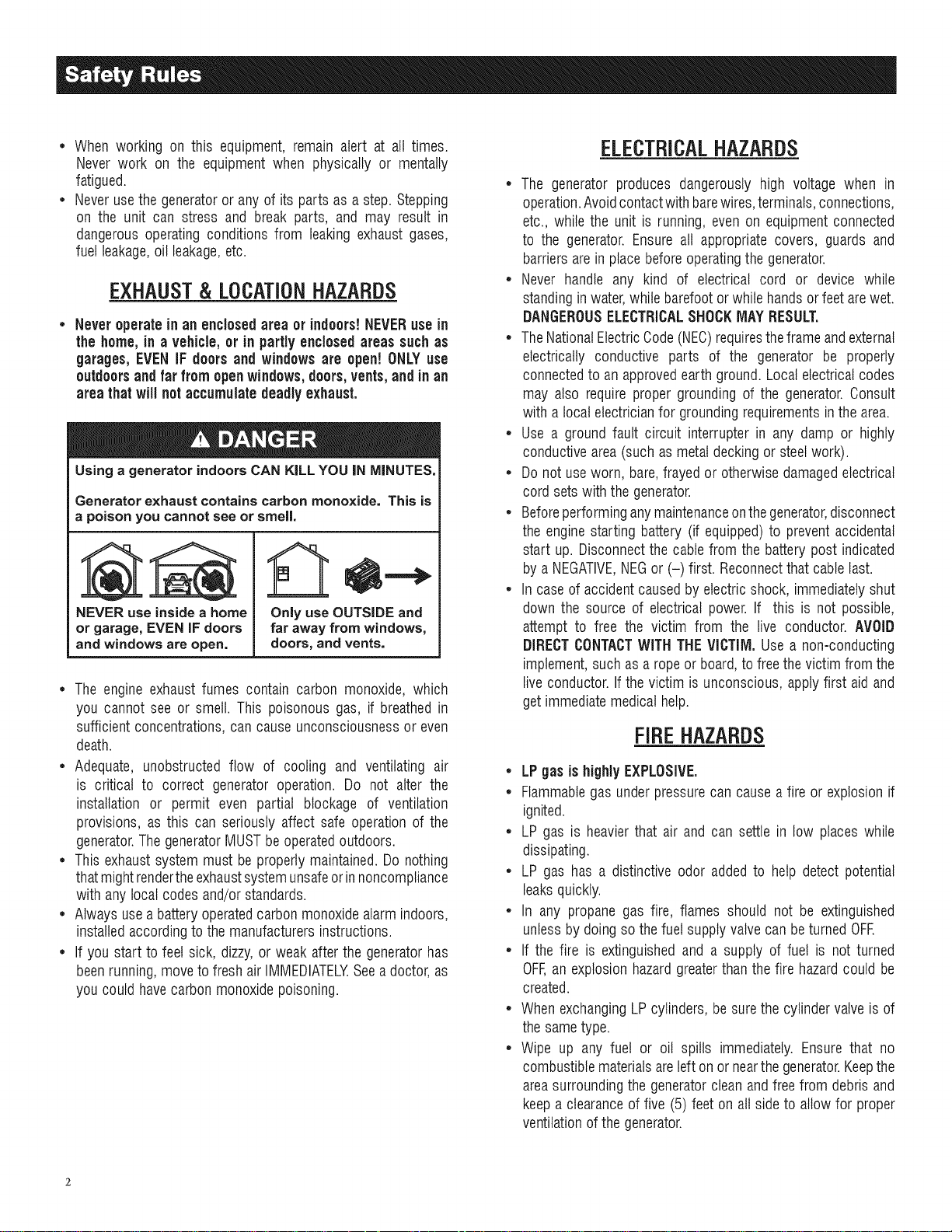

EXHAUST & LOCATIONHAZARDS

• Neveroperate in an enclosed areaor indoors!NEVERusein

the home,in a vehicle,or in partly enclosed areas suchas

garages,EVENIF doorsand windowsare open! ONLYuse

outdoors and far from openwindows, doors,vents,andinan

areathatwill notaccumulatedeadlyexhaust.

Using a generator indoors CAN KILL YOU IN MINUTES.

Generator exhaust contains carbon monoxide. This is

a poison you cannot see or smell,

NEVER use insidea home

or garage, EVEN iFdoors

and windows are open,

• The engine exhaustfumes contain carbon monoxide, which

you cannotsee or smell. This poisonous gas, if breathedin

sufficientconcentrations,can causeunconsciousnessor even

death.

• Adequate, unobstructed flow of cooling and ventilating air

is critical to correct generator operation. Do not alter the

installation or permit even partial blockage of ventilation

provisions, as this can seriously affect safe operationof the

generator.ThegeneratorMUSTbeoperatedoutdoors.

• Thisexhaustsystemmust beproperlymaintained.Do nothing

that mightrendertheexhaustsystemunsafeorinnoncompliance

with any localcodes and/or standards.

• Alwaysuse a batteryoperatedcarbonmonoxidealarmindoors,

installedaccordingto themanufacturersinstructions.

• If you start to feet sick, dizzy,or weak afterthe generatorhas

beenrunning,moveto fresh air IMMEDIATELYSeea doctor,as

you couldhave carbonmonoxidepoisoning.

Only use OUTSIDE and

far away from windows,

doors, and vents.

ELECTRICALHAZARDS

• The generator produces dangerously high voltage when in

operation.Avoidcontactwith barewires,terminals,connections,

etc., while the unit is running,even on equipmentconnected

to the generator. Ensureall appropriate covers, guards and

barriersarein place beforeoperatingthe generator.

• Never handle any kind of electrical cord or device while

standinginwater,while barefootorwhile handsor feet arewet.

DANGEROUSELECTRICALSHOCKMAYRESULT,

• TheNationalElectricCode(NEC)requirestheframe andexternal

electrically conductive parts of the generator be properly

connectedto an approvedearthground.Local electricalcodes

may also require proper groundingof the generator.Consult

with a local electricianfor groundingrequirementsin thearea.

• Use a ground fault circuit interrupter in any damp or highly

conductivearea(such as metaldecking orsteelwork).

• Do not useworn, bare,frayed or otherwisedamagedelectrical

cord setswith the generator.

• Beforeperforminganymaintenanceonthegenerator,disconnect

the enginestarting battery (if equipped)to preventaccidental

start up. Disconnectthe cablefrom the batterypost indicated

by aNEGATIVE,NEGor (-) first. Reconnectthatcable last.

• In caseof accidentcausedby electricshock, immediatelyshut

down the source of electrical power. If this is not possible,

attempt to free the victim from the live conductor. AVOID

DIRECTCONTACTWITHTHEVICTIIVl.Usea non-conducting

implement,such asa ropeorboard,to freethe victim fromthe

live conductor.If the victim is unconscious, apply first aid and

getimmediatemedical help.

FIREHAZARDS

• LPgas ishighlyEXPLOSIVE.

• Flammablegas underpressurecan causea fire or explosionif

ignited.

• LP gas is heavierthat air and can settle in low places while

dissipating.

• LP gas has a distinctive odor added to help detect potential

leaksquickly.

• In any propane gas fire, flames should not be extinguished

unlessby doing so thefuel supplyvalve can be turnedOFE

• If the fire is extinguishedand a supply of fuel is not turned

OFF,an explosion hazardgreaterthanthe fire hazardcould be

created.

• WhenexchangingLPcylinders, be surethe cylindervalveis of

thesametype.

• Wipe up any fuel or oil spills immediately.Ensure that no

combustiblematerialsareleft on ornearthegenerator.Keepthe

areasurroundingthe generatorcleanandfree from debrisand

keepa clearanceof five (5)feet on allside to allow for proper

ventilationof the generator.

* Do notinsert objectsthrough unit's cooling slots.

* Do not operatethe generator if connected electrical devices

overheat,if electricaloutputis lost, if engineorgeneratorsparks

or ifflames orsmokeare observedwhileunit is running.

* Keepafire extinguishernearthe generatoratall times.

STANDARDS/NDEZ

1. NationalFireProtectionAssociation(NFPA)70:TheNATIONAL

ELECTRICCODE(NEC)availablefrom www.nfpa.org

2. NationalFire ProtectionAssociation (NFPA)5000: BUILDING

CONSTRUCTIONAND SAFETYCODEavailablefrom www.

nfpa.org

3. InternationalBuildingCodeavailablefrom www.iccsafe.org

4. Agricultural Wiring Handbookavailablefrom www.rerc.org ,

Rural ElectricityResourceCouncil RO.Box 309 Wilmington,

OH45177-0309

5. ASAEEP-364.2Installationand Maintenanceof FarmStandby

Electric Power available from www.asabe.org, American

Society of Agricultural & Biological Engineers2950 Niles

Road,St. Joseph,MI 49085

This list is not all inclusive.Checkwith the Authority HavingLocal

Jurisdiction (AHJ)for any local codes or standardswhich may be

applicableto yourjurisdiction.

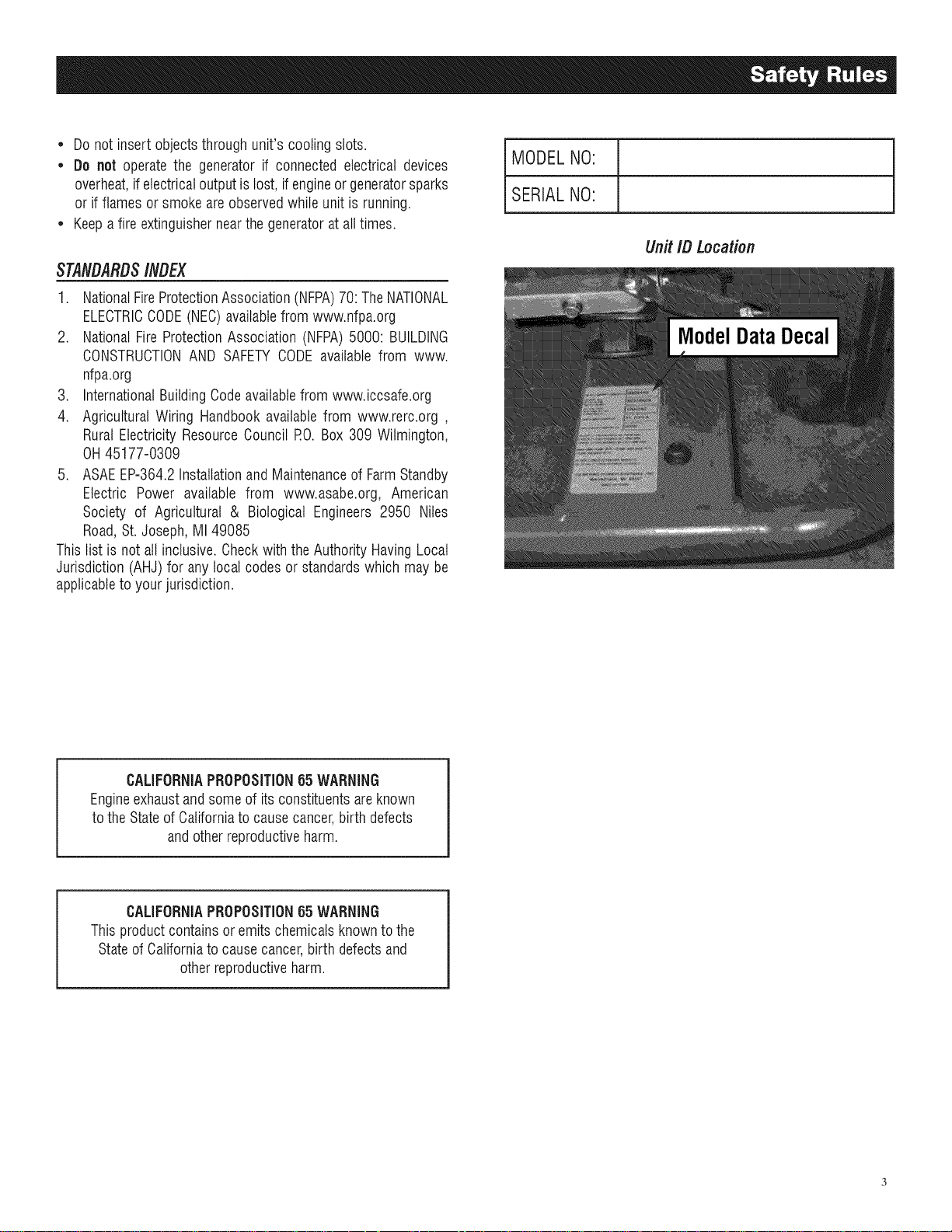

MODELNO:

SERIALNO:

Unit ID Location

CALIFORNIAPROPOSITION65 WARNING

Engineexhaustandsomeof its constituentsareknown

to theStateof Californiato causecancer,birth defects

andotherreproductiveharm.

CALIFORNIAPROPOSITION65 WARNING

This productcontainsoremitschemicalsknown tothe

Stateof Californiato causecancer,birth defectsand

otherreproductiveharm.

1.1 UNPACKING

* Removeall packagingmaterial.

* Removethe generatorfrom carton.

* Removeseparateaccessorybox.

NOTE:

Standard 20poundLPcylinder(tank)isnot included.

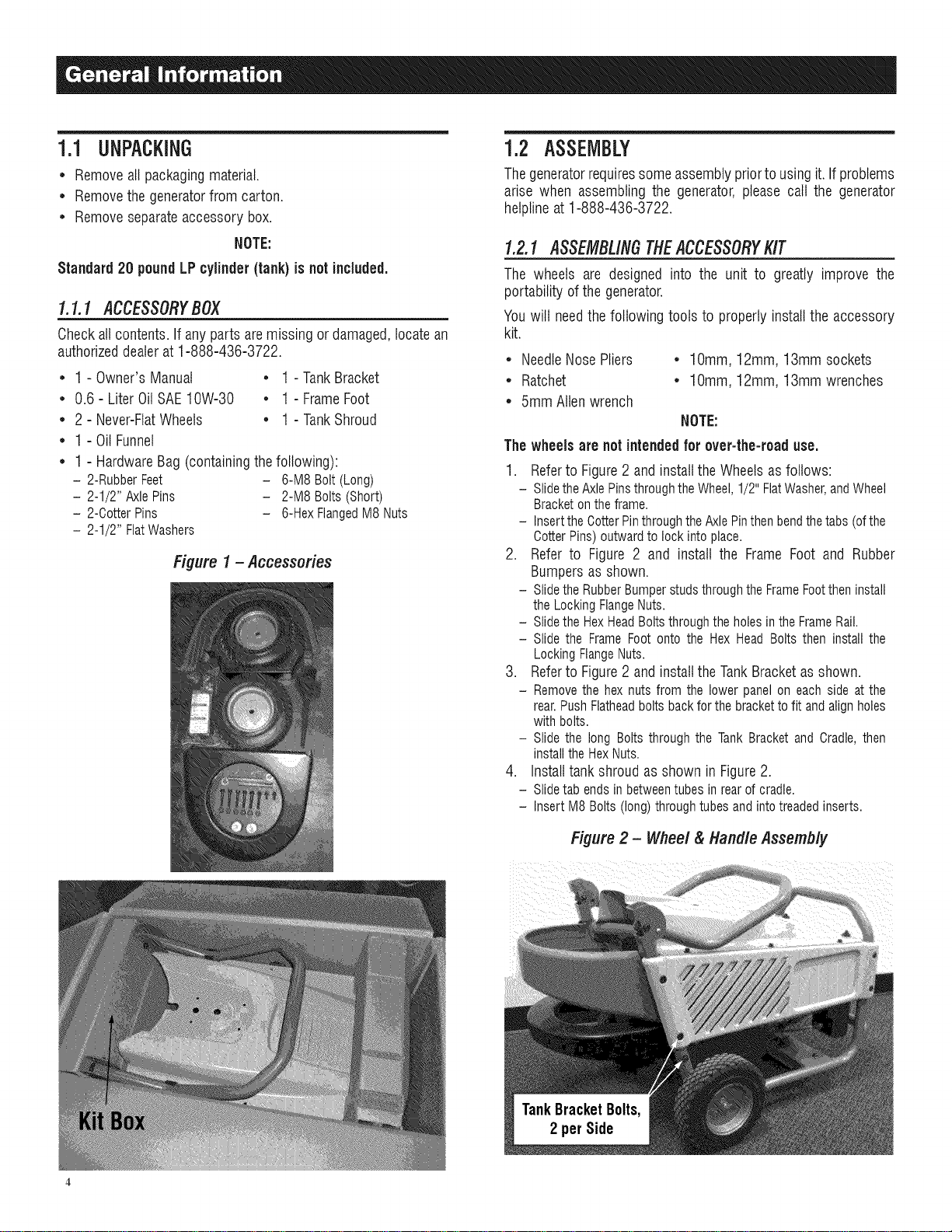

I.I.1 ACCESSORYBOX

Checkall contents.If anyparts aremissing or damaged,locatean

authorizeddealerat 1-888-436-3722.

* 1 - Owner'sManual * 1 -TankBracket

* 0.6 - Liter OilSAE10W-30 * 1 - FrameFoot

* 2 - Never-FlatWheels • 1 - TankShroud

* 1 - OilFunnel

* 1 - HardwareBag(containingthefollowing):

- 2-RubberFeet - 6-M8Bolt(Long)

- 2-1/2"AxlePins - 2-M8Bolts(Short)

- 2-CotterPins - 6-HexFlangedM8Nuts

- 2-1/2"FlatWashers

Figure 1 - Accessories

1.2 ASSEMBLY

Thegeneratorrequiressomeassemblypriorto usingit.If problems

arise when assemblingthe generator,please call the generator

hetplineat 1-888-436-3722.

1.2.1 ASSEMBLINGTHEACCESSORYKIT

The wheels are designed into the unit to greatly improve the

portability ofthe generator.

Youwilt needthe following tools to properly installthe accessory

kit.

* NeedleNosePliers * lOmm, 12mm, 13mmsockets

* Ratchet * lOmm, 12mm, 13mmwrenches

* 5mmAllenwrench

NOTE:

Thewheels are not intendedfor over-the-road use.

1. Refer to Figure 2 and install the Wheels as follows:

- Slidethe AxlePinsthroughthe Wheel,1/2" FlatWasher,andWheel

Bracketon theframe.

- Insertthe CotterPinthroughthe AxlePinthen bendthetabs (ofthe

CotterPins) outwardto lock into place.

2. Refer to Figure 2 and install the Frame Foot and Rubber

Bumpers as shown.

- Slidethe RubberBumperstuds throughthe FrameFootthen install

the LockingFlangeNuts.

- Slidethe HexHeadBoltsthrough theholes in the FrameRail.

- Slide the Frame Foot onto the Hex Head Bolts then install the

LockingFlangeNuts.

3. Refer to Figure 2 and install the Tank Bracket as shown.

- Removethe hex nuts from the lower panelon each side at the

rear.Push Flatheadbolts back forthe bracketto fit and alignholes

with bolts.

- Slide the long Bolts through the Tank Bracketand Cradle,then

installthe HexNuts.

4. Install tank shroud as shown in Figure 2.

- Slidetab ends in betweentubes in rear of cradle.

- Insert M8 Bolts (long) throughtubes andintotreaded inserts.

Figure 2 - Wheel & Handle Assembly

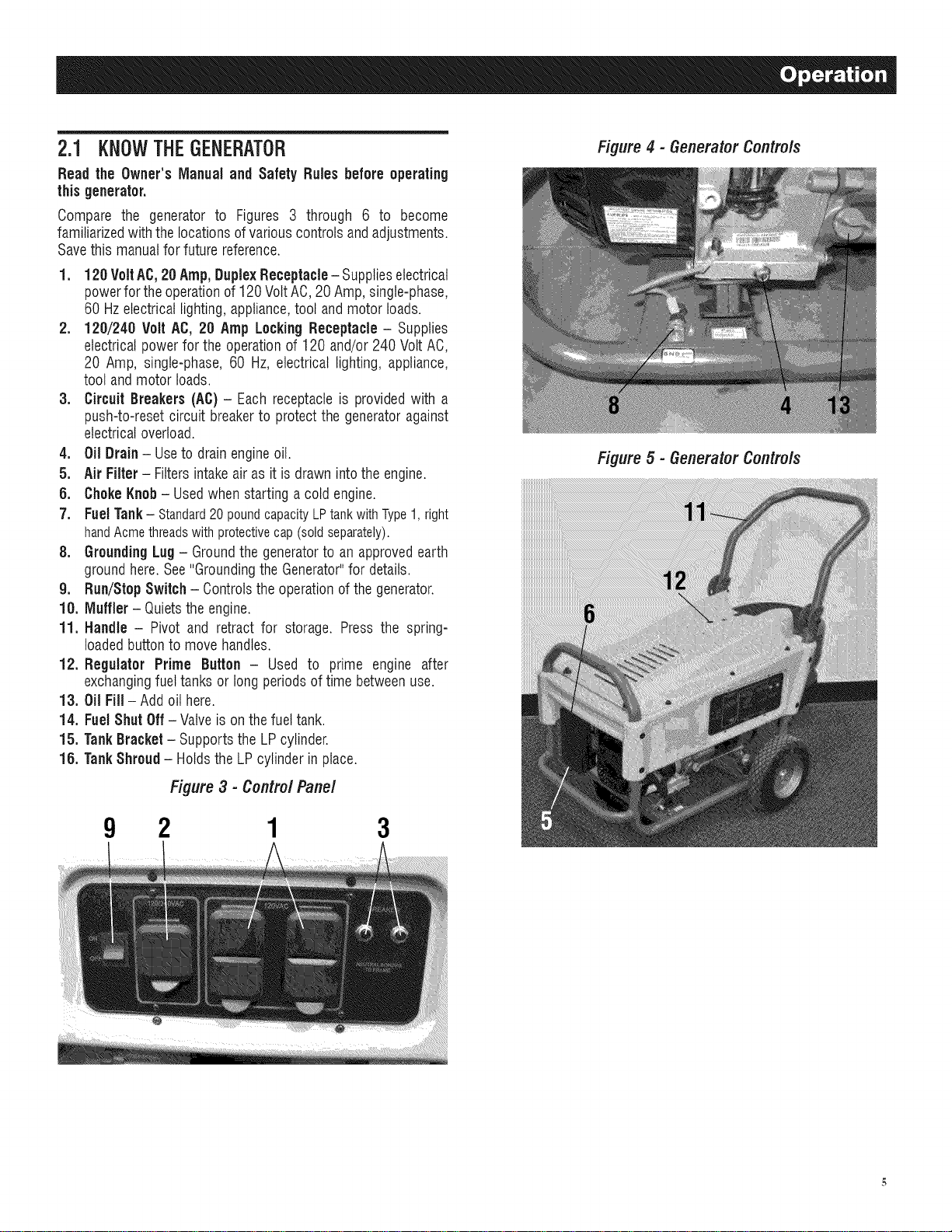

2.1 KNOWTHEGENERATOR

Read the Owner'sIVlanualand Safety Rules before operating

thisgenerator.

Compare the generator to Figures 3 through 6 to become

familiarizedwith thelocationsof variouscontrolsandadjustments.

Savethis manualfor futurereference.

1. 120 VoltAC,20 Amp,DuplexReceptacle- Supplieselectrical

powerfor theoperationof 120VoltAC, 20Amp,single-phase,

60 Hzelectrical lighting,appliance,tool andmotor loads.

2. 120/240 Volt AC, 20 Amp LockingReceptacle- Supplies

electricalpowerfor the operation of 120 and/or240 VoltAC,

20 Amp, single-phase,60 Hz, electrical lighting, appliance,

tool andmotor loads.

3. Circuit Breakers (AC)- Each receptacle is providedwith a

push-to-resetcircuit breakerto protectthe generatoragainst

electricaloverload.

4. Oil Drain- Useto drainengineoil.

5. Air Filter- Filters intakeair as it is drawn intothe engine.

6. ChokeKnob- Usedwhen startinga coldengine.

7. Fuel Tank- Standard20poundcapacityLPtankwithType1,right

handAcmethreadswithprotectivecap(soldseparately).

8. Grounding Lug- Groundthe generatorto anapprovedearth

groundhere.See"GroundingtheGenerator"for details.

9. Run/Stop Switch- Controlsthe operationof the generator.

10. IViuffler- Quietsthe engine.

11. Handle - Pivot and retract for storage. Press the spring-

loadedbuttonto move handles.

12. Regulator Prime Button - Used to prime engine after

exchangingfuel tanksor long periodsof time betweenuse.

13. Oil Fill-Add oil here.

14. FuelShut Off- Valve is on the fuel tank.

15. TankBracket- Supportsthe LPcylinder.

18. TankShroud- Holdsthe LP cylinderin place.

Figure4 - GeneratorControls

Figure 5 - GeneratorControls

Figure3 - Contro/Pane/

9 2 1 3

Figure 6 - Generator Contro/s

14

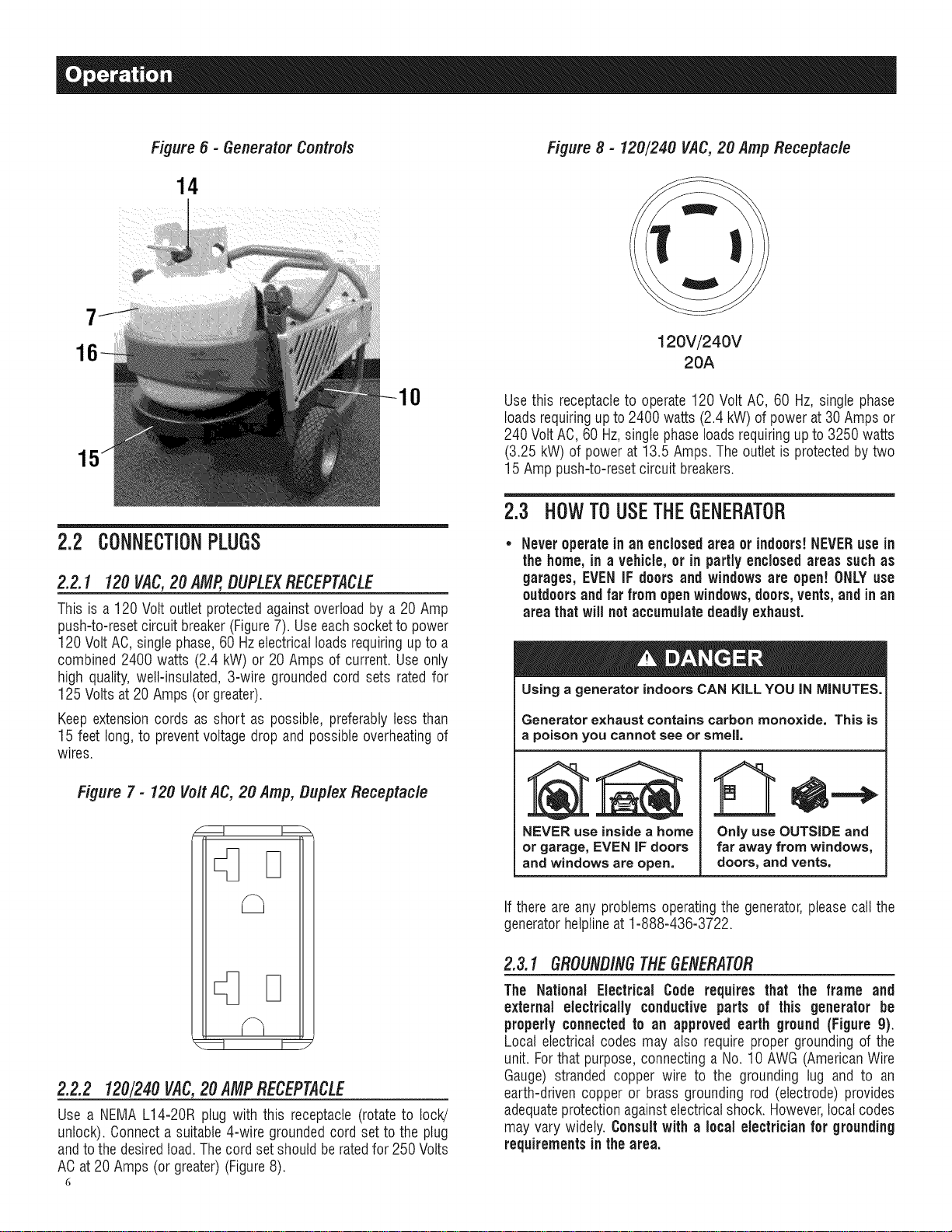

Figure 8 - 120/240 VAC,20 Amp Receptacle

120V/240V

20A

0

2.2 CONNECTIONPLUGS

2.2.1 120VAC,20 AMP,DUPLEXRECEPTACLE

This is a 120 Volt outletprotectedagainst overloadby a20 Amp

push-to-resetcircuitbreaker(Figure7). Useeachsocketto power

120 Volt AO,singlephase,60 Hzelectricalloadsrequiringupto a

combined 2400 watts (2.4 kW) or 20 Amps of current. Useonly

high quality,well-insulated, 3-wire grounded cord sets ratedfor

125 Volts at 20 Amps (or greater).

Keep extensioncords as short as possible, preferablyless than

15 feet long, to preventvoltage drop and possibleoverheatingof

wires.

Figure 7- 120 Volt AC, 20 Amp, Duplex Receptacle

Use this receptacleto operate120 Volt AC,60 Hz, singlephase

loadsrequiringup to 2400 watts (2.4kW) of power at 30 Ampsor

240 Volt AC,60 Hz,singlephase loadsrequiringup to 3250 watts

(3.25 kW)of power at 13.5 Amps.Theoutlet is protectedby two

15 Amp push-to-resetcircuit breakers.

2.3 HOW TO USETHEGENERATOR

Never operatein anenclosedareaor indoors!NEVERuse in

the home,in a vehicle, or in partly enclosed areas suchas

garages,EVENIF doorsand windows are open! ONLYuse

outdoors and far from openwindows,doors,vents,and inan

area that will not accumulate deadly exhaust.

Using a generator indoors CAN KILL YOU IN MINUTES.

Generator exhaust contains carbon monoxide. This is

a poison you cannot see or smell,

NEVER use insidea home

or garage, EVEN IF doors

and windows areopen.

Only use OUTSIDE and

far away from windows,

doors, and vents.

2.2.2 120/240VAC,20 AMPRECEPTACLE

Use a NEMA L14-20R plug with this receptacle(rotate to lock!

unlock). Oonnecta suitable4-wire groundedcord setto the plug

andto thedesiredtoad.Thecord set shouldbe ratedfor 250Volts

ACat20 Amps (or greater)(Figure8).

6

If thereare any problems operatingthe generator,pleasecall the

generatorhelplineat 1-888-436-3722.

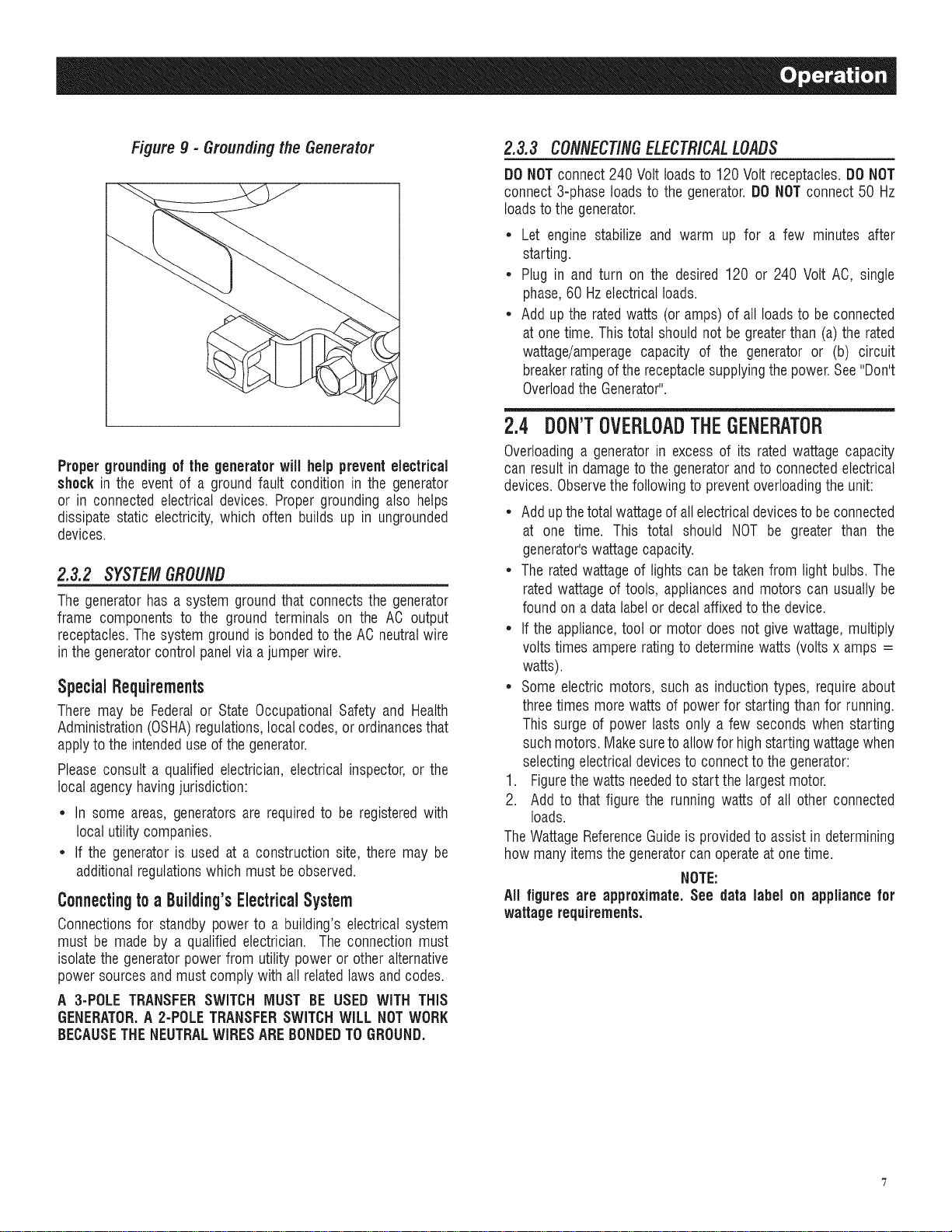

2.3.1 GROUNDINGTHEGENERATOR

The National Electrical Code requires that the frame and

external electrically conductive parts of this generator be

properlyconnectedto an approved earth ground (Figure g).

Local electrical codes may also requireproper grounding of the

unit. Forthat purpose,connectinga No. 10 AWG(AmericanWire

Gauge) stranded copper wire to the grounding lug and to an

earth-driven copper or brass grounding rod (electrode)provides

adequateprotectionagainstelectricalshock. However,localcodes

may vary widely. Consultwith a localelectrician for grounding

requirementsin the area.

Figure g - Grounding the Generator

Propergroundingof the generatorwill help preventelectrical

shockin the event of a ground fault condition in the generator

or in connectedelectrical devices. Proper grounding also helps

dissipate static electricity,which often builds up in ungrounded

devices.

2.3.2 SYSTEMGROUND

Thegeneratorhas a system groundthat connectsthe generator

frame components to the ground terminals on the AC output

receptacles.The system groundis bondedto the AC neutralwire

in the generatorcontrol panelvia ajumperwire.

SpecialRequirements

There may be Federalor State OccupationalSafety and Health

Administration(OSHA)regulations,localcodes,or ordinancesthat

applyto the intendeduse ofthe generator.

Pleaseconsult a qualified electrician,electrical inspector, or the

local agencyhavingjurisdiction:

,, In some areas, generatorsare requiredto be registeredwith

local utilitycompanies.

* If the generatoris used at a construction site, there may be

additionalregulationswhich must be observed.

ConnectingtoaBuiiding'sElectricalSystem

Oonnectionsfor standby power to a building's electricalsystem

must be made by a qualified electrician. The connection must

isolatethe generatorpower from utility poweror otheralternative

powersourcesandmust complywith all relatedlaws andcodes.

A 3-POLETRANSFERSWITCH MUST BE USED WiTH THiS

GENERATOR.A 2-POLETRANSFERSWITCHWILL NOTWORK

BECAUSETHENEUTRALWIRESAREBONDEDTOGROUND.

2.3.3 CONNECTINGELECTRICALLOADS

DONOTconnect240 Volt loadsto 120 Volt receptacles.DONOT

connect 3-phaseloads to the generator.DO NOTconnect 50 Hz

loadsto the generator.

• Let engine stabilize and warm up for a few minutes after

starting.

• Plug in and turn on the desired 120 or 240 Volt AO, single

phase,60 Hzelectricalloads.

• Addup the ratedwatts (or amps) of all loadsto beconnected

at onetime. Thistotal should not begreaterthan (a) therated

wattage/amperagecapacity of the generator or (b) circuit

breakerratingof thereceptaclesupplyingthe power.See"Don't

OverloadtheGenerator".

2.4 DON'TOVERLOADTHEGENERATOR

Overloadinga generator in excess of its rated wattage capacity

can resultin damageto the generatorandto connectedelectrical

devices.Observethefollowing to preventoverloadingthe unit:

• Addupthetotal wattageofall electricaldevicesto be connected

at one time. This total should NOT be greater than the

generator'swattagecapacity.

• The ratedwattageof lights can betaken from light bulbs.The

ratedwattageof tools, appliancesand motors can usually be

foundon a data labelor decalaffixedto the device.

• If the appliance,tool or motor does not give wattage,multiply

voltstimes ampererating to determinewatts (voltsx amps =

watts).

• Some electric motors, such as inductiontypes, require about

threetimes morewatts of powerfor startingthan for running.

This surge of power lasts only a few seconds when starting

suchmotors. Makesureto allowfor high startingwattagewhen

selectingelectrical devicesto connectto the generator:

1. Figurethe watts neededto start the largestmotor.

2. Add to that figure the running watts of all other connected

loads.

TheWattageReferenceGuideis providedto assist in determining

how manyitemsthegeneratorcan operateat onetime.

NOTE:

All figures are approximate. See data label on appliance for

wattage requirements.

2.5 WATTAGEREFERENCEGUIDE

Device................................... RunningWatts

*Air Conditioner(12,000 Btu).......................... 1700

*Air Conditioner(24,000 Btu).......................... 3800

*Air Conditioner(40,000 Btu).......................... 6000

BatteryCharger(20 Amp).............................. 500

BeltSander (3") .................................... 1000

ChainSaw ........................................ 1200

CircularSaw(6-1/2") ........................... 800 to 1000

*Clothes Dryer(Electric) ............................. 5750

*Clothes Dryer(Gas) ................................. 700

*Clothes Washer ................................... 1150

CoffeeMaker ...................................... 1750

*Compressor (1 HP)................................. 2000

*Compressor (3/4 HP)............................... 1800

*Compressor (1/2 HP)............................... 1400

CurlingIron......................................... 700

*Dehumidifier....................................... 650

Disc Sander(9").................................... 1200

EdgeTrimmer....................................... 500

Electric Blanket...................................... 400

Electric NailGun.................................... 1200

Electric Range(per element)........................... 1500

Electric Skillet...................................... 1250

*Freezer............................................ 700

*FurnaceFan(3/5 HP) ................................ 875

*GarageDoor Opener............................ 500 to 750

HairDryer......................................... 1200

Hand Drill.................................... 250 to 1100

HedgeTrimmer...................................... 450

Impact Wrench...................................... 500

Iron.............................................. 1200

*Jet Pump ......................................... 800

Lawn Mower....................................... 1200

Light Bulb.......................................... 1O0

Microwave Oven............................... 700 to 1000

*Milk Cooler....................................... 1100

OilBurneron Furnace................................. 300

OilFiredSpace Heater(140,000 Btu) ..................... 400

OilFiredSpace Heater(85,000 Btu) ...................... 225

OilFiredSpace Heater(30,000 Btu) ...................... 150

*Paint Sprayer,Airless(1/3 HP)......................... 600

PaintSprayer,Airless (handheld)......................... 150

Radio......................................... 50 to 200

*Refrigerator........................................ 700

SlowCooker........................................ 200

*SubmersiblePump (1-1/2 HP) ........................ 2800

*SubmersiblePump (1 HP) ........................... 2000

*SubmersiblePump (1/2 HP).......................... 1500

*Sump Pump................................. 800 to 1050

*Table Saw (10") ............................. 1750 to 2000

Television..................................... 200to 500

Toaster..................................... 1000 to 1650

WeedTrimmer ...................................... 500

* Allow 3 times the listedwatts for startingthese devices.

2.6 BEFORESTARTINGTHEGENERATOR

Priorto operatingthe generator,engineoil and LPfuelwill needto

be added,asfollows:

2.6.1 AOO/NGENGINEOIL

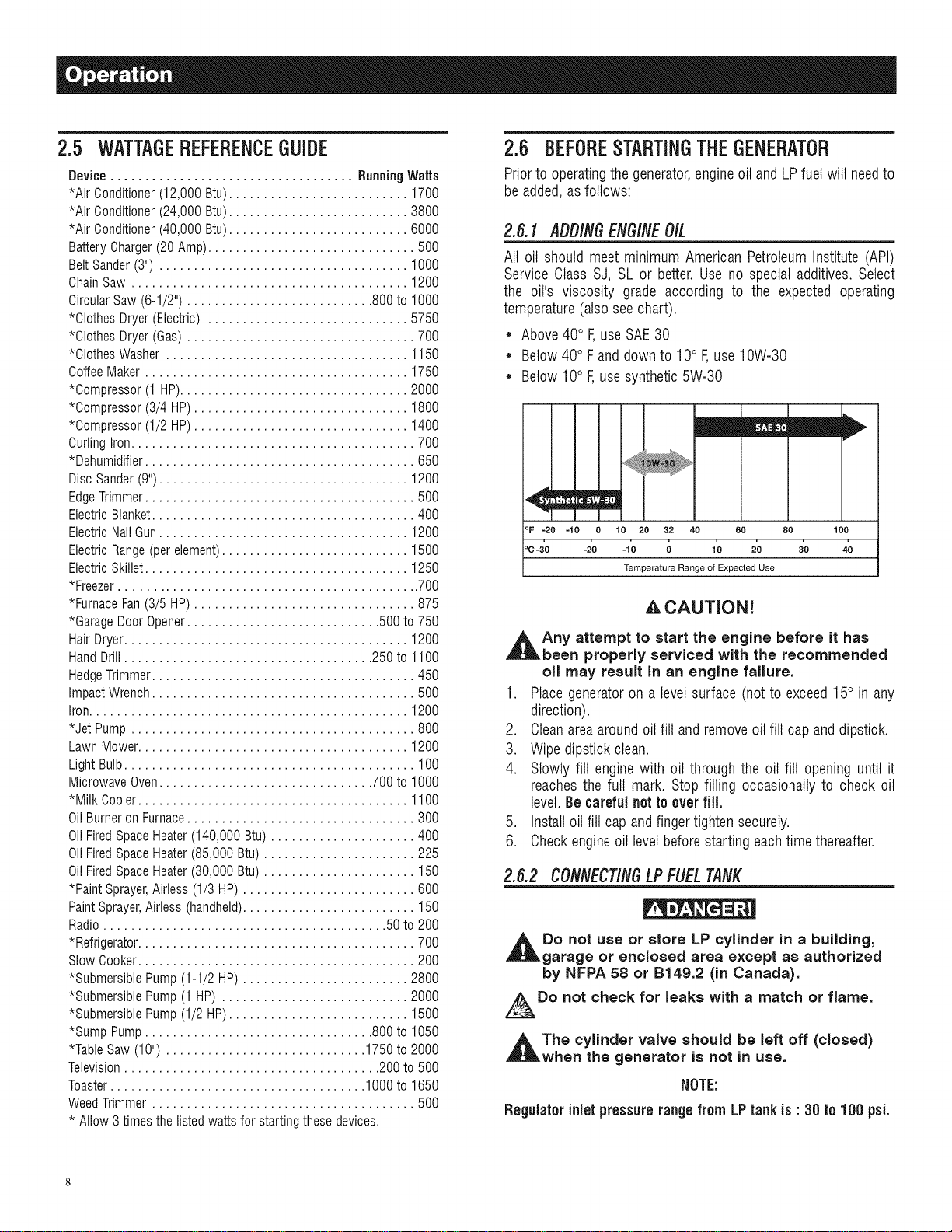

All oil should meet minimum American PetroleumInstitute (API)

Service Class SJ, SL or better. Use no special additives. Select

the oil's viscosity grade according to the expected operating

temperature(also see chart).

• Above40° F,useSAE30

• Below40° Fand down to 10° F,use10W-30

• Below10° F,use synthetic5W-30

°F =20 =10 0 10 20 32 40 60

'c4'o -2'0 -lo 0 lo 2o

Temperature Range of Expected Use

,&CAUTION!

_t ny attempt to start the engine before it has

been properly serviced with the recommended

oil may result in an engine failure.

1. Place generatoron a levelsurface (notto exceed15° in any

direction).

2. Cleanareaaroundoil fill andremoveoil fill cap anddipstick.

3. Wipe dipstick clean.

4. Slowly fill engine with oil through the oil fill opening until it

reachesthe full mark. Stop filling occasionally to check oil

level.Be carefulnotto overfill.

5. Install oil fill cap andfinger tighten securely.

6. Checkengineoil levelbefore starting eachtime thereafter.

2.6.2 CONNECTINGLPFUELTANK

Do not use or store LP cylinder in a building,

garage or enclosed area except as authorized

by NFPA 58 or B149.2 (in Canada).

Do not check for leaks with a match or flame.

,_The cylinder valve should be left off (closed)

when the generator is not in use.

NOTE:

Regulator inlet pressurerangefrom LPtankis : 30to 100 psi.

80 100

• Use only standard 20 or 30 pound capacity LP tanks with

Type1, righthandAcmethreadswith this generator.Verifythe

requalificationdate on the tank has not expired. Do not use

rusted or damagedcylinders.

• All new cylinders must be purgedof air andmoisture prior to

filling. Usedcylindersthat havenotbeenpluggedor keptclosed

must alsobe purged.

• The purging process should be done by your propane gas

supplier. (Cylindersfrom an exchangesupplier should have

beenpurgedandfilled properlyalready)

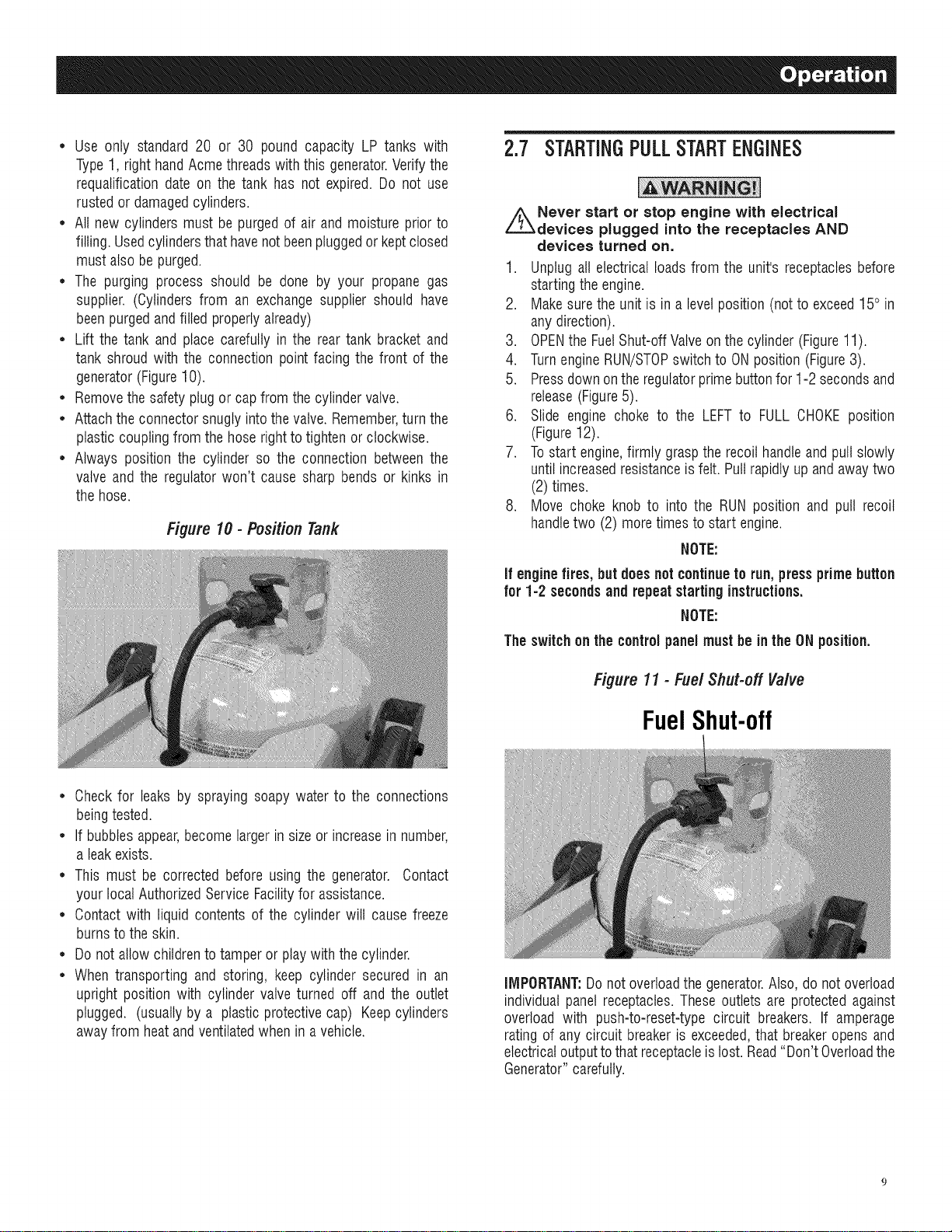

• Lift the tank and place carefully in the rear tank bracket and

tank shroudwith the connection pointfacing the front of the

generator(Figure10).

• Removethe safetyplugor capfrom thecylinder valve.

• Attachthe connectorsnuglyintothevalve.Remember,turn the

plasticcouplingfromthe hose rightto tightenor clockwise.

• Always position the cylinder so the connection betweenthe

valve and the regulatorwon't causesharp bends or kinks in

the hose.

Figure 10 - Position Tank

2.7 STARTINGPULLSTARTENGINES

//_Never start or stop engine with electrical

devices plugged into the receptacles AND

devices turned on.

1. Unplug all electricalloads from the unit's receptaclesbefore

startingthe engine.

2. Makesurethe unit is in a levelposition (notto exceed15° in

anydirection).

3. OPENthe FuelShut-offValveon thecylinder (Figure11).

4. TurnengineRUN/STOPswitch to ONposition (Figure3).

5. Pressdownonthe regulatorprimebuttonfor 1-2 secondsand

release(Figure5).

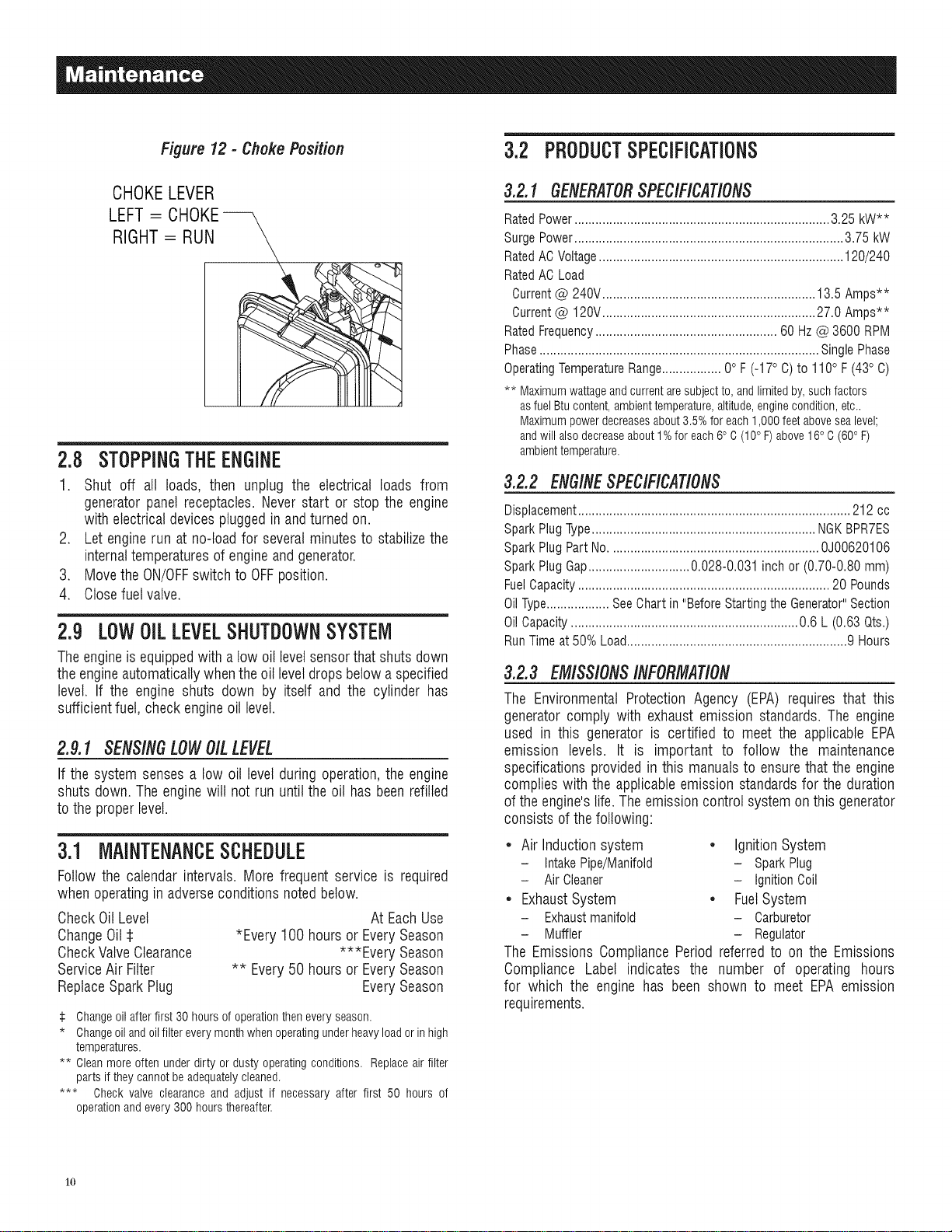

6. Slide engine choke to the LEFT to FULL CHOKEposition

(Figure12).

7. To start engine,firmly graspthe recoilhandleandpull slowly

until increasedresistanceis felt. Pullrapidly up andawaytwo

(2) times.

8. Move choke knob to into the RUN position and pull recoil

handletwo (2) moretimes to start engine.

NOTE:

If enginefires, but doesnot continueto run, pressprimebutton

for 1-2 secondsand repeatstarting instructions.

NOTE:

Theswitch on the controlpanelmust be inthe ONposition.

• Checkfor leaks by spraying soapy waterto the connections

beingtested.

• If bubblesappear,becomelargerin size or increasein number,

a leak exists.

• This must be corrected before using the generator. Contact

your localAuthorizedServiceFacilityfor assistance.

• Contactwith liquid contents of the cylinder will cause freeze

burnsto the skin.

• Do notallow childrento tamper or playwith thecylinder.

• When transporting and storing, keep cylinder secured in an

upright position with cylinder valve turned off and the outlet

plugged. (usuallyby a plastic protectivecap) Keepcylinders

awayfrom heat andventilatedwhen in a vehicle.

Figure 11 - Fuel Shut-off Valve

FuelShut-off

IMPORTANT:Donotoverloadthe generator.Also, do not overload

individual panelreceptacles.These outlets are protectedagainst

overload with push-to-reset-typecircuit breakers. If amperage

rating of any circuit breakeris exceeded,that breakeropens and

electricaloutputtothatreceptacleis lost.Read"Don't Overloadthe

Generator"carefully.

Figure 12 - Choke Position

3.2 PRODUCTSPECIFiCATiONS

CHOKELEVER

LEFT= CHOKE--

RIGHT= RUN

2.8 STOPPINGTHEENGINE

1. Shut off all loads, then unplug the

generatorpanel receptacles.Never start or stop the engine

with electrical devicespluggedin andturnedon.

2. Let enginerun at no-loadfor severalminutesto stabilizethe

internaltemperaturesof engineand generator.

3. Movethe ON/OFFswitch to OFFposition.

4. Closefuelvalve.

electrical loads from

2.9 LOWOiLLEVELSHUTDOWNSYSTEM

Theengineis equippedwitha low oil levelsensorthat shutsdown

the engineautomaticallywhenthe oil leveldropsbelowaspecified

level. If the engine shuts down by itself and the cylinder has

sufficientfuel, checkengineoil level.

2.9.1 SENSINGLOWOILLEVEL

If the system senses a low oil level during operation,the engine

shuts down.The enginewill not run untilthe oil has beenrefilled

to the properlevel.

3.1 MAINTENANCESCHEDULE

Follow the calendar intervals.More frequent service is required

whenoperatingin adverseconditions noted below.

CheckOil Level

ChangeOil

*Every 100 hoursor EverySeason

CheckValveClearance

ServiceAir Filter

** Every50 hoursor EverySeason

ReplaceSparkPlug

:i: Changeoil afterfirst 30 hours of operationthen every season.

* Changeoiland oilfilter every monthwhen operatingunder heavyload or inhigh

temperatures.

** Cleanmore often under dirty or dusty operating conditions. Replace air filter

parts ifthey cannot beadequatelycleaned.

*** Check valve clearance and adjust if necessary after first 50 hours of

operationand every300 hours thereafteK

At EachUse

***Every Season

EverySeason

3.2.1 GENERATORSPECIFICATIONS

RatedPower......................................................................... 3.25 kW**

SurgePower............................................................................. 3.75 kW

RatedACVoltage...................................................................... 120/240

RatedAC Load

Current@ 240V............................................................. 13.5 Amps**

Current@ 120V............................................................. 27.0 Amps**

RatedFrequency.................................................... 60 Hz@ 3600 RPM

Phase................................................................................ SinglePhase

OperatingTemperatureRange................. 0° F(-17° C) to 110° F(43° C)

** Maximumwattageandcurrentaresubjectto,andlimitedby,suchfactors

asfuelBtucontent,ambienttemperature,altitude,enginecondition,etc..

Maximumpowerdecreasesabout3.5%for each1,000feetabovesealevel;

andwillalsodecreaseabout1%for each6° C (10° F)above16° C(60° F)

ambienttemperature.

3.2.2 ENG/NESPECIFICATIONS

Displacement.............................................................................. 212 cc

SparkPlugType................................................................ NGKBPR7ES

SparkPlug PartNo............................................................ 0J00620106

SparkPlug Gap.............................0.028-0.031 inch or (0.70-0.80 mm)

FuelCapacity........................................................................ 20 Pounds

OilType.................. SeeChartin "BeforeStarting the Generator"Section

OilCapacity................................................................. 0.6 L (0.63 Qts.)

RunTime at 50% Load...............................................................9 Hours

3.2.3 EMISSIONSINFORMATION

The EnvironmentalProtection Agency (EPA) requires that this

generatorcomply with exhaust emission standards. The engine

used in this generator is certified to meet the applicable EPA

emission levels. It is important to follow the maintenance

specifications provided in this manualsto ensurethat the engine

complieswith the applicableemission standardsfor the duration

of theengine'slife. Theemissioncontrol system onthis generator

consists ofthe following:

• Air Induction system • Ignition System

- IntakePipe/Manifold - SparkPlug

- Air Cleaner - IgnitionCoil

• Exhaust System • Fuel System

- Exhaustmanifold - Carburetor

- Muffler - Regulator

The EmissionsCompliancePeriod referred to on the Emissions

Compliance Label indicates the number of operating hours

for which the engine has been shown to meet EPA emission

requirements.

1o

Loading...

Loading...