Page 1

GENERAC

Owner'siVl

GPSeriesPortabJeGenerator

Page 2

introduction.............................................................1

Maintenance.........................................................12

ReadthisManual Thoroughly.................................1

Safety Rules...........................................................1

StandardsIndex.............................................................3

Generalinformation................................................4

1.1 Unpacking......................................................................4

1.2 Assembly.......................................................................4

1.3 EmissionsInformation....................................................5

Operation................................................................5

2.1 Knowthe Generator.......................................................5

2.2 Hourmeter......................................................................6

2.3 ConnectionPlugs...........................................................6

2.4 Howto Usethe Generator..............................................7

2.5 Don'tOverloadthe Generator..........................................8

2.6 WattageReferenceGuide...............................................9

2.7 BeforeStartingthe Generator.........................................9

2.8 Starting Pull Start Engines............................................10

2.9 Starting ElectricStart Engines......................................11

2.10 Stoppingthe Engine.....................................................11

2.11 LowOil LevelShutdownSystem..................................11

2.12 Chargingthe Battery(ElectricStart UnitsOnly).............12

3.1 PerformingScheduledMaintenance.............................12

3.2 MaintenanceSchedule.................................................12

3.3 ProductSpecifications..................................................12

3.4 GeneralRecommendations...........................................13

3.5 ServiceAir Filter...........................................................14

3.6 ValveClearance............................................................15

3.7 General........................................................................15

3.8 Long TermStorage.......................................................15

3.9 OtherStorageTips.......................................................15

Troubleshooting....................................................16

4.1 TroubleshootingGuide..................................................16

Notes....................................................................17

MANUALDELPROPIETARIO.....................19

MANUELD'ENTRETIEN......................................39

WARNING!

California Proposition 65

Engine exhaust and some of its constituents are known to the state of California to cause cancer,

birth defects, and other reproductive harm.

WARNING!

California Proposition 65

This product contains or emits chemicals known to the state of California to cause cancer,

birth defects, and other reproductive harm.

Page 3

iNTRODUCTiON

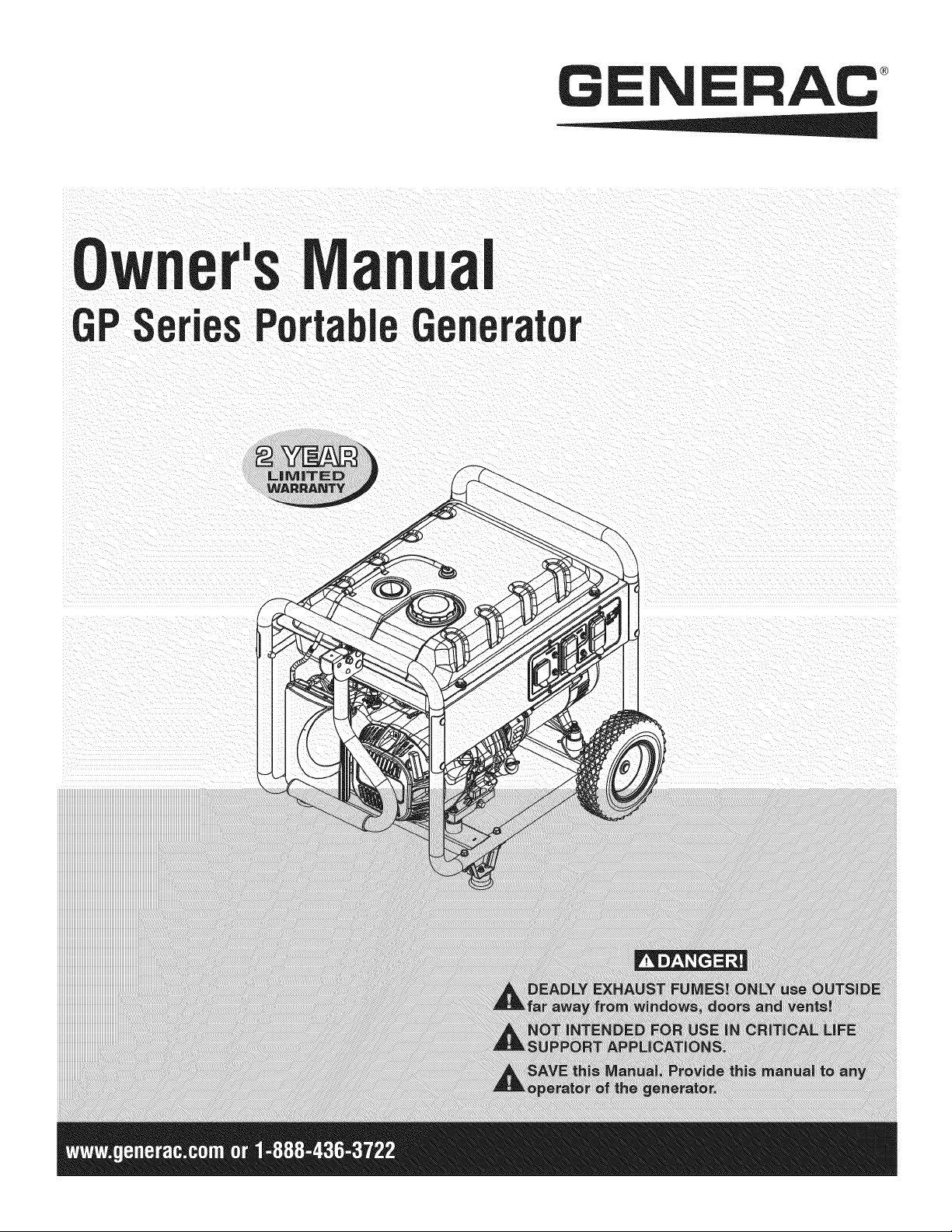

Thankyou for purchasingthis model by GeneracPowerSystems,

Inc. This model is a compact, high performance, air-cooled,

engine driven generatordesigned to supply electrical power to

operateelectrical loads where no utility power is availableor in

placeof utility dueto a poweroutage.

SAFETYRULES

Throughoutthis publication,and on tags and decals affixedto the

generator,DANGER,WARNING,CAUTIONand NOTEblocks are

usedto alert personnelto special instructions about a particular

operation that may be hazardous if performed incorrectly or

carelessly.Observethem carefully.Their definitionsareasfollows:

BEADTHiSMANUALTHOROUGHLY

If anyportion ofthis manualis not understood,contactthenearest

AuthorizedDealerfor starting, operatingandservicingprocedures.

The operator is responsible for proper and safe use of the

equipment.We strongly recommend that the operator read this

manualandthoroughlyunderstandallinstructions beforeusingthe

equipment.Wealsostronglyrecommendinstructingother usersto

properlystart andoperatethe unit.This preparesthemifthey need

to operatetheequipmentin an emergency.Savethese instructions

for future reference.If you loan this deviceto someone,ALWAYS

loanthese instructionsto the individualas well.

Thegeneratorcan operatesafely,efficiently and reliablyonly if it

is properlylocated, operatedandmaintained.Before operatingor

servicingthe generator:

• Becomefamiliar with and strictly adhereto all local, stateand

nationalcodes and regulations.

• Study all safety warnings in this manual and on the product

carefully.

• Becomefamiliarwith thismanualandthe unit beforeuse.

Themanufacturercannot anticipateevery possible circumstance

that might involvea hazard.The warnings inthis manual,and on

tags and decals affixedto the unit are, therefore,not all inclusive.

If using a procedure,work method or operatingtechniquethat the

manufacturerdoes not specifically recommend,ensurethat it is

safe for others. Also make sure the procedure,work method or

operatingtechniqueutilizeddoes not renderthe generatorunsafe.

THE INFORMATIONCONTAINEDHEREIN WAS BASED ON

MACHINESIN PRODUCTIONAT THE TIME OF PUBLICATION.

GENERACRESERVESTHERIGHTTOMODIFYTHISMANUALAT

ANYTIME.

INDICATESAHAZARDOUSSiTUATiONORACTIONWHICH,IF

NOTAVOIDED,WILLRESULTIN DEATHORSERIOUSINJURY.

Indicatesa hazardoussituationor action which,if not

avoided, couldresultin deathor seriousinjury.

_CAUTION!

Indicatesa hazardoussituationoraction which,if not

avoided, couldresultin minoror moderateinjury.

NOTE:

Notescontainadditionalinformationimportantto a procedure

and will be foundwithinthe regular textbody ofthis manual.

These safety warnings cannot eliminate the hazardsthat they

indicate. Common sense and strict compliancewith the special

instructionswhile performingthe action or serviceareessentialto

preventingaccidents.

Four commonly used safety symbols accompany the DANGER,

WARNINGand CAUTIONblocks. The type of information each

indicatesis as follows:

,_This symbol points out important safety

information that, if not followed, could

endanger personal safety and/or property of

others.

This symbol points out potential explosion

hazard.

i/_This symbol points out potential fire hazard.

This symbol points out potential electrical

shock hazard.

Page 4

GENERAL HAZARDS

EXHAUST & LOCATIONHAZARDS

• NEVERoperatein an enclosed area, in a vehicle, or indoors

EVENIFdoors and windows areopen.

• For safety reasons, the manufacturer recommendsthat the

maintenanceof this equipmentis carried out by an Authorized

Dealer.Inspectthe generatorregularly,and contactthe nearest

AuthorizedDealerfor parts needingrepair or replacement.

• Operategeneratoronly on levelsurfacesandwhereit will notbe

exposedto excessivemoisture,dirt, dust or corrosive vapors.

• Keephands, feet, clothing, etc., away from drive belts, fans,

and othermoving parts. Neverremoveany fan guardor shield

whilethe unit is operating.

• Certain parts of the generator get extremely hot during

operation. Keep clear of the generator until it has cooled to

avoidsevereburns.

• Do NOToperategeneratorinthe rain.

• Do not alter the construction of the generator or change

controlswhich might createan unsafeoperatingcondition.

• Never start or stop the unit with electrical loads connected

to receptaclesAND with connecteddevicesturned ON. Start

the engine and let it stabilize before connecting electrical

loads. Disconnectall electricalloadsbefore shuttingdown the

generator.

• Do notinsert objectsthrough unit's coolingslots.

• When working on this equipment, remain alert at all times.

Never work on the equipment when physically or mentally

fatigued.

• Neverusethe generatoror anyof its partsas a step. Stepping

on the unit can stress and break parts, and may result in

dangerousoperating conditions from leakingexhaust gases,

fuel leakage,oil leakage,etc.

NOTE:

This generatormaybe equippedwith a spark arrestormuffler.

The spark arrestor must be maintained in effective working

orderby theowner/operator.In theState of California, a spark

arrestor is required by law (Section4442 of the California

PublicResources Code). Other states may havesimilar laws.

Federal lawsapply on federallands.

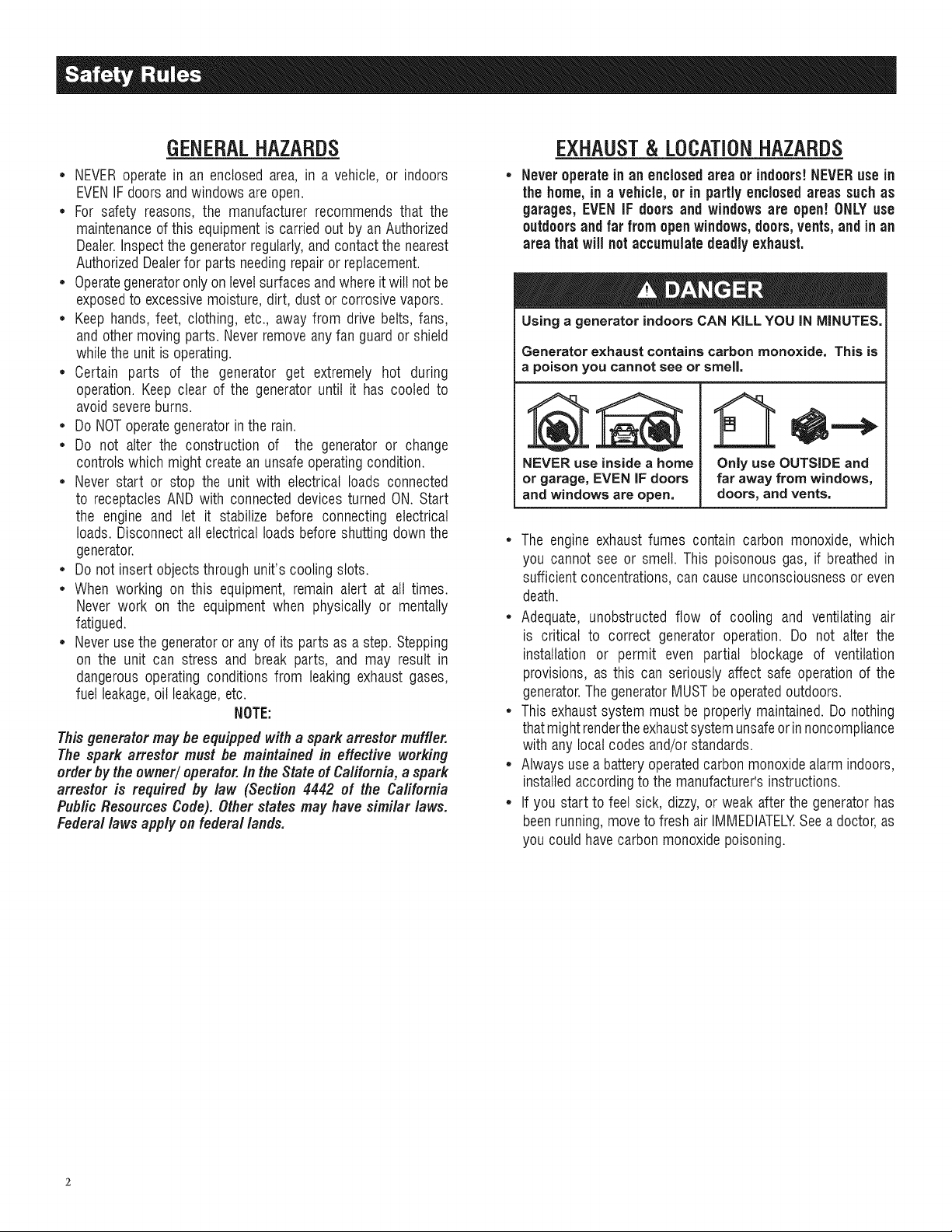

• Never operate in an enclosed area or indoors!NEVERuse in

the home,in a vehicle, or in partly enclosedareas suchas

garages,EVENIF doors and windowsare open! ONLYuse

outdoors and far from open windows,doors, vents,andinan

areathat will notaccumulate deadly exhaust.

Using a generator indoors CAN KILL YOU iN MINUTES.

Generator exhaust contains carbon monoxide. This is

a poison you cannot see or smell.

NEVER use insidea home

or garage, EVEN IF doors

and windows are open,

• The engineexhaustfumes contain carbon monoxide, which

you cannot see or smell. This poisonous gas, if breathed in

sufficientconcentrations,can cause unconsciousnessor even

death.

• Adequate, unobstructed flow of cooling and ventilating air

is critical to correct generator operation. Do not alter the

installation or permit even partial blockage of ventilation

provisions, as this can seriously affect safe operationof the

generator.ThegeneratorMUSTbeoperatedoutdoors.

• This exhaustsystem must be properlymaintained.Do nothing

thatmightrendertheexhaustsystemunsafeorinnoncompliance

with any localcodes and/or standards.

• Alwaysuse a battery operatedcarbonmonoxidealarmindoors,

installedaccordingto themanufacturer'sinstructions.

• If you start to feel sick, dizzy,or weak afterthe generatorhas

beenrunning,move tofresh air IMMEDIATELYSeea doctor,as

you couldhave carbonmonoxidepoisoning.

Only use OUTSIDE and

far away from windows,

doors, and vents.

Page 5

ELECTRICALHAZARDS

• The generator produces dangerously high voltage when in

operation.Avoidcontactwith barewires, terminals,connections,

etc., whilethe unitis running, even on equipmentconnectedto

thegenerator.Ensureallappropriatecovers,guardsandbarriers

are in place beforeoperatingthe generator.

• Never handle any kind of electrical cord or device while

standingin water,whilebarefootor while handsor feet arewet.

DANGEROUSELECTRICALSHOCKMAYRESULT.

• TheNationalElectricCode(NEC)requirestheframeandexternal

electrically conductive parts of the generator be properly

connectedto an approvedearth ground. Localelectricalcodes

may also require proper grounding of the generator.Consult

with a localelectricianfor groundingrequirementsin the area.

• Use a ground fault circuit interrupter in any damp or highly

conductivearea(such as metaldecking or steelwork).

• Do not useworn, bare,frayed or otherwisedamagedelectrical

cord setswith the generator.

• Beforeperforminganymaintenanceonthegenerator,disconnect

the engine starting battery (if equipped)to prevent accidental

start up. Disconnectthe cable from the battery post indicated

by a NEGATIVE,NEGor (-) first. Reconnectthatcable last.

• In caseof accidentcausedby electricshock, immediatelyshut

down the source of electrical power. If this is not possible,

attempt to free the victim from the live conductor. AVOID

DIRECTCONTACTWITH THE VICTIM. Use a non-conducting

implement,such asa ropeor board,to free thevictim fromthe

live conductor.If the victim is unconscious,applyfirst aid and

getimmediatemedical help.

• Do notinsert objectsthrough unit's cooling slots.

• Never operate the generator if connected electrical devices

overheat,if electricaloutputislost, if engineor generatorsparks

or if flames or smoke are observedwhileunit is running.

• Keepafire extinguishernearthe generatoratall times.

STANDARDS/NDEX

1. NationalFireProtectionAssociation(NFPA)70:TheNATIONAL

ELECTRICCODE(NEC)availablefrom www.nfpa.org

2. NationalFire ProtectionAssociation (NFPA)5000: BUILDING

CONSTRUCTIONAND SAFETYCODEavailable from www.

nfpa.org

3. InternationalBuildingCodeavailablefrom www.iccsafe.org

4. Agricultural Wiring Handbookavailablefrom www.rerc.org ,

Rural ElectricityResourceCouncil RO.Box 309 Wilmington,

OH45177=0309

5. ASAEEP-364.2Installationand Maintenanceof FarmStandby

Electric Power available from www.asabe.org, American

Society of Agricultural & Biological Engineers2950 Niles

Road,St. Joseph,MI 49085

This list is not all inclusive.Checkwith theAuthority HavingLocal

Jurisdiction (AHJ)for any localcodes or standardswhich maybe

applicableto your jurisdiction.

MODELNO:

SERIALNO:

FIREHAZARDS

• GasolineishighlyFLAMMABLEanditsvaporsareEXPLOSIVE.

Never permit smoking,open flames, sparksor heat in the

vicinitywhile handlinggasoline.

• Neveraddfuel while unitis runningor hot.Allow engineto cool

completelybeforeaddingfuel.

• Never fill fuel tank indoors, Comply with all laws regulating

storageand handlingof gasoline.

• Do not overfill the fuel tank. Always allow room for fuel

expansion.If tank is over-filled, fuel can overflow onto a hot

engineandcause FIREor an EXPLOSION.Neverstoregenerator

with fuel in tank where gasoline vapors might reachan open

flame, spark or pilot light (as on a furnace, water heater or

clothes dryer). FIREor EXPLOSIONmay result. Allow unit to

cool entirelybeforestorage.

• Wipe up any fuel or oil spills immediately. Ensure that no

combustiblematerialsareleft onor nearthe generator.Keepthe

areasurroundingthe generatorcleanand freefrom debrisand

keepa clearanceof five (5) feet on allsideto allow for proper

ventilationof the generator.

Unit ID Location

DATA

DECAL

Page 6

1.1 UNPACKING

Figure 1 - Wheel & Handle Assembly

• Removeall packagingmaterial.

• Removeseparateaccessorybox.

• Removethegeneratorfrom carton.

1.1.1 ACCESSORIES

Checkall contents.If anyparts aremissing or damaged,locatean

authorizeddealerat 1-888-436-3722.

• 1 - Owner'sManual • 1 - HandleAssembly

• 1-LiterOiISAE30 • 2-FrameFoot

• 2 - Never-FlatWheels • 1 - 20' PowerCord

• 3 - ProductRegistrationCards (006110-3 only)

• 1 - ServiceWarranty • 1 - EmissionsWarranty

e

1 - Battery Charger (Electric Start Models)

e

1 - Hardware Bag (containing the following):

- 2-Rubber Feet 6-M8 Bolt (Long)

- 2-1/2" AxlePins 2-M6 Bolts (Long)

- 2-Cotter Pins 2-M8 Acorn Nut

- 2-1/2" FlatWashers 4-HexFlangedM8 Nuts

- 2-Hex FlangedM6 Nuts

1.2 ASSEMBLY

The generator requires some assembly prior to using it. If

problems arise when assembling the generator,please call the

GeneratorHetplineat 1-888-436-3722.

1.2.1 ASSEMBLINGTHEACCESSORYKIT

The wheels are designed into the unit to greatly improve the

portability ofthe generator.

You will needthe following tools to properlyinstall the accessory

kit.

• NeedleNosePliers

• Ratchetand8mm, lOmm, and 13mm sockets

• 8mm, lOmm, and13mm boxwrenches

NOTE:

The wheels arenot intendedfor over-the-road use.

1. Refer to Figure 1 and install the Wheels as follows:

- Slidethe AxlePin throughthe Wheel, 1/2" FlatWasher,and Wheel

Bracketon the frame.

- Insertthe Cotter Pinthroughthe Axle Pinthenbendthetabs (ofthe

OotterPins)outward to lock into place.

2. Refer to Figure 1 and install the Frame Foot and Rubber

Bumpers as shown.

- Slidethe RubberBumperstudsthroughthe FrameFoottheninstall

the Locking FlangeNuts.

- Slidethe HexHeadBoltsthrough the holes in the FrameRail.

- Slide the Frame Foot onto the Hex Head Bolts then install the

LockingFlangeNuts.

3. Refer to Figure 1 and install the Handle as shown.

- Slidethe long Bolts through the HandleBracketand Handle,then

installthe HexNuts.

2 XM8BOLT(LONG)

2 XM8ACORNNUT

ASSEMBLY

_-'_ ....... 2 X FRAME FOOT

_Z'_ 4XM8NUTS

2 X RUBBER FOOT---_ _ 2 XM6 NUTS

4 X M8 BOLT

,(LONG)

2 X COTTER PIN

2 X I/2" FLATWASHER

2 X WHEEL

2 X AXLE PIN

2 XM6BOLT

(LONG)

1.2.2 BATTERYCABLECONNECTION(ELECTR/CSTART

ONLY_

The unit has been deliberatelyshipped with the battery cables

disconnected.

Toconnect the battery,you will needtwo 8mm boxwrenchesto

connectthe batterycables.(see Figure16for connectiondetails):

1. Cut off cable ties securing battery cables and remove red

coversfrom batteryterminals.

2. First,connectthe redcableto the positive (+) batteryterminal

with the bolt andnut supplied.

3. Makesureconnectionsare secureandsliderubber boot over

thepositive (+) batteryterminaland connectionhardware.

4. Connectthe black cable to the negative(-) battery terminal

with the bolt and nut suppliedand slide rubber boot overthe

negative(-) batteryterminal and connectionhardware.

5. Makesure all connectionsaresecure.

NOTE:

If the battery is unable to start the engine,charge it with the

12V chargerincludedinthe accessory box(seethe "Charginga

Battery"section for details).

Page 7

1.3 EMiSSiONSiNFORMATiON

TheEnvironmentalProtectionAgency(andCaliforniaAir Resource

Board for generators certified to CA standards) requires that

this generator comply with exhaust and evaporative emission

standards.Locatethe emissions compliancedecal on the engine

to determinewhatstandardsthegeneratormeets,andto determine

which warranty applies.This generatoris certified to operateon

gasoline. The emission control system includes the following

components(if equipped):

• Air InductionSystem

- IntakePipe/ Manifold

- AirCleaner

• FuelSystem

- Carburetor

- FuelTank/Cap

- FuelLines

- EvaporativeVentLines

- CarbonCanister

• IgnitionSystem

- SparkPlug

- IgnitionModule

• ExhaustSystem

- ExhaustManifold

- Muffler

- PulsedAirValve

- Catalyst

11. Handle - Pivot and retract for storage. Press the spring-

loadedbuttonto move handles.

12. GasCap- Fuelfill location.

l& FuelGauge- Showsfuel levelintank.

14. Oil Fill- Add oil here.

15. Recoil Starter - Useto start enginemanually.

15. FuelShut Off - Valve betweenfueltank and carburetor.

17. Roll OverValve- Passesfuelto the engineairbox.

18. Recovery Hose- Installbetweenthe carbon canister andthe

roll overvalve (if equipped).

19. Hourmeter- Trackshoursof operation.

20. Battery ChargerInput - This receptacleallowsthe capability

to rechargethe 12 volt DO storage battery provided with

the 12 Volt Adaptor Plug Chargerwhich is included in the

Accessory Box. Located behindthe battery chargerinput is

a 1.50 Amp in-line fuse which is insidethe control panelto

protectthe battery (electricstart models only).

21. Battery - Powersthe electric starter (electric start models

only).

22. Spark Arrestor - Reducesfire hazardsby containing sparks

(CARBmodels only).

Figure 2.4 - Contro/ Panel (49 State Models)

2.1 KNOWTHEGENERATOR

Read the Owner'sManual and Safety Rules before operating

thisgenerator.

Compare the generator to Figures 2 through 4 to become

familiarizedwith thelocationsof variouscontrolsandadjustments.

Savethis manualfor future reference.

1. 120 Volt AC, 20 Amp, Duplex Receptacle - Supplies

electrical power for the operationof 120 Volt AC, 20 Amp,

single-phase, 60 Hz electrical lighting, appliance, tool and

motor loads (CARBmodelsare equippedwith GFCIoutlets).

2. 120/240 Volt AC, 30 Amp LockingReceptacle - Supplies

electricalpower for the operationof 120 and/or 240 VoltAC,

30 Amp, single-phase,60 Hz, electrical lighting, appliance,

tool andmotor loads.

3. CircuitBreakers (AC)- Each receptacleis providedwith a

push-to-resetcircuit breakerto protect the generatoragainst

electricaloverload.

4. Oil Drain- Useto drainengineoil.

5. Air Filter- Filtersintakeair as itis drawn intothe engine.

6. ChokeKnob- Usedwhen starting a coldengine.

7. FuelTank- SeegeneratorSpecificationsfor tank capacity.

8. GroundingLug - Groundthe generatorto an approvedearth

groundhere.See"GroundingtheGenerator"for details.

9. Run/Stop Switch- Controls the operationof the generator

(pull start models).

9A. Start Switch - Used to start engine from the starter motor

(electricstart modelsonly).

10. Muffler- Quietsthe engine.

Figure 2B - Contro/ Panel (CARB Models)

Page 8

Figure 2C - Contro/ Pane/ (CSA Models)

Figure3 - GeneratorControls

2.2 HOURMETER

TheHourmetertrackshoursofoperationfor scheduledmaintenance

(Figure5):

Therewill bea"CHGOIL"messageevery100 hours.The message

will flash one hour before and one hour after each 100 hour

interval,providinga two hourwindowto perform service.

This messagewill actuallybeginflashing at 99 hoursand disable

itselfat 101 hoursagain,providingatwo hourwindow to perform

theservice.

Every200 hours the "SVC"icon on the lower left hand corner of

thedisplay will flash. Themessagewill flash one hourbeforeand

onehour aftereach200 hourintervalprovidingatwo hourwindow

to perform service.

Figure5 - Hourmeter

O000.O

Figure4 - Generator Controls

HOUR GLASS

GRAPHIC

Whenthe hour meter is inthe FlashAlert mode, the maintenance

message will always alternate with elapsedtime in hours and

tenths. The hours wilt flash four times, then alternate with the

maintenancemessagefourtimes until themeter resetsitself.

* 100 hours- CHGOIL-- OilChangeInterval(Every100 hrs)

* 200 hours- SVC-- ServiceAir Filter(Every200 hrs)

The hour glass graphic will flash on and off when the engine

is running.This signifies that the meter is tracking hours of

operation.

RESETBUTTON

(IF EQUIPPED)

Note:

2.3 CONNECTIONPLUGS

2.3.1 120VAC,20AMP,DUPLEXRECEPTACLE

This is a 120 Volt outlet protectedagainstoverloadby a20 Amp

push-to-resetcircuitbreaker (Figure6). Useeach socketto power

120 VoltAC, single phase,60 Hzelectricalloadsrequiringupto a

combined 2400 watts (2.4 kW) or 20 Ampsof current.Use only

high quality, well-insulated, 3-wire grounded cord sets ratedfor

125 Volts at 20 Amps (or greater).

Keep extensioncords as short as possible, preferablyless than

15 feet long, to preventvoltage drop and possibleoverheatingof

wires.

Page 9

Figure 6 - 120 Vo/t AC, 20 Amp, Duplex Receptac/e

2.3.2 120VAC,20AMP,GFC/DUPLEXRECEPTACLE

(CARBONLY)

This is a 120 Volt outlet protectedagainstoverloadby a20 Amp

push-to-reset circuit breaker (Figure 6A). Use each socket to

power 120 VoltAO,single phase,60 Hz electricalloadsrequiring

upto a combined2400 watts (2.4 kW)or 20 Amps of current.Use

only high quality,well-insulated,3-wire groundedcord sets rated

for 125 Volts at 20 Amps (or greater).

Keepextensioncords asshort as possibleto preventvoltagedrop

and possibleoverheatingof wires.

Figure 6A - 120 Vo/t AC, 20 Amp, GFC/ Duplex

Receptac/e

Figure 7 - 120/240 VAC, 30 Amp Receptac/e

120V/240V

30A

2.4 HOW TO USETHEGENERATOR

Seethe "To Start the Engine"sectionfor how to safelystart and

stop the generator and how to connect and disconnect loads. If

there are any problems operatingthe generator,please call the

generatorhelplineat 1-888-436-3722.

_t ever operate in an enclosed area or indoors!

NEVER use in the home, in a vehicle, or in

partly enclosed areas such as garages, EVEN

IF doors and windows are open! ONLY use

outdoors and far from open windows, doors,

vents, and in an area that will not accumulate

deadly exhaust.

_t The engine exhaust fumes contain carbon

monoxide, which you cannot see or smell.

This poisonous gas, if breathed in sufficient

concentrations, can cause unconsciousness or

even death.

2.3.3 120/240VAC,30AMPRECEPTACLE

Use a NEMA L14-30 plug with this receptacle (rotate to lock!

unlock). 0onnect a suitable4-wire groundedcord set to the plug

andto thedesiredtoad.Thecord set should be ratedfor 250 Volts

ACat 30 Amps (or greater)(Figure7).

Use this receptacleto operate120 Volt AC, 60 Hz, singlephase

loads requiringup to 3600 watts (3.6 kW) of powerat 30 Amps

or 240 Volt AC, 60 Hz,single phase loads requiring up to 7200

watts (7.2 kW) of power at 30 Amps. The outlet is protectedby

two 25 Amp (5.5kW)ortwo 30 Amp (6.5kW)push-to-resetor one

30 Amp 2-pole toggle switch ortwo 30 Amppush buttonto reset

(6.5/7.5kW) circuit breaker.

,_Adequate, unobstructed flow of cooling and

ventilating air is critical to correct generator

operation. Do not alter the installation or permit

even partial blockage of ventilation provisions,

as this can seriously affect safe operation

of the generator. The generator MUST be

operated outdoors.

_t This exhaust system must be properly

maintained. Do nothing that might render the

exhaust system unsafe or in noncompliance

with any local codes and/or standards.

_t Always use a battery operated carbon

monoxide alarm indoors, installed according to

the manufacturer's instructions.

Page 10

Using a generator indoors CAN KiLL YOU iN MINUTES.

Generator exhaust contains carbon monoxide. This is

a poison you cannot see or smell.

Figure8 - Groundingthe Generator

NEVER use inside a home

or garage, EVENiF doors

and windows are open.

Only use OUTSIDE and

far away from windows,

doors, and vents.

2.4.1 GROUNO/NGTHEGENERATORWHENUSEDASA

PORTABLE

This generator has an equipment ground that connects the

generatorframe componentsto the ground terminals on the AC

output receptacles (see NEC 250.34 (A) for explanation).This

allows the generatorto beused as a portable without grounding

the frame ofthe generatoras specifiedin NEC250.34.

SpecialRequirements

There may be Federalor State Occupational Safety and Health

Administration(OSHA)regulations,localcodes,or ordinancesthat

applyto the intendeduse ofthe generator.

Pleaseconsult a qualified electrician,electrical inspector, or the

local agencyhavingjurisdiction:

* In some areas, generators are requiredto be registeredwith

local utilitycompanies.

* If the generatoris used at a construction site, there may be

additionalregulationswhich must be observed.

2.=/.2 CONNECT/NGTHEGENERATORTOABU/LO/NG'$

ELECTRICALSYSTEM

When connecting directly to a building's electrical system, it is

recommendedthata manualtransfer switch is used. Connections

for a portable generatorto a building's electricalsystem must be

made by a qualified electrician and in strict compliance with all

nationaland local electricalcodes and laws.

GROUNDING

2.5 DON'TOVERLOADTHEGENERATOR

Overloadinga generatorin excess of its ratedwattage capacity

can result in damageto the generatorandto connectedelectrical

devices.Observethefollowing to preventoverloadingthe unit:

* Addupthe total wattageofall electricaldevicesto be connected

at one time. This total should NOT be greater than the

generator'swattagecapacity.

* The ratedwattageof lights can betaken from light bulbs. The

ratedwattage of tools, appliancesand motors can usually be

foundon a data labelor decal affixedto the device.

* If the appliance,tool or motor does not give wattage,multiply

voltstimes ampereratingto determinewatts (voltsx amps =

watts).

* Some electric motors, such as induction types, require about

threetimes more watts of powerfor startingthan for running.

This surge of power lasts only a few seconds when starting

suchmotors. Makesureto allowfor high startingwattagewhen

selectingelectrical devicesto connect to the generator:

1. Figurethe watts neededto start the largestmotor.

2. Add to that figure the running watts of all other connected

loads.

TheWattageReferenceGuideis providedto assist in determining

how many itemsthegeneratorcan operateat onetime.

NOTE:

All figures are approximate. See data label on appliance for

wattage requirements.

Page 11

2.6 WATTAGEREFERENCEGUIDE

Device................................... RunningWatts

*Air Conditioner (12,000 Btu).......................... 1700

*Air Conditioner (24,000 Btu).......................... 3800

*Air Conditioner (40,000 Btu).......................... 6000

BatteryCharger(20 Amp).............................. 500

BeltSander(3") .................................... 1000

ChainSaw ........................................ 1200

CircularSaw (6-1/2") ........................... 800 to 1000

*Clothes Dryer (Electric) ............................. 5750

*Clothes Dryer (Gas) ................................. 700

*Clothes Washer ................................... 1150

CoffeeMaker ...................................... 1750

*Compressor (1 HP)................................. 2000

*Compressor (3/4 HP)............................... 1800

*Compressor (1/2 HP)............................... 1400

CurlingIron......................................... 700

*Dehumidifier....................................... 650

Disc Sander(9").................................... 1200

EdgeTrimmer....................................... 500

Electric Blanket...................................... 400

Electric NailGun.................................... 1200

Electric Range(per element)........................... 1500

Electric Skillet...................................... 1250

*Freezer............................................ 700

*FurnaceFan (3/5 HP) ................................ 875

*GarageDoor Opener............................ 500to 750

HairDryer......................................... 1200

Hand Drill.................................... 250 to 1100

HedgeTrimmer...................................... 450

Impact Wrench...................................... 500

Iron.............................................. 1200

*Jet Pump ......................................... 800

Lawn Mower....................................... 1200

Light Bulb.......................................... 100

Microwave Oven............................... 700 to 1000

*Milk Cooler....................................... 1100

OilBurneron Furnace................................. 300

OilFiredSpaceHeater(140,000 Btu) ..................... 400

OilFiredSpaceHeater(85,000 Btu) ...................... 225

OilFiredSpaceHeater(30,000 Btu) ...................... 150

*Paint Sprayer,Airless (1/3 HP) ......................... 600

PaintSprayer,Airless (handheld)......................... 150

Radio......................................... 50 to 200

*Refrigerator........................................ 700

SlowCooker........................................ 200

*SubmersiblePump (1-1/2 HP) ........................ 2800

*SubmersiblePump (1 HP) ........................... 2000

*SubmersiblePump (1/2 HP).......................... 1500

*Sump Pump................................. 800 to 1050

*Table Saw(10") ............................. 1750 to 2000

Television..................................... 200 to 500

Toaster..................................... 1000 to 1650

WeedTrimmer ...................................... 500

* Allow 3 times the listedwatts for starting these devices.

2.7 BEFORESTARTINGTHEGENERATOR

Priorto operatingthe generator,engineoil and gasolinewill need

to be added,asfollows:

2.7.1 IlL}g/fiGEtVG/flEO/L

All oil should meet minimum American PetroleumInstitute (API)

Service Class SJ, SL or better.Use no special additives. Select

the oil's viscosity grade according to the expected operating

temperature(also seechart).

* Above40° F,useSAE30

* Below 40° Fand downto 10° F,use10W-30

* All temperatures,usesynthetic5W-30

41111E====mmD

°F =20 =10 0 10 20 32 40 60 80 100

oc40 -_o -1o _ 1"o 2"o 3"o 40

,_Any attempt to crank or start the engine

before it has been properly serviced with the

recommended oil may result in an engine

failure.

1. Placegeneratoron a levelsurface (not to exceed15° in any

direction).

2. Cleanareaaroundoil fill andremoveoil fill cap anddipstick.

3. Wipedipstick clean.

4. Slowly fill engine with oil through the oil fill opening until it

reachesthe full mark. Stopfilling occasionally to check oil

level.Becareful netto ever fill.

5. Installoil fill capandfinger tighten securely.

6. Checkengineoil levelbefore starting eachtimethereafter.

2.7.2 IIL}L}/tVGGASOLINE

Never fill fuel tank indoors. Never fill fuel tank

when engine is running or hot. Avoid spilling

gasoline on a hot engine. Allow engine to cool

entirely before filling fuel tank. DO NOT light a

cigarette or smoke when filling the fuel tank.

Do not overfill the fuel tank. Always leave room

for fuel expansion. If the fuel tank is overfilled,

fuel can overflow onto a hot engine and cause

FIRE or EXPLOSION. Wipe up any spilled fuel

immediately.

! !

Temperature Range of Expected Use

,&,CAUTION!

Page 12

Neverlighta cigarette or smoke when filling

the fuel tank. Gasoline is highly FLAMMABLE

and its vapors are EXPLOSIVE. Never permit

smoking, open flames, sparks or heat in the

vicinity while handling gasoline.

1. UseregularUNLEADEDgasolinewith thegeneratorengine.Do

not use anygasoline with morethan 10% addedethanol. Do

not useE85 gasoline.Donot mix oil with gasoline.

2. Cleanareaaroundfuel fill cap, removecap.

3. Slowly add unleadedregulargasolineto fuel tank. Becareful

nottooverfill (Figure9).

4. Installfuel cap andwipe up any spilledgasoline.

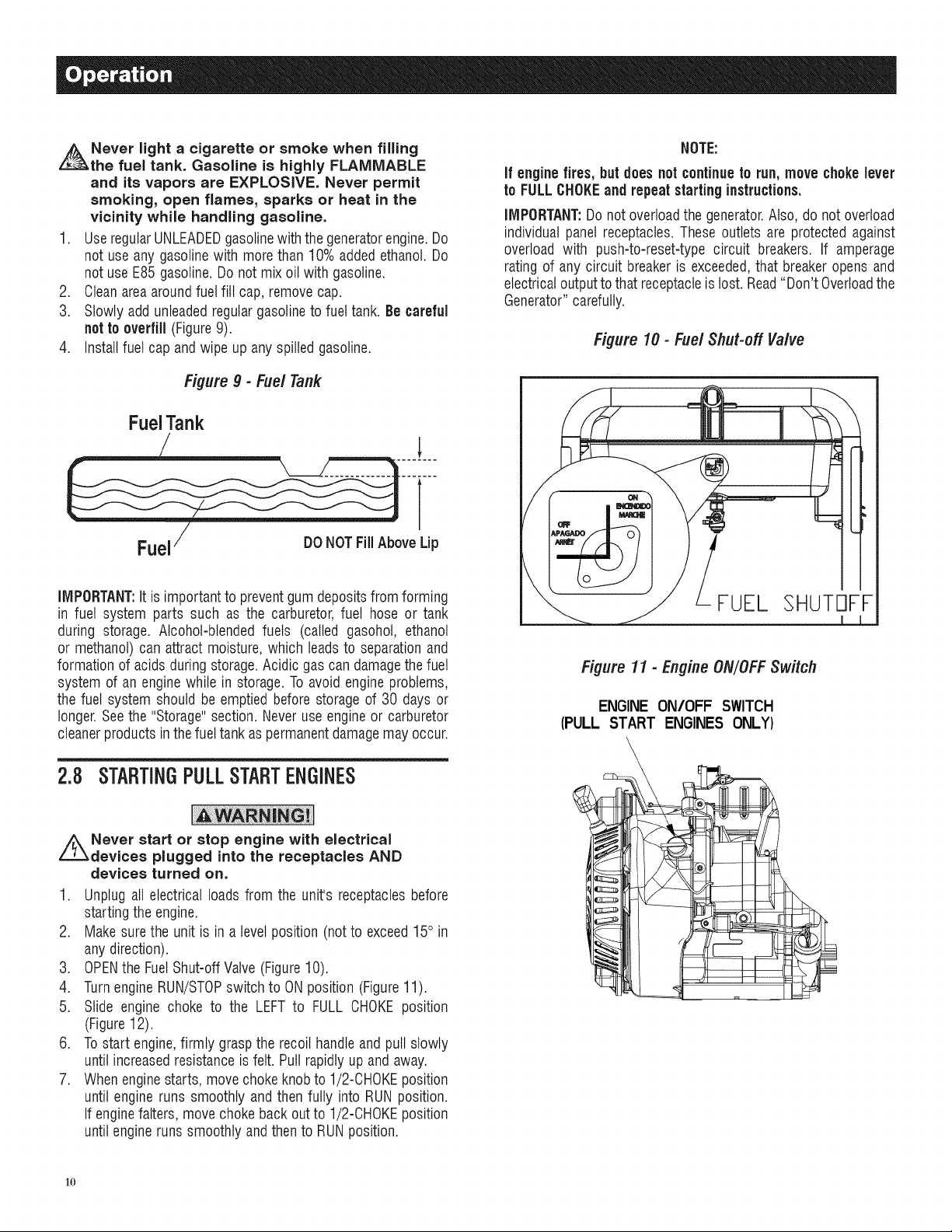

Figure g - Fuel Tank

FuelTank

Fuel/ Do NOTFillAboveLip

llVlPORTANT:It isimportant to preventgumdepositsfromforming

in fuel system parts such as the carburetor,fuel hose or tank

during storage. Alcohol-blended fuels (called gasohol, ethanol

or methanol)can attract moisture, which leadsto separationand

formation of acids duringstorage.Acidic gascandamagethefuel

system of an enginewhile in storage.To avoid engineproblems,

the fuel system should be emptiedbefore storageof 30 days or

longer.Seethe "Storage"section. Neveruseengineor carburetor

cleanerproductsin thefueltank aspermanentdamagemay occur.

NOTE:

If engine fires, but does not continueto run,movechokelever

to FULLCHOKEand repeatstartinginstructions.

IMPORTANT:Do not overloadthe generator.Also,do not overload

individual panel receptacles.Theseoutlets are protected against

overload with push-to-reset-type circuit breakers. If amperage

rating of any circuit breakeris exceeded,that breaker opensand

electricaloutputto that receptacleis lost.Read"Don't Overloadthe

Generator"carefully.

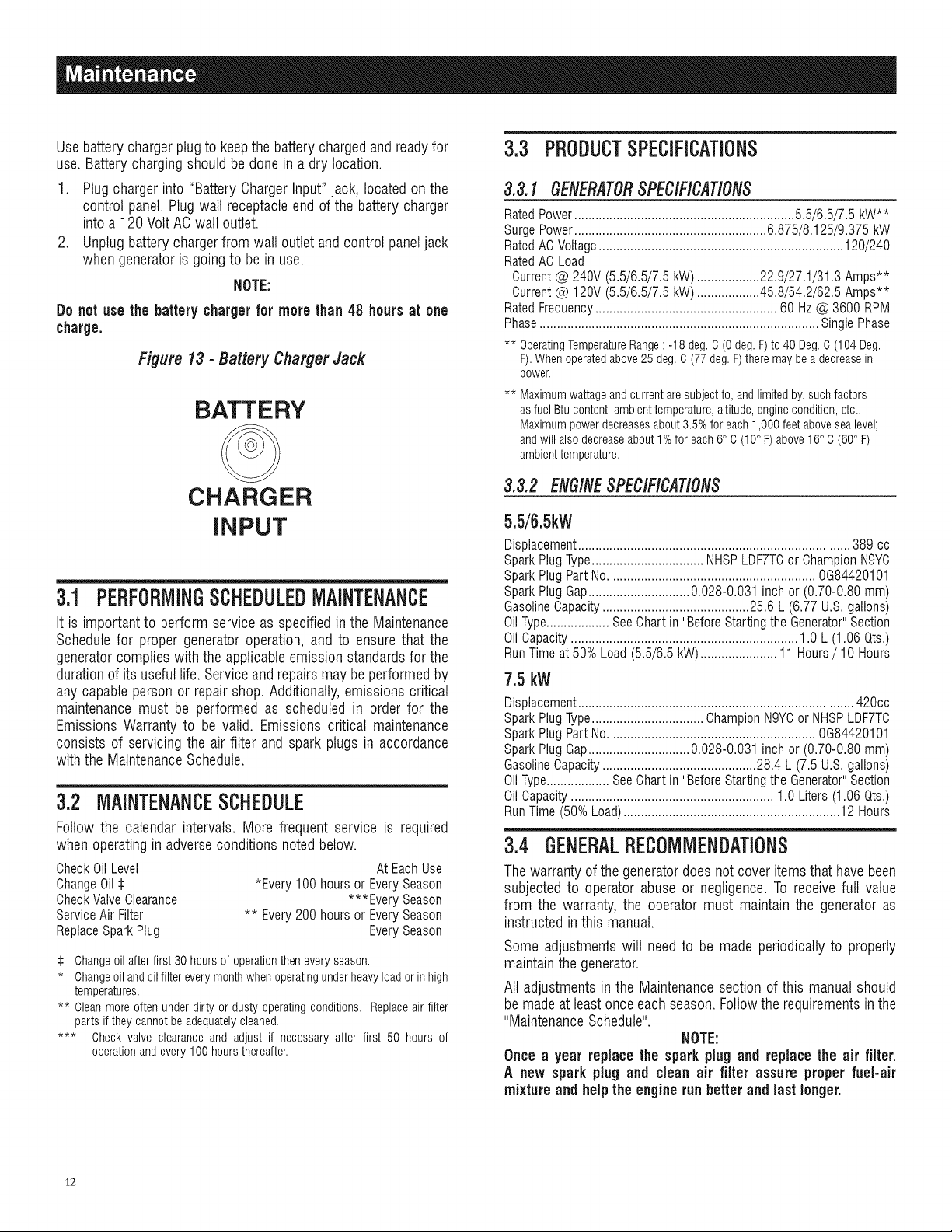

Figure 10 - Fuel Shut-eft Valve

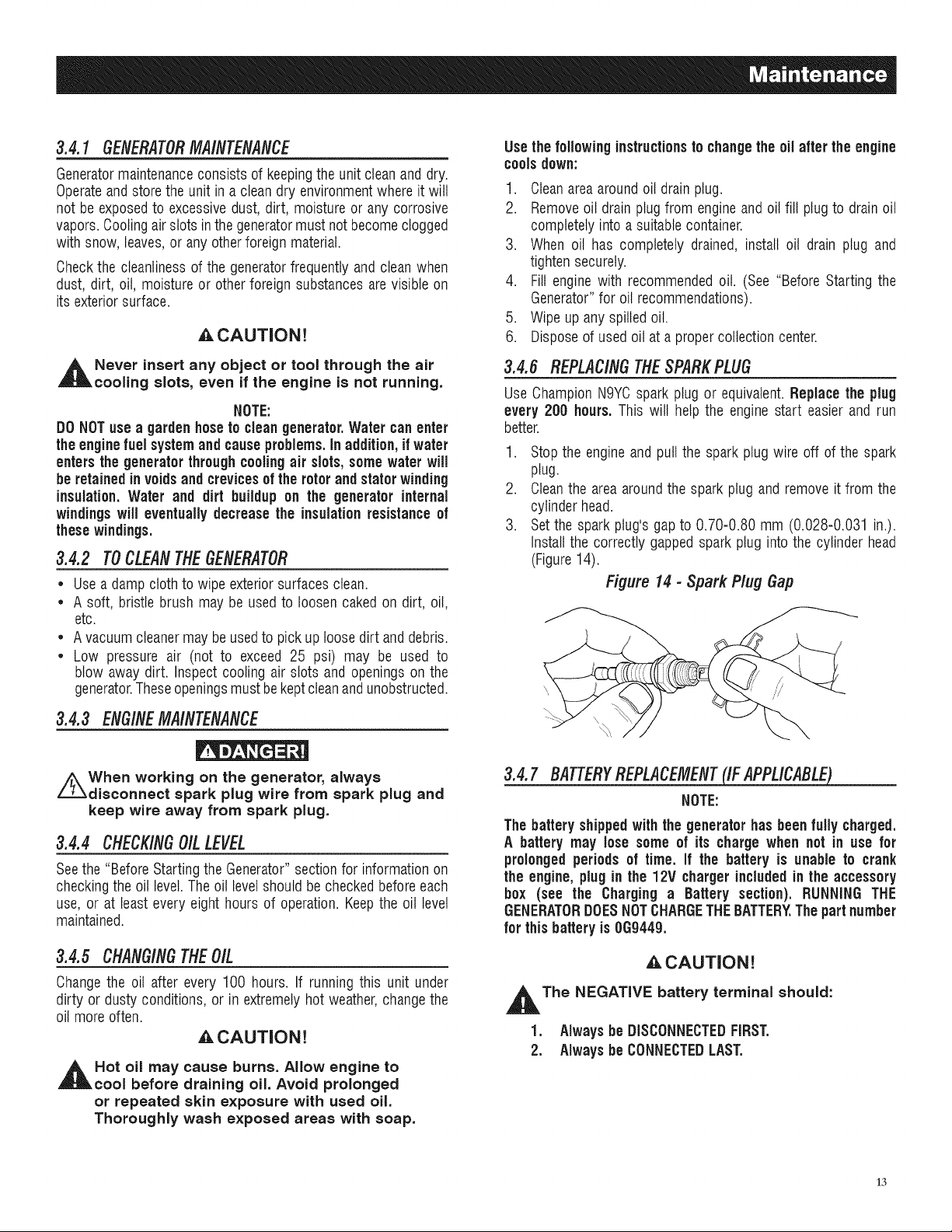

Figure 11-Engine ON/OFF Switch

ENGINE ON/OFF SWITCH

(PULL START ENGINES ONLY)

2.8 STARTINGPULLSTARTENGINES

i/_X,kNever start or stop engine with electrical

devices plugged into the receptacles AND

devices turned on.

1. Unplugall electrical loadsfrom the unit's receptaclesbefore

startingthe engine.

2. Make surethe unitis in a levelposition (notto exceed15° in

anydirection).

3. OPENthe FuelShut-offValve(Figure10).

4. TurnengineRUN/STOPswitch to ONposition (Figure11).

5. Slide engine choke to the LEFT to FULL CHOKEposition

(Figure12).

6. Tostart engine,firmly graspthe recoil handleandpull slowly

until increasedresistanceisfelt. Pullrapidly up and away.

7. Whenenginestarts, move chokeknob to 1/2-CHOKEposition

until engine runs smoothly andthen fully into RUN position.

If enginefalters,move chokeback outto 1/2-CHOKEposition

untilengine runssmoothly andthento RUNposition.

1o

Page 13

Figure 12 - Choke Position

CHOKELEVER

LEFT= CHOKE(START)

RIGHT= RUN

IMPORTANT:Do not overloadthe generator.Also,do not overload

individual panel receptacles.Theseoutlets are protected against

overload with push-to-reset-type circuit breakers. If amperage

rating of any circuit breakeris exceeded,that breaker opensand

electricaloutputto that receptacleis lost.Read"Don't Overloadthe

Generator"carefully.

2.10STOPPINGTHEENGINE

1. Shut off all loads, then unplug the electrical loads from

generatorpanel receptacles.Never start or stop the engine

with electricaldevicespluggedin andturnedon.

2. Let enginerun at no-load for severalminutesto stabilizethe

internaltemperaturesof engineand generator.

3. Move Run/Stopswitchto OFFposition.

4. Closefuelvalve.

2.9 STARTINGELECTRICSTARTENGINES

Never start or stop engine with electrical

devices plugged into the receptacles AND

devices turned on.

1. Unplugall electrical loadsfrom the unit's receptaclesbefore

startingthe engine.

2. Make surethe unitis in a levelposition (notto exceed15° in

anydirection).

3. Openthefuel shut-off valve (Figures10).

4. Move engine CHOKEknoboutward to FULLCHOKEposition

(Figure12).

5. Tostart engine, press and hold the Start/Run/Stopswitch in

the"Start" position. Theenginewill crankandattemptto start.

Whenthe enginestarts, releasethe switchto the run position.

6. Whenthe engine starts, move choke knob to "1/2 Choke"

position untilthe engineruns smoothly andthenfully into the

"Run" position.If enginefalters, movechokeknobbackout to

"1/2 Choke"position untilthe engine runssmoothly andthen

to "Run" position.

2.9.1 MANUALSTART

This generatoris also equippedwith amanualrecoilstarter which

may be used if the battery is discharged.

NOTE:

The switch must be in the RUN position. Use one of the

generator's receptacleoutlets along withthe includedbattery

chargerto chargethe battery while the generator is running.

* Tostart manually,firmly grasp therecoil handleand pull slowly

until increasedresistance is felt. Pull rapidly up and away to

start engine.Thenfollow the samechoke sequence.

NOTE:

if enginefires, but does not continueto run,move chokelever

to FULLCHOKEand repeatstarting instructions.

2.11LOWOiLLEVELSHUTDOWNSYSTEM

Theengineis equippedwith a low oil levelsensorthat shuts down

theengineautomaticallywhenthe oil leveldrops belowa specified

level. If the engine shuts down by itself and the fuel tank has

enoughgasoline,checkengineoil level.

2.11.1 SENSINGLOWO/LLEVEL

If the system senses a low oil level during operation,the engine

shuts down. Theenginewill not run until the oil has beenrefilled

to theproper level.

2.12CHARGINGTHEBATTERY(ELECTRICSTART

UNITSONLY)

Storage batteries give off explosive hydrogen

gas while recharging. An explosive mixture will

remain around the battery for a long time after

it has been charged. The slightest spark can

ignite the hydrogen and cause an explosion.

Such an explosion can shatter the battery and

cause blindness or other serious injury.

_tDo not permit smoking, flame, sparks

or any other source of heat around a battery.

Wear protective goggles, rubber apron and

rubber gloves when working around a battery.

Battery electrolyte fluid is an extremely

corrosive sulfuric acid solution that can cause

severe burns, if spill occurs flush area with

clear water immediately.

Thebattery shippedwiththe generatorhasbeen fully charged.

A battery may lose some of its charge when not in use for

prolongedperiodsoftime. if the battery is unable to crankthe

engine,plugin the12V chargerincludedin the accessorybox.

RUNNINGTHEGENERATORDOESNOTCHARGETHEBATTERY.

open

NOTE:

11

Page 14

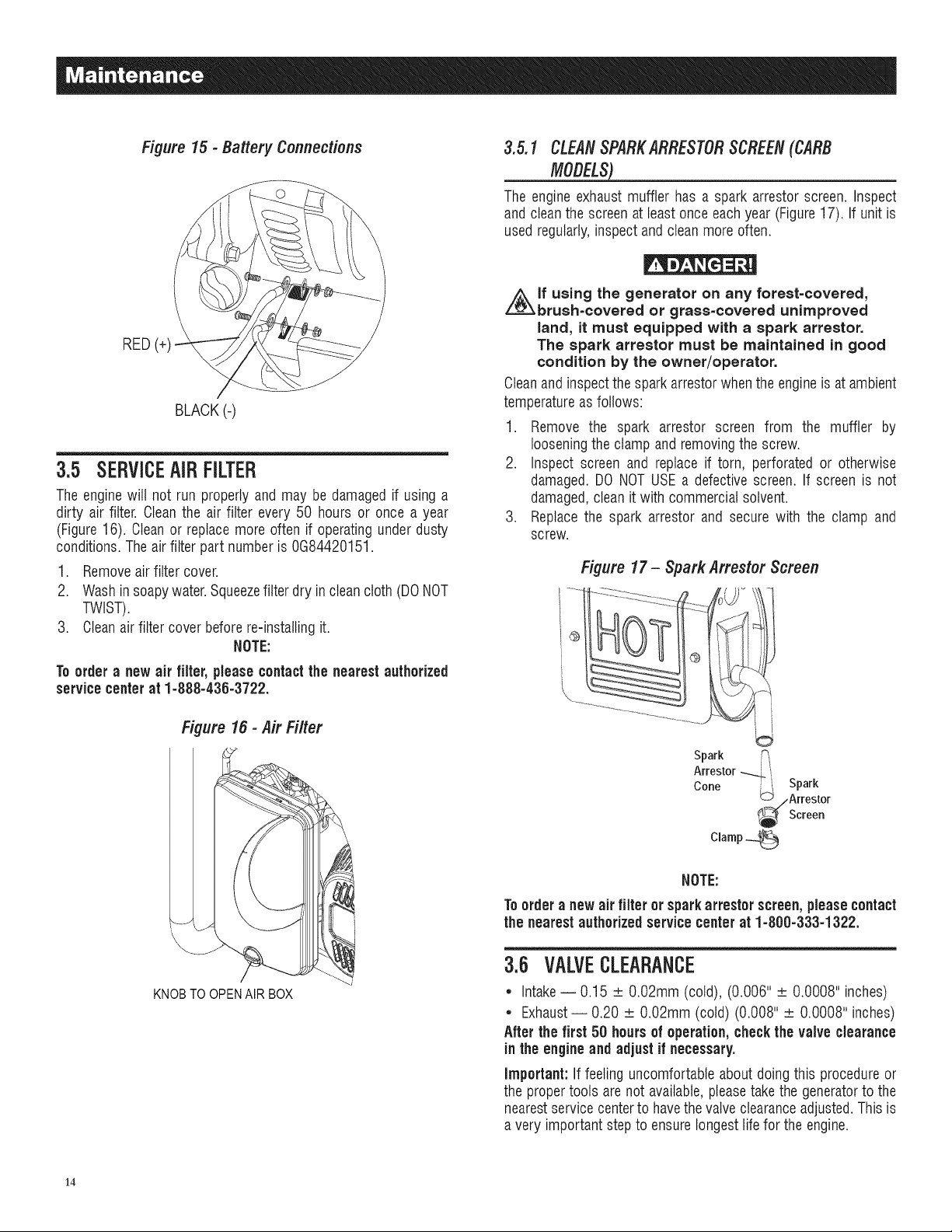

Usebatterychargerplugto keepthe batterychargedandreadyfor

use. Batterychargingshouldbe done ina dry location.

1. Plugchargerinto "Battery ChargerInput"jack, locatedon the

control panel.Plug wall receptacleendof the batterycharger

into a 120 Volt AC wall outlet.

2. Unplugbattery chargerfrom walt outletand control paneljack

whengeneratoris goingto be in use.

NOTE:

Do not use the battery chargerfor more than48 hoursat one

charge.

Figure13 - Battery Charger Jack

BATTERY

3.3 PRODUCTSPECIFICATIONS

3.3.1 GENERATORSPECIFICATIONS

RatedPower............................................................... 5.5/6.5/7.5 kW**

SurgePower....................................................... 6.875/8.125/9.375 kW

RatedACVoltage...................................................................... 120/240

RatedAC Load

Current@ 240V (5.5/6.5/7.5 kW)..................22.9/27.1/31.3 Amps**

Current@ 120V (5.5/6.5/7.5 kW)..................45.8/54.2/62.5 Amps**

RatedFrequency.................................................... 60 Hz@ 3600 RPM

Phase................................................................................ SinglePhase

** OperatingTemperatureRange: -18deg.C(0deg.F)to40Deg.C(104Deg.

F).Whenoperatedabove25deg.C(77deg.F)theremaybea decreasein

power.

** Maximumwattageandcurrentaresubjectto,andlimitedby,suchfactors

asfuelBtucontent,ambienttemperature,altitude,enginecondition,etc..

Maximumpowerdecreasesabout3.5%foreach1,000feetabovesealevel;

andwillalsodecreaseabout1%foreach6° C (10° F)above16° C(60°F)

ambienttemperature.

CHARGER

iNPUT

3.1 PERFORMINGSCHEDULEDMAINTENANCE

It is important to perform serviceas specifiedin the Maintenance

Schedulefor proper generatoroperation,and to ensure that the

generatorcomplies with the applicableemissionstandardsfor the

durationof its useful life.Serviceandrepairsmaybe performedby

any capableperson or repairshop.Additionally,emissionscritical

maintenancemust be performed as scheduled in order for the

Emissions Warrantyto be valid. Emissions critical maintenance

consists of servicing the air filter and spark plugs in accordance

with the MaintenanceSchedule.

3.2 MAINTENANCESCHEDULE

Follow the calendar intervals. More frequent service is required

whenoperatingin adverseconditions notedbelow.

CheckOilLevel AtEachUse

ChangeOil$ *Every100hoursorEverySeason

CheckValveClearance ***EverySeason

ServiceAirFilter ** Every200hoursorEverySeason

ReplaceSparkPlug EverySeason

$ Changeoil after first 30 hours of operationthenevery season.

* Changeoiland oilfilter everymonth whenoperatingunderheavy load or in high

temperatures.

** Clean more often under dirty or dusty operating conditions. Replaceair filter

parts ifthey cannot beadequatelycleaned.

*** Check valve clearance and adjust if necessary after first 50 hours of

operationand every 100 hours thereafter.

3.3.2 ENGINESPECIFICATIONS

5.5/6.5kW

Displacement.............................................................................. 389 cc

SparkPlugType................................ NHSPLDF7TCor ChampionN9YC

SparkPlug Part No........................................................... 0G84420101

SparkPlug Gap............................. 0.028-0.031 inch or (0.70-0.80 mm)

GasolineCapacity.......................................... 25.6 L (6.77 U.S. gallons)

OilType.................. SeeChart in "Before Startingthe Generator"Section

OilCapacity................................................................. 1.0 L (1.06 Qts.)

RunTimeat 50% Load (5.5/6.5 kW)...................... 11 Hours/ 10 Hours

7.5kW

Displacement............................................................................... 420cc

SparkPlugType................................ ChampionN9YCorNHSPLDF7TC

SparkPlug Part No........................................................... 0G84420101

SparkPlug Gap............................. 0.028-0.031 inch or (0.70-0.80 mm)

GasolineCapacity............................................28.4 L (7.5 U.S.gallons)

OilType.................. SeeChart in "Before Startingthe Generator"Section

OilCapacity.......................................................... 1.0 Liters (1.06 Qts.)

RunTime (50%Load)..............................................................12 Hours

3.4 GENERALRECOMMENDATIONS

Thewarranty of thegeneratordoes notcover itemsthat havebeen

subjectedto operator abuse or negligence.To receivefull value

from the warranty, the operator must maintain the generatoras

instructed inthis manual.

Some adjustmentswilt need to be made periodically to properly

maintainthegenerator.

All adjustmentsin the Maintenancesectionof this manualshould

be madeat leastonce eachseason.Followthe requirementsinthe

"MaintenanceSchedule".

NOTE:

Once a year replace the spark plug and replace the air filter.

A new spark plug and clean air filter assure proper fuel-air

mixture andhelp the engine run better andlast longer.

12

Page 15

3.4.1 GENERATORMAINTENANCE

Generatormaintenanceconsistsof keepingthe unit clean and dry.

Operateandstorethe unit in a cleandry environmentwhereit will

not be exposedto excessivedust,dirt, moistureor any corrosive

vapors.Coolingair slotsin the generatormustnot becomeclogged

with snow, leaves,or anyotherforeign material.

Checkthe cleanlinessof the generatorfrequentlyand cleanwhen

dust, dirt, oil, moisture or otherforeign substancesarevisible on

its exteriorsurface.

,ACAUTION!

Usethe followinginstructionsto changetheoil after the engine

coolsdown:

1. Cleanareaaroundoil drainplug.

2. Removeoil drain plugfrom engineandoil fill plug to drainoil

completelyinto a suitablecontainer.

3. When oil has completely drained, install oil drain plug and

tightensecurely.

4. Fill engine with recommendedoil. (See "Before Starting the

Generator"for oil recommendations).

5. Wipeup anyspilled oil.

6. Disposeof used oil at a propercollectioncenter.

,_ Never insert any object or tool through the air

cooling slots, even if the engine is not running.

NOTE:

DONOTuse a gardenhoseto cleangenerator.Water canenter

the enginefuel systemandcauseproblems.In addition,ifwater

entersthegeneratorthroughcoolingair slots,somewater will

be retainedin voidsand crevicesof the rotorand statorwinding

insulation.Water and dirt buildup on the generatorinternal

windingswill eventually decrease the insulationresistanceof

thesewindings.

3.4.2 TOCLEANTHEGENERATOR

• Usea damp cloth to wipe exteriorsurfaces clean.

• A soft, bristlebrush may be usedto loosencaked on dirt, oil,

etc.

• A vacuumcleanermay be usedto pick up loosedirt anddebris.

• Low pressure air (not to exceed 25 psi) may be used to

blow away dirt. Inspectcooling air slots and openingson the

generator.Theseopeningsmustbekeptcleanandunobstructed.

3.4.3 ENG/NEMAINTENANCE

When working on the generator, always

disconnect spark plug wire from spark plug and

keep wire away from spark plug.

3.4.4 CHECKINGOILLEVEL

Seethe "BeforeStarting the Generator"sectionfor informationon

checkingthe oil level.The oil levelshouldbe checkedbefore each

use, or at least every eight hours of operation. Keepthe oil level

maintained.

3.4.5 CHANGINGTHEOIL

Changethe oil after every 100 hours. If running this unit under

dirty or dusty conditions, or inextremelyhot weather,changethe

oil more often.

ACAUTION!

,_Hot oil may cause burns. Allow engine to

cool before draining oil. Avoid prolonged

or repeated skin exposure with used oil,

Thoroughly wash exposed areas with soap.

3.4.6 REPLACINGTHESPARKPLUG

Use ChampionN9YCspark plug or equivalent.Replace the plug

every 200 hours.This will help the engine start easier and run

better.

1. Stopthe engineand pull the spark plug wire off of the spark

plug.

2. Cleanthe area aroundthe spark plug and remove it from the

cylinder head.

3. Setthe spark plug'sgap to 0.70-0.80 mm (0.028-0.031 in.).

Installthe correctly gappedspark plug intothe cylinder head

(Figure14).

Figure 14 - Spark Plug Gap

3.4.7 BATTERYREPLACEMENT(IFAPPLICABLE)

NOTE:

Thebatteryshippedwiththe generator has beenfully charged.

A battery may lose some of its charge when not in use for

prolongedperiodsof time. If the battery is unable to crank

the engine,plug in the 12V chargerincludedin the accessory

box (see the Charging a Battery section). RUNNINGTHE

GENERATORDOESNOTCHARGETHEBATTERY.Thepartnumber

for this battery is 0Gg44g.

,_.CAUTION!

,_The NEGATIVE battery terminal should:

1. Always be DISCONNECTEDFIRST.

2. Alwaysbe CONNECTEDLAST.

13

Page 16

Figure 15 - Battery Connections

RED(+)

BLACK(-)

3.5 SERVICEAIRFILTER

Theenginewill not run properlyand may be damagedif using a

dirty air filter. Cleanthe air filter every 50 hours or once ayear

(Figure16). Clean or replacemore often if operating underdusty

conditions.Theair filter part numberis 0G84420151.

1. Removeairfilter cover.

2. Washinsoapywater.Squeezefilter dry incleancloth (DONOT

TWIST).

3. Cleanair filter cover before re-installingit.

NOTE:

3.5.1 CLEANSPARKARRESTORSCREEN(CARB

MODELS)_

The engineexhaustmuffler has a spark arrestor screen. Inspect

and cleanthe screenat least onceeach year (Figure17). Ifunit is

usedregularly,inspect and clean moreoften.

i/_lf using the generator on any forest=covered,

brush=covered or grass=covered unimproved

land, it must equipped with a spark arrestor.

The spark arrestor must be maintained in good

condition by the owner/operator.

Cleanandinspectthe sparkarrestorwhenthe engineisat ambient

temperatureasfollows:

1. Remove the spark arrestor screen from the muffler by

looseningthe clamp andremovingthe screw.

2. Inspect screen and replace if torn, perforated or otherwise

damaged. DONOT USEa defective screen. If screen is not

damaged,cleanit with commercialsolvent.

3. Replacethe spark arrestor and secure with the clamp and

screw.

Figure 17 - Spark Arrestor Screen

Toordera new air filter, pleasecontactthe nearestauthorized

servicecenterat 1-888-436-3722.

Figure 15- Air Filter

KNOBTOOPENAIR BOX

Spark

Arrestor "-_/

Cone i Spark

_/Arrestor

_ Screen

C,a,.p

NOTE:

Toordera newair filter or sparkarrestor screen,pleasecontact

the nearestauthorizedservice centerat 1-800-333-1322.

3.6 VALVECLEARANCE

• Intake-- 0.15 _ O.02mm(cold), (0.006" _ 0.0008" inches)

• Exhaust-- 0.20 _ O.02mm(cold) (0.008" _ 0.0008" inches)

After the first 50 hoursof operation, checkthe valve clearance

in the engine and adjust if necessary.

Important: If feeling uncomfortableaboutdoing this procedureor

theproper tools are not available,pleasetake the generatorto the

nearestservicecenterto havethevalveclearanceadjusted.This is

a very importantstepto ensurelongestlifefor theengine.

14

Page 17

3.7 GENERAL

Thegeneratorshould be started at least once every 30 days and

be allowedto run at least 30 minutes. If this cannotbe done and

the unit must be stored for more than 30 days, use thefollowing

informationas a guideto prepareitfor storage.

NEVER store engine with fuel in tank indoors

or in enclosed, poorly ventilated areas where

fumes may reach an open flame, spark or pilot

light as on a furnace, water heater, clothes dryer

or other gas appliance.

_t Allow unit to cool entirely before storage.

3.8 LONGTERMSTORAGE

It is important to preventgum depositsfrom forming in essential

fuel systemparts such asthe carburetor,fuel hose or tankduring

storage. Also, experience indicates that alcohol-blended fuels

(called gasohol,ethanolor methanol)can attract moisture,which

leadsto separationandformation of acids during storage.Acidic

gascan damagethefuel system of an enginewhile in storage.

To avoid engine problems, the fuel system should be emptied

beforestorageof 30 daysor longer,asfollows:

1. Addaqualitygasolinestabilizertothefuelperthemanufacturer's

specifications,and run the unitfor 10-15 minutes.

2. After engine cools down, remove all gasolinefrom the fuel

tank. Use a commerciallyavailable, non-conductivevacuum

siphon.

_CAUTION!

Avoid spray from spark plug hole when

cranking engine.

6. Installandtightenspark plug.Do not connectsparkplugwire.

7. Cleanthe generator outer surfaces. Check that cooling air

slots andopeningson generatorareopen and unobstructed.

8. Storethe unit in a clean, dry place.

3.9 OTHERSTORAGETiPS

* Do not store gasolinefrom oneseasonto another.

* Replacethe gasoline can if it starts to rust. Rust and/ordirt in

the gasolinewill cause problems with the carburetor and fuel

system.

* If possible,storethe unit indoors andcover it to give protection

from dust anddirt. BESURETOEMPTYTIlE FUELTANK,

* If it is not practicalto empty the fuel tank and the unit is to

be stored for some time, use a commercially availablefuel

stabilizer added to the gasoline to increase the life of the

gasoline.Runthe unit for 10-15 minutes,turn off thefuel valve

and allowto run until enginestops from lackof fuel.

* Cover the unit with a suitable protective cover that does not

retainmoisture.

_t NEVER cover the generator while engine and

exhaust areas are warm.

Drain fuel into approved container outdoors,

away from open flame. Be sure engine is cool.

Do not smoke.

3. Start and run engineuntilenginestops from lackof fuel.

4. After engine cools down, drain oil from engine. Refill with

recommendedgrade.

5. Remove spark plug and pour about 1/2 ounce (15 mt) of

engineoil intothecylinder.Coverspark plugholewith rag.Pull

the recoil starter a couple times to lubricatethe piston rings

and cylinder bore.A fogging agent can also be used in the

placeof oil.

15

Page 18

4.1TBOUBLESHOOTINGGUIDE

Engineis running,but no AC output

isavailable.

1. Circuitbreakeris open.

2. Poorconnectionor defectivecord set.

3. Connecteddeviceis bad.

4. Faultin generator.

1. Resetcircuit breaker.

2. Checkand repair.

3. Connectanotherdevicethat is in goodcondition.

4. ContactAuthorizedServiceFacility.

Engineruns well hut bogs down 1. Short circuit in a connectedload. 1. Disconnectshorted electrical load.

whenloadsare connected. 2. Generatoris overloaded. 2. See"Don't Overloadthe Generator".

3. Enginespeedis too slow. 3. ContactAuthorizedServiceFacility.

4. Shorted generatorcircuit. 4. ContactAuthorizedServiceFacility.

I I

Enginewill notstart;orstartsand

runsrough.

1. FuelShut-off is OFF.

2. Dirty airfilter.

3. Outof gasoline.

4. Stalegasoline.

5. Sparkplug wire not connectedto spark plug.

6. Bad sparkplug.

7. Waterin gasoline.

8. Overchoking.

9. Low oil level.

10. Excessiverichfuel mixture.

11. Intakevalve stuck openor closed.

12. Enginehas lostcompression.

= I

1. TurnFuelShut-off ON.

2. Cleanor replaceairfilter.

3. Fillfuel tank.

4. Drainfuel tank andfill with fresh fuel.

5. Connectwire to sparkplug.

6. Replacespark plug.

7. Drainfuel tank; fill with fresh fuel.

8. Putchoke knob to NoChokeposition.

9. Fillcrankcaseto properlevel.

10. Contact AuthorizedServiceFacility.

11. Contact AuthorizedServiceFacility.

12. Contact AuthorizedServiceFacility.

Engineshuts downduring 1. Outof gasoline. 1. Fillfuel tank.

operation. 2. Low oil level. 2. Fillcrankcaseto properlevel.

3. Faultin engine. 3. ContactAuthorizedServiceFacility.

m R

Enginelacks power. 1. Loadis too high. 1. Reduceload (see"Don't Overloadthe Generator").

2. Dirty airfilter. 2. Cleanor replaceairfilter.

3. Engineneedsto be serviced. 3. ContactAuthorizedService Facility.

= I

Engine"hunts" or falters. 1. Chokeis openedtoo soon. 1. Movechoketo halfway positionuntil engineruns

smoothly.

2. Carburetoris running too rich or too lean. 2. ContactAuthorizedServiceFacility.

16

Page 19

17

Page 20

Manual PartNo. 0K0172 Rev.F(12/13/13) Printedin China

Page 21

G ®

• • _ • ®

anual propietari

eneradorportatiJSerie

GARANTiA

LIMI A D

19

Page 22

Introduccion..........................................................21

Mantenimiento ...................................................... 32

Leaestemanualminuciosamente........................21

Reglasdeseguridad.............................................21

[ndicedenormas ............................................................................... 23

Informationgeneral..............................................24

1.1 Desembalaje.......................................................................... 24

1.2 Armado.................................................................................. 24

1.3 Informacionsobre emisiones................................................. 25

Funcionamiento....................................................25

2.1 Conozcaelgenerador............................................................ 25

2.2 Horometro............................................................................. 26

2.3 Enchufesdeconexion............................................................ 26

2.4 Come usar el generador......................................................... 27

2.5 No sobrecargueel generador.................................................28

2.6 Guiadereferenciade potencia enwatts................................. 29

2.7 Antes dearrancarel generador.............................................. 29

2.8 Arranquede motores con arranquecon tirador.......................30

2.9 Arranquede motores con arranqueelectrico..........................31

2.10 Paradadelmotor ................................................................... 31

2.11 Sistemadeapagadoper nivelde aceitebajo..........................31

2.12 Oargade la bateria (unidadescon arranque

electricosolamente)...............................................................32

3.1 Realizacbn delmantenimientoprogramado............................32

3.2 Programade mantenimiento................................................... 32

3.3 Especificacionesdel producto................................................ 32

3.4 Recomendacionesgenerales..................................................33

3.5 Servicio delfiltro deaire......................................................... 34

3.6 Holguradevalvulas................................................................ 35

3.7 Generalidades........................................................................ 35

3.8 Almacenamientoa largoplazo................................................ 35

3.9 Otrosconsejos sobre el almacenamiento...............................35

Resolucionde problemas.....................................36

4.1 Guiade resolucionde problemas...........................................36

Netas .................................................................... 37

ADVERTENCIA!

Proposicion 65 de California

Elescape del motory algunosde sus componentesson conocidospore elEstadode Californiacome

causa de cancer,defectos congenitosy otrosdaSosreproductivos.

ADVERTENCIA!

Proposicion 65de California

Este productocontiene o emite sustanciasquimicas que son conocidas per el Estadode California come

causa de cancer,defectos congenitosy otrosdaSosreproductivos.

20

Page 23

INTBODUCCiON

r

Muchas gracias per haber comprado este modelo de Generac Power

Systems, Inc. Este modelo es un generador impulsado per motor,

compacto, de alto rendimiento y enfriado per aire disefiado para

suministrar alimentacionelectricapara utilizarcargaselectricasdonde no

haya alimentacionde servicio publico disponible o come reemplazode

dicha alimentaciondebidoa un apagon.

LEAESTEMANUALMINUCIOSAMENTE

Si una parte de este manual no se comprende, comuniquese con el

concesionarioautorizadomas cercanopara conocer los procedimientos

de arranque,operaciony mantenimiento.

El operador es responsable del use correcto y seguro del equipo.

Recomendamosfirmementeque eloperadorleaestemanualy comprenda

completamentetodas las instruccionesantesde usar el equipo.Tambien

recomendamos firmemente instruir a otras personas en el arranque y

la operacion correctos de la unidad.Esto las preparaen el case de que

deban operar el equipo en una emergencia.Guarde estas instrucciones

para referencia en el future. Si presta este dispositivo a otra persona,

SlEMPREentregueletambien esta instrucciones.

El generadorpuede funcionar de manerasegura, eficiente y fiable solo

si es ubicado,operado y mantenidocorrectamente.Antes de operar el

generadoro darle servicio:

• Familiaricesecontodos los codigos y reglamentoslocales, estatalesy

nacionales,y cumplalosde maneraestricta.

• Estudietodas las advertenciasdeseguridadindicadasen estemanual

y en el producto minuciosamente.

• Familiaricesecon este manualy la unidadantes del use.

El fabricante no puede prever todas las circunstancias posibles que

podrian involucrar un peligro. Las advertenciasde este manual y los

rotulos y etiquetasadhesivasfijados en la unidad,per Io tanto, no son

exhaustivos. Si usa un procedimiento, metodo de trabajo o tecnica

de funcionamiento que el fabricante no recomienda especificamente,

aseguresede que sea seguropara otras personas.Aseguresetambien

de que el procedimiento,metodo detrabajo o tecnica defuncionamiento

utilizadonovuelvaninseguro al generador.

LA INFORMACIONQUE FIGURA EN EL PRESENTESE BAS0 EN

MAQUINASQUE ESTABANEN PRODUCCIONAL MEMENTO DE LA

PUBLICACl0N.GENERACSE RESERVAEL DERECHODE MODtFICAR

ESTEMANUALENCUALQUIERMEMENTO.

BEGLASDESEGURIDAD

Entodaestapublicaci6n,enlos r6tulosyen las etiquetasadhesivasfijadas

en el generador,los bloquesde PELIGRO,ADVERTENCIA,PRECAUCION

y NOTAse usan para alertar al personalsobre instrucciones especiales

acerca de una operacion en particular que puede ser peligrosa si se

efectuade maneraincorrectao imprudente.Observeloscuidadosamente.

Sus definicionesson lassiguientes:

INDICAUNA SITUACI6N0 ACCIONPELIGROSAQUE,SI NOSE EVITA,

OCASIONARALA iVlUERTE0 LESIONESGRAVES.

Indica unasituacion e accion peligrosaque, si no se

evita, podriaocasionarla rnuerteo lesiones graves.

CUIDADO

Indica unasituacion o accion peligrosaque, si no se

evita, podriaocasionarlesionesleves o rnoderadas.

NOTA:

Las notas contienen informacion adicional importante para un

procedimiento y se encuentran dentro del texto del cuerpo de este

manual.

Estas advertencias de seguridad no pueden eliminar los peligros que

indican. Elsentidocomun y elcumplimiento estrictode lasinstrucciones

especialesmientras se desarrollala accion o el servicio son esenciales

para la prevenciondeaccidentes.

Cuatrosimbolosdeseguridaddeusecomun acompafianalos bloquesde

PELIGRO,ADVERTENCIAy PRECAUCION.Cada un0 indica el siguiente

tip0 de inf0rmaci0n:

_i ste sfmbolo sehala informaci6n de seguridad

importante que, si no se respeta, podrfa porter

en peligro la seguridad personal y/o material de

terceros.

Este sfmbolo sehaia un posible peligro de expiosi6n.

//_Este sfmbolo sehaia un posible peligro de incendio.

Este sfmbolo sehala un posible peligro de choque

el_ctrico.

21

Page 24

PELIGROSGENERALES

• NUNCAoperela unidaden una zona confinada, en un vehiculoo en

interiores,AUNSIlas puertas y ventanasestanabiertas.

• Per motives de seguridad, el fabricante recomienda que el

mantenimientode este equipo sea efectuado per un concesionario

autorizado. Inspeccione el generador regularmente,y pongase en

contacto conel concesionarioautorizadomascercano enrelaci6ncon

las piezasquenecesitanreparaciono sustitucion.

• Utilice el generador solamente sobre superficies niveladas y donde

no este expuestoa humedad, suciedad, polvo o vapores corrosives

excesivos.

• Mantenga las manes, pies, ropa, etc. alejados de las correas de

transmision y otras piezas en movimiento. Nunca retire ningun

protectoro escudo de ventilador mientrasla unidadestefuncionando.

• AIgunas piezas del generador se calientan en extreme durante el

funcionamiento.Mantengasealejado de] generadorhastaque se haya

enfriadoparaevitarquemadurasgraves.

• NOuse elgeneradordebajode la Nuvia.

• No modifiquelaconstruccion del generadoro cambielos controles,ya

quepodriangenerasecondiciones defuncionamiento inseguro.

• Nunca arranqueo pare la unidadcon cargas electricas conectadasa

tomacorrientesY condispositivosconectadosencendidos.Arranqueel

motory permitaque se estabiNceantes de conectar cargaselectricas.

Desconectetodas las cargas electricasantesde apagarel generador.

• No inserteobjetosa travesdelas ranurasdeenfriamientodela unidad.

• Cuandotrabaje en este equipo,mantengasealerta en todo memento.

Nuncatrabajeen el equipocuando estefatigadofisica o mentalmente.

• Nunca useel generadoro cualquierade sus piezascome un escal6n.

Pararse sobre la unidad puede forzar y romper piezas y podria

ocasionar condiciones de funcionamiento peligrosas per fugas de

gasesdeescape,fugas decombustible,fugas de aceite, etc.

NOTA:

Estegenerador puede estar equipado con un silenciador supresor de

chispas. El supresor de chispas debe ser mantenido en condiciones

de trabajo eficaces per el propietario/operador. En el Estado de

California, se requiere per ley un supresor de chispas (Seccibn 4442

del California PublicResources Code[Codigo de recursos p[/blicos de

California]). Otros estados pueden tener leyes similares. Se aplican

leyes federales en las tierras federales.

PELiGROSRELACIONADOSCONELESCAPE

Y LAUBICACION

• iNnunca use la unidad en una zona cenfinada e en interiores!

iNUNCA use la unidad en el begat, en un vehiculo e en zenas

parciaimenteconfinadastales comegarajes, AUN SI las puertasy

ventanasest;in abiertas!UseSOLAMENTEen exteri0res y lejos de

ventanas,puertasy ventilacionesabiertas, y en unazonaderideno

se acumulen vaporesde escape mortales.

Usar un generador en interiores LO PUEDE

MATAR EN MINUTOS,

Los gases de escape del generador contienen monoxide

de carbono. Este es un veneno que no se puede vet u oler.

NUNCA Io use dentro de una

casa o garaje,AUN SI la puerta

y las ventanas se encuentran

abiertas.

• Los vapores de escape del motor contienenmonoxido de carbono,

que no se puede ver ni oler. Estegas venenoso, si se respira en

concentraciones suficientes, puede causar perdida de conocimiento

o incluso la muerte.

• El flujo adecuado y sin obstrucciones del aire de enfriamiento y

ventilaci6n resulta critico para el funcionamiento adecuado del

generador.No altere la instalacion ni permita el bloqueo, ni siquiera

parcial, del suministro de ventilacion, dado que esto puede afectar

seriamenteel funcionamiento seguro del generador.El generadorSE

DEBEusar enexteriores.

• Estesistema de escapedebe sermantenido adecuadamente.Nohaga

nada que pueda volver inseguro al sistema de escape o que infrinja

cualquiercodigo y/o norma local.

• Siempre use en interiores una alarma de monoxido de carbono

alimentada por bateria instalada conforme alas instrucciones del

fabricante.

• Si comienza a sentirse enfermo, mareado o debil despues de que el

generador ha estado funcionando, salga INMEDIATAMENTEal aire

fresco. Oonsultea un medico, ya que podria sufrir envenenamiento

por monoxidodecarbono.

Use unicamente en

EXTERIORES, y alejado de

ventanas, puertas

y ventilaciones.

22

Page 25

PELIGROELI CTRICO

• Elgeneradorproduce un voltaje peligrosamentealto cuando esta en

funcionamiento.Eviteelcontacto con cables,terminales, conexiones,

etc.desnudosmientraslaunidadestafuncionando,aun en los equipos

conectados al generador. Asegurese de que todas las cubiertas,

proteccionesy barrerasadecuadas esten colocadas antes de utilizar

el generador.

• Nunca maneje ningun tipo de cable o dispositivo electrico mientras

este parado sobre agua o este descalzoo cuando tenga las manos

o los pies mojados. PUEDEPRODUCIRSEUN CHOQUEELF:CTRICO

PELIGROSO.

• El Codigo Electrico Nacional de los EE. UU. (NEC) requiere que

el bastidor y las piezas conductoras de electricidad externas del

generadoresten correctamente conectadas a una conexion a tierra

aprobada. Los codigos de electricidad locales tambien pueden

requerirla conexiona tierra apropiadadelgenerador.Consultecon un

electricistalocal los requisites deconexion atierra desu zona.

• Useun interrupter decircuito per fallo deconexionatierra entodaslas

zonashumedaso altamenteconductoras (talescome zonasdetrabajo

con tarimas metalicas o estructurasde acero).

• No use el generador con juegos de cables electricos de conexion

gastados,desnudos, deshilachados o que tengan algun otro tipo de

da5o.

• Antesdeefectuarcualquiermantenimientoen elgenerador,desconecte

la bateria de arranquedel motor (de tenerla) para evitarun arranque

accidental. Desconecteprimero el cable del borne de bateriaindicado

perNEGATIVO,NEGo (-). Vuelvaa conectarese cableenultimo lugar.

• En case de accidente causado per cheque electrico, apague de

inmediatola fuente de alimentacionelectrica. Si esto no es posible,

intente liberar a la victima del conductor alimentado. EVITE EL

CONTACTODIRECTOCON LA V[CTIIVlA.Use un implemento no

conductor, como una cuerda o tabla, para liberar a la victima

del conductor alimentado. Si la victima esta inconsciente, aplique

primeros auxiliosy obtengaayudamedicade inmediato.

PELIGRODEINCENDIO

* La gasoiina es aitamente INFLAMABLE y sus vapores son

EXPLOSIVOS.Nunca permita que se fume e que haya llamas

abiertas, chispasocaler en la zona mientras maneje gasolina.

, Nunca agregue combustible mientras la unidad esta funcionando o

caNente.Espere a que el motor se enfrie completamenteantes de

agregarcombustible.

* Nunca llene el tanque de combustibleen interiores. Cumpla todas

las leyesque reglamentanel almacenamientoy manejode gasolina.

, No Ilene el tanque de combustible en excese. Siempre deje

lugar para la expansi6ndel combustible.Si se Nenael tanque en

exceso, el combustible puede rebasar sobre un motor caliente y

causar INCENDIOo EXPLOSION.Nunca almacene el generador con

combustible en el tanque deride los vapores de la gasolina podrian

alcanzar una llama abierta, chispa o luz piloto (come de un homo,

calderaosecador deropa). PuedeocasionarINCENDtOo EXPLOSION.

Permitaque la unidadse enfriecompletamente antesde almacenarla.

, Recoja y seque inmediatamentetodos los derramesde combustible

o aceite.Aseguresede queno quedenmaterialescombustibles en el

generadoro cerca de este.Mantenga la zona alrededordel generador

limpia y sin residues, y deje un espaciolibre de 4.6 m (5 ft) enredes

los costados a fin depermitir la ventilacionapropiadadelgenerador.

• No inserteobjetosa travesdelas ranurasdeenfriamientodela unidad.

• Nunca use el generador si los dispositivos electricos conectados se

recalientan,si se pierde la salidaelectrica, si el motor o el generador

producenchispaso si se observanllamas o humo mientrasla unidad

estafuncionando.

• Mantenga un extintor de incendio cerca del generador en todo

momento.

INO/CEDENORMAS

1. National Fire Protection Association (Asociacion nacional de

proteccion contra incendios [NFPA])de los EE.UU. 70: NATIONAL

ELECTRICCODE(Codigo electrico nacional de los EE. UU., NEC)

disponibleen www.nfpa.org

2. National Fire Protection Association (Asociacion nacional de

proteccioncontra incendios [NFPA])delos EE.UU.5000: BUILDING

CONSTRUCTIONAND SAFETYCODE (Codigo de construccion y

seguridadde edificios) disponible enwww.nfpa.org

3. International BuildingCode (Codigo de construccion internacional)

disponibleen www.iccsafe.org

4. Agricultural Wiring Handbook (Manual de cableado agricola)

disponible en www.rerc.org, RuralElectricity Resource Council RO.

Box309 Wilmington,OH45177-0309, EE.UU.

5. ASAE EP-364.2 Installation and Maintenance of Farm Standby

ElectricPower(lnstalaci6nymantenimientodealimentaci6nelectrica

rural de reserva) disponible en www.asabe.org,American Society

of Agricultural & Biological Engineers (Sociedad estadounidense

de ingenieros agricolasy biologicos) 2950 Niles Road, St. Joseph,

MI 49085, EE.UU.

Esta lista no es exhaustiva. Compruebe con la autoridad que tiene

jurisdiccion local (AHJ, per sus siglas en ingles) todos los codigos o

normas quepodrian corresponderasu jurisdiccion.

NUM. DE

MODELO:

NOM. DE

SERIE:

Ubicacion de la IO de la unidad

UETA

DEDATOS

DELMODELO

23

Page 26

1.1 DESElVlBALAJE

• Retiretodo elmaterialdeembalaje.

• Retirela caja de accesoriosseparada.

• Retireel generadorde la caja.

1.1.1 ACCESORIOS

Revisetodo el contenido.Si falta algunapiezao hayalgunapiezadahada,

comuniquesecon unconcesionario autorizadoal1-888-436-3722.

• 1 - Manualdelpropietario

• 1 - Litro de aceiteSAE30

• 2 - RuedasNever-Flat

• 3 - Tarjetasde registrodel producto

• 1 - ServiceWarranty

• 1 - Cargadorde baterias (modeloscon arranqueelectrico)

• 1 - Bolsadetornilleria (contieneIo siguiente):

- 2-Pies de caucho 6-PernosM8 (largos)

- 2-Pasadoresdeeje de 1/2 in 2-PernosM6 (largos)

- 2-Pasadoreshendidos 2-Tuercasciegas M8

- 2-Arandelasplanas de1/2 in 4-Tuercashexagonales

- 2-TuercashexagonalesembridadasM6

1 - Conjuntode manija

2 - Piedel bastidor

1 - Cablede alimentacion

de 6 m (20 ft)

(006110-3 solamente)

1 - EmissionsWarranty

embridadasM8

1.2 ARIVIADO

Elgeneradorrequierearmadoantesdel uso. Si surgenproblemas durante

el armado del generador,Namea la Linea de ayudapara generadoresal

1-888-436-3722.

1.2.1 ARMADODELKITDEACCESORIOS

Las ruedas de launidad se han disehadopara aumentaren gran medida

la facilidad detransporte delgenerador.

Necesitaralas siguientesherramientaspara instalar el kit de accesorios

de maneraapropiada.

• Pinzasde puntade aguja

• Trinquetey casquillos de8 mm, 10 mm y 13 mm

• Llavesde boca de 8 mm, 10 mmy 13 mm

NOTA:

Lasruedas no est;in destinadas al usoeo caminos.